Dynamic Response Characteristics of EMU under Excitation of Rail Straightening Irregularity

-

摘要:

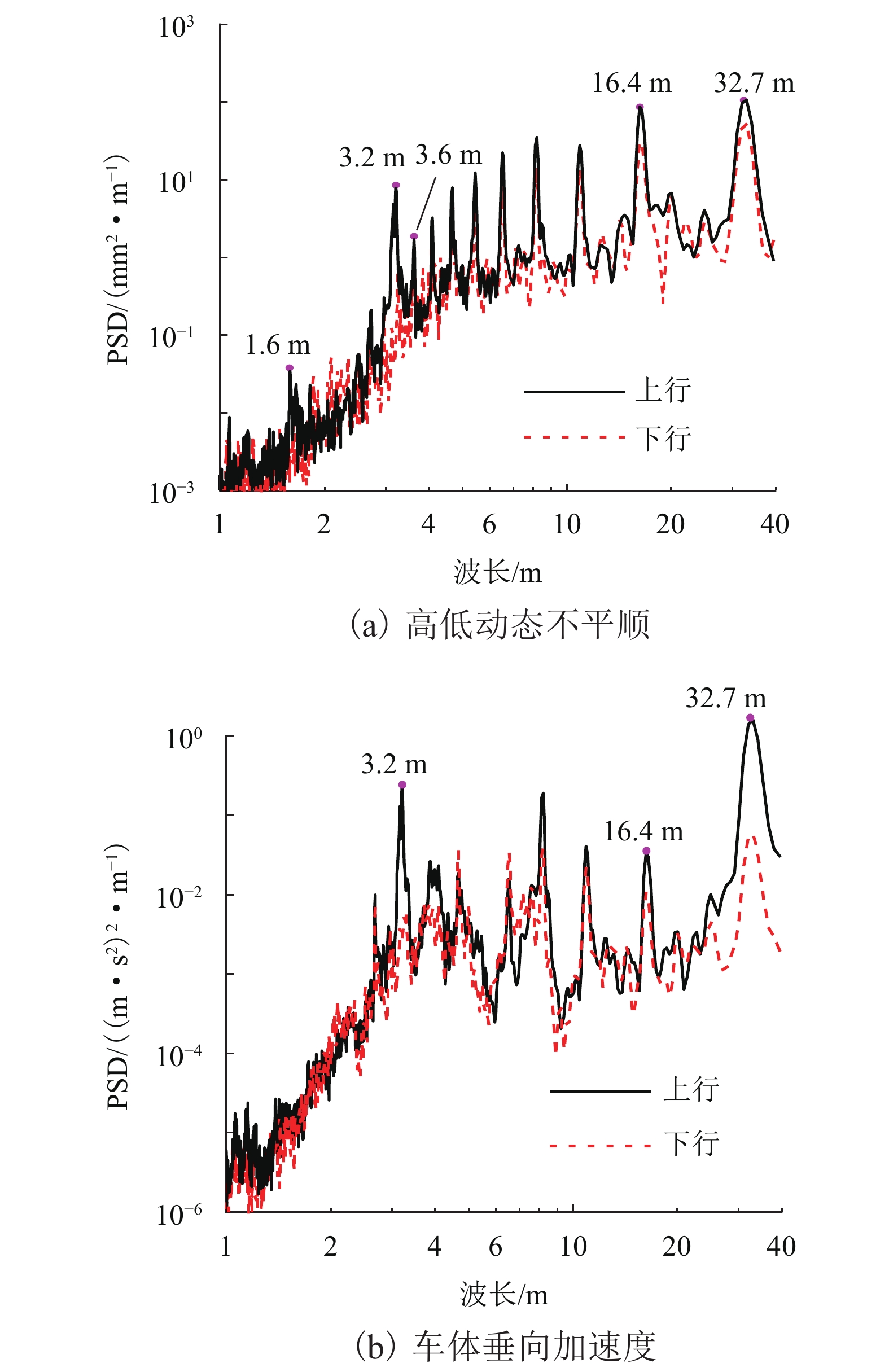

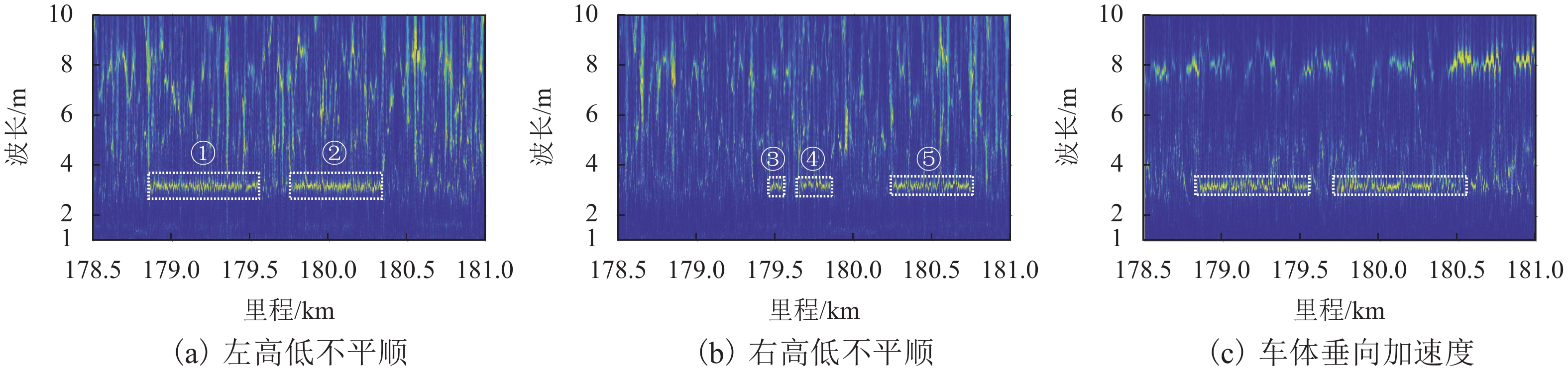

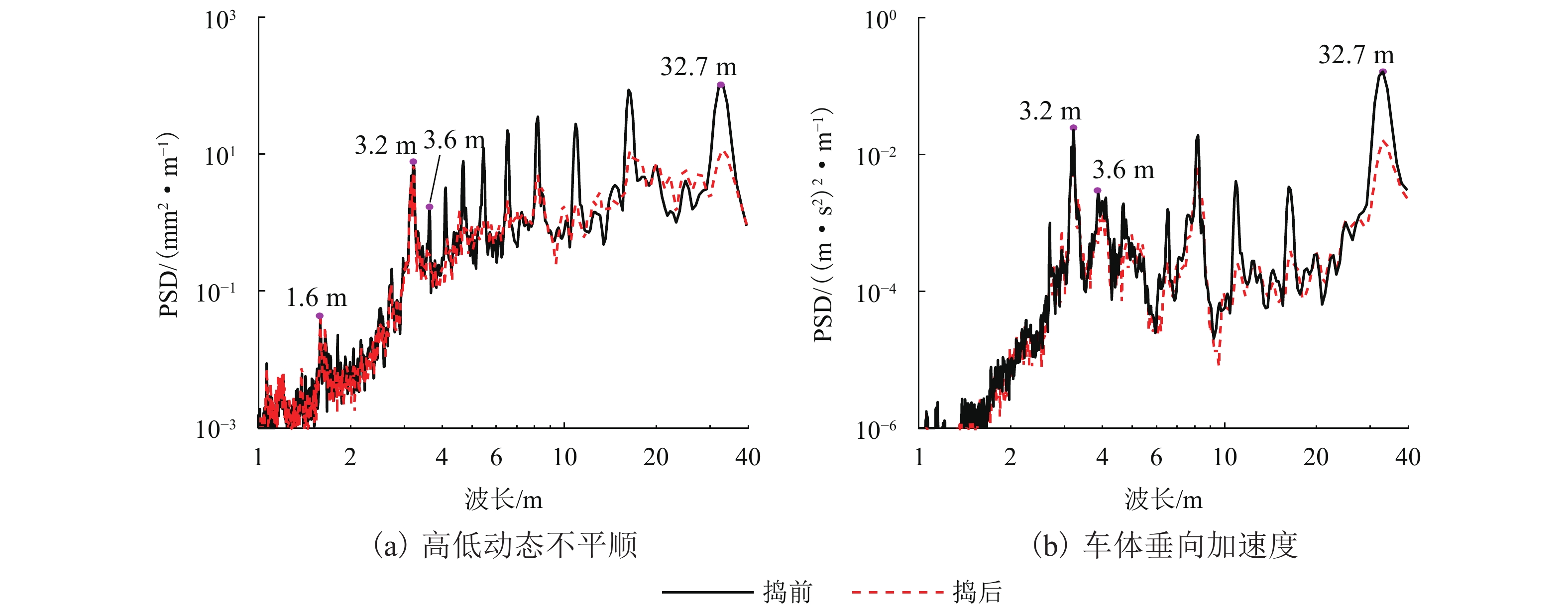

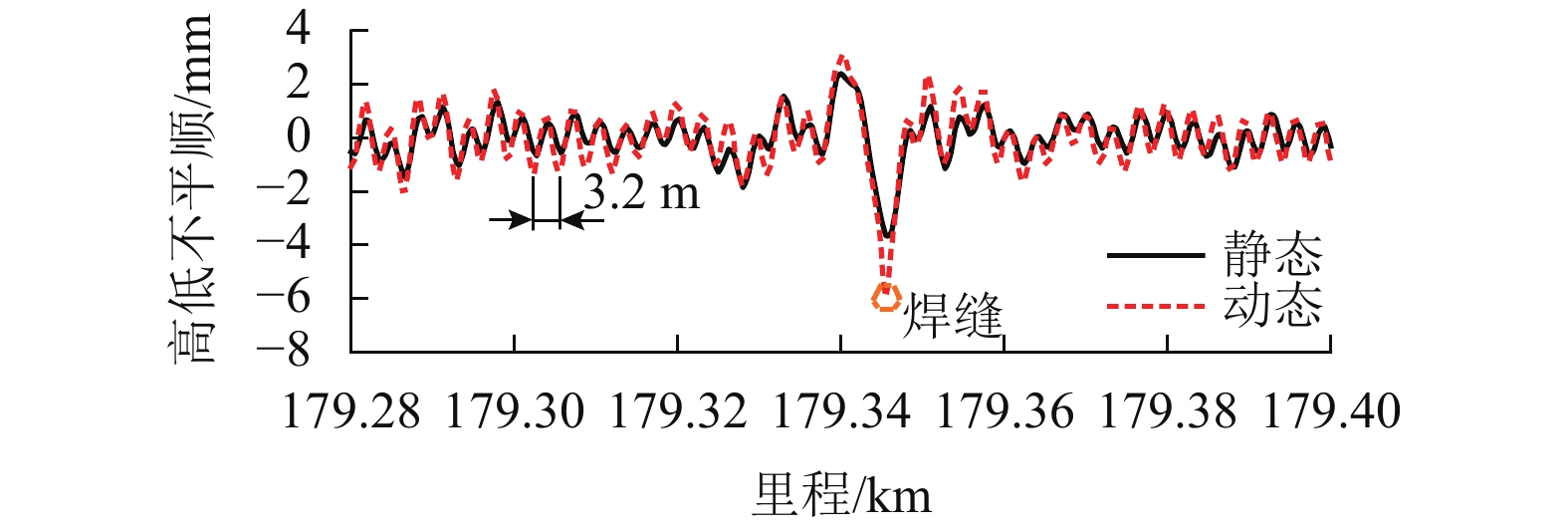

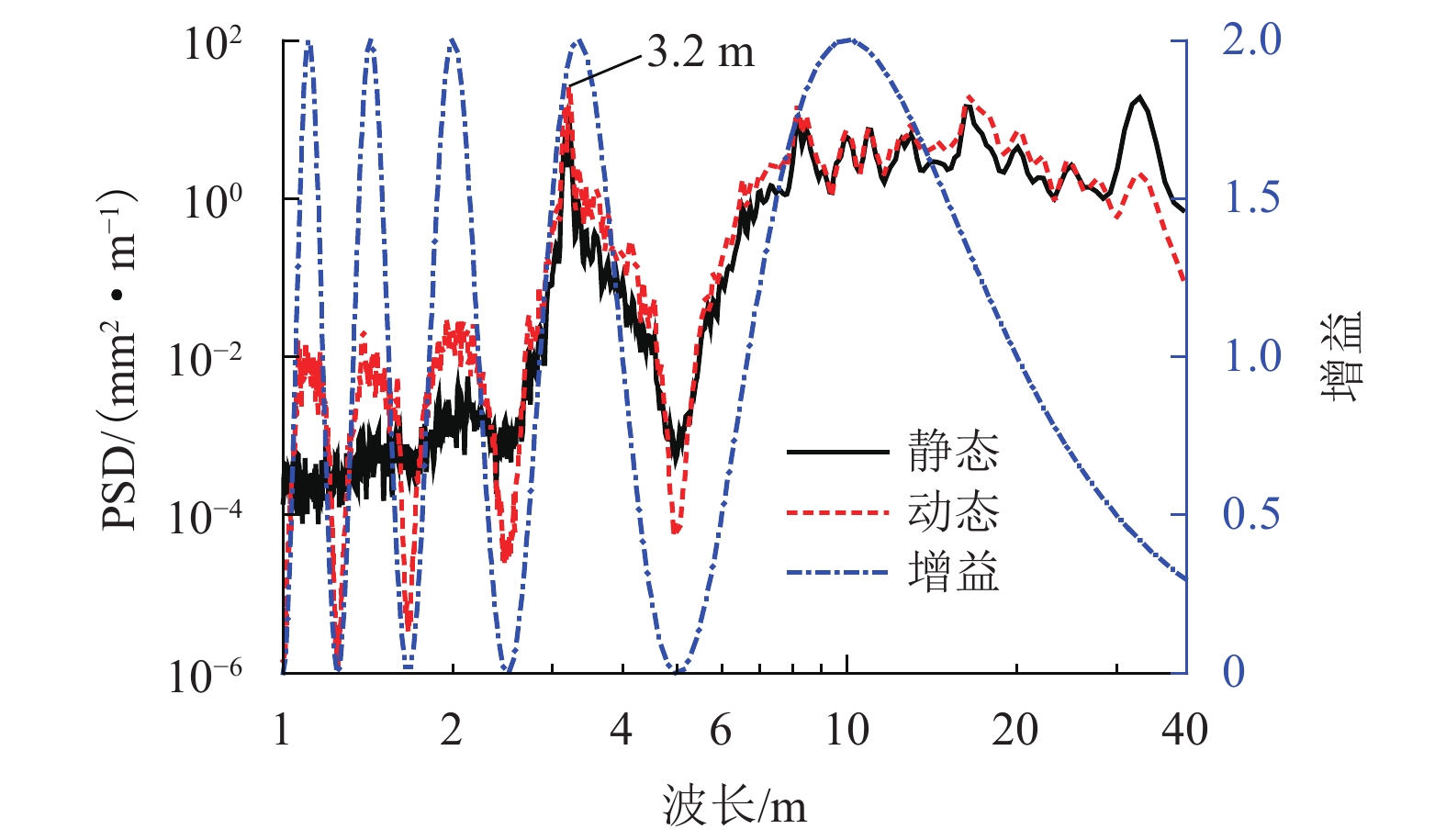

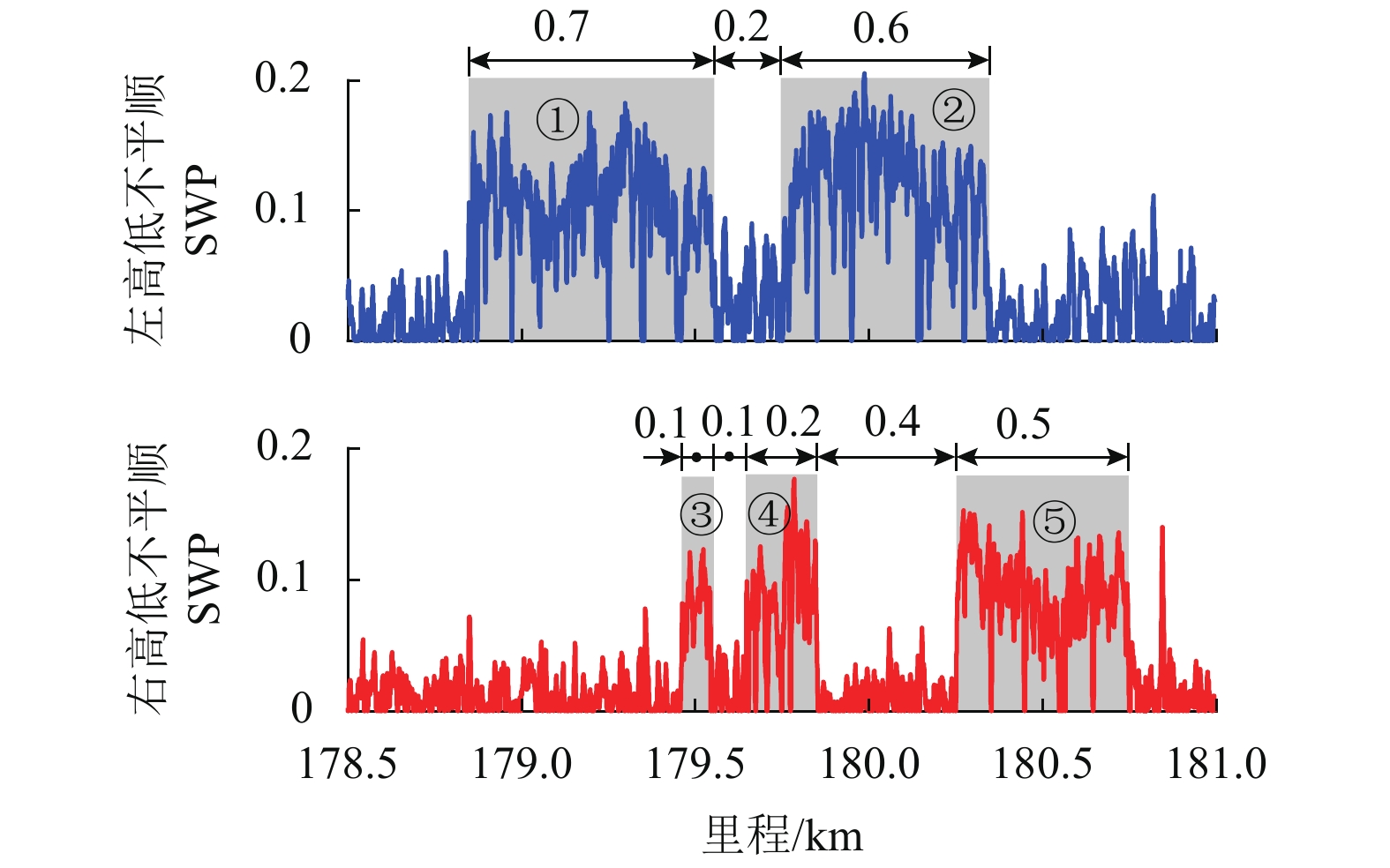

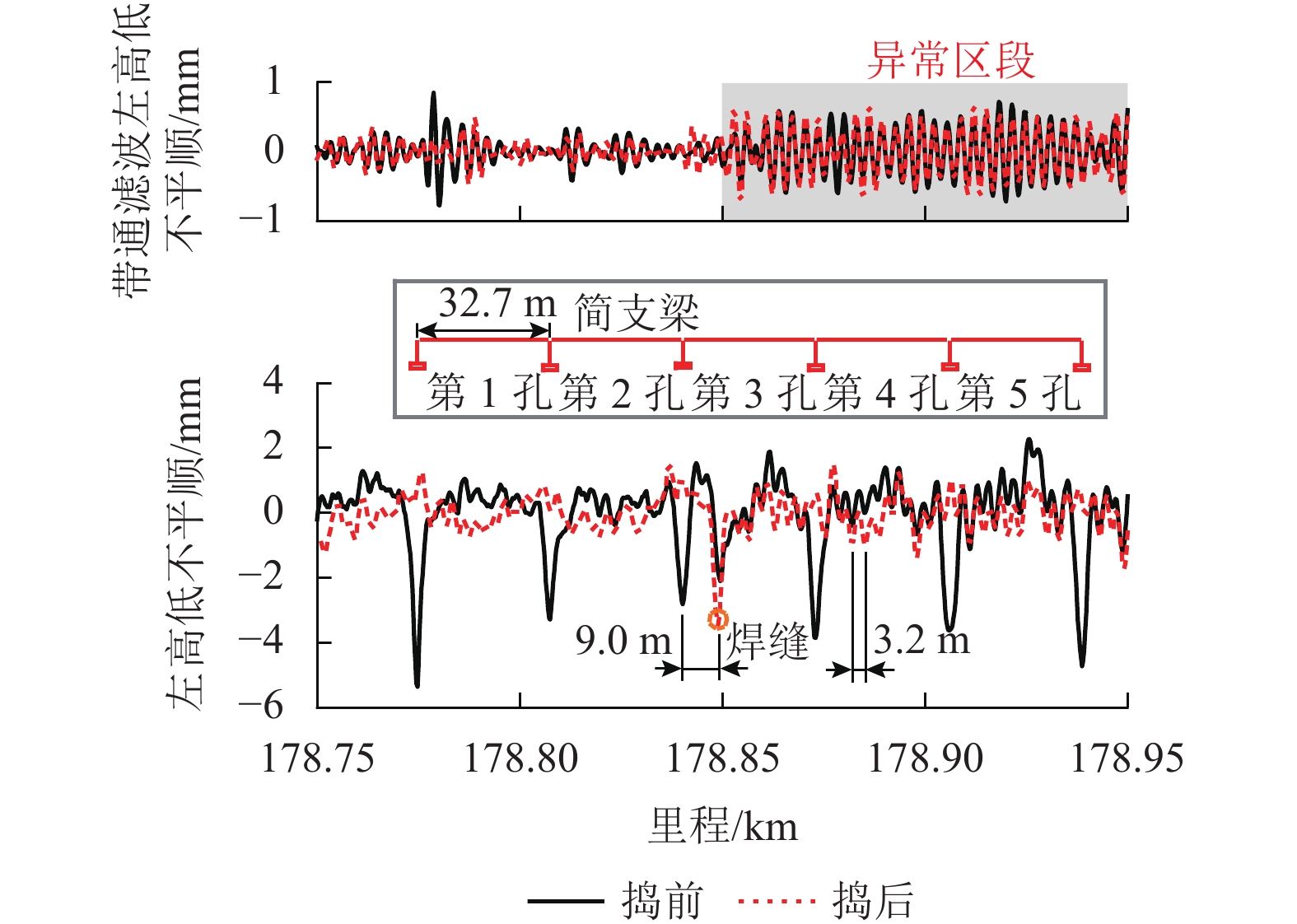

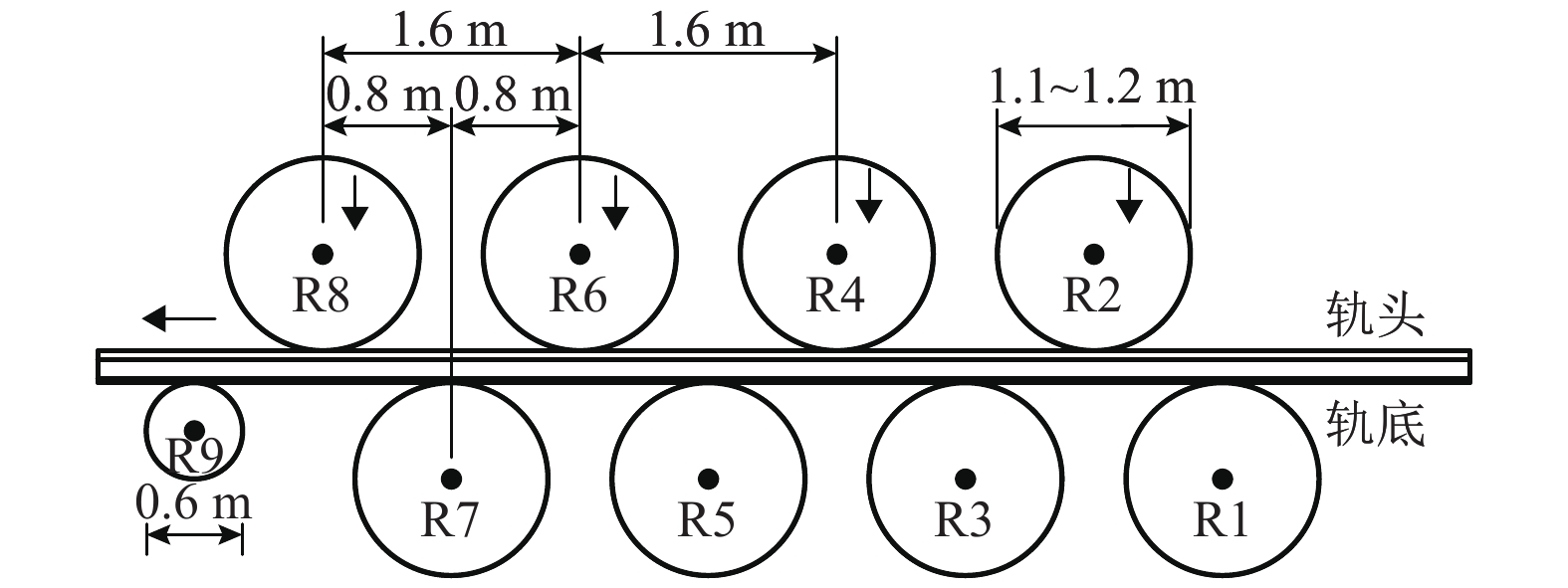

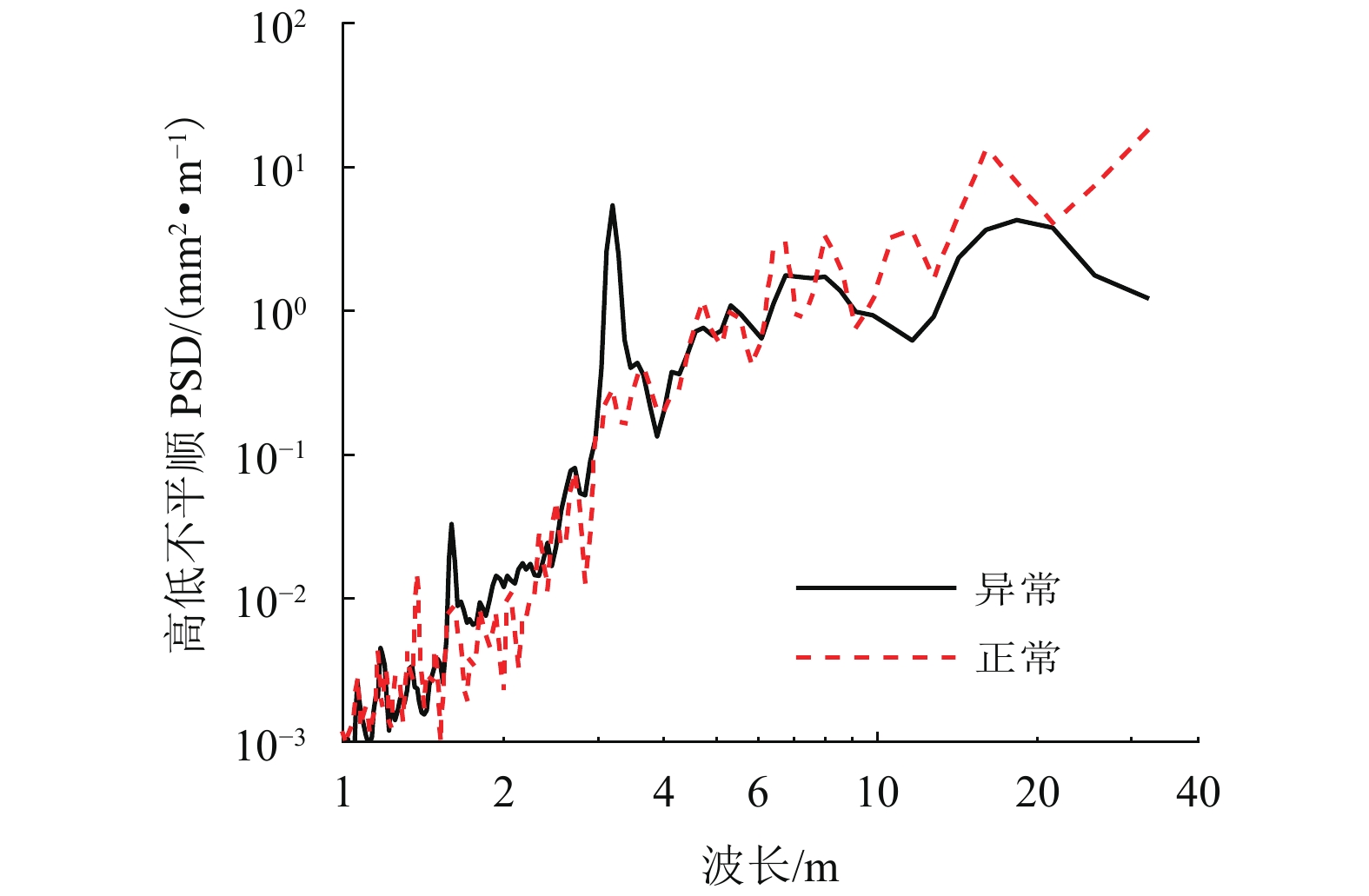

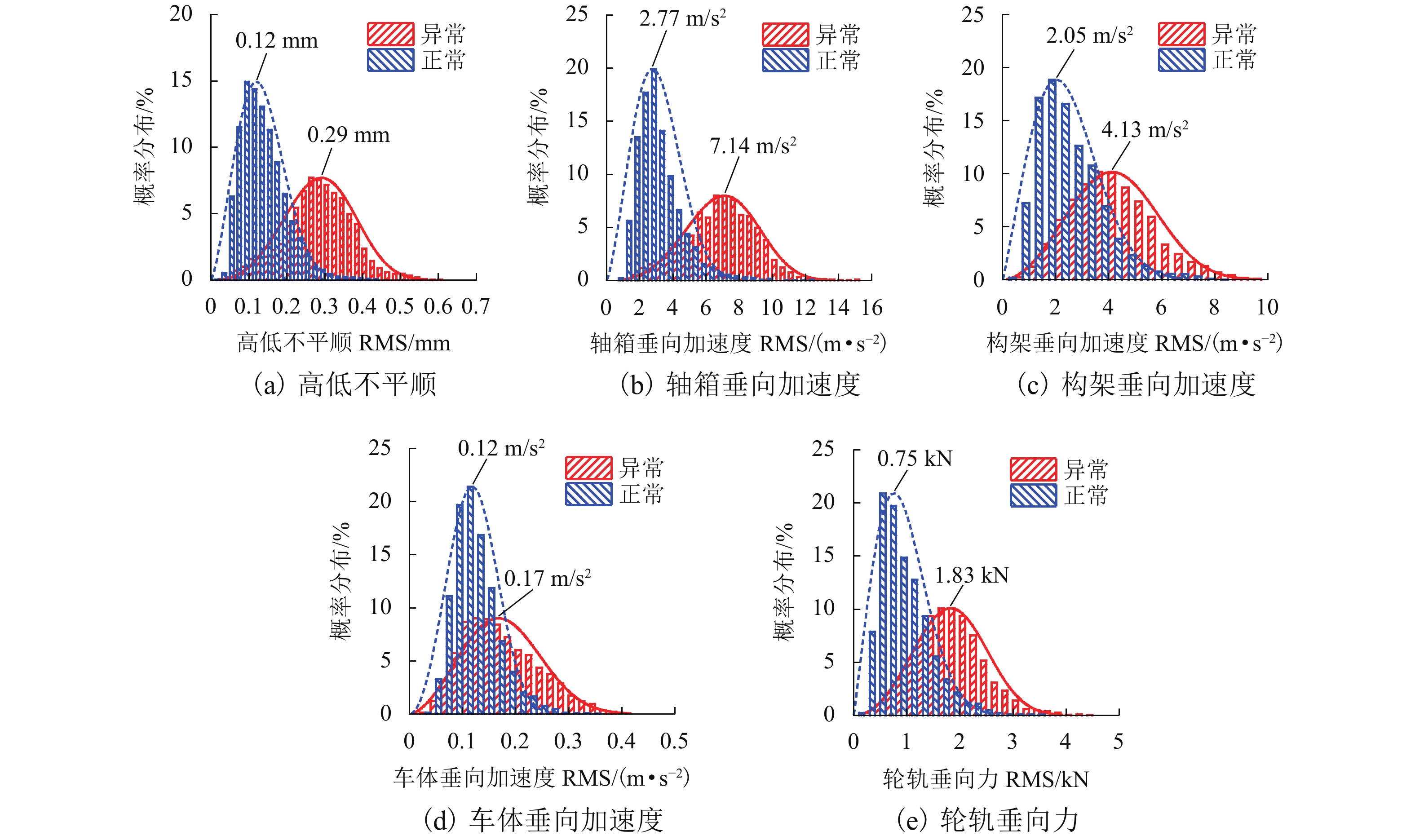

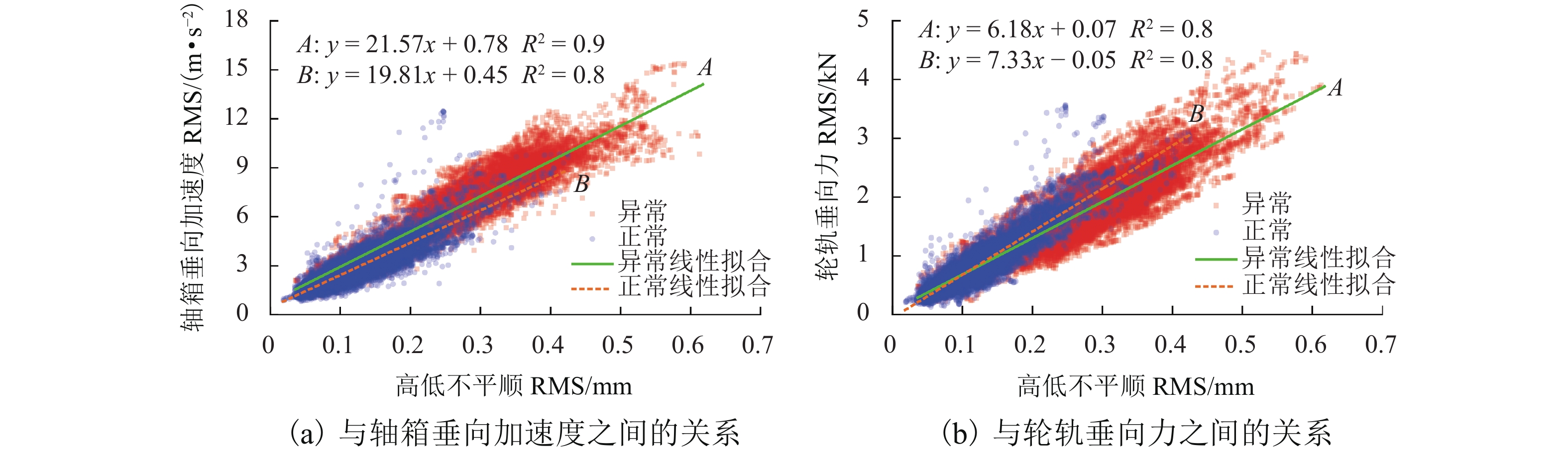

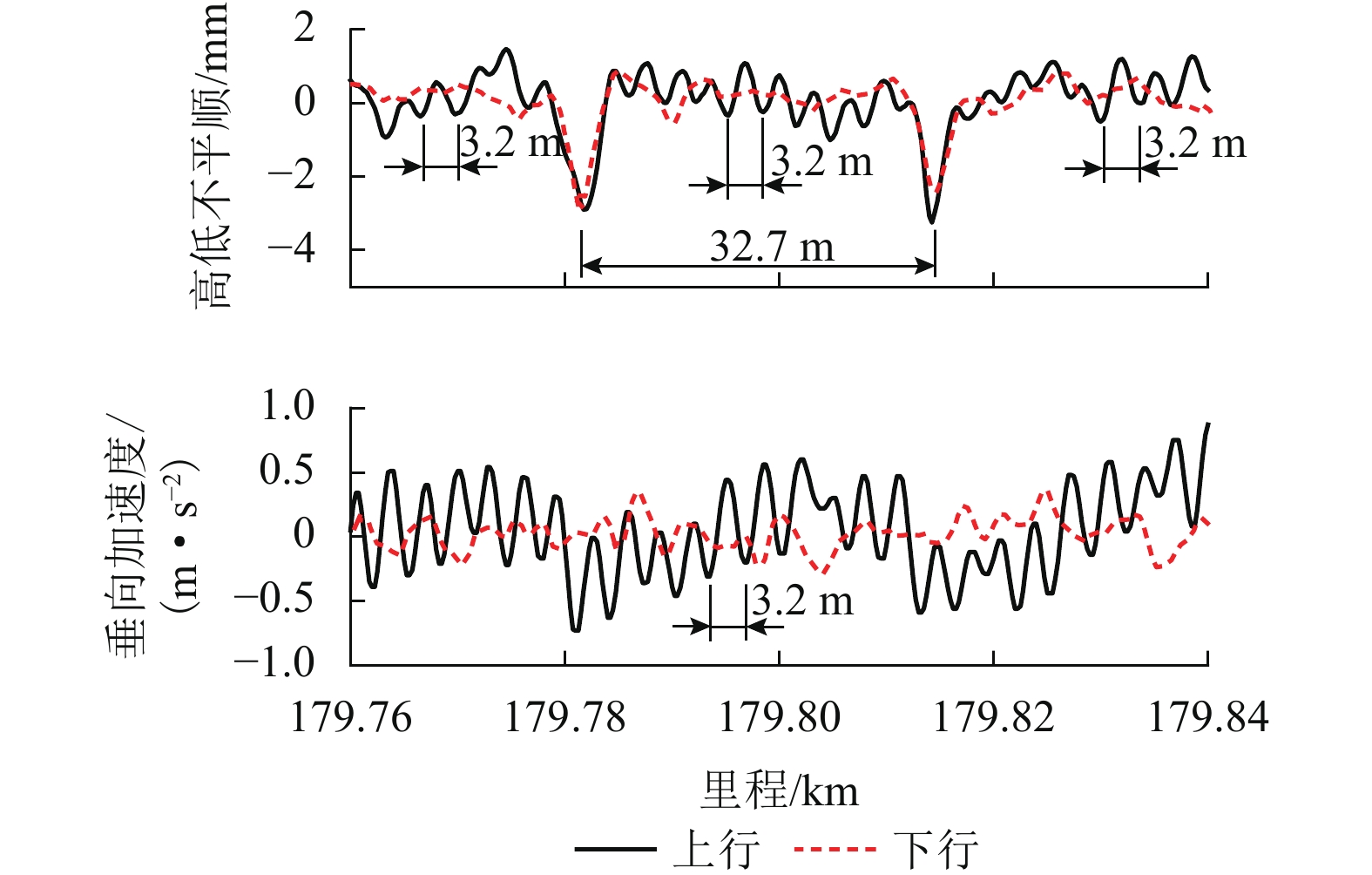

以某有砟客运专线中出现波长为3.2 m的轨道周期性高低不平顺、继而引起“抖车”现象的线路区段为对象,基于同步压缩小波变换提取了轨道几何动、静态检测数据在大机捣固前后的时频分布特征,并结合钢轨轧制流程的梳理分析,明确了轨道周期性高低不平顺的成因,即可能由钢轨轧制过程中复合矫直工艺不良引起. 在此基础上,探究了钢轨轧制不平顺与车辆各部件振动加速度以及轮轨接触力的关联关系,获取了钢轨轧制不平顺对车辆动力响应的影响规律. 结果表明:轧制不平顺使得轴箱、转向架、车体垂向加速度的相干函数分别达到0.97、0.96和0.76,较正常区段分别增长了5%、25%和300%;轮轨垂向力相干函数增长42%,达到0.94,说明轧制不平顺与车辆各部件的振动响应和轮轨接触力密切相关;轧制不平顺将轴箱和车体垂向加速度均方根(root mean square,RMS)值分别放大1.00 m/s2和0.05 m/s2左右;轧制不平顺与轴箱垂向加速度和轮轨垂向力RMS值线性相关性最强,相关系数分别达到0.9和0.8.

Abstract:A section on a ballasted passenger dedicated line is targeted, where the periodic longitudinal unevenness occurs with the wavelength of 3.2 m, leading to vehicle shaking. Based on the synchrosqueezed wavelet transform, the time-frequency distribution of the dynamic and static track geometry detection data before and after machine tamping is extracted. Combined with the analysis on rail straightening process, the causes of periodic longitudinal unevenness are clarified, which may be caused by poor composite straightening process in rail rolling. On this basis, the relationship between rail straightening irregularity, vibration acceleration of vehicle components, and wheel rail contact force are explored, and the influence of rail straightening irregularity on vehicle dynamic performance is obtained. The results show that the coherence functions of vertical accelerations at axle box, bogie and car body are 0.97, 0.96 and 0.76 respectively, which increase 5%, 25% and 300% respectively than that on the normal section. The coherence function of wheel rail vertical force is increased by 42% to 0.94, revealing that straightening irregularity is closely related to the vibration response of vehicle components and wheel-rail contact force. Due to straightening irregularity, the RMS value of vertical acceleration at axle box and car body are amplified by about 1.00 m/s2 and 0.05 m/s2 respectively. Straightening irregularity has a strongest linear correlation with the RMS values of vertical accelerations at axle box and wheel-rail vertical force with the correlation coefficients of 0.9 and 0.8 respectively.

-

表 1 异常区段里程定位信息

Table 1. Mileage positioning information forabnormal section

区段编号 钢轨 起点里程 终点里程 总长/m ① 左轨 K178 + 850 K179 + 558 708 ② 左轨 K179 + 745 K180 + 345 600 ③ 右轨 K179 + 458 K179 + 558 100 ④ 右轨 K179 + 646 K179 + 848 202 ⑤ 右轨 K180 + 245 K180 + 745 500 -

[1] 李炜,宋伟军,戴安,等. 两种焊接工艺下过共析钢轨接头的冲击磨损性能[J]. 西南交通大学学报,2021,56(2): 403-410.LI Wei, SONG Weijun, DAI An, et al. Impact wear properties of hypereutectic rail joints welded by two welding processes[J]. Journal of Southwest Jiaotong University, 2021, 56(2): 403-410. [2] 李闯,张银花,田常海,等. 高速铁路钢轨服役状态及病害整治研究[J]. 铁道建筑,2020,60(8): 126-129,142. doi: 10.3969/j.issn.1003-1995.2020.08.29LI Chuang, ZHANG Yinhua, TIAN Changhai, et al. Study on rail service status and disease treatment of rail for high speed railway[J]. Railway Engineering, 2020, 60(8): 126-129,142. doi: 10.3969/j.issn.1003-1995.2020.08.29 [3] 高建敏,翟婉明. 高速铁路钢轨焊接区不平顺的动力效应及其安全限值研究[J]. 中国科学:技术科学,2014,44(7): 697-706. doi: 10.1360/N092014-00081GAO Jianmin, ZHAI Wanming. Dynamic effect and safety limits of rail weld irregularity on high-speed railways[J]. Scientia Sinica (Technologica), 2014, 44(7): 697-706. doi: 10.1360/N092014-00081 [4] DENG X Y, LI Z L, QIAN Z W, et al. Pre-cracking development of weld-induced squats due to plastic deformation:five-year field monitoring and numerical analysis[J]. International Journal of Fatigue, 2019, 127: 431-444. doi: 10.1016/j.ijfatigue.2019.06.013 [5] 刘永乾,郭猛刚,侯银庆,等. 有砟客运专线钢轨周期性不平顺整治技术研究[J]. 中国铁路,2020(9): 98-105.LIU Yongqian, GUO Menggang, HOU Yinqing, et al. Rail periodic irregularity treatment on ballasted passenger dedicated line[J]. China Railway, 2020(9): 98-105. [6] 魏子龙,刘丙强,杨飞,等. 轨枕空吊对钢轨焊接不平顺区轮轨接触的影响[J]. 同济大学学报(自然科学版),2021,49(4): 517-525.WEI Zilong, LIU Bingqiang, YANG Fei, et al. Influence of unsupported sleeper on wheel-rail contact at rail weld irregularity[J]. Journal of Tongji University (Natural Science), 2021, 49(4): 517-525. [7] ESVELD C. Modern railway track[M]. 2nd edition. Zaltbommel: MRT-Productions, 2001: 282-283. [8] SRIMANI S L, PANKAJ A C, BASU J. Analysis of end straightness of rail during manufacturing[J]. International Journal of Mechanical Sciences, 2005, 47(12): 1874-1884. doi: 10.1016/j.ijmecsci.2005.07.005 [9] WANG P L, SONG H, CHEN M. Study on the geometry dimension effect of heavy rail through compound roll straightening[C]//Proceeding of the International Conference on Mechatronics and Information Technology 2009. Gwangju: SPIE, 2010: 457-462. [10] 刘秀波. 基于经验模式分解的钢轨波浪弯曲不平顺提取方法[J]. 中国铁道科学,2006,27(2): 26-30. doi: 10.3321/j.issn:1001-4632.2006.02.006LIU Xiubo. Method for picking up rail wavy irregularities based on empirical mode decomposition method[J]. China Railway Science, 2006, 27(2): 26-30. doi: 10.3321/j.issn:1001-4632.2006.02.006 [11] 马晓川,王平,徐金辉,等. 钢轨轧制不平顺对车岔耦合系统垂向动力特性的影响[J]. 中南大学学报(自然科学版),2017,48(7): 1942-1950.MA Xiaochuan, WANG Ping, XU Jinhui, et al. Effect of rail straightening irregularity on vertical dynamic characteristics of vehicle-turnout coupling system[J]. Journal of Central South University (Science and Technology), 2017, 48(7): 1942-1950. [12] 陈宪麦,徐磊,徐伟昌,等. 高速铁路(京沪、沪宁、沪杭线)轨道不平顺谱分析[J]. 铁道科学与工程学报,2013,10(4): 1-6. doi: 10.3969/j.issn.1672-7029.2013.04.001CHEN Xianmai, XU Lei, XU Weichang, et al. Analysis of track irregularity spectrum for high-speed railway (Beijing—Shanghai,Shanghai—Hangzhou and Shanghai—Hangzhou Railway)[J]. Journal of Railway Science and Engineering, 2013, 10(4): 1-6. doi: 10.3969/j.issn.1672-7029.2013.04.001 [13] DAUBECHIES I, LU J F, WU H T. Synchrosqueezed wavelet transforms:an empirical mode decomposition-like tool[J]. Applied and Computational Harmonic Analysis, 2011, 30(2): 243-261. doi: 10.1016/j.acha.2010.08.002 [14] 田新宇,高亮,杨飞,等. 基于动态短弦的无砟轨道板周期性不平顺管理标准[J]. 中国铁道科学,2020,41(6): 30-38. doi: 10.3969/j.issn.1001-4632.2020.06.04TIAN Xinyu, GAO Liang, YANG Fei, et al. Management standard for cyclic irregularity of ballastless track slab based on dynamic short chord[J]. China Railway Science, 2020, 41(6): 30-38. doi: 10.3969/j.issn.1001-4632.2020.06.04 [15] 张银花,刘丰收,李闯,等. 中法高速铁路钢轨技术对比[J]. 中国铁路,2020(11): 115-121.ZHANG Yinhua, LIU Fengshou, LI Chuang, et al. Comparison of rail technology for high speed railway between China and France[J]. China Railway, 2020(11): 115-121. [16] 中华人民共和国铁道部. 高速铁路用钢轨: TB/T 3276—2011[S]. 北京: 中国铁道出版社, 2011 [17] 中华人民共和国铁道部. 高速铁路有砟轨道线路维修规则(试行): TG/GW 116—2013[S]. 北京: 中国铁道出版社, 2013. [18] 练松良,黄俊飞. 客货共运线路轨道不平顺不利波长的分析研究[J]. 铁道学报,2004,26(2): 111-115. doi: 10.3321/j.issn:1001-8360.2004.02.021LIAN Songliang, HUANG Junfei. Study of the detrimental wavelengths of track irregularities for railways with passenger and freight traffic[J]. Journal of the China Railway Society, 2004, 26(2): 111-115. doi: 10.3321/j.issn:1001-8360.2004.02.021 [19] 杨飞,赵钢,尤明熙,等. 滑动标准差在轨道几何区段状态评价中的应用[J]. 铁道标准设计,2017,61(12): 10-13.YANG Fei, ZHAO Gang, YOU Mingxi, et al. Application of slip standard deviation in the evaluation of track geometry[J]. Railway Standard Design, 2017, 61(12): 10-13. -

下载:

下载: