Finite Element Analysis on Layered Mechanical Properties of Carbon Fiber Wires Under Influence of Temperature

-

摘要:

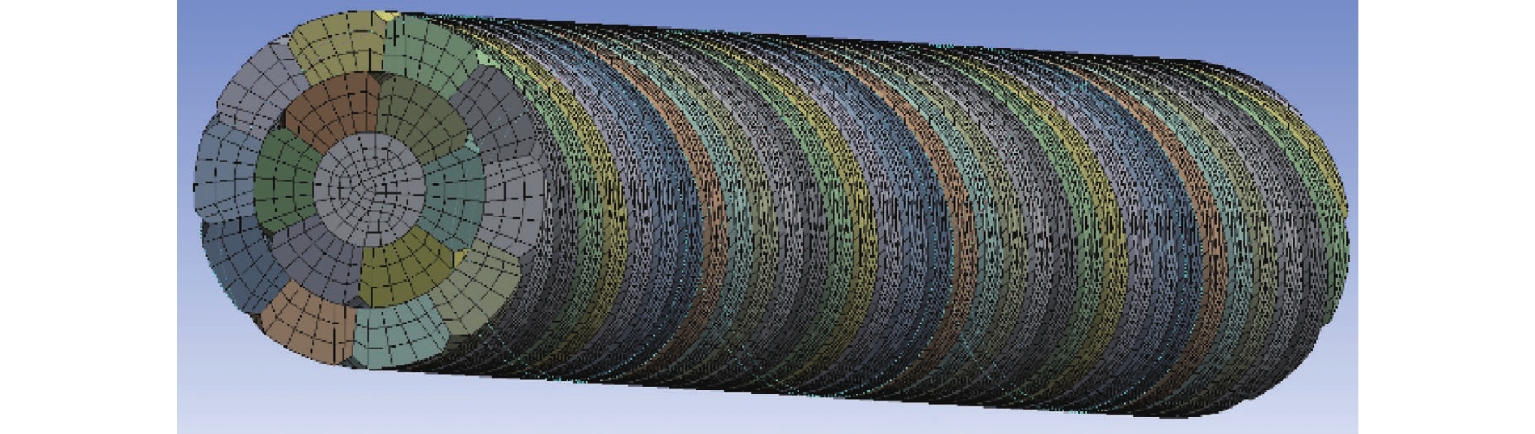

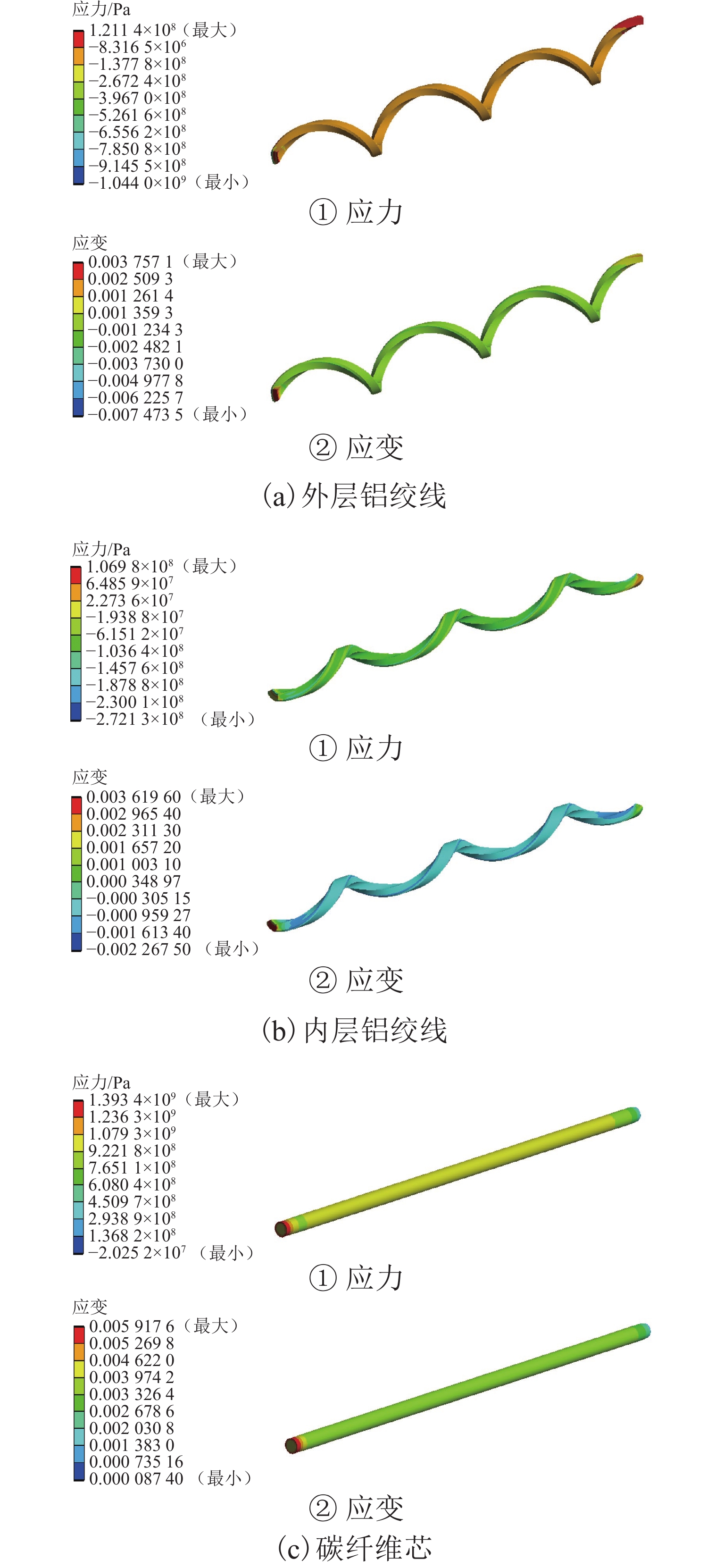

为探明温度对碳纤维导线分层力学特性的影响,考虑拐点温度,利用电热模块施加不同电压得到多种温度,并计算分析不同温度和拉断力条件下碳纤维导线的各层、各股和各截面应力应变分布. 研究结果表明:拐点温度后,碳芯受到正向应力但铝绞线承受负向应力,使碳纤维导线失去了承担拉断力的作用;各股线的最大应力和应变均出现在线的两端,倒角位置的应力和应变结果略大于对应股线主体上的应力;碳纤维导线各个截面的最大应力均为正值,均出现在碳芯上,其靠近外力施加端截面的最大应力出现突然下降的现象;碳纤维导线更适用于各种温度条件,但应注意导线两端夹持位置和梯形截面中小截面的力学特性变化.

Abstract:In order to clarify the effect of temperature on the layered mechanical properties of carbon fiber wires, while the critical temperature is considered, the gravitational strain distributions of each wire layer, strand and section in the breaking force conditions are calculated at temperatures driven by different voltages of an electric heating. The results show that, above the critical temperature, the carbon core is subjected to positive stress and the aluminum strand to a negative stress, making the wire unable to bear the breaking force. The maximum stress and strain of each strand appear at both ends of the wire, and the stress and strain at the chamfer position are slightly larger than the stress on the main body of the strand. The maximum stress at each wire cross-section is positive and occurs at the core, and near the end where the force acts it drops sharply. Carbon fiber wires are more suitable for various temperatures, but the changes in the mechanical characteristics at the clamping position at wire ends and at the small and medium trapezoidal sections need more exploration.

-

表 1 JRLX/F1B-240/30碳纤维导线的参数

Table 1. Parameters of carbon fiber wire JRLX/F1B-240/30

参数 取值 参数 取值 标称总截面积/mm2 246.4 导线弹性模量/(N·mm−2) 117 标称铝截面积/mm2 218.4 碳芯弹性模量/(N·mm−2) 65 标称环形铝

面积/mm2234.8 导线线膨胀系数/

(×10−6 ℃)12.9 导线计算外径/mm 18.29 碳芯线膨胀系数/

(×10−6 ℃)1.6 碳芯直径/mm 5.97 导线结构重量/(kg·km−1) 714.1 内层铝线根数/根 6 导线额定拉断力/kN 73.2 外层铝线根数/根 10 表 2 ANSYS仿真和MATLAB求解温度及相对误差

Table 2. Temperature results and relative errors from ANSYS and MATLAB

电压/

VANSYS

温度/℃MATLAB 求解

温度/℃相对

误差/%0.00576 40.38 39.26 2.78 0.01070 80.32 80.89 −0.71 0.01430 120.92 120.82 0.08 0.01689 160.78 159.92 0.53 表 3 ANSYS和MATLAB最大应力数据

Table 3. Stress data from ANSYS and MATLAB

工况 ANSYS/

MPaMATLAB/

MPa相对误差/

%40℃,15%RRTS 149.14 129.66 13.06 80℃,15%RRTS 591.81 529.90 10.46 120℃,15%RRTS 824.53 778.73 5.55 160℃,15%RRTS 981.04 941.99 3.98 40℃,25%RRTS 222.45 187.34 15.78 80℃,25%RRTS 664.81 585.80 11.88 120℃,25%RRTS 897.53 851.28 5.15 160℃,25%RRTS 1054.00 1040.44 1.29 40℃,35%RRTS 297.14 263.71 11.25 80℃,35%RRTS 737.81 667.56 9.52 120℃,35%RRTS 970.53 946.98 2.43 160℃,35%RTS 1127.00 1119.38 0.68 表 4 ANSYS和MATLAB最大应变数据

Table 4. Strain data from ANSYS and MATLAB

工况 ANSYS MATLAB 相对误差/% 40 ℃,15%RRTS 1.0493 0.8869 15.48 80 ℃,15%RRTS 2.4572 2.2230 9.53 120 ℃,15%RRTS 3.4129 3.2251 5.50 160 ℃,15%RRTS 3.9450 3.8106 3.41 40 ℃,25%RRTS 1.7933 1.4836 17.27 80 ℃,25%RRTS 2.7760 2.5288 8.90 120 ℃,25%RRTS 3.7317 3.5314 5.37 160 ℃,25%RRTS 4.2659 4.1133 3.58 40 ℃,35%RRTS 2.5374 2.2045 13.12 80 ℃,35%RRTS 3.0948 2.9110 5.94 120 ℃,35%RRTS 4.0505 3.9642 2.13 160 ℃,35%RRTS 4.5869 4.4916 2.08 表 5 LGJ-240/30型钢芯铝绞线相关参数

Table 5. Parameter of steel-cored aluminum strand LGJ-240/30

材料 根数/根,直径/mm 计算截面积/mm2 弹性模量/GPa 泊松比 外径/mm 芯铝绞线温度膨胀系数/(×10−6 ℃) 铝 24,3.60 244.29 60 0.31 21.60 1.96 钢 7,2.40 31.67 206 0.28 合计 275.96 表 6 不同温度及外力下碳纤维导线各层内力占比

Table 6. Proportion of internal forces in each layer of carbon fiber wires at different temperatures

% 外力 层数 40 ℃ 80 ℃ 120 ℃ 160 ℃ 15%RRTS 外层铝 39.70 −26.78 −61.42 −84.49 内层铝 23.32 −18.80 −40.83 −55.55 碳芯 36.98 145.58 202.26 240.04 25%RRTS 外层铝 41.91 2.09 −18.45 −32.41 内层铝 24.75 −0.49 −13.64 −22.45 碳芯 33.34 98.40 132.09 154.86 35%RRTS 外层铝 42.86 14.43 −0.35 −10.17 内层铝 25.36 7.34 −2.05 −8.32 碳芯 31.78 78.22 102.40 118.49 -

[1] 于广辉,邓云坤. 碳纤维复合导线发展综述[J]. 热加工工艺,2019,48(20): 1-5,9.YU Guanghui, DENG Yunkun. Review on development of carbon fiber composite conductor[J]. Hot Working Technology,2019,48(20): 1-5,9. [2] 赵丹妮. 大负荷条件下碳纤维复合芯导线热特性及载流能力研究[D]. 吉林:东北电力大学,2018. [3] 袁贝尔,应展烽,齐保军,等. 高压碳纤维复合芯导线输电线路热过载运行的风险评估方法[J]. 电力系统自动化,2018,42(1): 111-117.YUAN Beier, YING Zhanfeng, QI Baojun, et al. Overheating risk assessment method for high voltage transmission line using aluminum conductor composite core[J]. Automation of Electric Power Systems,2018,42(1): 111-117. [4] 刘春城,陈诚. 考虑流固耦合效应的碳纤维复合芯导线风振响应分析[J]. 应用基础与工程科学学报,2013,21(6): 1116-1124.LIU Chuncheng, CHEN Cheng. Wind-induced dynamic response of carbon fiber core wire by considering fluid structure interaction effect[J]. Journal of Basic Science and Engineering,2013,21(6): 1116-1124. [5] 刘亮,姚一鸣,蒋鑫,等. 架空线路碳纤维复合芯导线舞动特性实验[J]. 振动. 测试与诊断,2019,39(4): 816-821.LIU Liang, YAO Yiming, JIANG Xin, et al. Experimental research on galloping properties of carbon fiber composite core on overhead line[J]. Journal of Vibration, Measurement & Diagnosis,2019,39(4): 816-821. [6] 朱院院,张晓敏,龙鹏,等. 考虑接触摩擦与各向异性性能的碳纤维复合芯导线(ACCC)径向耐压性能的有限元分析[J]. 玻璃钢/复合材料,2019(8): 29-34.ZHU Yuanyuan, ZHANG Xiaomin, LONG Peng, et al. Finite element analysis of radial compressive behavior of accc considering contact friction and anisotropic properties[J]. Fiber Reinforced Plastics/Composites,2019(8): 29-34. [7] 秦力,刘芳卉,宋阳. 碳纤维复合芯导线股线应力有限元分析[J]. 水电能源科学,2017,35(5): 182-186.QIN Li, LIU Fanghui, SONG Yang. Finite element analysis of ACCC strands stress[J]. Water Resources and Power,2017,35(5): 182-186. [8] 沈楚莹,尹芳辉,燕秀,等. 绞合型碳纤维复合芯导线的弧垂特性研究[J]. 电网技术,2021,45(12): 4964-4970.SHEN Chuying, YIN Fanghui, YAN Xiu, et al. Sag characteristics of stranded carbon fiber composite core conductor[J]. Power System Technology,2021,45(12): 4964-4970. [9] 鲍星辉,杨长龙,张玉良,等. 具有过渡点温度特性导线的力学计算及工程应用[J]. 玻璃钢/复合材料,2016(8): 82-86.BAO Xinghui, YANG Changlong, ZHANG Yuliang, et al. Mechanical calculation and engineering application for the conductor with the inflection point temperature characteristic[J]. Fiber Reinforced Plastics/Composites,2016(8): 82-86. [10] 祝贺,刘雨菲,张瑾,等. 输电线路导线分层力学特性仿真及试验研究[J]. 应用力学学报,2020,37(4): 1812-1817.ZHU He, LIU Yufei, ZHANG Jin, et al. Simulation and experimental study on layered mechanical characteristics of transmission lines[J]. Chinese Journal of Applied Mechanics,2020,37(4): 1812-1817. [11] 芮晓明,赵国良,赵泽中,等. 输电导线新型模型的应力分层特性研究[J]. 华北电力大学学报(自然科学版),2021,48(3): 57-64,107.RUI Xiaoming, ZHAO Guoliang, ZHAO Zezhong, et al. Research on stress layering characteristics of new transmission conductor model[J]. Journal of North China Electric Power University (Natural Science Edition),2021,48(3): 57-64,107. [12] 祝贺,刘雨菲,张瑾,等. 输电线路弯曲导线分层力学特性模型及仿真分析[J]. 水电能源科学,2020,38(4): 162-166.ZHU He, LIU Yufei, ZHANG Jin, et al. Modeling and simulation analysis of layered mechanical characteristics of bending wires in transmission lines[J]. Water Resources and Power,2020,38(4): 162-166. [13] 孟遂民,孔伟. 架空输电线路设计[M]. 北京:中国电力出版社,2007. -

下载:

下载: