Mechanical Properties of Wet Concrete Inside Double-Block Ballastless Tracks in Rainy Areas

-

摘要:

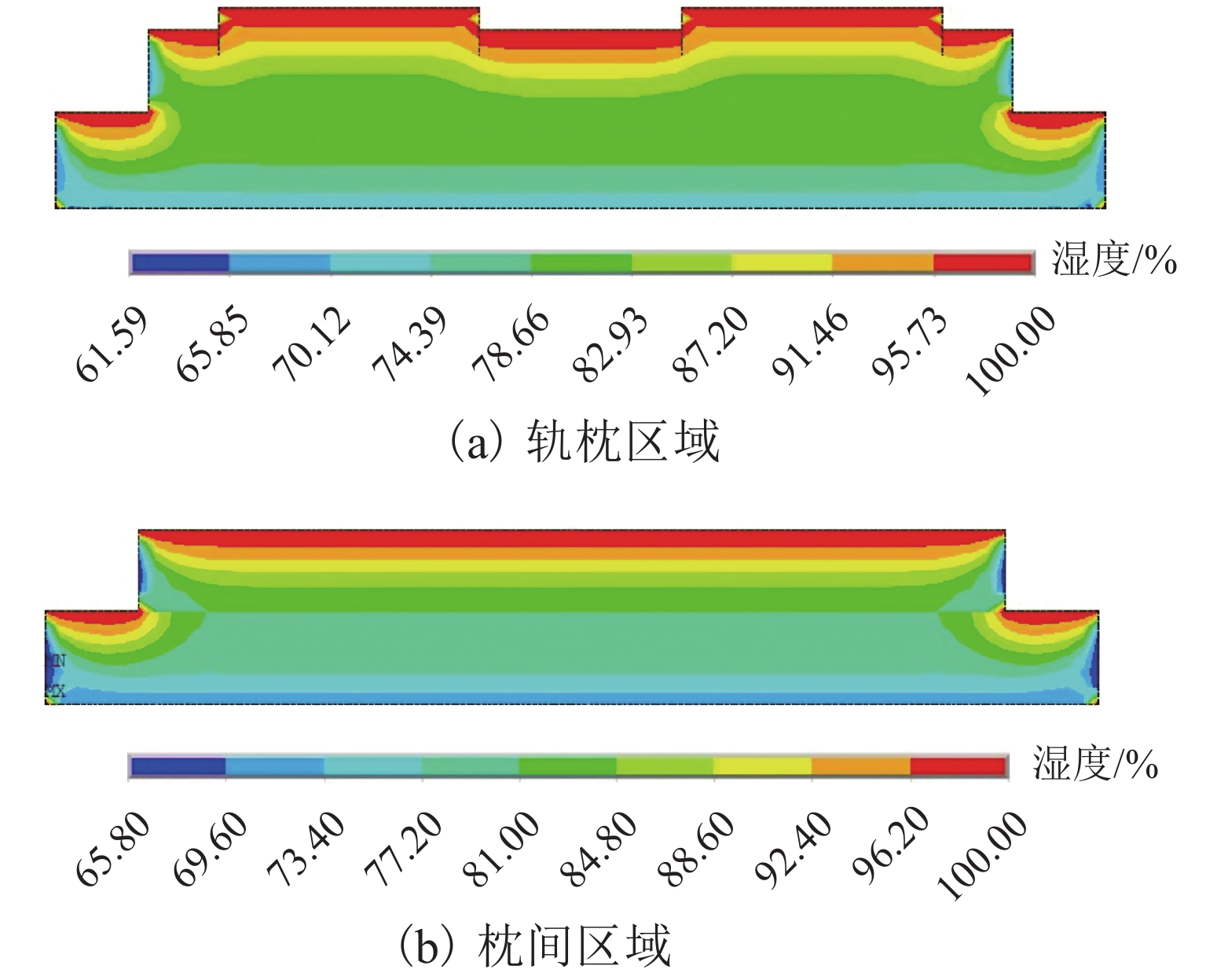

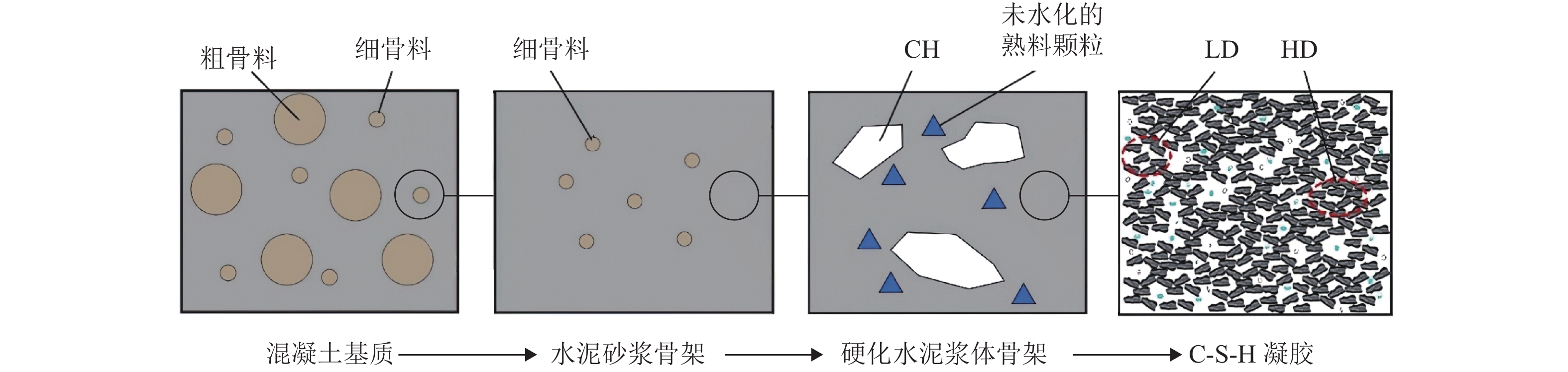

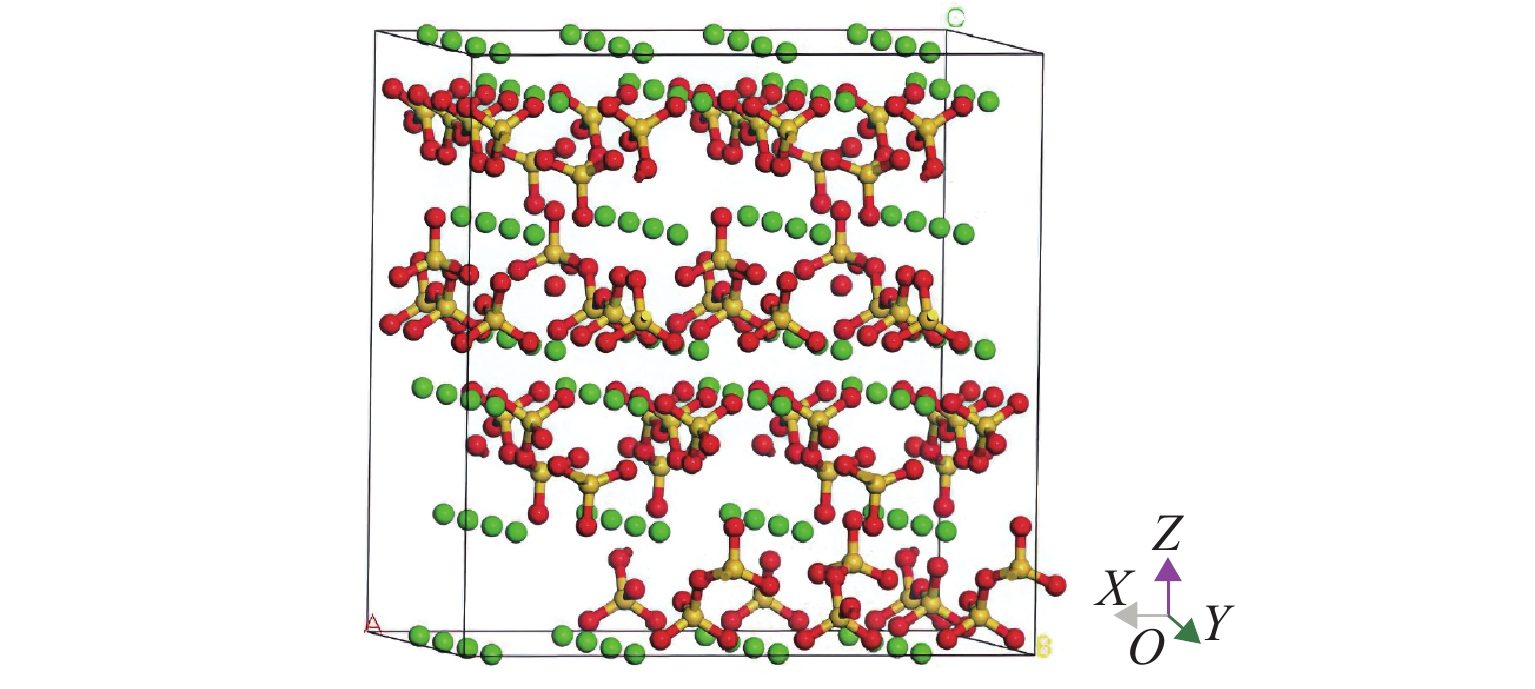

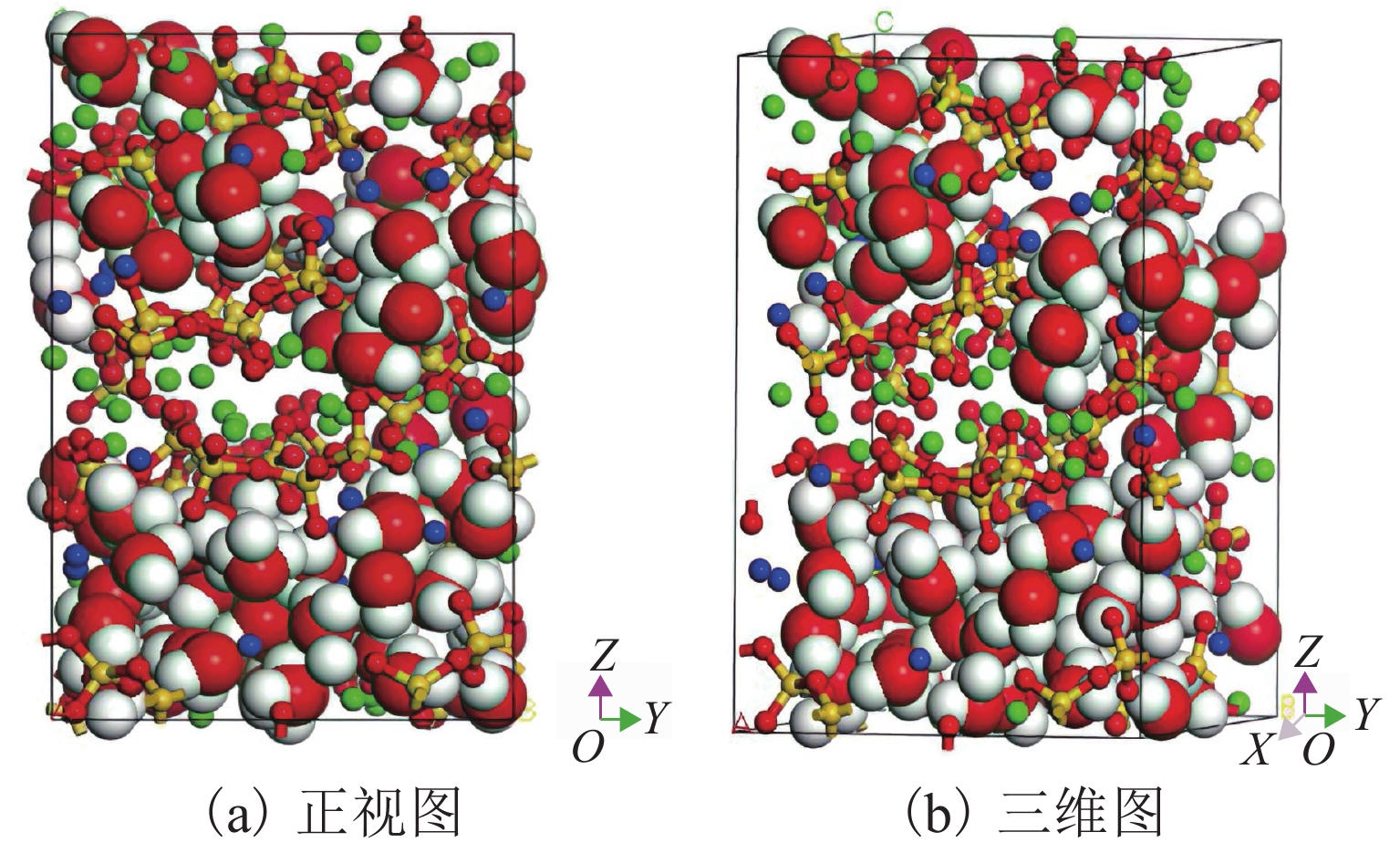

长期处于水环境中的双块式无砟轨道内部存在不均匀的湿度场,而湿度会对轨道结构的力学性能产生一定的影响. 为研究水环境中双块式无砟轨道内部不同湿度状态下混凝土宏观力学性能,结合水环境中双块式无砟轨道的湿度分布情况,建立了混凝土基质纳观组分(C-S-H)分子动力学模型,对混凝土基质展开多尺度计算,并进行两级均匀化分析. 结果表明:水环境中的双块式无砟轨道结构表层湿度的梯级分化明显,轨道内部的湿度差最高可达38.41%;混凝土的弹性模量和泊松比随饱和度的增加而增大;混凝土饱和度由0增加到100.00%时,支承层、道床板及轨枕混凝土弹性模量的增幅分别可达35.0%、19.5%、16.2%.

Abstract:An uneven humidity field forms inside double-block ballastless tracks long located in the water environment, and humidity will affect the mechanical properties of track structures. In order to study the macroscopic mechanical properties of concrete under different humidity conditions inside the double-block ballastless tracks in the water environment, combined with the humidity distribution of the double-block ballastless track in the water environment, the molecular dynamics of the nano-component (C-S-H) of the concrete matrix is established. Multi-scale calculation of concrete matrix and two-level homogenization analysis are conducted. The results show that the surface humidity of double-block ballastless tracks in the water environment show distinct gradient differentiation, and the maximum humidity difference inside the tracks can reach up to 38.41%; the elastic modulus and Poisson’s ratio of concrete increase with saturation; when concrete saturation is increased from 0 to 100%, the increases of the elastic modulus of the bearing layer, the track bed slab and the sleeper concrete attain 35.0%, 19.5% and 16.2%, respectively.

-

Key words:

- double-block ballastless track /

- water environment /

- humidity filed /

- wet concrete /

- material property

-

表 1 双块式无砟轨道构件尺寸及材料参数

Table 1. Dimensions and material parameters of double-block ballastless track components

构件 参数 取值 C60 混凝土轨枕块 水灰比 0.32 长、宽、高/mm 800、300、150 密度(kg·m−3) 2500 C40 混凝土道床板 水灰比 0.38 宽、高/mm 2800、260 密度/(kg·m−3) 2450 C20 混凝土支承层 水灰比 0.66 宽、高/mm 3400、300 密度/(kg·m−3) 2300 表 2 水环境中双块式无砟轨道湿度区间及其代表值

Table 2. Humidity interval and representative values of double-block ballastless tracks in water environment

% 湿度

区间轨枕区域 枕间区域 湿度 代表湿度 湿度 代表

湿度1 [61.59,65.85] 64.00 [65.80,69.60] 68.00 2 (65.85,70.12] 68.00 (69.60,73.40] 72.00 3 (70.12,74.39] 72.00 (73.40,77.20] 75.00 4 (74.39,78.66] 77.00 (77.20,81.00] 79.00 5 (78.66,82.93] 81.00 (81.00,84.80] 83.00 6 (82.93,87.20] 85.00 (84.80,88.60] 87.00 7 (87.20,91.46] 89.00 (88.60,92.40] 91.00 8 (91.46,95.73] 94.00 (92.40,96.20] 94.00 9 (95.73,100.00] 98.00 (96.20,100.00] 98.00 表 3 各层级两相复合材料的具体组分

Table 3. Specific components of two-phase composite at each level

研究

对象层级 两相

复合材料夹杂相 基质相 C-S-H

凝胶Ⅰ HD/LD

C-S-H凝胶孔及

内部水C-S-H 胶束 C-S-H 凝胶 LD/HD

C-S-HHD/LD

C-S-H硬化水泥浆体骨架 Ⅱ 水化产物 CH 晶体 C-S-H 凝胶 硬化水泥浆体骨架 未水化

水泥颗粒水化产物 水泥砂浆骨架 Ⅲ 水泥砂浆骨架 细骨料 硬化水泥

浆体骨架混凝土基质 Ⅳ 混凝土基质 粗骨料 水泥砂浆骨架 表 4 各层级夹杂相的力学参数

Table 4. Mechanical parameters of inclusion at each level

层级 夹杂相 弹性模量

E/GPa体积

模量/GPa剪切

模量/GPa泊松比

υⅠ 饱和凝胶孔 2.20 0 非饱和

凝胶孔0 0 Ⅱ CH晶体 40.00 160.00 未水化

水泥颗粒135.00 0.27 Ⅲ 细骨料 34.60 0.21 Ⅳ 粗骨料 54.00 0.20 表 5 C-S-H胶束力学性能参数

Table 5. Mechanical properties of C-S-H micelles

表 6 混凝土基质等效力学参数计算结果

Table 6. Calculation results of equivalent mechanical parameters for concrete matrix

混凝土强度等级 湿度/% 等效体积模量/GPa 等效剪切模量/GPa 等效弹性模量/GPa υ C20 64.00 ~ 98.00 24.59 16.12 39.69 0.23 C40 64.00 27.00 17.01 42.17 0.24 68.00 27.09 17.00 42.18 0.24 72.00 ~ 98.00 27.20 16.94 42.09 0.24 C60 64.00 27.47 17.02 42.31 0.24 68.00 27.53 17.03 42.37 0.24 72.00 27.67 17.03 42.39 0.24 75.00 ~ 98.00 27.76 16.99 42.33 0.25 表 7 轨枕区域不同湿度状态混凝土的有效力学参数

Table 7. Effective mechanical parameters of concrete in different humidity states in track-sleeper areas

湿度区间 代表湿度/% C20 混凝土(支承层) C40 混凝土(道床板) C60 混凝土(轨枕) S/% E/GPa υ S/% E/GPa υ S/% E/GPa υ 1 64.00 0.05 24.71 0.22 0 29.43 0.22 0 30.91 0.23 2 68.00 0.11 24.71 0.22 0 29.43 0.23 0 30.91 0.23 3 72.00 0.21 24.71 0.22 0.30 29.44 0.23 0 30.91 0.23 4 77.00 0.51 26.72 0.22 2.54 29.66 0.23 10.67 31.60 0.23 5 81.00 1.16 28.74 0.23 6.88 29.94 0.23 36.06 32.56 0.23 6 85.00 3.32 28.93 0.23 17.83 30.85 0.23 70.36 33.38 0.23 7 89.00 13.78 29.91 0.23 45.16 32.16 0.23 81.53 34.34 0.23 8 94.00 79.17 31.43 0.24 79.84 34.03 0.24 81.60 35.89 0.23 9 98.00 100.00 33.35 0.25 100.00 35.17 0.24 100.00 35.93 0.23 表 8 枕间区域不同湿度状态混凝土的有效力学参数

Table 8. Effective mechanical parameters of concrete in different humidity states in areas between sleepers

湿度区间 代表湿度/% C20 混凝土(支承层) C40 混凝土(道床板) S/% E/GPa υ S/% E/GPa υ 1 68.00 0.11 24.71 0.22 0 29.43 0.22 2 72.00 0.21 24.71 0.22 0.30 29.44 0.23 3 75.00 0.35 24.71 0.22 1.39 29.55 0.23 4 79.00 0.75 26.72 0.22 4.25 29.77 0.23 5 83.00 1.89 28.74 0.23 11.06 30.11 0.23 6 87.00 6.41 29.36 0.23 28.73 30.91 0.23 7 91.00 31.88 30.91 0.23 64.92 32.84 0.23 8 94.00 79.17 31.43 0.24 79.84 34.03 0.24 9 98.00 100.00 33.35 0.25 100.00 35.17 0.24 -

[1] 曹世豪,杨荣山,刘学毅,等. 无砟轨道层间裂纹内动水压力特性分析[J]. 西南交通大学学报,2016,51(1): 36-42. doi: 10.3969/j.issn.0258-2724.2016.01.006CAO Shihao, YANG Rongshan, LIU Xueyi, et al. Analysis of water pressure in ballastless track crack[J]. Journal of Southwest Jiaotong University, 2016, 51(1): 36-42. doi: 10.3969/j.issn.0258-2724.2016.01.006 [2] 刘佳,杨荣山,胡猛,等. 无砟轨道层间离缝浸水条件下湿度影响范围分析[J]. 铁道科学与工程学报,2019,16(5): 1113-1119.LIU Jia, YANG Rongshan, HU Meng, et al. Analysis of humidity influence range under immersion between interlayer seams in a ballastless track[J]. Journal of Railway Science and Engineering, 2019, 16(5): 1113-1119. [3] PARROTT L J. Moisture profiles in drying concrete[J]. Advances in Cement Research, 1988, 1(3): 164-170. doi: 10.1680/1988.1.3.164 [4] 王海龙,李庆斌. 孔隙水对湿态混凝土抗压强度的影响[J]. 工程力学,2006,23(10): 141-144,179. doi: 10.3969/j.issn.1000-4750.2006.10.027WANG Hailong, LI Qingbin. Effect of pore water on the compressive strength of wet concrete[J]. Engineering Mechanics, 2006, 23(10): 141-144,179. doi: 10.3969/j.issn.1000-4750.2006.10.027 [5] 王海龙,李庆斌. 湿态混凝土抗压强度与本构关系的细观力学分析[J]. 岩石力学与工程学报,2006,25(8): 1531-1536. doi: 10.3321/j.issn:1000-6915.2006.08.003WANG Hailong, LI Qingbin. Mesomechanics analysis of compressive strength and constitutive equation of wet concrete[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(8): 1531-1536. doi: 10.3321/j.issn:1000-6915.2006.08.003 [6] 王海龙,李庆斌. 不同加载速率下干燥与饱和混凝土抗压性能试验研究分析[J]. 水力发电学报,2007,26(1): 84-89. doi: 10.3969/j.issn.1003-1243.2007.01.017WANG Hailong, LI Qingbin. Experiments of the compressive properties of dry and saturated concrete under different loading rates[J]. Journal of Hydroelectric Engineering, 2007, 26(1): 84-89. doi: 10.3969/j.issn.1003-1243.2007.01.017 [7] LI G. The effect of moisture content on the tensile strength properties of concrete[D]. Gainesvile: University of Florida, 2004. [8] 侯东伟,张君,陈浩宇,等. 干燥与潮湿环境下混凝土抗压强度和弹性模量发展分析[J]. 水利学报,2012,43(2): 198-208.HOU Dongwei, ZHANG Jun, CHEN Haoyu, et al. Development of strength and elastic modulus of concrete under moisture and drying curing conditions[J]. Journal of Hydraulic Engineering, 2012, 43(2): 198-208. [9] 孙国文,孙伟,王彩辉. 现代混凝土传输行为与其微结构之间关系的研究方法及其进展[J]. 材料导报,2018,32(17): 3010-3022. doi: 10.11896/j.issn.1005-023X.2018.17.014SUN Guowen, SUN Wei, WANG Caihui. Relationship between the transport behavior of modern concrete and its microstructures:research methods and progress[J]. Materials Review, 2018, 32(17): 3010-3022. doi: 10.11896/j.issn.1005-023X.2018.17.014 [10] 杜修力,金浏. 细观均匀化方法预测非饱和混凝土宏观力学性质[J]. 水利学报,2013,44(11): 1317-1325,1332.DU Xiuli, JIN Liu. Micro-scale homogenization for prediction of the macroscopic mechanical properties of unsaturated concrete[J]. Journal of Hydraulic Engineering, 2013, 44(11): 1317-1325,1332. [11] BERNARD O, ULM F J, LEMARCHAND E. A multiscale micromechanics-hydration model for the early-age elastic properties of cement-based materials[J]. Cement and Concrete Research, 2003, 33(9): 1293-1309. doi: 10.1016/S0008-8846(03)00039-5 [12] 王永宝,贾毅,赵人达. 基于ANSYS的混凝土内湿度场计算方法[J]. 西南交通大学学报,2017,52(1): 54-60. doi: 10.3969/j.issn.0258-2724.2017.01.008WANG Yongbao, JIA Yi, ZHAO Renda. Calculation of internal humidity field of concrete based on ANSYS[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 54-60. doi: 10.3969/j.issn.0258-2724.2017.01.008 [13] 吴梦瑶. 水环境下双块式无砟轨道材料软化分布研究[D]. 成都: 西南交通大学, 2018. [14] 龚灵力. 自密实混凝土性能及混凝土多场耦合时变性分析研究[D]. 杭州: 浙江大学, 2010. [15] XI Y P, BAŽANT Z P, MOLINA L, et al. Moisture diffusion in cementitious materials moisture capacity and diffusivity[J]. Advanced Cement Based Materials, 1994, 1(6): 258-266. doi: 10.1016/1065-7355(94)90034-5 [16] AKITA H, FUJIWARA T, OZAKA Y. A practical procedure for the analysis of moisture transfer within concrete due to drying[J]. Magazine of Concrete Research, 1997, 49(179): 129-137. doi: 10.1680/macr.1997.49.179.129 [17] 张君,侯东伟. 基于内部湿度试验的早龄期混凝土水分扩散系数求解[J]. 清华大学学报(自然科学版),2008,48(12): 2033-2035,2040. doi: 10.3321/j.issn:1000-0054.2008.12.002ZHANG Jun, HOU Dongwei. Calculation of moisture diffusion coefficient in early age concrete from interior humidity tests[J]. Journal of Tsinghua University (Science and Technology), 2008, 48(12): 2033-2035,2040. doi: 10.3321/j.issn:1000-0054.2008.12.002 [18] Comite Euro-International Du Beton. CEB-FIP model code 1990[S]. Lausanne: Thomas Thelford, 1993. [19] PERSSON B. Experimental studies on shrinkage of high-performance concrete[J]. Cement and Concrete Research, 1998, 28(7): 1023-1036. doi: 10.1016/S0008-8846(98)00068-4 [20] 蒋正武,王培铭. 等温干燥条件下混凝土内部相对湿度的分布[J]. 武汉理工大学学报,2003,25(7): 18-21. doi: 10.3321/j.issn:1671-4431.2003.07.006JIANG Zhengwu, WANG Peiming. Internal relative humidity distribution of concrete under isothermal drying conditions[J]. Journal of Wuhan University of Technology, 2003, 25(7): 18-21. doi: 10.3321/j.issn:1671-4431.2003.07.006 [21] KIM J K, LEE C S. Moisture diffusion of concrete considering self-desiccation at early ages[J]. Cement and Concrete Research, 1999, 29(12): 1921-1927. doi: 10.1016/S0008-8846(99)00192-1 [22] 杨明. 高等级公路沥青路面雨季施工[J]. 交通世界(工程技术),2014(20): 114-115. [23] CONSTANTINIDES G, ULM F J. The effect of two types of C-S-H on the elasticity of cement-based materials: results from nanoindentation and micromechanical modeling[J]. Cement and Concrete Research, 2004, 34(1): 67-80. doi: 10.1016/S0008-8846(03)00230-8 [24] ULM F J, CONSTANTINIDES G, HEUKAMP F H. Is concrete a poromechanics materials?—a multiscale investigation of poroelastic properties[J]. Materials and Structures, 2004, 37(1): 43-58. doi: 10.1007/BF02481626 [25] MAEKAWA K, ISHIDA T, KISHI T. Multi-scale modeling of concrete performance[J]. Journal of Advanced Concrete Technology, 2003, 1(2): 91-126. doi: 10.3151/jact.1.91 [26] 林枫,MEYER Christian. 硬化水泥浆体弹性模量细观力学模型[J]. 复合材料学报,2007,24(2): 184-189. doi: 10.3321/j.issn:1000-3851.2007.02.030LIN Feng, MEYER Christian. Micromechanics model for the effective elastic properties of hardened cement pastes[J]. Acta Materiae Compositae Sinica, 2007, 24(2): 184-189. doi: 10.3321/j.issn:1000-3851.2007.02.030 [27] ESHELBY J D. The determination of the elastic field of an ellipsoidal inclusion, and related problems[J]. Proceedings of the Royal Society of Series A:Mathematical and Physical Sciences, 1957, 241(1226): 376-396. [28] MORI T, TANAKA K. Average stress in matrix and average elastic energy of materials with misfitting inclusions[J]. Acta Metallurgica, 1973, 21(5): 571-574. doi: 10.1016/0001-6160(73)90064-3 [29] BONACCORSI E, MERLINO S, TAYLOR H F W. The crystal structure of jennite, Ca9Si6O18(OH)6·8H2O[J]. Cement and Concrete Research, 2004, 34(9): 1481-1488. doi: 10.1016/j.cemconres.2003.12.033 [30] BERENDSEN H J C, GRIGERA J R, STRAATSMA T P. The missing term in effective pair potentials[J]. The Journal of Physical Chemistry, 1987, 91(24): 6269-6271. doi: 10.1021/j100308a038 [31] ALLEN A J, THOMAS J J, JENNINGS H M. Composition and density of nanoscale calcium-silicate-hydrate in cement[J]. Nature Materials, 2007, 6(4): 311-316. doi: 10.1038/nmat1871 [32] 魏鹏. 不同温度下水化硅酸钙复合材料力学性能的分子动力学研究[D]. 深圳: 深圳大学, 2017. [33] PELLENQ R J M, KUSHIMA A, SHAHSAVARI R, et al. A realistic molecular model of cement hydrates[J]. Proceedings of the National Academy of Sciences of the United States of America, 2009, 106(38): 16102-16107. doi: 10.1073/pnas.0902180106 [34] DU X L, JIN L, MA G W. Macroscopic effective mechanical properties of porous dry concrete[J]. Cement and Concrete Research, 2013, 44: 87-96. doi: 10.1016/j.cemconres.2012.10.012 -

下载:

下载: