Simulation and Analysis of Chloride Ion Diffusion in Cracked Concrete Based on Cellular Automata

-

摘要:

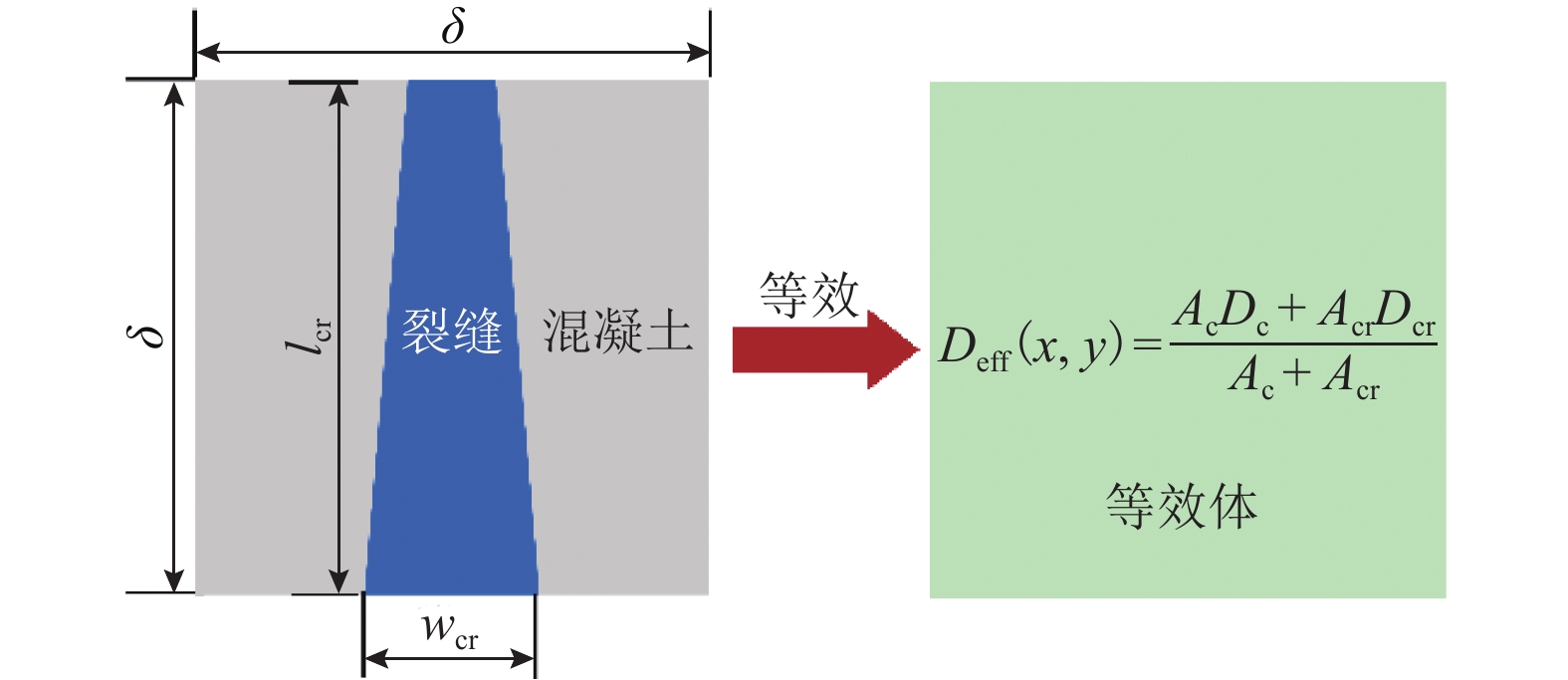

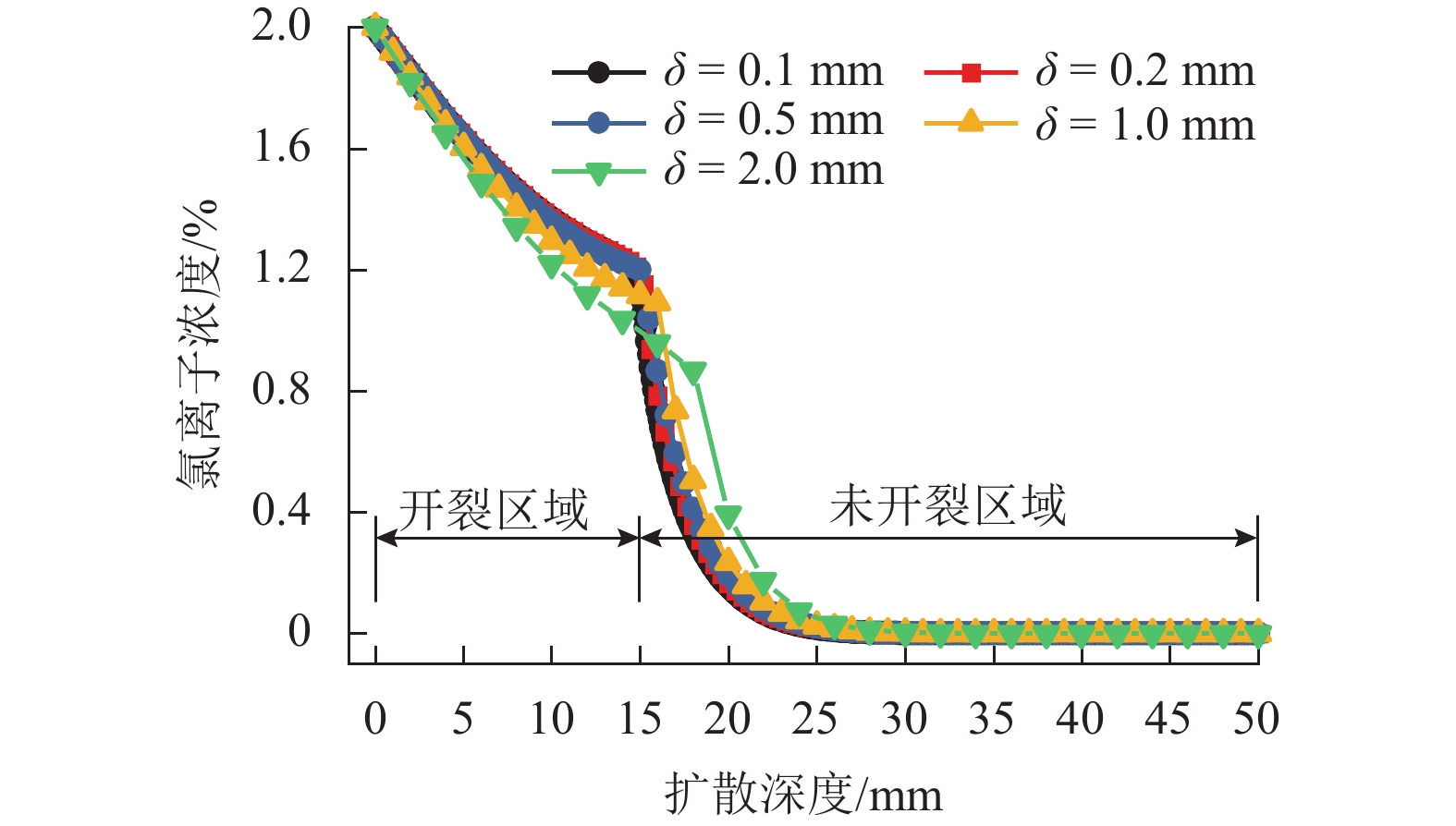

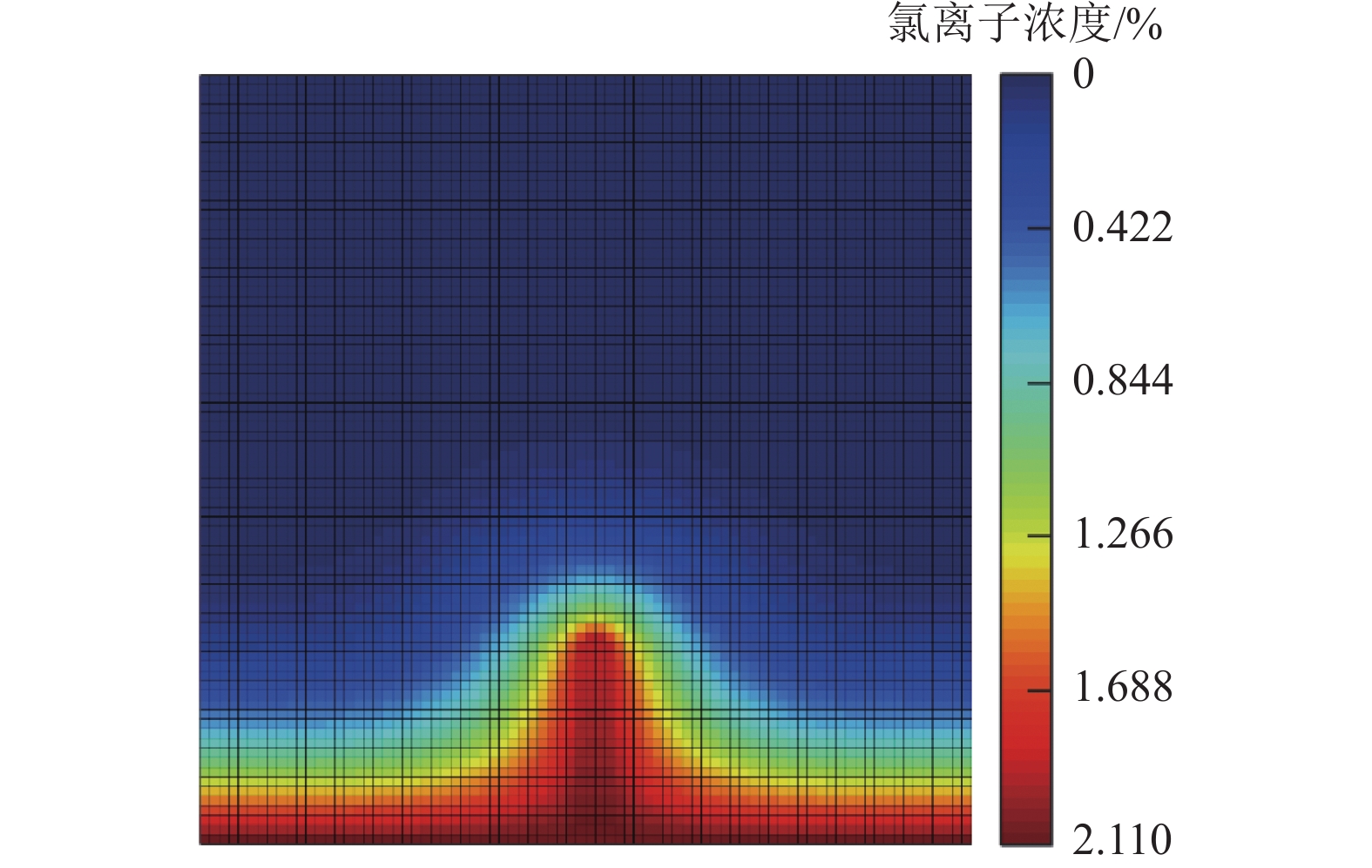

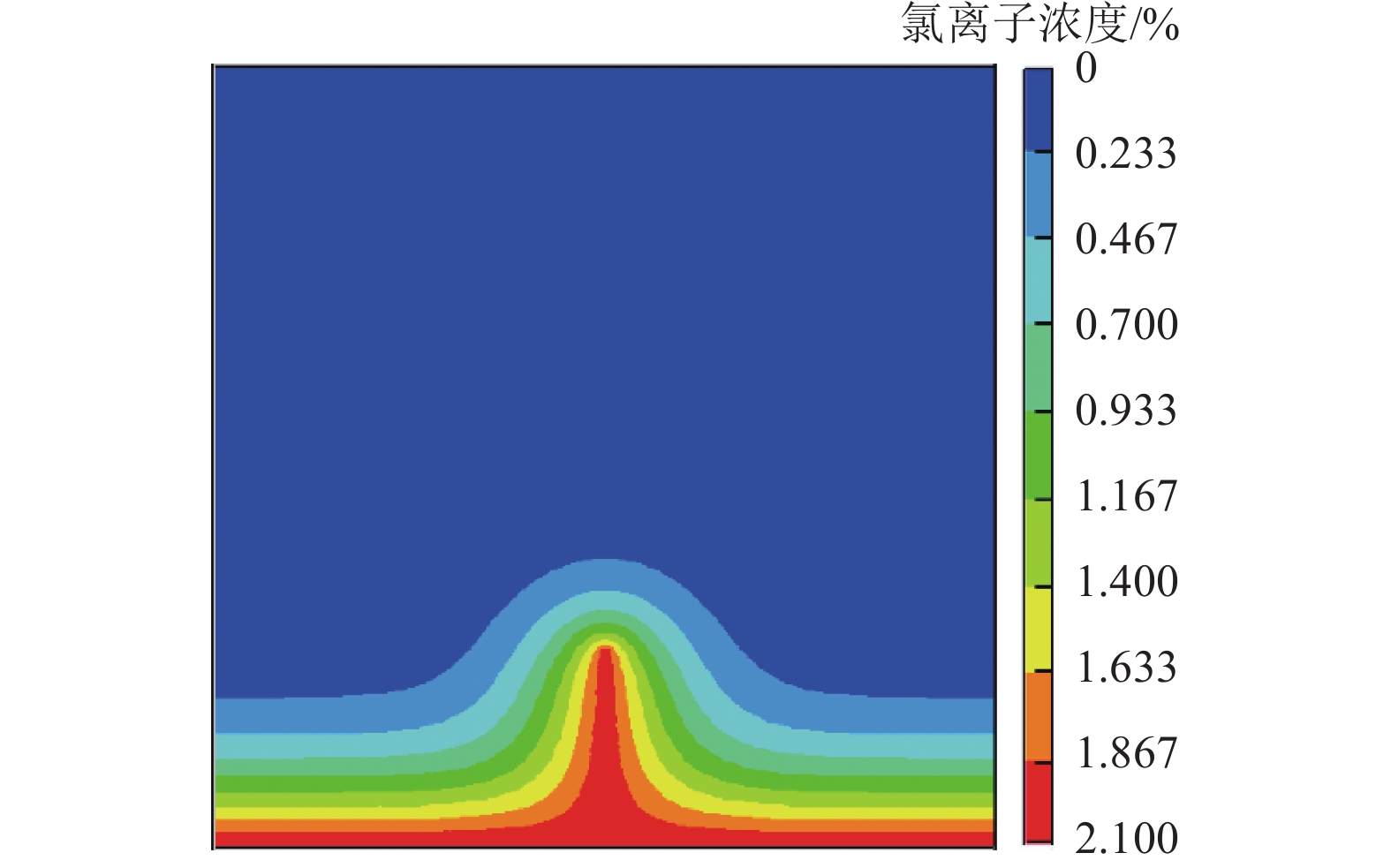

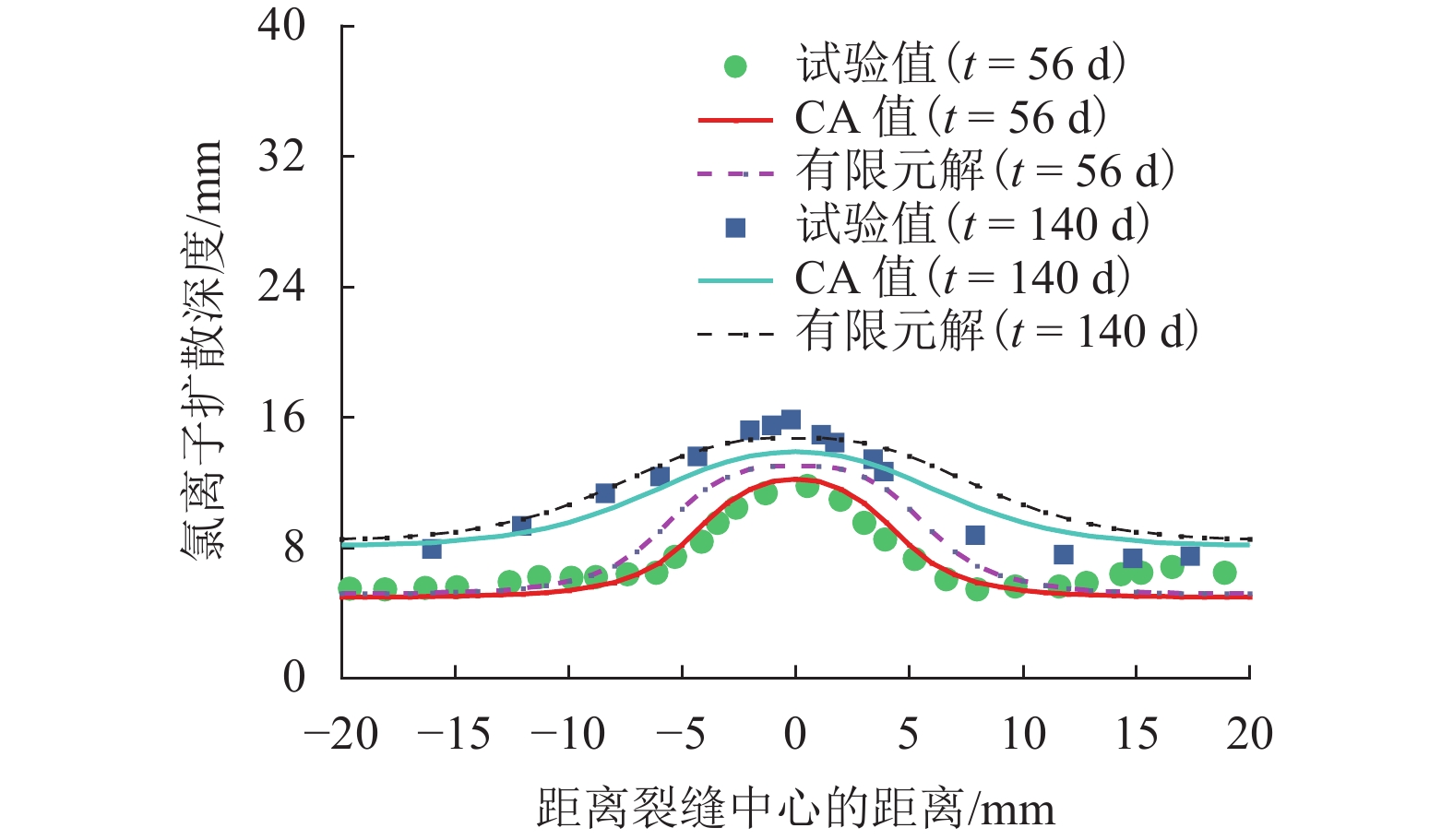

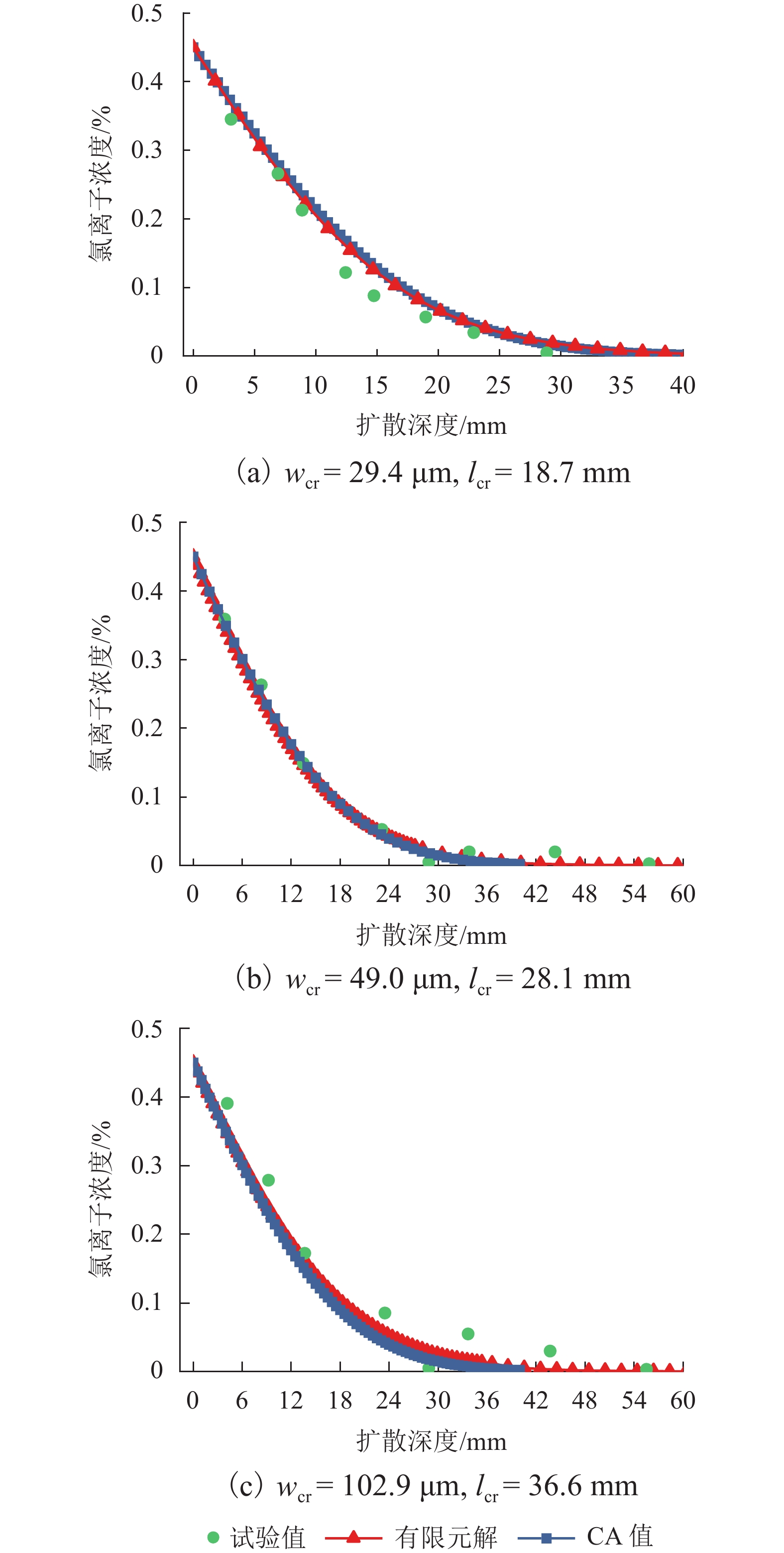

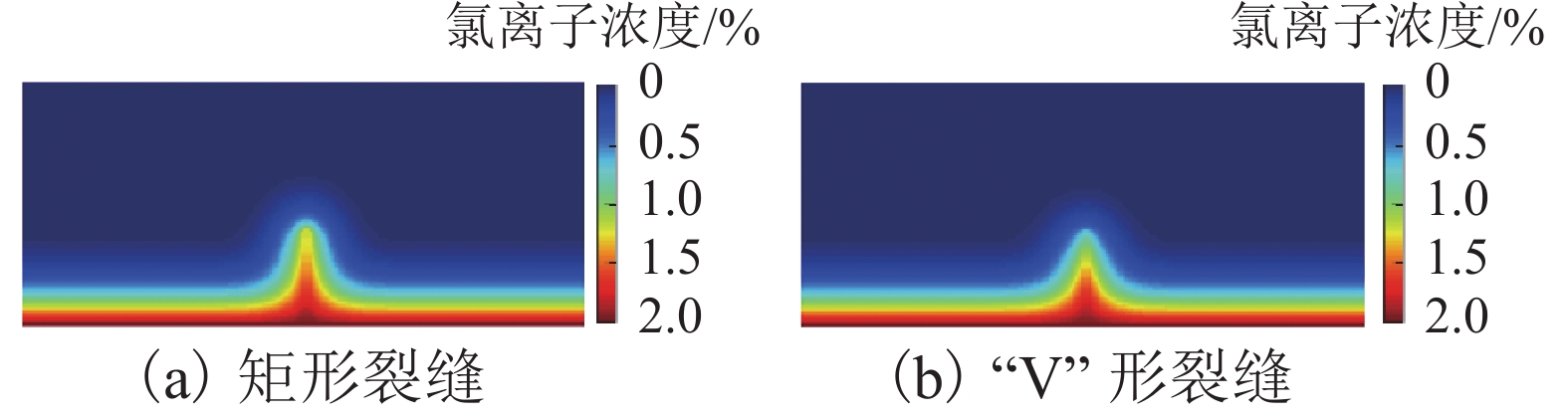

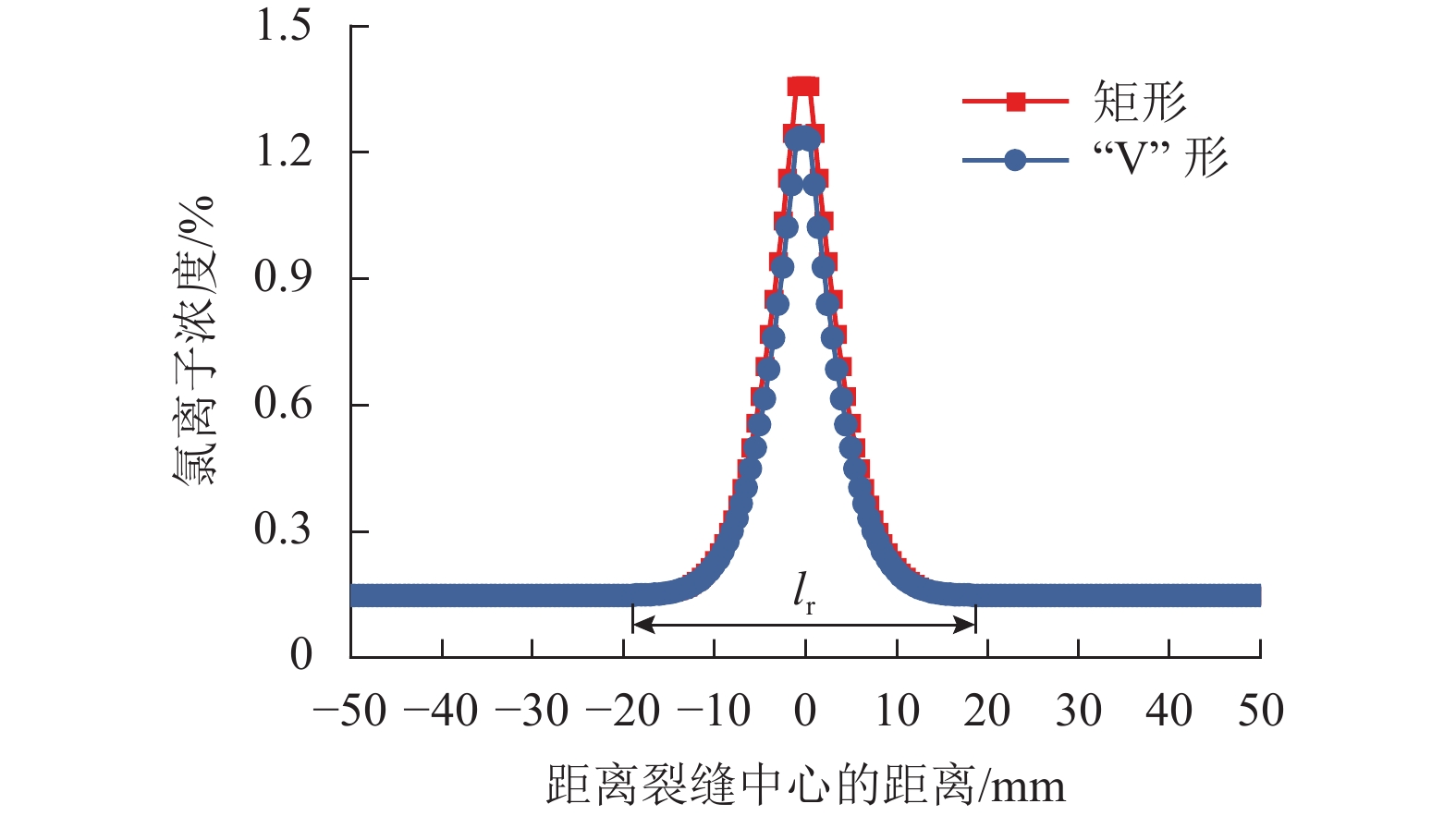

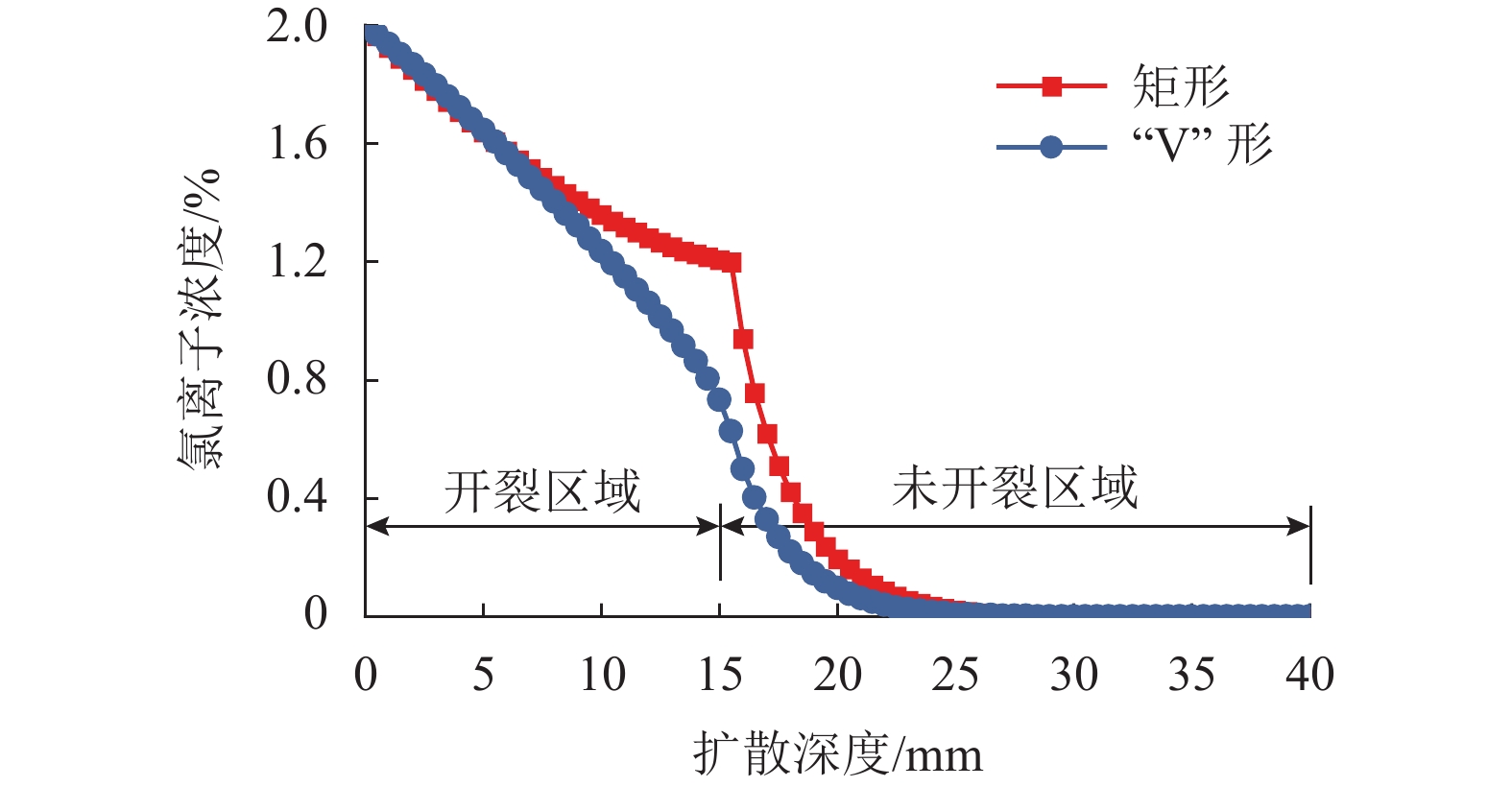

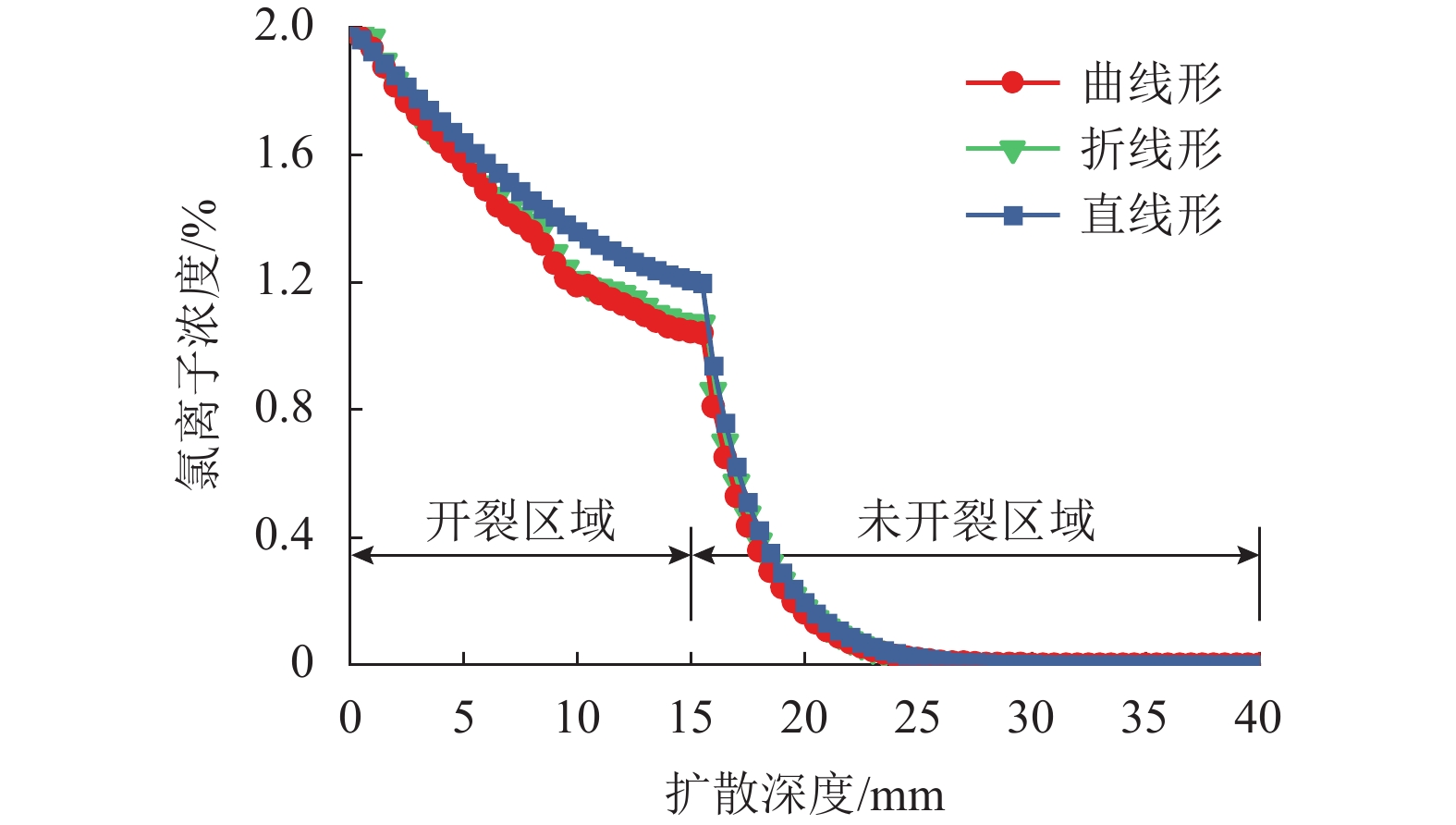

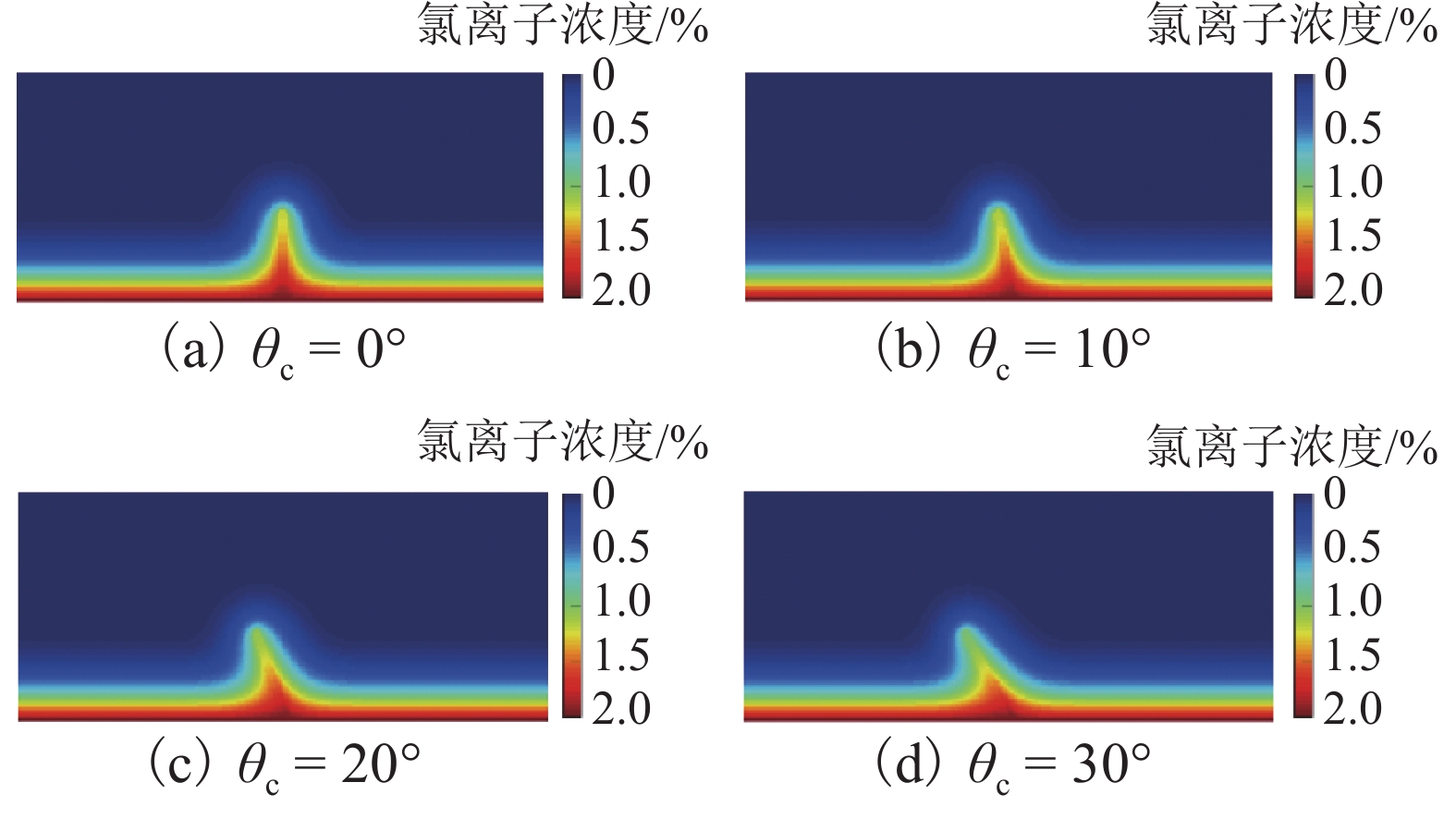

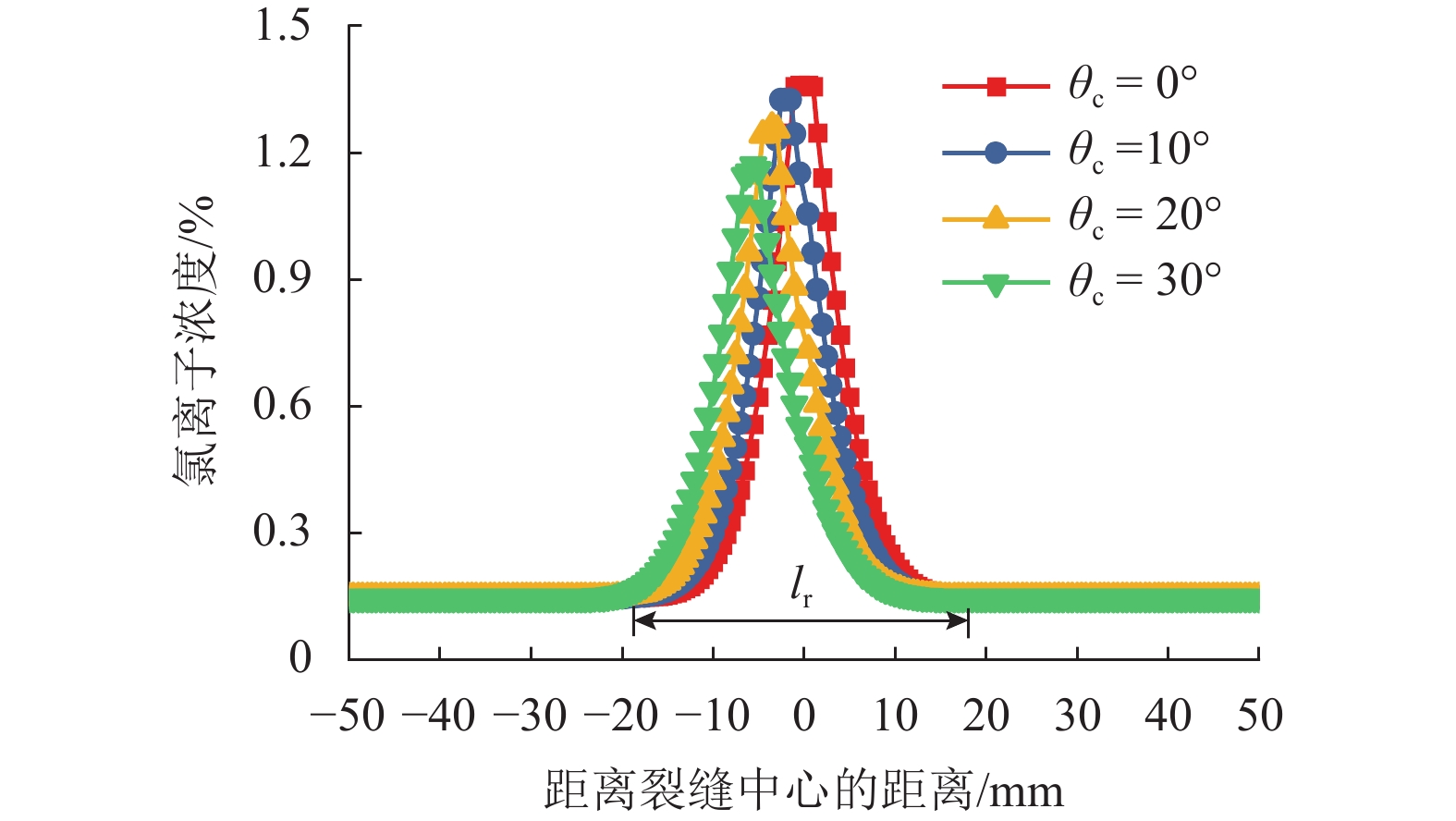

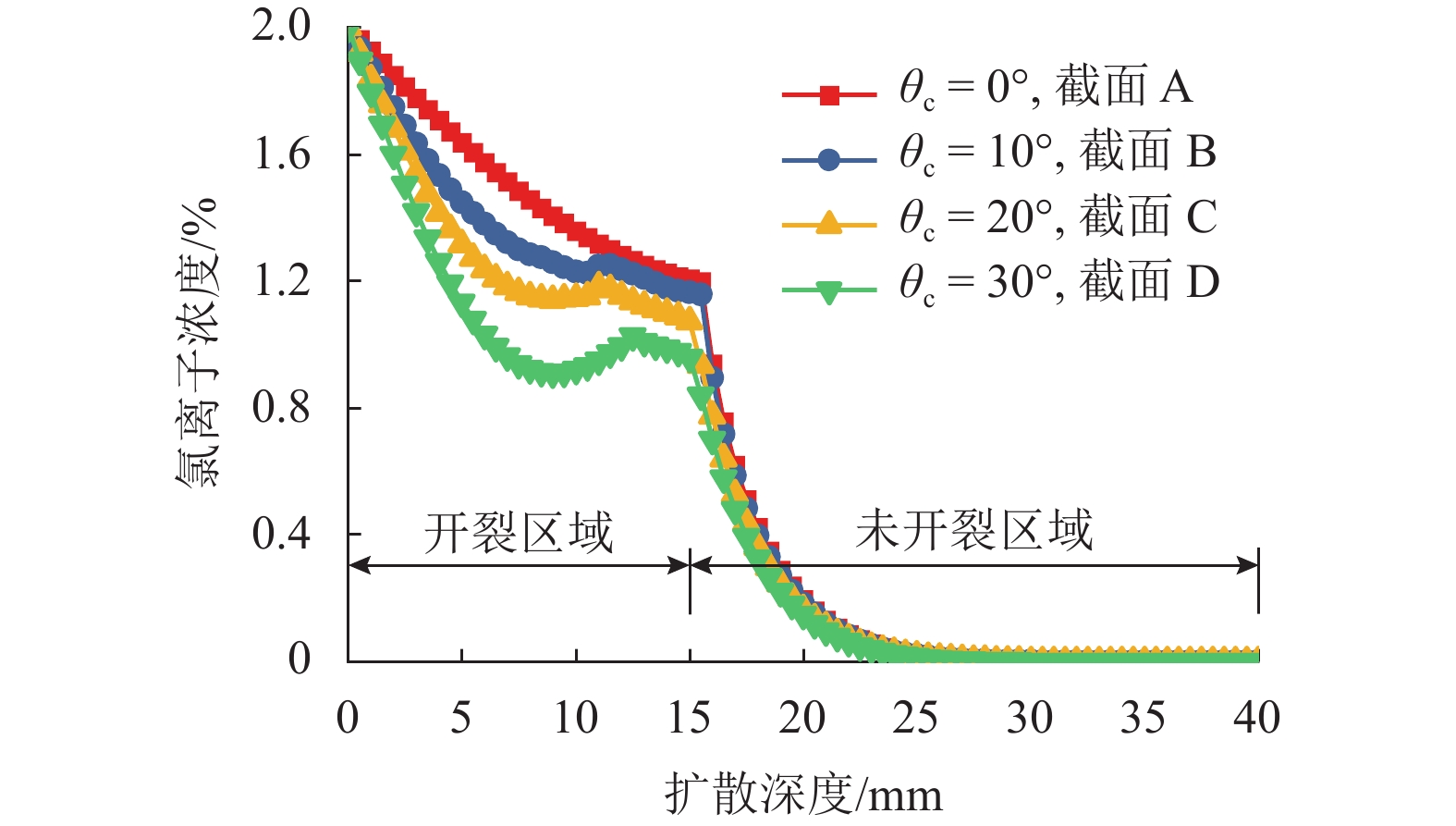

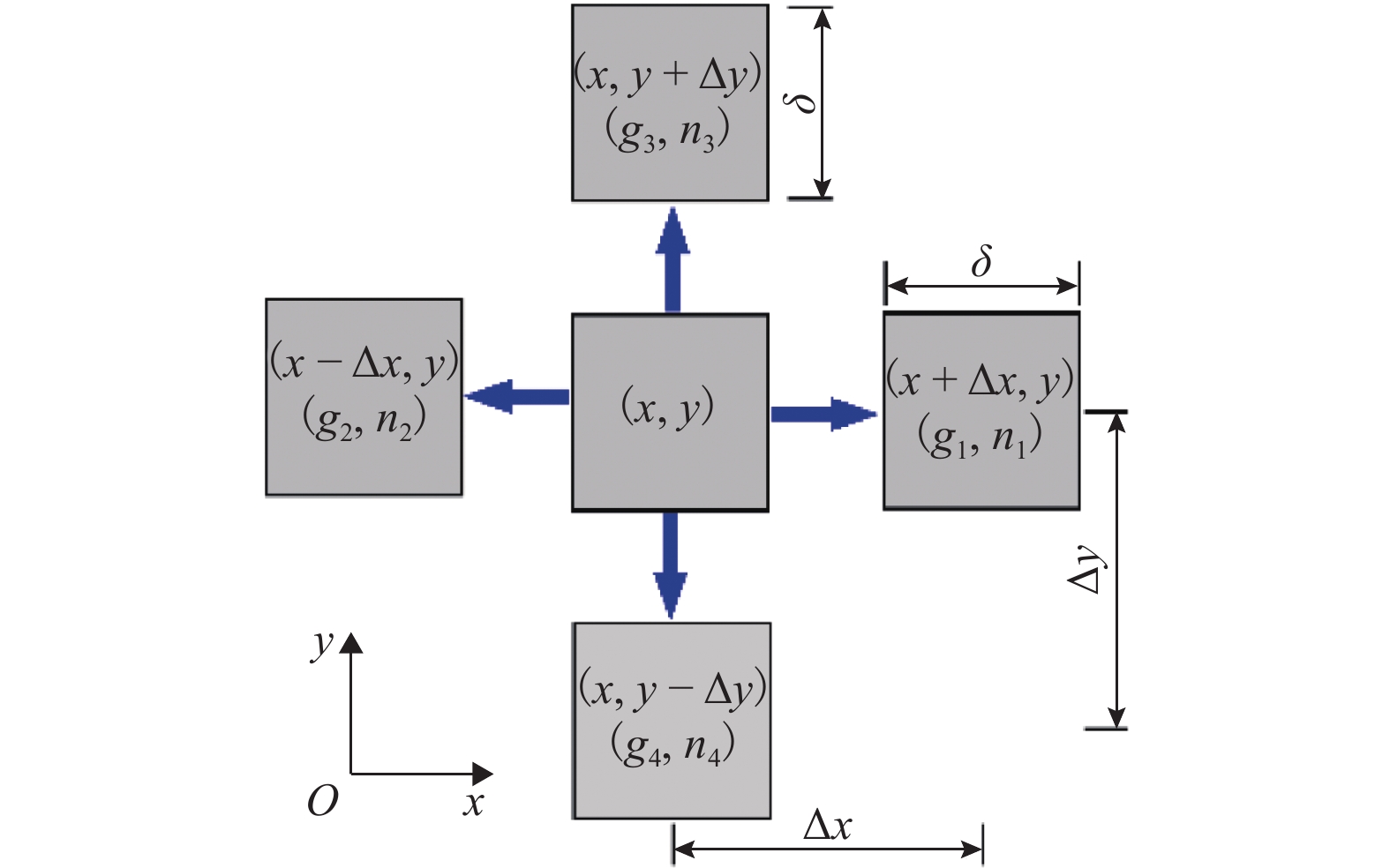

为获得氯离子在开裂混凝土中的浓度分布以及分析裂缝形状、分布形式、偏转角度对混凝土中氯离子扩散效应的影响,根据氯离子在开裂混凝土中的扩散机理,利用元胞自动机和均匀化等效分析方法,建立了模拟开裂混凝土中氯离子扩散过程的元胞自动机模型,并利用数值试验对模型中元胞尺寸进行了优化. 研究结果表明:在不影响计算精度的情况下,为提高模型的计算效率,推荐采用元胞尺寸大小为0.5 mm;除个别数据外,模型模拟结果、试验结果与有限元分析结果吻合良好,最大偏差不超过10%;“V”形裂缝中氯离子浓度约为矩形裂缝的0.52倍;曲线形裂缝和折线形裂缝中氯离子浓度约为直线形裂缝的0.87倍和0.89倍;当裂缝偏转角从0° 分别增大至10°、20°、30° 时,裂缝端部氯离子浓度分别减小3.3%、21.9%、29.8%;裂缝对其周围氯离子扩散区域的影响范围与裂缝形状、分布形式和偏转角度无关,对裂缝周围氯离子扩散效应的影响主要集中在裂缝左右18 mm的范围内.

Abstract:In order to obtain the concentration distribution of chloride ions in cracked concrete and analyze the influence of crack shape, distribution form and deflection angle on the chloride ion diffusion in concrete, a cellular automata model for simulating the diffusion process of chloride ions in cracked concrete is established by using cellular automata and homogenization equivalent analysis methods according to the diffusion mechanism of chloride ions in cracked concrete; the cell size in the model is optimized by numerical experiments. The results show that the computational efficiency of the model can be improved with a high calculation accuracy when the cell size of is 0.5 mm. Except for individual data, the model simulation results are in good agreement with the test results and finite element analysis results, and the maximum deviation is no more than 10%. The chloride ion concentration in the "V" crack is about 0.52 times that in the rectangular crack. The chloride ion concentration in curved cracks and broken line cracks is about 0.87 times and 0.89 times that in linear cracks, respectively. When the fracture deflection angle increases from 0° to 10°, 20°, and 30°, the chloride ion concentration at the fracture end decreases by 3.3%, 21.9%, and 29.8%, respectively. The influence range of the crack on the chloride diffusion zone around the crack is independent of the shape, distribution form, and deflection angle of the crack. The influenced area is mainly concentrated on the range of about 18 mm perpendicular to the crack.

-

Key words:

- cracks /

- cellular automata /

- durability /

- concrete /

- chloride ion

-

-

[1] 金伟良,延永东,王海龙. 氯离子在受荷混凝土内的传输研究进展[J]. 硅酸盐学报,2010,38(11): 2217-2224.JIN Weiliang, YAN Yongdong, WANG Hailong. Research progress on the chloride transportation in stressed concrete[J]. Journal of the Chinese Ceramic Society, 2010, 38(11): 2217-2224. [2] ZHANG W, FRANCOIS R, CAI Y, et al. Influence of artificial cracks and interfacial defects on the corrosion behavior of steel in concrete during corrosion initiation under a chloride environment[J]. Construction and Building Materials, 2020, 253: 119-165. [3] DJERBI A, BONNET S, KHELIDJ A, et al. Influence of traversing crack on chloride diffusion into concrete[J]. Cement and Concrete Research, 2008, 38(6): 877-883. doi: 10.1016/j.cemconres.2007.10.007 [4] 何世钦,贡金鑫. 弯曲荷载作用对混凝土中氯离子扩散的影响[J]. 建筑材料学报,2005,8(2): 134-138. doi: 10.3969/j.issn.1007-9629.2005.02.004HE Shiqin, GONG Jinxin. Influence of flexural loading on permeability of chloride ion in concrete[J]. Journal of Building Materials, 2005, 8(2): 134-138. doi: 10.3969/j.issn.1007-9629.2005.02.004 [5] SAHMARAN M. Effect of flexure induced transverse crack and self-healing on chloride diffusivity of reinforced mortar[J]. Journal of Materials Science, 2007, 42(22): 9131-9136. doi: 10.1007/s10853-007-1932-z [6] ZHU H, HUO Q, FAN J, et al. The depth-width correlation for shrinkage-induced cracks and its influence on chloride diffusion into concrete[J]. Materials, 2020, 13(12): 2751. doi: 10.3390/ma13122751 [7] 张菊辉,刘颖慧,时哲敏. 氯离子在开裂混凝土中的扩散特性研究[J]. 建筑材料学报,2018,21(2): 299-303. doi: 10.3969/j.issn.1007-9629.2018.02.020ZHANG Juhui, LIU Yinghui, SHI Zhemin. Diffusion property of chloride in cracked concrete[J]. Journal of Building Materials, 2018, 21(2): 299-303. doi: 10.3969/j.issn.1007-9629.2018.02.020 [8] LI Y, CHEN X, JIN L, et al. Experimental and numerical study on chloride transmission in cracked concrete[J]. Construction and Building Materials, 2016, 127(30): 425-435. doi: 10.1016/j.conbuildmat.2016.10.044 [9] JANG S Y, KIM B S, OH B H. Effect of crack width on chloride diffusion coefficients of concrete by steady-state migration tests[J]. Cement and Concrete Research, 2011, 41(1): 9-19. doi: 10.1016/j.cemconres.2010.08.018 [10] ISMAIL M, TOUMI A, FRANÇOIS R, et al. Effect of crack opening on the local diffusion of chloride in cracked mortar samples[J]. Cement and Concrete Research, 2008, 38(8/9): 1106-1111. doi: 10.1016/j.cemconres.2008.03.009 [11] 张斌,陈红帅,张权,等. 细观层次开裂混凝土中氯离子扩散数值模拟[J]. 公路交通科技(应用技术版),2020,16(6): 124-129. [12] GÉRARD B, MARCHAND J. Influence of cracking on the diffusion properties of cement-based materials:part I:influence of continuous cracks on the steady-state regime[J]. Cement and Concrete Research, 2000, 30(1): 37-43. doi: 10.1016/S0008-8846(99)00201-X [13] KWON S J, NA U J, PARK S S, et al. Service life prediction of concrete wharves with early-aged crack:Probabilistic approach for chloride diffusion[J]. Structural Safety, 2009, 31(1): 75-83. doi: 10.1016/j.strusafe.2008.03.004 [14] PARK S S, KWON S J, JUNG S H. Analysis technique for chloride penetration in cracked concrete using equivalent diffusion and permeation[J]. Construction and Building Materials, 2012, 29: 183-192. doi: 10.1016/j.conbuildmat.2011.09.019 [15] 马俊军,蔺鹏臻. 混凝土桥梁中氯离子传输的元胞自动机模型[J]. 铁道科学与工程学报,2018,15(12): 3135-3140.MA Junjun, LIN Pengzhen. Cellular automata model for chloride ion transport in concrete bridges[J]. Journal of Railway Science and Engineering, 2018, 15(12): 3135-3140. [16] BIONDINI F, BONTEMPI F, FRANGOPOL D M, et al. Cellular automata approach to durability analysis of concrete structures in aggressive environments[J]. Journal of Structural Engineering, 2004, 130(11): 1724-1737. doi: 10.1061/(ASCE)0733-9445(2004)130:11(1724) [17] DU X, JIN L, ZHANG R, et al. Effect of cracks on concrete diffusivity:a meso-scale numerical study[J]. Ocean Engineering, 2015, 108: 539-551. doi: 10.1016/j.oceaneng.2015.08.054 [18] SCHUTTER G D. Quantification of the influence of cracks in concrete structures on carbonation and chloride penetration[J]. Magazine of Concrete Research, 1999, 51(6): 427-435. doi: 10.1680/macr.1999.51.6.427 -

下载:

下载: