Optimum Structural Design of Active Magnetic Bearing Based on RBF Approximation Model

-

摘要:

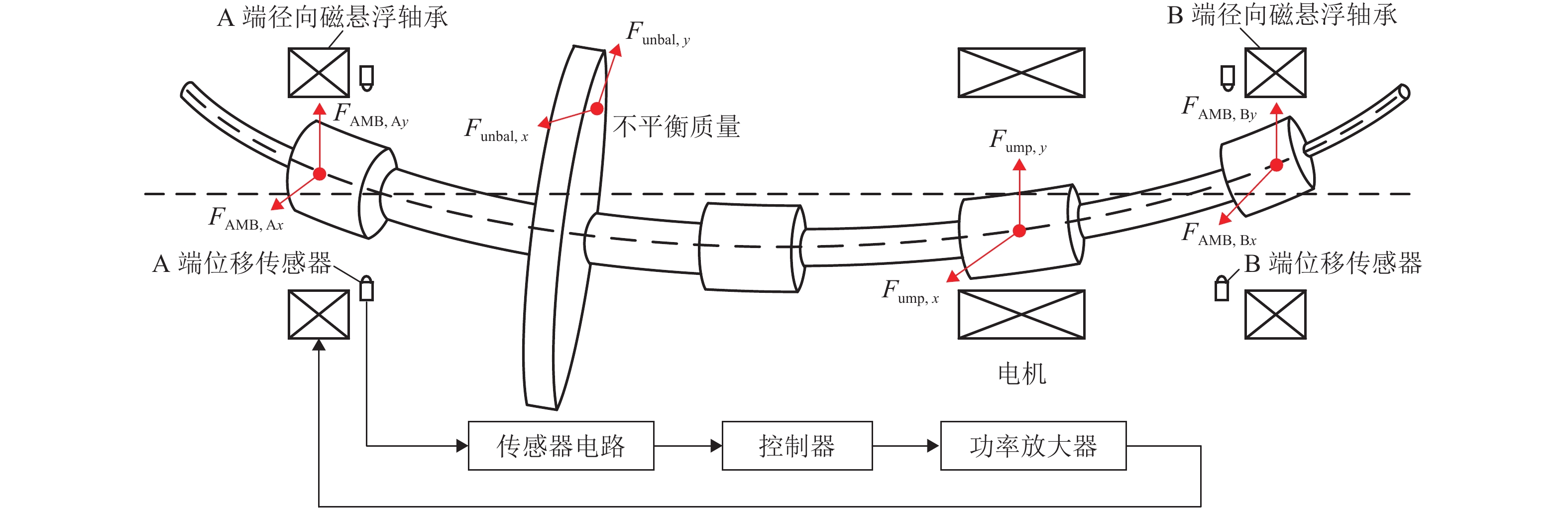

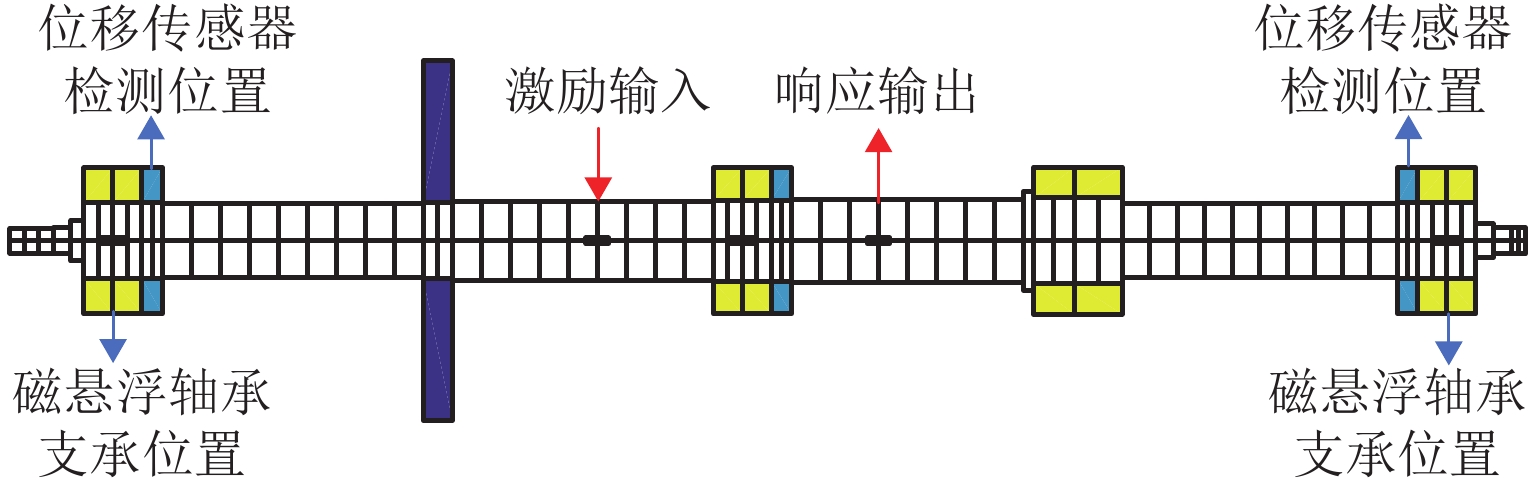

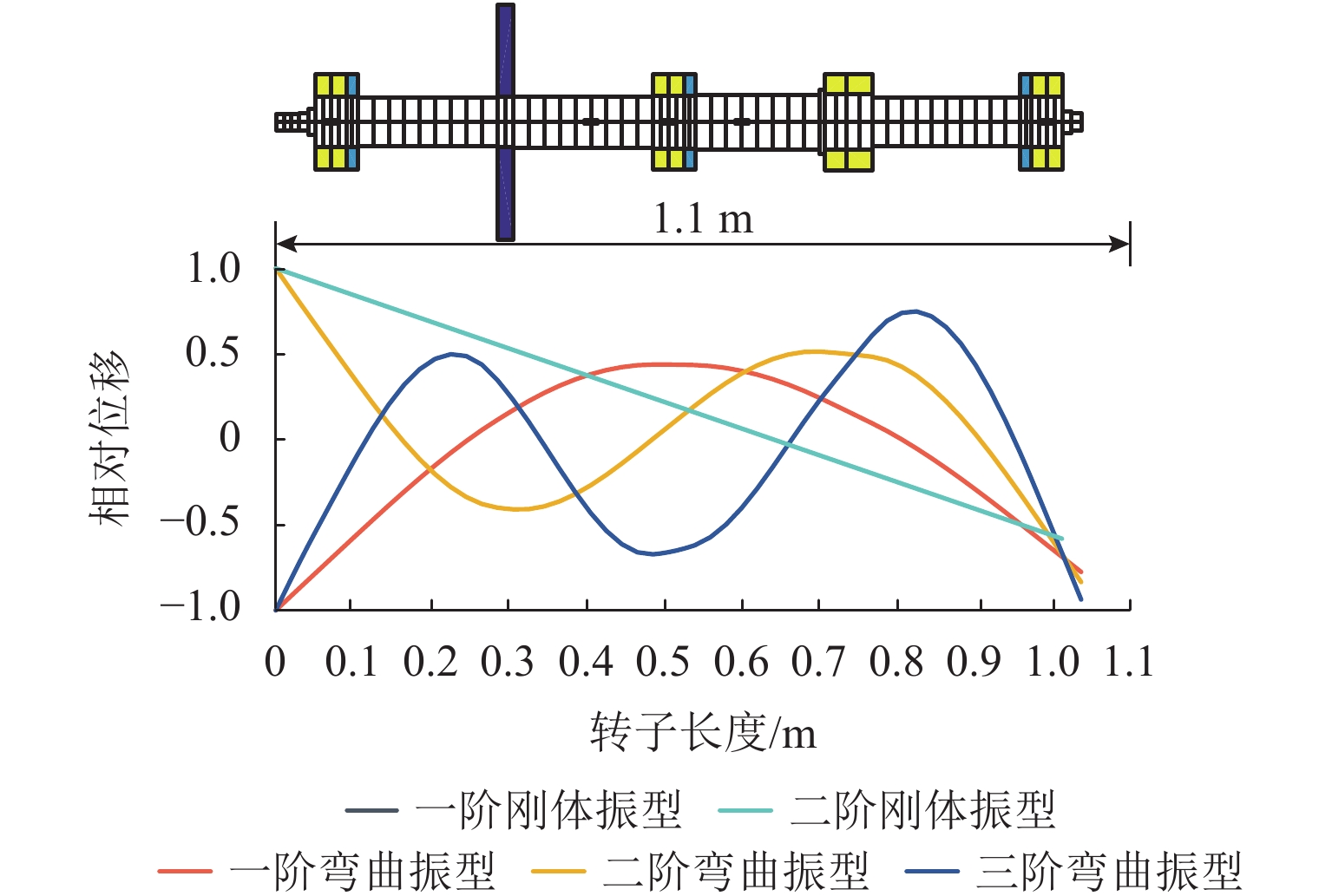

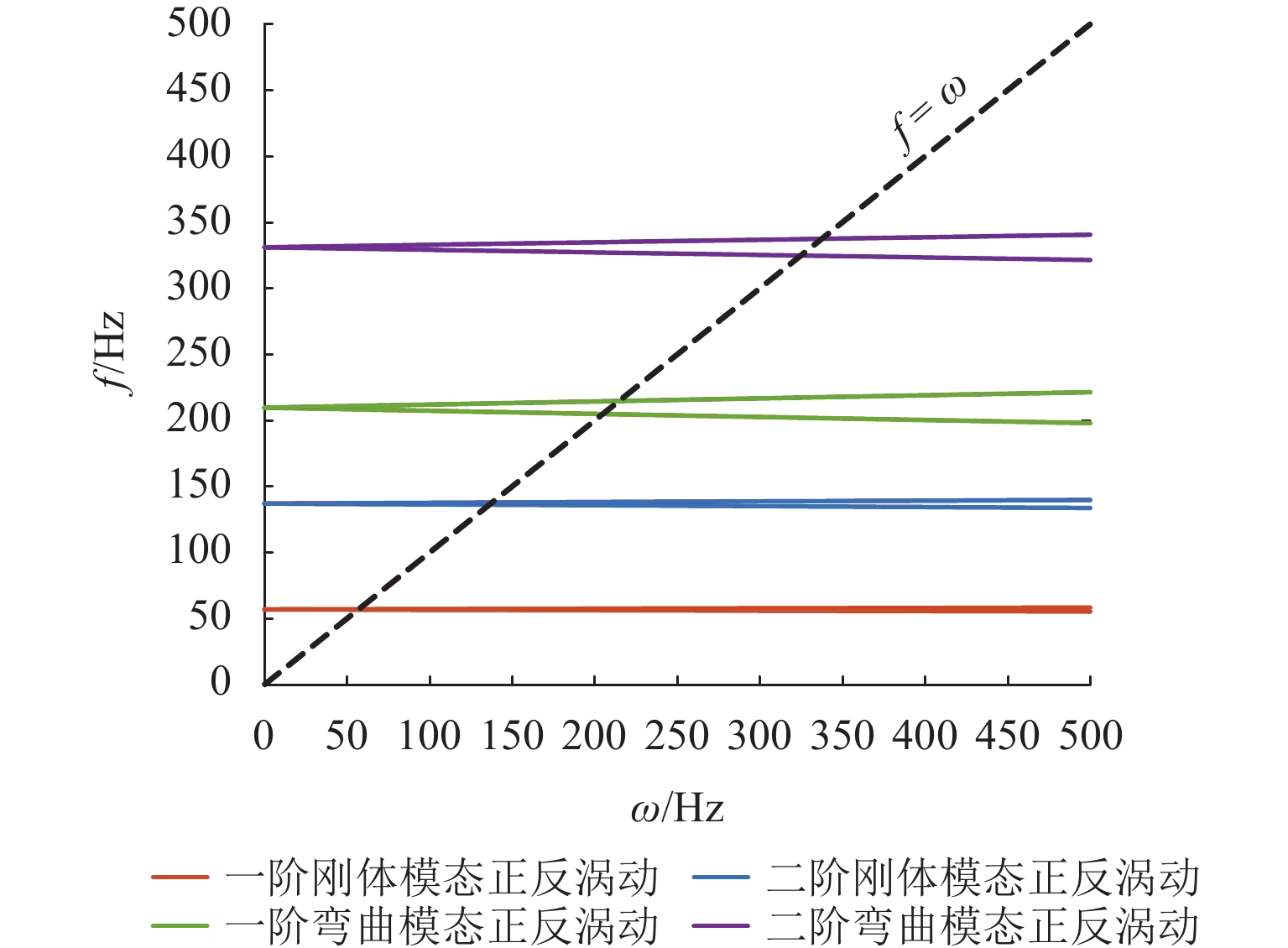

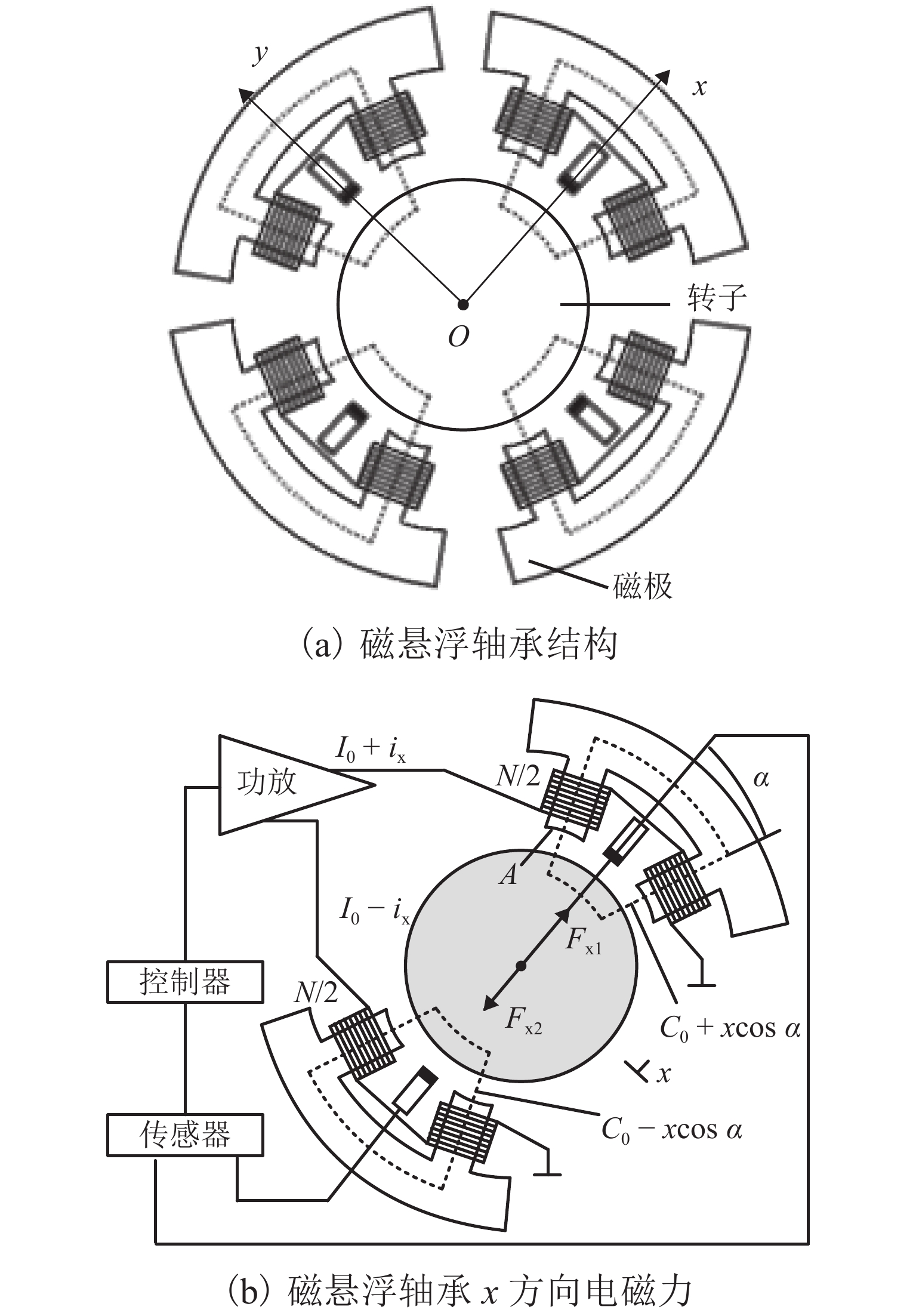

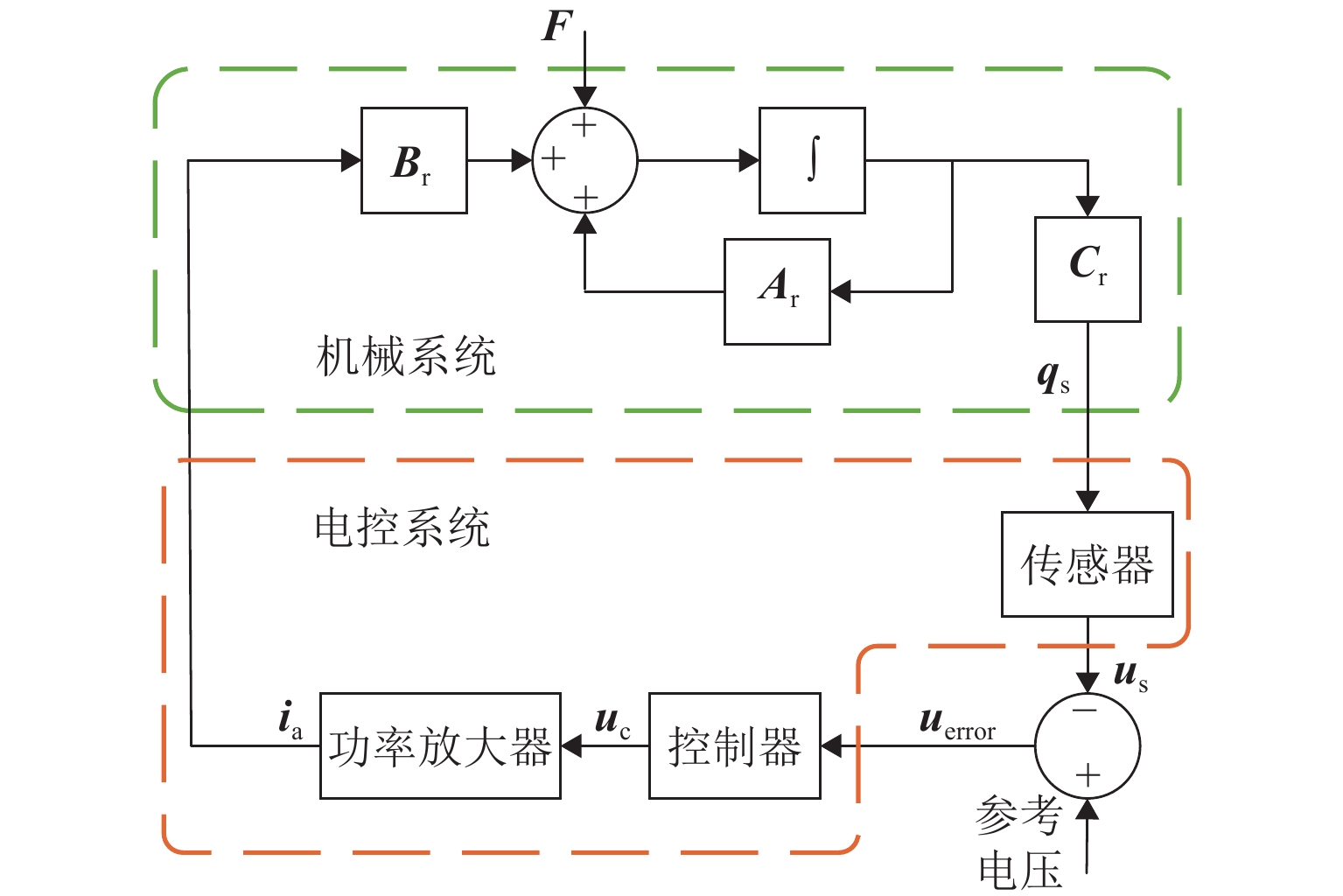

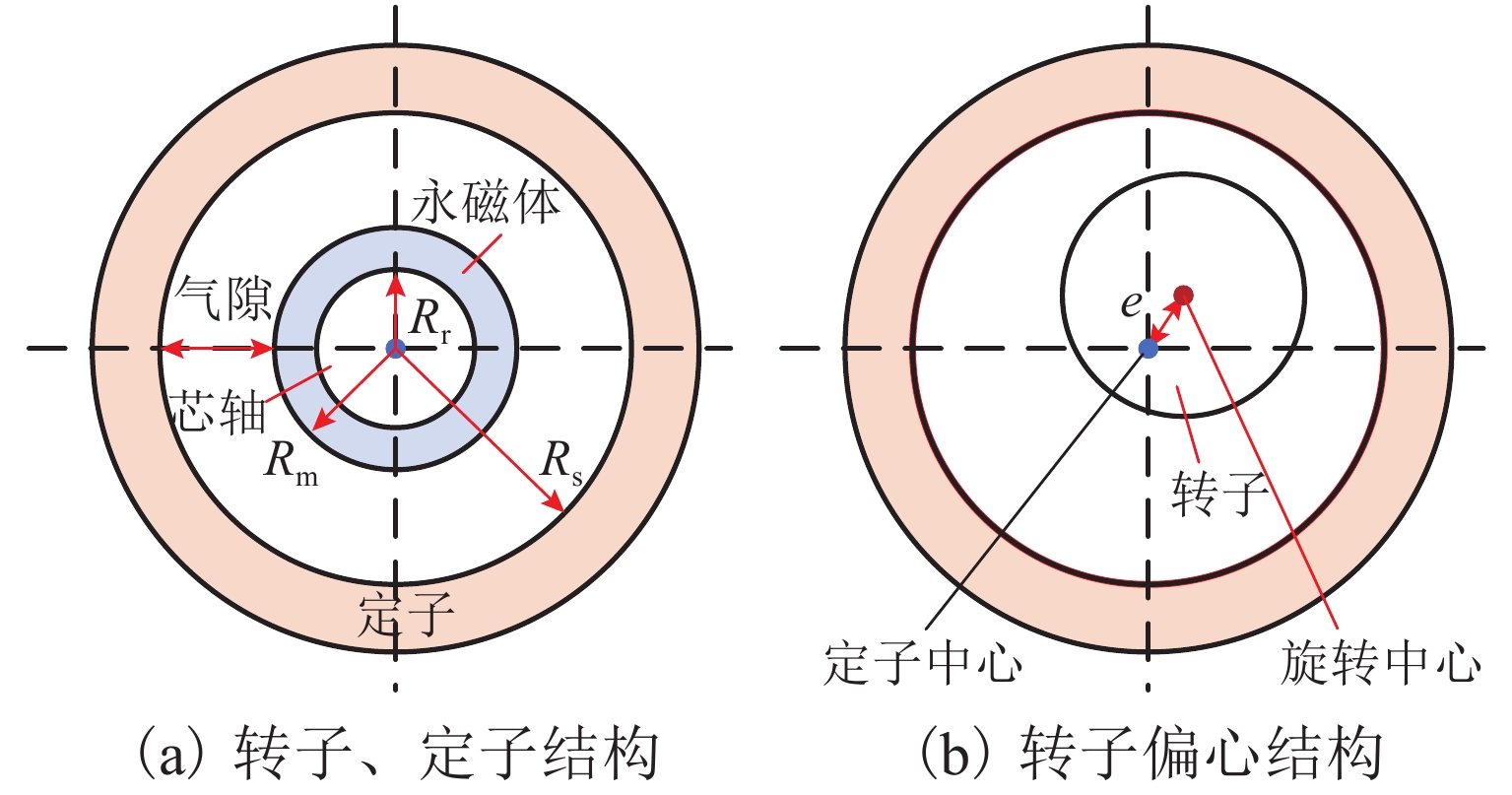

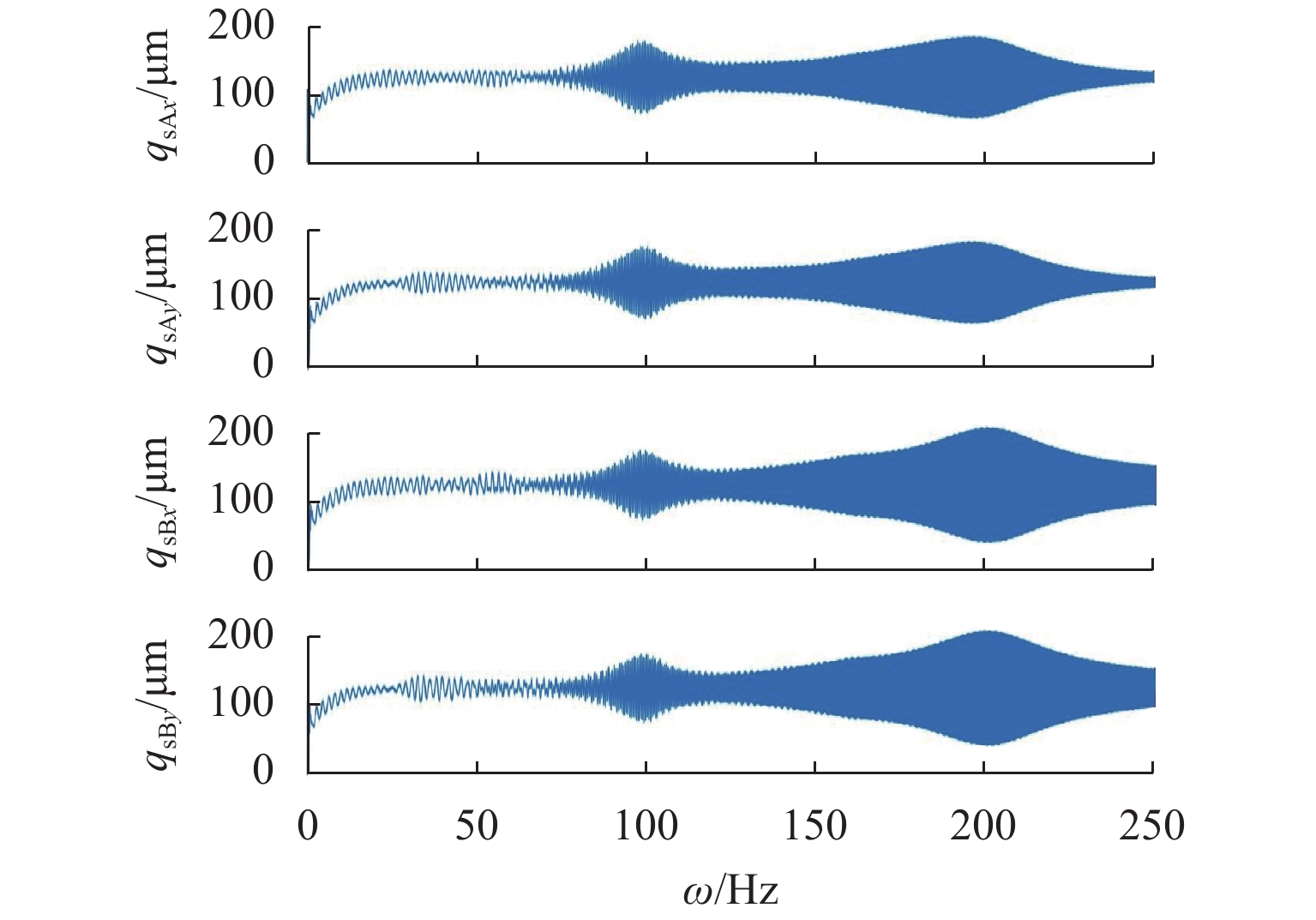

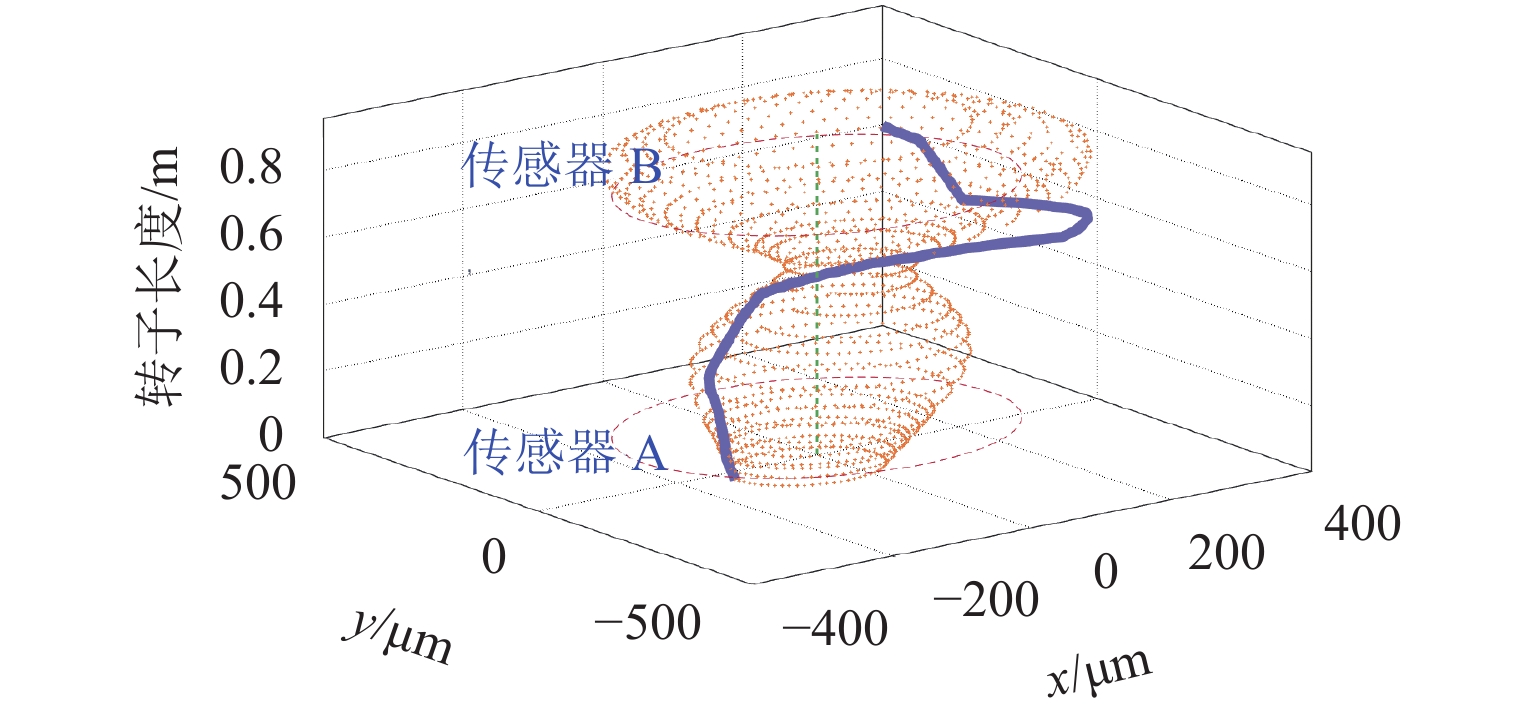

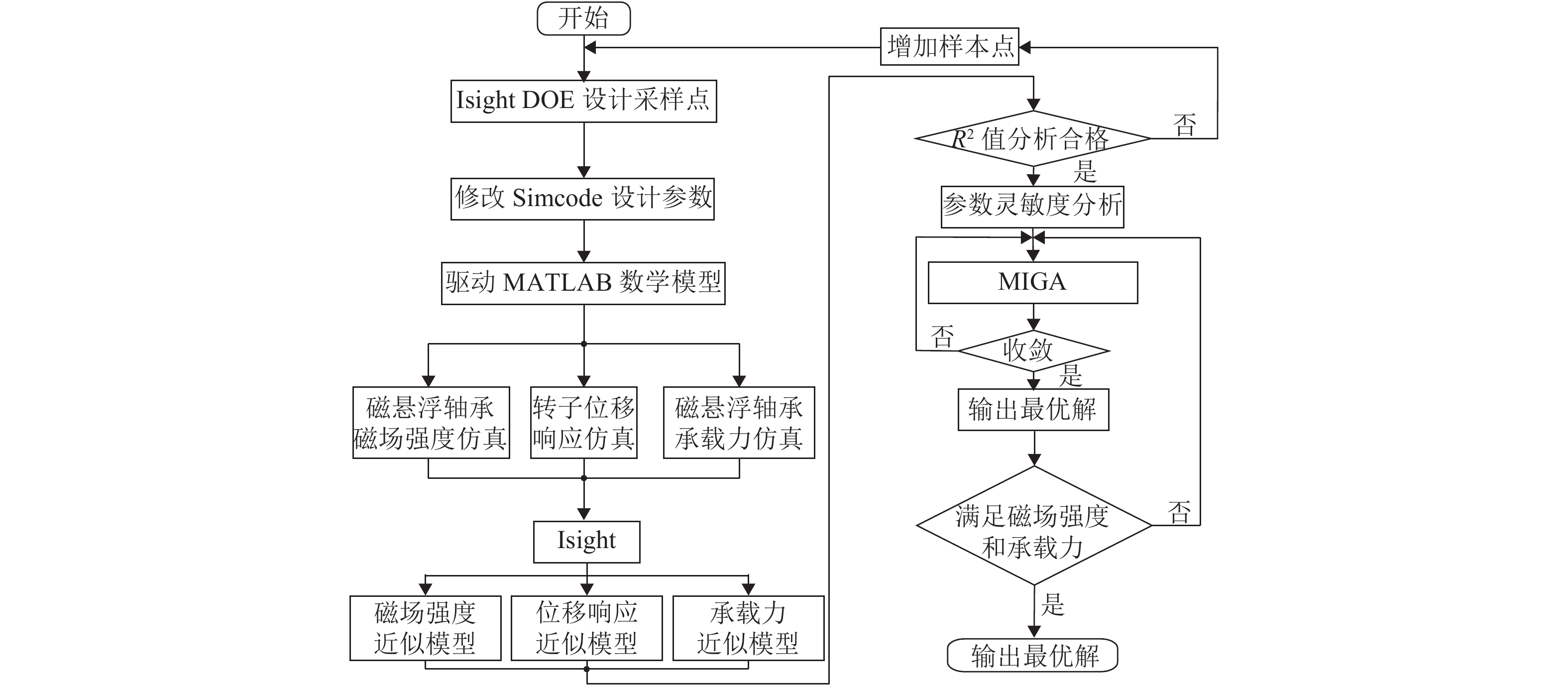

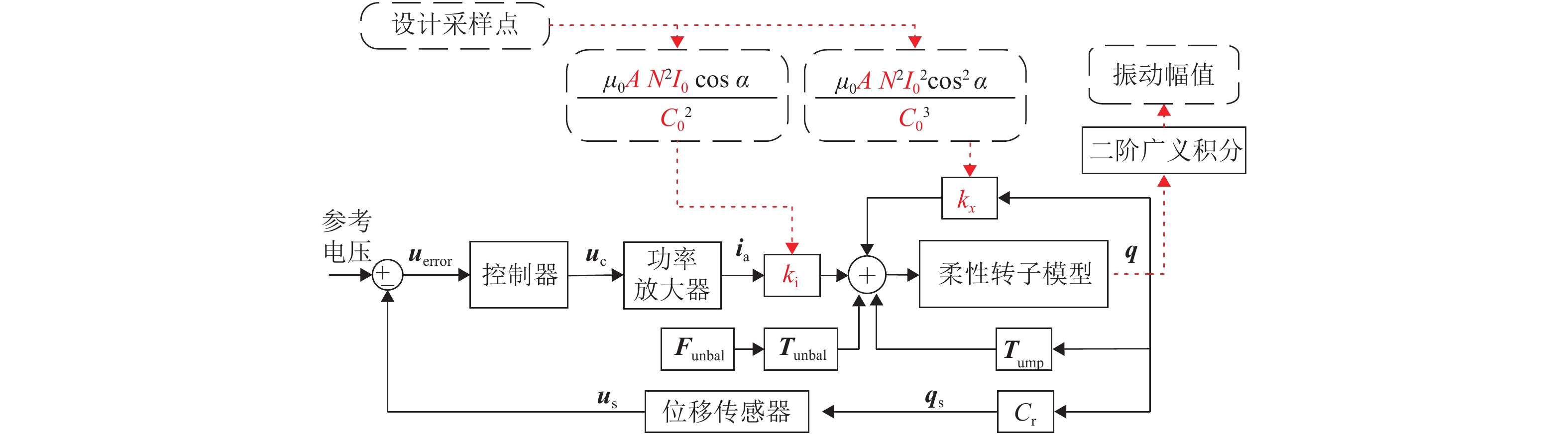

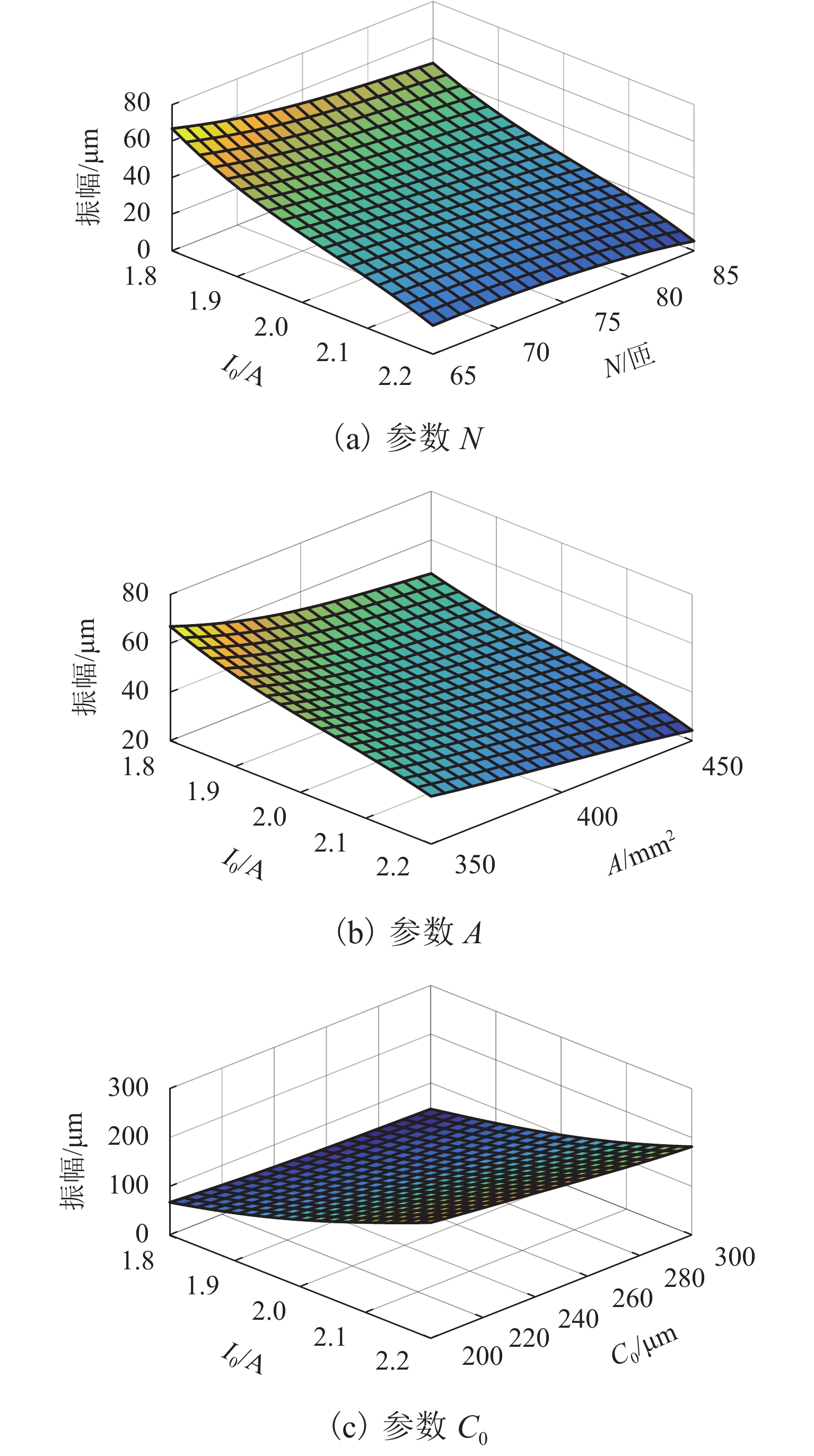

主动磁悬浮轴承(active magnetic bearing,AMB)-转子系统中,转子质量分布上的不平衡引起不平衡振动,为提高系统的稳定性、减小转子在一阶弯曲临界转速处的不平衡振动,建立了考虑不平衡力和不平衡磁拉力的磁悬浮柔性转子机电一体化模型,并结合径向基(radial basis function,RBF)神经网络算法,得到转子振幅关于磁悬浮轴承结构参数的近似模型;以振幅最小为目标,通过参数灵敏度分析和多岛遗传算法(multi-island genetic algorithm,MIGA)对磁悬浮轴承进行结构优化设计. 数值仿真结果表明:在一定范围内增大磁悬浮轴承的偏置电流、磁极面积、线圈匝数,减少单边气隙能够增大系统阻尼,可以降低一阶弯曲临界转速处的不平衡振动幅值,优化后不平衡振幅较优化前减少近50%.

Abstract:In active magnetic bearing (AMB)-rotor system, the unbalance vibration of system is caused by the uneven mass distribution with respect to the axis. In order to improve the system stability and reduce the unbalance vibration of the rotor at first-order bending critical speed, the mechatronic model of AMB-flexible rotor system considering unbalanced force and unbalanced magnetic pull is established, and combined with the radial basis function (RBF) neural network algorithm, an approximation model of rotor vibration amplitude related to the structure parameters of AMB is obtained. Combined with parametric sensitivity analysis and multi-island genetic algorithm (MIGA), the structural parameters are optimizied with the goal of minimizing the amplitude of rotor vibration. Numerical simulation results show that increasing bias current, area of magnetic poles, number of turns and decreasing air gap within a certain range can increase the system damping, and can reduce unbalanced amplitude at the first-order bending critical speed. The unbalance amplitude is reduced by nearly 50% than before.

-

表 1 径向磁悬浮轴承结构参数

Table 1. Structural parameters of radial AMB

参数 值 单个磁极线圈/匝 75 磁极面积/m2 4.05 × 10−4 偏置电流/A 2 气隙/mm 0.25 表 2 结构参数范围

Table 2. Range of structural parameters

取值 A/mm2 I0/A C0/μm N/匝 标准值 405 2.0 250 75 最小值 350 1.8 200 65 最大值 450 2.8 300 85 表 3 参数优化结果

Table 3. Parameter optimization results

项目 A/mm2 I0/A C0/μm N/匝 优化前 405 2.0 250 75 优化后 380 2.1 200 85 -

[1] MASLEN E H, SCHWEITZER G, BLEULER H, et al. Magnetic bearings—theory, design and application to rotating machinery[M]. Berlin: Springer, 2009. [2] 高辉. 主动磁悬浮轴承系统不平衡振动补偿研究[D]. 南京: 南京航空航天大学, 2011. [3] 钟一谔. 转子动力学[M]. 北京: 清华大学出版社, 1987: 34-35. [4] 王正. 转动机械的转子动力学设计[M]. 北京: 清华大学出版社, 2015: 38-39. . [5] 韩辅君,房建成. 磁悬浮飞轮转子系统的现场动平衡方法[J]. 航空学报,2010,31(1): 184-190.HAN Fujun, FANG Jiancheng. Field balancing method for rotor system of a magnetic suspending flywheel[J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(1): 184-190. [6] 章璟璇. 柔性转子动平衡及转子动力特性的研究[D]. 南京: 南京航空航天大学, 2005. [7] 王星星,吴贞焕,杨国安,等. 基于改进粒子群算法的最小二乘影响系数法的理论及实验研究[J]. 振动与冲击,2013,32(8): 100-104. doi: 10.3969/j.issn.1000-3835.2013.08.018WANG Xingxing, WU Zhenhuan, YANG Guoan, et al. Theory and tests for least square influence coefficient method based on an improved particle swarm optimization algorithm[J]. Journal of Vibration and Shock, 2013, 32(8): 100-104. doi: 10.3969/j.issn.1000-3835.2013.08.018 [8] LEI S L, PALAZZOLO A. Control of flexible rotor systems with active magnetic bearings[J]. Journal of Sound and Vibration, 2008, 314(1/2): 19-38. [9] INOUE T, LIU J, ISHIDA Y, et al. Vibration control and unbalance estimation of a nonlinear rotor system using disturbance observer[J]. Journal of Vibration and Acoustics, 2009, 131(3): 11-17. [10] CUI P L, LIU Z Y, XU H, et al. Harmonic vibration force suppression of magnetically suspended rotor with frequency-domain adaptive LMS[J]. IEEE Sensors Journal, 2020, 20(3): 1166-1175. doi: 10.1109/JSEN.2019.2946628 [11] CUI P L, ZHANG G X, LIU Z Y, et al. A second-order dual mode repetitive control for magnetically suspended rotor[J]. IEEE Transactions on Industrial Electronics, 2020, 67(6): 4946-4956. doi: 10.1109/TIE.2019.2927184 [12] 万金贵,汪希平,李文鹏,等. 径向磁力轴承的结构分析与优化设计方法[J]. 武汉理工大学学报(信息与管理工程版),2010,32(1): 62-65.WAN Jingui, WANG Xiping, LI Wenpeng, et al. Structure analysis and optimized design method for radial magnetic bearing[J]. Journal of Wuhan University of Technology (Information & Management Engineering), 2010, 32(1): 62-65. [13] 嵇尚华,张维煜,黄振跃,等. 交流主动磁轴承参数设计与优化[J]. 中国电机工程学报,2011,31(21): 150-158.JI Shanghua, ZHANG Weiyu, HUANG Zhenyue, et al. Parameter design and optimization of AC active magnetic bearing[J]. Proceedings of the CSEE, 2011, 31(21): 150-158. [14] 张松山,周瑾,张发品. 基于多目标遗传算法的磁轴承结构优化设计[J]. 机械与电子,2013,31(8): 3-6. doi: 10.3969/j.issn.1001-2257.2013.08.001ZHANG Songshan, ZHOU Jin, ZHANG Fapin. Structural optimization design for magnetic bearings based on multi-objective genetic algorithm[J]. Machinery & Electronics, 2013, 31(8): 3-6. doi: 10.3969/j.issn.1001-2257.2013.08.001 [15] 陈帝伊. 径向磁悬浮轴承的电磁场分析和结构优化设计[D]. 济南: 山东大学, 2008. [16] 景轩. 磁悬浮轴承的结构优化设计及其磁路解耦自适应控制[D]. 湘潭: 湘潭大学, 2017. [17] 肖林京,张绪帅,常龙,等. 基于ANSYS和iSIGHT的磁悬浮轴承结构优化设计[J]. 轴承,2012(5): 5-8.XIAO Linjing, ZHANG Xushuai, CHANG Long, et al. Design and optimization of magnetic bearings based on ANSYS and iSIGHT[J]. Bearing, 2012(5): 5-8. [18] 王晓远,张德政,高鹏,等. 飞轮储能用径向磁悬浮轴承结构优化设计[J]. 机械科学与技术,2018,37(7): 1048-1054.WANG Xiaoyuan, ZHANG Dezheng, GAO Peng, et al. Structural optimization design of radial magnetic bearing for flywheel energy storage[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(7): 1048-1054. [19] XU Y P, ZHOU J, DI L, et al. Active magnetic bearing rotor model updating using resonance and MAC error[J]. Shock and Vibration, 2015, 2015: 263062.1-263062.9. [20] 徐园平. 柔性转子磁悬浮轴承支承特性辨识[D]. 南京: 南京航空航天大学, 2018. [21] 吴海同. 磁悬浮高速永磁电机偏心不平衡分析与补偿研究[D]. 南京: 南京航空航天大学, 2020 [22] 刘雪杰,周瑾,金超武,等. 基于RBF近似模型的低速永磁电机齿槽转矩优化[J]. 微特电机,2020,48(1): 25-29. doi: 10.3969/j.issn.1004-7018.2020.01.006LIU Xuejie, ZHOU Jin, JIN Chaowu, et al. Optimization of cogging torque for low-speed permanent magnet motor based on RBF approximation model[J]. Small & Special Electrical Machines, 2020, 48(1): 25-29. doi: 10.3969/j.issn.1004-7018.2020.01.006 [23] 吴海同,周瑾,纪历. 基于单相坐标变换的磁悬浮转子不平衡补偿[J]. 浙江大学学报(工学版),2020,54(5): 963-971.WU Haitong, ZHOU Jin, JI Li. Unbalance compensation of magnetically suspended rotor based on single phase coordinate transformation[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(5): 963-971. [24] 周瑾,高天宇,董继勇,等. 基于Isight的径向磁悬浮轴承结构优化设计[J]. 轴承,2018(7): 6-11.ZHOU Jin, GAO Tianyu, DONG Jiyong, et al. Optimal design for structure of radial magnetic bearings based on isight[J]. Bearing, 2018(7): 6-11. -

下载:

下载: