Summary of Research on Key Technologies and Energy Management of Electro-Hydraulic Hybrid Powertrain

-

摘要:

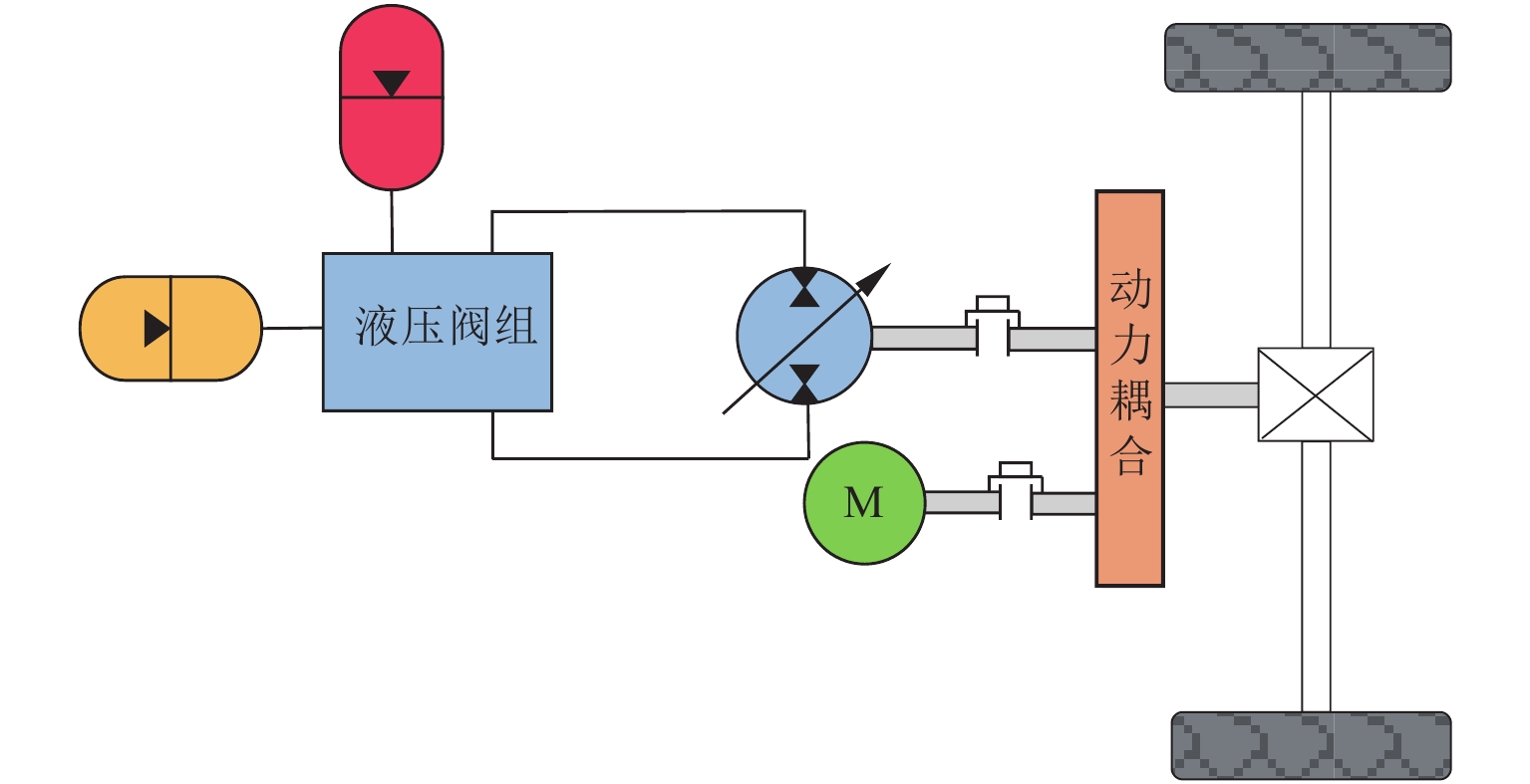

现有混合动力驱动技术以油电、油液混合动力为主,旨在提高传统燃油车辆的能量利用率、降低油耗和排放. 基于液压技术的大功率密度及能量再生优势,电液混合动力系统可在全速工况范围内实现能量高效利用,提高纯电驱系统的功率密度,有效改善电动车辆续驶里程及蓄电池循环使用寿命. 本文对电液混合动力系统构型、能量回收技术、能量释放模式及控制策略等相关研究成果的进展、现状及发展趋势进行综述,分析了利用电液混合动力构型与先进能量管理策略提升纯电动车辆动力性能与能量利用率的可行性技术方案与应用前景. 根据已有研究成果,装备电液混合动力系统后车辆最大可降低约40%的能量消耗,在能量高效利用方面具有显著优势. 对于电液混合动力系统而言,液压能再生、耦合与释放等与行驶场景及电机工况点密切相关,研究重点应解决动力耦合、再生制动与能量管理等关键技术,从而提升动力系统的综合性能特别是功率密度与节能特性.

Abstract:The existing hybrid drive technology is mainly based on the hybrid power of oil electricity or liquid, and it aims to improve the energy utilization rate of conventional fuel vehicles and reduce fuel consumption and emissions. Based on the high power density and energy regeneration advantages of hydraulic technology, the electro-hydraulic hybrid powertrain can achieve efficient energy utilization within the full-speed operating range, increase the power density of pure electric drive system, and effectively improve the driving range of electric vehicles and cycling life of batteries. This paper summarizes the progress, current situation, and development trend of research on electro-hydraulic hybrid powertrain configuration, energy recovery technology, energy release mode, and control strategy and analyzes the feasibility and application prospect of using electro-hydraulic hybrid configuration and advanced energy management strategy to improve the power performance and energy utilization rate of pure electric vehicles. According to the existing research results, the vehicle equipped with an electro-hydraulic hybrid powertrain can reduce energy consumption by about 40% at most, which has significant advantages in efficient energy utilization. For an electro-hydraulic hybrid powertrain, hydraulic energy regeneration, coupling, and release are closely related to driving scenarios and motor operating conditions. The research should focus on solving key technologies such as power coupling, regenerative braking, and energy management, so as to improve the overall performance of the powertrain, especially the power density and energy-saving characteristics.

-

表 1 不同动力混合型式的比较

Table 1. Comparison of different power hybrid types

类别 优势 劣势 串联电液混合动力 电机与机械负载解耦并无级调速、保护蓄电池、布局灵活 能量多次转化导致利用率低、系统惯性负载大 并联电液混合动力 能量损失小、驱动效率高、结构简单 电机工作环境难以调节、控制复杂 混联电液混合动力 能量利用率高、动力性能好、布局灵活、有效保护蓄电池 结构复杂、控制难度大 表 2 不同控制策略的优缺点对比及其应用

Table 2. Comparison of the advantages and disadvantages of different control strategies and their applications

类别 优势 劣势 应用 基于确定规则控制 结构简单、控制响应快速 控制参数选取依赖经验 各种混合动力车辆 基于模糊规则控制 具有较强适应性,易于应用 需人为优化,适用范围小 部分混合动力车辆 瞬时优化控制 易获近似最优解,性能好 计算量较大,控制复杂 部分混合动力试验车 全局优化控制 易获理论最优解,无需校正 需预知大量行驶信息,计算量大 多用于引导简单控制

策略的制定 -

[1] KWON H, IVANTYSYNOV A M. Experimental and the oretical studies on energy characteristics of hydraulic hybrids for thermal management[J]. Energy, 2021, 223: 120033.1-120033.13. [2] OSMAN M, MEHREZ M W, DAOUD M A, et al. A generic multi-sensor fusion scheme for localization of autonomous platforms using moving horizon estimation[J]. Transactions of the Institute of Measurement and Control, 2021, 43(15): 3413-3427. doi: 10.1177/01423312211011454 [3] ZHU Y Y. The key technologies for powertrain system of intelligent vehicles based on switched reluctance motors[M]. Singapore: Springer, 2022. [4] LI Y Y, WANG S Q, DUAN X B, et al. Multi-objective energy management for Atkinson cycle engine and series hybrid electric vehicle based on evolutionary NSGA-II algorithm using digital twins[J]. Energy Conversion and Management, 2021, 230: 113788.1-113788.19. [5] TAN W, XIE S H, CAI Y D, et al. Transformation of highly stable Pt single sites on defect engineered ceria into robust Pt clusters for vehicle emission control[J]. Environmental Science & Technology, 2021, 55(18): 12607-12618. [6] MA M, MENG W D, LI Y Y, et al. Impact of dual credit policy on new energy vehicles technology innovation with information asymmetry[J]. Applied Energy, 2023, 332(15): 120524.1-120524.14. [7] ZHOU H C, XU Z P, LIU L, et al. Design and validation of a novel hydraulic hybrid vehicle with wheel motors[J]. Science Progress, 2020, 103(1): 36850419878024.1-36850419878024.11. [8] LI C S, CHEN L, WANG X, et al. Energy-saving system of secondary balance for the hybrid power of the pumping unit[J]. The Journal of Engineering, 2019, 2019(13): 190-195. doi: 10.1049/joe.2018.9013 [9] QI C Y, ZHU Y W, SONG C X, et al. Self-supervised reinforcement learning-based energy management for a hybrid electric vehicle[J]. Journal of Power Sources, 2021, 514: 230584.1-230584.10. [10] CHEN J X, SHU H, TANG X L, et al. Deep reinforcement learning-based multi-objective control of hybrid power system combined with road recognition under time-varying environment[J]. Energy, 2022, 239: 122123.1-122123.15. [11] JUFRI F H, ARYANI D R, GARNIWA I, et al. Optimal battery energy storage dispatch strategy for small-scale isolated hybrid renewable energy system with different load profile patterns[J]. Energies, 2021, 14(11): 3139.1-3139.19. [12] AKPOLAT A N, DURSUN E, SIANO P. Inverter-based modeling and energy efficiency analysis of off-grid hybrid power system in distributed generation[J]. Computers & Electrical Engineering, 2021, 96: 107476.1-107476.13. [13] LI C S, WANG X, WANG J Y, et al. Research on variable pressure characteristics of step variable hydraulic hybrid system based on cartridge value group[J]. The Journal of Engineering, 2019, 2019(13): 415-420. doi: 10.1049/joe.2018.9333 [14] MENG Z W, ZHANG H X, YANG J, et al. Research on matching of power transmission system of electro-hydraulic hybrid electric vehicle[J]. IOP Conference Series: Earth and Environmental Science, 2021, 632(3): 032007.1-032007.9. [15] URISHEV B, BEYTULLAYEVA R, UMIROV А, et al. Hydraulic energy storage of wind power plants[J]. E3S Web of Conferences, 2021, 264: 04053.1-04053.9. doi: 10.1051/e3sconf/202126404053 [16] 刘昕晖,李春爽,陈琳,等. 游梁式抽油机节能技术综述[J]. 吉林大学学报(工学版),2021,51(1): 1-26. doi: 10.13229/j.cnki.jdxbgxb20190951LIU Xinhui, LI Chunshuang, CHEN Lin, et al. Review of energy saving technologies for beam pumping units[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(1): 1-26. doi: 10.13229/j.cnki.jdxbgxb20190951 [17] WANG C Y, ZHAO W Z, LI W K, et al. Multi-objective optimisation of electro-hydraulic braking system based on MOEA/D algorithm[J]. IET Intelligent Transport Systems, 2019, 13(1): 183-193. doi: 10.1049/iet-its.2018.5090 [18] LE SOLLIEC G, CHASSE A, VAN-FRANK J, et al. Dual mode vehicle with in-wheel motor: regenerative braking optimization[J]. Oil & Gas Science and Technology-Revue d’IFP Energies Nouvelles, 2013, 68(1): 95-108. [19] SHI B F, XIONG L, YU Z P. Pressure estimation of the electro-hydraulic brake system based on signal fusion[J]. Actuators, 2021, 10(9): 240.1-240.19. [20] SHI B F, XIONG L, YU Z P. Pressure estimation based on vehicle dynamics considering the evolution of the brake linings’ coefficient of friction[J]. Actuators, 2021, 10(4): 76.1-76.20. [21] HU J Y, LI J Q, HU Z Y, et al. Power distribution strategy of a dual-engine system for heavy-duty hybrid electric vehicles using dynamic programming[J]. Energy, 2021, 215: 118851.1-118851.15. [22] 曾小华,崔臣,张轩铭,等. 液压轮毂马达辅助驱动系统控制策略实车验证[J]. 哈尔滨工业大学学报,2020,52(1): 50-55. doi: 10.11918/201810050ZENG Xiaohua, CUI Chen, ZHANG Xuanming, et al. Verification of control strategy of hydraulic hub-motor auxiliary system on actual vehicle[J]. Journal of Harbin Institute of Technology, 2020, 52(1): 50-55. doi: 10.11918/201810050 [23] BARAKAT A A, DIAB J H, BADAWI N S, et al. Combined cycle gas turbine system optimization for extended range electric vehicles[J]. Energy Conversion and Management, 2020, 226: 113538.1-113538.18. [24] XU H, YUAN Y B, WANG H W. Plug-in hybrid electric vehicle utility factor in China cities: influencing factors, empirical research, and energy and environmental application[J]. eTransportation, 2021, 10: 100138.1-100138.14. [25] CHOUDHARI V G, DHOBLE A S, PANCHAL S. Numerical investigation on thermal behaviour of 5 × 5 cell configured battery pack using phase change material and fin structure layout[J]. Journal of Energy Storage, 2021, 43: 103234.1-103234.15. [26] ZHANG B, ZHANG J Y, Shen T L. Optimal control design for comfortable-driving of hybrid electric vehicles in acceleration mode[J]. Applied Energy, 2022, 305: 117885.1-117885.17. [27] LIU H L, JIANG Y, LI S. Design and downhill speed control of an electric-hydrostatic hydraulic hybrid powertrain in battery-powered rail vehicles[J]. Energy, 2019, 187: 115957.1-115957.12. [28] BAER K, ERICSON L, KRUS P. Framework for simulation-based simultaneous system optimization for a series hydraulic hybrid vehicle[J]. International Journal of Fluid Power, 2018: 1-13. [29] 冯磊,刘桓龙. 轨道车的电液混合功率迁移与耦合特性[J]. 液压与气动,2018(6): 88-93. doi: 10.11832/j.issn.1000-4858.2018.06.017FENG Lei, LIU Huanlong. Electro-hydraulic hybrid power transfer and coupling characteristics of rail vehicle[J]. Chinese Hydraulics & Pneumatics, 2018(6): 88-93. doi: 10.11832/j.issn.1000-4858.2018.06.017 [30] HE Y P, FAN A L, WANG Z, et al. Two-phase energy efficiency optimisation for ships using parallel hybrid electric propulsion system[J]. Ocean Engineering, 2021, 238: 109733.1-109733.12. [31] 孙魁. 基于测功机加载的液压混合动力模拟试验台[D]. 长春: 吉林大学, 2019. [32] 董兵兵. CVT并联混合动力汽车能量优化与模式切换协调控制研究[D]. 长春: 吉林大学, 2019. [33] 丁静. 重载工程车辆并联式液压混合动力系统设计与控制研究[D]. 杭州: 浙江大学, 2019. [34] 孟凡涛. 并联液压混合动力汽车城市循环工况能量回收特性研究[D]. 秦皇岛: 燕山大学, 2019. [35] 张浩翔. 功率分流型液压变速器特性及系统应用方法研究[D]. 杭州: 浙江大学, 2019. [36] CHEN G P, LIU H L. Design and energy utilization of electro-hydrostatic hydraulic hybrid system for battery bus[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2021, 235(2/3): 759-772. [37] 王炳超. 液压混合动力垃圾车的动力系统设计与仿真研究[D]. 青岛: 青岛大学, 2017. [38] 洪健. 多级串联复合电源再生制动系统设计与仿真研究[D]. 镇江: 江苏大学, 2020. [39] 方桂花,王鹤川,曾标,等. 电机发电特性优化再生制动控制策略的方法[J]. 机械设计与制造,2021(1): 134-137. doi: 10.3969/j.issn.1001-3997.2021.01.031FANG Guihua, WANG Hechuan, ZENG Biao, et al. Method of optimizing regenerative braking control strategy for motor generation characteristics[J]. Machinery Design & Manufacture, 2021(1): 134-137. doi: 10.3969/j.issn.1001-3997.2021.01.031 [40] 王茹洁,武志斐,邹纯. 纯电动物流车最优制动能量回收控制策略研究[J]. 机械设计与制造,2020(4): 301-304. doi: 10.3969/j.issn.1001-3997.2020.04.073WANG Rujie, WU Zhifei, ZOU Chun. Study on optimal braking energy recovery control strategy of pure electric logistics vehicle[J]. Machinery Design & Manufacture, 2020(4): 301-304. doi: 10.3969/j.issn.1001-3997.2020.04.073 [41] LIU H L, CHEN G P, LI D F, et al. Energy active adjustment and bidirectional transfer management strategy of the electro-hydrostatic hydraulic hybrid powertrain for battery bus[J]. Energy, 2021, 230: 120794.1-120794.14. [42] ZHOU S L, PAUL W, ZHANG N. Parametric design and regenerative braking control of a parallel hydraulic hybrid vehicle[J]. Mechanism and Machine Theory, 2020, 146: 103714.1-103714.15. [43] WU W, LIU H, ZHOU J J, et al. Energy efficiency of hydraulic regenerative braking for an automobile hydraulic hybrid propulsion method[J]. International Journal of Green Energy, 2019, 16(13): 1046-1053. doi: 10.1080/15435075.2019.1653875 [44] 马家启. 前置式液压混合动力车辆制动转矩控制的研究[D]. 长春: 吉林大学, 2019. [45] 王波. 复合蓄能器液压混合动力系统匹配方法及控制策略研究[D]. 秦皇岛: 燕山大学, 2019. [46] 张涛,何晓晖,王强,等. 轮边驱动液压混合动力车辆能量回收系统性能研究[J]. 液压与气动,2019(10): 90-96. doi: 10.11832/j.issn.1000-4858.2019.10.015ZHANG Tao, HE Xiaohui, WANG Qiang, et al. Research on energy recovery system of wheel drive hydraulic hybrid vehicle[J]. Chinese Hydraulics & Pneumatics, 2019(10): 90-96. doi: 10.11832/j.issn.1000-4858.2019.10.015 [47] 李柏林. 混合动力汽车再生制动与防抱死系统协调控制研究[D]. 重庆: 重庆大学, 2019. [48] 李光政. 搭载制动电子助力器的四驱混合动力汽车电液复合制动系统研究[D]. 重庆: 重庆大学, 2019. [49] 刘延旭. 液压混合动力式半挂汽车列车稳定性研究[D]. 济南: 齐鲁工业大学, 2019. [50] 曾小华,李广含,宋大凤,等. 重型车辆液压再生制动能量回收率的研究[J]. 汽车工程,2017,39(7): 729-735. doi: 10.19562/j.chinasae.qcgc.2017.07.001ZENG Xiaohua, LI Guanghan, SONG Dafeng, et al. A research on the energy recovery rate of hydraulic regenerative braking for heavy vehicle[J]. Automotive Engineering, 2017, 39(7): 729-735. doi: 10.19562/j.chinasae.qcgc.2017.07.001 [51] 蒋越. 蓄电池液压混合动力轨道工程车的再生和复合制动特性研究[D]. 成都: 西南交通大学, 2019. [52] WALDEMAR L. A new type of hydrokinetic accumulator and its simulation in hydraulic lift with energy recovery system[J]. Energy, 2018, 153: 836-848. doi: 10.1016/j.energy.2018.04.040 [53] 李顺,刘桓龙,陈冠鹏. 不同液压能耦合模式下蓄电池轨道工程车的加速功率特性[J]. 中国机械工程,2020,31(12): 1452-1460.LI Shun, LIU Huanlong, CHEN Guanpeng. Acceleration power characteristics of battery track engineering vehicles under different hydraulic energy coupling modes[J]. China Mechanical Engineering, 2020, 31(12): 1452-1460. [54] 刘桓龙,李顺,谢迟新. 基于液压泵/马达逆向驱动的电机启动电流控制方法[J]. 西南交通大学学报,2021,56(4): 720-729.LIU Huanlong, LI Shun, XIE Chixin. A method of motor starting current control based on hydraulic pump/motor reverse driving[J]. Journal of Southwest Jiaotong University, 2021, 56(4): 720-729. [55] LEI Z Z, QIN D T, LIU Y G, et al. Dynamic energy management for a novel hybrid electric system based on driving pattern recognition[J]. Applied Mathematical Modelling, 2017, 45: 940-954. doi: 10.1016/j.apm.2017.01.036 [56] ZHOU Y, RAVEY A, PéRA M-C. Multi-mode predictive energy management for fuel cell hybrid electric vehicles using Markov driving pattern recognizer[J]. Applied Energy, 2020, 258: 114057.1-114057.17. [57] RUAN J G, SONG Q, YANG W W. The application of hybrid energy storage system with electrified continuously variable transmission in battery electric vehicle[J]. Energy, 2019, 183: 315-330. doi: 10.1016/j.energy.2019.06.095 [58] LIN X Y, FENG Q G, MO L P, et al. Optimal adaptation equivalent factor of energy management strategy for plug-in CVT HEV[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2019, 233(4): 877-889. doi: 10.1177/0954407018755612 [59] GAO J P, XU Z H, GAO X J. Control strategy for PHEB based on actual driving cycle with driving style characteristic[J]. Journal of Control Science and Engineering, 2019, 2019: 1-14. [60] DU Z K, CHEONG K L, LI P Y. Energy management strategy for a power-split hydraulic hybrid vehicle based on Lagrange multiplier and its modifications[J]. Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2019, 233(5): 511-523. doi: 10.1177/0959651818801416 [61] RANA L B, SHRESTHA A, PHUYAL S, et al. Design and performance evaluation of series hybrid electric vehicle using backward model[J]. The Journal of Engineering, 2020, 2020(11): 1095-1102. doi: 10.1049/joe.2019.1314 [62] LIU H L, CHEN G P, XIE C X, et al. Research on energy-saving characteristics of battery-powered electric-hydrostatic hydraulic hybrid rail vehicles[J]. Energy, 2020, 205: 118079.1-118079.13. [63] CHEN Y Q, LIU X H, WANG X, et al. Control strategies and optimization analyses of front-mounted parallel system[J]. Cluster Computing, 2019, 22(3): 5151-5163. [64] 余忠云. 基于复合蓄能器的液压混合动力汽车节能机理分析[D]. 秦皇岛: 燕山大学, 2019. [65] ZHOU H C, XU Z P, LIU L, et al. A rule-based energy management strategy based on dynamic programming for hydraulic hybrid vehicles[J]. Mathematical Problems in Engineering, 2018: 1-10. [66] 刘桓龙,蒋越,李志伟. 基于模糊PID的轨道工程车下坡缓速控制[J]. 液压与气动,2020(2): 78-85. doi: 10.11832/j.issn.1000-4858.2020.02.012LIU Huanlong, JIANG Yue, LI Zhiwei. Downhill speed control of the railway engineering vehicles based on fuzzy PID[J]. Chinese Hydraulics & Pneumatics, 2020(2): 78-85. doi: 10.11832/j.issn.1000-4858.2020.02.012 [67] 傅必升. 基于双蓄能器的液压再生制动能量回收系统研究和优化[D]. 杭州: 浙江工业大学, 2019. [68] ZHOU H, ZHAO P Y, CHEN Y L. Fuzzy logic control for a hydraulic hybrid excavator based on torque prediction and genetic algorithm optimization[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2018, 232(8): 983-994. doi: 10.1177/0954407017724590 [69] YANG Y, ZHANG Y T, TIAN J Y, et al. Adaptive real-time optimal energy management strategy for extender range electric vehicle[J]. Energy, 2020, 197: 117237.1-117237.14. [70] 杨业,张幽彤,张彪,等. 基于等效因子优化的插电式混合动力客车自适应能量管理策略[J]. 汽车工程,2020,42(3): 292-298,306. doi: 10.19562/j.chinasae.qcgc.2020.03.003YANG Ye, ZHANG Youtong, ZHANG Biao, et al. Adaptive energy management strategy for plug-in hybrid ElectricBus based on equivalent factor optimization[J]. Automotive Engineering, 2020, 42(3): 292-298,306. doi: 10.19562/j.chinasae.qcgc.2020.03.003 [71] DONATEO T, DE PASCALIS C L, FICARELLA A. An application of the ECMS strategy to a wankel hybrid electric UAV[J]. MATEC Web of Conferences, 2019, 304: 03010.1-03010.8. [72] LI X M, HAN L J, LIU H, et al. Real-time optimal energy management strategy for a dual-mode power-split hybrid electric vehicle based on an explicit model predictive control algorithm[J]. Energy, 2019, 172: 1161-1178. doi: 10.1016/j.energy.2019.01.052 [73] 孙可华. 双行星排混联式液压混合动力汽车的能量优化与协调控制[D]. 长春: 吉林大学, 2019. [74] WILLIAMS K, IVANTYSYNOVA M. Approximate stochastic differential dynamic programming for hybrid vehicle energy management[J]. Journal of Dynamic Systems, Measurement, and Control, 2019, 141(5): 051003.1-051003.9. [75] 刘洋,林慕义,陈勇. 液压混合动力工程车辆联合制动系统优化与仿真[J]. 机床与液压,2019,47(1): 104-108. doi: 10.3969/j.issn.1001-3881.2019.01.024LIU Yang, LIN Muyi, CHEN Yong. Optimization and simulation for combined braking system of hydraulic hybrid electric vehicle[J]. Machine Tool & Hydraulics, 2019, 47(1): 104-108. doi: 10.3969/j.issn.1001-3881.2019.01.024 [76] 陈有权. 前置并联式液压混合动力起重机制动能量管理及控制策略研究[D]. 长春: 吉林大学, 2018. [77] SPRENGEL M, IVANTYSYNOVA M. Neural network based power management of hydraulic hybrid vehicles[J]. International Journal of Fluid Power, 2017, 18(2): 79-91. doi: 10.1080/14399776.2016.1232117 [78] 樊伟,刘天琦. 采用动态规划算法优化的液压混合动力车辆能源消耗仿真研究[J]. 中国工程机械学报,2018,16(6): 526-530. doi: 10.15999/j.cnki.311926.2018.06.011FAN Wei, LIU Tianqi. Simulation study on energy consumption of hydraulic hybrid vehicle optimized by dynamic programming algorithm[J]. Chinese Journal of Construction Machinery, 2018, 16(6): 526-530. doi: 10.15999/j.cnki.311926.2018.06.011 [79] 李洪亮,朱灯林,李洪璠. 液压混合动力矿用卡车系统参数多目标优化研究[J]. 液压与气动,2018(10): 70-77. doi: 10.11832/j.issn.1000-4858.2018.10.012LI Hongliang, ZHU Denglin, LI Hongfan. Multi-objective optimization of hydraulic hybrid mining truck system parameters[J]. Chinese Hydraulics & Pneumatics, 2018(10): 70-77. doi: 10.11832/j.issn.1000-4858.2018.10.012 [80] ZHAO W Z, LUAN Z K, WANG C Y. Parametric optimization of novel electric-hydraulic hybrid steering system based on a shuffled particle swarm optimization algorithm[J]. Journal of Cleaner Production, 2018, 186: 865-876. doi: 10.1016/j.jclepro.2018.03.180 [81] 尹晨辉. 商用车混合动力电控转向系统性能研究与优化设计[D]. 镇江: 江苏大学, 2019. [82] 郭斌,李金成,陈虹,等. 基于改进全局优化算法的轮毂液压动力系统能量管理策略[J]. 中国公路学报,2020,33(8): 23-30. doi: 10.19721/j.cnki.1001-7372.2020.08.003GUO Bin, LI Jincheng, CHEN Hong, et al. Energy management strategy of hydraulic hub-motor hybrid system based on improved global optimization algorithm[J]. China Journal of Highway and Transport, 2020, 33(8): 23-30. doi: 10.19721/j.cnki.1001-7372.2020.08.003 [83] 高锋阳,张浩然,王文祥,等. 规则控制与行驶工况相结合的现代有轨电车能量管理策略[J]. 机械工程学报,2023,59(4): 221-231.GAO Fengyang, ZHANG Haoran, WANG Wenxiang, et al. Modern tram energy management strategy combining rule control and driving conditions[J]. Chinese Journal of Mechanical Engineering, 2023, 59(4): 221-231. [84] 曾晓帆,胡明辉,徐磊. 基于实车试验大数据分析的插电式混合动力汽车能量管理策略解析[J]. 重庆大学学报,2023,46(2): 11-29,42.ZENG Xiaofan, HU Minghui, XU Lei. Analysis of plug-in hybrid electric vehicle energy management strategy based on big data analysis of real vehicle test[J]. Journal of Chongqing University, 2023, 46(2): 11-29,42. -

下载:

下载: