Design of Automatic Flotation Separation Structure Based on First-Order Buoyancy of Magnetic Liquids

-

摘要:

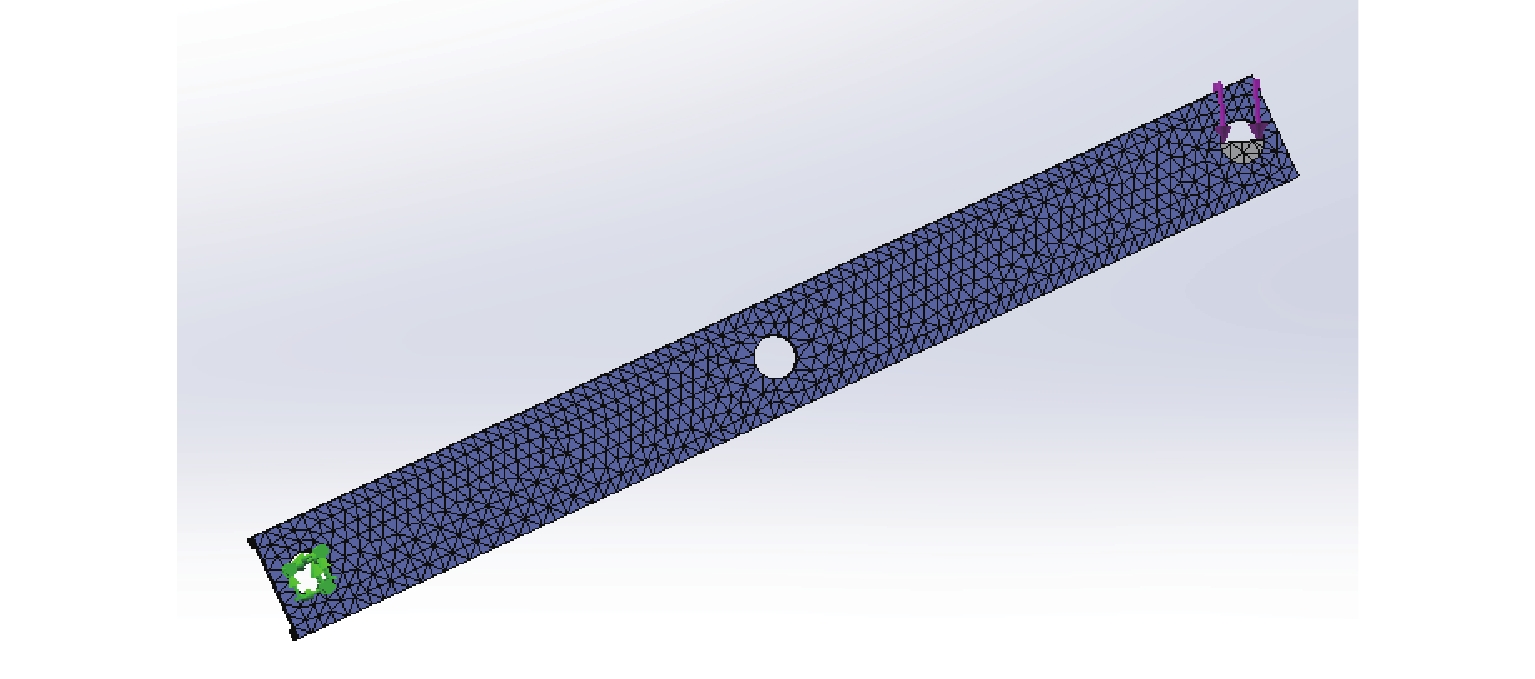

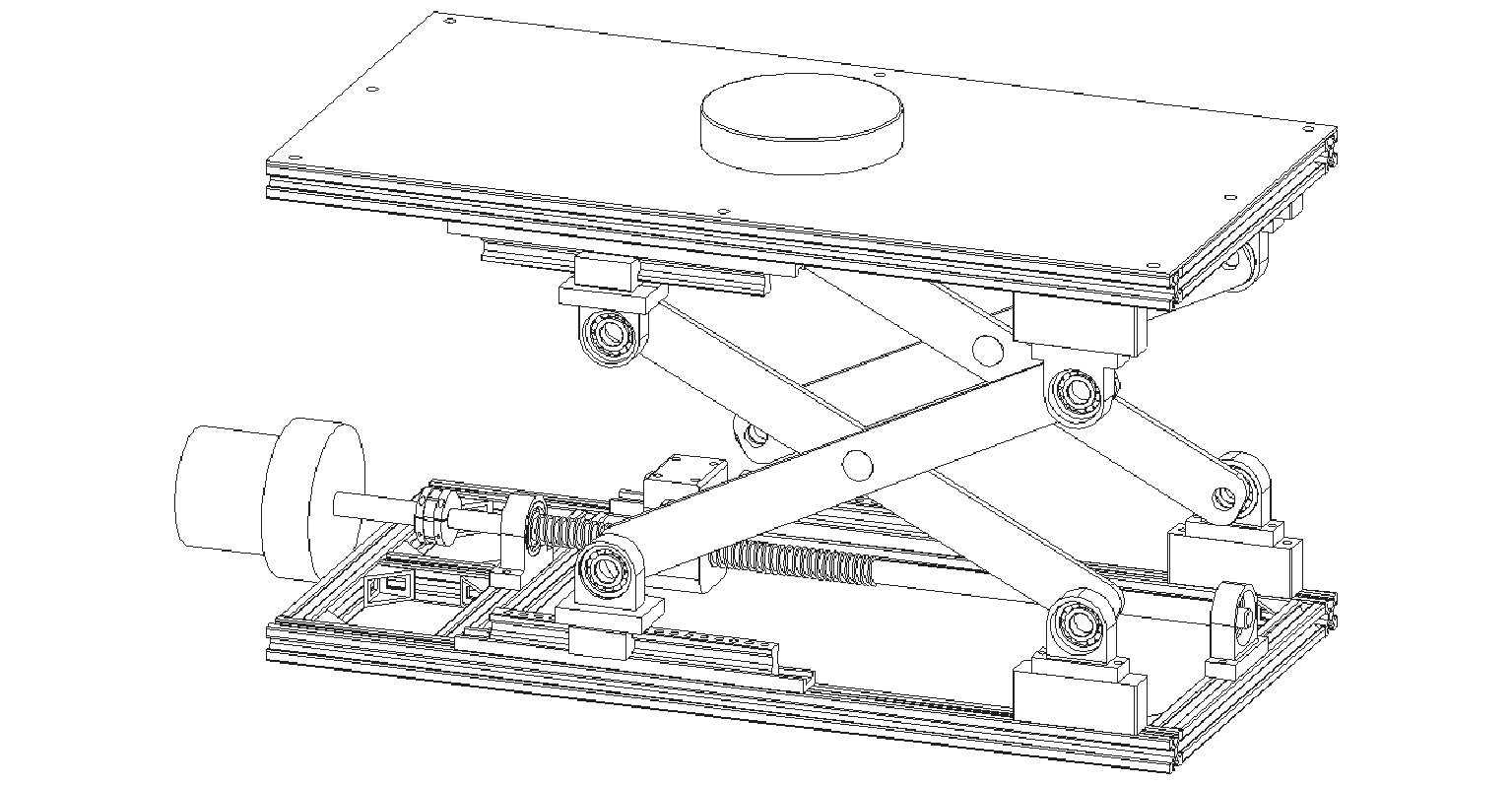

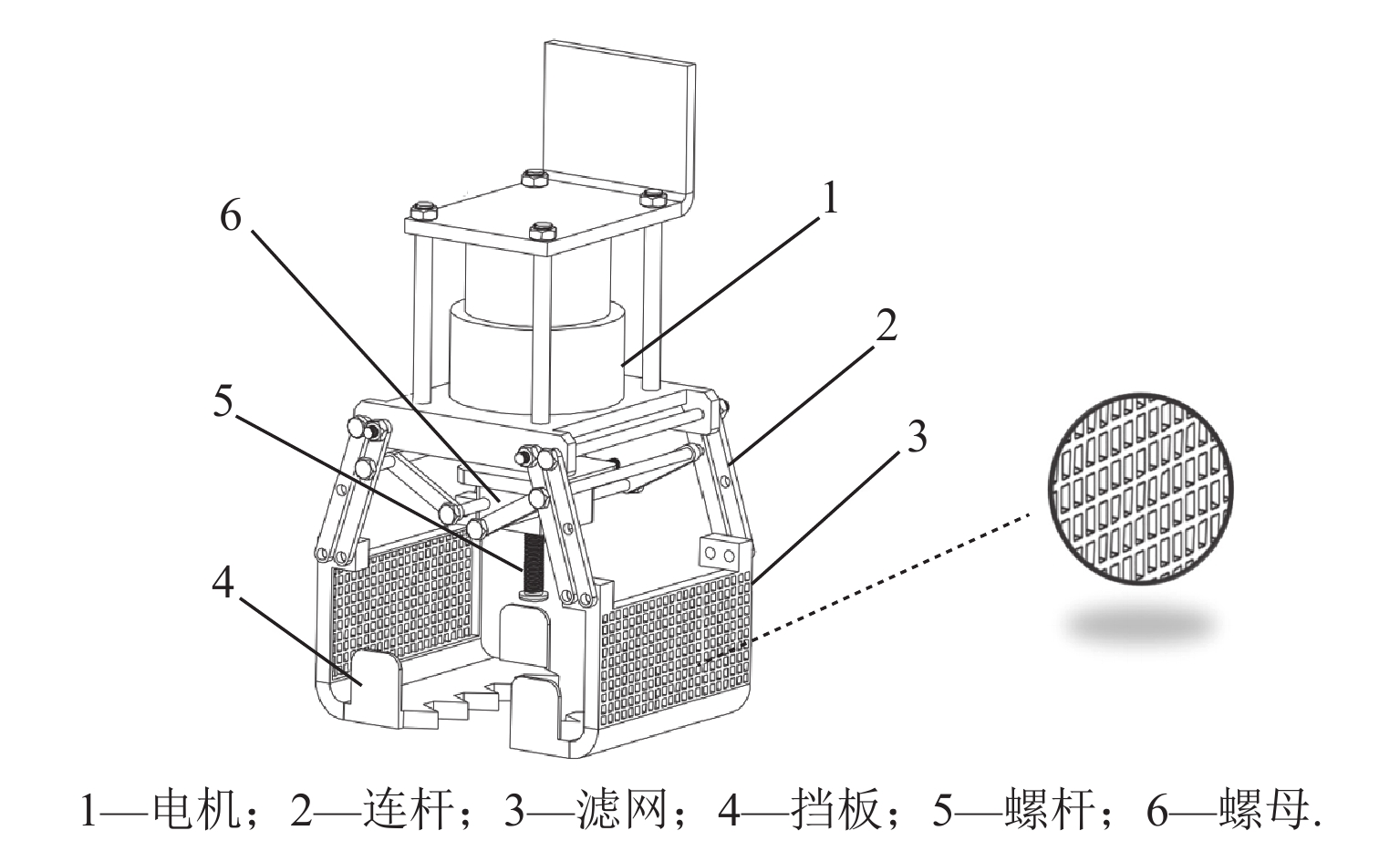

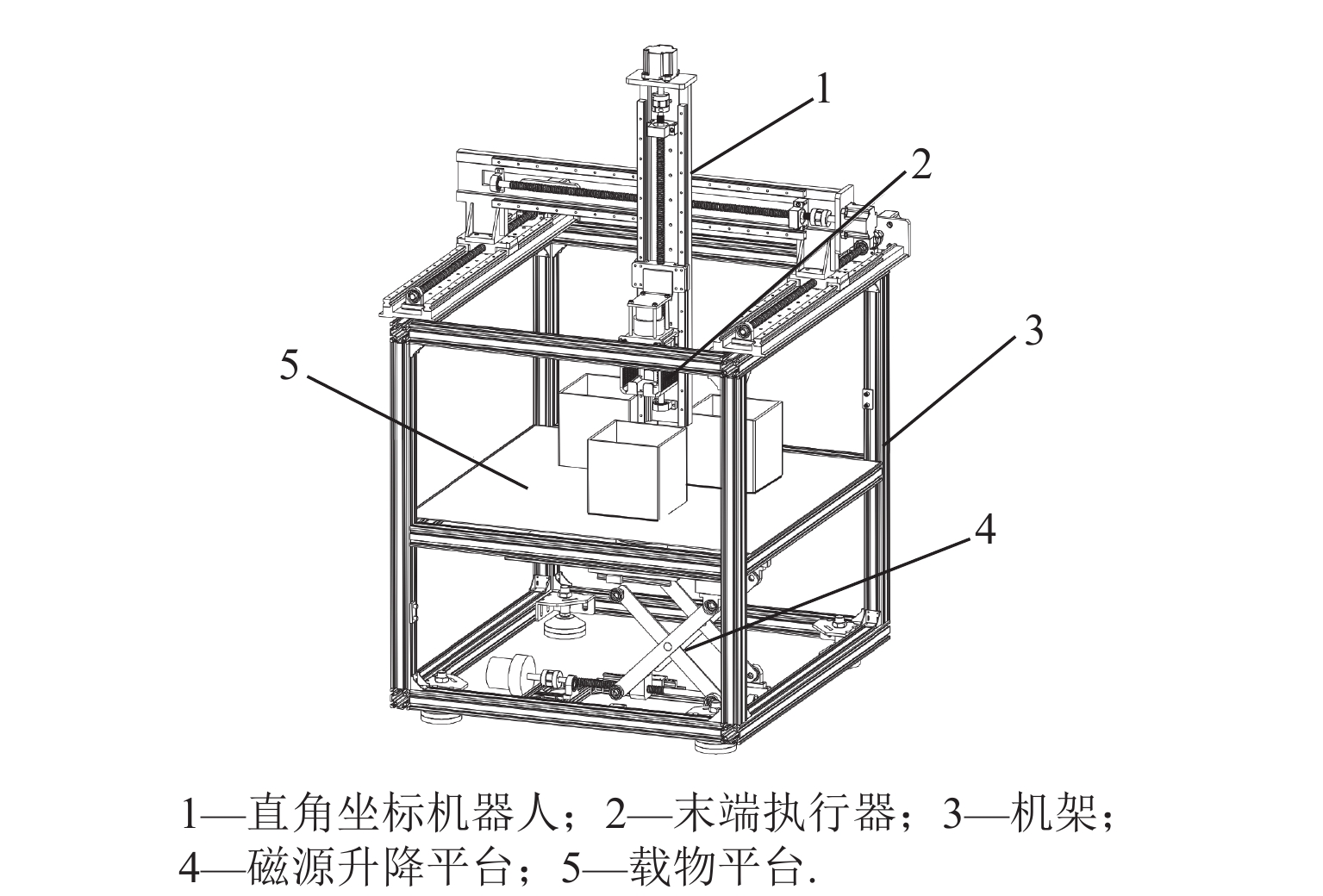

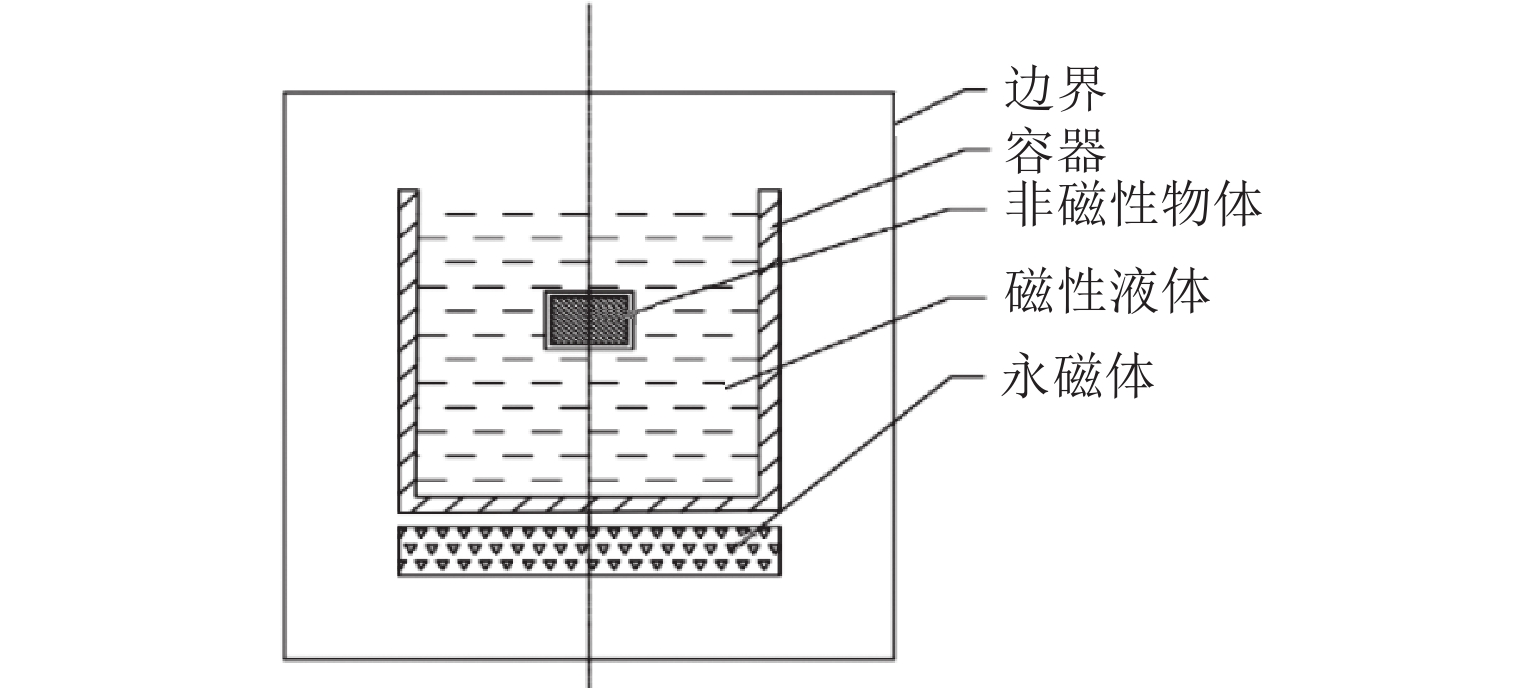

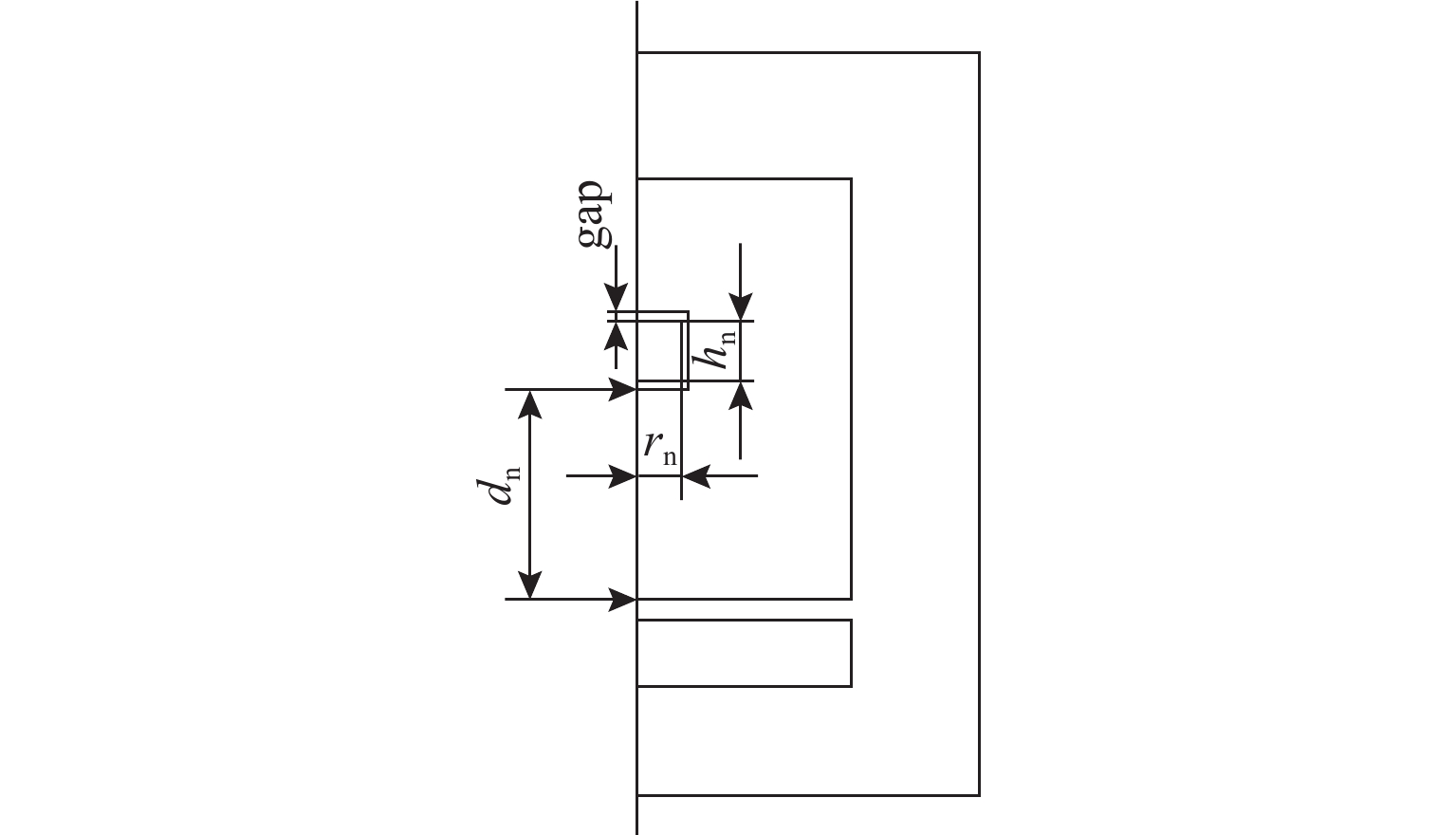

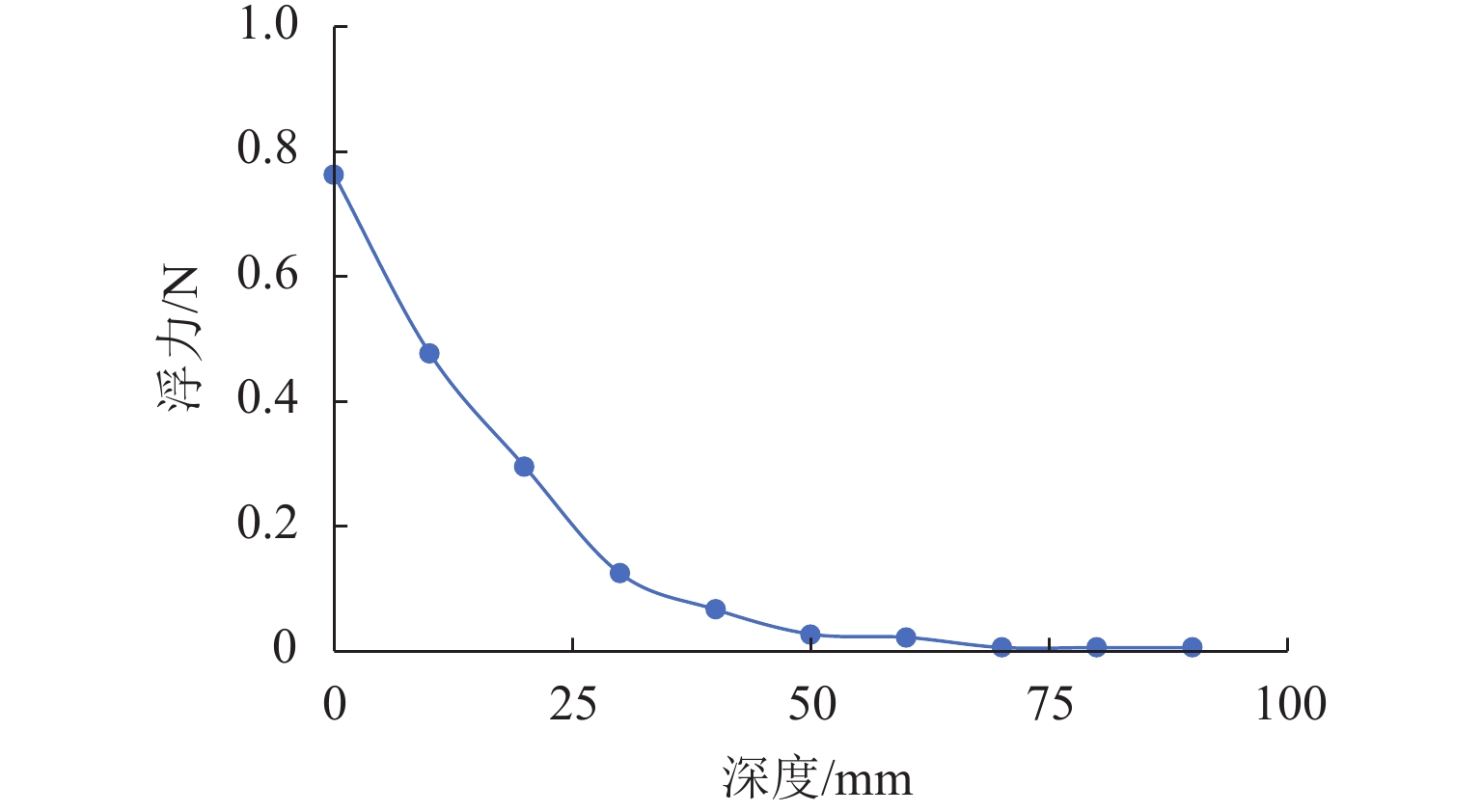

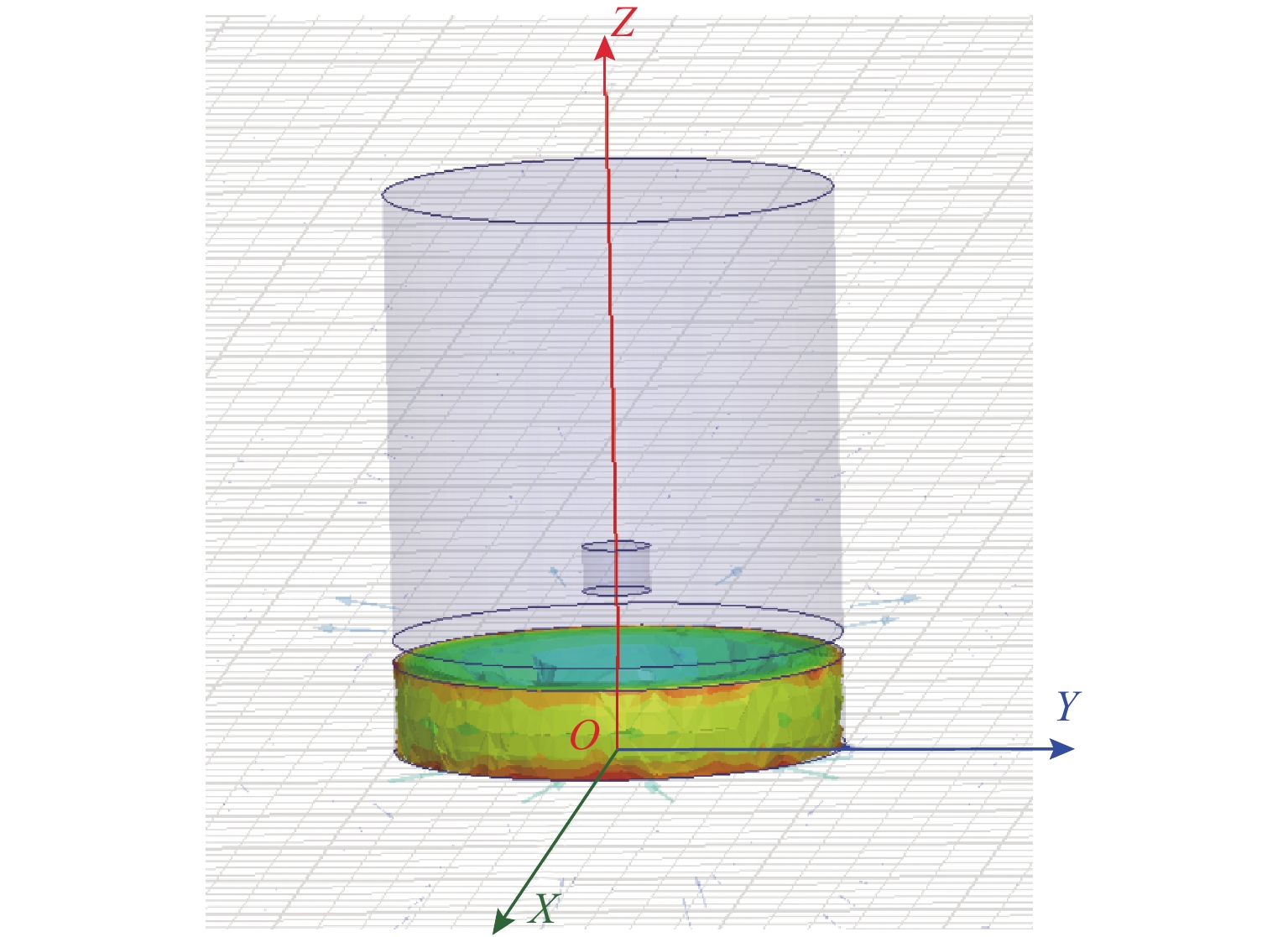

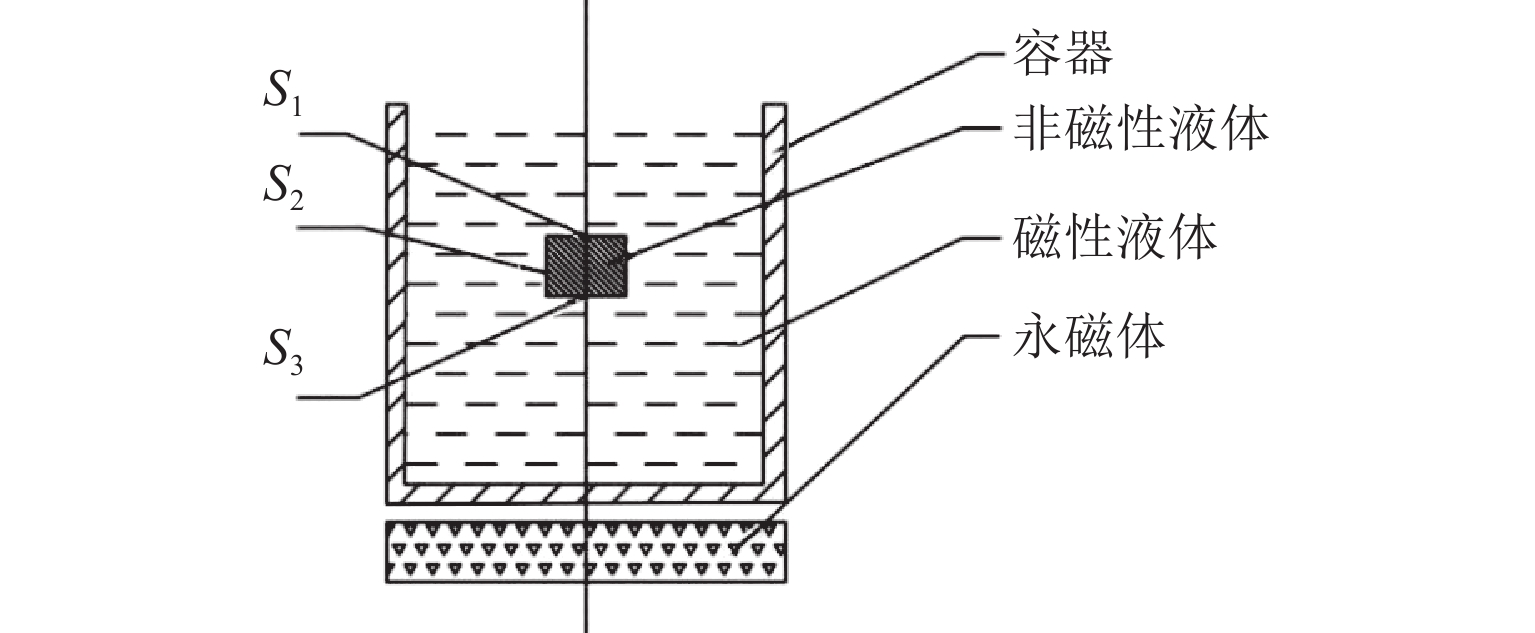

为了研究在选矿分离过程中实现对非导磁物质进行精密分选的问题,基于磁性液体一阶浮力原理,探讨永磁体作为磁源时,通过改变永磁体与磁性液体的距离从而改变浸没在磁性液体中的非磁性物体的受力情况;设计了自动浮选分离结构模型,其中用于磁源升降的电动剪叉式升降平台的升降行程为100 mm,通过磁源升降给磁性液体提供不同的磁场强度;设计了用于分离非磁性物料的直角坐标机器人和末端执行器,实现对悬浮在不同高度的非磁性物体的打捞分离;利用ANSYS Maxwell软件对设计的模型进行二维和三维仿真,近似计算出非磁性物体所受到的一阶浮力,为升降平台的承重能力设计提供了依据. 仿真计算结果表明:指定非导磁圆柱体在磁性液体中悬浮的高度为距离容器底部60~70 mm处,为浮选分离装置设计提供了理论依据;使用高30 mm、半径80 mm的圆柱形永磁体提供磁场,将非导磁体所受一阶浮力换算为密度,得出了本设计可浮选的非导磁体的密度范围为1.65 × 103~6.66 × 103 kg/m3.

Abstract:To determine the mineral separation process for the non-magnetic material precision sorting problem based on the first-order buoyancy of a magnetic fluid, this study examines the stress of non-magnetic objects immersed in a magnetic fluid by changing the distance between the permanent magnet and the magnetic fluid when the permanent magnet is used as a magnetic source. A structural model of automatic flotation separation is then designed. In the design plan, the lifting stroke of the electric scissor lift platform used for the lifting of the magnetic source was 100 mm; different magnetic field strengths can be provided to the magnetic liquid by lifting the magnetic source. Accordingly, a Cartesian robot and an end effector are designed to separate the non-magnetic materials to salvage and separate non-magnetic objects suspended at different heights. Then, the ANSYS Maxwell software is used to conduct two-dimensional and three-dimensional simulations of the design situation. The approximately calculated first-order buoyancy of the non-magnetic objects provides a certain basis for the design of the lifting platform’s load-bearing capacity. The results show that the suspension height of the specified non-magnetic cylinder in the magnetic liquid is 60–70 mm from the bottom of the container according to the simulation data calculation, which provides a theoretical basis for the design of a flotation separation device. A cylindrical permanent magnet with a height of 30 mm and a radius of 80 mm is used to provide the magnetic field. Converting the first-order buoyancy of the non-permeable magnet into density, the density range of the non-permeable magnet that can be floated using this design is approximately 1.65 × 103‒ 6.66 × 103 kg/m3.

-

Key words:

- magnetic liquid /

- first order buoyancy /

- magnetic separation /

- structural design

-

表 1 梯形丝杠尺寸参数

Table 1. Trapezoidal screw size parameters

mm 螺纹种类 螺距 p 导程 s 公称直径 d 外螺纹中径 d2 外螺纹小径 d3 内螺纹大径 D4 牙顶间隙 ac 梯形单头螺纹 3 3 16 14.5 12 17 0.5 表 2 测距模块电器参数

Table 2. Electrical parameters of the ranging module

参数名 数值 工作电流/mA 15 工作电压 DC5V 最近射程/cm 2 最远射程/m 4 测量角度/(°) 15 输入触发信号 10 μs 的TTL脉冲 输出回响信号 输出TTL电平信号,与测距成正比 规格尺寸 45 mm×20 mm ×15 mm 表 3 滚珠丝杠设计要求

Table 3. Ball screw design requirements

设计指标 规格 被移动负载的质量/kg 3 丝杠行程 520 负载最大移动速度/(m·s−1) 0.1 加速时间/s 1 重复定位精度/mm 0.1 表 4 尺寸参数

Table 4. Dimension parameters

mm 非导磁体半径 非导磁体高度 永磁体

半径永磁体

高度容器

半径容器

高度7.5 10 50 20 50 100 表 5 其他仿真参数

Table 5. Other simulation parameters

永磁体

半径/mm永磁体

高度/mm永磁体矫

顽力/(A·m−1)磁性液体

磁导率悬浮

位置/mm80 30 −890000 1.37 70 表 6 Hp与一阶浮力及视密度的关系

Table 6. Relationship between Hp, first-order buoyancy and apparent density

距离/mm 一阶浮力/N 视密度/(×103 kg·m−3) 2 0.089669 6.66 5 0.051339 4.45 8 0.031368 3.29 11 0.023086 2.81 14 0.015351 2.37 17 0.010354 2.08 20 0.002941 1.65 -

[1] 李德才. 磁性液体密封理论及应用[M]. 北京: 科学出版社, 2010. [2] 谢君,李德才,朱锐棋. 霍尔式磁性液体微压差传感器的设计及特性研究[J]. 仪器仪表学报,2020,41(6): 27-34. doi: 10.19650/j.cnki.cjsi.J202006XIE Jun, LI Decai, ZHU Ruiqi. Design and characteristic research on the magnetic fluid micro-pressure difference sensor based on Hall elements[J]. Chinese Journal of Scientific Instrument, 2020, 41(6): 27-34. doi: 10.19650/j.cnki.cjsi.J202006 [3] MANDEL K, STRAßER M, GRANATH T, et al. Surfactant free superparamagnetic iron oxide nanoparticles for stable ferrofluids in physiological solutions[J]. Chemical Communications (Cambridge, England), 2015, 51(14): 2863-2866. doi: 10.1039/C4CC09277E [4] 谢君,鲁妍池,刘宇童,等. 磁性液体触觉传感器的设计及特性研究[J]. 仪器仪表学报,2021,42(1): 30-38. doi: 10.19650/j.cnki.cjsi.J2007150XIE Jun, LU Yanchi, LIU Yutong, et al. Design and characteristics research on the magnetic fluid tactile sensor[J]. Chinese Journal of Scientific Instrument, 2021, 42(1): 30-38. doi: 10.19650/j.cnki.cjsi.J2007150 [5] 翟耀,杨文荣,吴佳男,等. 纳米磁流体磁性能与一阶磁浮力的研究[J]. 功能材料,2018,49(11): 11107-11113.ZHAI Yao, YANG Wenrong, WU Jianan, et al. Study on magnetic performance and first order buoyancy of nano magnetic fluids[J]. Journal of Functional Materials, 2018, 49(11): 11107-11113. [6] ZHU T T, MARRERO F, MAO L D. Continuous separation of non-magnetic particles inside ferrofluids[J]. Microfluidics and Nanofluidics, 2010, 9(4/5): 1003-1009. [7] LEE J H, NAM Y J, PARK M K. Magnetic fluid actuator based on passive levitation phenomenon[J]. Journal of Intelligent Material Systems and Structures, 2011, 22(3): 283-290. doi: 10.1177/1045389X11399487 [8] QIAN L P, LI D C, YU J. Study of the second-order levitation force in the magnetic fluid accelerometer[J]. IEEE Sensors Journal, 2015, 15(12): 6805-6810. doi: 10.1109/JSEN.2015.2464686 [9] 何新智,毕树生,李德才,等. 磁性液体二阶浮力原理的实验研究[J]. 功能材料,2012,43(21): 3023-3027. doi: 10.3969/j.issn.1001-9731.2012.21.034HE Xinzhi, BI Shusheng, LI Decai, et al. Experimental study on the second-order buoyancy of magnetic fluid[J]. Journal of Functional Materials, 2012, 43(21): 3023-3027. doi: 10.3969/j.issn.1001-9731.2012.21.034 [10] 李艳琴. 磁性液体一阶磁浮力原理实验研究[J]. 大学物理,2014,33(7): 24-29. doi: 10.16854/j.cnki.1000-0712.2014.07.016LI Yanqin. Experimental study of first-order magnetic buoyancy for ferrofluid[J]. College Physics, 2014, 33(7): 24-29. doi: 10.16854/j.cnki.1000-0712.2014.07.016 [11] 南进喜, 叶盛旗, 曾位勇, 等. 一种矿业用铁磁流体静力分选机装置: CN212916118U[P]. 2021-04-09. [12] 张应强,魏镜弢,吴张永,等. 非磁性矿粒在磁流体静力分选中的力学模型[J]. 有色金属(选矿部分),2013(4): 49-52.ZHANG Yingqiang, WEI Jingtao, WU Zhangyong, et al. Mechanical model of non-magnetic mineral particles in magneto hydrostatic static separation[J]. Nonferrous Metals (Mineral Processing Section), 2013(4): 49-52. [13] 荀勇. 实现磁性和非磁性物质分离的方法: CN102641777A[P]. 2015-10-28. [14] 刘桂雄, 蒲尧萍, 徐晨. 磁流体浸没物磁场力分析及磁浮特性[C]//第六届中国功能材料及其应用学术会议. 武汉: [出版者不祥], 2007: 4. [15] 李冬旭. 一种磁性矿物分选装置: CN210646586U[P]. 2020-06-02. [16] 姚杰. 基于铁磁流体第一类悬浮特性的新型动力吸振器研究[D]. 北京: 北京交通大学, 2018. [17] 马宏宇. 磁性液体一阶浮力原理的应用基础研究[D]. 北京: 北京交通大学, 2018. [18] 成大先. 机械设计手册[M]. 北京: 化学工业出版社, 2017. -

下载:

下载: