Laboratory Thermo-Mechanical Coupling Test of Tunnel Lining Concrete

-

摘要:

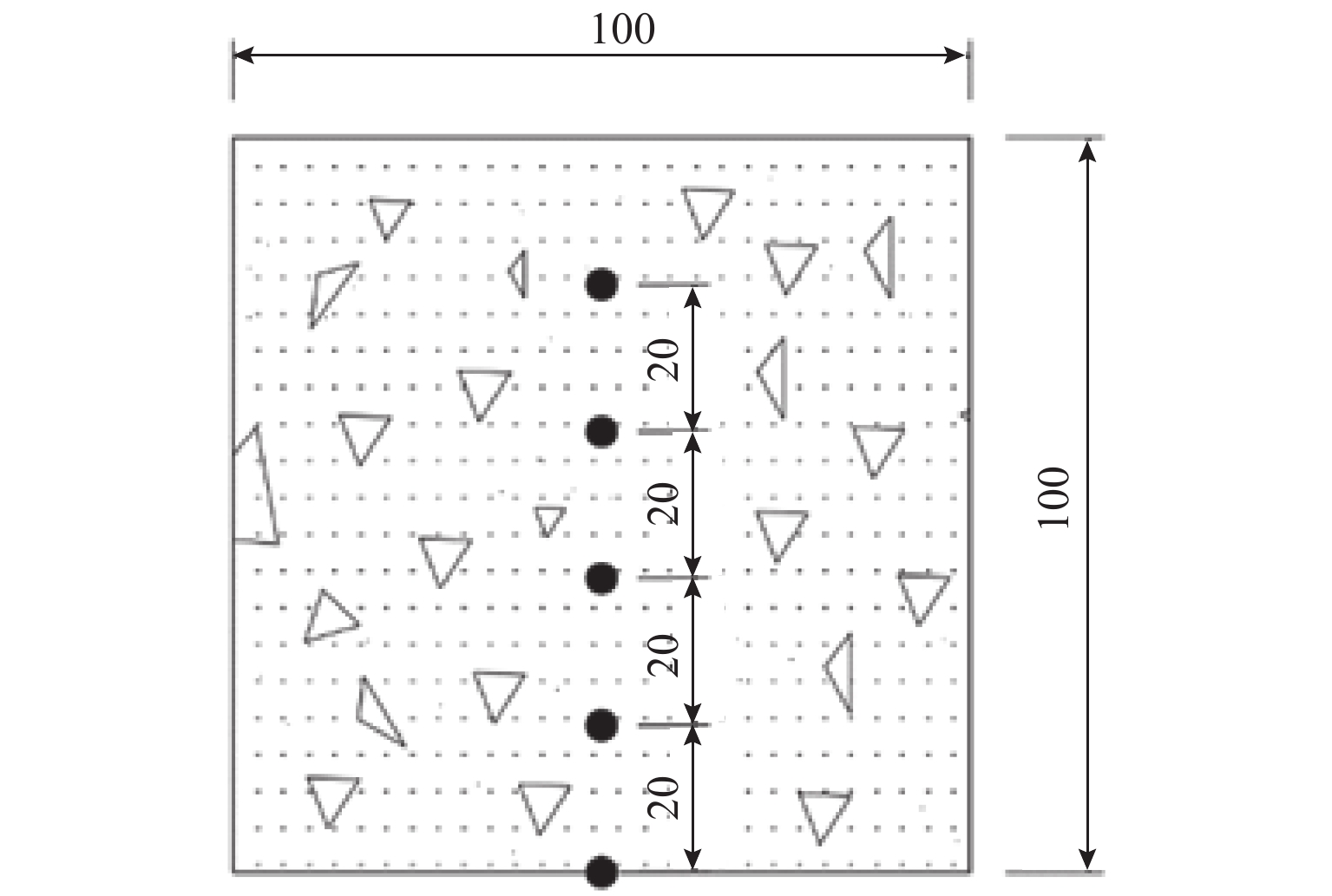

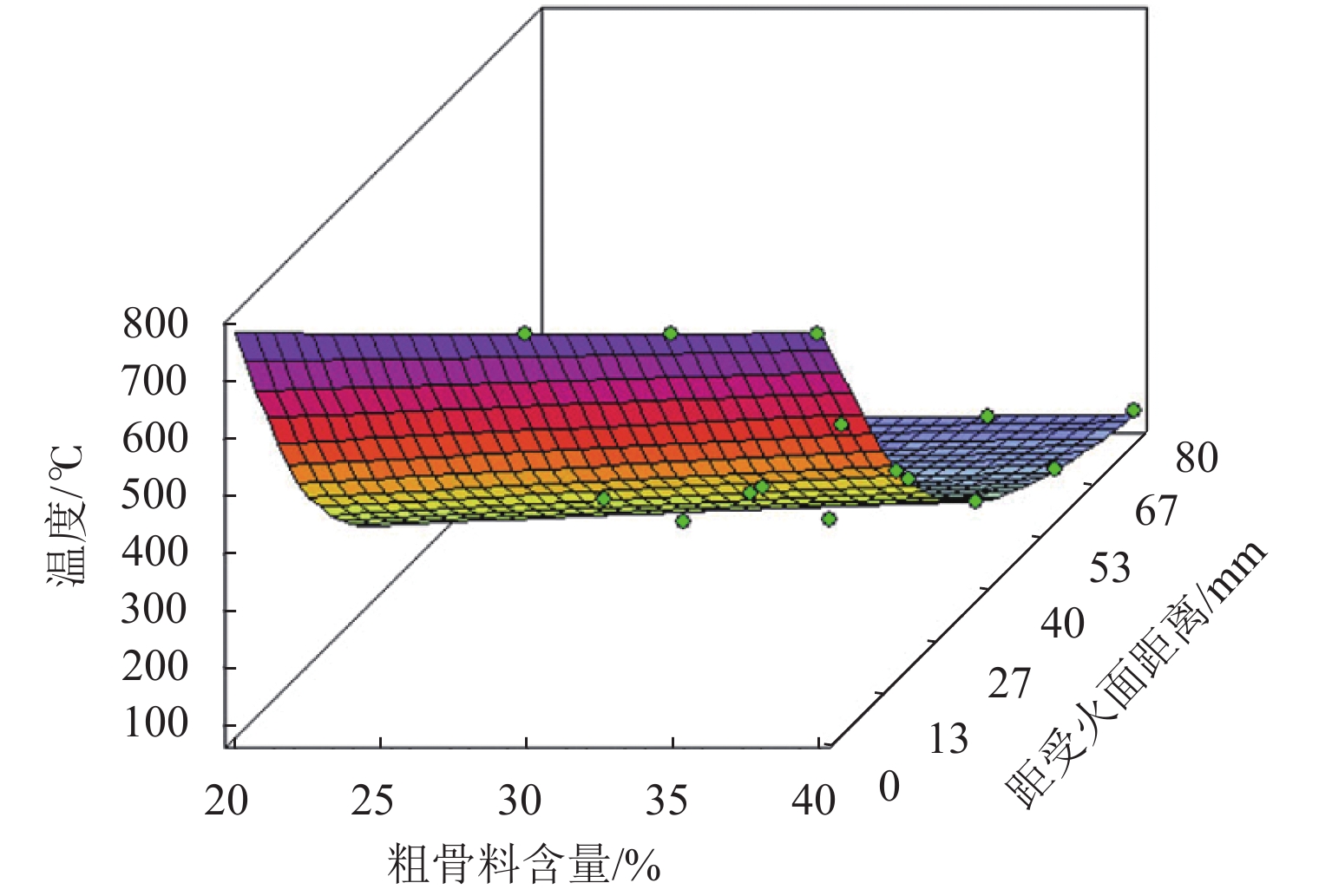

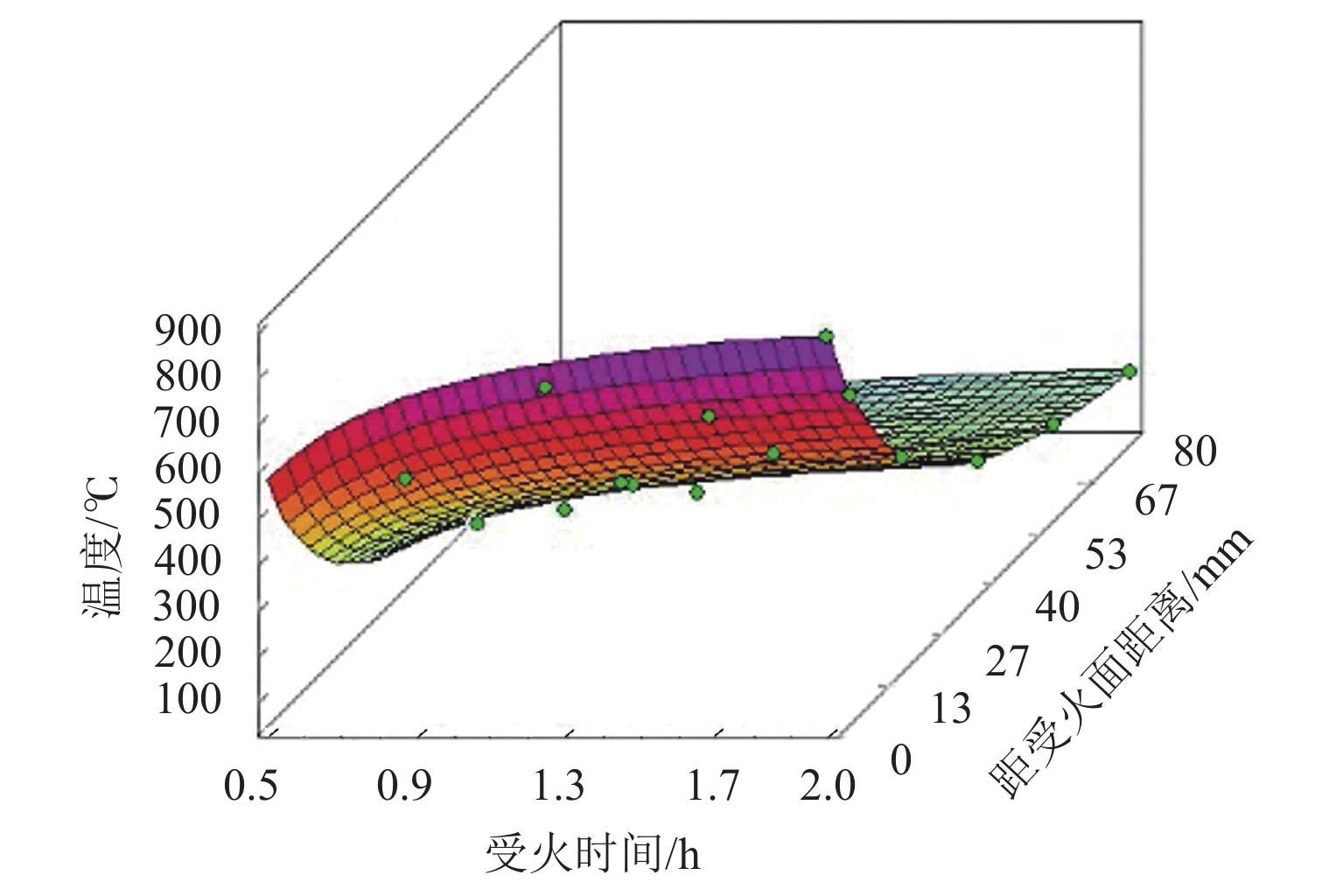

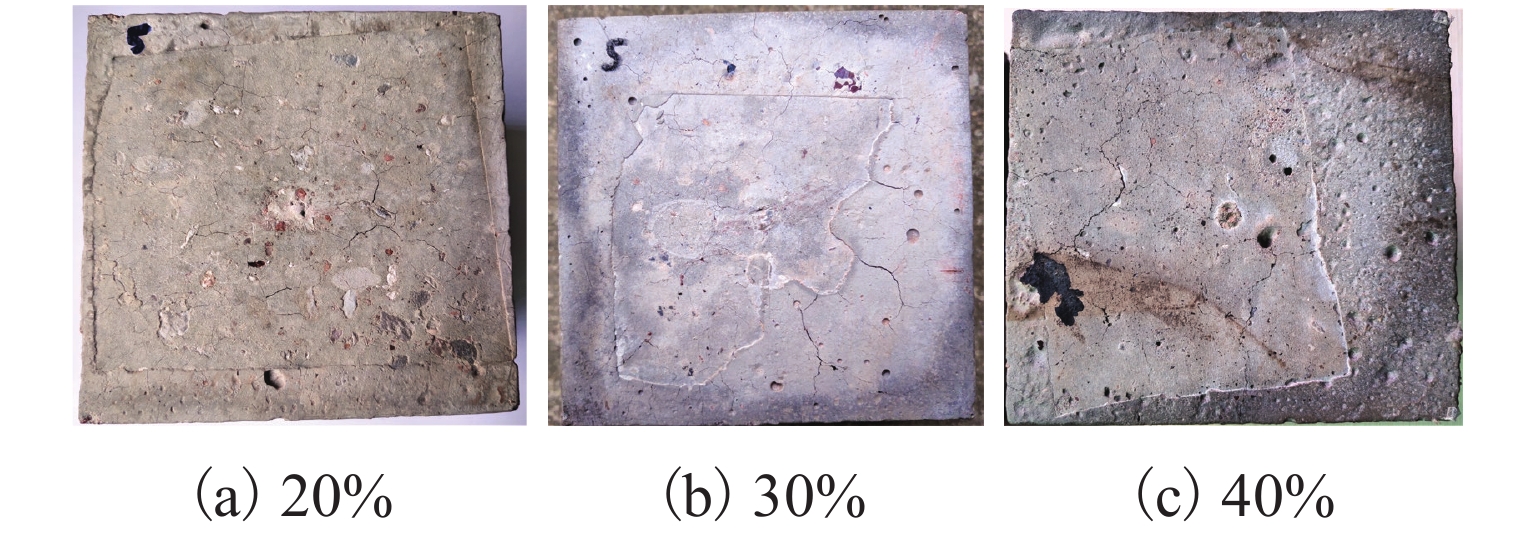

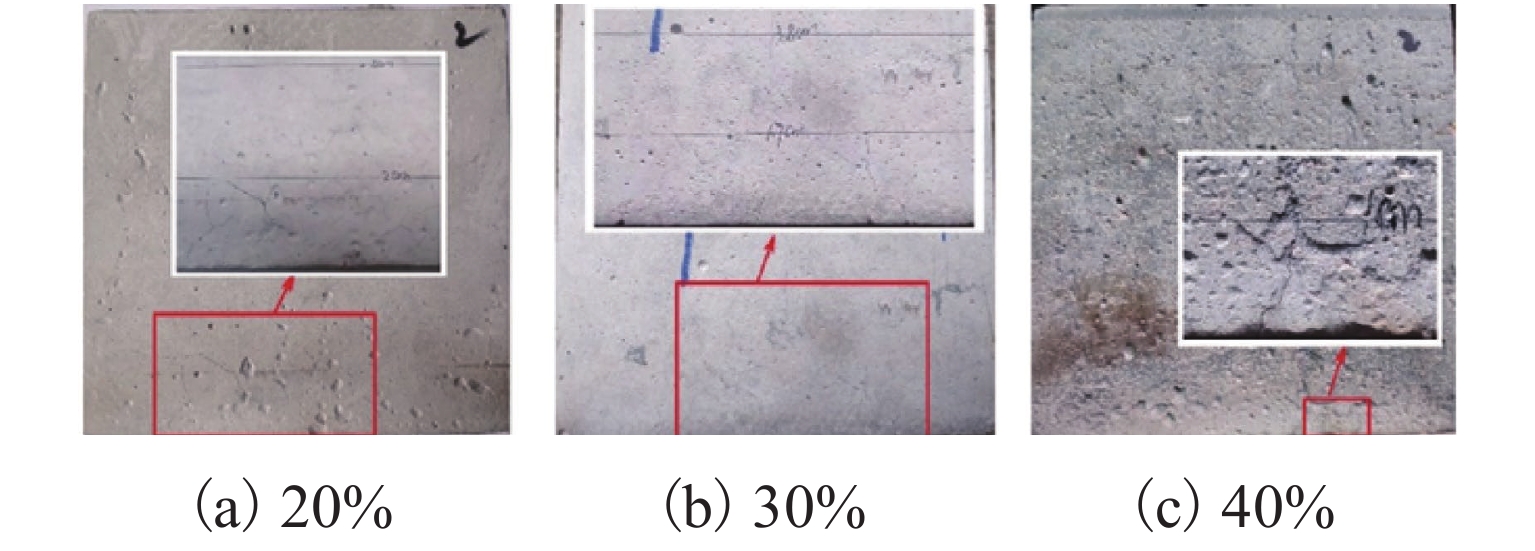

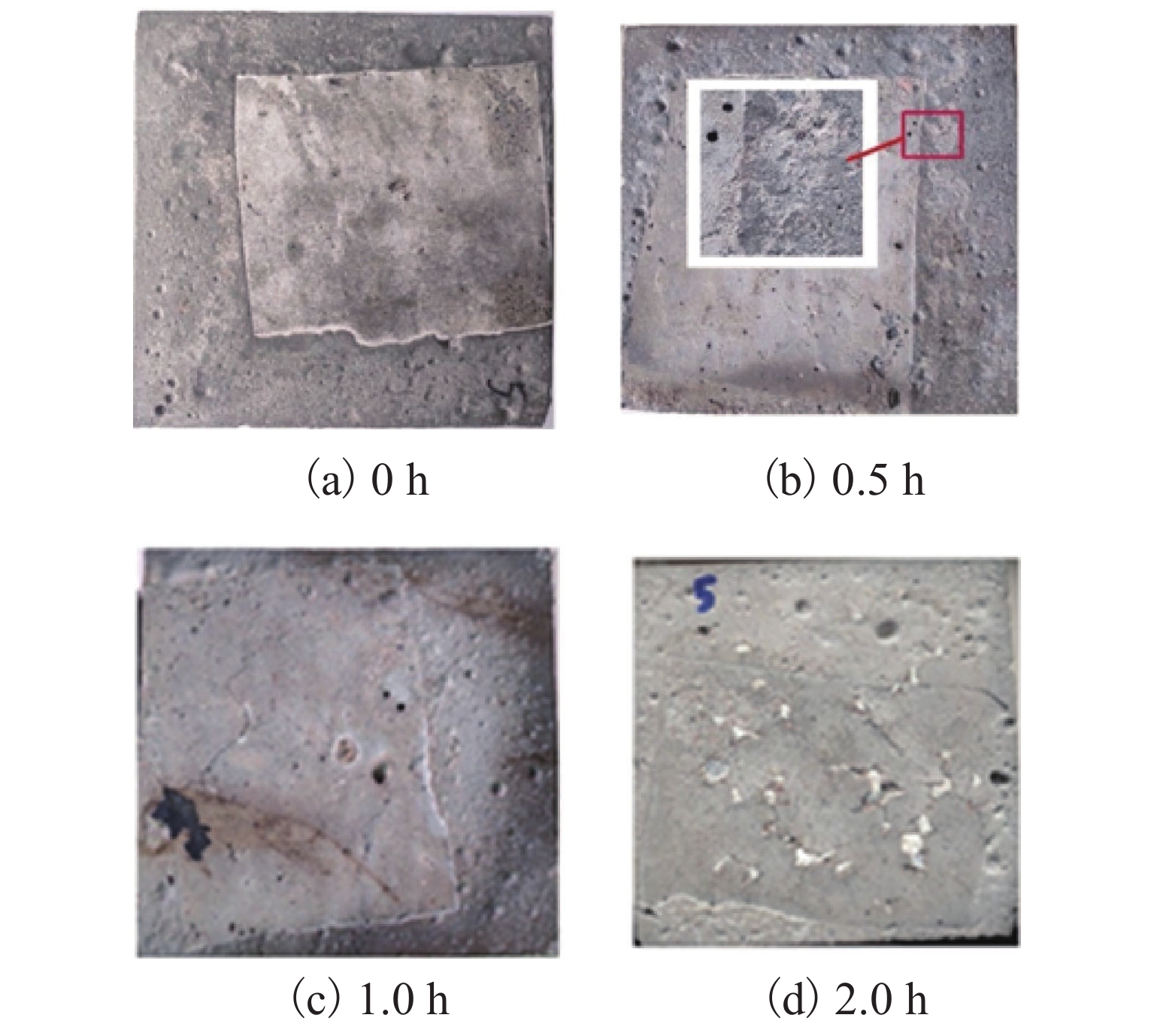

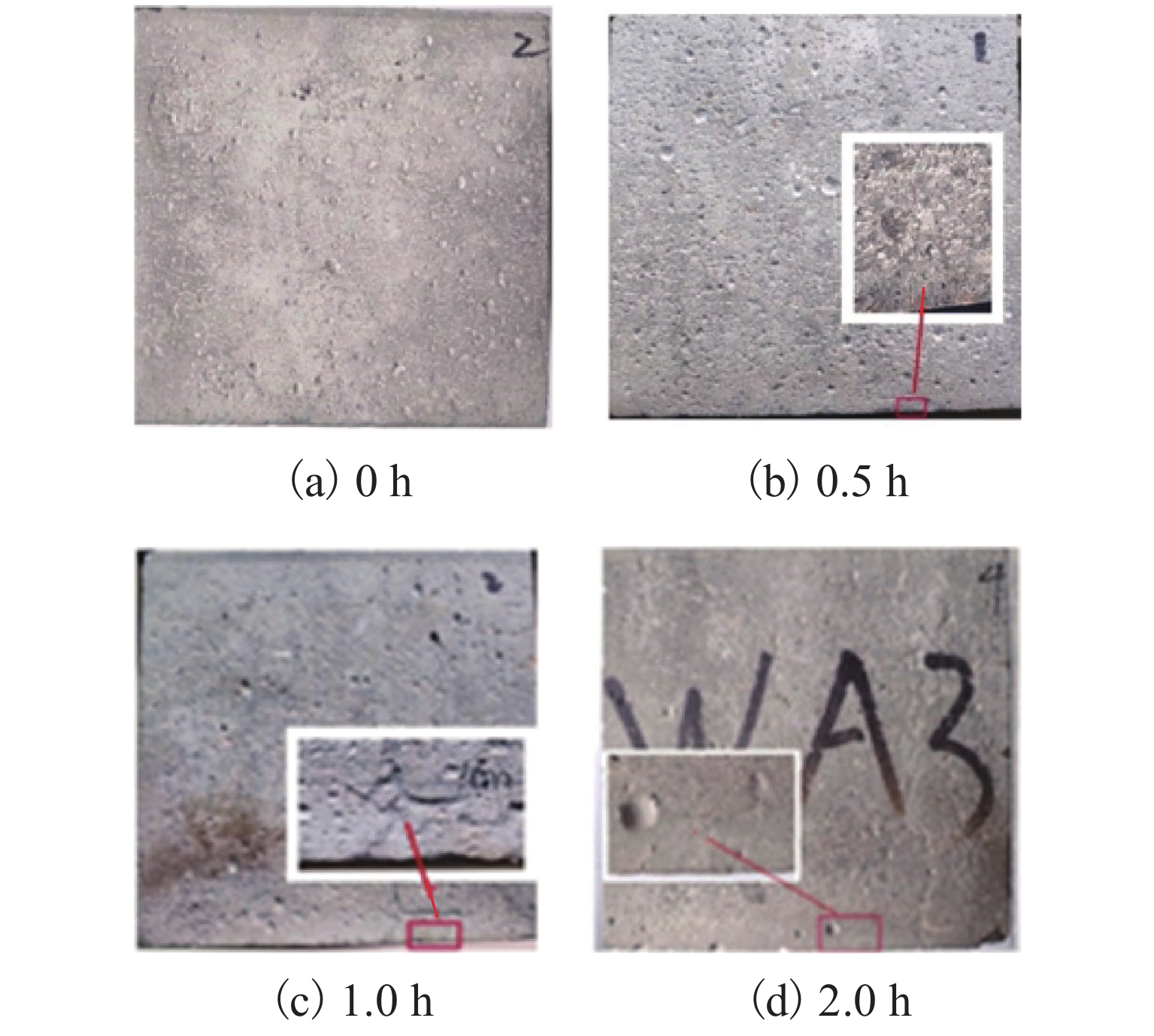

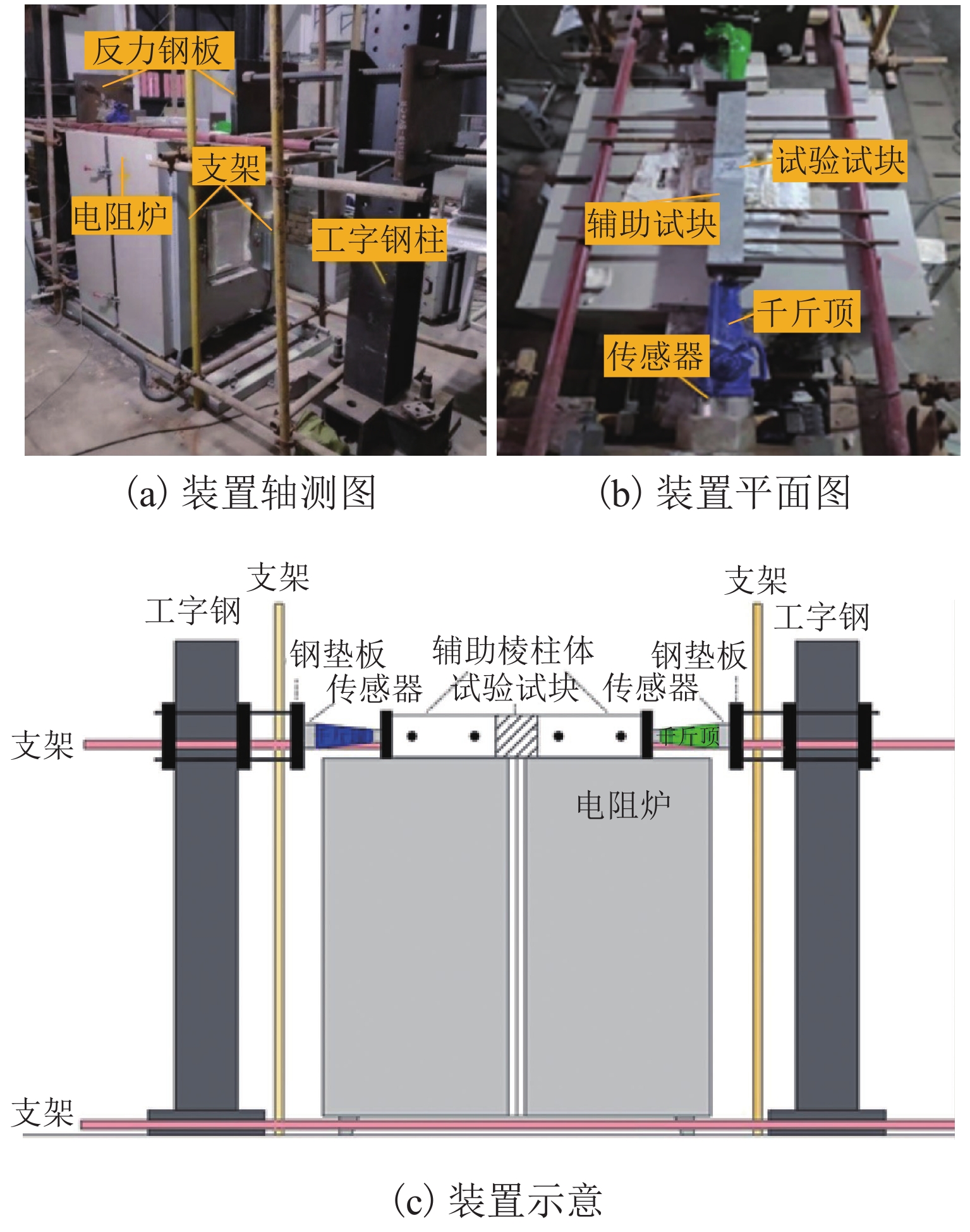

为研究受火时间和粗骨料含量与隧道衬砌混凝土宏观损伤的关系,根据隧道衬砌实际受火特点,自主改良设计一套衬砌混凝土热力耦合试验装置,研究粗骨料含量为20%、30%和40%的混凝土试块在载荷比恒为28%且不同受火时间下的损伤规律. 研究结果表明:无火灾发生时,衬砌混凝土受较小荷载作用下,表面无劣化现象,质量无明显变化,残余抗压强度增加;热力耦合作用下,随着火灾时间增加,受火0.5 h后,试块表面有少许微裂纹形成,1.0 h后表面出现较宽的裂缝,细小裂缝分布较多且部分裂缝相互交叉,受火达到2.0 h,试块底面损伤严重,可以看出火灾的发展时间和程度对衬砌结构的损伤至关重要;随着混凝土粗骨料含量的降低,混凝土内部温度传导速度减慢,相同位置处的温度值变小,其表观损伤显著增加,20%粗骨料含量下质量损失率可达8.14%,而40%粗骨料含量混凝土质量损失率仅为4.10%,强度相同时,高含量粗骨料混凝土的抗火性能更优.

Abstract:In order to study the relationship among the fire exposure time, the content of coarse aggregate, and the macroscopic damage of tunnel lining concrete, a thermo-mechanical coupling test device of lining concrete was independently improved according to the actual fire exposure characteristics of tunnel lining, and the damage law of concrete test blocks with 20%, 30%, and 40% coarse aggregate was studied under the load ratio constant of 28% and different fire exposure time. The results show that when there is no fire accident, no deterioration appears on the surface of the lining concrete under a small load, and the quality does not change greatly. The residual compressive strength increases. Under the action of thermo-mechanical coupling, as the fire continues, a few micro-cracks form on the surface of the test block after 0.5 h of fire exposure, and wide cracks appear on the surface after 1.0 h of fire exposure, with many small cracks distributed and some cracks crossing each other. After 2.0 h of fire exposure, the bottom surface of the test block is seriously damaged. The time and degree of fire development are crucial to the damage to the lining structure. As the content of coarse aggregate of concrete decreases, the internal temperature conduction velocity of concrete slows down; the temperature value at the same position becomes smaller, and the apparent damage increases significantly. The mass loss rate of concrete with 20% coarse aggregate can reach 8.14%, while that of concrete with 40% coarse aggregate is only 4.10%, which indicates that when the strength is the same, concrete with high-content coarse aggregate has better fire resistance.

-

表 1 混凝土试块配合比

Table 1. Mix ratio of concrete test blocks

kg/m3 粗骨料

含量%水胶比 水 水泥 粉煤灰 矿粉 大碎石 小碎石 河砂 减水剂 40 0.35 147 189 105 126 733 314 775 4.20 30 0.35 228 292 163 195 563 242 606 0.40 20 0.35 318 408 227 272 375 161 404 0.16 表 2 试验工况

Table 2. Test conditions

试验类型 受火时间/h 有无比 粗骨料/% 试件编号 试件总数/个 静载试验 0 无 40 WS1-WS3、WS1'- WS3' 18 (WS1'−WS9'试块用于热力

耦合试验前确定强度)30 WS4-WS6、WS4'-WS6' 20 WS7-WS9、WS7'-WS9' 受火试验 0.5 有 40 WA1 5 1.0 40 WA2 2.0 40 WA3 1.0 30 WB 1.0 20 WC 静载试验 0 无 40 WA 6 0.5 无 40 WA1 1.0 无 40 WA2 2.0 无 40 WA3 1.0 有 30 WB 1.0 有 20 WC 注:1. 除用于强度标定的试块为一组外,其余试块均制作相同的2组,一组用于扫描,一组用于温度测量,编号 按WAT等形式进行,因此,试块总数为30个;2. 荷载比即为试验时所加荷载与试验前极限抗压强度之比. 表 3 相对质量变化

Table 3. Relative mass change

试块编号 m1/g m2/g Δm/g α/% WA 2 443 2 433 10 0.41 WA1 2 450 2 373 77 3.14 WA2 2 440 2 340 100 4.10 WA3 2 448 2 333 115 4.70 WB 2 380 2 251 129 5.42 WC 2 229 2 111 118 8.14 表 4 28 d混凝土抗压强度值

Table 4. Concrete compressive strength value after 28 d

粗骨料含量/% 抗压强度/MPa 20 57.16 30 58.01 40 61.72 表 5 不同龄期混凝土强度值

Table 5. Concrete strength values of different ages

粗骨料含量/

%28 d 强度/

MPa90 d 强度/

MPa强度变化率/

%40 61.72 66.3 7.4 30 58.01 68.9 18.8 20 57.16 71.7 25.4 表 6 不同粗骨料含量下的抗压强度损失率

Table 6. Compressive strength loss rate under different coarse aggregate contents

粗骨料含量/% σ0/MPa σs/MPa f/% 40 66.3 60.41 8.88 30 68.9 63.10 8.42 40 71.7 62.36 13.03 表 7 不同受火时间下的抗压强度损失率

Table 7. Compressive strength loss rate under different fire exposure time

受火时间/h σ0/MPa σs/MPa f/% 0 66.3 70.50 −6.33 0.5 66.3 65.80 0.75 1.0 66.3 60.41 8.88 2.0 66.3 55.50 16.30 -

[1] PICHLER C, LACKNER R, MANG H A. Safety assessment of concrete tunnel linings under fire load[J]. Journal of Structural Engineering, 2006, 132(6): 961-969. doi: 10.1061/(ASCE)0733-9445(2006)132:6(961) [2] 闫治国,朱合华,梁利. 火灾高温下隧道衬砌管片力学性能试验[J]. 同济大学学报(自然科学版),2012,40(6): 823-828.YAN Zhiguo, ZHU Hehua, LIANG Li. Experimental study on mechanical performance of lining segments in fire accidents[J]. Journal of Tongji University (Natural Science), 2012, 40(6): 823-828. [3] 李忠友,刘元雪,刘树林,等. 火灾作用下隧道衬砌结构变形理论分析模型[J]. 岩土力学,2012,33(增2): 307-310.LI Zhongyou, LIU Yuanxue, LIU Shulin, et al. Theoretical analysis model of deformation behavior of tunnel linings subjected to fire load[J]. Rock and Soil Mechanics, 2012, 33(S2): 307-310. [4] YAN Z G, ZHU H H, WOODY J, et al. Full-scale fire tests of RC metro shield TBM tunnel linings[J]. Construction and Building Materials, 2012, 36: 484-494. doi: 10.1016/j.conbuildmat.2012.06.006 [5] 郭军,刘帅,蒋树屏. 海底隧道管节结构防火试验与数值模拟[J]. 中国公路学报,2016,29(1): 96-104,114.GUO Jun, LIU Shuai, JIANG Shuping. Fire-proof test and numerical simulation on tube structure of subsea tunnel[J]. China Journal of Highway and Transport, 2016, 29(1): 96-104,114. [6] QIAO R J, SHAO Z S, WEI W, et al. Theoretical investigation into the thermo-mechanical behaviours of tunnel lining during RABT fire development[J]. Arabian Journal for Science and Engineering, 2019, 44(5): 4807-4818. doi: 10.1007/s13369-018-3555-x [7] ZHANG Q, WANG W Y, BAI S S, et al. Response analysis of tunnel lining structure under impact and fire loading[J]. Advances in Mechanical Engineering, 2019, 11(3): 168781401983447.1-168781401983447.6. [8] 王明年,田源,于丽,等. 基于混凝土循环剥落的隧道火灾损伤数值模型研究[J]. 中国安全生产科学技术,2020,16(3): 105-110.WANG Mingnian, TIAN Yuan, YU Li, et al. Study on numerical model of tunnel fire damage based on concrete cyclic spalling[J]. Journal of Safety Science and Technology, 2020, 16(3): 105-110. [9] CHAN Y N, PENG G F, ANSON M. Residual strength and pore structure of high-strength concrete and normal strength concrete after exposure to high temperatures[J]. Cement and Concrete Composites, 1999, 21(1): 23-27. doi: 10.1016/S0958-9465(98)00034-1 [10] 黄涛,王珍,张泽江. 公路隧道衬砌高性能混凝土的高温烧损试验研究[J]. 中国矿业大学学报,2012,41(1): 139-144.HUANG Tao, WANG Zhen, ZHANG Zejiang. Experimental research on the high-temperature burning of a highway tunnel lining made from high performance concrete[J]. Journal of China University of Mining & Technology, 2012, 41(1): 139-144. [11] MA Q M, GUO R X, ZHAO Z M, et al. Mechanical properties of concrete at high temperature-A review[J]. Construction and Building Materials, 2015, 93: 371-383. doi: 10.1016/j.conbuildmat.2015.05.131 [12] DU S, ZHANG Y C, SUN Q, et al. Experimental study on color change and compression strength of concrete tunnel lining in a fire[J]. Tunnelling and Underground Space Technology, 2018, 71: 106-114. doi: 10.1016/j.tust.2017.08.025 [13] 张秋实,周川胜,孙春平,等. 高温环境下钢筋混凝土结构温度传播规律研究[J]. 现代隧道技术,2021,58(4): 185-193.ZHANG Qiushi, ZHOU Chuansheng, SUN Chunping, et al. Study on the pattern of temperature propagation of reinforced concrete structure under high-temperature environment[J]. Modern Tunnelling Technology, 2021, 58(4): 185-193. [14] 中国建筑科学研究院, 中华人民共和国建设部, 国家质量监督检验检疫总局. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2002. [15] 巴光忠,苗吉军,张伟平,等. 高温下混凝土裂缝对温度场的影响[J]. 建筑材料学报,2016,19(4): 730-736. doi: 10.3969/j.issn.1007-9629.2016.04.021BA Guangzhong, MIAO Jijun, ZHANG Weiping, et al. Influence of crack on temperature field of concrete at elevated temperature[J]. Journal of Building Materials, 2016, 19(4): 730-736. doi: 10.3969/j.issn.1007-9629.2016.04.021 [16] 中华人民共和国公安部. 建筑设计防火规范: GB 50016—2014[S]. 北京: 中国计划出版社, 2014. [17] 韩宇栋,张君,高原. 粗骨料体积含量对混凝土断裂参数的影响[J]. 工程力学,2013,30(3): 191-197,205.HAN Yudong, ZHANG Jun, GAO Yuan. Effect of coarse aggregate content on fracture parameters of concrete[J]. Engineering Mechanics, 2013, 30(3): 191-197,205. -

下载:

下载: