Effect of Artificial Crust Layer on Pile-Soil Stress Ratio of Pipe Pile Composite Foundation

-

摘要:

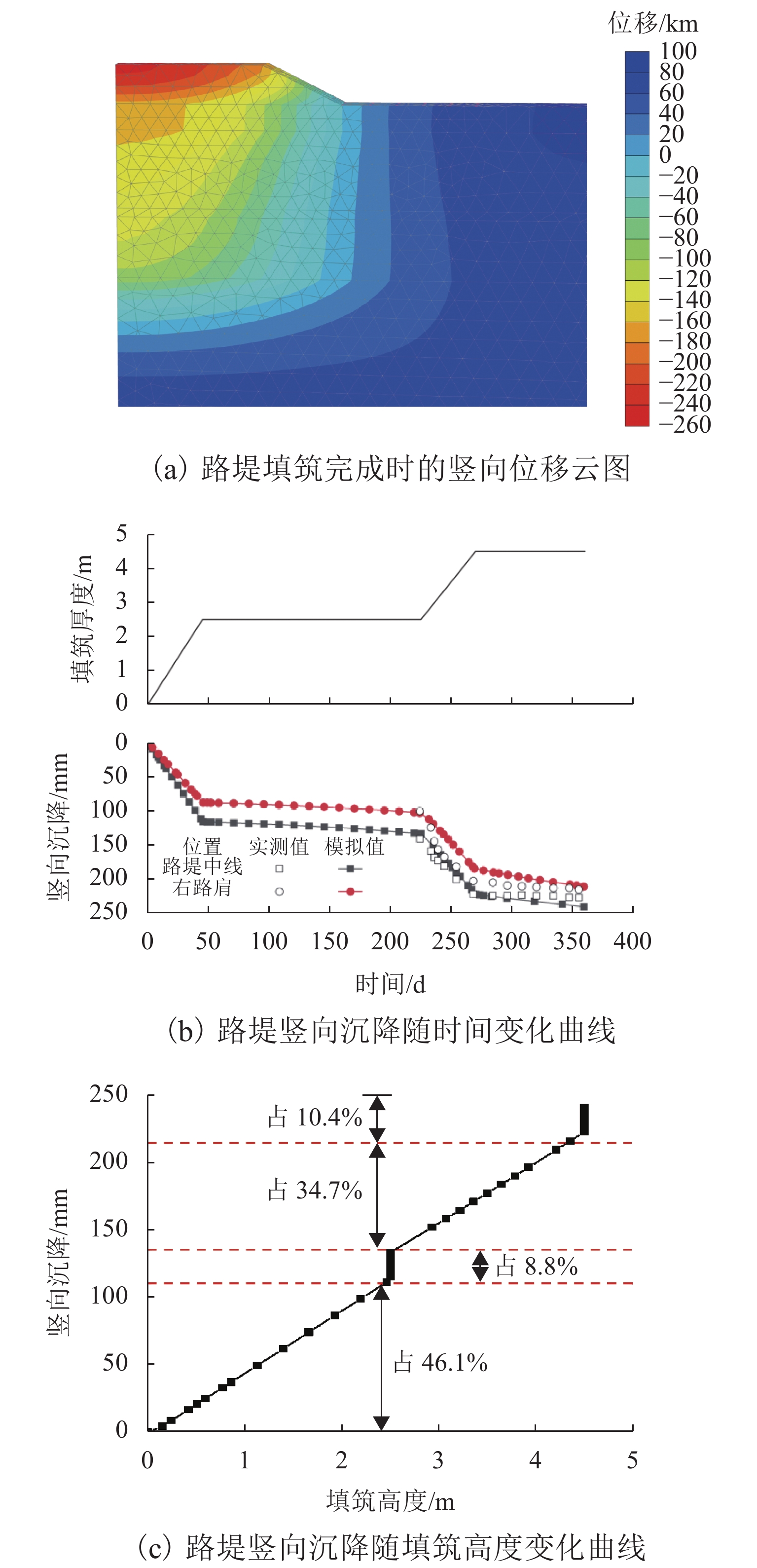

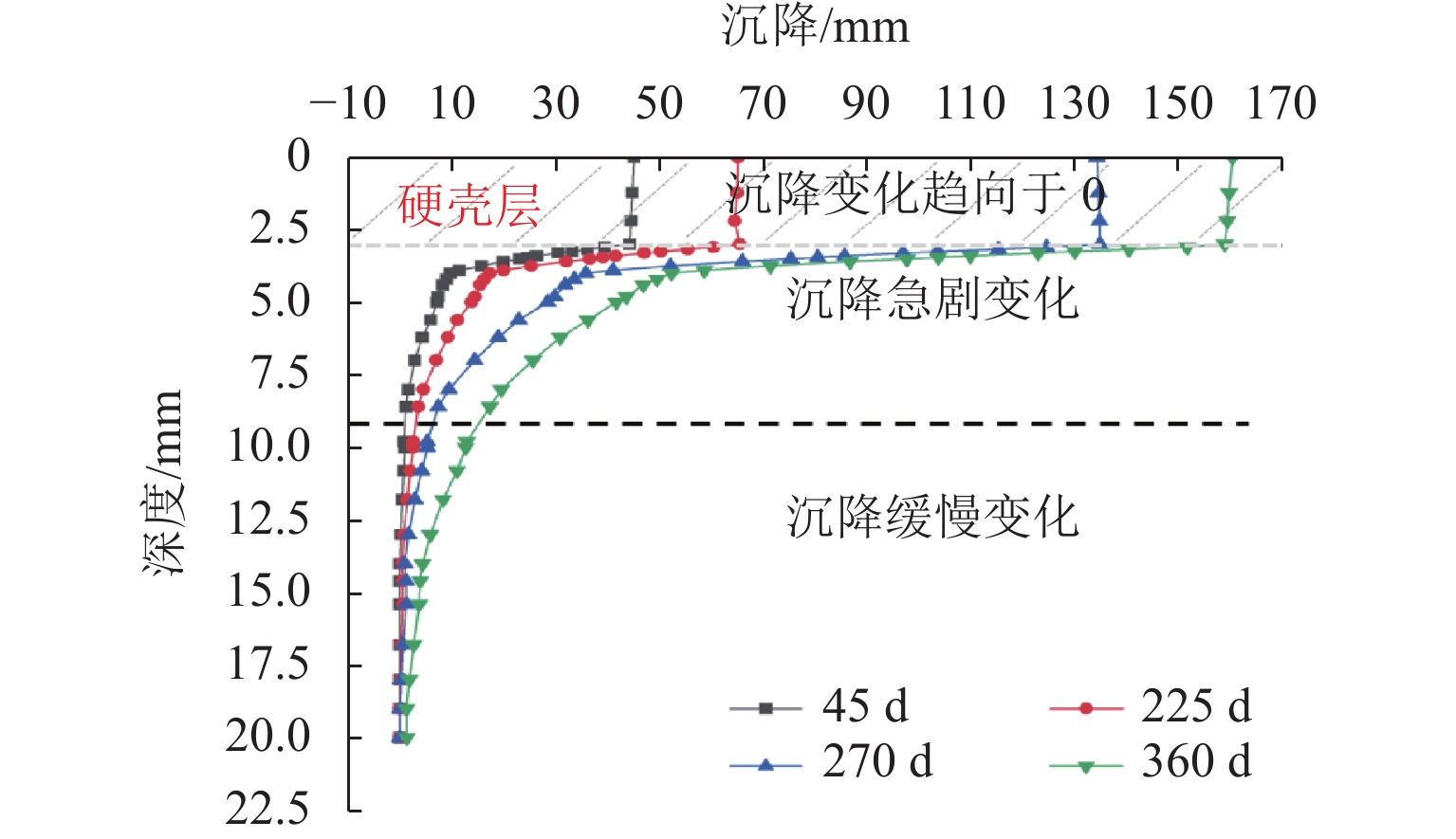

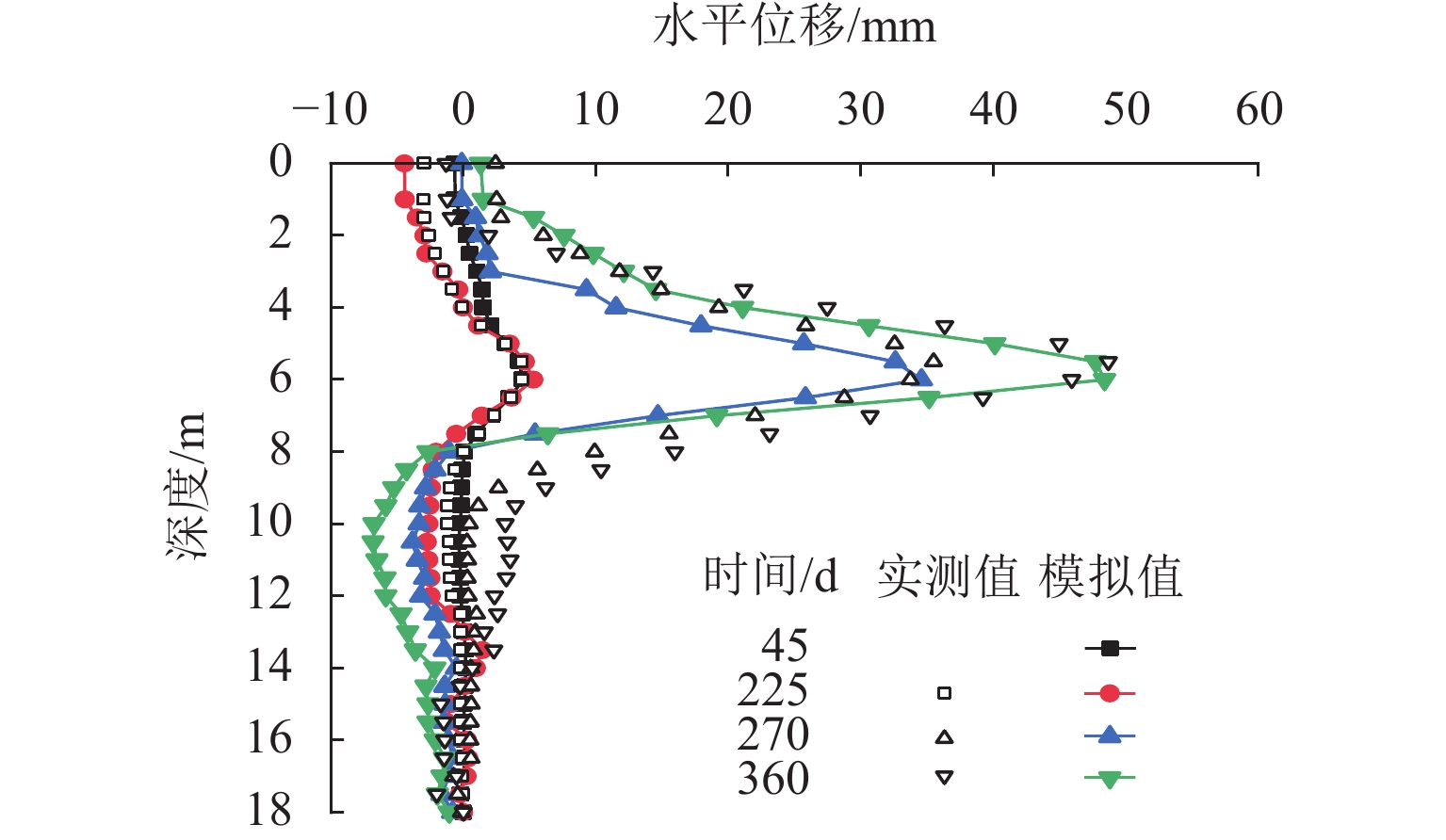

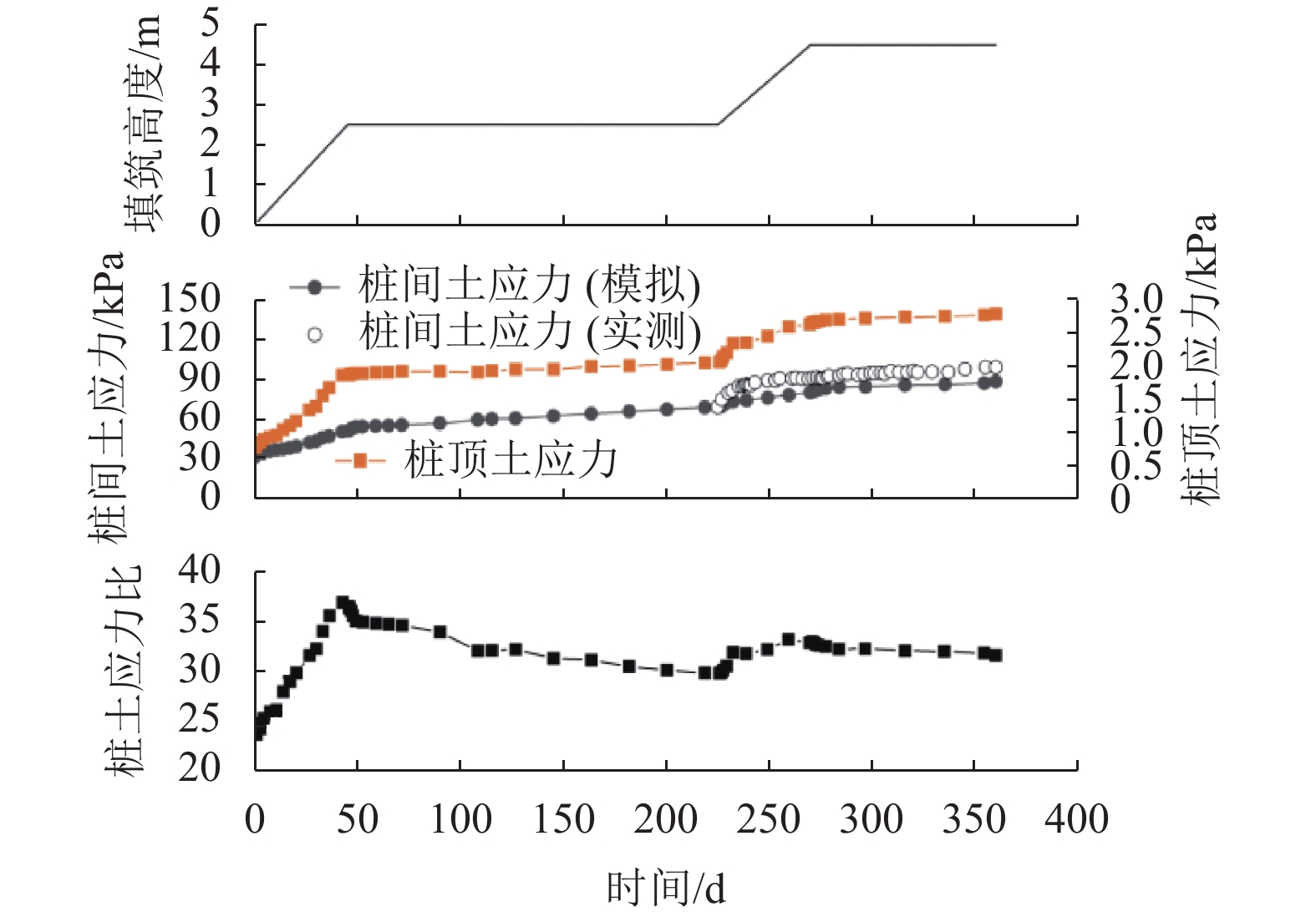

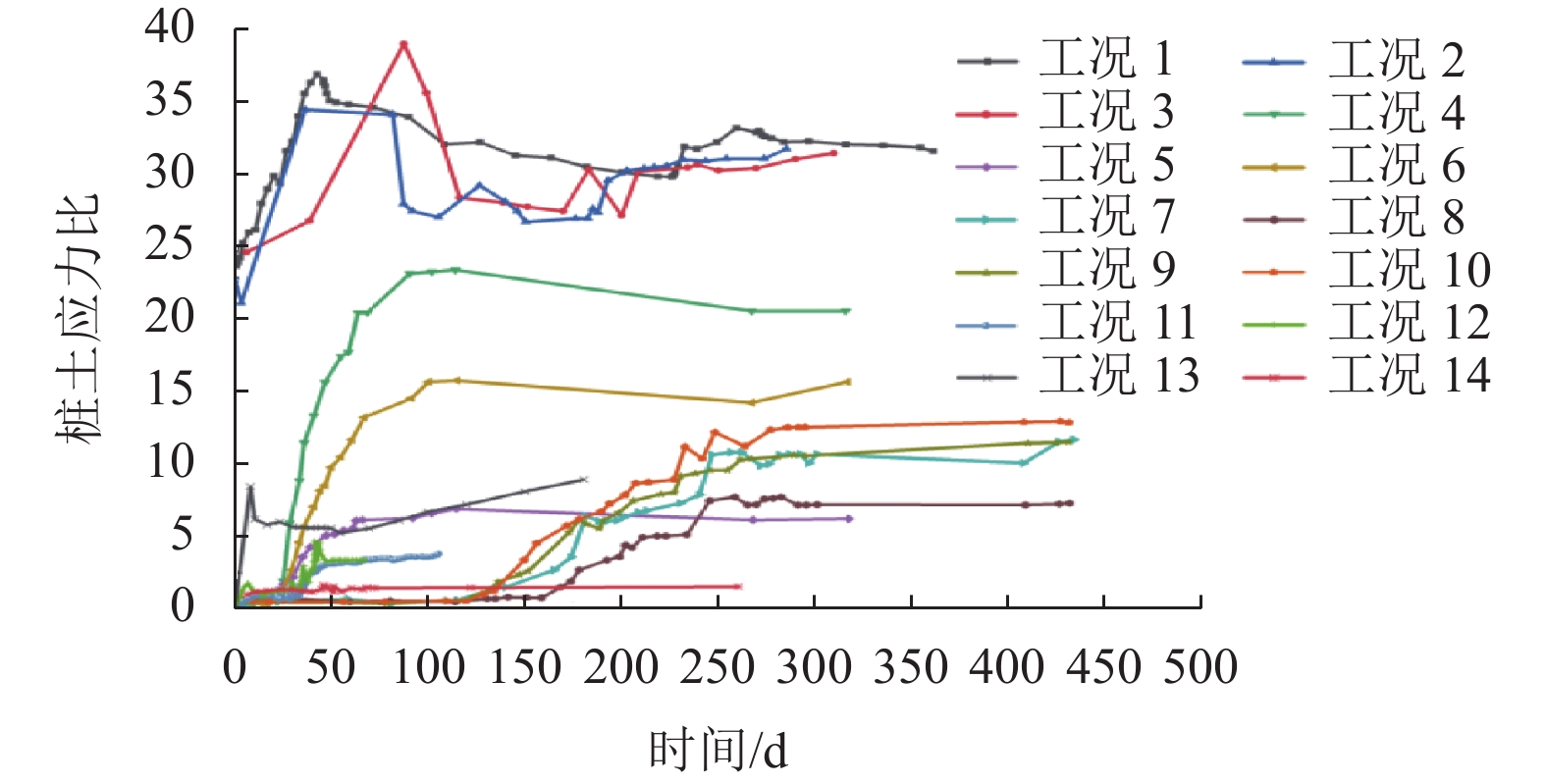

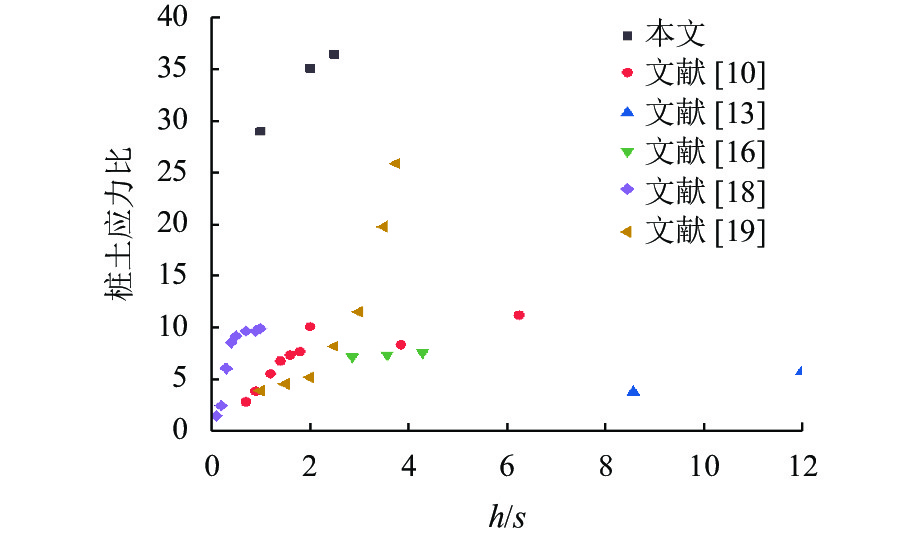

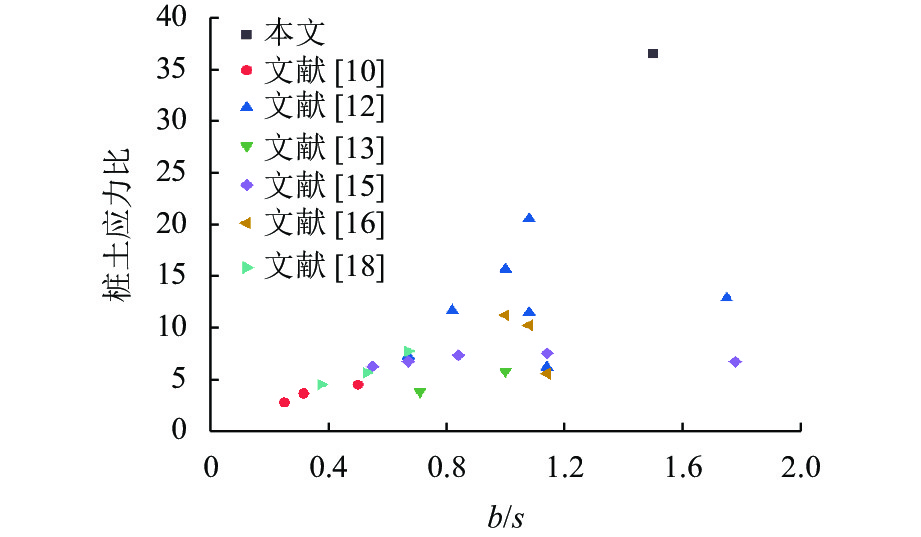

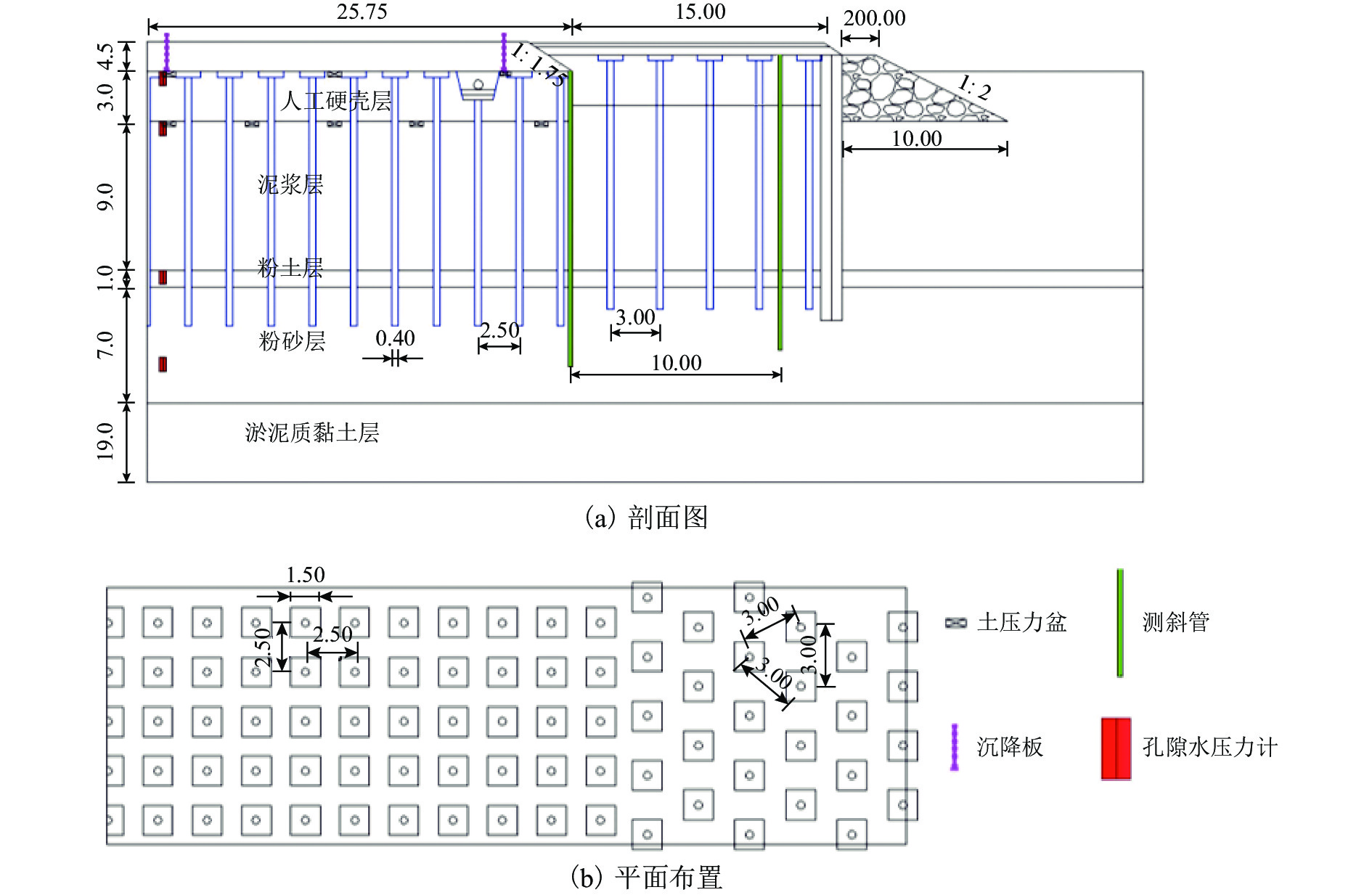

为研究就地固化硬壳层对预应力管桩复合地基桩-土应力比的影响,以绍兴钱滨线泥浆池路段为背景,开展现场试验和数值模拟分析,研究路堤荷载作用下预应力管桩复合地基的受力和变形;从桩-土应力比的角度,着重探讨硬壳层对桩基复合地基承载性能的影响规律;分析路堤高度与桩帽净间距之比、桩帽宽度与桩帽净间距之比等设计参数对桩-土应力比发展的影响机制. 研究结果表明:硬壳层的存在能够有效提高桩基复合地基的承载特性;在本文试验条件下,就地固化硬壳层的预应力管桩复合地基最大水平位移发生在地表以下5~6 m处,区别于传统桩基复合地基的土体水平位移沿深度逐渐降低的规律;桩-土应力比在23~37,高于传统桩基复合地基.

Abstract:In order to study the influence of artificial crust layer formed by in-situ solidified on the pile-soil stress ratio of prestressed pipe pile composite foundation, field experiments and numerical simulation analysis were carried out based on the mud pit section of Qianqing-Binhai highway in Shaoxing. On this basis, both the stress response and deformation of prestressed pipe pile composite foundation under embankment load were studied. From the pile-soil stress ratio, the influence of artificial crust layer on the bearing performance of pile composite foundation was emphatically discussed. In addition, the influence mechanism of design parameters such as the ratio of embankment height to net distance between pile caps and the ratio of pile cap width to net distance between pile caps on the development of pile-soil stress ratio were preliminarily studied. It shows that artificial crust layer can improve the bearing capacity. Under the experimental conditions, the maximum horizontal displacement of artificial crust layer combined prestressed pipe pile composite foundation occurs 5~6 m below the ground surface, which is different from traditional composite foundation decreases gradually along the depth. The pile-soil stress ratio is between 23 and 37, which is higher than that of traditional pile composite foundation.

-

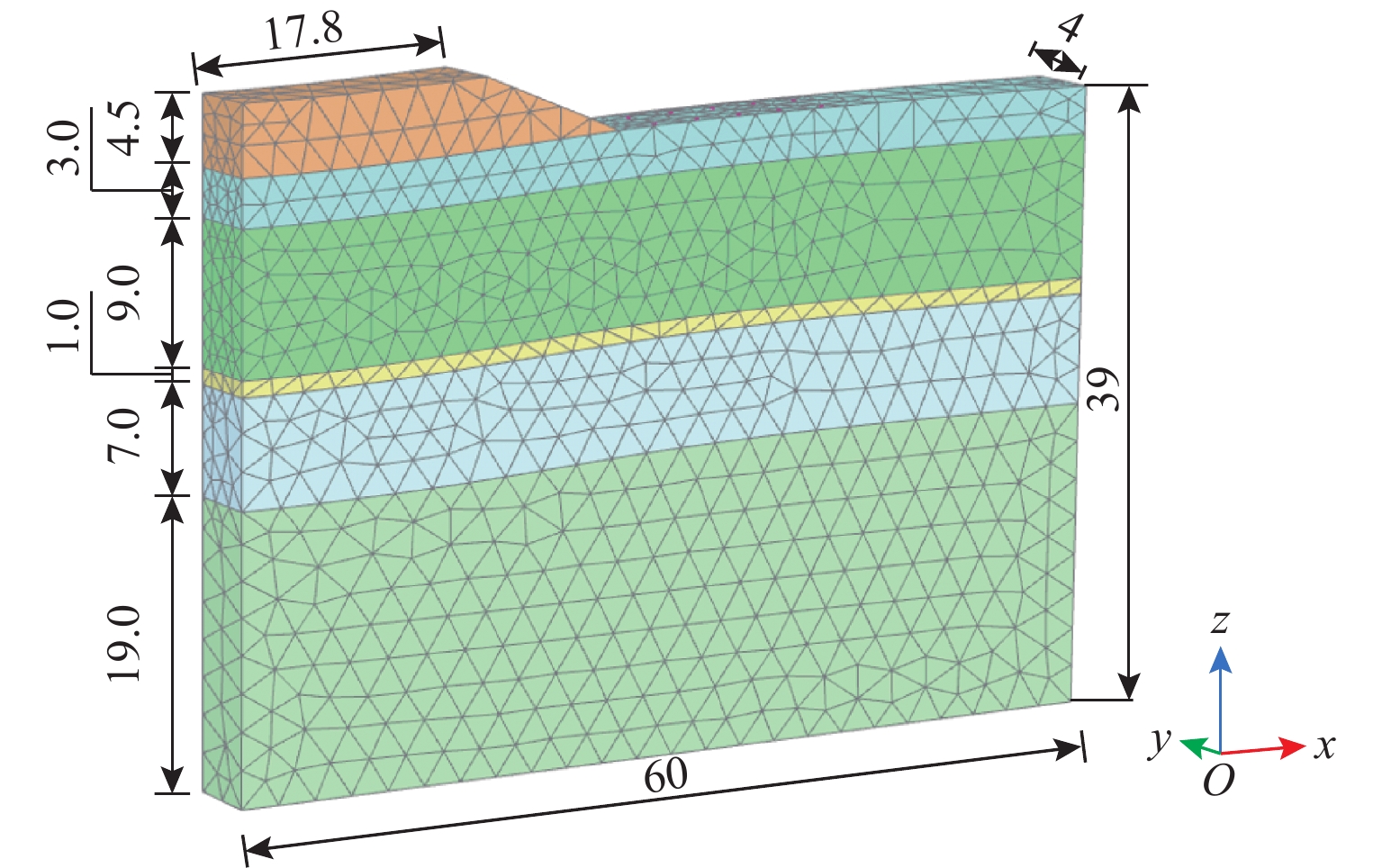

表 1 试验段土层的基本物理力学指标

Table 1. Basic physical and mechanical indexes of soil layer

土层 厚度/m 天然湿密度/

(g•cm−3)天然

孔隙比黏聚力/kPa 内摩擦

角/(°)弹性模量/

MPa泊松比 渗透率/

(×10−4 m•d−1)路堤 4.5 2.0 38.0 35.00 0.30 1000.0 土工格栅 3500.00 0.30 桩 80000.00 0.15 硬壳层 3.0 1.85 0.380 300.0 16.0 300.00 0.30 1.0 泥浆 9.0 1.69 2.060 10.0 10.1 2.50 0.35 1.7 粉土 1.0 1.79 0.902 8.2 29.2 4.46 0.35 4.3 粉砂 7.0 1.79 0.735 6.4 30.9 6.32 0.35 43.2 淤泥质黏土 19.0 1.78 1.212 15.0 3.7 2.73 0.35 4.3 表 2 施工参数对比表

Table 2. Comparison of construction parameters

工况 来源 桩长/m 桩径/m 桩间距/m 桩间土

应力/kPa桩顶土

应力/kPa桩-土

应力比褥垫层/硬壳层 1 本文 16.0 0.40 2.5 88.3 2785.8 31.6 3.0 m 硬壳层 2 文献[6] 16.0 0.40 2.5 90.8 2851.1 31.4 3.0 m 硬壳层 3 文献[7] 16.0 0.40 3.0 97.0 3073.8 31.7 3.0 m 硬壳层 4 文献[12] 20.0 0.40 2.0 18.2 375.0 20.6 加筋垫层(土工格栅抗拉

模量1000 kN/m,垫层和整平层

压缩模量 25 MPa)5 2.5 46.6 289.9 6.2 6 3.0 24.3 381.1 15.7 7 文献[12] 14.0 0.40 2.0 24.1 281.0 11.7 加筋垫层(土工格栅抗

拉模量 600 kN/m,垫层和整

平层压缩模量 25 MPa)8 0.30 2.5 40.1 292.2 7.3 9 文献[12] 13.5 0.48 2.7 30.4 350.8 11.5 10 2.2 20.9 269.3 12.9 11 文献[13] 7.0~8.0 0.50 1.2 3.8 0.5 m 砂性土 12 5.0 0.5 m 碎石垫层 13 文献[14] 16.0 1.00 3.0 58.9 624.9 8.9 0.5 m 碎石垫层+土工格栅

(抗拉模量 1180 kN/m)14 文献[20] 3.0~6.0 0.50 1.6 115.1 177.3 1.5 0.5 m 碎石垫层+土工格栅

(抗拉模量 300 kN/m)表 3 参数影响程度

Table 3. Influence degree of parameters

影响因素 影响程度/% 结论 h/s 108.6 高(+) b/s 63.0 高(+) 注:表中“ + ”表示积极影响. -

[1] 刘汉龙,赵明华. 地基处理研究进展[J]. 土木工程学报,2016,49(1): 96-115.LIU Hanlong, ZHAO Minghua. Review of ground improvement technical and its application in China[J]. China Civil Engineering Journal, 2016, 49(1): 96-115. [2] 郑刚,龚晓南,谢永利,等. 地基处理技术发展综述[J]. 土木工程学报,2012,45(2): 127-146.ZHENG Gang, GONG Xiaonan, XIE Yongli, et al. State-of-the-art techniques for ground improvement in China[J]. China Civil Engineering Journal, 2012, 45(2): 127-146. [3] HAN J. Recent research and development of ground column technologies[J]. Proceedings of the Institution of Civil Engineers-Ground Improvement, 2015, 168(4): 246-264. doi: 10.1680/grim.13.00016 [4] CHEN Y H, GAO S H, CHEN L, et al. Laboratory and field test study on the improvement of marine clay slurry by in situ solidification[J]. Marine Georesources & Geotechnology, 2019, 37(6): 695-703. [5] ISHIKURA R, YASUFUKU N, BROWN M J. An estimation method for predicting final consolidation settlement of ground improved by floating soil cement columns[J]. Soils and Foundations, 2016, 56(2): 213-227. doi: 10.1016/j.sandf.2016.02.005 [6] 王颖. 道路软基就地固化形成硬壳层的承载和变形特性研究[D]. 南京: 河海大学, 2016. [7] 李肖. 跨越大面积深厚超软土路堤变形机理及设计方法研究[D]. 淮南: 安徽理工大学, 2019. [8] 邵国霞,苏谦,尹紫红,等. 不同垫层下管桩复合地基现场对比试验研究[J]. 西南交通大学学报,2018,53(2): 279-285.SHAO Guoxia, SU Qian, YIN Zihong, et al. Field comparative experimental study on pipe pile composite foundation under different cushion[J]. Journal of Southwest Jiaotong University, 2018, 53(2): 279-285. [9] 陆清元,罗强,蒋良潍. 路堤下刚性桩复合地基桩-土应力比计算[J]. 岩土力学,2018,39(39): 2473-2482.LU Qingyuan, LUO Qiang, JIANG Liangwei. Calculation of pile-soil stress ratio of rigid pile composite foundation under embankment[J]. Rock and Soil Mechanics, 2018, 39(39): 2473-2482. [10] CHEN Y M, CAO W P, CHEN R P. An experimental investigation of soil arching within basal reinforced and unreinforced piled embankments[J]. Geotextiles and Geomembranes, 2008, 26(2): 164-174. doi: 10.1016/j.geotexmem.2007.05.004 [11] ZHAO M, CAO W P. An analysis of pile-soil interaction under embankment load[J]. Applied Mechanics and Materials, 2014, 488/489: 458-461. doi: 10.4028/www.scientific.net/AMM.488-489.458 [12] CHEN R P, XU Z Z, CHEN Y M, et al. Field tests on pile-supported embankments over soft ground[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2010, 136(6): 777-785. doi: 10.1061/(ASCE)GT.1943-5606.0000295 [13] 刘吉福. 路堤下复合地基桩、土应力比分析[J]. 岩石力学与工程学报,2003,22(4): 674-677.LIU Jifu. Analysis on pile-soil stress ratio for composite ground under embankment[J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(4): 674-677. [14] 费康,刘汉龙. 桩承式加筋路堤的现场试验及数值分析[J]. 岩土力学,2009,30(4): 1004-1012.FEI Kang, LIU Hanlong. Field test study and numerical analysis of a geogrid-reinforced and pile-supported embankment[J]. Rock and Soil Mechanics, 2009, 30(4): 1004-1012. [15] 曹卫平,陈云敏,陈仁朋. 考虑路堤填筑过程与地基土固结相耦合的桩承式路堤土拱效应分析[J]. 岩石力学与工程学报,2008,27(8): 1610-1617.CAO Weiping, CHEN Yunmin, CHEN Renpeng. Analysis of soil arching in piled embankments considering coupled effect of embankment filling and soil consolidation[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(8): 1610-1617. [16] 曹卫平,胡伟伟. 桩承式加筋路堤三维土拱效应试验研究[J]. 岩土力学,2014,35(2): 351-358. doi: 10.16285/j.rsm.2014.02.027CAO Weiping, HU Weiwei. Experimental study of 3D soil arching in piled reinforced embankments[J]. Rock and Soil Mechanics, 2014, 35(2): 351-358. doi: 10.16285/j.rsm.2014.02.027 [17] ROWE R K, LI A L. Geosynthetic-reinforced embankments over soft foundations[J]. Geosynthetics International, 2005, 12(1): 50-85. doi: 10.1680/gein.2005.12.1.50 [18] LIU W Z, QU S, ZHANG H, et al. An integrated method for analyzing load transfer in geosynthetic-reinforced and pile-supported embankment[J]. KSCE Journal of Civil Engineering, 2017, 21(3): 687-702. doi: 10.1007/s12205-016-0605-3 [19] 费康,王军军,陈毅. 桩承式路堤土拱效应的试验和数值研究[J]. 岩土力学,2011,32(7): 1975-1983. doi: 10.3969/j.issn.1000-7598.2011.07.010FEI Kang, WANG Junjun, CHEN Yi. Experimental and numerical studies of soil arching in piled embankment[J]. Rock and Soil Mechanics, 2011, 32(7): 1975-1983. doi: 10.3969/j.issn.1000-7598.2011.07.010 [20] CAO W Z, ZHENG J J, ZHANG J, et al. Field test of a geogrid-reinforced and floating pile-supported embankment[J]. Geosynthetics International, 2016, 23(5): 348-361. doi: 10.1680/jgein.16.00002 [21] BOURGEOIS E, BUHAN P, HASSEN G. Settlement analysis of piled-raft foundations by means of a multiphase model accounting for soil-pile interactions[J]. Computers and Geotechnics, 2012, 46: 26-38. doi: 10.1016/j.compgeo.2012.05.015 [22] LENG J, GABR M A. Numerical analysis of stress-deformation response in reinforced unpaved road sections[J]. Geosynthetics International, 2005, 12(2): 111-119. doi: 10.1680/gein.2005.12.2.111 [23] LEE C J, BOLTON M D, AL-TABBAA A. Numerical modelling of group effects on the distribution of dragloads in pile foundations[J]. Géotechnique, 2002, 52(5): 325-335. [24] TAVENAS F, MIEUSSENS C, BOURGES F. Lateral displacements in clay foundations under embankments[J]. Canadian Geotechnical Journal, 1979, 16(3): 532-550. doi: 10.1139/t79-059 [25] HUANG J, HAN J. Two-dimensional parametric study of geosynthetic-reinforced column-supported embankments by coupled hydraulic and mechanical modeling[J]. Computers and Geotechnics, 2010, 37(5): 638-648. doi: 10.1016/j.compgeo.2010.04.002 -

下载:

下载: