Numerical Analysis of Seismic Energy Dissipation Performance of Corrugated Steel Plate Shear Wall with Low Yield Point

-

摘要:

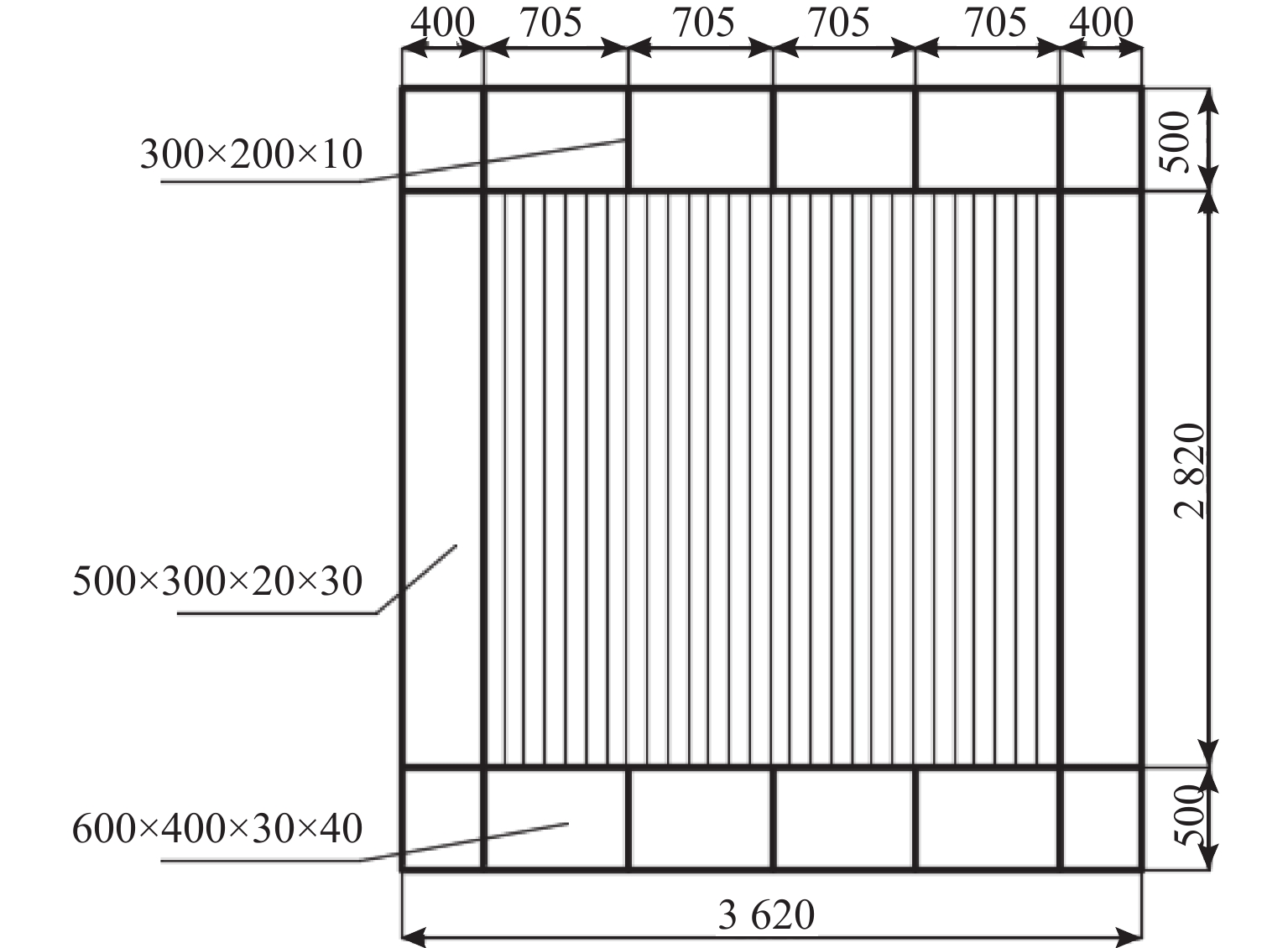

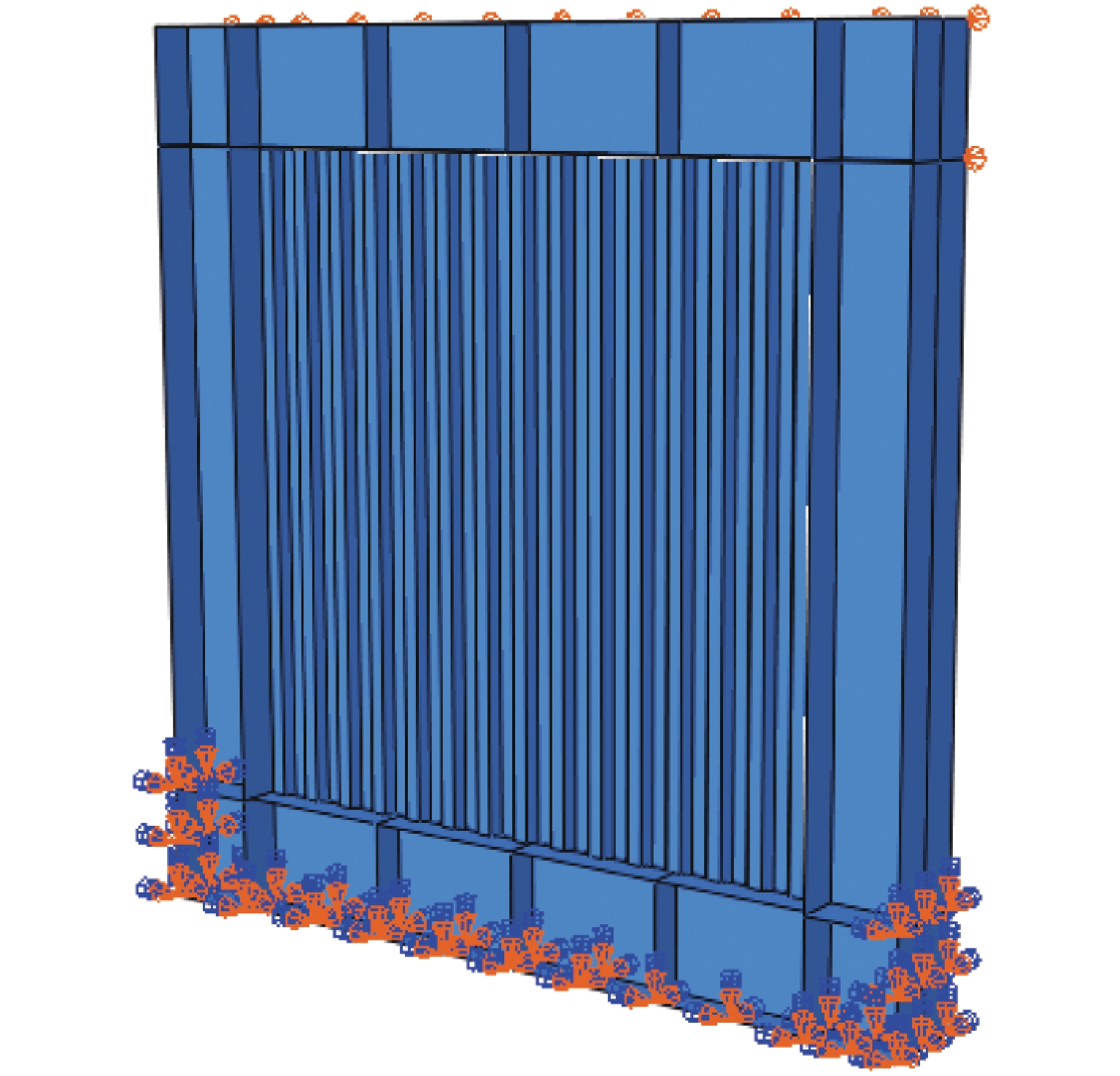

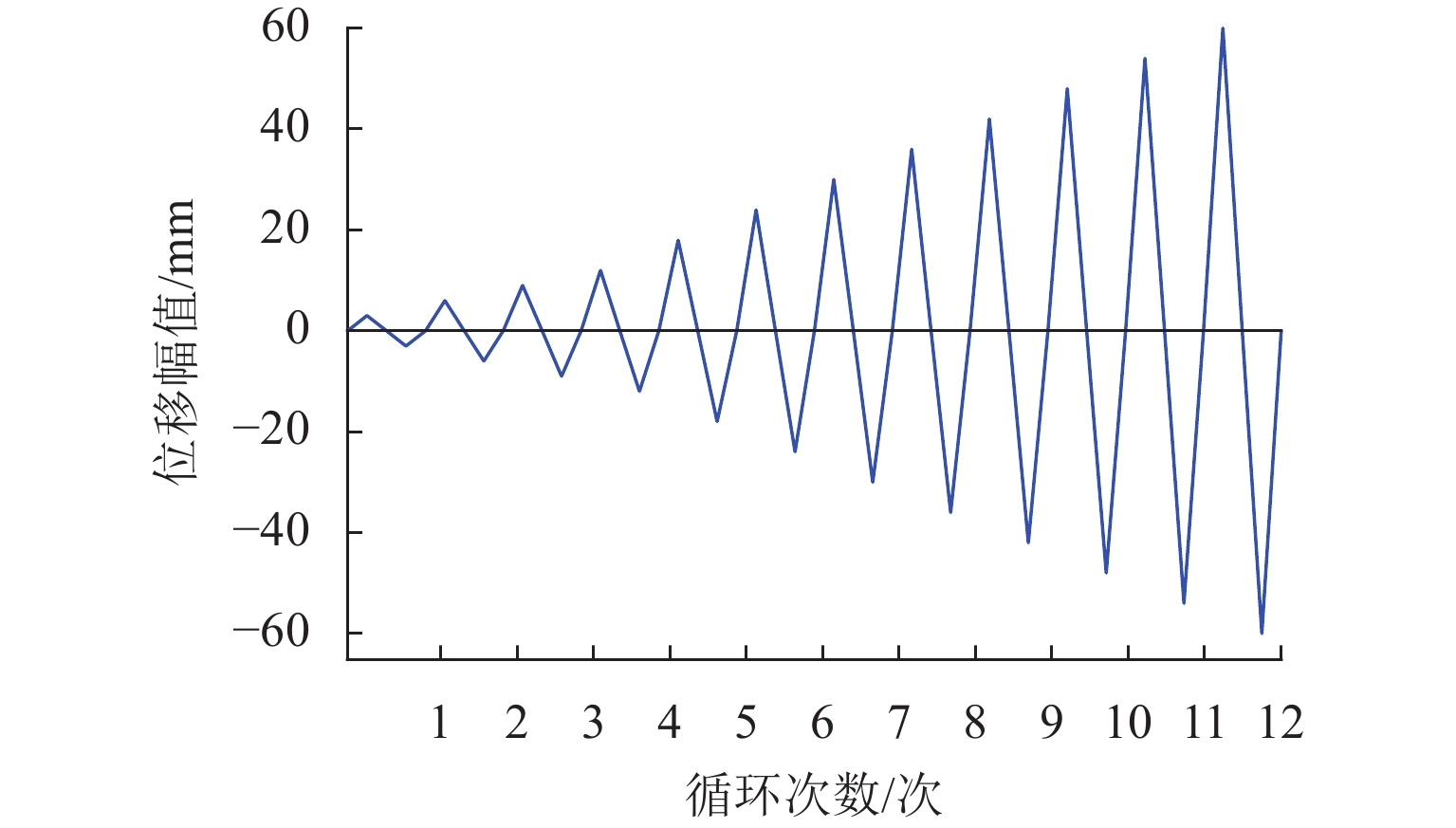

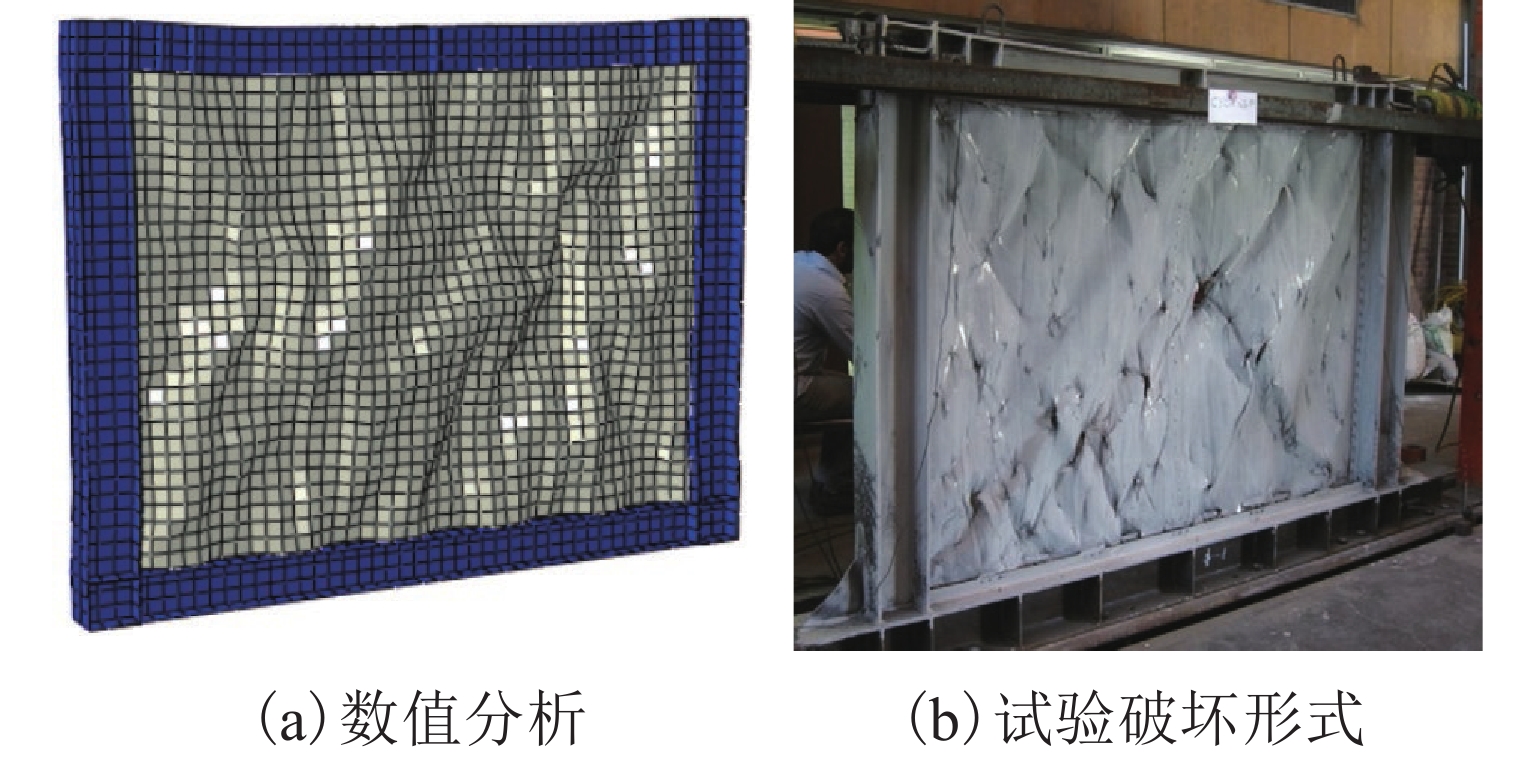

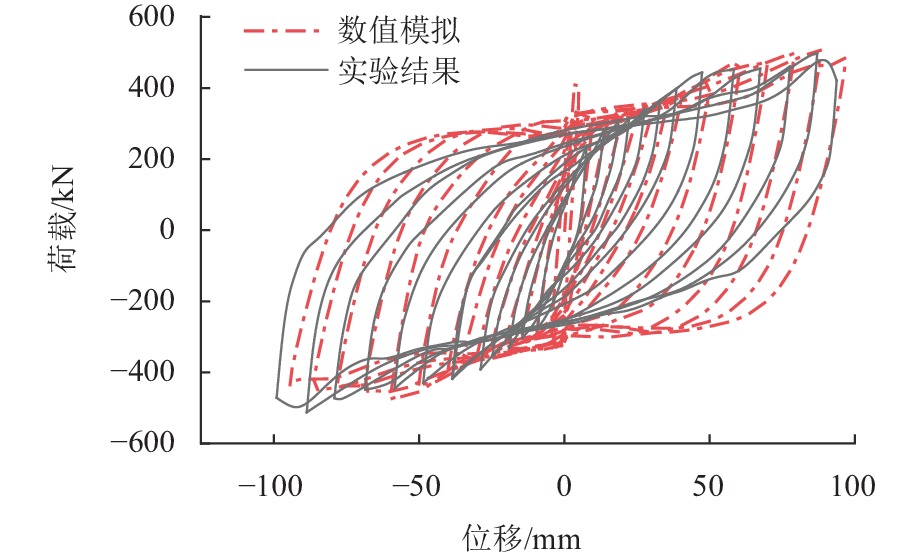

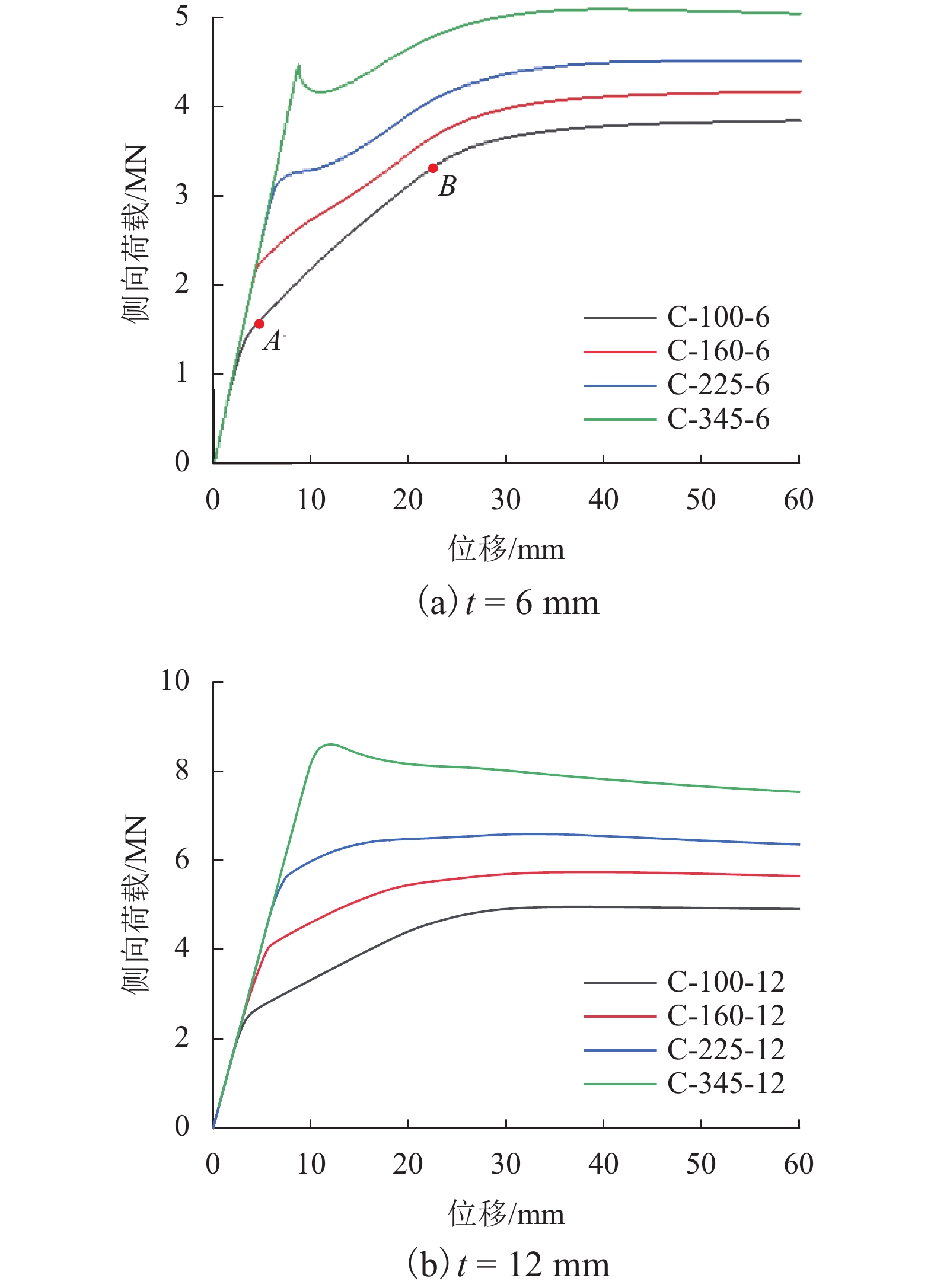

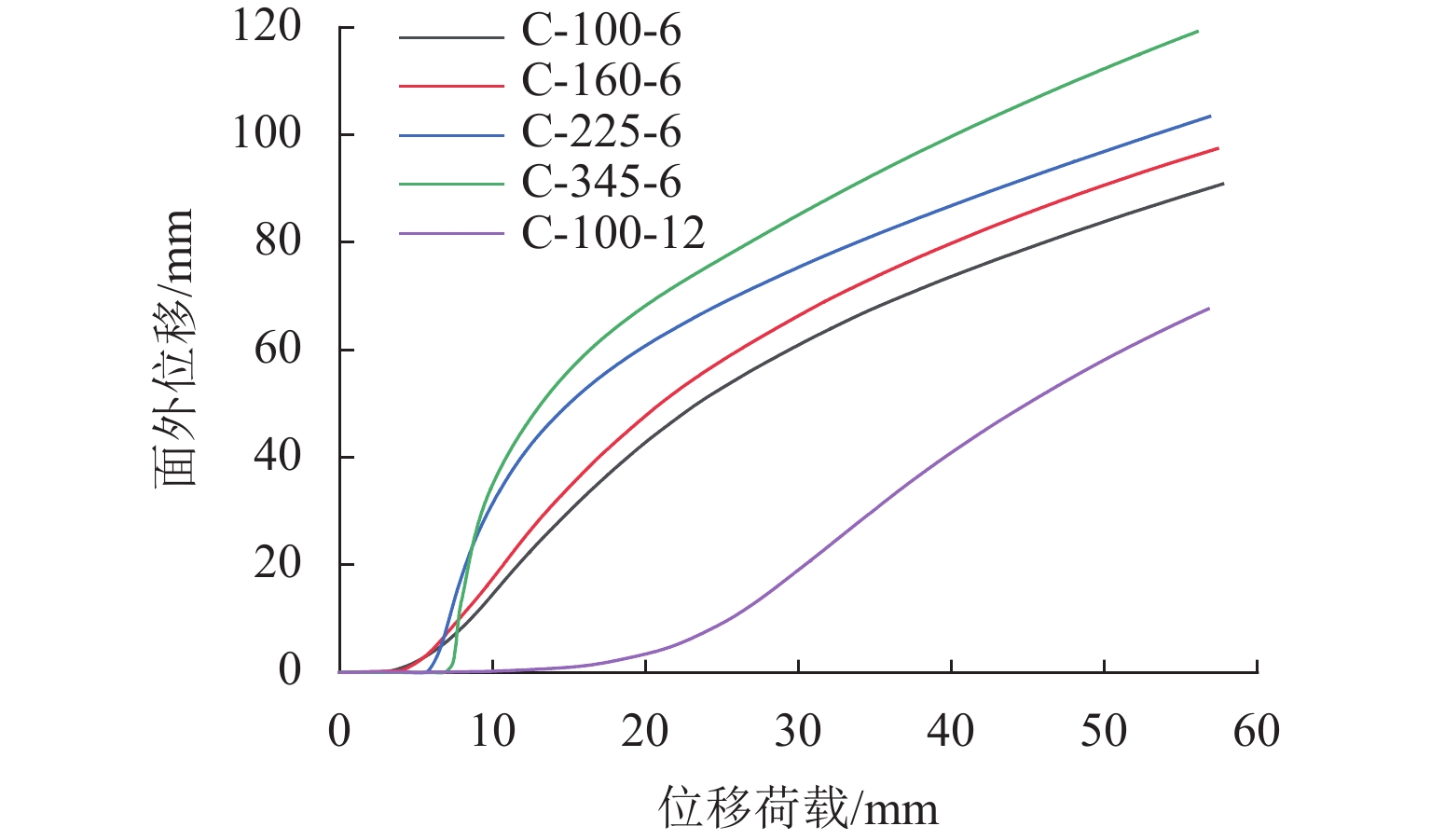

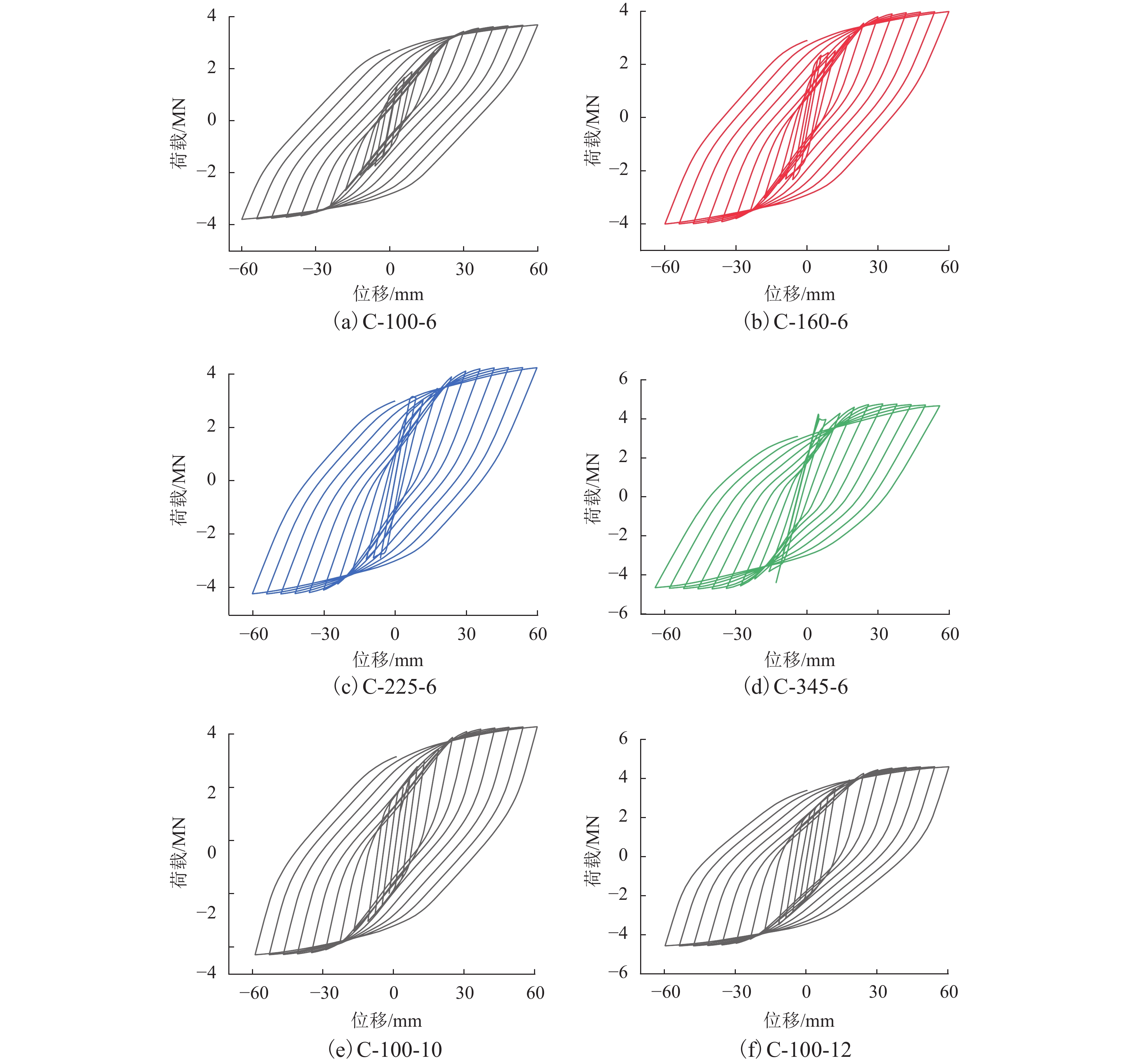

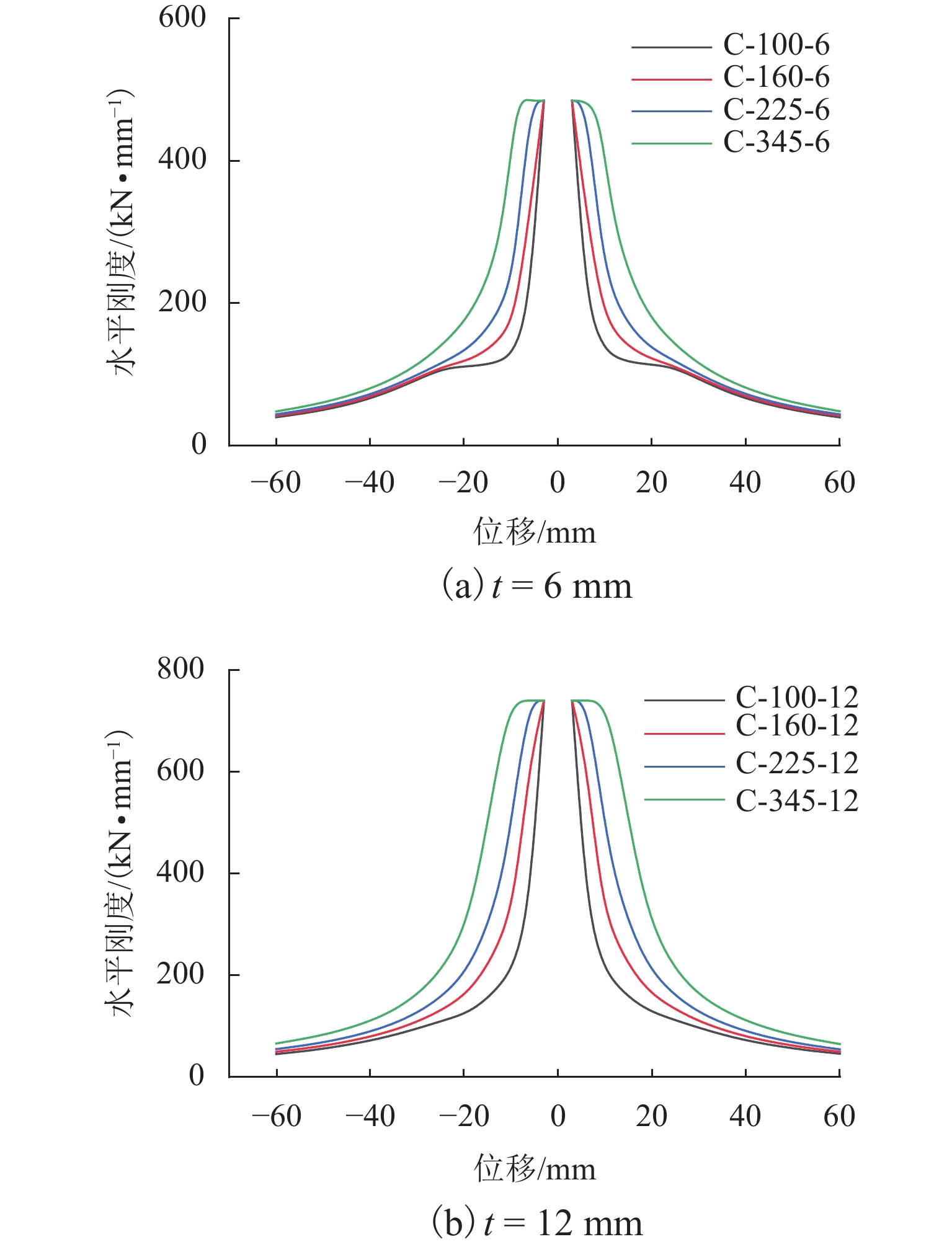

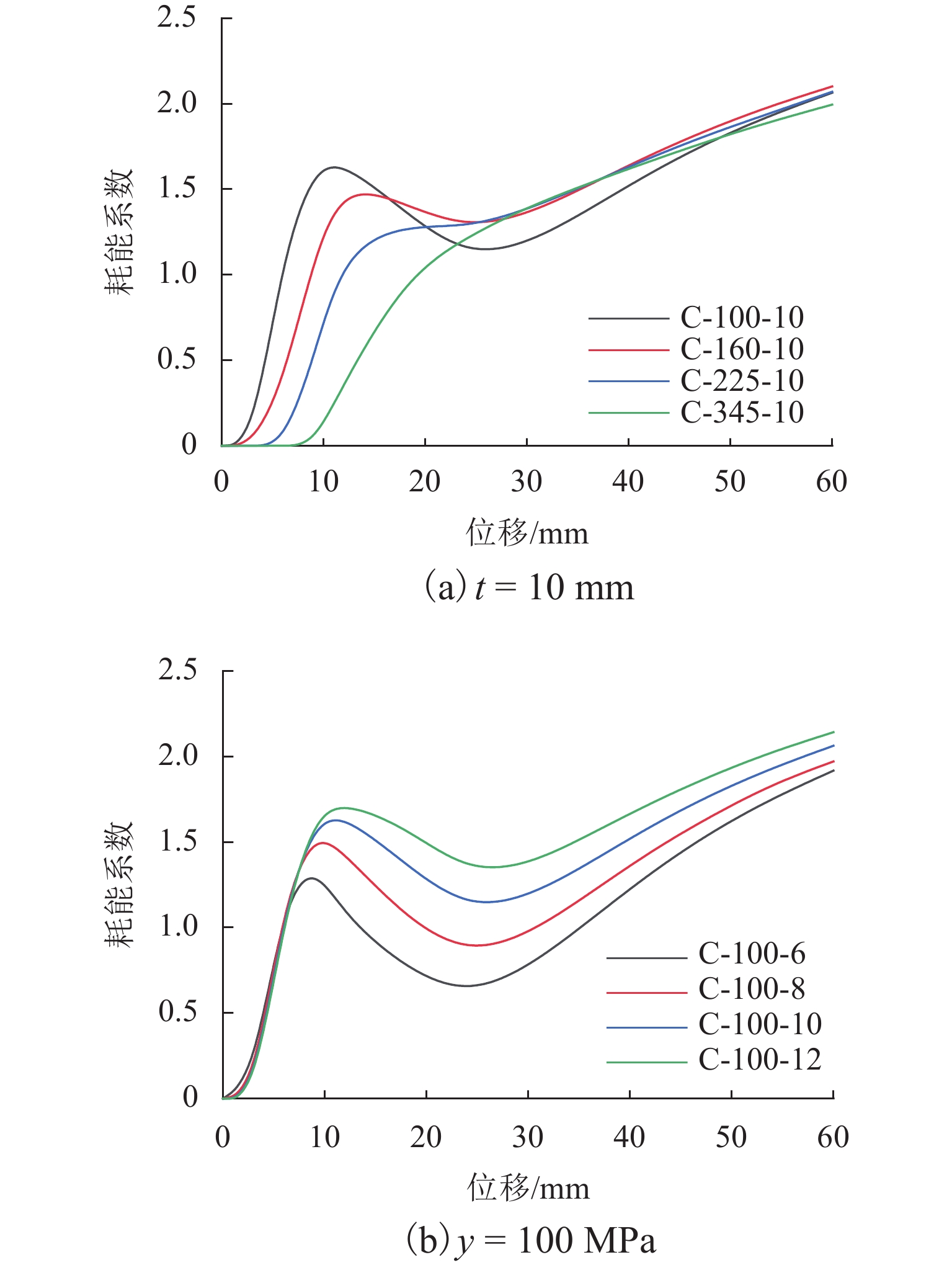

为了研究低屈服点波形钢板剪力墙(corrugated steel plate shear wall,CSPSW)新型抗侧向荷载系统减震耗能性能,利用有限元软件ABAQUS,对16个CSPSW有限元模型进行横向单调和循环荷载作用下的减震耗能性能数值分析,并以波形钢板屈服强度和板厚为关键参数,综合分析其对结构抗侧性能、滞回性能、刚度退化、延性和能量耗散等性能的影响规律. 研究结果表明:低屈服点CSPSW与普通钢板剪力墙初始刚度相同,但抗侧性能弱于后者;与普通屈服强度CSPSW相比,低屈服点CSPSW滞回曲线更饱满,耗能性能更好,且延性更好;随着波形钢板屈服强度降低,低屈服点CSPSW延性和耗能性能均提高,结构水平刚度退化加快;随着波形钢板厚度增大,低屈服点CSPSW初始刚度和结构耗能性能均提高,承载能力变化较小.

Abstract:In order to study the seismic performance of low-yield-point corrugated steel plate shear walls (CSPSWs), a new type of lateral-resistant load system, the finite element software ABAQUS was used to numerically analyze the seismic energy dissipation behavior of 16 CSPSWs under lateral monotonic and cyclic loads. The yield strength and thickness of the infill CSPSWs were selected as the key parameters in the parametric study of the new wall system to assess their impact on the lateral resistance performance, hysteresis performance, stiffness degradation, ductility, and energy dissipation. The results show that the low-yield-point CSPSWs possess the same initial stiffness as that of the ordinary steel plate shear wall, but has a weaker lateral resistance than the latter. Compared with the ordinary-yield-strength CSPSWs, the low-yield-point CSPSWs is capable of developing a fuller hysteresis curve. The energy dissipation and ductility of the new wall system are also better than those of the ordinary-yield-strength CSPSWs. As the yield strength of the CSPSWs decreases, the ductility and energy dissipation of the low-yield-point CSPSWs increase, and the degradation of structural horizontal stiffness accelerates. As the thickness of the low-yield-point stress CSPSWs increases, the initial rigidity and structural energy dissipation increase, while the load-bearing capacity changes less.

-

表 1 低屈服点CSPSW模型特征描述

Table 1. Characteristic description of low-yield-point CSPSW models

y/MPa t/mm 100 6、8、10、12 160 225 345 表 2 特征位移和延性系数

Table 2. Characteristic displacement and ductility factor

模型编号 屈服位移/mm 极限位移/mm μ C-100-6 3.00 60.00 20.00 C-160-6 4.00 60.00 15.00 C-225-6 5.98 60.00 10.04 C-345-6 7.47 60.00 8.03 C-100-8 3.00 60.00 20.00 C-160-8 4.00 60.00 15.00 C-225-8 5.87 60.00 10.21 C-345-8 8.75 60.00 6.86 C-100-10 3.00 60.00 20.00 C-160-10 4.94 60.00 12.13 C-225-10 6.94 60.00 8.64 C-345-10 9.66 60.00 6.21 C-100-12 3.00 60.00 20.00 C-160-12 4.94 60.00 12.13 C-225-12 6.96 60.00 8.61 C-345-12 9.93 34.35 3.46 -

[1] 黄育琪. 低屈服点钢板剪力墙力学性能研究[D]. 西安: 西安建筑科技大学, 2013. [2] 赵秋红,李楠,孙军浩. 波纹钢板剪力墙结构的抗侧性能分析[J]. 天津大学学报(自然科学与工程技术版),2016,49(增1): 152-160.ZHAO Qiuhong, LI Nan, SUN Junhao. Analysis on lateral performance of sinusoidally corrugated steel plate shear walls[J]. Journal of Tianjin University (Science and Technology), 2016, 49(S1): 152-160. [3] 谭平,魏瑶,李洋,等. 波纹钢板剪力墙抗震性能试验研究[J]. 土木工程学报,2018,51(5): 8-15. doi: 10.15951/j.tmgcxb.2018.05.002TAN Ping, WEI Yao, LI Yang, et al. Experimental investigation on performance of corrugated steel plate shear wall[J]. China Civil Engineering Journal, 2018, 51(5): 8-15. doi: 10.15951/j.tmgcxb.2018.05.002 [4] EMAMI F, MOFID M, VAFAI A. Experimental study on cyclic behavior of trapezoidally corrugated steel shear walls[J]. Engineering Structures, 2013, 48: 750-762. doi: 10.1016/j.engstruct.2012.11.028 [5] 李志安,王伟,吴泽锋,等. 波形钢板剪力墙滞回性能有限元分析[J]. 施工技术,2018,47(15): 8-12.LI Zhian, WANG Wei, WU Zefeng. Finite element analysis of hysteretic behavior of corrugated steel plate shear wall[J]. Construction Technology, 2018, 47(15): 8-12. [6] 孙军浩. 波纹钢板剪力墙的抗侧及抗震性能研究[D]. 天津: 天津大学, 2016. [7] KALALI H, GHAZIJAHANI T G, HAJSADEGHI M, et al. Numerical study on steel shear walls with sinusoidal corrugated plates[J]. Latin American Journal of Solids and Structures, 2016, 13(15): 2802-2814. doi: 10.1590/1679-78252837 [8] 赵秋红,邱静,李楠,等. 梯形波纹钢板剪力墙抗震性能试验研究[J]. 建筑结构学报,2018,39(增2): 112-120.ZHAO Qiuhong, QIU Jing, LI Nan, et al. Experimental study on seismic performance of trapezoidally corrugated steel plate shear walls[J]. Journal of Building Structures, 2018, 39(S2): 112-120. [9] 郑宏,杨瑞鹏,王玮,等. 往复加载下十字加劲波纹钢板剪力墙的滞回性能分析[J]. 结构工程师,2021,37(1): 15-23.ZHENG Hong, YANG Ruipeng, WANG Wei, et al. Hysteresis performance analysis of shear wall with cross-stiffening corrugated steel plate under cyclic loading[J]. Structural Engineers, 2021, 37(1): 15-23. [10] 施刚,王珣,高阳,等. 国产低屈服点钢材循环加载试验研究[J]. 工程力学,2018,35(8): 30-38. doi: 10.6052/j.issn.1000-4750.2017.08.0617SHI Gang, WANG Xun, GAO Yang, et al. Experimental study on domestic low yield point steels under cyclic loading[J]. Engineering Mechanics, 2018, 35(8): 30-38. doi: 10.6052/j.issn.1000-4750.2017.08.0617 [11] 中国工程建设标准化协会. 波纹腹板钢结构技术规程: CECS 291—2011[S]. 北京: 中国计划出版社, 2011. [12] Canadian Standards Association (CSA). Limit states design of steel structures: CAN/CSA S16[S]. Ontario: [s.n.], 1994. [13] Canadian Standards Association (CSA). Limit states design of steel structures: CAN/CSA S16-01[S]. Ontario: [s.n.], 2001. [14] 中国工程建设标准化协会. 波纹腹板钢结构技术规程CECS291—2001[S]. 北京: 中国计划出版社, 2012. [15] 中华人民共和国铁道部. 建筑抗震设计规范: GB 50011—2010[S]. 北京: 中国建筑工业出版社, 2010. [16] SABOURI-GHOMI S, VENTURA C E, KHARRAZI M H. Shear analysis and design of ductile steel plate walls[J]. Journal of Structural Engineering, 2005, 131(6): 878-889. doi: 10.1061/(ASCE)0733-9445(2005)131:6(878) [17] 顾强. 钢结构滞回性能及抗震设计[M]. 北京: 中国建筑工业出版社, 2009: 431-432. -

下载:

下载: