Image Processing Based Method for Measuring Contact Force in Pantograph-Catenary System

-

摘要:

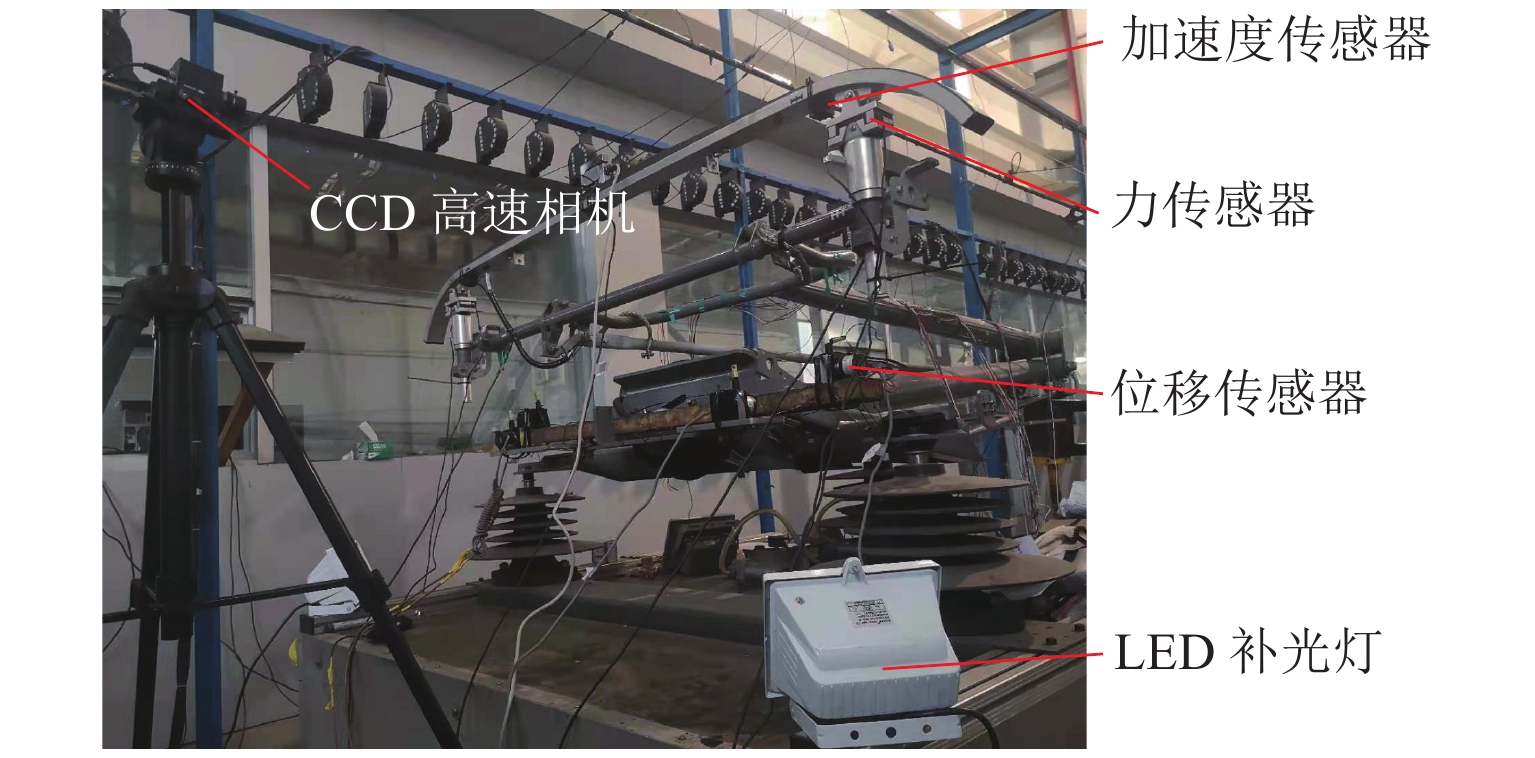

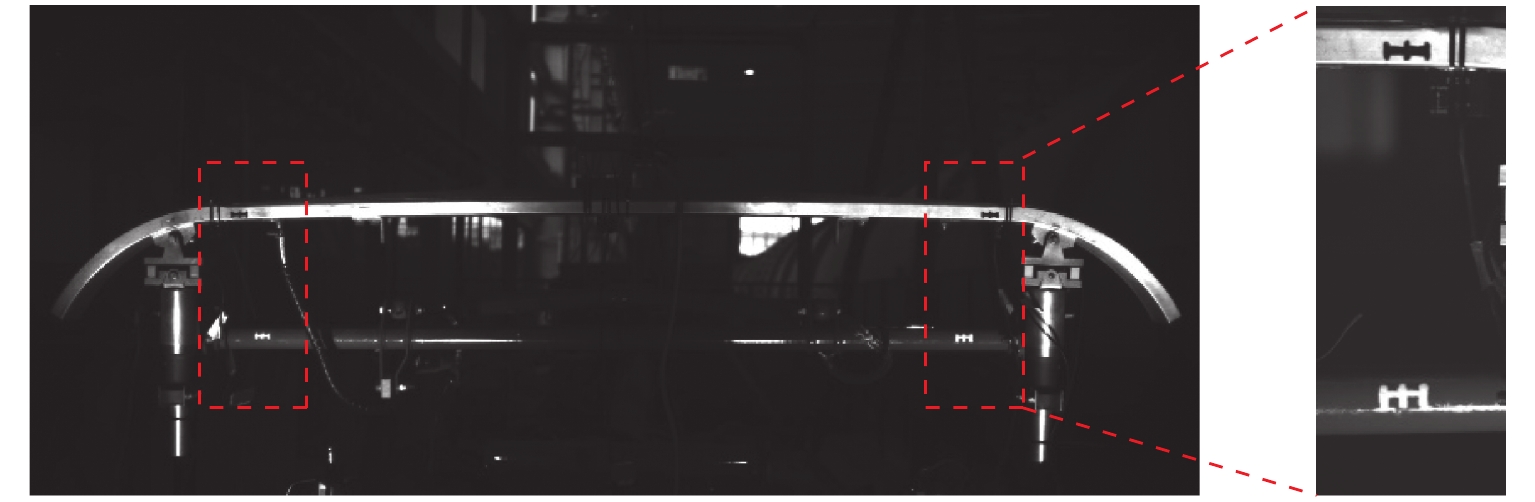

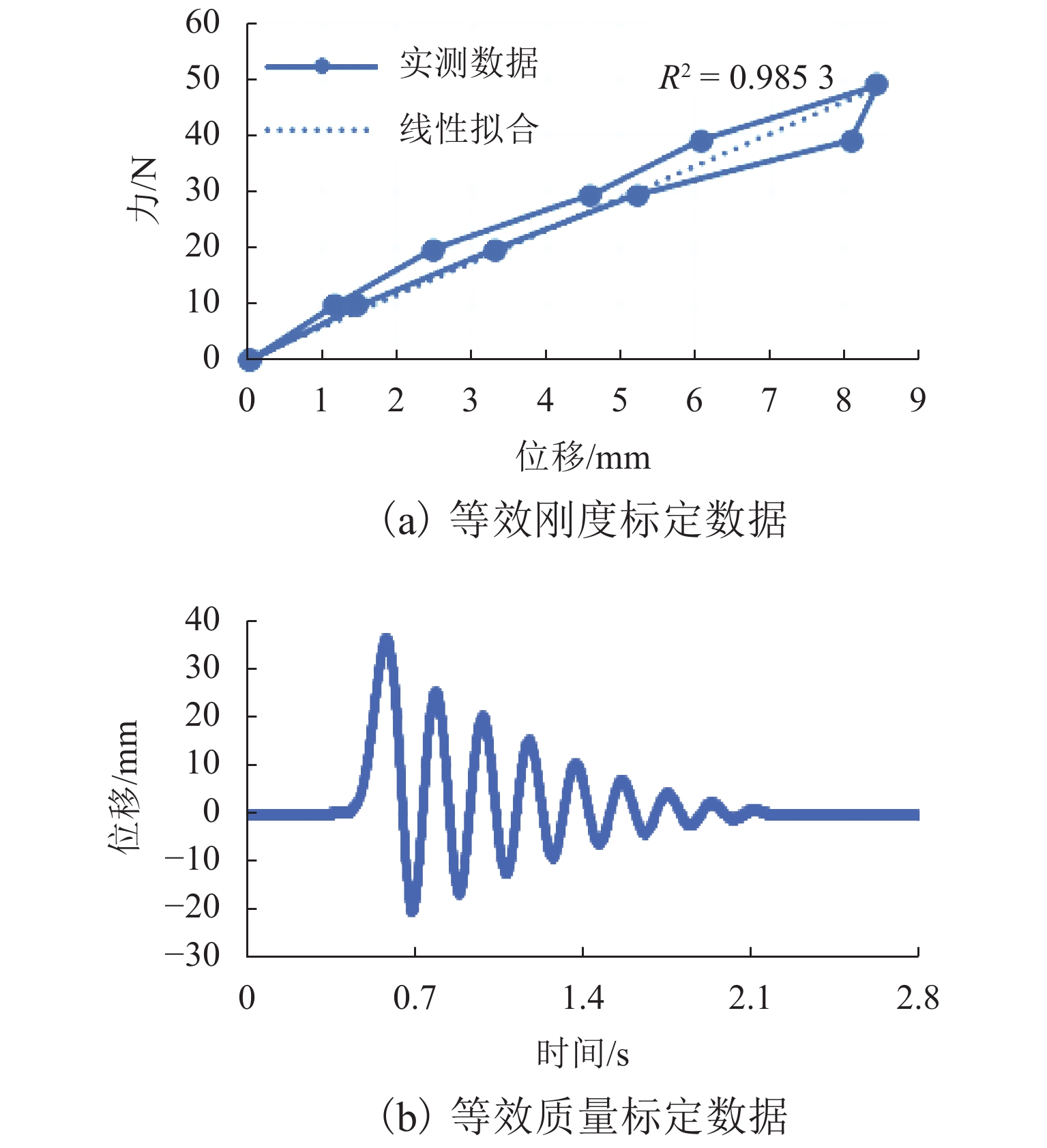

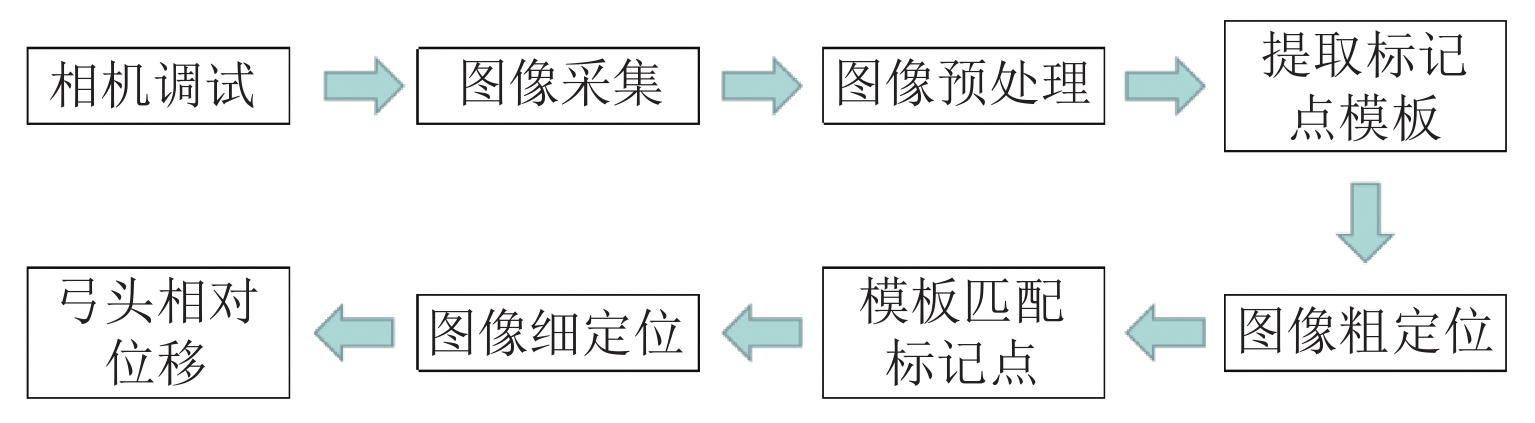

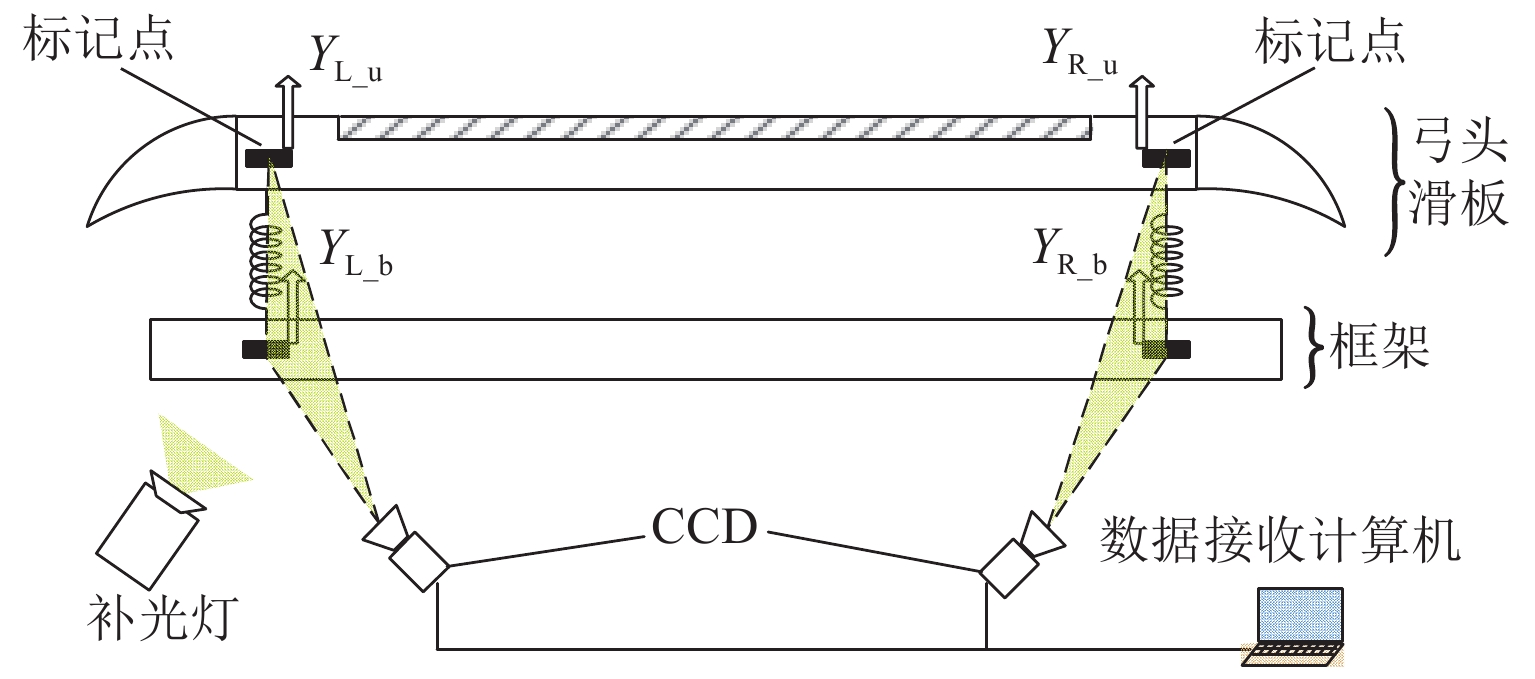

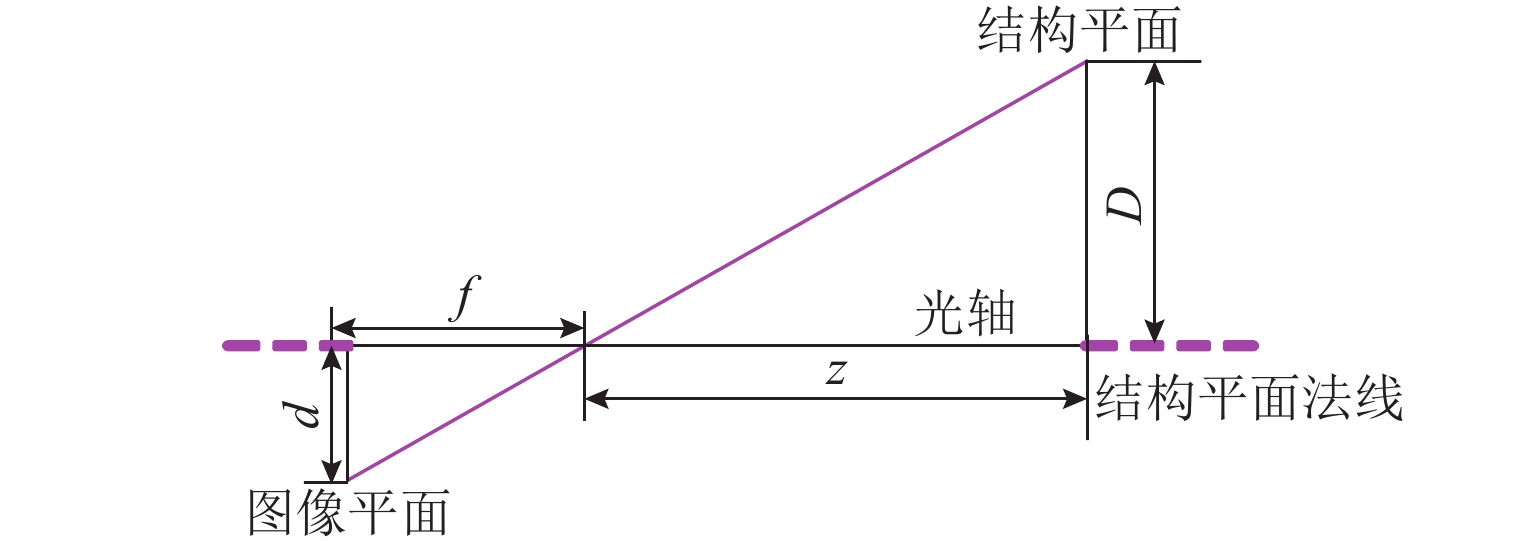

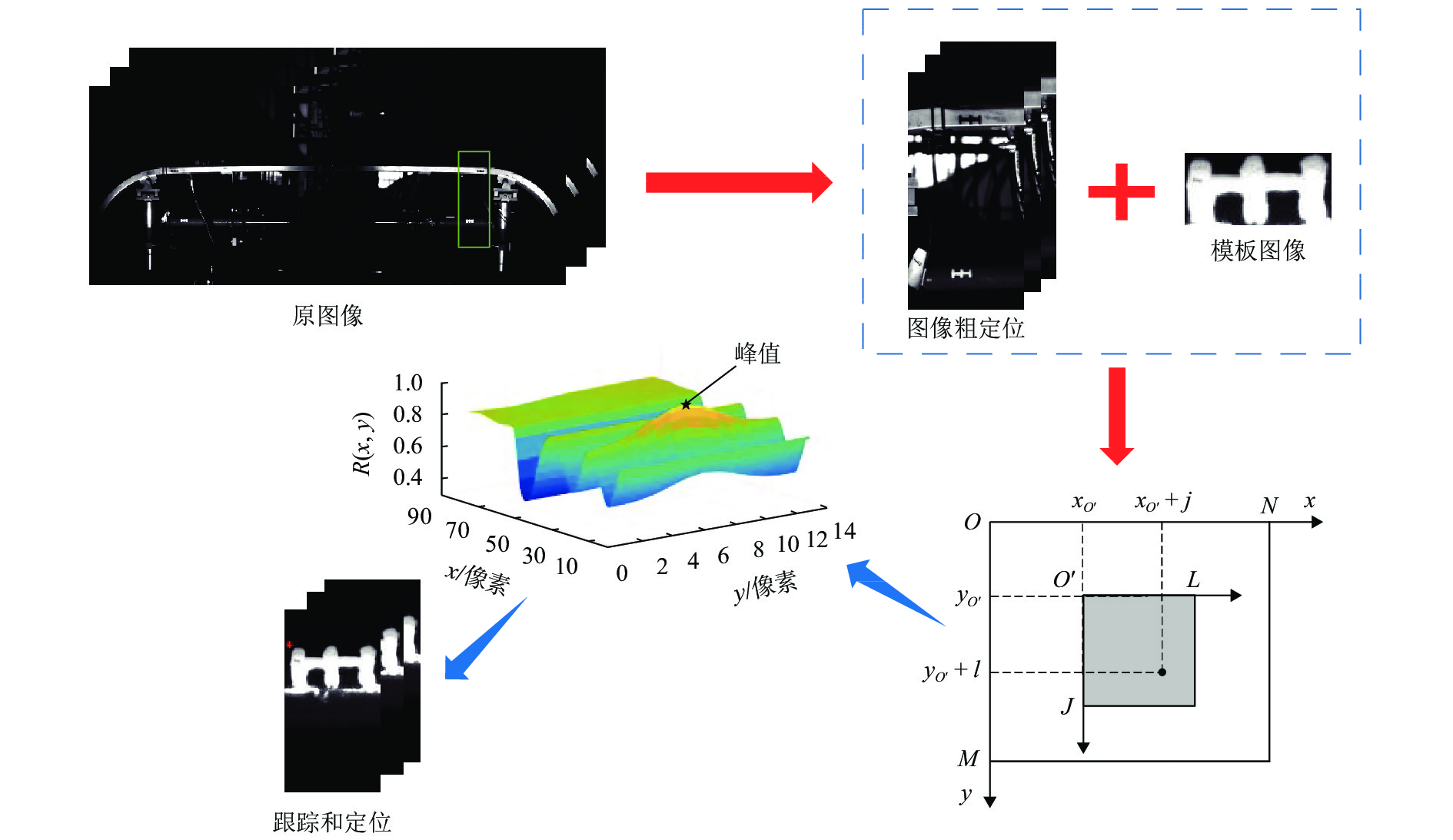

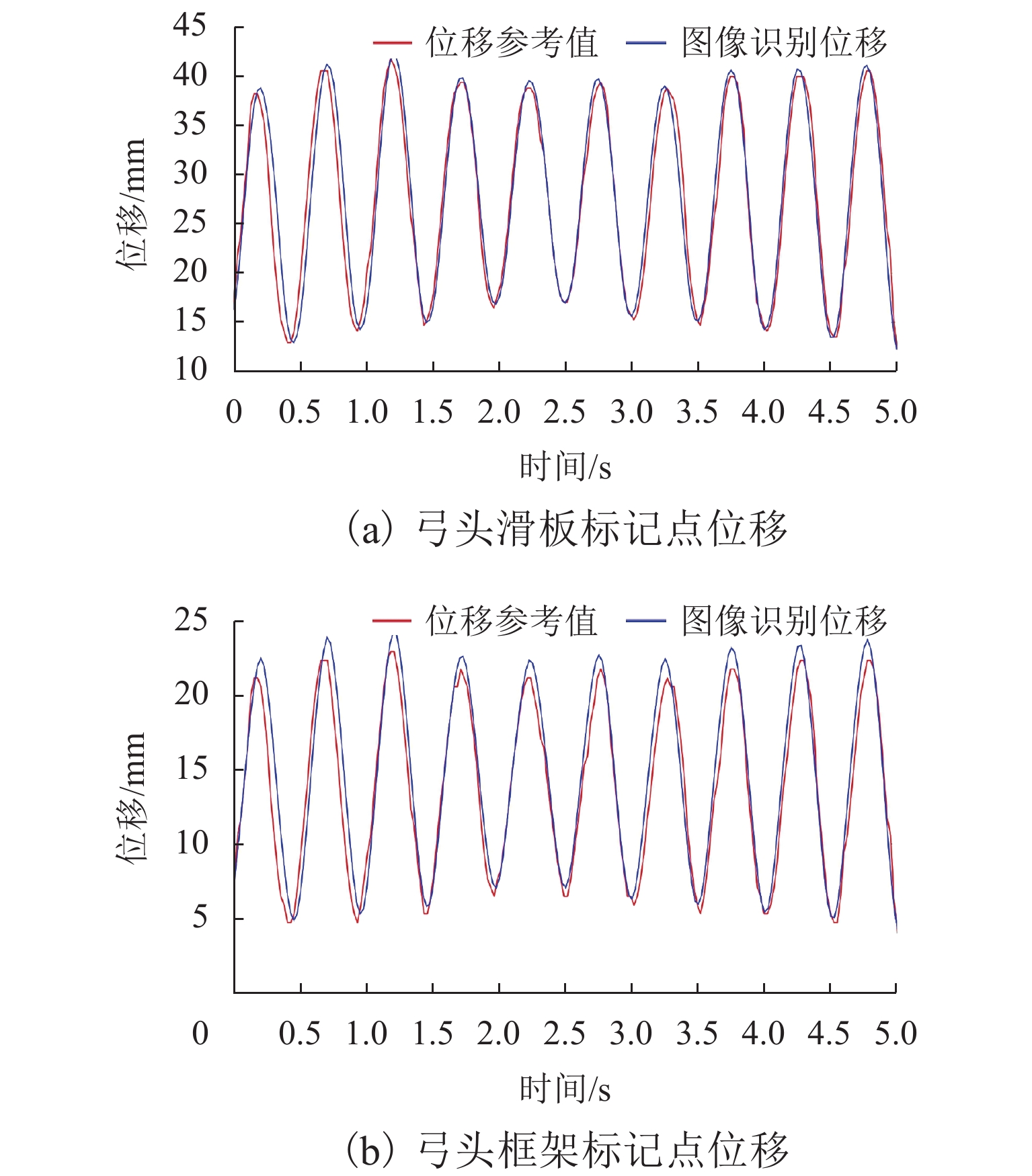

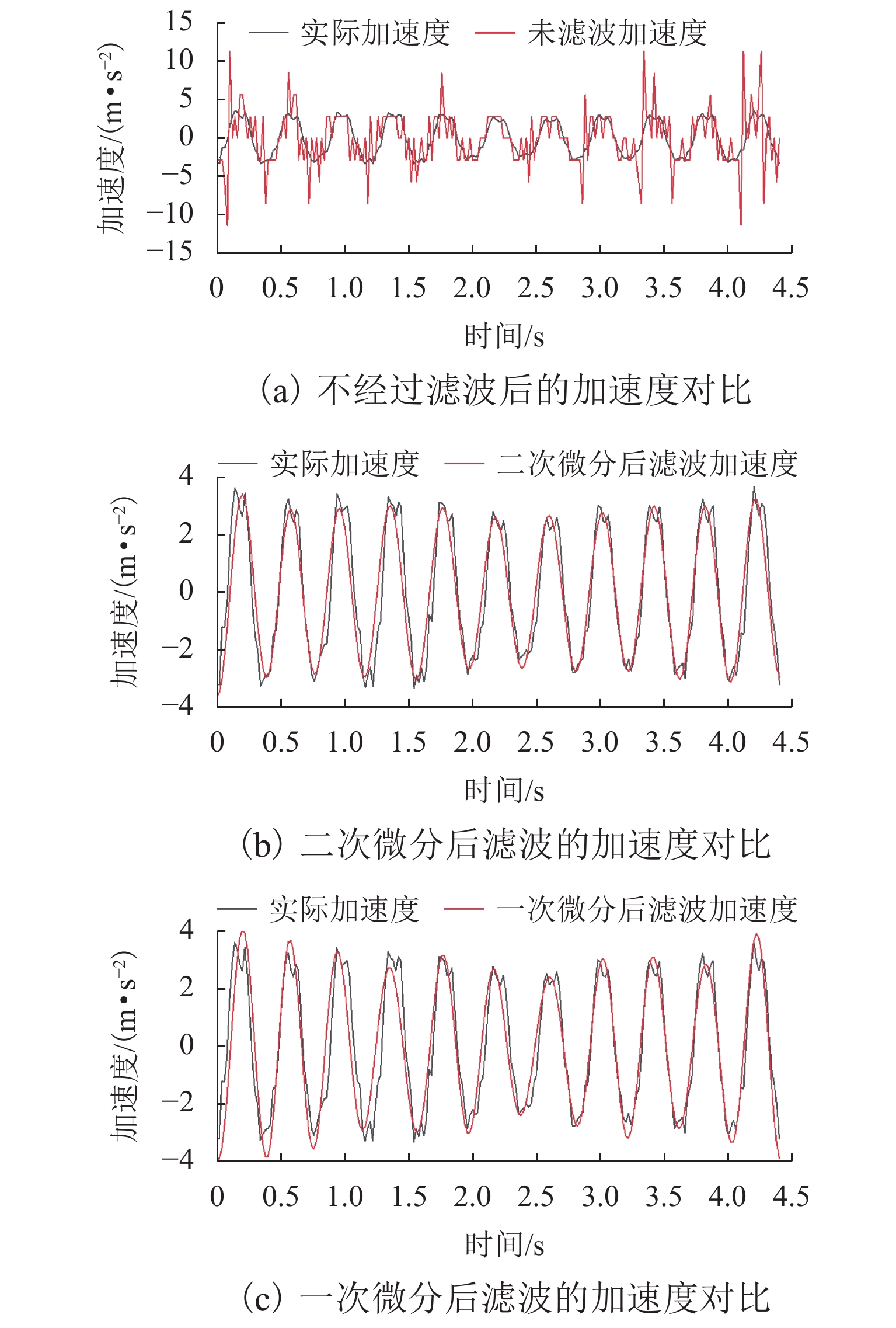

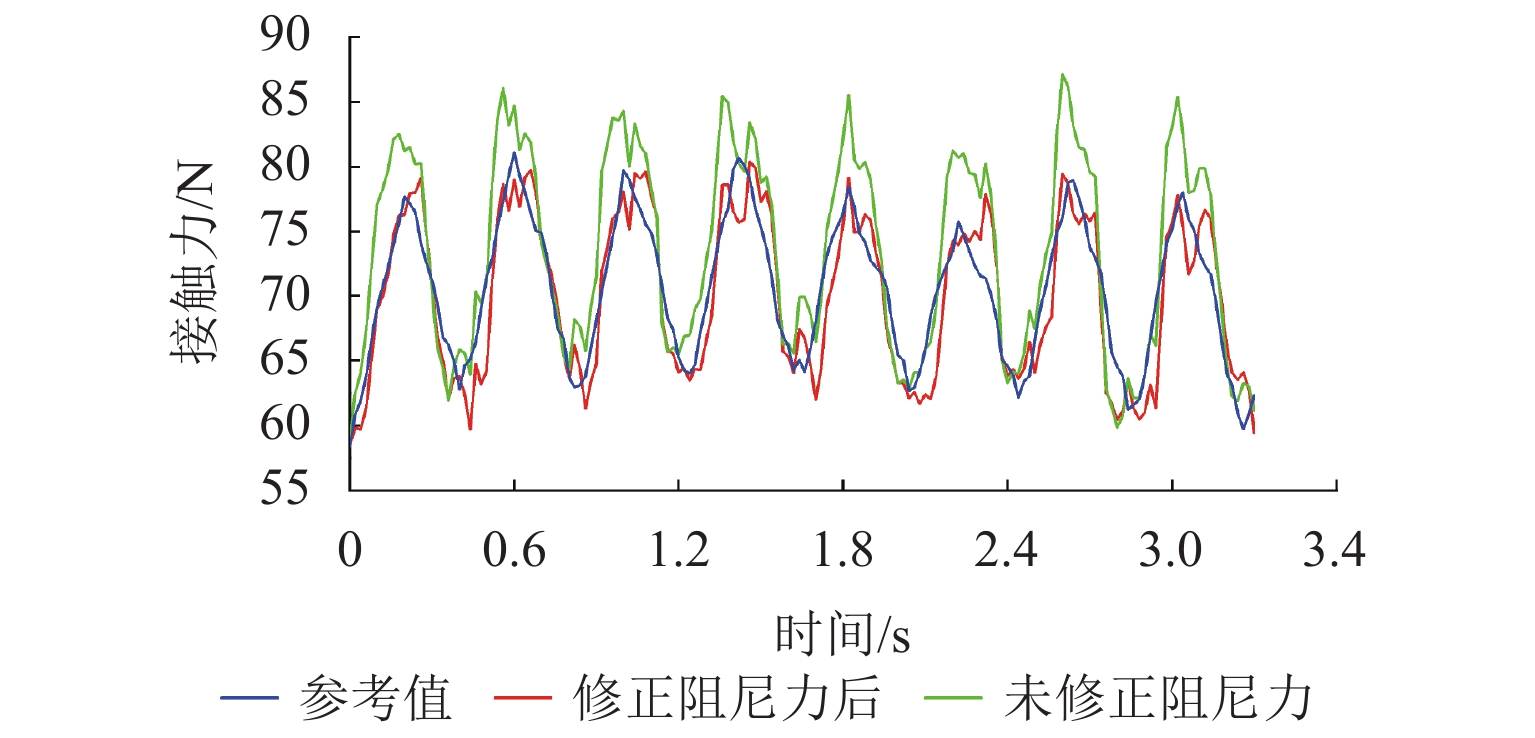

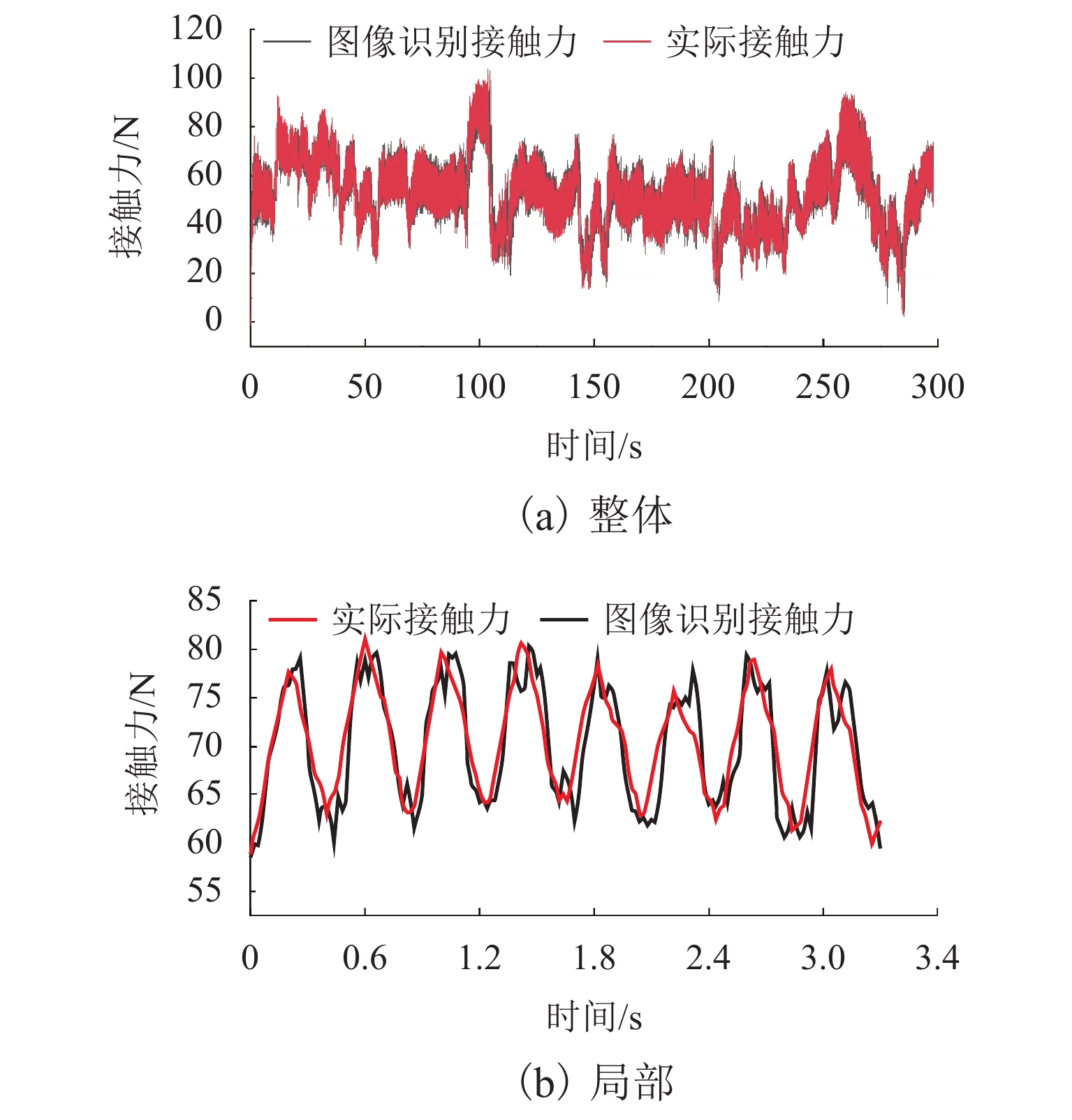

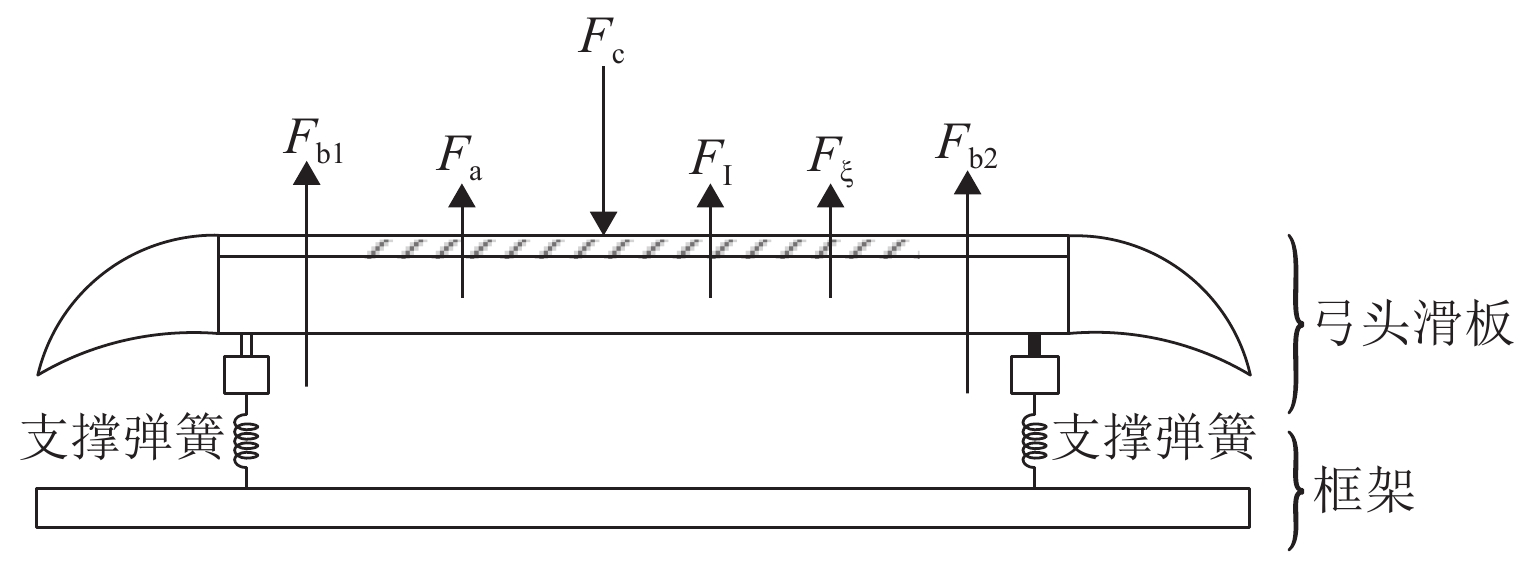

接触网和受电弓是电气化铁路供电系统中的重要组成部分,其中弓网之间的动态接触又是保证电力机车良好受流的关键条件,所以寻求良好的弓网关系是铁路供电系统设计的一个重点. 考虑到目前弓网接触力大多采用接触式检测手段,对于非接触检测的研究方法较少,故提出了一种基于图像处理算法检测弓网接触力的新方法. 简化受电弓弓头结构,分析了弓网接触力与弓头位移之间的关系,建立弓网接触力计算模型;并在弓网混合模拟试验台进行地面验证实验:首先,利用图像处理模块对采集到的图像进行标记点的目标跟踪与特征提取;然后,通过数据处理模块对得到的位移信息进一步分析得到弓头加速度等信息,修正得到加速度信号;最后,对经过惯性力和阻尼力修正后的接触力结果进行分析. 结果表明:通过图像处理检测得到的弓头位移最大测量误差仅为1.3 mm,精度较高;同时检测得到的弓网动态接触力的最大值、平均值和标准差的最大相对误差仅为5.46%、5.15%和4.58%,测量误差较小. 结果证实此方法检测弓网接触力是可行的,且检测精度满足要求.

Abstract:Catenary and pantograph are important parts in the power supply system for electrified railways. The dynamic contact between the pantograph and the catenary is pivotal to ensure that the electric locomotives acquire good electricity. Therefore, good dynamic contact between the pantograph and the catenary is a key in the design of the railway power supply system. Given that the contact detection method is common for pantograph catenary contact force at present, and there are few research methods for non-contact detection, a new method based on the image processing algorithm is proposed for detecting pantograph catenary contact force. First, the structure of the pantograph head is simplified, the relationship between the pantograph dynamic contact force and the pantograph head displacement is analyzed, and a new model for calculating the contact force is developed. Next, the ground validation test is conducted on the pantograph-catenary hybrid simulation platform. In tests, the image processing module is used for target tracking and feature extraction of marked points in the collected image. Then, the displacement information is further analyzed by the data processing module to obtain the pantograph head acceleration and other information, and the acceleration signal is corrected. Finally, the contact force results corrected by inertia force and damping force are analyzed. The test results show that the maximum error of the pantograph head displacement detected by image processing is 1.3 mm, showing a high accuracy. Meanwhile, the maximum relative errors of the maximum, average and standard deviation of the dynamic pantograph-catenary contact force are only 5.46%, 5.15% and 4.58%, demonstrating that the measurement error is small. Thus, this method is feasible in detecting the pantograph-catenary contact force and its detection accuracy meets the requirements.

-

Key words:

- pantograph /

- catenary /

- contact force /

- image processing /

- machine vision /

- template matching

-

表 1 实验加载工况

Table 1. Loading conditions in tests

加载工况 力/N 位移/mm 1 9.8 1.1575 2 19.6 2.4888 3 29.4 4.5951 4 39.2 6.0655 5 49.0 8.4103 6 39.2 8.0725 7 29.4 5.2111 8 19.6 3.3035 9 9.8 1.4754 表 2 标记点特征定位计算时间

Table 2. Calculation time for positioning markers

数据

类型图像大小

(宽×高)/

像素模板大小

(宽×高)/

像素图像

数量/

张计算

时间/

s平均每

帧计算

时间/s原图像 228×491 38×20 1000 265.87 0.26587 粗定位后图像 50×105 38×20 1000 9.39 0.00939 表 3 动态实验接触力统计结果

Table 3. Statistical results of contact forces from dynamical tests

修正类型 最小值 最大值 平均值 标准差 实际

值/N测量

值/N相对误

差/%实际

值/N测量

值/N相对误

差/%实际

值/N测量

值/N相对误

差/%实际

值/N测量

值/N相对误

差/%不考虑惯性力 −0.57 −2.40 321.10 103.67 119.82 15.58 52.61 55.32 5.15 15.49 23.67 52.81 考虑惯性力 −0.57 −1.63 185.96 103.67 109.33 5.46 52.61 55.32 5.15 15.49 16.20 4.58 不考虑阻尼力 −0.57 −1.70 198.25 103.67 108.38 4.54 52.61 55.31 5.13 15.49 16.41 5.94 考虑阻尼力 −0.57 −1.63 186.96 103.67 109.33 5.46 52.61 55.32 5.15 15.49 16.20 4.58 -

[1] 刘志刚,宋洋,韩烨,等. 高速铁路接触网研究进展[J]. 西南交通大学学报,2016,51(3): 495-518. doi: 10.3969/j.issn.0258-2724.2016.03.009LIU Zhigang, SONG Yang, HAN Ye, et al. Advances of research on high-speed railway catenary[J]. Journal of Southwest Jiaotong University, 2016, 51(3): 495-518. doi: 10.3969/j.issn.0258-2724.2016.03.009 [2] 周宁,蔚超,谭梦颖,等. 弓网系统动态及受流性能测试技术研究及应用[J]. 铁道学报,2020,42(3): 47-54.ZHOU Ning, WEI Chao, TAN Mengying, et al. Investigation on and application of measurement technology of dynamic performance and current collection quality of pantograph-catenary system[J]. Journal of the China Railway Society, 2020, 42(3): 47-54. [3] 张晓林,高晓蓉,王黎,等. 弓网接触力检测方法介绍[J]. 铁道技术监督,2010,38(8): 11-13,16. doi: 10.3969/j.issn.1006-9178.2010.08.004ZHANG Xiaolin, GAO Xiaorong, WANG Li, et al. Introduction on the detection of pantograph catenary contact force[J]. Railway Quality Control, 2010, 38(8): 11-13,16. doi: 10.3969/j.issn.1006-9178.2010.08.004 [4] 刘芳,王黎,高晓蓉,等. 受电弓与接触网间的接触压力检测研究[J]. 电力机车与城轨车辆,2006,29(6): 19-21,54.LIU Fang, WANG Li, GAO Xiaorong, et al. Study of measuring the contact force between pantograph and catenary[J]. Electric Locomotives & Mass Transit Vehicles, 2006, 29(6): 19-21,54. [5] 王亚春,徐超,杨才智. 弓网动态接触压力测量方法研究[J]. 铁道技术监督,2014,42(12): 41-43.WANG Yachun, XU Chao, YANG Caizhi. Research on the measurement method of pantograph-catenary dynamic contant force[J]. Railway Quality Control, 2014, 42(12): 41-43. [6] 谭梦颖,邹栋,李瑞平,等. 基于应变响应测量弓网接触力的新方法[J]. 西南交通大学学报,2017,52(6): 1208-1215.TAN Mengying, ZOU Dong, LI Ruiping, et al. New contact force measuring method for overhead catenary systems based on strain[J]. Journal of Southwest Jiaotong University, 2017, 52(6): 1208-1215. [7] SCHRÖDER K, ECKE W, KAUTZ M, et al. An approach to continuous on-site monitoring of contact forces in current collectors by a fiber optic sensing system[J]. Optics and Lasers in Engineering, 2013, 51(2): 172-179. doi: 10.1016/j.optlaseng.2012.08.007 [8] WAGNER R, MAICZ D, VIEL W, et al. A fibre optic sensor instrumented pantograph as part of a continuous structural health monitoring system for railway overhead lines[C]//7th European Workshop on Structural Health Monitoring. Nantes: HAL CCSD, 2014: 151-158. [9] KARAKOSE E, GENCOGLU M T, KARAKOSE M, et al. A new experimental approach using image processing based tracking for an efficient fault diagnosis in pantograph-catenary systems[J]. IEEE Transactions on Industrial Informatics, 2017, 13(2): 635-643. [10] 韩志伟,刘志刚,陈坤峰,等. 基于二代曲波系数定向映射的受电弓滑板裂纹检测技术[J]. 铁道学报,2011,33(11): 63-69. doi: 10.3969/j.issn.1001-8360.2011.11.011HAN Zhiwei, LIU Zhigang, CHEN Kunfeng, et al. Pantograph slide cracks detection technology based on curvelet coefficients directional projection (CCDP)[J]. Journal of the China Railway Society, 2011, 33(11): 63-69. doi: 10.3969/j.issn.1001-8360.2011.11.011 [11] 陈坤峰. 基于曲波变换的受电弓滑板裂纹故障检测[D]. 成都: 西南交通大学, 2011. [12] NA K M, LEE K, KIM H, et al. Implementation of image processing in studying contact conditions of overhead contact line-pantograph at 400 km/h[J]. Journal of Electrical Engineering & Technology, 2020, 15(2): 989-995. [13] MIN N K, KIWON L, KWON S S, et al. Detecting deformation on pantograph contact strip of railway vehicle on image processing and deep learning[J]. Applied Sciences-Basel, 2020, 10(23): 8509.1-8509.14. [14] AYDIN I, KARAKÖSE M, AKIN E. A new contactless fault diagnosis approach for pantograph-catenary system using pattern recognition and image processing methods[J]. Advances in Electrical and Computer Engineering, 2014, 14(3): 79-88. doi: 10.4316/AECE.2014.03010 [15] SHEN Y, PAN X, CHANG L N. Online intelligent perception of pantograph and catenary system status based on parameter adaptation[J]. Applied Sciences, 2021, 11(4): 1948.1-1948.19. [16] 蔚超. 适用于AC 25 kV 160 km/h刚性接触网的受电弓选型研究[D]. 成都: 西南交通大学, 2019. [17] 叶肖伟,董传智. 基于计算机视觉的结构位移监测综述[J]. 中国公路学报,2019,32(11): 21-39.YE Xiaowei, DONG Chuanzhi. Review of computer vision-based structural displacement monitoring[J]. China Journal of Highway and Transport, 2019, 32(11): 21-39. [18] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 轨道交通 受流系统 受电弓与接触网动态相互作用测量的要求和验证: GB/T 32592—2016[S]. 北京: 中国标准出版社, 2016. -

下载:

下载: