Particle Discrete Element Layered Modeling Method and Particle Size Effect

-

摘要:

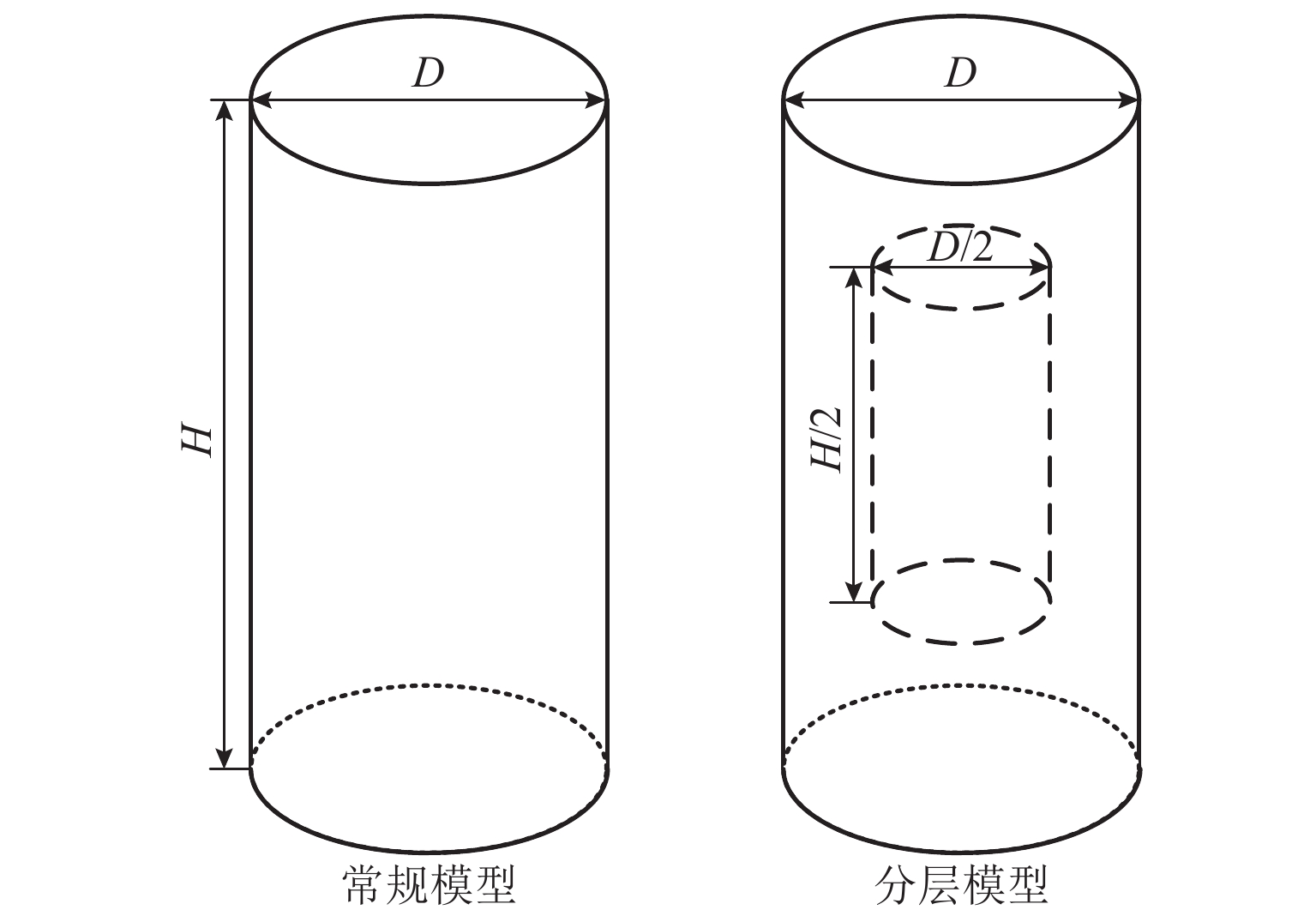

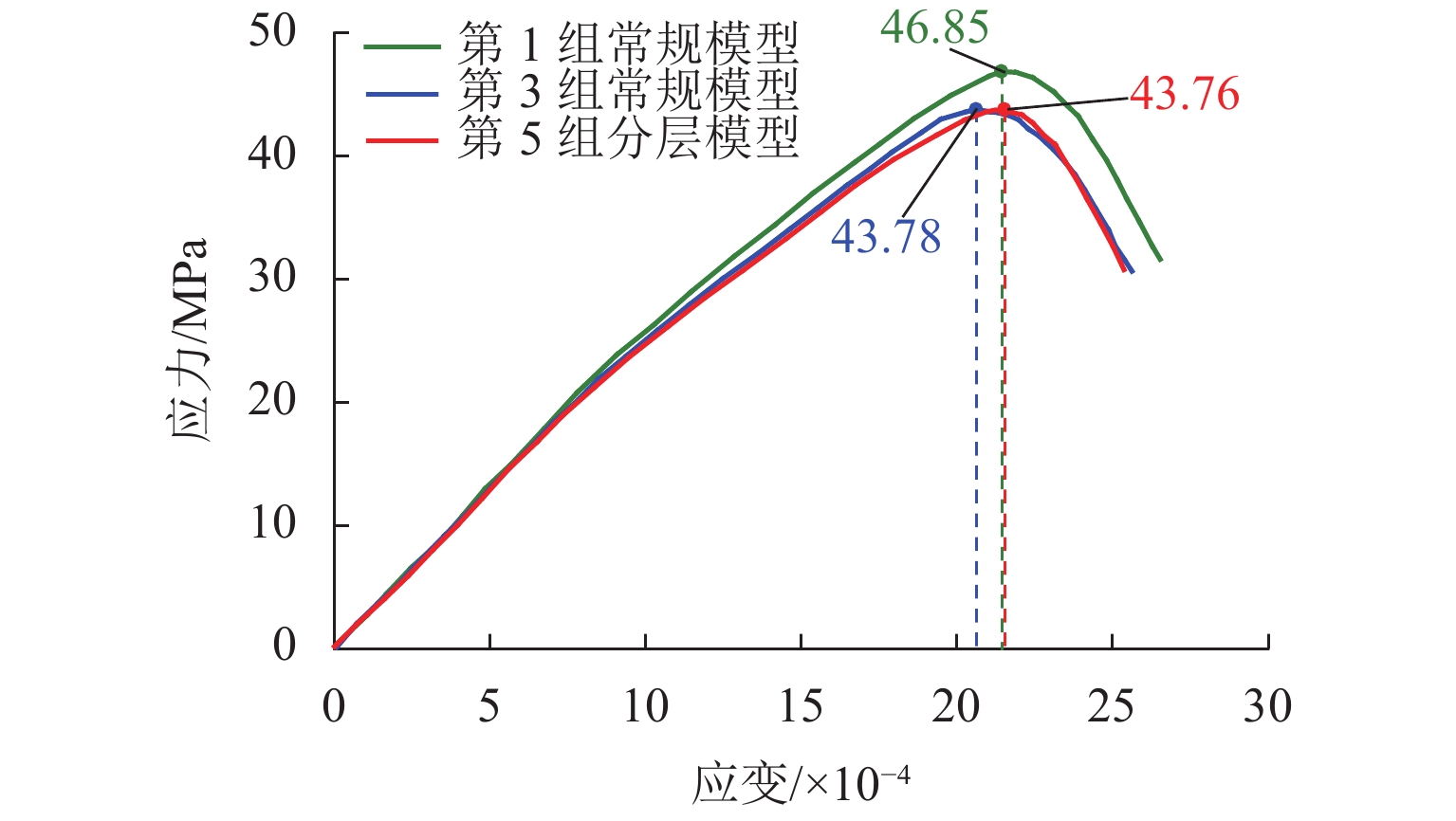

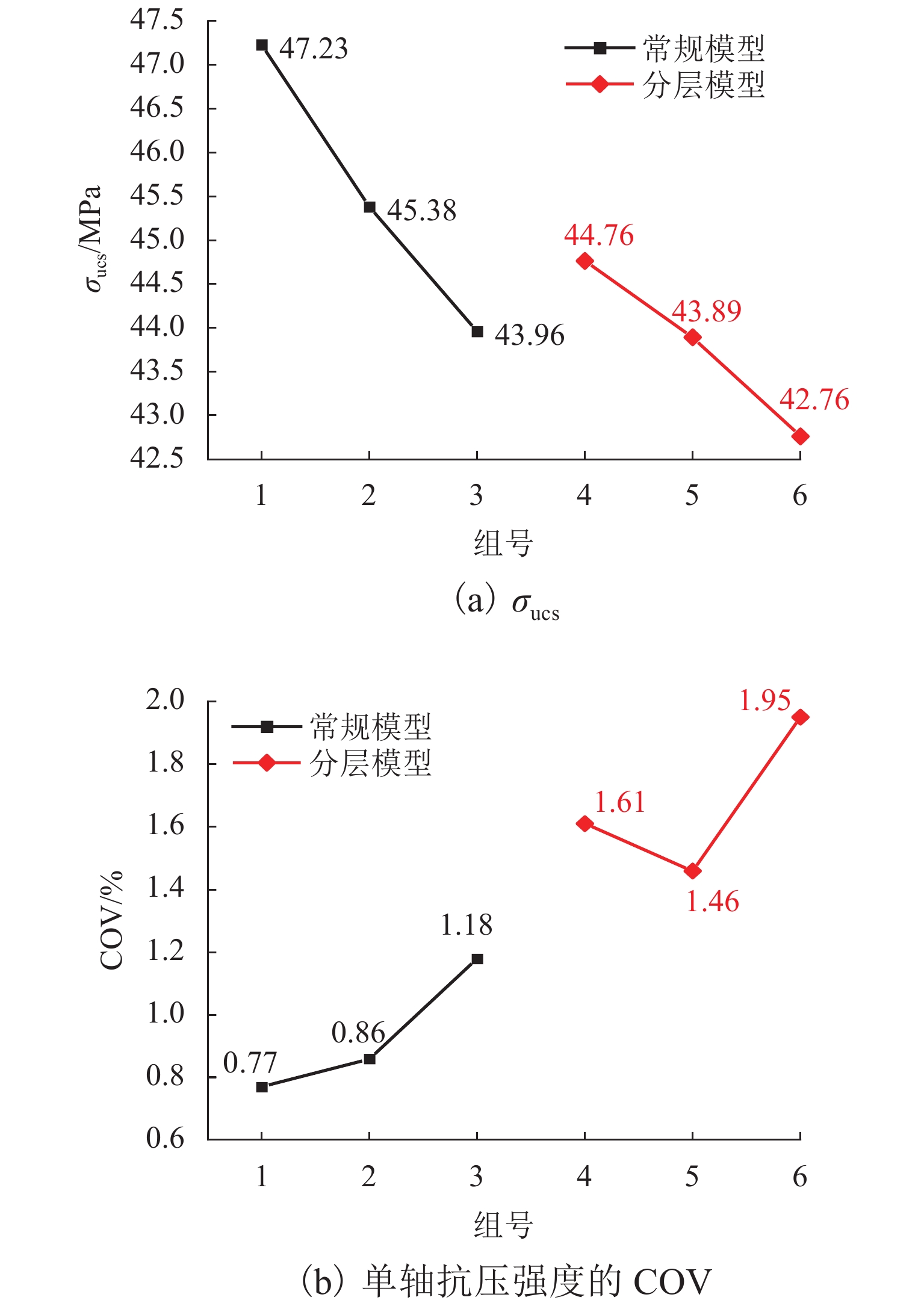

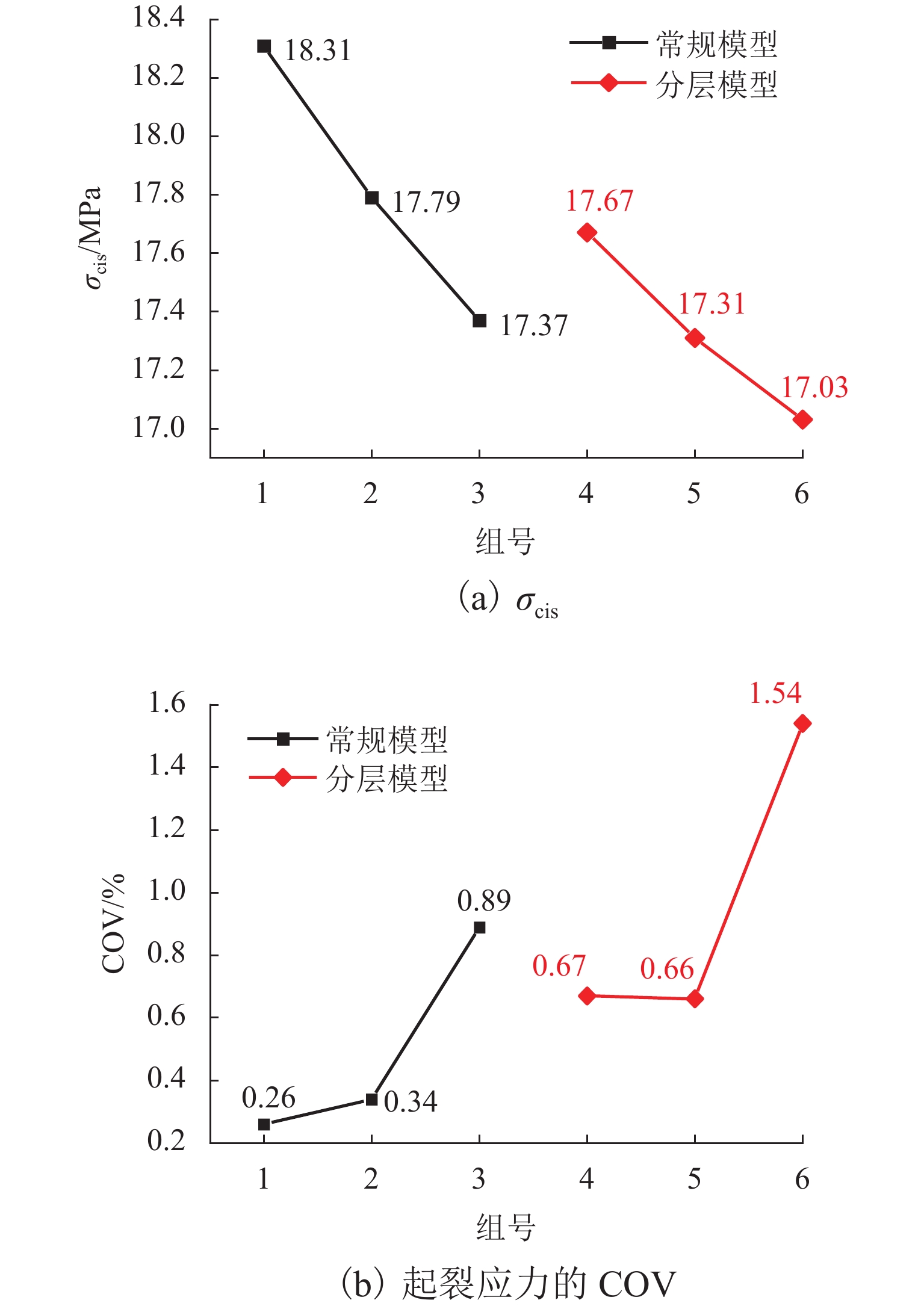

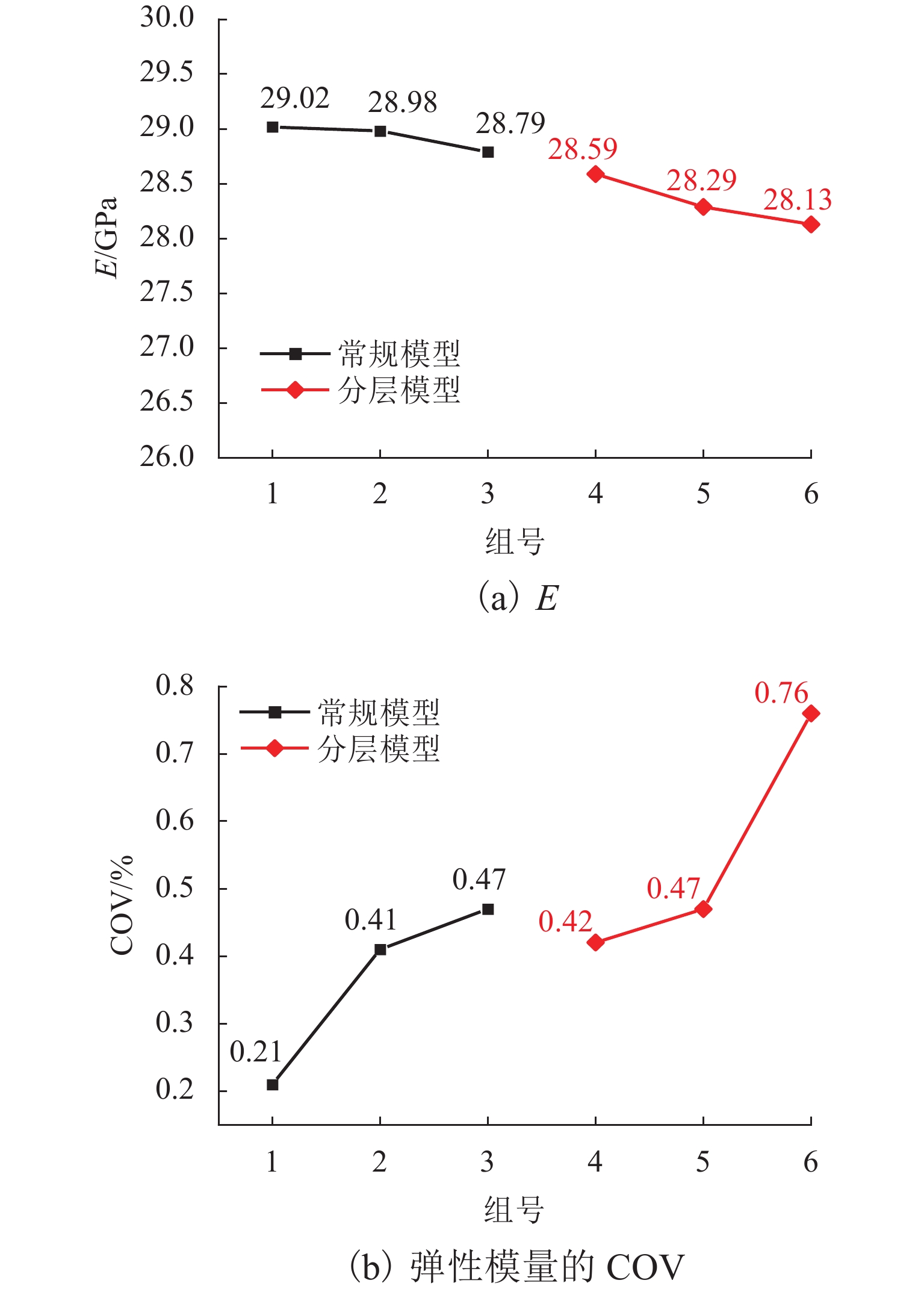

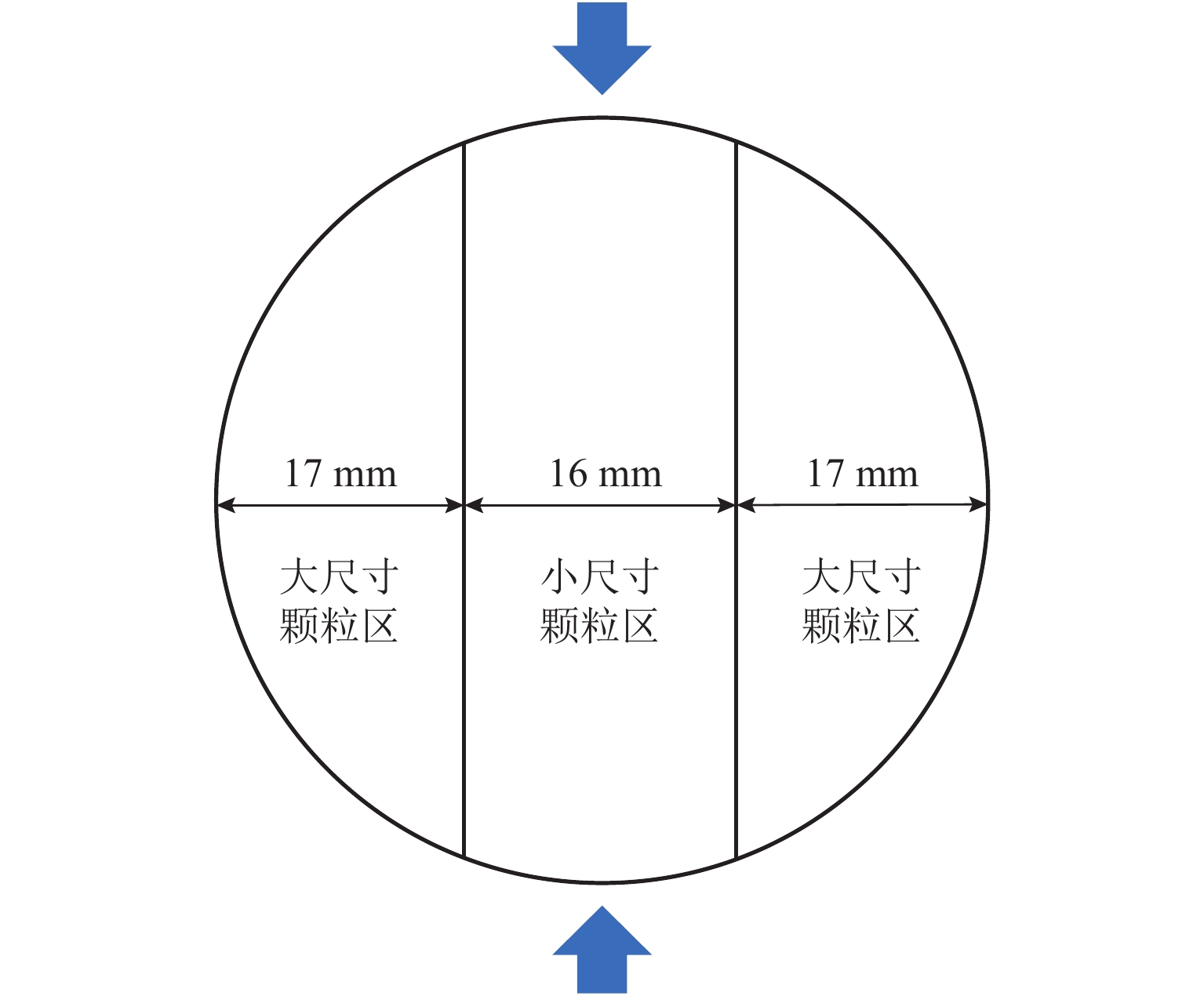

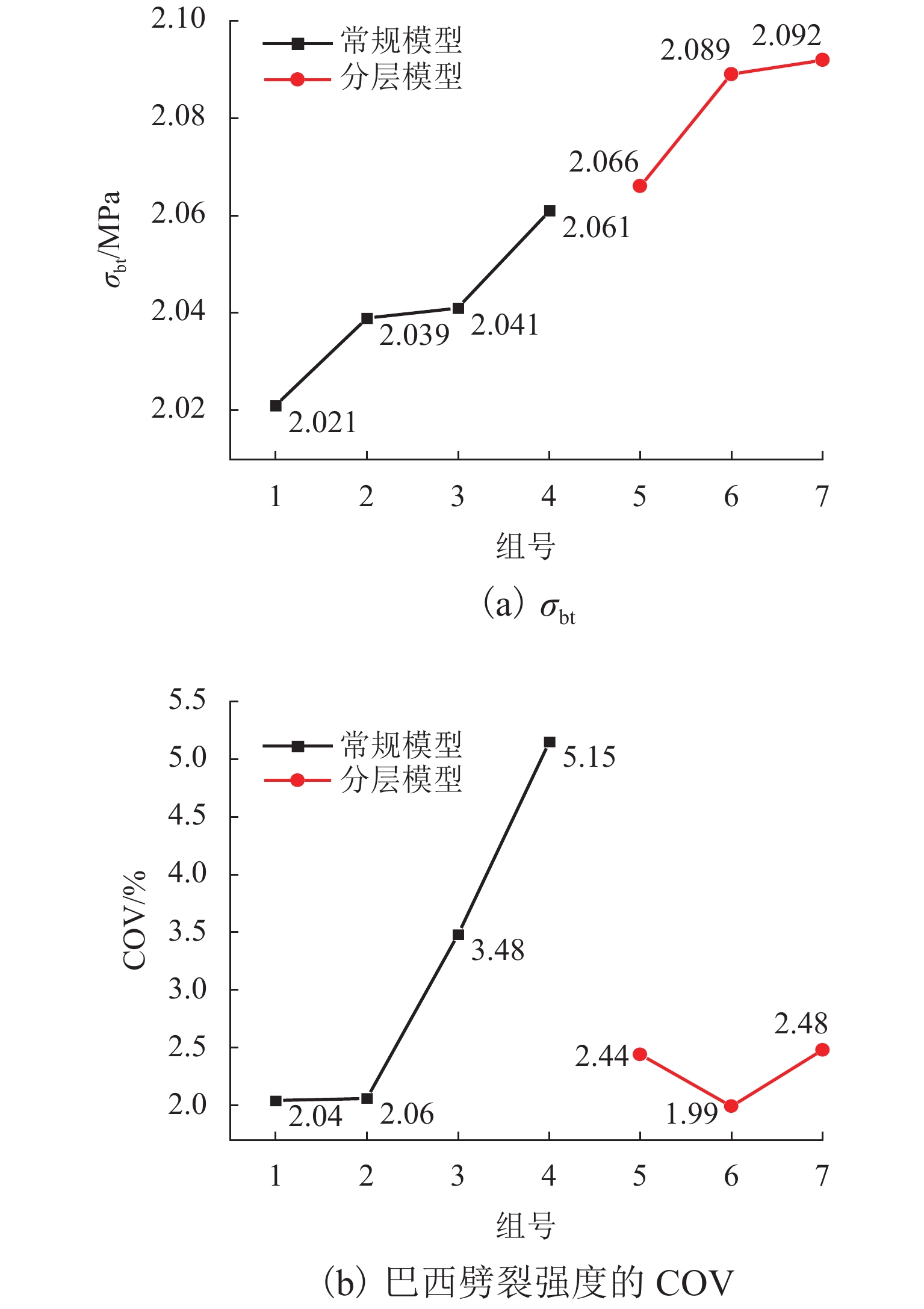

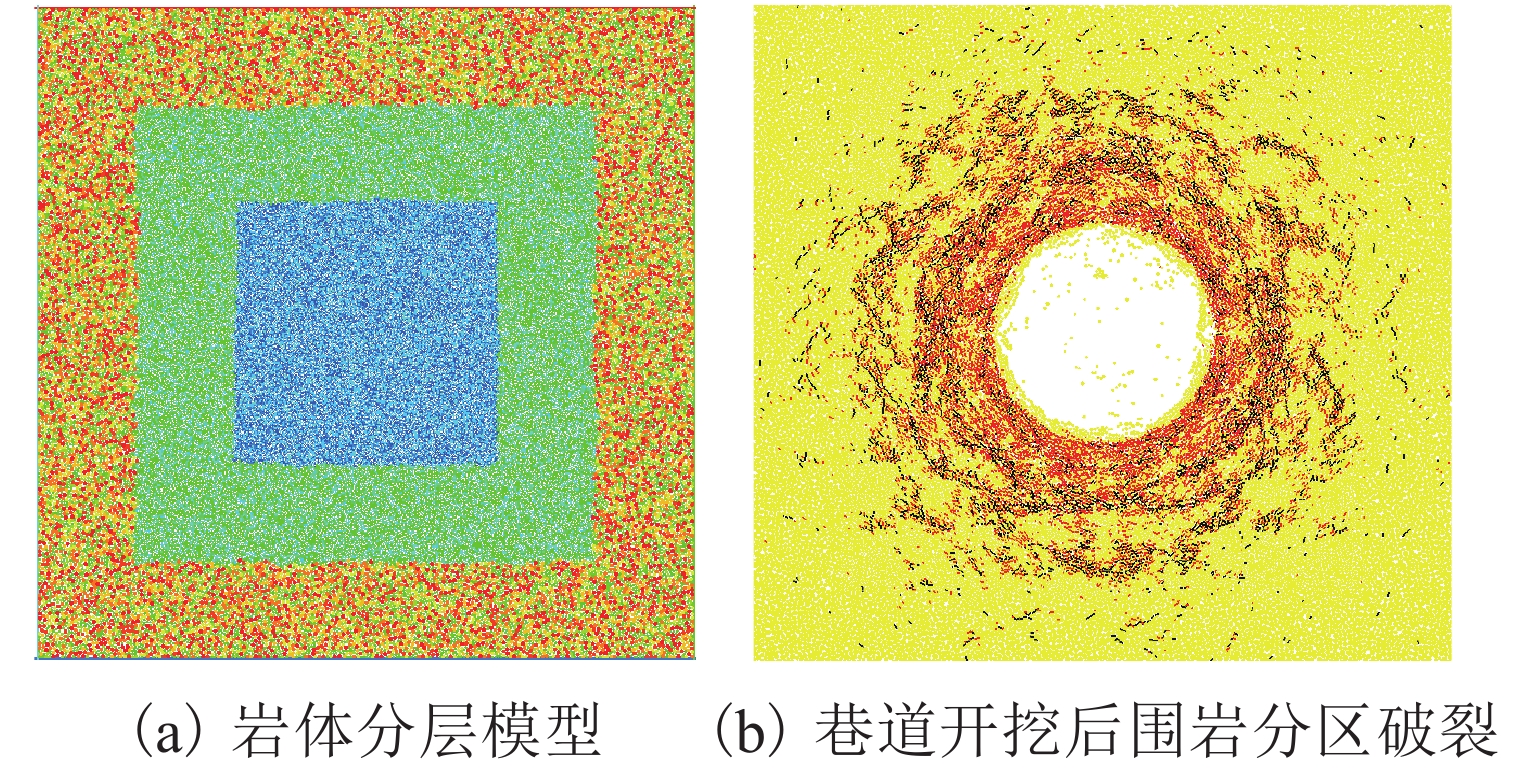

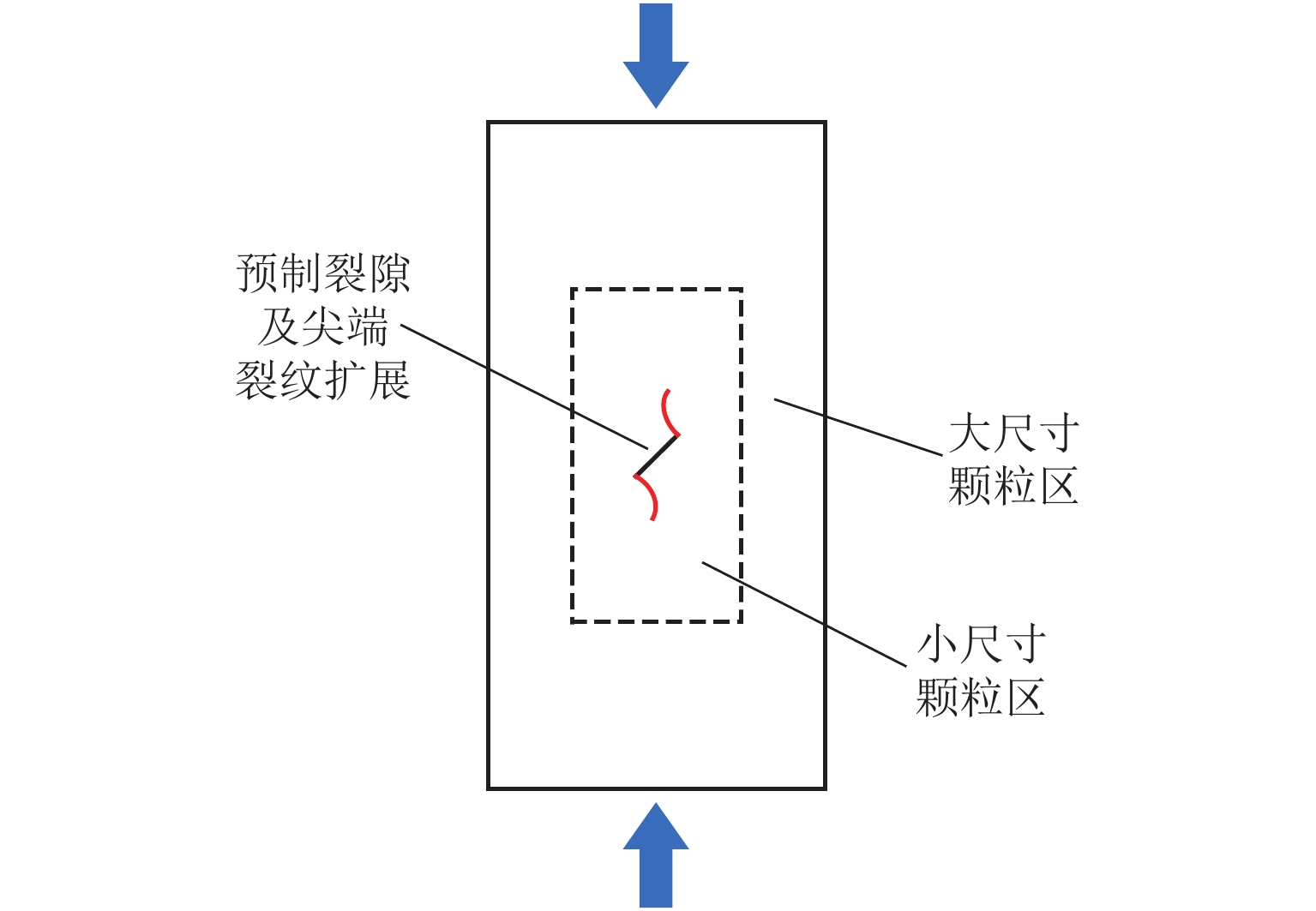

离散元分析方法是研究岩石力学行为、完善岩石力学基础理论的重要工具之一,为提高颗粒离散元法模拟室内岩石力学及大规模工程尺度试验的精确度,提出分层建模法,该方法对岩石或岩体关注区域采用小尺寸颗粒进行精细化模拟,外侧非重点关注区域采用大尺寸颗粒建模以扩大计算区域. 采用分层建模法进行单轴压缩、巴西劈裂试验并与常规建模计算结果进行对比,初步验证了分层建模法模拟室内力学试验的可行性. 研究结果表明:分层建模法与常规建模一样受颗粒尺寸效应影响,但可以减少颗粒流模型中的颗粒数量,计算效率提高50%以上;分层模型的单轴抗压强度和起裂应力分别与外层对应的常规模型相比,最多仅减小2.7%和1.9%,匹配单轴抗压强度时可先以外层材料常规模型作参照,单轴抗压强度和起裂应力的变异系数(coefficient of variation,COV)普遍大于常规模型,但依然在2%的可接受范围内;分层模型中粒径分布的不均匀性对模型弹性阶段的变形性质影响较小,分层模型的弹性模量与外层对应的常规模型相比减小1.3% ~ 2.3%;分层模型的巴西劈裂抗拉强度与外层对应的常规模型增大了1.32% ~ 2.35%,宏观破裂特征与小粒径常规模型相似,但在加载板附近有更多的裂纹.

Abstract:Discrete element analysis method is one of the important tools for studying rock mechanics behavior and refining the basic theory of rock mechanics. In order to improve the accuracy of the particle discrete element method to simulate indoor rock mechanics and large-scale engineering scale tests, a layered modeling method is proposed. This method adopts small-size particles for fine simulation of the rock or key rock mass area, and large-size particles for the outside area to expand the calculation area. The layered modeling method is used to carry out uniaxial compression and Brazilian splitting tests, and compared with the conventional modeling calculation results, which preliminarily verifies its feasibility to simulate indoor mechanical tests. The results show that the layered modeling method is affected by the particle size like conventional modeling, but it can reduce the number of particles in the particle flow code model and increase the calculation efficiency by more than 50%. The uniaxial compressive strength and crack initiation stress of the layered model are reduced by only 2.7% and 1.9% at most, compared with those of the conventional model with the corresponding outer layer. The coefficient of variation (COV) of uniaxial compressive strength and crack initiation stress is generally larger than that of the conventional model, but it is still within the acceptable range of 2%. The inhomogeneity of particle size distribution in the layered model has minor effect on the deformation properties of the model at the elastic stage, and the elastic modulus of the layered model is reduced by 1.3%−2.3% compared with the conventional model with the corresponding outer layer. The overall Brazilian splitting tensile strength of the layered model is increased by 1.32%−2.35% compared to that of the conventional model with the corresponding outer layer, and the macroscopic fracture characteristics are similar to those of the conventional small-particle model, but there are more cracks near the loading plate.

-

Key words:

- layered modeling method /

- discrete element method /

- particle size /

- 3D modeling

-

表 1 FJM3D各细观力学参数取值

Table 1. FJM3D meso-mechanical parameters

细观力学参数 数值 安装间距比 gratio 0.3 类型 B 单元比例 φB 0.9 类型 S 单元比例 φS 0.1 接触单元数 N/个 3 颗粒的有效模量 ${{{E}_{\rm c}} }$/GPa 30 黏结的有效模量${\overline {{E}}_{\rm c } }$/GPa 30 颗粒的法向与切向刚度比 $ k_{\rm{n}}/k_{\rm{s} }$ 1.9 黏结的法向与切向刚度比$\overline k_{\rm{n}}/ \overline k_{\rm{s} }$ 1.9 摩擦系数 μ1 0.3 黏结张拉强度平均值和标准偏差 σb/MPa 3.5, 0 黏结内聚力平均值和标准偏差 cb/MPa 36, 0 摩擦角 Фb/ (°) 10 表 2 单轴压缩模型粒径设置

Table 2. Particle size setting for uniaxial compression model

模型 组号 dmin/mm dmax/mm d

/mmL/d 备注 常规 1 1.50 2.50 2.00 25.00 2 1.88 3.12 2.50 20.00 3 2.26 3.74 3.00 16.67 分层 4 1.50 2.50 2.00 25.00 内层 1.88 3.12 2.50 20.00 外层 5 1.50 2.50 2.00 25.00 内层 2.26 3.74 3.00 16.67 外层 6 1.88 3.12 2.50 20.00 内层 2.26 3.74 3.00 16.67 外层 表 3 巴西劈裂模型粒径设置

Table 3. Particle size setting for Brazilian splitting model

模型 组号 dmin/mm dmax/mm d/mm L/d 备注 常规 1 1.13 1.87 1.50 33.33 2 1.50 2.50 2.00 25.00 3 1.88 3.12 2.50 20.00 4 2.26 3.74 3.00 16.67 分层 5 1.13 1.87 1.50 33.33 内层 1.50 2.50 2.00 25.00 外层 6 1.13 1.87 1.50 33.33 内层 1.88 3.12 2.50 20.00 外层 7 1.13 1.87 1.50 33.33 内层 2.26 3.74 3.00 16.67 外层 表 4 分层模型与常规模型颗粒数、计算时长对比

Table 4. Comparison of particle number and calculation time between layered model and conventional model

模型 d/mm 颗粒数/

个计算

时长/h计算时长

降低率/%单轴

压缩2.00 27 324 9.57 0 2.00(内),2.50(外) 15 721 4.72 50.68 2.00(内),3.00(外) 10 622 2.98 68.86 巴西

劈裂1.50 16 966 5.02 0 1.50(内),2.00(外) 11 085 2.28 54.58 1.50(内),2.50(外) 8 994 2.24 55.38 1.50(内),3.00(外) 8 042 2.13 57.57 -

[1] CUNDALL P A. The measurement and analysis of acceleration on rock slopes[D]. London: University of London, 1971. [2] CUNDALL P A. UDEC—a generalized distinct element program for modelling jointed rock, peter cundall associates[R]. [S.l.]: European Research Office, 1980 [3] CUNDALL P A, STRACK O D L. A discrete numerical model for granular assemblies[J]. Géotechnique, 1979, 29(1): 47-65. [4] ZHANG X P, WONG L N Y. Cracking processes in rock-like material containing a single flaw under uniaxial compression:a numerical study based on parallel bonded-particle model approach[J]. Rock Mechanics and Rock Engineering, 2012, 45(5): 711-737. [5] DUAN K, KWOK C Y, MA X. DEM simulations of sandstone under true triaxial compressive tests[J]. Acta Geotechnica, 2017, 12(3): 495-510. doi: 10.1007/s11440-016-0480-6 [6] CAI M, KAISER P K. Numerical simulation of the Brazilian test and the tensile strength of anisotropic rocks and rocks with pre-existing cracks[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41: 478-483. doi: 10.1016/j.ijrmms.2004.03.086 [7] JIANG M J, LEROUEIL S, KONRAD J M. Insight into shear strength functions of unsaturated granulates by DEM analyses[J]. Computers and Geotechnics, 2004, 31(6): 473-489. doi: 10.1016/j.compgeo.2004.07.001 [8] 刘宁,张春生,褚卫江,等. 锦屏二级水电站深埋隧洞开挖损伤区特征分析[J]. 岩石力学与工程学报,2013,32(11): 2235-2241.LIU Ning, ZHANG Chunsheng, CHU Weijiang, et al. Excavation damaged zone characteristics in deep tunnel of Jinping Ⅱ hydropower station[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(11): 2235-2241. [9] 李涛,朱连华,李彬如,等. 深基坑开挖土拱效应影响因素研究[J]. 中国矿业大学学报,2017,46(1): 58-65. doi: 10.13247/j.cnki.jcumt.000626LI Tao, ZHU Lianhua, LI Binru, et al. Study of the influence factors of soil arching effect for deep foundation pit excavation[J]. Journal of China University of Mining & Technology, 2017, 46(1): 58-65. doi: 10.13247/j.cnki.jcumt.000626 [10] WU S C, CHEN L, CHENG Z Q. Macro and meso research on the zonal disintegration phenomenon and the mechanism of deep brittle rock mass[J]. Engineering Fracture Mechanics, 2019, 211: 254-268. doi: 10.1016/j.engfracmech.2019.02.023 [11] 刘春,乐天呈,施斌,等. 颗粒离散元法工程应用的三大问题探讨[J]. 岩石力学与工程学报,2020,39(6): 1142-1152. doi: 10.13722/j.cnki.jrme.2019.0977LIU Chun, LE Tiancheng, SHI Bin, et al. Discussion on three major problems of engineering application of the particle discrete element method[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(6): 1142-1152. doi: 10.13722/j.cnki.jrme.2019.0977 [12] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329-1364. doi: 10.1016/j.ijrmms.2004.09.011 [13] YANG B D, JIAO Y, LEI S T. A study on the effects of microparameters on macroproperties for specimens created by bonded particles[J]. Engineering Computations, 2006, 23(6): 607-631. doi: 10.1108/02644400610680333 [14] YOON J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(6): 871-889. doi: 10.1016/j.ijrmms.2007.01.004 [15] DING X B, ZHANG L Y, ZHU H H, et al. Effect of model scale and particle size distribution on PFC3D simulation results[J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 2139-2156. doi: 10.1007/s00603-013-0533-1 [16] XU X L, WU S C, GAO Y T, et al. Effects of micro-structure and micro-parameters on Brazilian tensile strength using flat-joint model[J]. Rock Mechanics and Rock Engineering, 2016, 49(9): 3575-3595. doi: 10.1007/s00603-016-1021-1 [17] POTYONDY D O. PFC3D flat joint contact model[R]. Minneapolis: ITASCA Consulting Group, 2013. [18] WU S C, XU X L. A study of three intrinsic problems of the classic discrete element method using flat-joint model[J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1813-1830. doi: 10.1007/s00603-015-0890-z [19] SUITS L D, SHEAHAN T C, FUENKAJORN K, et al. Laboratory determination of direct tensile strength and deformability of intact rocks[J]. Geotechnical Testing Journal, 2011, 34(1): 103134. doi: 10.1520/GTJ103134 [20] MA J, WU S C, ZHANG X P, et al. Modeling acoustic emission in the Brazilian test using moment tensor inversion[J]. Computers and Geotechnics, 2020, 123: 103567. doi: 10.1016/j.compgeo.2020.103567 [21] NAKASHIMA S, TAGUCHI K, MORITOSHI A, et al. Loading conditions in the Brazilian test simulation by DEM[C]//47th US Rock Mechanics/Geomechanics Symposium, American Rock Mechanics Association. San Francisco: [s.n.], 2013: 1833-1838. [22] XU X L, WU S C, JIN A B, et al. Review of the relationships between crack initiation stress, mode I fracture toughness and tensile strength of geo-materials[J]. International Journal of Geomechanics, 2018, 18(10): 04018136.1-04018136.20. -

下载:

下载: