Independent Cascade Control Method for Permanent Magnetic Levitation Platform

-

摘要:

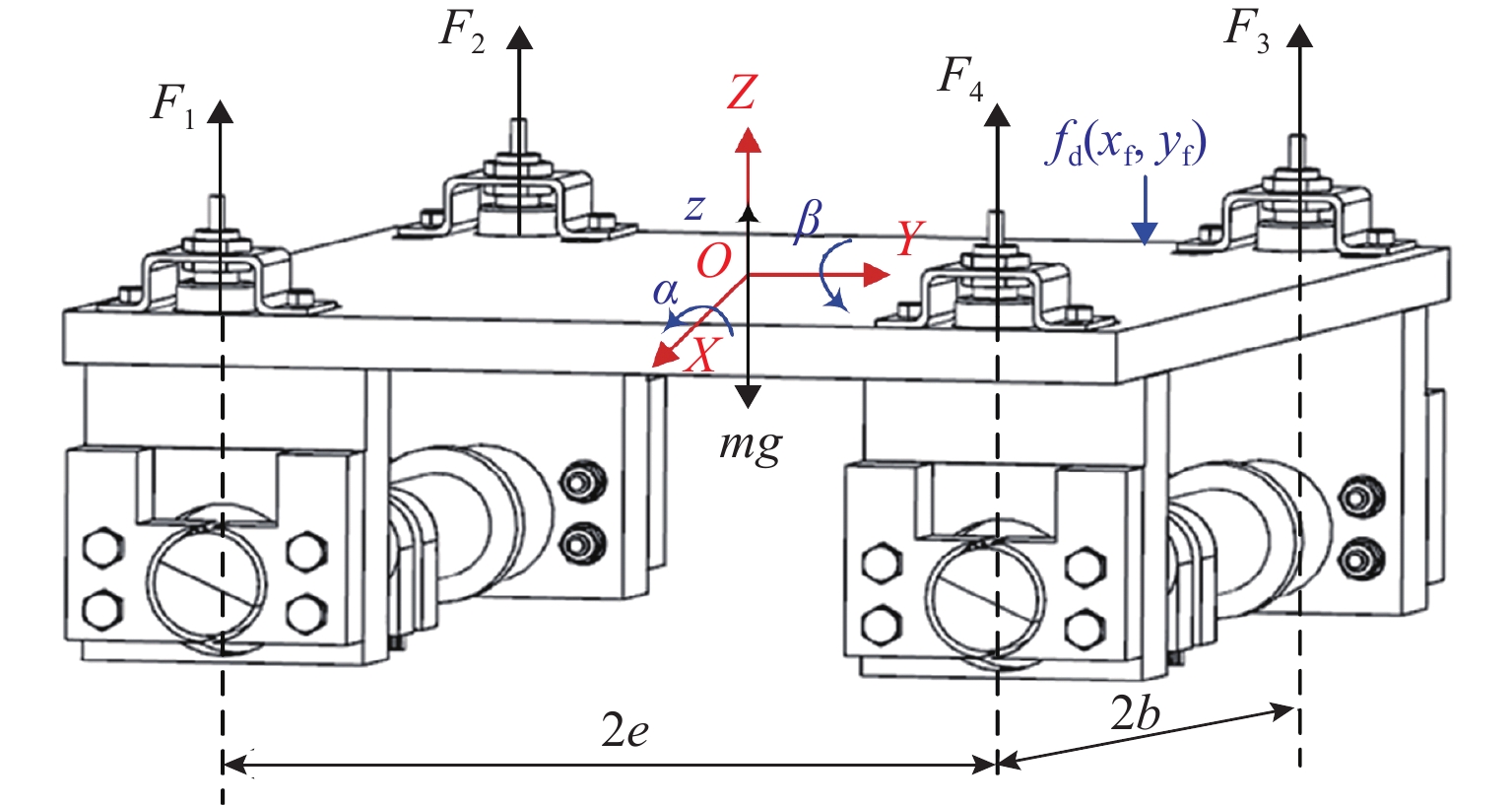

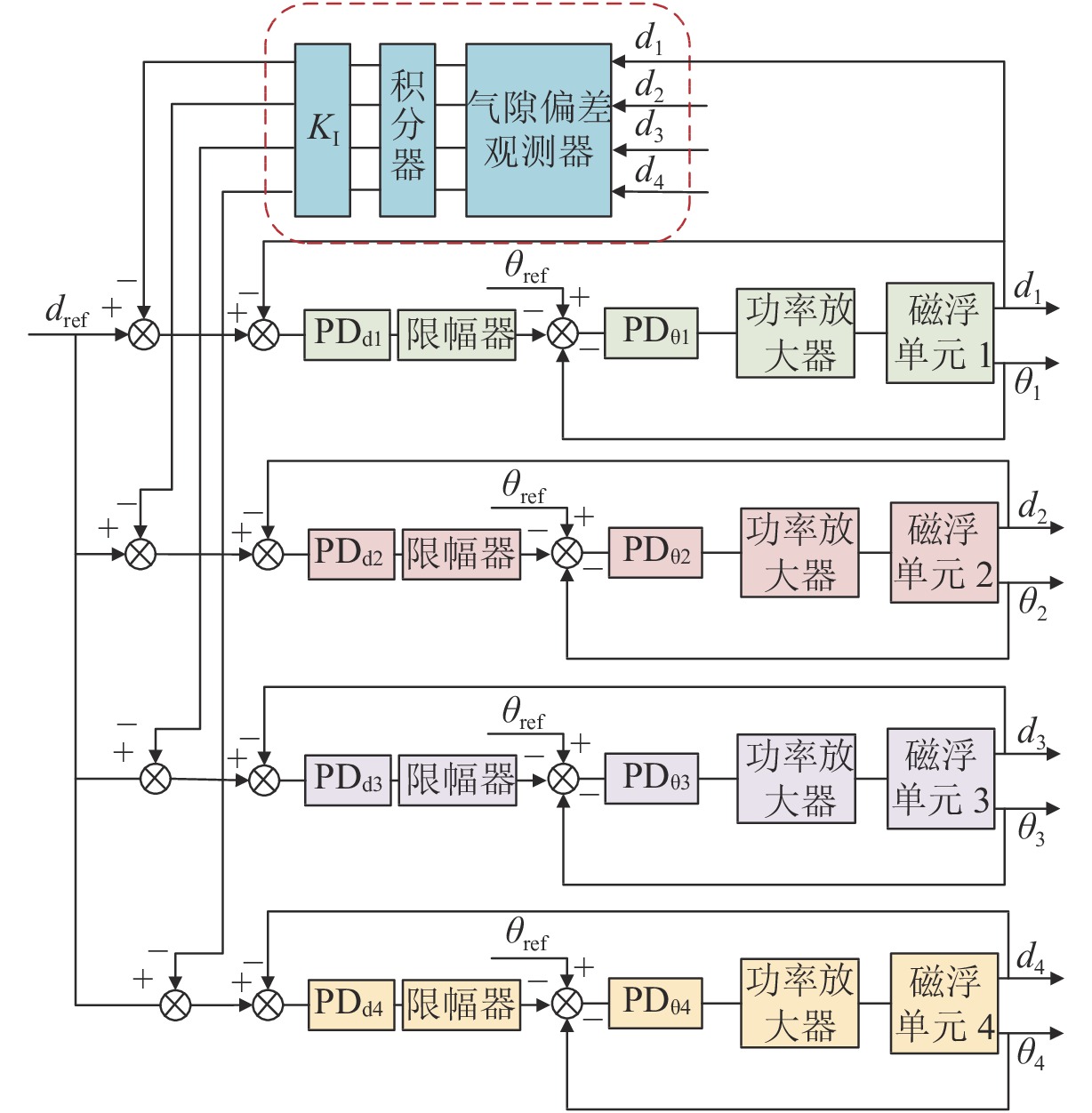

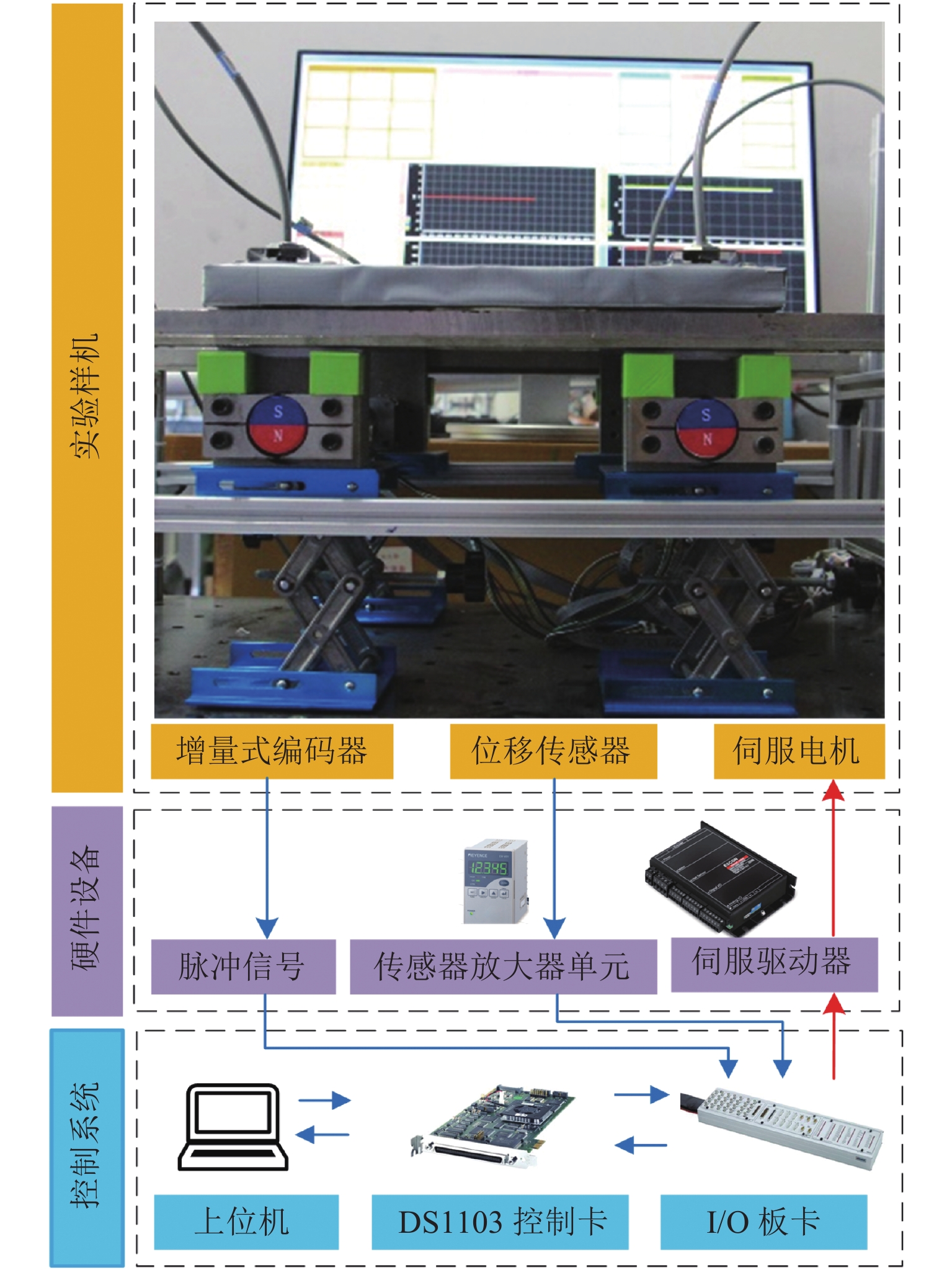

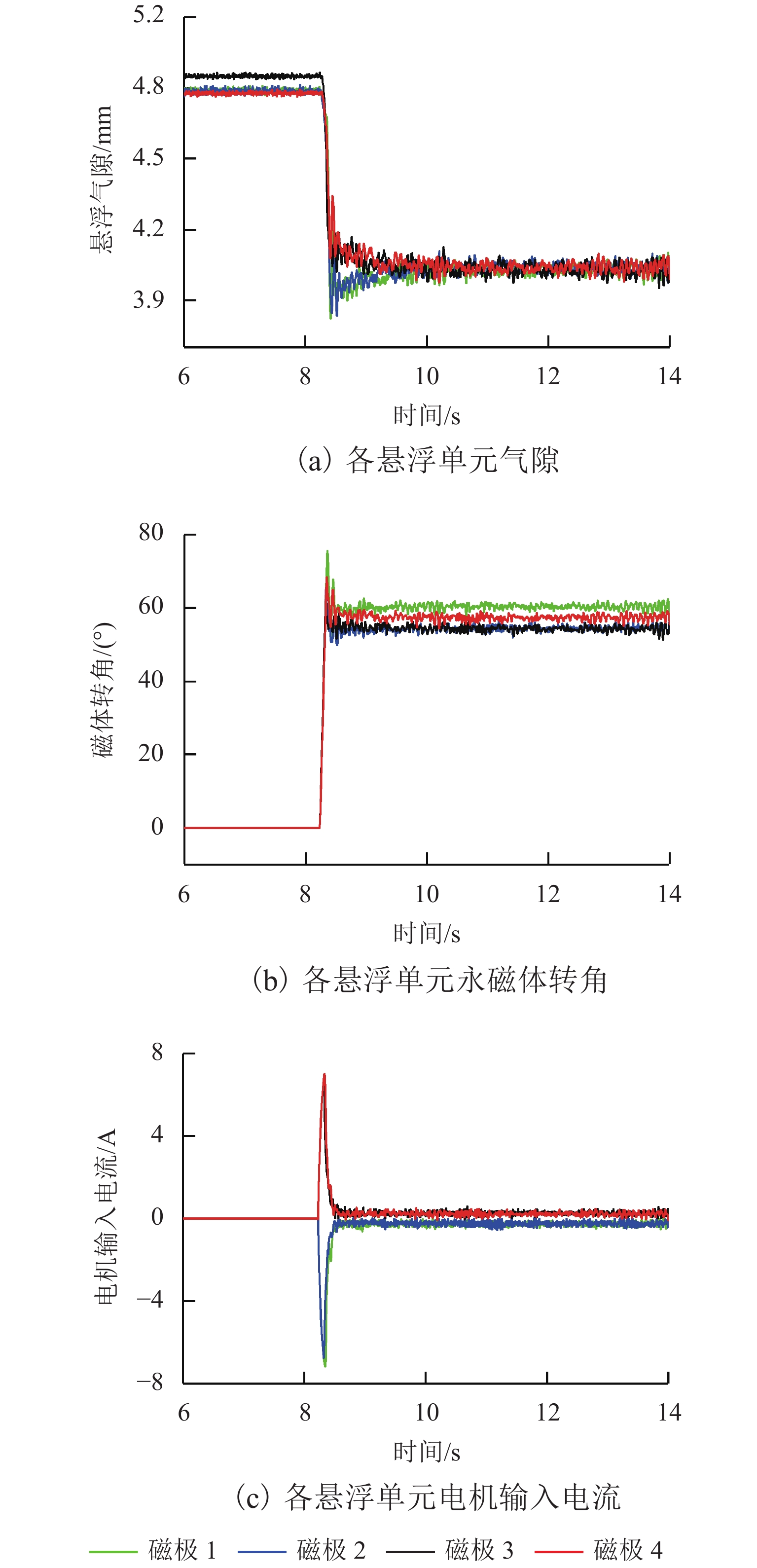

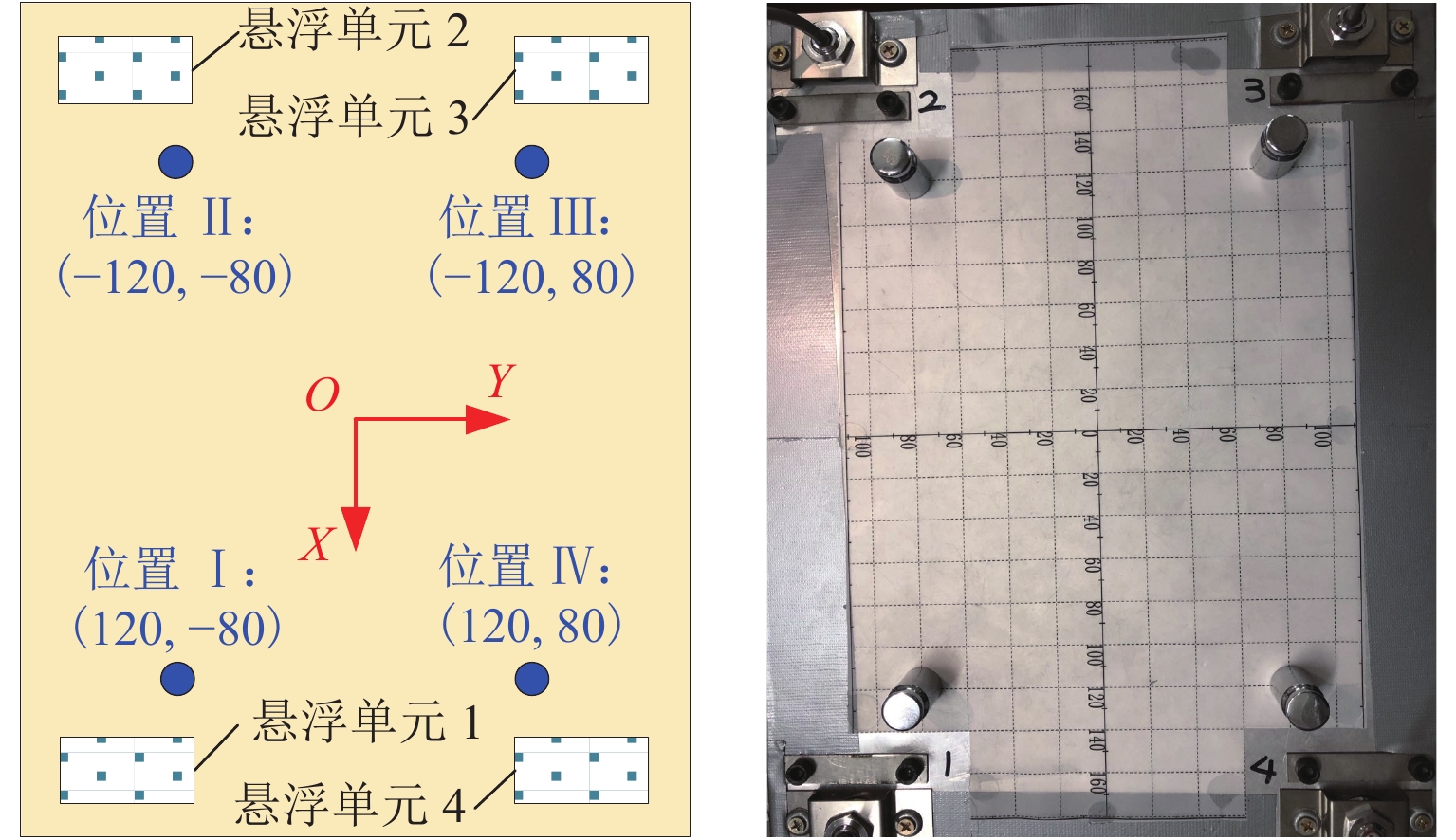

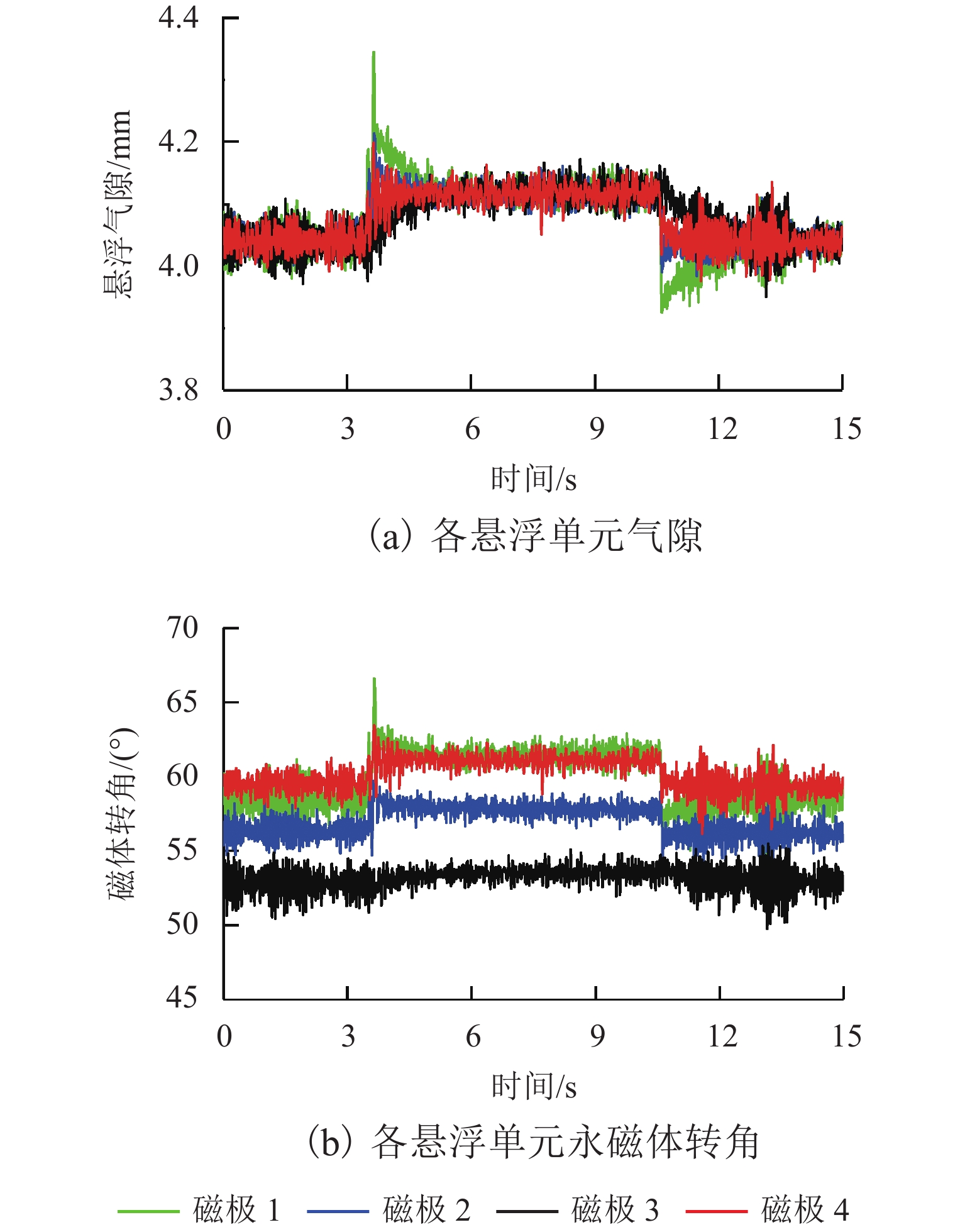

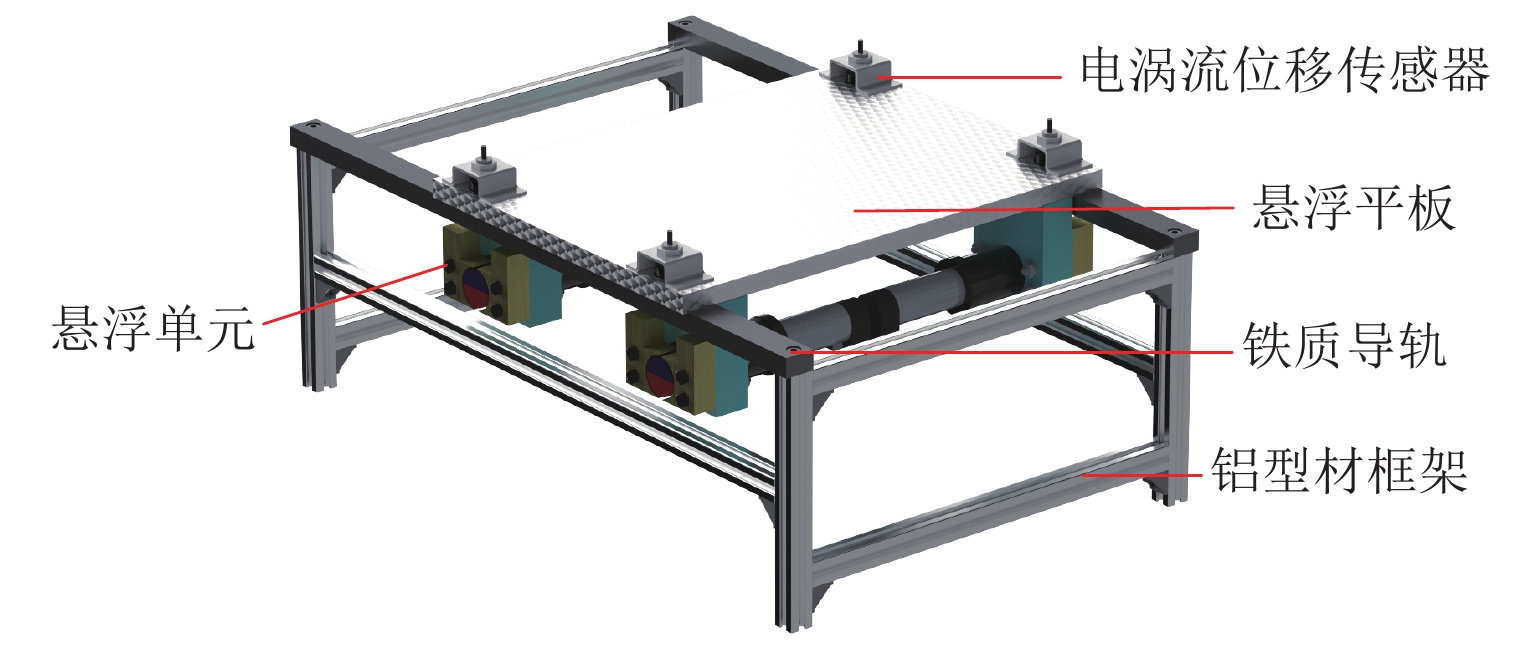

针对各悬浮单元磁力特性差异导致的倾斜问题,设计一种用于无接触传送的永磁悬浮平台,提出了具有气隙偏差积分反馈的分散式串级控制方法. 首先,分析了悬浮平台的动力学模型与平衡条件,获得各悬浮单元气隙与平台三自由度之间的变换关系;其次,根据悬浮单元系统特点设计了双闭环串级控制系统,外环是以气隙为被控对象的主调节回路,内环是以转角为被控对象的随动回路,并引入气隙偏差进行积分反馈;最后,通过悬浮实验进行验证. 结果表明:引入积分反馈后,起浮后各磁悬浮单元气隙一致,向不同位置施加0.1 kg重物,各悬浮单元气隙同步增大0.12 mm;悬浮平台能够通过调节内环转角弥补磁力特性差异并实现偏载下水平悬浮,但系统的调节时间比无积分反馈的分散串级控制系统增加约1.4倍.

Abstract:Aiming at tilt caused by the difference of magnetic characteristics of each MLU (magnetic levitation unit), a permanent magnetic levitation platform is designed for contactless transportation; and an independent cascade control method is presented, which allows integral feedback of air gap deviation. Firstly, the dynamic model and equilibrium conditions of the levitation are analyzed to establish the transformation relationship between the air gap of each suspension unit and three degrees of freedom of the platform. Secondly, given each MLU features, the cascade control system with a double closed-loop is designed, in which the outer loop plays a major regulating role for the air gap, the inner loop works as a follow-up control for the rotation angle, and air gap error among each MLU runs as the integral feedback. Finally, the levitation experiment is conducted to verify the proposed controller. The results show that, when introducing the integral feedback, the air gap of each MLU is the same after levitating, and the air gap increases 0.12 mm synchronously when 0.1 kg of weight is applied to different positions. The platform adjusts the rotational angle to control the difference of magnetic characteristics and fulfill the horizontal levitation under eccentric load. However, the adjusting time of the system is about 1.4 times that of the independent cascade control system without integrated feedback.

-

Key words:

- magnetic levitation /

- PD control /

- cascade control systems /

- integrated feedback

-

表 1 施加偏载后悬浮系统的稳态气隙

Table 1. Steady-state air gap length of levitation system under eccentric load

mm 加载位置编号 无气隙偏差补偿 有气隙偏差补偿 1 2 3 4 1 2 3 4 0 3.94 3.92 4.11 4.17 4.00 4.00 4.00 4.00 Ⅰ 4.15 4.02 4.08 4.24 4.12 4.12 4.12 4.12 Ⅱ 4.05 4.16 4.21 4.11 4.12 4.12 4.12 4.12 Ⅲ 3.90 4.0 4.33 4.26 4.12 4.12 4.12 4.12 Ⅳ 4.00 3.87 4.20 4.39 4.12 4.12 4.12 4.12 表 2 施加偏载后永磁体的转角

Table 2. Rotational angle of permanent magnet under eccentric load

(°) 加载位置编号 无气隙偏差补偿 有气隙偏差补偿 1 2 3 4 1 2 3 4 0 59.5 52.9 55.2 59.1 58.4 56.3 53.1 59.6 Ⅰ 64.3 54.7 54.6 60.9 61.4 57.8 53.6 61.1 Ⅱ 61.9 57.4 57.0 57.7 60.4 58.6 54.5 59.7 Ⅲ 58.6 54.3 59.3 61.2 58.8 57.7 55.3 60.8 Ⅳ 60.9 51.9 57.0 64.2 60.2 56.2 54.4 61.9 -

[1] 王念先,胡业发,吴华春,等. 大气隙混合磁悬浮轴承承载力模型的研究[J]. 机械工程学报,2015,51(1): 153-160. doi: 10.3901/JME.2015.01.153WANG Nianxian, HU Yefa, WU Huachun, et al. Research on bearing capacity model of large-air-gap hybrid magnetic bearings[J]. Journal of Mechanical Engineering, 2015, 51(1): 153-160. doi: 10.3901/JME.2015.01.153 [2] 邓自刚,王家素,王素玉,等. 高温超导磁悬浮轴承研发现状[J]. 电工技术学报,2009,24(9): 1-8. doi: 10.3321/j.issn:1000-6753.2009.09.001DENG Zigang, WANG Jiasu, WANG Suyu, et al. Research and development status of high temperature superconducting magnetic bearings[J]. Transactions of China Electrotechnical Society, 2009, 24(9): 1-8. doi: 10.3321/j.issn:1000-6753.2009.09.001 [3] LI H, DENG Z, HUANG H, et al. Experiments and simulations of the secondary suspension system to improve the dynamic characteristics of HTS maglev[J]. IEEE Transactions on Applied Superconductivity, 2021, 31(6): 1-8. [4] ZHU H Y, JOO T T, KHIANG P C. Magnetically levitated parallel actuated dual-stage (maglev-PAD) system for six-axis precision positioning[J]. IEEE/ASME Transactions on Mechatronics, 2019, 24(4): 1829-1838. doi: 10.1109/TMECH.2019.2928978 [5] 王莉,张昆仑. 基于零功率控制策略的混合磁悬浮系统[J]. 西南交通大学学报,2005,40(5): 667-672. doi: 10.3969/j.issn.0258-2724.2005.05.022WANG Li, ZHANG Kunlun. Hybrid magnetic suspension system based on zero power control strategy[J]. Journal of Southwest Jiaotong University, 2005, 40(5): 667-672. doi: 10.3969/j.issn.0258-2724.2005.05.022 [6] 张钢,孟庆涛,钟永彦,等. 五自由度全永磁轴承系统的稳定悬浮特性分析[J]. 机械工程学报,2015,51(5): 56-63. doi: 10.3901/JME.2015.05.056ZHANG Gang, MENG Qingtao, ZHONG Yongyan, et al. Stable levitation performance analysis of five degrees of freedom all permanent magnetic bearing system[J]. Journal of Mechanical Engineering, 2015, 51(5): 56-63. doi: 10.3901/JME.2015.05.056 [7] 胡坤,王爽,李德永,等. 一种永磁磁垫式带式输送机的气隙特性研究[J]. 煤炭学报,2015,40(3): 701-706.HU Kun, WANG Shuang, LI Deyong, et al. Research on air gap characteristics of permanent magnetic cushion belt conveyor[J]. Journal of China Coal Society, 2015, 40(3): 701-706. [8] OKA K, YAMAMOTO K, HARADA A. Magnetic suspension mechanism using rotary permanent magnets[J]. International Journal of Applied Electromagnetics and Mechanics, 2020, 64(1/2/3/4): 977-983. [9] AKABAYSHI A, MIZUNO T, TAKASAKI M, et al. Development of flux-path control magnetic suspension system using flux concentration[J]. Transactions of the Japan Society of Mechanical Engineers, 2013, 79(801): 1483-1494. doi: 10.1299/kikaic.79.1483 [10] 孙凤,韦伟,金俊杰,等. 可控磁路式并联型永磁悬浮系统[J]. 仪器仪表学报,2017,38(7): 1714-1722. doi: 10.3969/j.issn.0254-3087.2017.07.019SUN Feng, WEI Wei, JIN Junjie, et al. Parallel permanent magnetic suspension system with flux path control[J]. Chinese Journal of Scientific Instrument, 2017, 38(7): 1714-1722. doi: 10.3969/j.issn.0254-3087.2017.07.019 [11] 李强,唐敬虎,孙凤,等. 可变磁路式永磁悬浮系统的防跌落防吸附控制[J]. 仪器仪表学报,2019,40(3): 246-254.LI Qiang, TANG Jinghu, SUN Feng, et al. Anti-fall and anti-adsorption control of permanent magnetism levitation system with flux path control[J]. Chinese Journal of Scientific Instrument, 2019, 40(3): 246-254. [12] 孙凤,唐敬虎,李强,等. 可变磁路式永磁悬浮系统刚度特性分析及变刚度控制[J]. 振动与冲击,2020,39(7): 132-139.SUN Feng, TANG Jinghu, LI Qiang, et al. Stiffness characteristics analysis and variable stiffness control for a permanent magnetic levitation system with variable magnetic circuit[J]. Journal of Vibration and Shock, 2020, 39(7): 132-139. [13] ZHAO C, SUN F, JIN J, et al. Analysis of quasi-zero power characteristic for a permanent magnetic levitation system with a variable flux path control mechanism[J]. IEEE/ASME Transactions on Mechatronics, 2021, 26(1): 437-447. [14] 寇宝泉,张赫. 多自由度短行程超精密平面电机技术发展综述[J]. 电工技术学报,2013,28(7): 1-11. doi: 10.3969/j.issn.1000-6753.2013.07.001KOU Baoquan, ZHANG He. Development of multi-DOF micro-motion ultra-precision planar motors[J]. Transactions of China Electrotechnical Society, 2013, 28(7): 1-11. doi: 10.3969/j.issn.1000-6753.2013.07.001 [15] 李广,张鸣,朱煜,等. 六自由度磁浮微动台电磁场建模与计算[J]. 清华大学学报(自然科学版),2010,50(12): 1978-1982.LI Guang, ZHANG Ming, ZHU Yu, et al. Six degree-of-freedom maglev microstage electromagnetic field modeling and calculation[J]. Journal of Tsinghua University (Science and Technology), 2010, 50(12): 1978-1982. [16] 李黎川,丁玉成,卢秉恒. 超精密磁悬浮工作台及其解耦控制[J]. 机械工程学报,2004,40(9): 84-88,94. doi: 10.3321/j.issn:0577-6686.2004.09.018LI Lichuan, DING Yucheng, LU Bingheng. High-precision magnetically suspended table and its decoupling control[J]. Chinese Journal of Mechanical Engineering, 2004, 40(9): 84-88,94. doi: 10.3321/j.issn:0577-6686.2004.09.018 [17] 陈启会,李群明,胥晓. 平面型磁悬浮平台的结构与分散控制[J]. 机械设计与研究,2013,29(2): 21-25. doi: 10.3969/j.issn.1006-2343.2013.02.006CHEN Qihui, LI Qunming, XU Xiao. Structure and decentralized control of planar magnetic levitation platform[J]. Machine Design & Research, 2013, 29(2): 21-25. doi: 10.3969/j.issn.1006-2343.2013.02.006 [18] 孙兴伟,路英园,孙凤,等. 可变磁路式永磁悬浮系统的动力学特性研究[J]. 中国机械工程,2014,25(20): 2782-2787. doi: 10.3969/j.issn.1004-132X.2014.20.015SUN Xingwei, LU Yingyuan, SUN Feng, et al. Research on dynamics performance of permanent magnet suspension system with variable magnetic circuit[J]. China Mechanical Engineering, 2014, 25(20): 2782-2787. doi: 10.3969/j.issn.1004-132X.2014.20.015 -

下载:

下载: