Optimization of Wagon Flow Assignment with Transship Work for Multiple Marshaling Stations at Railroad Terminals

-

摘要:

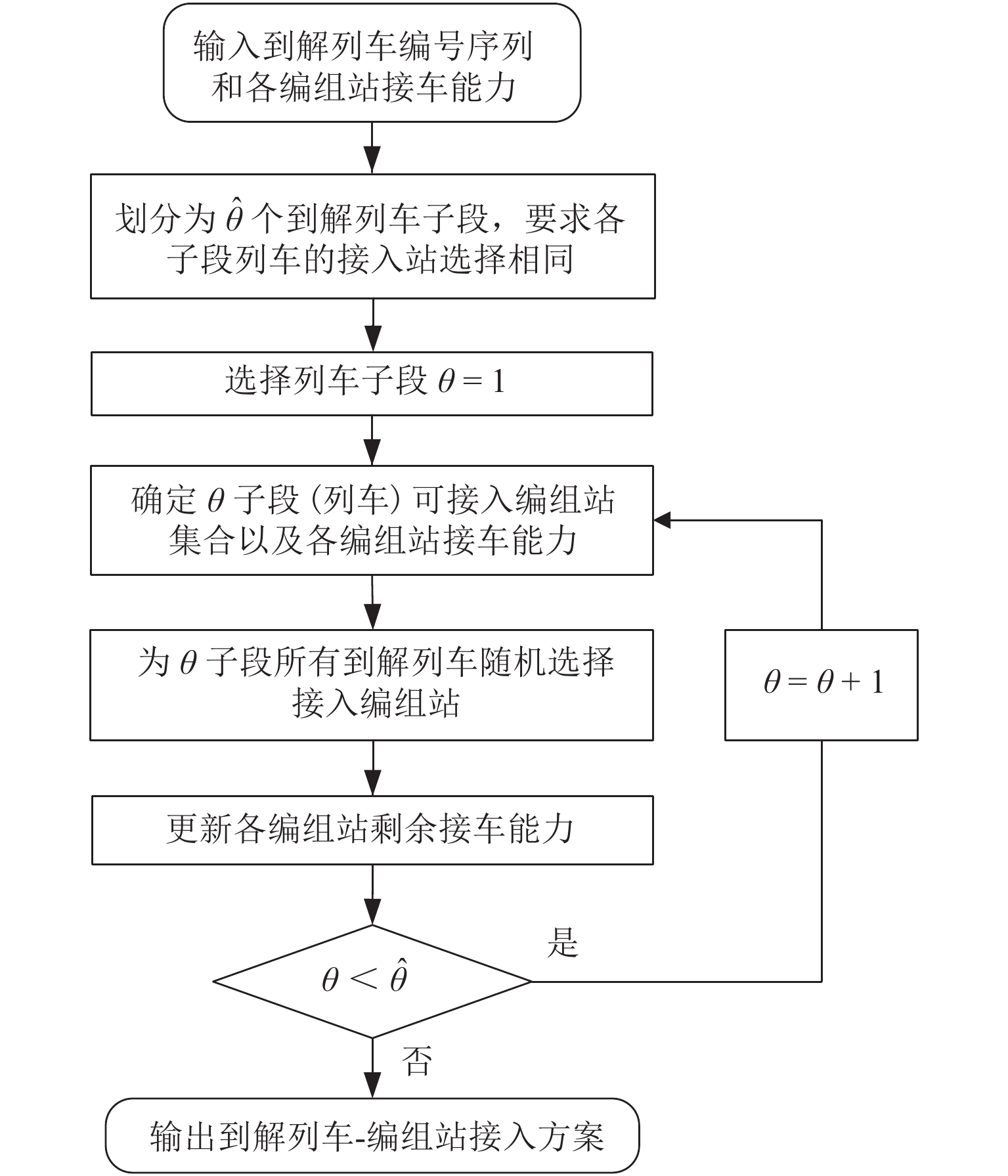

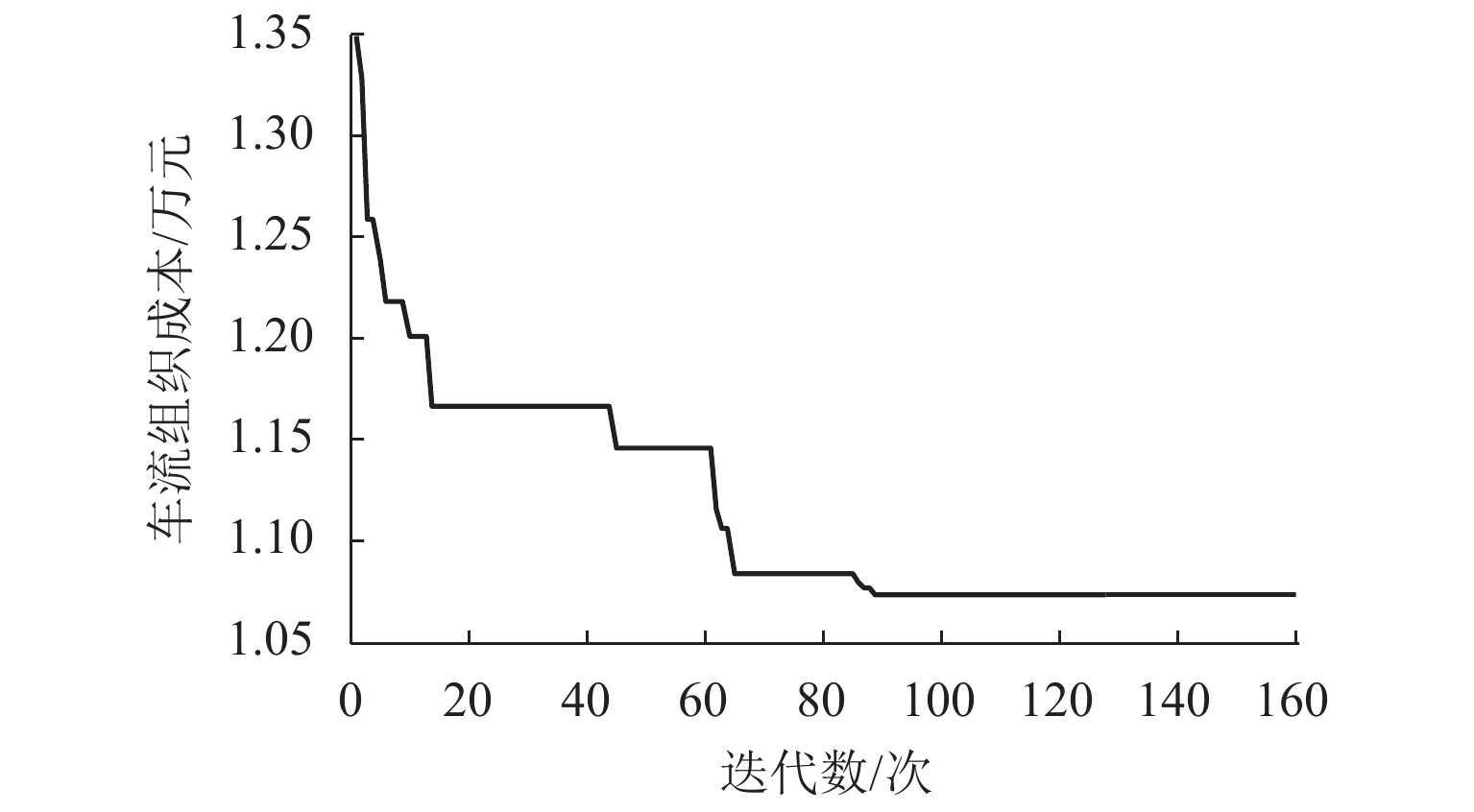

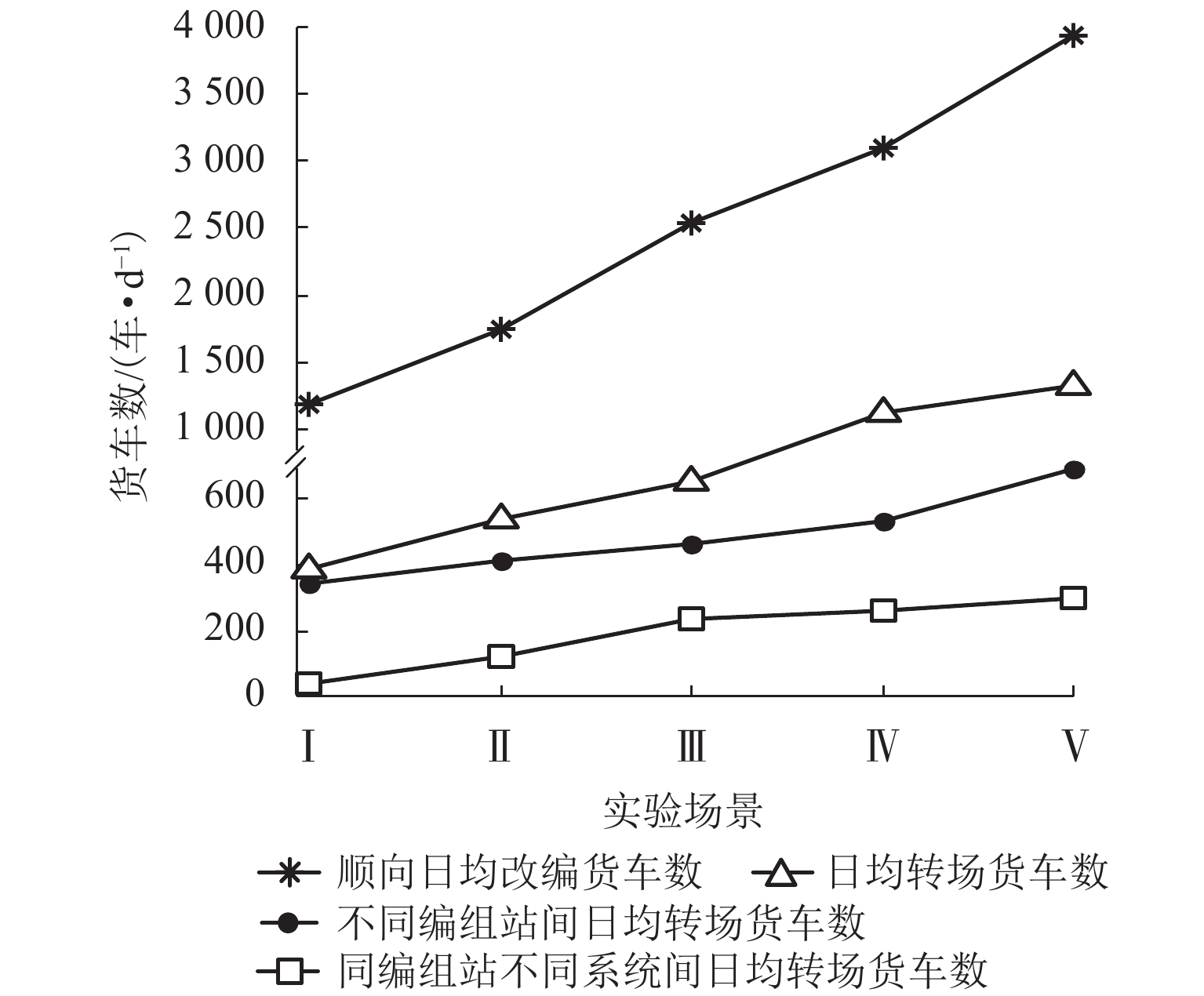

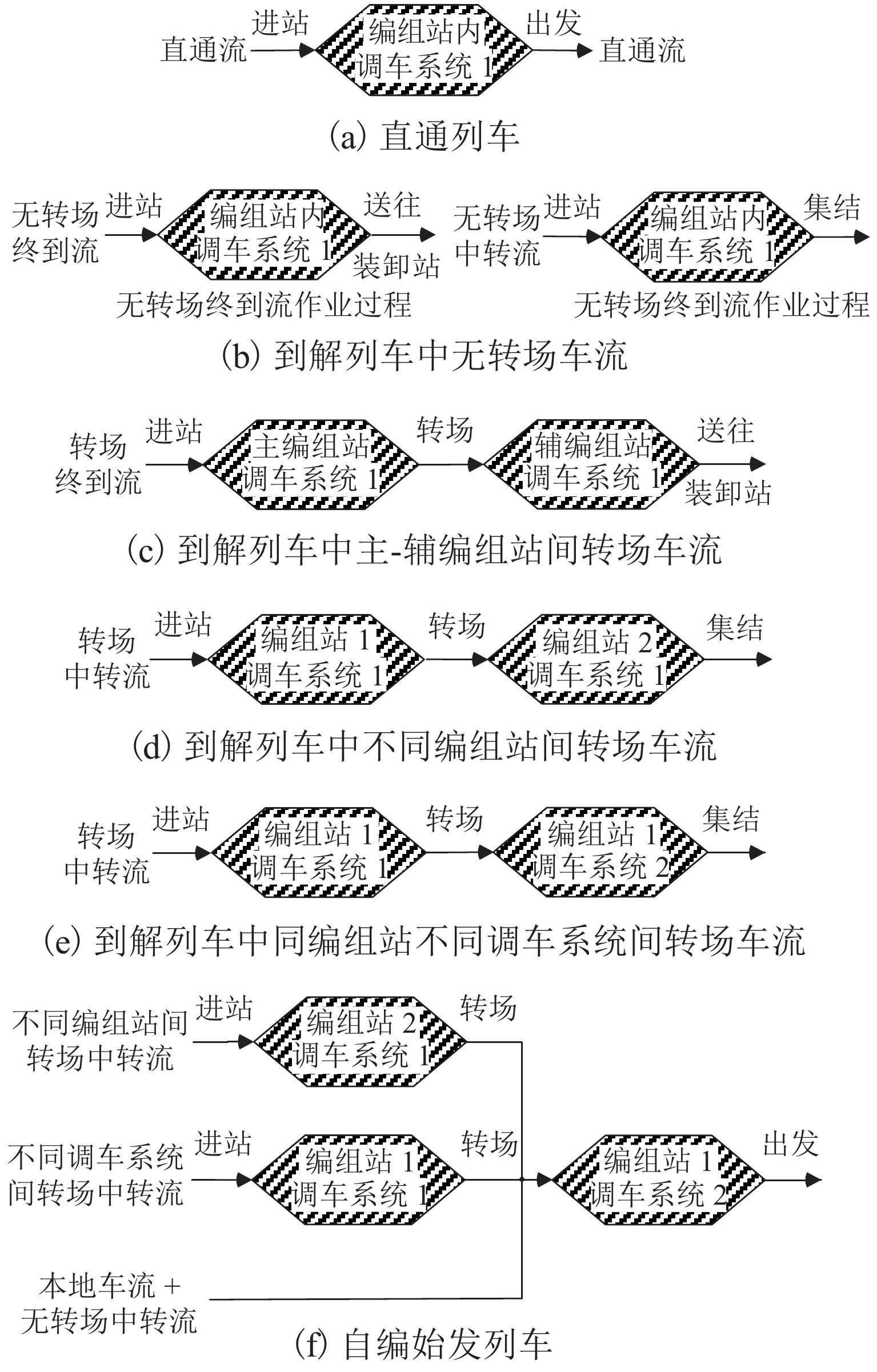

为提升多编组站铁路枢纽车流运转效率,首先,在分析枢纽内不同类型车流作业过程的基础上,以枢纽内列车进出站走行、车流改编、列车集结和转场扰动惩罚费用最小化为目标,构建数学模型;其次,根据接入枢纽铁路方向和场站接发列车能力,生成列车-编组站-调车系统初始匹配方案,进而利用转场-解集编能力对匹配方案进行调整与检验;再次,给出列车-编组站-调车系统匹配方案的双层编码方案,并利用嵌入替换-扰动-交叉操作的异步循环更新过程,完成匹配方案的群体寻优;最后,设计仿真试验对所提模型与算法进行测试. 结果表明:所提方法能够完成对多编组站的合理分工,5组试验测试分别在369、422、516、641、763 s的计算时间内得到列车-编组站-调车系统匹配方案,在优化分工后的车流组织方案中,转场货车占到解车流比例均能稳定在20%,从而达到减少转场货车数、降低车流组织成本的目的.

Abstract:To improve the operation efficiency of wagon flow at railroad terminals with multiple marshaling stations, firstly based on the analysis of different types of wagon flow operations at the terminal, the mathematical model is constructed with the goal of minimizing the total costs of wagons entering and leaving a station, wagon flow reorganization, wagon assembly and transship. Secondly, according to the railroad direction and the capacity of receiving and dispatching trains at the station, an initial matching scheme of the train−marshaling station−shunting system is designed, and then the matching scheme is adjusted and tested by using the transship and disaggregation capacity. Thirdly, a double-layer coding scheme for the matching scheme of the train−marshalling station−shunting system is provided, and the group optimization of the matching scheme is completed with the asynchronous iteration updating process of the embedded replacement–disturbance–crossing operation. Finally, a simulation experiment is conducted to test the proposed model and algorithm. The experimental results show that the proposed method can complete the reasonable division of assignments for multiple marshalling stations. Five groups of test tests can obtain the matching scheme of train−marshalling station−shunting system in the calculation time of 369, 422, 516, 641 and 763 s, respectively. In the optimized division of assignments, the proportion of wagon transship in arrival wagons flow can be stabilized at 20%, so as to reduce the number of wagon transships and reduce the cost of traffic flow organization.

-

表 1 编组站间距离及衔接方向

Table 1. Traveling distance between multiple marshaling stations and railway direction connecting marshaling stations

编组站 编组站间距离/km 衔接方向 m1 m2 m3 m1 0 36.4 44.6 1,2,3,4,5 m2 36.4 0 31.6 1,2,3,4,6 m3 44.6 31.6 0 1,2,3,6 表 2 枢纽内编组站与枢纽外相邻技术站间走行距离

Table 2. Traveling distance between marshalling stations inside terminal and adjacent technical stations outside terminal

km 方向 编组站 衔接方向 1 2 3 4 5 6 进入

枢纽m1 3.8 36.2 38.7 3.6 15.5 16.6 m2 33.2 4.8 27.4 29.4 17.2 14.5 m3 41.5 31.7 4.4 38.6 39.3 42.1 离开

枢纽m1 4.2 34.6 44.5 5.3 14.9 15.3 m2 29.6 6.7 23.8 30.6 16.6 13.2 m3 41.2 30.4 5.2 42.1 43.4 45.3 表 3 编组站作业能力

Table 3. Technical operation capability of marshalling stations

车/d 编组站 调车

系统技术作业能力 到达 解体 集结 编组 出发 m1 k0 700 850 800 750 650 k1 650 800 750 750 700 m2 k0 250 400 450 450 300 k1 250 450 400 350 300 m3 k0 350 500 450 450 300 k1 300 350 350 400 350 表 4 编组站作业费用

Table 4. Operation cost of marshalling stations

编组站 顺向改编/

(元•车−1)集结消耗/

(元•车−1•h−1)转场费用/(元•车−1) m1 m2 m3 m1 1.02 0.16 2.05 2.22 2.18 m2 1.09 0.18 2.22 2.04 2.21 m3 1.08 0.17 2.18 2.21 2.12 表 5 枢纽各衔接方向接发列车信息

Table 5. Data of arrival and departure trains from different railway directions

列车

类型衔接方向 1 2 3 4 5 6 到解列车 a1~a15 a16~a21 a22~a25 a26~a28 a29~a31 a32~a33 始发列车 d1~d4 d5~d14 d15~d20 d21~d23 d24~d25 d26 直通接入 e1~e3 e4~e5 e6~e7 直通编发 e4 e1 e2~e3 e6 e5 e7 表 8 列车-编组站-调车系统匹配方案

Table 8. Matching scheme of train–marshaling station–shunting system

列车 匹配方案 列车 匹配方案 列车 匹配方案 a1 m1, k0 a23 m3, k1 d12 m1, k1 a2 m1, k0 a24 m1, k1 d13 m2, k1 a3 m1, k0 a25 m1, k1 d14 m1, k1 a4 m1, k0 a26 m2, k0 d15 m1, k1 a5 m1, k0 a27 m2, k0 d16 m1, k0 a6 m1, k1 a28 m2, k0 d17 m3, k1 a7 m1, k1 a29 m1, k0 d18 m1, k0 a8 m1, k1 a30 m1, k1 d19 m1, k0 a9 m1, k0 a31 m1, k0 d20 m1, k0 a10 m1, k0 a32 m3, k1 d21 m1, k1 a11 m3, k0 a33 m2, k1 d22 m2, k1 a12 m3, k0 d1 m1, k0 d23 m1, k1 a13 m2, k1 d2 m1, k0 d24 m1, k1 a14 m1, k1 d3 m1, k0 d25 m1, k0 a15 m3, k1 d4 m3, k1 d26 m2, k0 a16 m1, k0 d5 m1, k0 e1 m1, k0 a17 m1, k0 d6 m1, k0 e2 m1, k0 a18 m1, k0 d7 m1, k0 e3 m1, k1 a19 m1, k0 d8 m2, k0 e4 m2, k0 a20 m1, k0 d9 m3, k0 e5 m2, k1 a21 m1, k0 d10 m1, k0 e6 m1, k0 a22 m3, k0 d11 m3, k0 e7 m3, k0 表 6 到解列车车流结构信息表

Table 6. Data of wagon groups in arrival train flows

列车 车组编号 货车数/车 列车 车组编号 货车数/车 a1 42-43-44 5-20-25 a18 26-27-28 22-14-14 a2 45-46-47 3-20-26 a19 29-30-31 11-23-16 a3 48-49-50 3-22-25 a20 0-32-33 24-20-6 a4 0-51-52 4-22-24 a21 0-34-35 16-22-12 a5 0-53-54 4-21-25 a22 0-12 35-15 a6 0-55-56 6-21-26 a23 13-14-15 16-24-10 a7 0-57-58 3-20-24 a24 0-16-17-18 11-10-15-14 a8 59-60 24-26 a25 0-19 43-7 a9 0-61-62 3-22-25 a26 0-36-37 10-12-28 a10 0-63 22-28 a27 0-38-39 12-14-22 a11 0-64 23-27 a28 0-40-41 5-17-28 a12 0-65-66 10-17-23 a29 0-1-2 19-20-21 a13 0 50 a30 0-3-4 15-10-25 a14 0 50 a31 0-5-6-7 26-3-10-11 a15 0 50 a32 0-8 26-23 a16 20-21-22 20-13-17 a33 0-9-10-11 16-6-11-15 a17 0-23-24-25 7-10-21-12 注:货车数与车组编号相互对应,例如:列车a1由42号车组(5车)、43号车组(20车)和44号车组(25车)构成,表7同. 表 7 始发列车车流结构信息表

Table 7. Data of wagon groups in departure train flows

列车 车组编号 货车数/车 列车 车组编号 货车数/车 d1 0-34-35 5-22-23 d15 1-3-57 20-10-20 d2 0-5-24-26 4-3-21-22 d16 43-46-6 20-20-10 d3 0-20-32 10-20-20 d17 8-21-27 23-13-14 d4 0-14 26-24 d18 0-49-51 6-22-22 d5 44-50 25/25 d19 0-53-55 8-21-21 d6 47-52 26-24 d20 0-59-61 4-24-22 d7 54-62 25-25 d21 28-31-33-35 16-16-6-12 d8 37-39 28-22 d22 0-22-25 21-17-12 d 9 64-66 27-23 d23 0-4-11 20-25-15 d10 2-7-63 11-11-28 d24 65-13-16-19 17-16-10-7 d11 10-12-15-18 13-15-10-14 d25 0-9-29- 7-6-11- d12 56-58 26-24 36-38 12-14 d13 0-41 22-28 d26 17-40-23- 15-17-7- d14 0-60 24-26 42-45-48 5-3-3 表 9 5种不同规模试验场景下的求解结果评测

Table 9. Evaluation of solution results under five test scenarios of different scales

场景 运行时间/s 车流组织

成本/元顺向日均改编车

货数/(车•d−1)同编组站不同调车系统间日均转场货车数/(车•d−1) 不同编组站间日均转场货车数/

(车•d−1)转场货车占到解车流比例/% 场景Ⅰ 369 11070 1261 48 341 23.6 场景Ⅱ 422 13276 1864 124 412 22.3 场景Ⅲ 516 19377 2601 238 461 21.2 场景Ⅳ 641 25683 3186 265 549 20.5 场景Ⅴ 763 33126 3926 298 726 20.7 表 10 5种不同规模试验场景下的算法性能比对

Table 10. Performance comparison of algorithms under five test scenarios of different scales

试验场景 车流组织成本/元 CPU 运行时间/s 改进率/% MTY-GA MTY-AFSA HHTS MTY-GA MTY-AFSA HHTS ℓ1 ℓ2 场景Ⅰ 11697.2 11553.2 11120.2 196.2 307.6 373.2 5.2 3.9 场景Ⅱ 14236.1 13996.1 13292.1 213.3 368.1 415.3 7.1 5.3 场景Ⅲ 21859.3 20507.2 19304.2 248.8 445.7 525.7 13.2 6.2 场景Ⅳ 28683.4 27783.4 25732.4 287.6 547.8 634.5 11.5 8.0 场景Ⅴ 37636.5 36471.9 33107.7 324.3 636.4 769.8 13.7 10.2 -

[1] 严余松,朱松年,杜文. 枢纽小运转列车运行组织的网络流优化模型[J]. 西南交通大学学报,2001,36(2): 117-120.YAN Yusong, ZHU Songnian, DU Wen. Network flow models for organization of transship trains in railway terminals[J]. Journal of Southwest Jiaotong University, 2001, 36(2): 117-120. [2] 毕明凯,何世伟,陈胜波,等. 铁路枢纽小运转列车径路优化[J]. 大连交通大学学报,2015,36(4): 1-4. doi: 10.11953/j.issn.1673-9550.2015.04.001BI Mingkai, HE Shiwei, CHEN Shengbo, et al. Routing optimization study of local train in railway terminal[J]. Journal of Dalian Jiaotong University, 2015, 36(4): 1-4. doi: 10.11953/j.issn.1673-9550.2015.04.001 [3] 李冰,张志宁,轩华. 基于树枝形铁路专用线网络的小运转货物作业系统优化[J]. 系统管理学报,2021,30(2): 201-214.LI Bing, ZHANG Zhining, XUAN Hua. Optimization of local freight train transship system based on branch-shaped siding network[J]. Journal of Systems & Management, 2021, 30(2): 201-214. [4] LI B, QU W Y, XUAN H, et al. Shunting strategy for placing-in and taking-out wagons on branch-shaped freight operation network with simulation method[J]. Journal of Advanced Transportation, 2020, 2020: 3410481.1-3410481.25. [5] 郭垂江. 基于阶段计划的取送车调车作业计划编制优化研究[J]. 铁道学报,2019,41(10): 10-16.GUO Chuijiang. Research on optimization of formulation for shunting operation plan of placing-in and taking-out wagon based on phase plan[J]. Journal of the China Railway Society, 2019, 41(10): 10-16. [6] GHILAS V, CORDEAU J F, DEMIR E, et al. Branch-and-price for the pickup and delivery problem with time windows and scheduled lines[J]. Transportation Science, 2018, 52(5): 1191-1210. doi: 10.1287/trsc.2017.0798 [7] JAEHN F, OTTO A, SEIFRIED K. Shunting operations at flat yards: retrieving freight railcars from storage tracks[J]. OR Spectrum, 2018, 40(2): 367-393. [8] 陈皓,王文宪,李雪芹. 铁路网多流向超限货物运输路径优化模型及算法[J]. 西南交通大学学报,2016,51(1): 145-151.CHEN Hao, WANG Wenxian, LI Xueqin. Routing optimization model and algorithm for out-of-gauge freights in multiple flow railway network[J]. Journal of Southwest Jiaotong University, 2016, 51(1): 145-151. [9] 高明明. 北京铁路枢纽货运系统布局规划研究[J]. 铁道工程学报,2010,27(4): 101-106.GAO Mingming. Research on the arrangement planning for freight traffic system of Beijing railway terminal[J]. Journal of Railway Engineering Society, 2010, 27(4): 101-106. [10] MARINOV M, GIOVANNI L D, BELLISAI G, et al. Analysis of rail yard and terminal performances[J]. Journal of Transport Literature, 2014, 8(2): 178-200. doi: 10.1590/S2238-10312014000200008 [11] 王志美. 铁路网车流组织与双向编组站作业分工综合优化[D]. 北京: 北京交通大学, 2013. -

下载:

下载: