Optimization of Automobile Firewall Acoustic Package for Multi-level Goals

-

摘要:

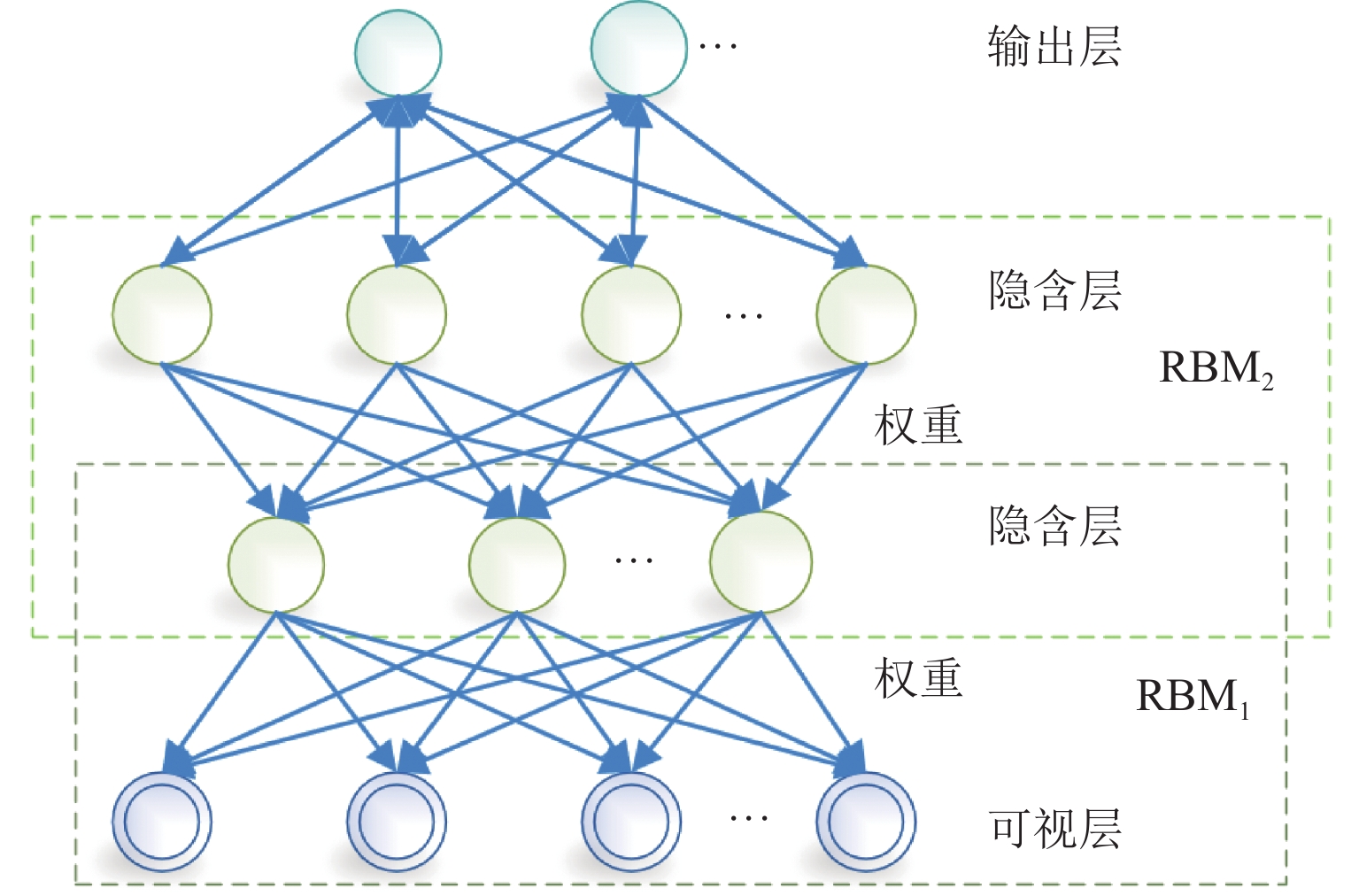

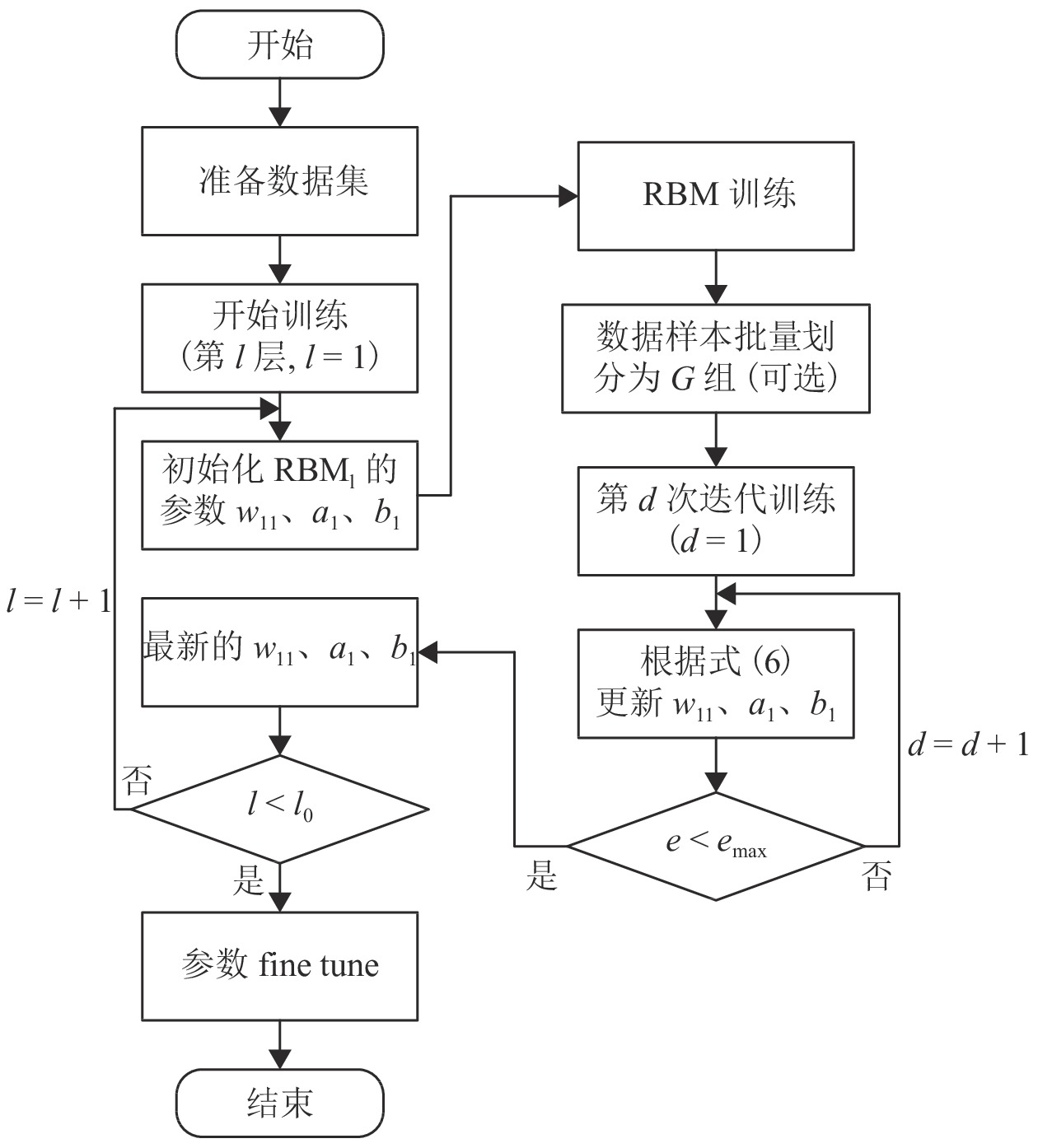

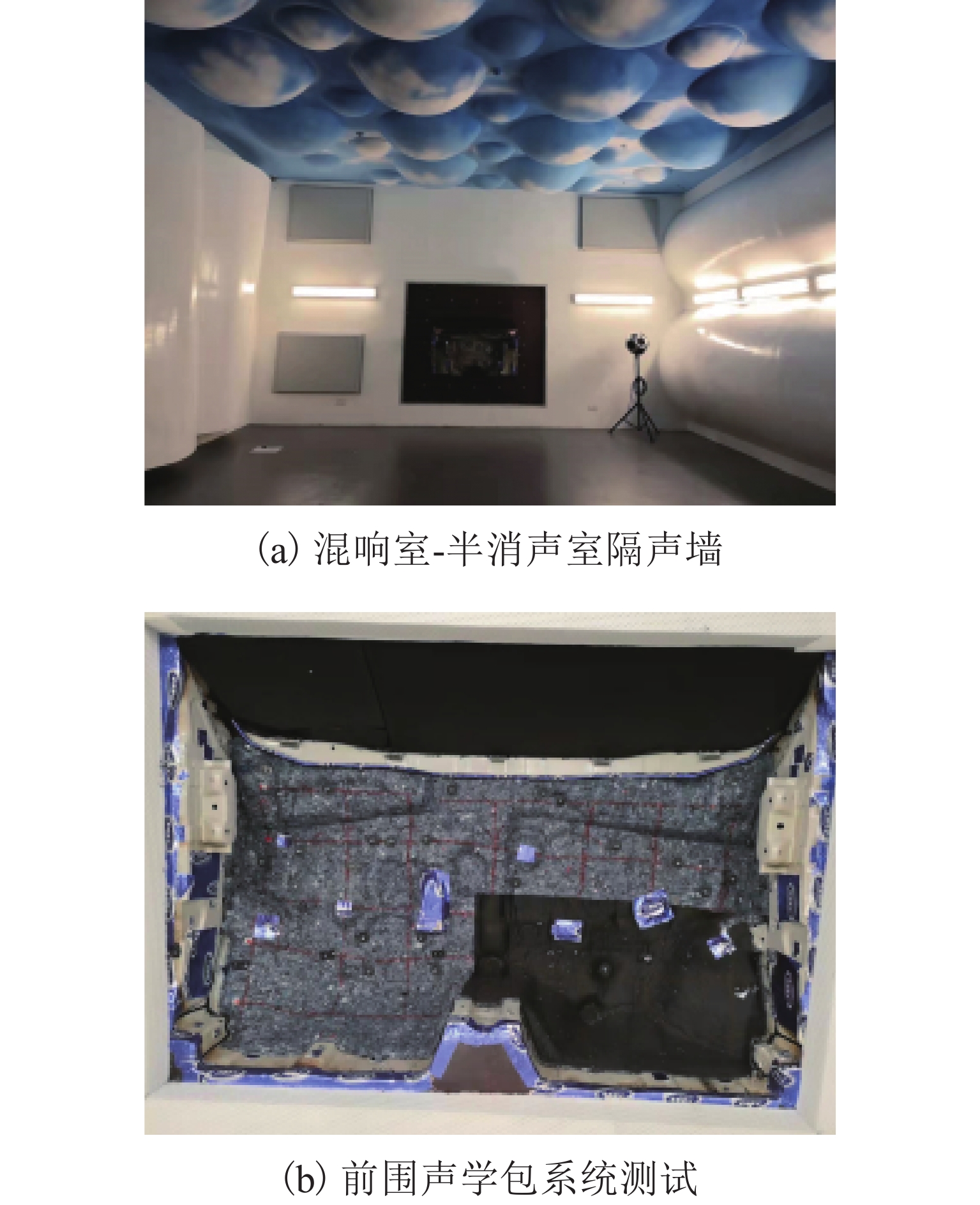

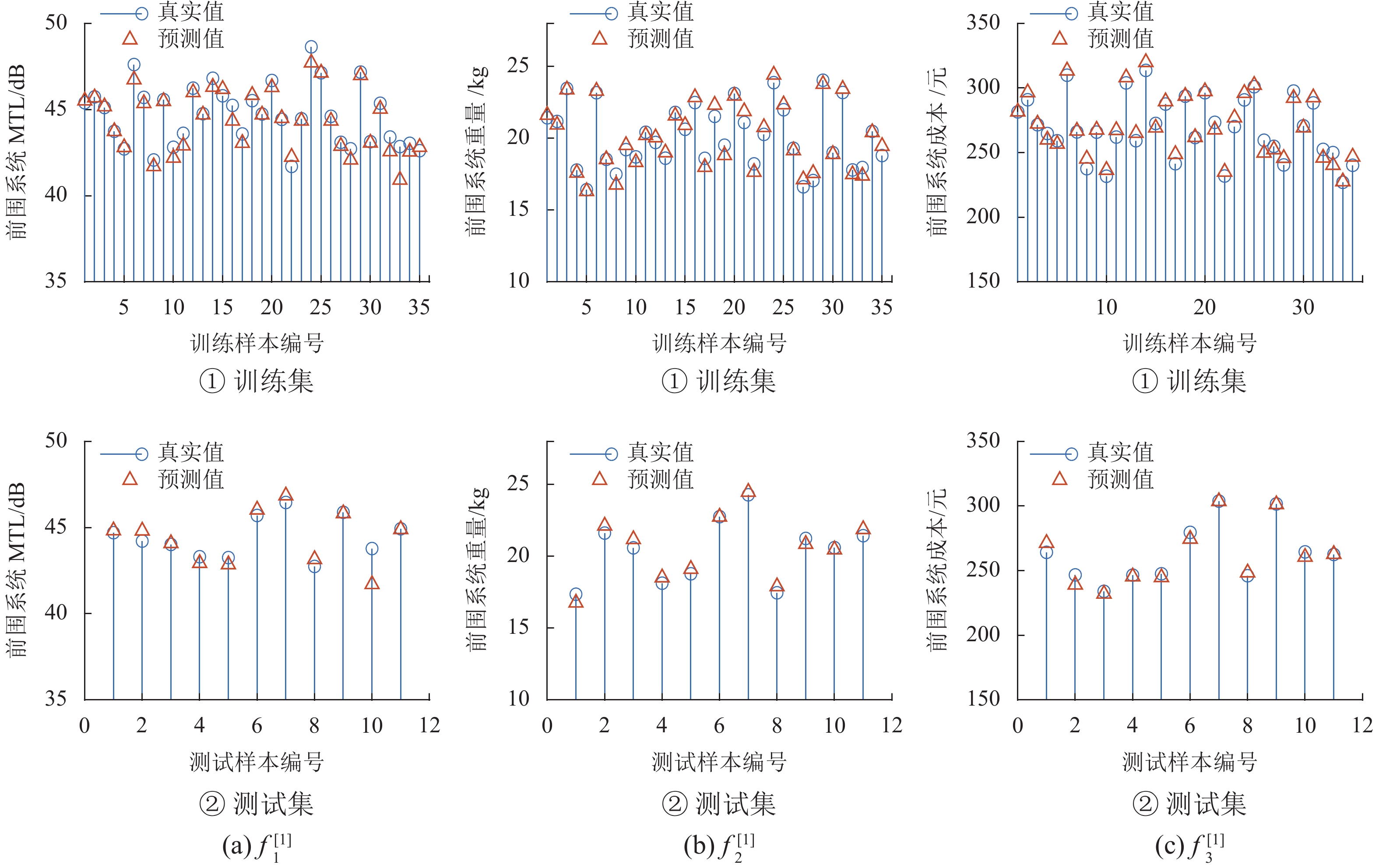

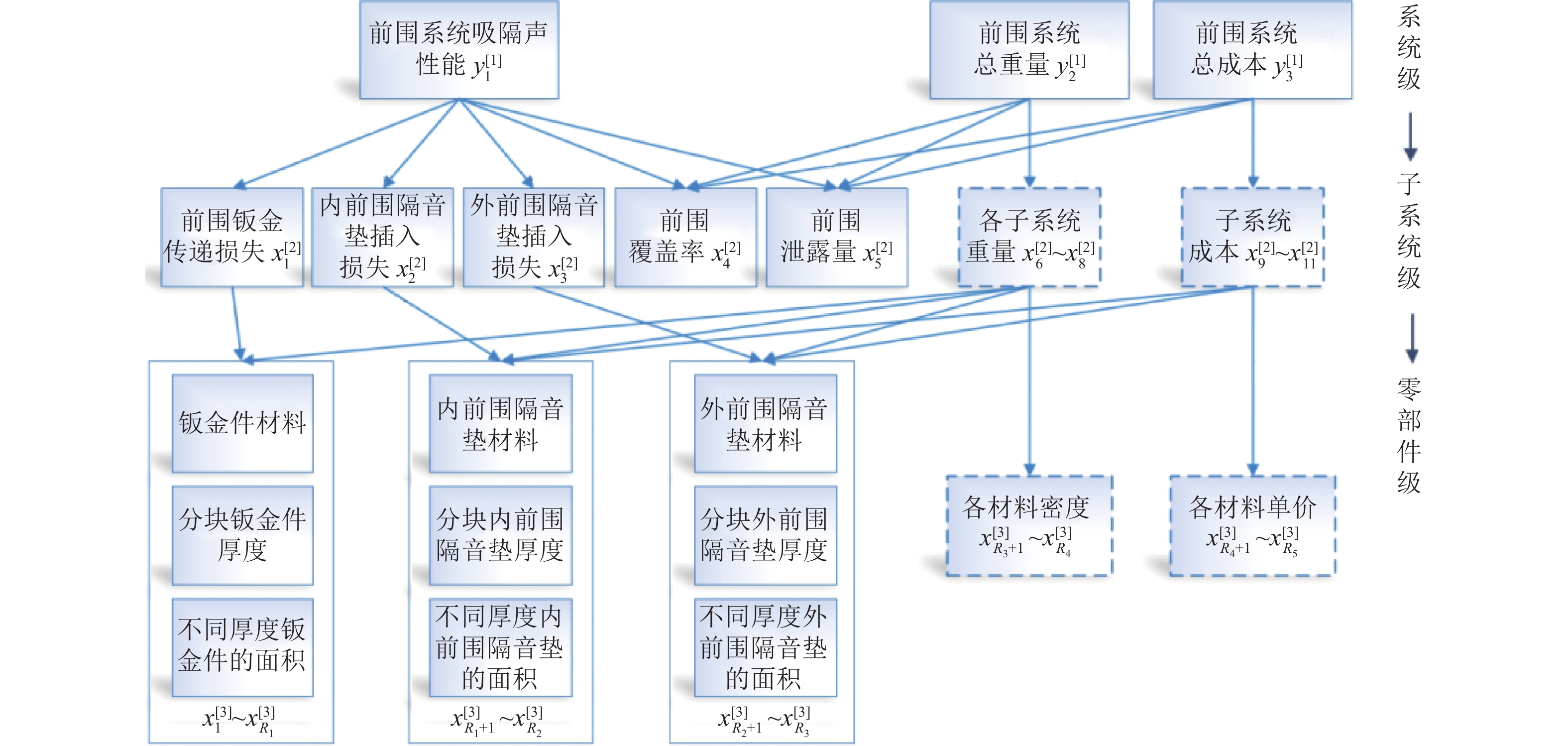

为了研究汽车声学包设计参数对其多性能目标的影响,首先,改进了传统的深度信念网络(DBNs)方法,并提出SVR-DBNs (support vector regression- deep belief networks)模型,提升了模型映射的准确度;其次,从车辆噪声传递关系与层级目标分解角度出发,提出了一种多层级目标预测与分析方法;最后,将所提方法应用于具体车型的前围声学包性能、重量与成本多目标预测与优化分析. 研究结果表明:SVR-DBNs方法对前围声学包性能、重量与成本目标预测准确度均在0.975以上,优于传统的反向传播神经网络(BPNN)、SVR与DBNs模型;基于SVR-DBNs模型的优化结果与实测结果接近,两者加权目标相对误差为1.09%(平均传递损失(MTL)、重量和成本相对误差绝对值分别为1.44%、1.04%与0.71%),优化后的实测结果较前围声学包原始状态性能、重量和成本分别提升了5.51%、9.01%与4.40%.

-

关键词:

- 噪声、振动及声振粗糙度 /

- 声学包 /

- 吸隔声 /

- SVR-DBNs /

- 优化设计

Abstract:To study the influence of automotive acoustic package design parameters on its multi-performance objectives, firstly, the traditional DBNs (deep belief networks) method was modified, and the SVR-DBNs (support vector regression-deep belief networks) model was proposed to improve the accuracy of model mapping. Secondly, from the perspective of vehicle noise transfer relationship and hierarchical target decomposition, a multi-level target prediction and analysis method was proposed. Finally, the proposed method was applied to the multi-objective prediction and optimization analysis of the MTL (mean transmission loss), weight and cost of the acoustic package for a real vehicle.The results show that the accuracy of SVR-DBNs method for the MTL, weight and cost target prediction of the acoustic package is higher than 0.975, which is better than that of the traditional BPNN(back propagation neural network), SVR and DBNs models. The optimization results based on the SVR-DBNs model are appropriate to the measured results, the comprehensive relative error of the predicted and tested targets is 1.09% (the absolute values of the relative errors of MTL, weight and cost are 1.44%, 1.04% and 0.71%, respectively). Compared with the original status, the MTL, weight and cost of the acoustic package have increased by 5.51%, 9.01% and 4.40%, respectively.

-

表 1 前围声学包系统及零部件原始状态

Table 1. Original state of firewall acoustic package system

部件名称 材料名称 厚度/

mm面积

占比/%密度/

(kg·m−3)单价/

(元·m−3)前围钣金 高强度钢 ① 1.0 ② 30 7820 39100 ③ 1.2 ④ 70 外前围

隔音垫玻璃纤维 ⑤ 10.0 ⑥ 20 100 5800 ⑦ 20.0 ⑧ 80 内前围

隔音垫PU 泡沫 ⑨ 5.0 ⑩ 35 64 7200 ⑪ 10.0 ⑫ 65 棉毡 ⑬ 3.0 ⑭ 20 113 4000 ⑮ 5.0 ⑯ 80 前围覆盖率 ⑰ 99.5% ±0.1%, ±25 元 前围泄漏量 ⑱ 0.20% ±0.05%, ±35 元 注:①~⑱表示构建预测模型的设计变量. 表 2 多层级分解模型在测试集上的准确度

Table 2. Accuracy of multi-level model on test set

目标 第一~二层级(R2) 第二~三层级(R2) MTL 0.975 0.970、0.974、0.968 重量 0.983 0.979、0.984、0.981 成本 0.986 0.988、0.978、0.980 表 3 声学包多目标优化结果

Table 3. Multi-goals optimization results of acoustic package

预测模型 MTL 重量 成本 R2 MSE/dB R2 MSE/kg R2 MSE/元 BPNN 0.917 0.771 0.924 1.267 0.931 13.457 SVR 0.955 0.364 0.959 0.846 0.961 7.950 DBNs 0.971 0.341 0.979 0.611 0.974 7.491 SVR-DBNs 0.975 0.296 0.983 0.579 0.986 4.360 表 4 前围声学包多目标优化设计参数

Table 4. Multi-goals optimization design parameters of firewall acoustic package

部件名称 材料名称 厚度/mm 面积占比/% 前围钣金 高强度钢 1.0 32 1.2 68 外前围隔音垫 玻璃纤维 14.0 28 20.0 72 内前围隔音垫 PU 泡沫 6.0 37 10.0 63 棉毡 4.0 28 5.0 72 前围覆盖率/% 99.6 前围泄露量/% 0.20 表 5 前围声学包多目标优化结果与实测结果

Table 5. Multi-goals optimization results and measured results of firewall acoustic package

状态 MTL/dB 重量/kg 成本/元 加权目标 原始状态 45.4 21.4 281.6 1.0247 优化后 预测值 48.6 19.3 267.3 0.9588 实测值 47.9 19.5 269.2 0.9693 -

[1] PANG J. Noise and vibration control in automotive bodies[M]. Chichester: John Wiley & Sons, Ltd., 2018. [2] 《中国公路学报》编辑部. 中国路基工程学术研究综述·2021[J]. 中国公路学报,2021,34(3): 1-49. doi: 10.3969/j.issn.1001-7372.2021.03.001Editorial Department of China Journal of Highway and Transport. Review on China’s subgrade engineering research·2021[J]. China Journal of Highway and Transport, 2021, 34(3): 1-49. doi: 10.3969/j.issn.1001-7372.2021.03.001 [3] 董俊红. 面向汽车高频噪声分析的不确定性理论与应用研究[D]. 长春: 吉林大学, 2020. [4] EGAB L, WANG X. On the analysis of coupling strength of a stiffened plate-cavity coupling system using a deterministic-statistical energy analysis method[J]. Mechanical Systems and Signal Processing, 2022, 164: 108234.1-108234.13. [5] 唐荣江,李申芳,郑伟光,等. 利用混合FE-SEA方法的前围隔声性能优化设计[J]. 应用声学,2019,38(1): 22-28.TANG Rongjiang, LI Shenfang, ZHENG Weiguang, et al. Optimization design of sound insulation property in front wall using hybrid FE-SEA method[J]. Journal of Applied Acoustics, 2019, 38(1): 22-28. [6] LEE H R, KIM H Y, JEON J H, et al. Application of global sensitivity analysis to statistical energy analysis: vehicle model development and transmission path contribution[J]. Applied Acoustics, 2019, 146: 368-389. doi: 10.1016/j.apacoust.2018.11.023 [7] HUANG H B, HUANG X R, DING W P, et al. Uncertainty optimization of pure electric vehicle interior tire/road noise comfort based on data-driven[J]. Mechanical Systems and Signal Processing, 2022, 165: 108300.1-108300.23. [8] CHAUDHARI V V, RADHIKA V, VIJAY R. Frontloading approach for sound package design for noise reduction and weight optimization using statistical energy analysis[J]. SAE International Journal of Vehicle Dynamics, Stability, and NVH, 2017, 1(1): 66-72. doi: 10.4271/2017-26-0222 [9] 周信,肖新标,何宾,等. 高速铁路声屏障插入损失影响因素及规律[J]. 西南交通大学学报,2014,49(6): 1024-1031. doi: 10.3969/j.issn.0258-2724.2014.06.014ZHOU Xin, XIAO Xinbiao, HE Bin, et al. Influential factors and rules for insertion loss of high-speed railway noise barriers[J]. Journal of Southwest Jiaotong University, 2014, 49(6): 1024-1031. doi: 10.3969/j.issn.0258-2724.2014.06.014 [10] 代浩,金铭,陈星,等. 数据驱动的应用自适应技术综述[J]. 计算机研究与发展,2022,59(11): 2549-2568.DAI Hao, JIN Ming, CHEN Xing, et al. Data-driven application adaptive technology: a survey[J]. Computer Research and Development, 2022, 59(11): 2549-2568. [11] 贺岩松,张辉,夏小均,等. 轿车车内声学包多目标优化与分析[J]. 机械科学与技术,2017,36(3): 455-461.HE Yansong, ZHANG Hui, XIA Xiaojun, et al. Multi-objective optimization analysis of a passenger car’s interior sound packages[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(3): 455-461. [12] SCHAEFER N, BERGEN B, KEPPENS T, et al. A design space exploration framework for automotive sound packages in the mid-frequency range[C]//Noise and Vibration Conference and Exhibition. Leuven: SAE International, 2017: 1751.1-1751.11. [13] 孙志军,薛磊,许阳明,等. 深度学习研究综述[J]. 计算机应用研究,2012,29(8): 2806-2810. doi: 10.3969/j.issn.1001-3695.2012.08.002SUN Zhijun, XUE Lei, XU Yangming, et al. Overview of deep learning[J]. Application Research of Computers, 2012, 29(8): 2806-2810. doi: 10.3969/j.issn.1001-3695.2012.08.002 [14] MOHAMED A R, DAHL G E, HINTON G. Acoustic modeling using deep belief networks[J]. IEEE Transactions on Audio, Speech, and Language Processing, 2012, 20(1): 14-22. doi: 10.1109/TASL.2011.2109382 [15] SRIVASTAVA N, SALAKHUTDINOV R. Learning representations for multimodal data with deep belief nets[C]//International Conference on Machine Learning Workshop.Edinburgh: [s.n.], 2012: 1-8. [16] 黄海波. 基于系统目标决策的汽车NVH设计理论与方法研究[D]. 成都: 西南交通大学, 2017. [17] ZHANG J, PANG J, ZHANG S W, et al. A lightweight dash insulator development and engineering application for the vehicle NVH improvement[C]//Noise and Vibration Conference and Exhibition. Leuven: SAE International, 2015: 2342.1-2342.5. [18] 姜东明,丁渭平,苏瑞强,等. 汽车前围声学包中频插入损失仿真计算[J]. 噪声与振动控制,2018,38(4): 106-110,202.JIANG Dongming, DING Weiping, SU Ruiqiang, et al. Simulation of insertion loss of vehicle firewall’s sound package in intermediate frequency range[J]. Noise and Vibration Control, 2018, 38(4): 106-110,202. [19] 潘广源,柴伟,乔俊飞. DBN网络的深度确定方法[J]. 控制与决策,2015,30(2): 256-260. doi: 10.13195/j.kzyjc.2013.1390PAN Guangyuan, CHAI Wei, QIAO Junfei. Calculation for depth of deep belief network[J]. Control and Decision, 2015, 30(2): 256-260. doi: 10.13195/j.kzyjc.2013.1390 [20] 黄海波,李人宪,杨琪,等. 基于DBNs的车辆悬架减振器异响鉴别方法[J]. 西南交通大学学报,2015,50(5): 776-782. doi: 10.3969/j.issn.0258-2724.2015.05.002HUANG Haibo, LI Renxian, YANG Qi, et al. Identifying abnormal noise of vehicle suspension shock absorber based on deep belief networks[J]. Journal of Southwest Jiaotong University, 2015, 50(5): 776-782. doi: 10.3969/j.issn.0258-2724.2015.05.002 [21] BENGIO Y, DELALLEAU O. Justifying and generalizing contrastive divergence[J]. Neural Computation, 2009, 21(6): 1601-1621. doi: 10.1162/neco.2008.11-07-647 [22] LI Y, WANG N, SHI J, et al. Adaptive batch normalization for practical domain adaptation[J]. Pattern Recognition, 2018, 80: 109-117. doi: 10.1016/j.patcog.2018.03.005 [23] SAE. Laboratory measurement of the airborne sound barrier performance: J1400—2017[S]. [S. l.]: SAE international, 2017. -

下载:

下载: