Experimental Study on Bearing Capacity of Geosynthetic-Encased Recycled Concrete Aggregate Column

-

摘要:

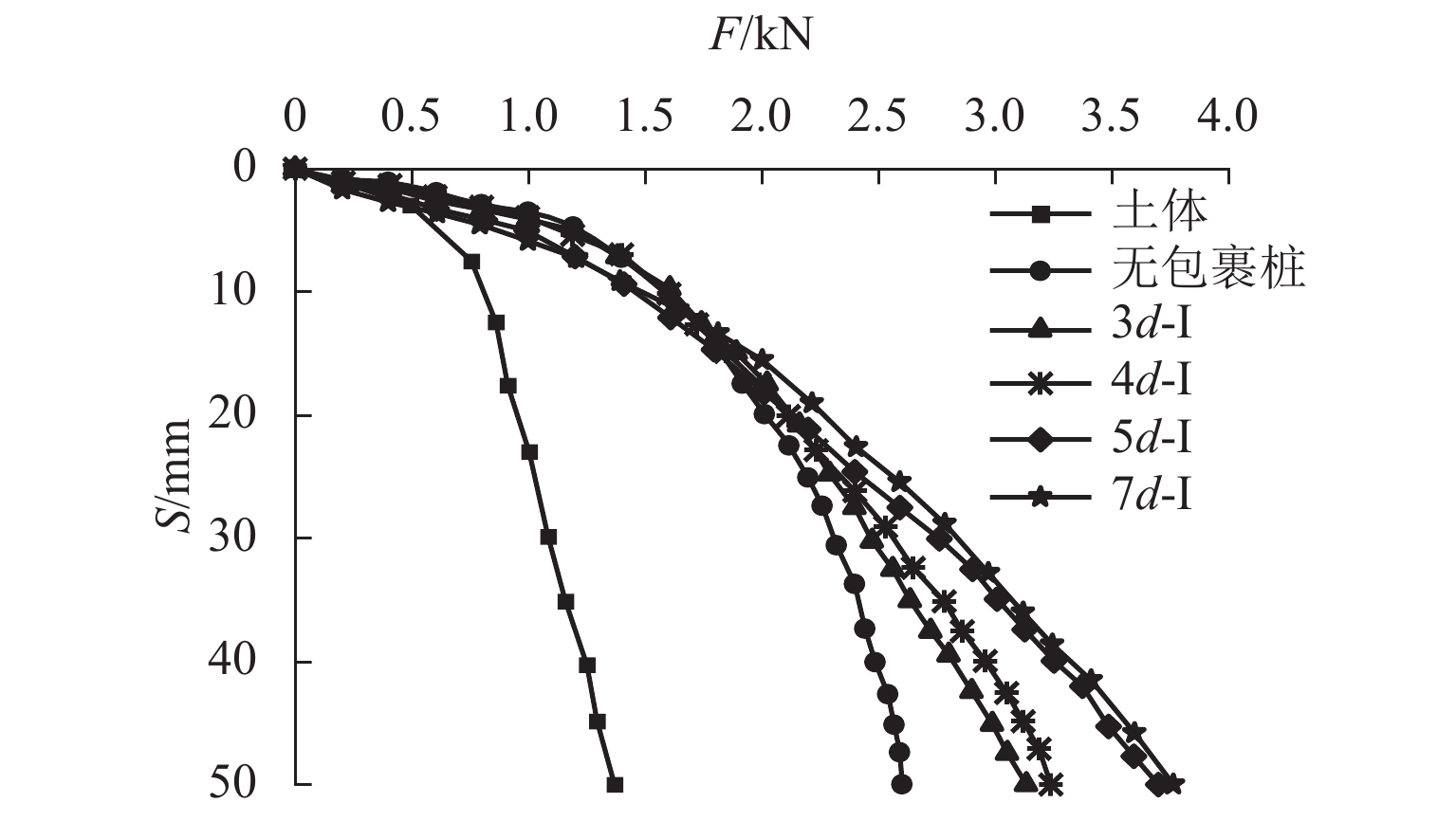

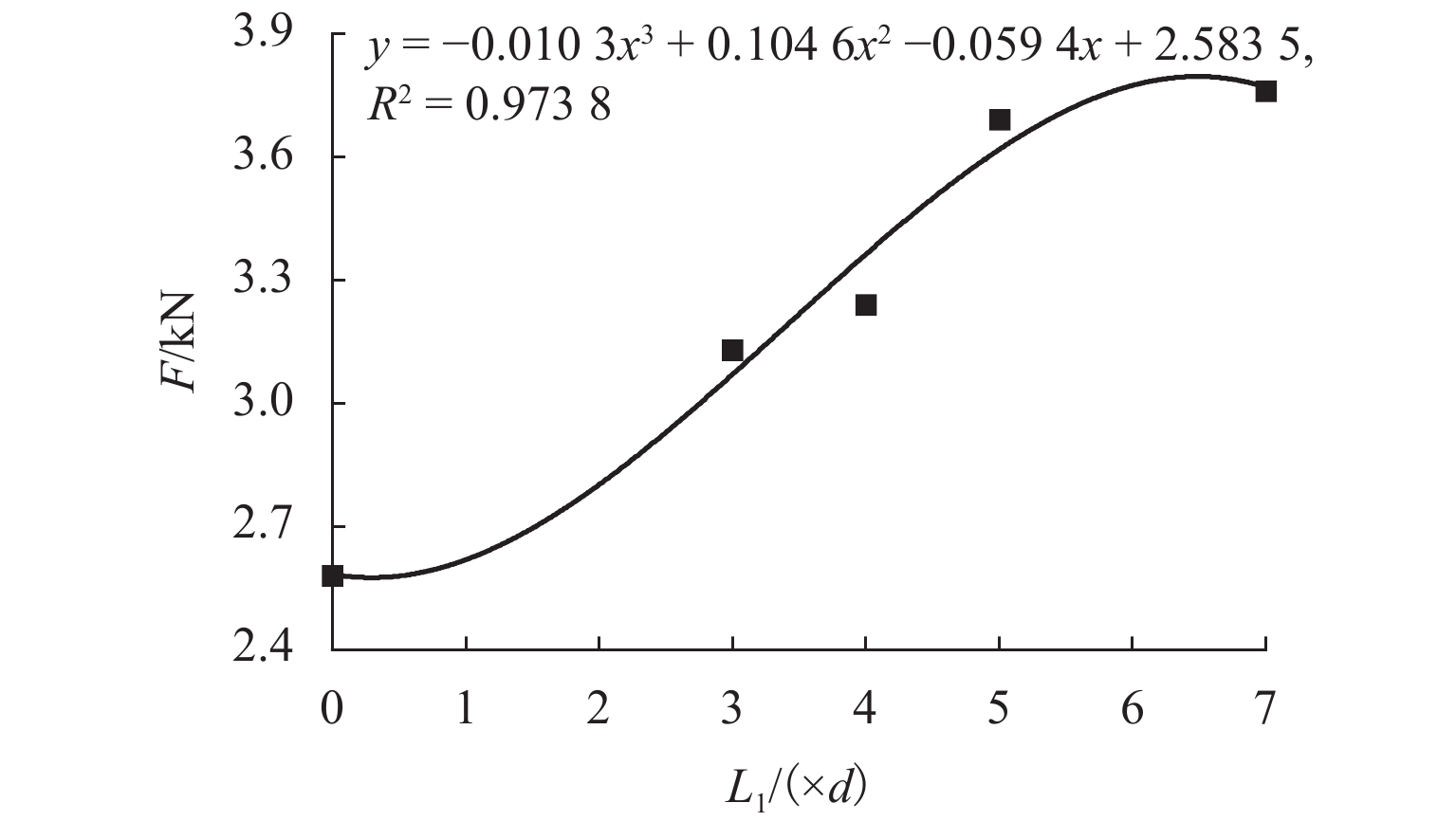

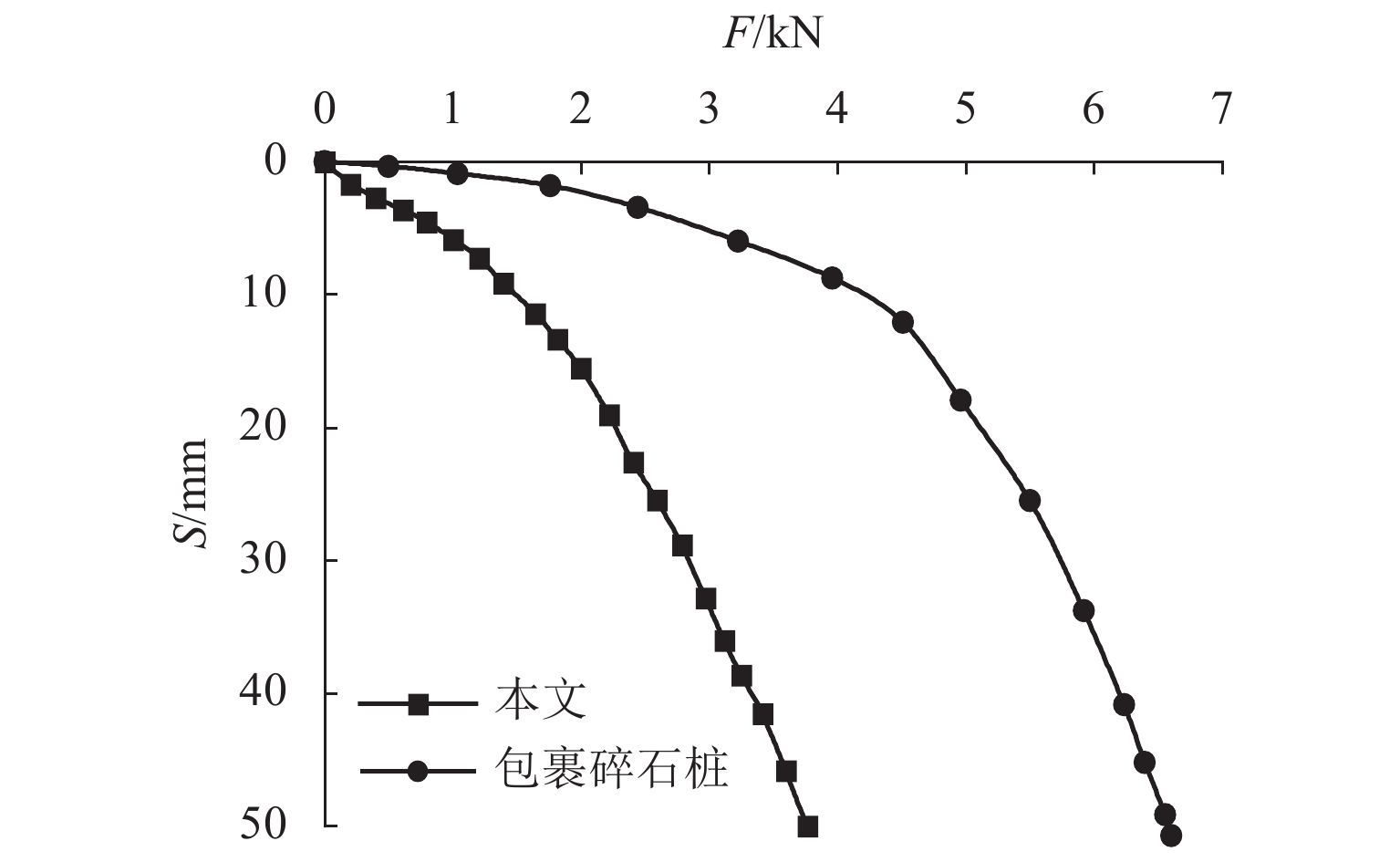

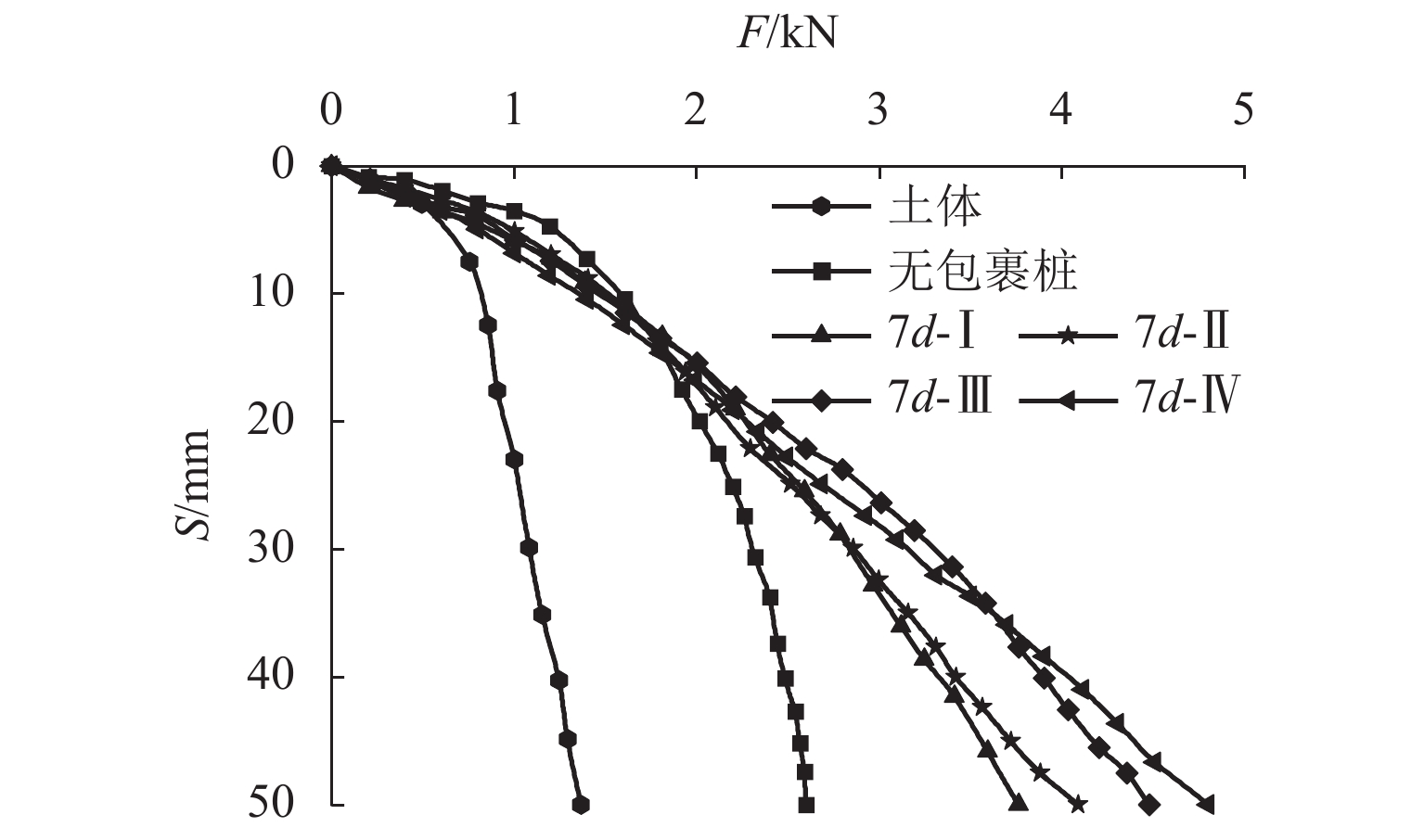

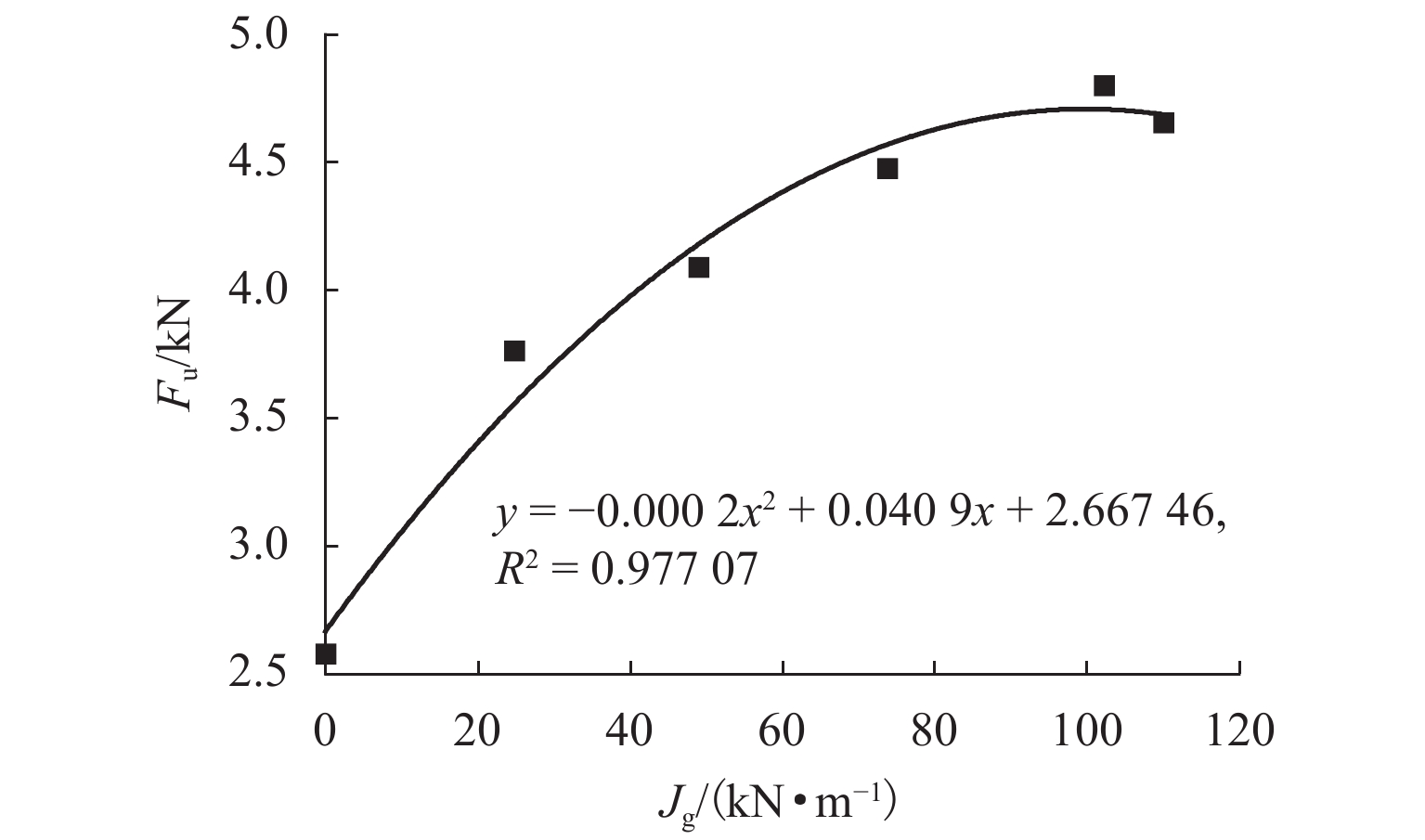

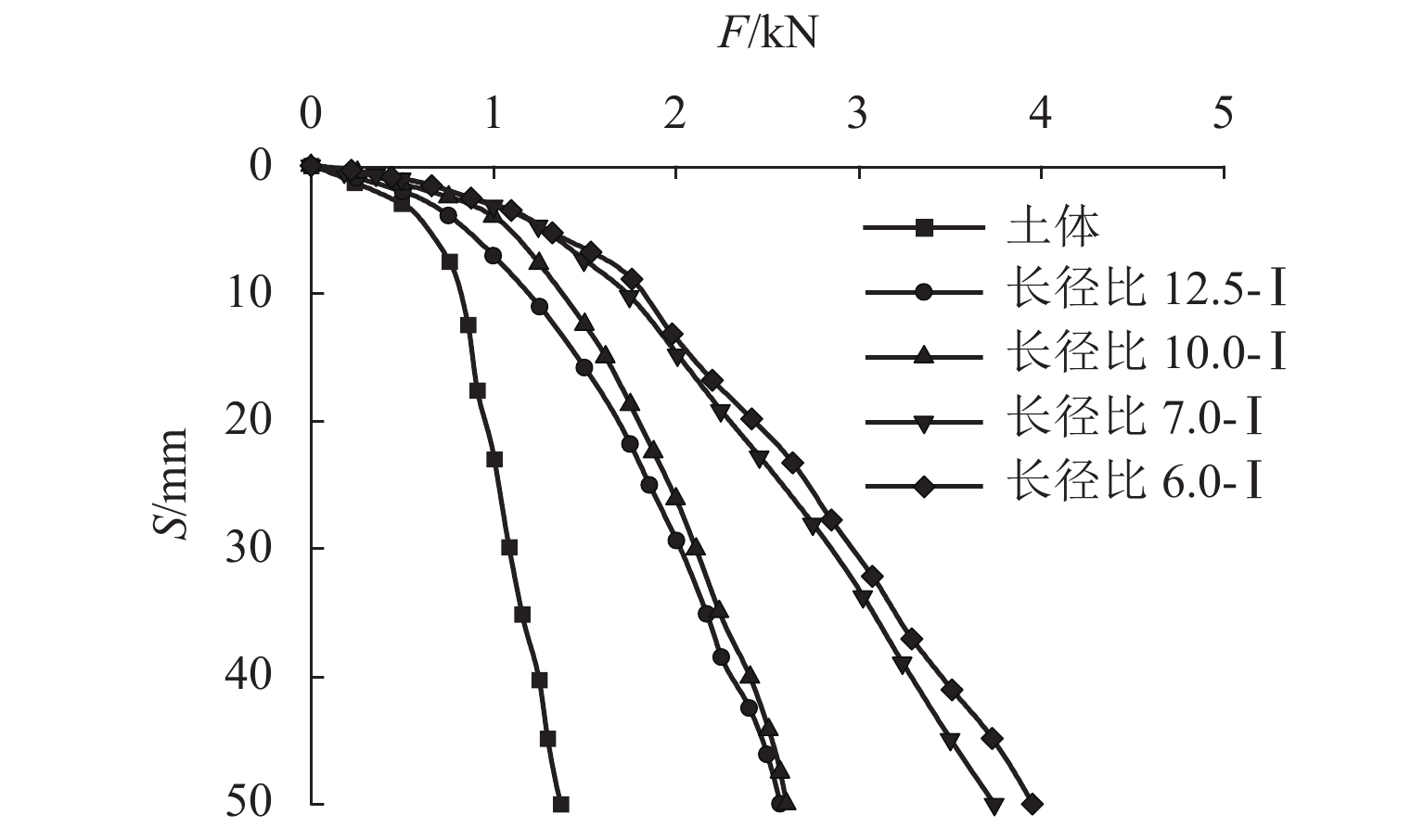

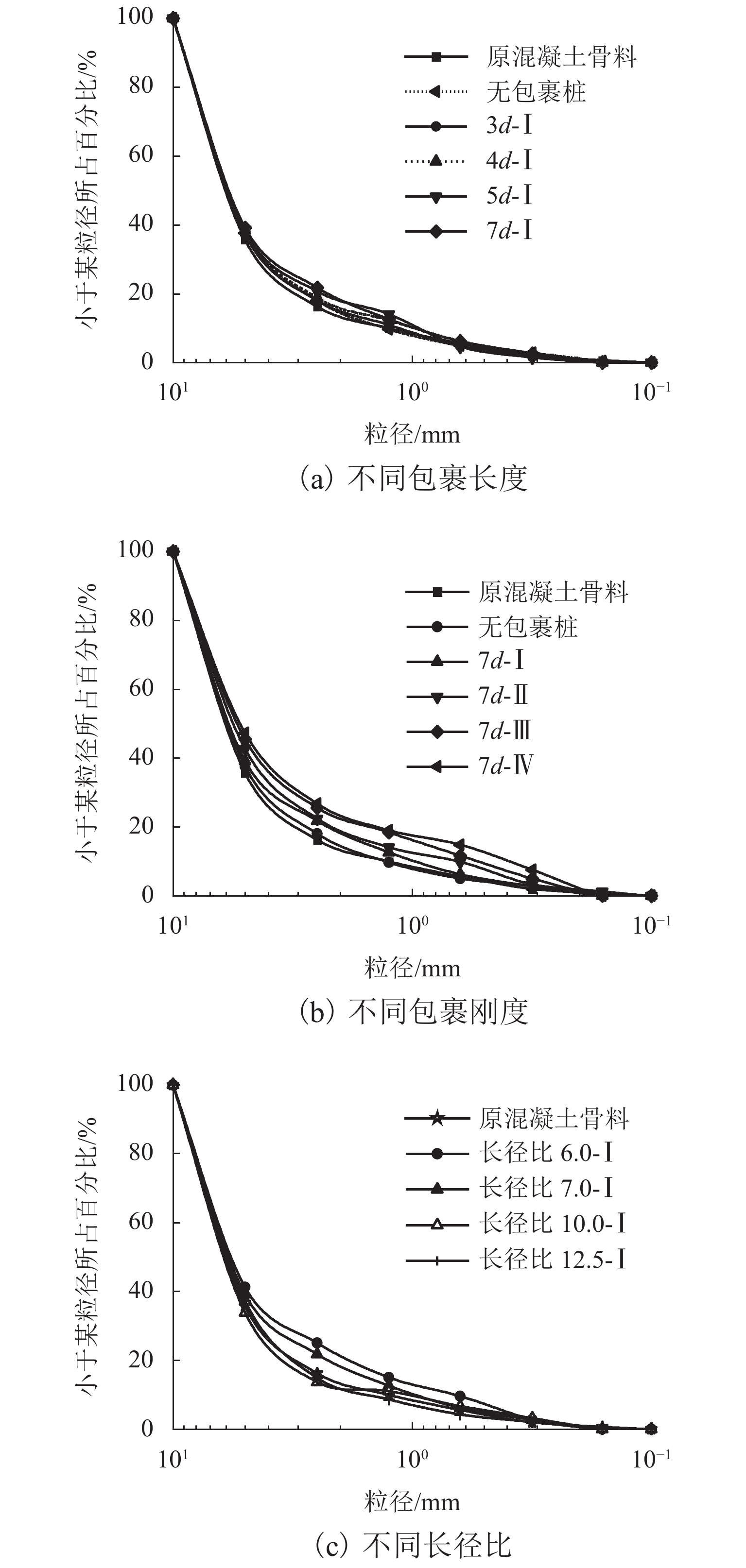

采用再生混凝土骨料替换包裹碎石桩碎石芯料,形成一种新型地基处理方式——再生混凝土骨料包裹桩,以改善采用包裹碎石桩处理液化及软弱土地基时碎石强度未能充分发挥的问题. 开展了模型试验,研究包裹长度、刚度及长径比对再生混凝土骨料包裹桩单桩承载特性和骨料破碎度的影响. 研究结果表明:包裹长度为1倍~6倍桩径时,延长包裹长度可显著提高桩体承载力,包裹长度小于1倍或大于6倍桩径时,包裹长度对承载力改善不明显;包裹材料的临界刚度约为100 kN/m,当小于临界刚度时,增加包裹刚度能显著提高桩体承载力,大于临界刚度时,增加包裹刚度不再明显改善桩体承载力;再生混凝土骨料包裹桩桩长不变时,长径比大于10的桩体承载力较低,桩体主要在10~30 cm深度内产生不同程度的局部弯曲,长径比小于7的桩体承载力较高,桩体主要发生轻微鼓胀变形,无局部弯曲;混凝土骨料的破碎度与桩体能承受的极限荷载呈正相关,增加包裹长度、刚度及桩径均会增加芯料的破碎度. 因此,进行再生混凝土骨料包裹桩单桩设计时应充分考虑包裹长度、刚度和长径比与芯料破碎度之间的关系,以获取最优设计方案.

Abstract:Recycled concrete aggregates are used to replace the gravel core material of encased stone columns, forming a new foundation treatment method—recycled concrete aggregate encased column, to improve the problem that the gravel strength cannot be fully exerted when the encased stone column is used to treat liquefied and soft soil foundations. Laboratory model tests were performed to study the effect of encasement length, stiffness, and the ratio of column length to diameter on the bearing characteristics and aggregate fragmentation degree of the encased recycled concrete aggregate column. The results show that when the length of encasement is 1 to 6 times the column diameter, the bearing capacity of the column can be significantly increased by increasing the encasement length. When the length of encasement is less than 1 or more than 6 times the column diameter, the length change of encasement does not significantly influence the bearing capacity of the column. The critical stiffness of encasement is about 100 kN/m. When the stiffness of the encasement is less than the critical stiffness, increasing the encasement stiffness can prominently improve the bearing capacity of the column. However, when the stiffness of the encasement is greater than the critical stiffness value, increasing the encasement stiffness cannot significantly improve the bearing capacity of the column. When the length of the geosynthetic-encased recycled concrete aggregate column is fixed, columns with a length-to-diameter ratio greater than 10 have a lower bearing capacity, and mainly produce local bending to varying degrees within the depth range from 10 cm to 30 cm, while columns with a length-to-diameter ratio less than 7 have a relatively higher bearing capacity and mainly experience slight bulging deformation without local bending. Besides, there is a positive correlation between the fragmentation degree of the recycled concrete aggregate and the ultimate load that the column can withstand. Increasing the encasement length, stiffness and column diameter will increase the fragmentation degree of the core material. Therefore, when designing a single geosynthetic-encased recycled concrete aggregate column, full consideration should be given to the relationship between the encasement length, stiffness, the ratio of column length to diameter, and the fragmentation degree of the concrete aggregate, to obtain the optimal design scheme.

-

Key words:

- recycled concrete aggregate /

- encased column /

- bearing capacity /

- geosynthetics /

- model tests

-

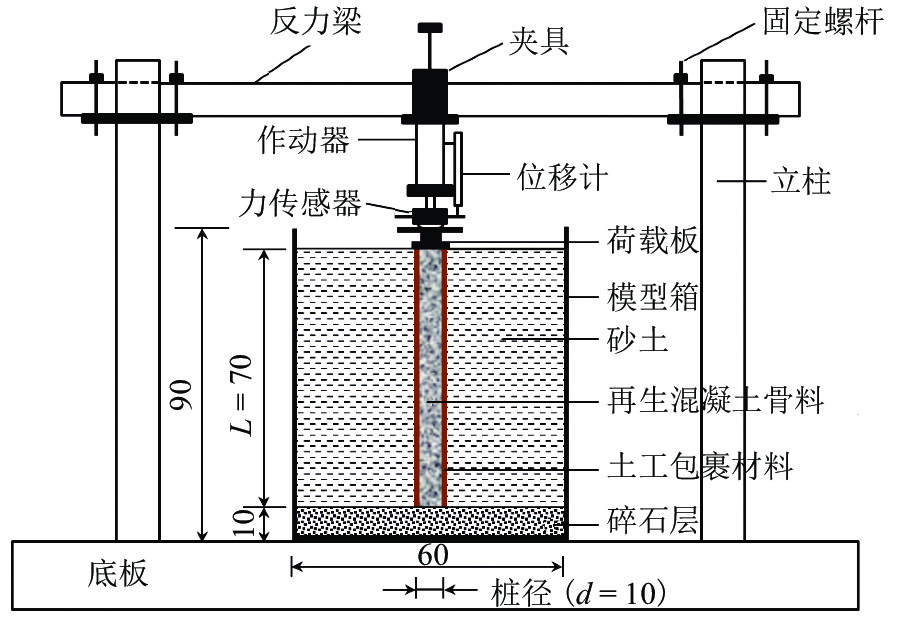

表 1 试验模型相似比

Table 1. Similarity ratio for model test

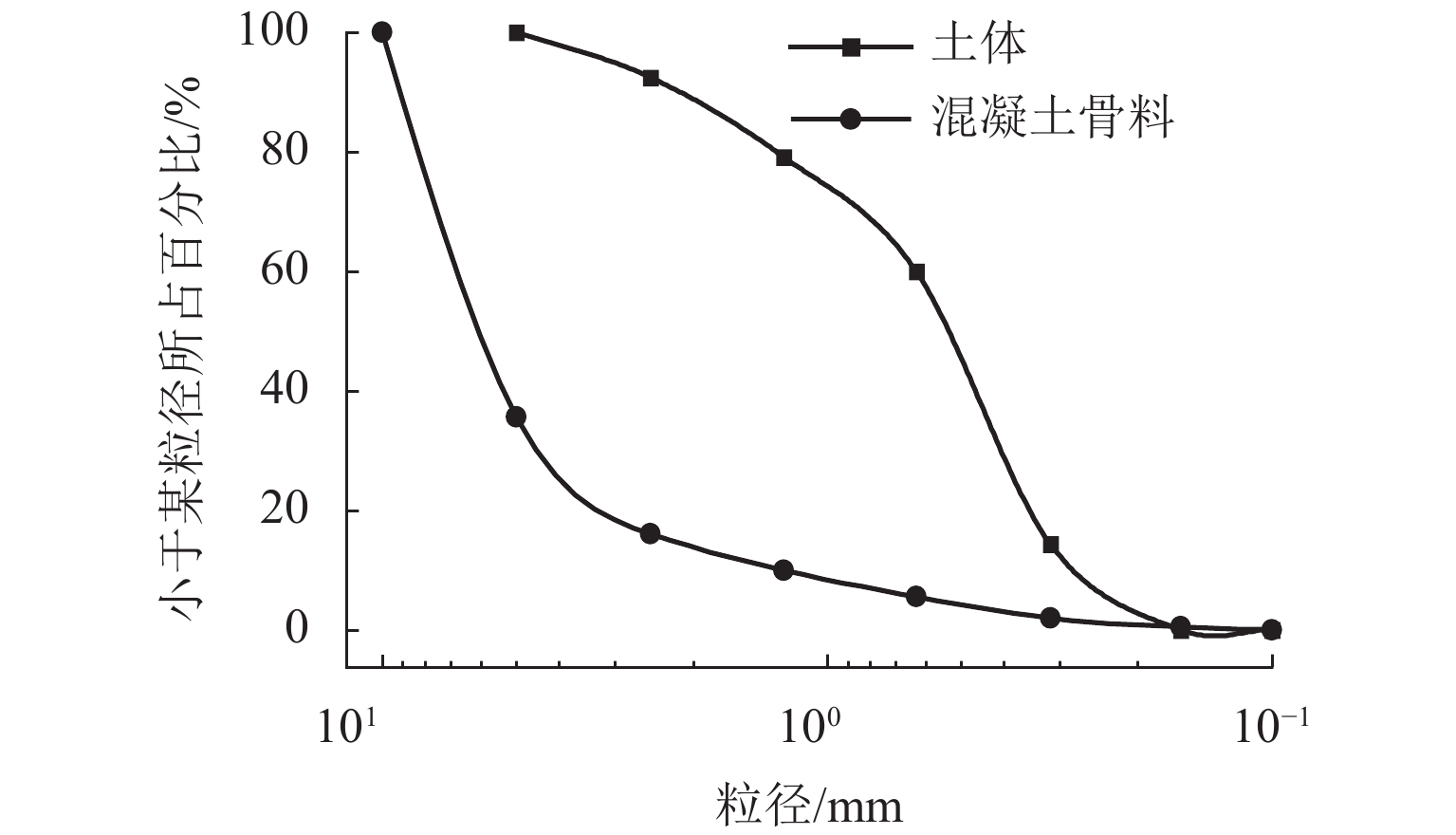

无量纲因子 参数 原型 模型 相似比 π1=lL l/cm 700 70 10 π2=dL d/cm 100 10 10 π3=FρgLA F/kN 5 000 5 1 000 π3=TgρgLtg Tg/ (kN·m−1) 130 13 10 π4=JgρgLtg Jg/ (kN·m−1) 1 400 140 10 表 2 砂土及混凝土骨料参数

Table 2. Properties of soil layers and concrete aggregate

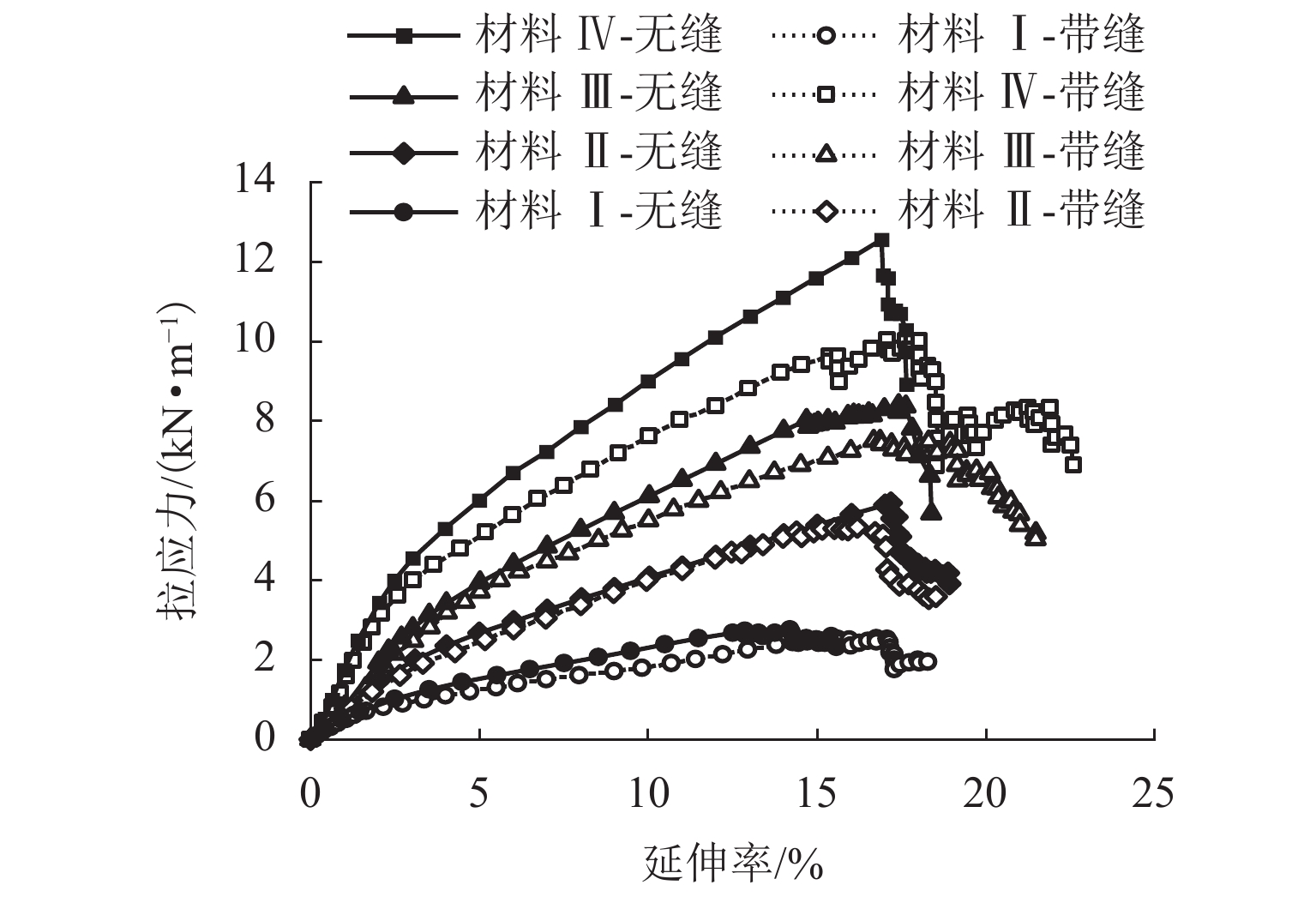

材料 密度/(kg•m−3) 相对密度/% 含水率/% 颗粒密度/(g•cm−3) 内摩擦角/(º) 土体(GP) 1 664.1 55 3 2.65 39.12 再生混凝土骨料(SP) 1 528.0 70 0 2.83 42.00 表 3 包裹材料拉伸强度指标

Table 3. Tensile strength indices of geosynthetics

名称 极限强度/

(kN•m−1)最大延伸率/% 延伸率 5% 的拉应力/

(kN•m−1)包裹材料刚度/

(kN•m−1)材料Ⅰ 2.58 15.42 1.24 24.80 材料Ⅱ 5.21 14.40 2.45 49.00 材料Ⅲ 7.51 16.70 3.69 73.80 材料Ⅳ 10.04 15.33 5.11 102.20 表 4 试验分组

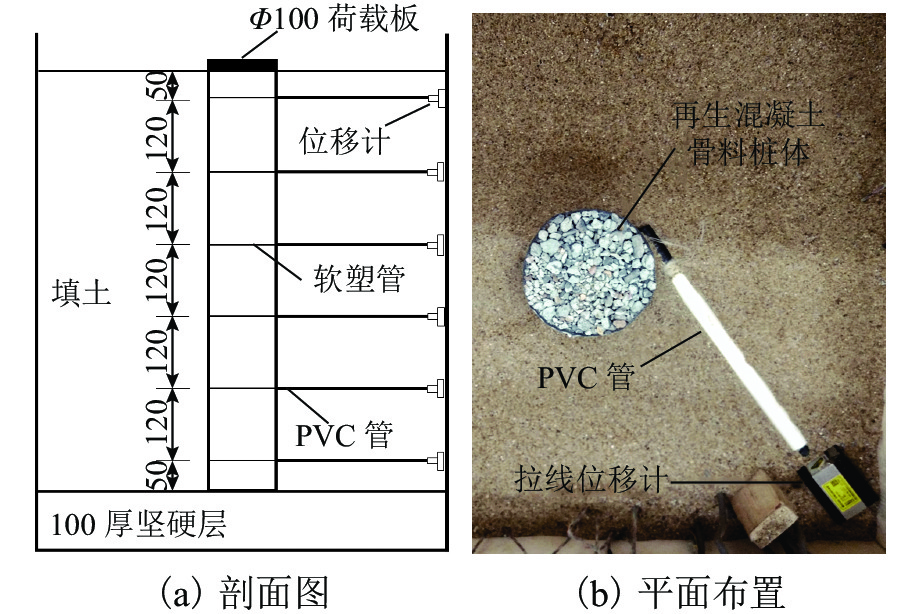

Table 4. Details of group tests

组号 试验工况 d/mm L/mm 包裹长度L1/mm 1 土体 2 无包裹 100 700 0 3 3d- Ⅰ 100 700 300 4 4d- Ⅰ 100 700 400 5 5d- Ⅰ 100 700 500 6 7d- Ⅰ 100 700 700 7 7d- Ⅱ 100 700 700 8 7d- Ⅲ 100 700 700 9 7d- Ⅳ 100 700 700 10 长径比 12.5- Ⅰ 56 700 700 11 长径比 10.0- Ⅰ 70 700 700 12 长径比 6.0- Ⅰ 117 700 700 表 5 包裹桩极限承载力取值

Table 5. Values of ultimate bearing capacity of encased columns

表 6 不同包裹长度下桩的极限荷载

Table 6. Ultimate load of columns with different encased lengths

编号 试验工况 Jg/(kN▪m−1) Fu/kN 1 土体 1.37 2 再生骨料桩 0 2.58 3 3d- Ⅰ 24.8 3.13 4 4d- Ⅰ 24.8 3.24 5 5d- Ⅰ 24.8 3.69 6 7d- Ⅰ 24.8 3.76 表 7 不同包裹刚度下桩体承载力

Table 7. Bearing capacity of columns with different stiffnesses

编号 试验工况 Jg/(kN·m−1) Fu/kN 1 土体 1.37 2 再生骨料桩 0 2.58 3 7d- Ⅰ 24.8 3.76 4 7d- Ⅱ 49.0 4.09 5 7d- Ⅲ 73.8 4.48 6 7d-Ⅳ 102.2 4.82 表 8 混凝土骨料破碎度

Table 8. Degree of fragmentation of concrete aggregate

试验工况 Fu/ kN Br/% 土体 1.36 无包裹桩 2.63 2.48 3d- Ⅰ 3.13 2.37 4d- Ⅰ 3.24 4.14 5d- Ⅰ 3.73 4.87 7d- Ⅰ 3.76 6.27 7d- Ⅱ 4.18 10.33 7d- Ⅲ 4.53 15.41 7d- Ⅳ 4.80 18.22 长径比 12.5- Ⅰ 2.57 0.36 长径比 10.0- Ⅰ 2.60 0 长径比 7.0- Ⅰ 3.76 6.27 长径比 6.0- Ⅰ 4.52 10.38 -

[1] HE Q, SHI S Y, HU M M. Exploring a long-term mechanism of construction and demolition waste recycling: a case of Chongqing[C]//Proceedings of the 17th International Symposium on Advancement of Construction Management and Real Estate. Shenzhen: Springer Berlin Heidelberg, 2013: 109-1120. [2] ALKHORSHID N R, ARAUJO G L S, PALMEIRA E M, et al. Large-scale load capacity tests on a geosynthetic encased column[J]. Geotextiles and Geomembranes, 2019, 47(5): 632-641. doi: 10.1016/j.geotexmem.2019.103458 [3] HUGHES J M O, WITHERS N J. Reinforcing of soft cohesive soils with stone columns[J]. Ground Engineering, 1974, 7(3): 42-49. [4] VAN IMPE W F. Soil improvement techniques and their evolution[J]. Animal Science Papers and Reports, 1989, 20(1): 169-178. [5] RAITHEL M, KEMPFERT H G, KIRCHNER A. Geotextile-encased columns (GEC)for foundation of a dike on very soft soils[C]//In: Proceedings of the Seventh International Conference on Geosynthetics. Nice: [s.n.], 2002: 1025-1028. [6] 欧阳芳,张建经,付晓,等. 包裹碎石桩承载特性试验研究[J]. 岩土力学,2016,37(7): 1929-1936. doi: 10.16285/j.rsm.2016.07.013OUYANG Fang, ZHANG Jianjing, FU Xiao, et al. Experimental analysis of bearing behavior of geosynthetic encased stone columns[J]. Rock and Soil Mechanics, 2016, 37(7): 1929-1936. doi: 10.16285/j.rsm.2016.07.013 [7] TANDEL Y K, SOLANKI C H, DESAI A K. Field behaviour geotextile reinforced sand column[J]. Geomechanics and Engineering, 2014, 6(2): 195-211. doi: 10.12989/gae.2014.6.2.195 [8] MURUGESAN S, RAJAGOPAL K. Geosynthetic-encased stone columns: numerical evaluation[J]. Geotextiles and Geomembranes, 2006, 24(6): 349-358. doi: 10.1016/j.geotexmem.2006.05.001 [9] MALARVIZHI S N, ILAMPARUTHI K. Comparative study on the behavior of encased stone column and conventional stone column[J]. Soils and Foundations, 2007, 47(5): 873-885. doi: 10.3208/sandf.47.873 [10] NAZARI AFSHAR J, GHAZAVI M. Experimental studies on bearing capacity of geosynthetic reinforced stone columns[J]. Arabian Journal for Science and Engineering, 2014, 39(3): 1559-1571. doi: 10.1007/s13369-013-0709-8 [11] MURUGESAN S, RAJAGOPAL K. Studies on the behavior of single and group of geosynthetic encased stone columns[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2010, 136(1): 129-139. doi: 10.1061/(ASCE)GT.1943-5606.0000187 [12] 浙江省住房与城乡建设厅. 复合地基技术规范: GB/T 50783—2012[S]. 北京: 中国计划出版社, 2012 [13] BUCKINGHAM E. On physically similar systems: illustrations of the use of dimensional equations[J]. Physical Review Journals Archive, 1914, 4(4): 345-376. doi: 10.1103/PhysRev.4.345 [14] GHAZAVI M, NAZARI AFSHAR J. Bearing capacity of geosynthetic encased stone columns[J]. Geotextiles and Geomembranes, 2013, 38: 26-36. doi: 10.1016/j.geotexmem.2013.04.003 [15] ASTM D 4595. Standard test method for tensile properties of geotextiles by the wide-width strip method[S].West Conshohocken: American Society for Testing and Materials, 2005 [16] CASTRO J. Numerical modelling of stone columns beneath a rigid footing[J]. Computers and Geotechnics, 2014, 60: 77-87. doi: 10.1016/j.compgeo.2014.03.016 [17] FARAH R E, NALBANTOGLU Z. Behavior of geotextile-encased single stone column in soft soils[J]. Arabian Journal for Science and Engineering, 2020, 45(5): 3877-3890. doi: 10.1007/s13369-019-04299-3 [18] 赵明华,顾美湘,张玲,等. 竖向土工加筋体对碎石桩承载变形影响的模型试验研究[J]. 岩土工程学报,2014,36(9): 1587-1593. doi: 10.11779/CJGE201409003ZHAO Minghua, GU Meixiang, ZHANG Ling, et al. Model tests on influence of vertical geosynthetic-encasement on performance of stone columns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(9): 1587-1593. doi: 10.11779/CJGE201409003 [19] DEBNATH P, DEY A K. Bearing capacity of geogrid reinforced sand over encased stone columns in soft clay[J]. Geotextiles and Geomembranes, 2017, 45(6): 653-664. doi: 10.1016/j.geotexmem.2017.08.006 [20] HATAF N, NABIPOUR N, SADR A. Experimental and numerical study on the bearing capacity of encased stone columns[J]. International Journal of Geo-Engineering, 2020, 11(1): 1-19. doi: 10.1186/s40703-020-0108-4 [21] HARDIN, B O. Crushing of soil particles[J]. Journal of Geotechnical Engineering, 1985, 111: 1177-1192. doi: 10.1061/(ASCE)0733-9410(1985)111:10(1177) 期刊类型引用(1)

1. 王欢,康玲,牟廷敏,周孝军,邹圻. 建筑固废材料资源化再生利用的研究现状. 四川水泥. 2023(12): 118-120 .  百度学术

百度学术其他类型引用(2)

-

下载:

下载:

百度学术

百度学术