Experimental Study on Bond Characteristics Between Concrete-Filled Steel Tube and Steel Bar Under Cyclic Loading

-

摘要:

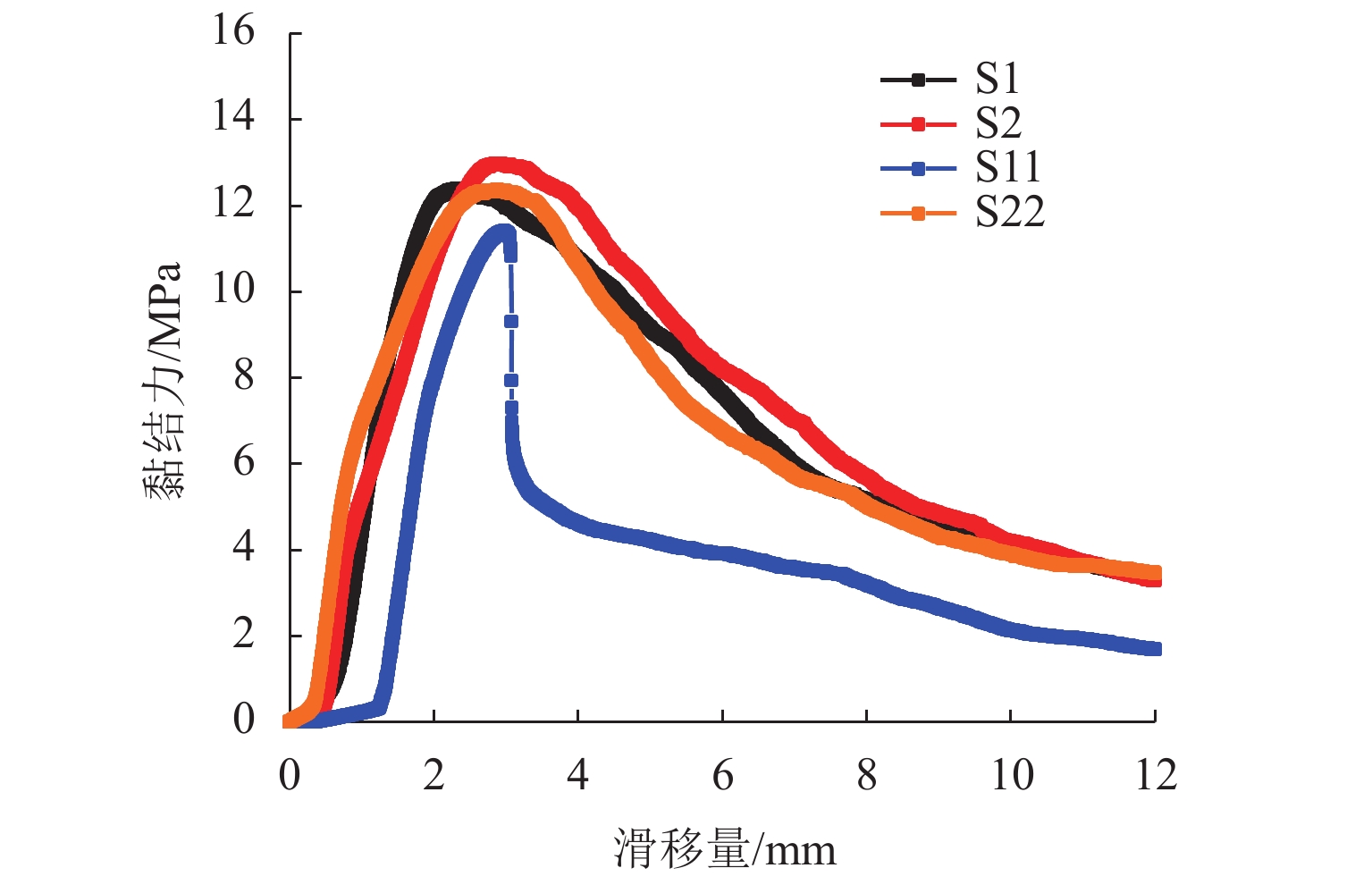

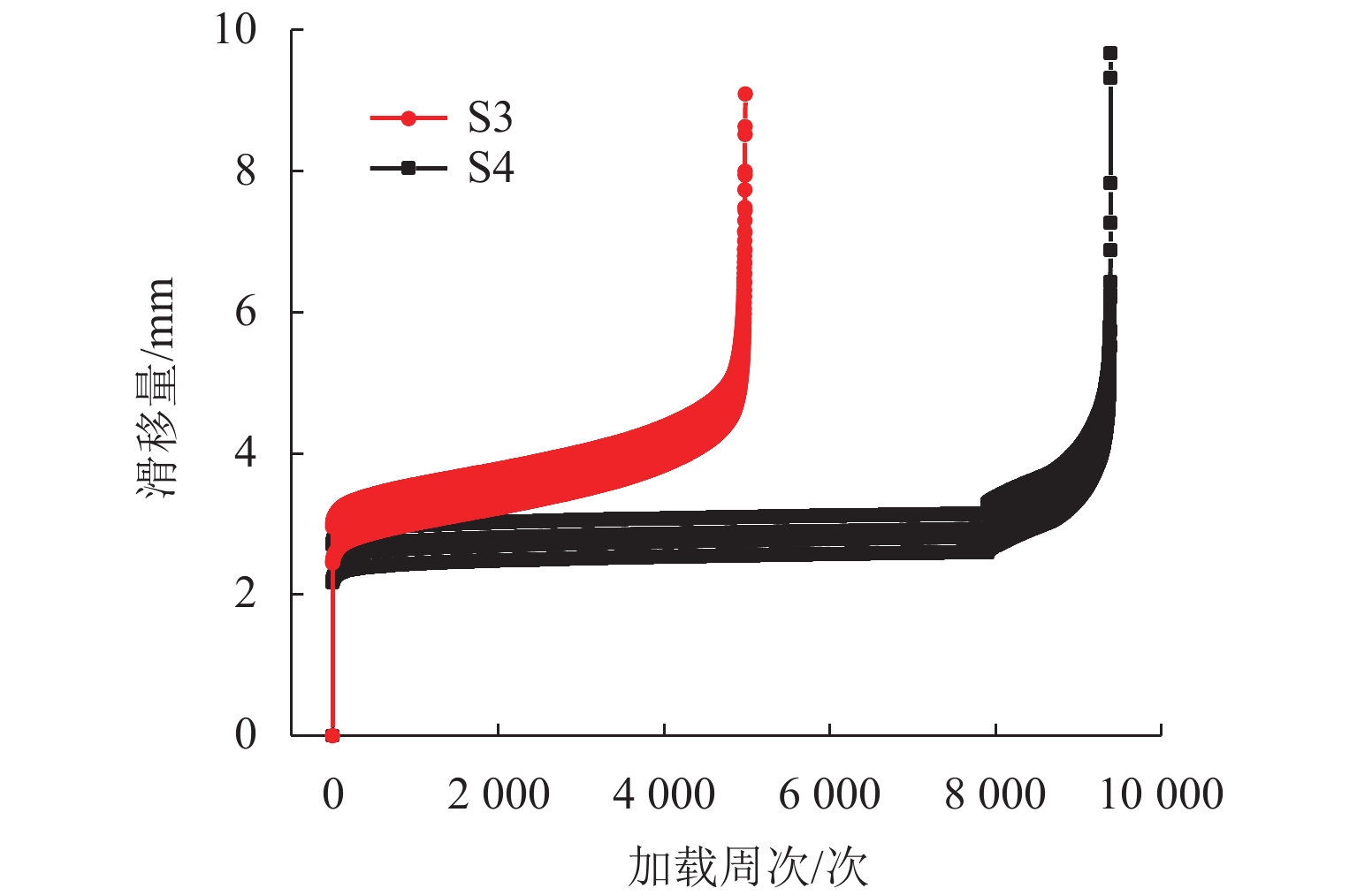

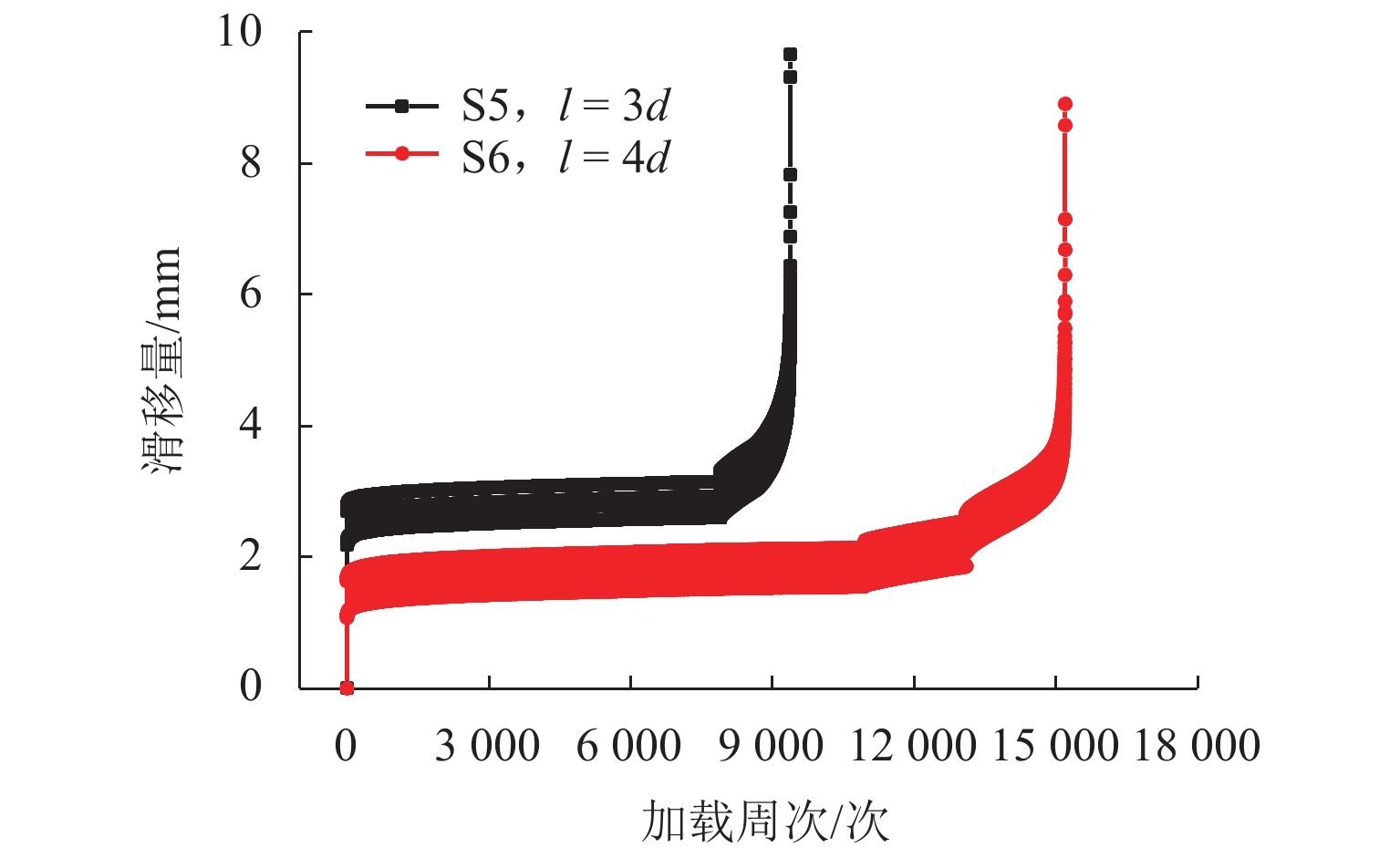

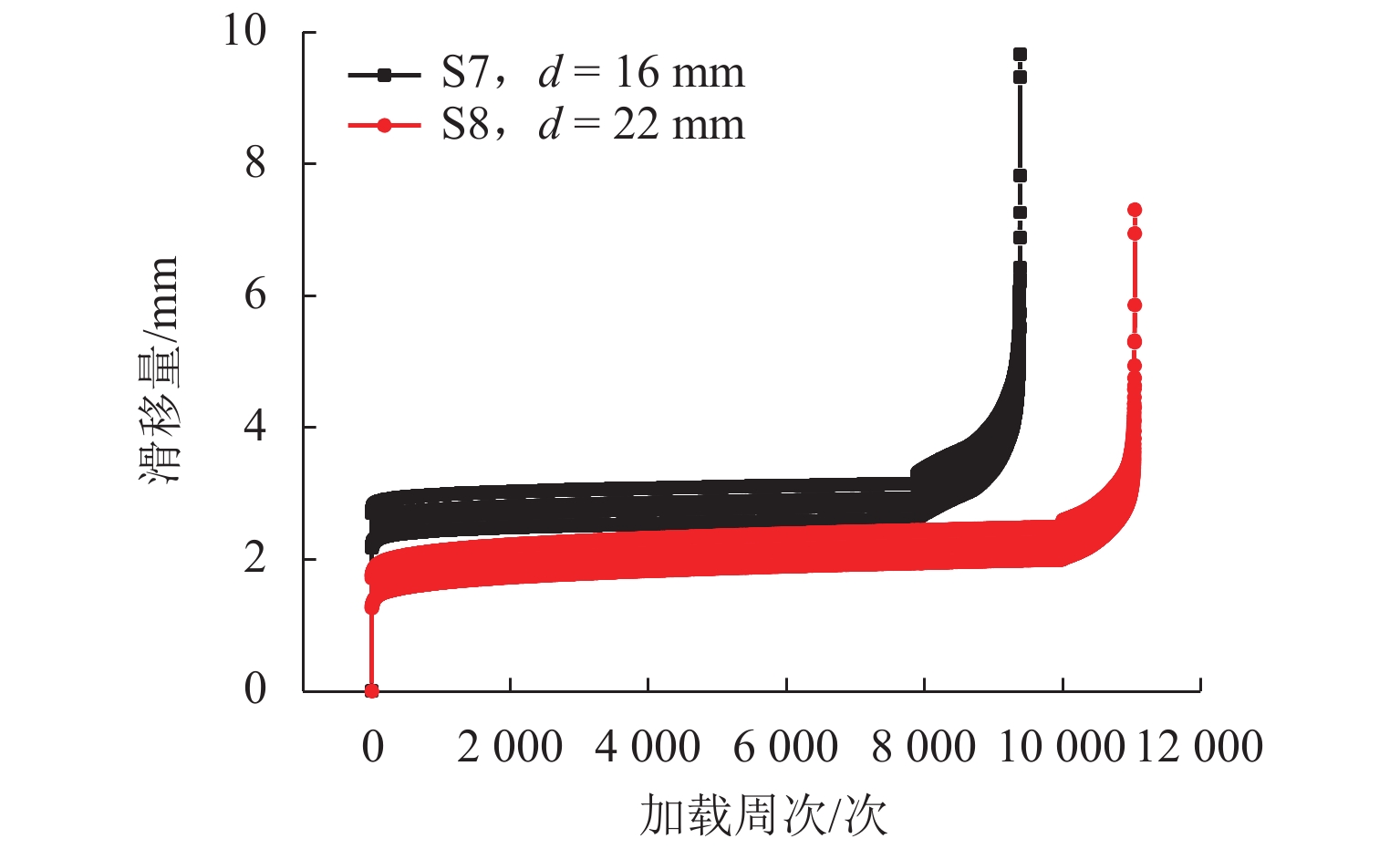

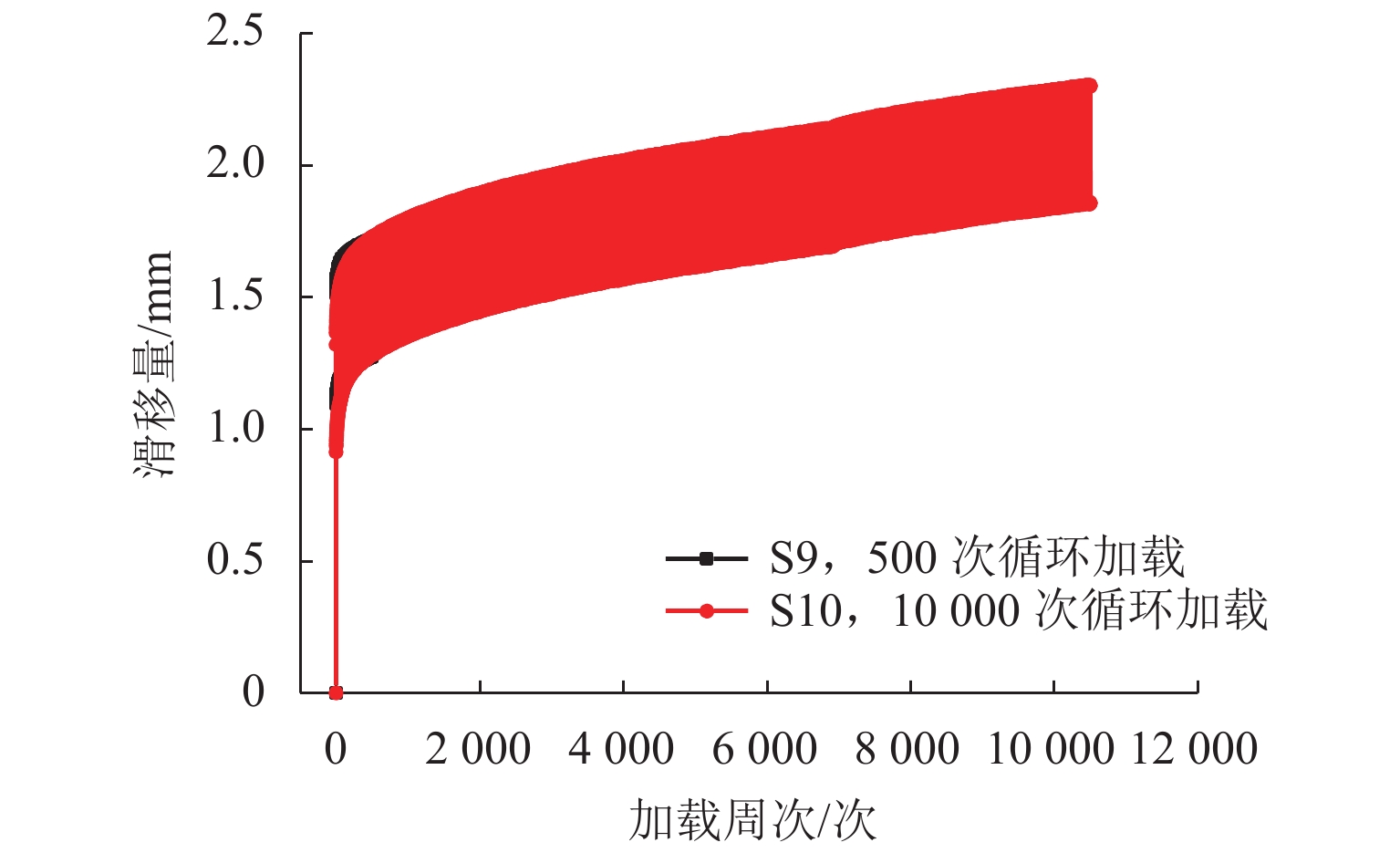

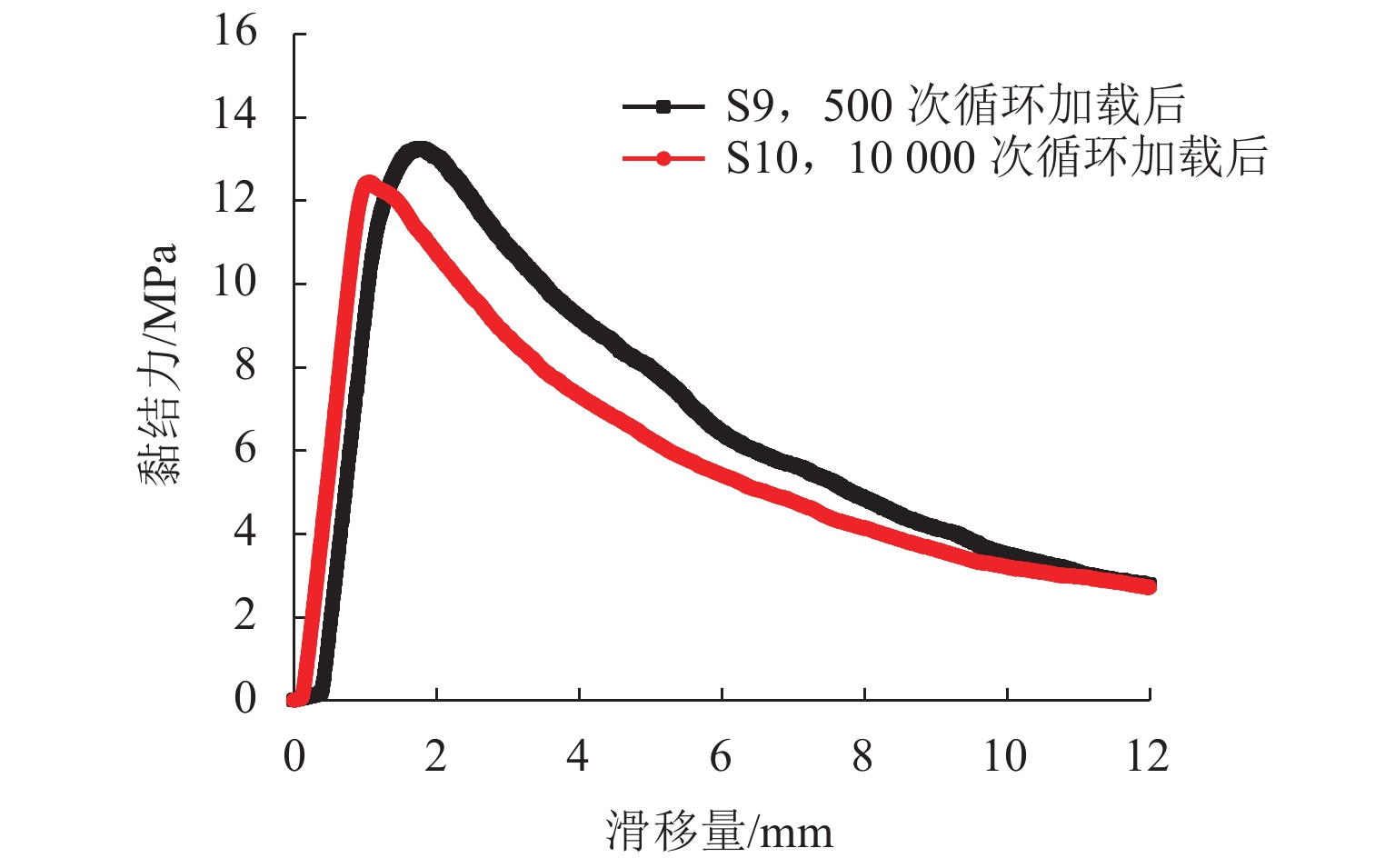

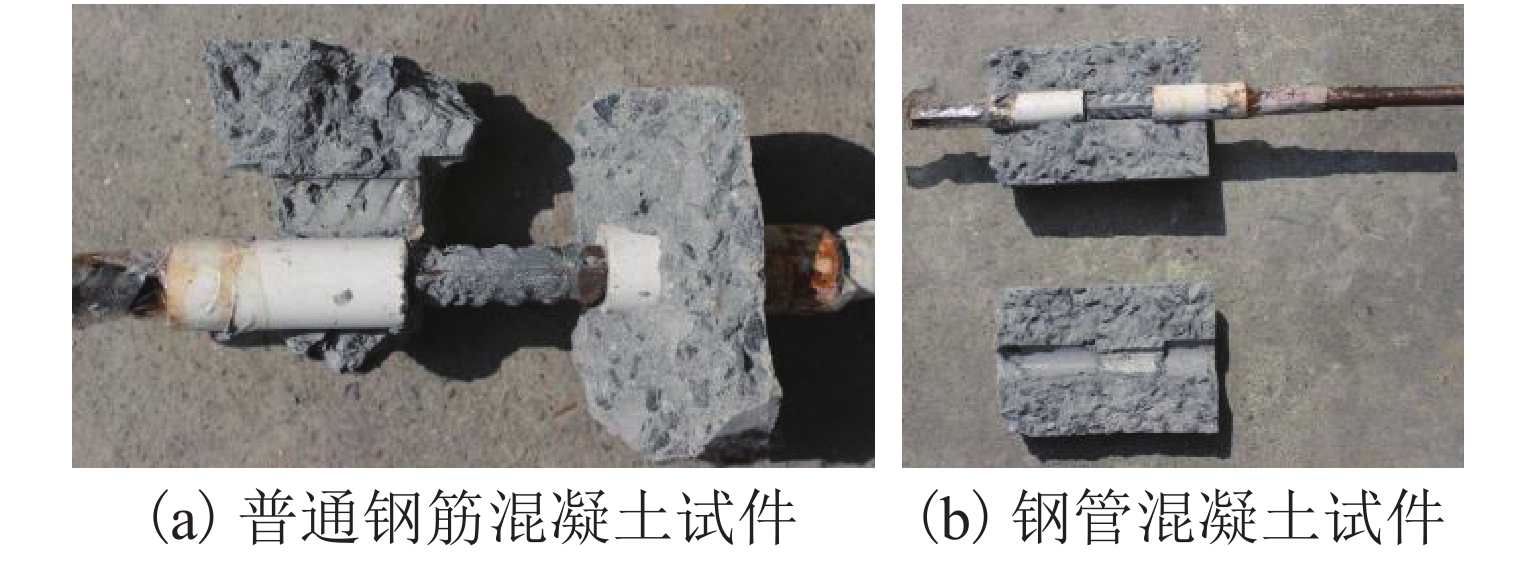

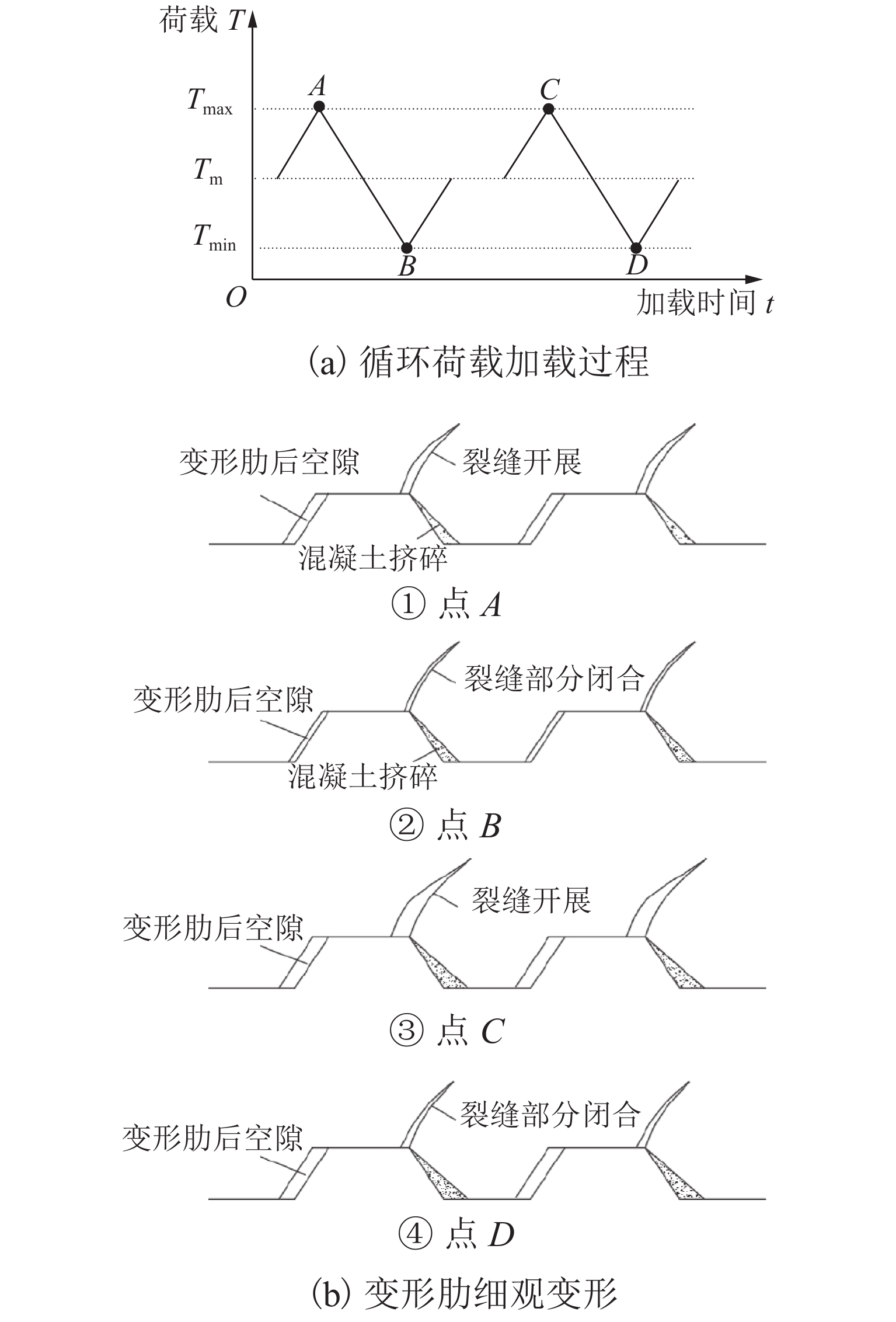

为探究循环荷载下配筋钢管混凝土构件黏结锚固性能,对配筋钢管混凝土试件开展了单调加载和循环加载试验. 通过单调加载试验,对比分析了黏结力与滑移量之间的响应关系;基于单调加载试验结果,对若干配筋钢管混凝土试件在单轴循环荷载作用下的黏结特性进行了试验研究,考虑包括箍筋配置、黏结长度、钢筋直径、加载次数等因素对黏结性能的影响规律,分析了不同试件黏结力的退化机制及其破坏模式. 结果表明:箍筋提高了试件承受循环荷载作用的能力,配筋钢管混凝土试件的黏结力和延性随黏结长度、钢筋直径的增加而增大,配筋钢管混凝土试件中钢筋的黏结力及延性随着前期承受循环荷载的加载次数的增加而降低,配筋钢管混凝土黏结破坏时整个黏结区域相对比较平滑,变形肋印迹不明显.

Abstract:In order to explore the bonding and anchoring performance of the reinforced concrete-filled steel tube (R-CFST) under cyclic loading, monotonic loading and cyclic loading tests were carried out on R-CFST specimens. The monotonic loading test is used to compare and analyze the response relationship between the bonding force and slip. Based on the monotonic loading test results, the bond behavior was experimentally investigated for several R-CFST specimens under uniaxial cyclic loading. The factors considered include the stirrup arrangement, the bond length, the rebar diameter, and the number of loading cycles. The effects of these factors on the bond behavior were explored. The bonding force degradation mechanism and failure modes of different specimens were analyzed. The results show that the stirrups increase the ability of the specimens to withstand cyclic loading; the bonding force and ductility of the R-CFST specimens increase with the increase of the bond length and the diameter of the steel bars; and the cohesive force and ductility decrease with the increase of the loading times of the cyclic load in the early stage. When the reinforced steel tube concrete bond fails, the entire bond zone is relatively smooth, and the deformation rib imprint is not obvious.

-

Key words:

- reinforced concrete-filled steel tube /

- bond /

- cyclic loads /

- crack propagation /

- slip distance

-

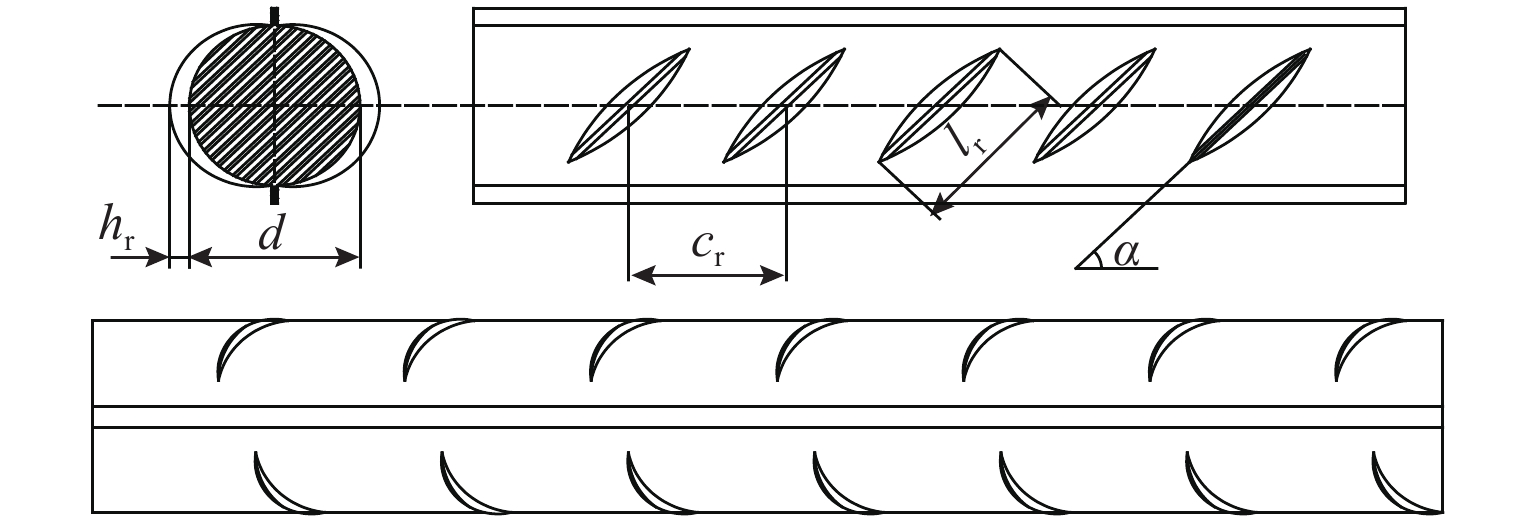

表 1 钢筋几何和力学特性

Table 1. Geometric and mechanical properties of steel bars

钢筋类型 d/mm hr/mm lr/mm cr/mm α/(°) 屈服强度/MPa 抗拉强度/MPa 弹性模量/GPa 带肋钢筋 A 16 1.4 15.4 9.5 57.2 335 455 210 带肋钢筋 B 22 1.8 21.2 10.5 56.9 335 455 210 光圆钢筋(箍筋) 6 300 420 200 表 2 试验方案与参数

Table 2. Test plan and parameters

加载方式 试验

目标试件编号 试件类型 d/

mml/mm 是否配置箍筋 加载周次 加载过程 单调加载 滑移量-黏结力 S1 钢管混凝土 16 48 S2 16 48 是 S11 普通钢筋

混凝土16 48 S22 16 48 是 箍筋配置影响 S3 16 48 循环加载至拔出 Tmax=24 kN, Tmin=4 kN S4 16 48 是 循环加载至拔出 Tmax=24 kN, Tmin=4 kN→Tmax=28 kN, Tmin=4 kN 黏结长度影响 S5 16 48 是 循环加载至拔出 Tmax=24 kN, Tmin=4 kN→Tmax=28 kN, Tmin=4 kN S6 16 64 是 循环加载至拔出 Tmax=24 kN, Tmin=4 kN→Tmax=28 kN,

Tmin=4 kN→Tmax=32 kN, Tmin=4 kN循环加载 钢筋直径影响 S7 钢管混凝土 16 48 是 循环加载至拔出 Tmax=24 kN, Tmin=4 kN→Tmax=28 kN, Tmin=4 kN S8 22 48 是 循环加载至拔出 Tmax=24 kN, Tmin=4 kN→Tmax=28 kN, Tmin=4 kN 循环次数影响 S9 16 48 是 先 500 次循环加载,后单调加载至拔出 Tmax=24 kN, Tmin=4 kN→单调加载拔出 S10 16 48 是 先 10 000 次循环加载,后单调加载至拔出 Tmax=24 kN, Tmin=4 kN→单调加载拔出 -

[1] 郝兆峰,张戎令,王起才,等. 钢管混凝土缺陷对徐变性能的影响[J]. 复合材料学报,2020,37(5): 1191-1199.HAO Zhaofeng, ZHANG Rongling, WANG Qicai, et al. Effect of concrete filled steel tube defect on creep property[J]. Acta Materiae Compositae Sinica, 2020, 37(5): 1191-1199. [2] 陈宝春,韦建刚,周俊,等. 我国钢管混凝土拱桥应用现状与展望[J]. 土木工程学报,2017,50(6): 50-61.CHEN Baochun, WEI Jiangang, ZHOU Jun, et al. Application of concrete-filled steel tube arch bridges in China: current status and prospects[J]. China Civil Engineering Journal, 2017, 50(6): 50-61. [3] 王浩祚. 内配螺旋箍筋方钢管超高强混凝土柱轴压及抗震性能研究[D]. 泉州: 华侨大学, 2020. [4] ELREMAILY A, AZIZINAMINI A. Behavior and strength of circular concrete-filled tube columns[J]. Journal of Constructional Steel Research, 2002, 58(12): 1567-1591. doi: 10.1016/S0143-974X(02)00005-6 [5] ROMERO M L, MOLINER V, ESPINOS A, et al. Fire behavior of axially loaded slender high strength concrete-filled tubular columns[J]. Journal of Constructional Steel Research, 2011, 67(12): 1953-1965. doi: 10.1016/j.jcsr.2011.06.012 [6] 张玉琢,吕学涛,王微微. 受火后方钢管钢筋混凝土短柱剩余承载力研究[J]. 工程力学,2016,33(11): 113-120. doi: 10.6052/j.issn.1000-4750.2015.03.0244ZHANG Yuzhuo, LÜ Xuetao, WANG Weiwei. Post-fire behavior of reinforced concrete-filled square steel tubular stub columns under axially compressive loading[J]. Engineering Mechanics, 2016, 33(11): 113-120. doi: 10.6052/j.issn.1000-4750.2015.03.0244 [7] 王庆利,车媛,谭鹏宇,等. CFRP-钢管混凝土结构研究的进展与展望[J]. 工程力学,2010,27(增2): 48-60.WANG Qingli, CHE Yuan, TAN Pengyu, et al. Progress and prospect in rearch on concrete filled CFRP-steel tubular structures[J]. Engineering Mechanics, 2010, 27(S2): 48-60. [8] 张松. 持荷配筋圆钢管混凝土受火后抗冲击性能的数值模拟[D]. 秦皇岛: 燕山大学, 2018. [9] LIE T T, IRWIN R J. Fire resistance of rectangular steel columns filled with bar-reinforced concrete[J]. Journal of Structural Engineering, 1995, 121(5): 797-805. doi: 10.1061/(ASCE)0733-9445(1995)121:5(797) [10] KODUR V K R, LIE T T. Evaluation of fire resistance of rectangular steel columns filled with fiber-reinforced concrete[J]. Canadian Journal of Civil Engineering, 1997, 24(3): 339-349. doi: 10.1139/l96-114 [11] XIAMUXI A, HASEGAWA A. Experimental study on reinforcement ratio of RCFT columns under axial compression[J]. Advanced Materials Research, 2011, 250/251/252/253: 3790-3797. [12] XIAMUXI A, HASEGAWA A. A study on axial compressive behaviors of reinforced concrete filled tubular steel columns[J]. Journal of Constructional Steel Research, 2012, 76: 144-154. doi: 10.1016/j.jcsr.2012.03.023 [13] 阿里甫江·夏木西,吐迪买买提·巴克,刘晓蕊. 配筋钢管混凝土短柱中环向箍筋的受力机理[J]. 工程科学与技术,2020,52(4): 77-88.ALIFUJIANG Xiamuxi, TUDIMAIMAITI Bake, LIU Xiaorui. Load transfer mechanism of lateral hoops in reinforced concrete filled steel tubular column[J]. Advanced Engineering Sciences, 2020, 52(4): 77-88. [14] 尹玉霞,周伟华,王凯. 高温下配筋钢管再生混凝土柱承载力试验研究[J]. 建筑技术,2017,48(12): 1295-1298.YIN Yuxia, ZHOU Weihua, WANG Kai. Experimental study of bearing capacity of reinforced steel at high temperatures recycled concrete columns[J]. Architecture Technology, 2017, 48(12): 1295-1298. [15] TOMII M, SAKINO K, XIAO Y, et al. Earthquake- resisting hysteretic behavior of reinforced concrete short columns confined by steel tube-experimental results of preliminary research[C]//Proceedings of the International Speciality Conference on Concrete Filled Steel Tubular Structures. Harbin: Harbin Architectual and Civil Engineering Institute, 1985: 119-125. [16] 康希良,程耀芳,涂昀,等. 钢管混凝土粘结-滑移性能试验研究及数值分析[J]. 工程力学,2010,27(9): 102-106.KANG Xiliang, CHENG Yaofang, TU Yun, et al. Experimental study and numerical analysis of bond-slip performance for concrete filled steel tube[J]. Engineering Mechanics, 2010, 27(9): 102-106. [17] 张俊. 薄壁圆钢管高强混凝土受压构件力学性能研究 [D]. 沈阳: 东北大学, 2017. [18] CABRERA J G. Deterioration of concrete due to reinforcement steel corrosion[J]. Cement and Concrete Composites, 1996, 18(1): 47-59. doi: 10.1016/0958-9465(95)00043-7 [19] AUYEUNG Y B, BALAGUR P, CHUNG L. Bond behavior of corroded reinforcement bars[J]. Materials Journal, 2000, 97(2): 214-220. [20] PAPAKONSTANTINOU C G, BALAGURU P N, AUYEUNG Y. Influence of FRP confinement on bond behavior of corroded steel reinforcement[J]. Cement and Concrete Composites, 2011, 33(5): 611-621. doi: 10.1016/j.cemconcomp.2011.02.006 [21] AMLEH L, MIRZA S. Corrosion influence on bond between steel and concrete[J]. ACI Structural Journal, 1999, 96(3): 415-423. [22] HARAJLI M, HAMAD B, KARAM K. Bond-slip response of reinforcing bars embedded in plain and fiber concrete[J]. Journal of Materials in Civil Engineering, 2002, 14(6): 503-511. doi: 10.1061/(ASCE)0899-1561(2002)14:6(503) [23] BALAZS G L. Fatigue of bond[J]. ACI Materials Journal, 1991, 88(6): 620-630. [24] SUN Y, SHEN S L, XIA X H, et al. A numerical approach for predicting shakedown limit in ratcheting behavior of materials[J]. Materials & Design, 2013, 47: 106-114. [25] WEN M J, LI H, YU D J, et al. Uniaxial ratcheting behavior of Zircaloy-4 tubes at room temperature[J]. Materials & Design, 2013, 46: 426-434. -

下载:

下载: