Damage of Post-Tensioned PC Girders in Alpine Regions Due to Frost Heaving in Ducts

-

摘要:

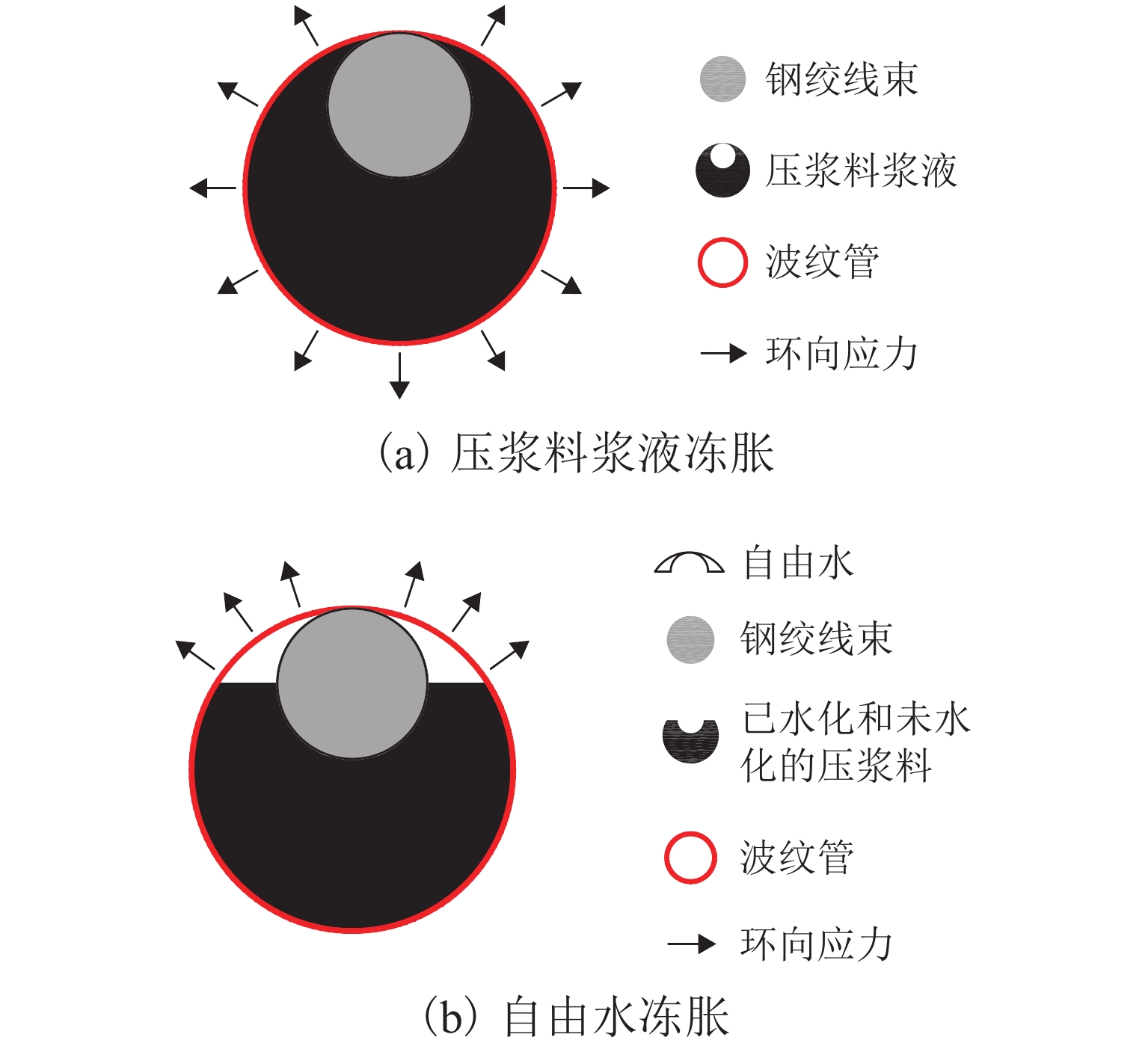

预应力孔道内压浆料浆液及自由水冻胀致使混凝土沿纵向开裂,是高寒地区后张预应力混凝土(PC)梁特有的病害,严重影响结构的安全性、适用性、耐久性. 为了明确病害特征,对冻胀受损梁体进行钻孔和解剖检测,进一步精细定量地研究冻胀效应,采用有限元软件ABAQUS建立孔道冻胀非线性模型,开展压浆料浆液冻胀行为分析和自由水冻胀参数分析,研究孔道内压浆液冻胀率和自由水体积的控制指标. 研究结果表明:高寒地区后张PC结构孔道压浆后,受冻并先后发生压浆料浆液冻胀和自由水冻胀,致使孔道周围混凝土反复受拉而沿纵向开裂;压浆料浆液的体积膨胀率宜控制在0.80%以内,最高不得超过1.73%;泌水体积比宜控制在0.04%以内,最高不得超过0.52%,由此可有效降低孔道内压浆液及自由水冻胀的风险.

Abstract:Longitudinal cracks of concrete caused by frost heaving of grouting slurry and free water in ducts is a special damage of post-tensioned PC girders in alpine regions, which affects the safety, serviceability, and durability of the structures significantly. In order to study damage characteristics, borehole and anatomical detections were conducted on damaged girders. The finite element software ABAQUS was used to establish the nonlinear models of frost heaving. Frost heave analysis of grouting slurry and parametric analysis of free water were carried out to study frost heave effects quantitatively. Control indexes of the frost heave ratio of grouting slurry and the volume of free water were obtained. The results show that the frost heaving of grouting slurry and free water occurs successively after grouting the ducts of the post-tensioned PC structures in alpine region, causing concrete to be tensioned repeatedly and cracked along the longitudinal direction. The volume expansion ratio of grouting slurry needs to be controlled within 0.80%, and the maximum should not exceed 1.73%. The volume ratio of bleeding water should be controlled within 0.04%, and the maximum should not exceed 0.52%. Thus, the frost heaving risk of grouting slurry and free water in ducts can be reduced effectively.

-

-

[1] 郭栋良. 高寒地区后张梁混凝土沿波纹管裂缝形成的机理研究[D]. 成都: 西南交通大学, 2006. [2] 何凌. 32 m预应力后张梁波纹管道浆体早期冻胀与沿管道裂纹成因关系的试验研究[D]. 成都: 西南交通大学, 2006. [3] 于本田,王起才. 青藏铁路桥梁压浆材料冻胀变形试验研究[J]. 中国铁道科学,2010,31(4): 27-32.YU Bentian, WANG Qicai. Experimental study on the frost heave deformation of the grouting material for the concrete bridge in Qinghai-Tibet railway[J]. China Railway Science, 2010, 31(4): 27-32. [4] 何晓东,穆飞. 后张法预应力混凝土T梁压浆孔道胀裂原因分析和影响研究[J]. 低温建筑技术,2018,40(12): 142-144.HE Xiaodong, MU Fei. Cause analysis and influence study on the bulging of prestressed concrete T-beam grouting channel[J]. Low Temperature Architecture Technology, 2018, 40(12): 142-144. [5] 张艳梅,向敏,冯冲. 混凝土T梁裂缝形成机理试验研究[J]. 交通世界·工程技术,2015(12): 102-107. [6] 刘阳. 复兴泡大桥40 m T梁裂缝的分析与处理[J]. 黑龙江交通科技,2007,30(7): 81-82. doi: 10.3969/j.issn.1008-3383.2007.07.056 [7] 蒋平江. 寒区32 m后张法预应力梁裂缝成因与防治[J]. 南京工程学院学报(自然科学版),2010,8(4): 57-60.JIANG Pingjiang. The causes and prevention of cracks in the post-tensioned prestressing, 32-meter-long beams in cold regions[J]. Journal of Nanjing Institute of Technology (Natural Science Edition), 2010, 8(4): 57-60. [8] SPRINKEL M M, BALAKUMARAN S S G. Problems with continuous spliced posttensioned-prestressed concrete bulb-tee girder center spans at west point, Virginia[J]. Transportation Research Record: Journal of the Transportation Research Board, 2017, 2642(1): 46-54. doi: 10.3141/2642-06 [9] QIN X C, MENG S P, CAO D F, et al. Evaluation of freeze-thaw damage on concrete material and prestressed concrete specimens[J]. Construction and Building Materials, 2016, 125: 892-904. doi: 10.1016/j.conbuildmat.2016.08.098 [10] CAO D F, QIN X C, MENG S P, et al. Evaluation of prestress losses in prestressed concrete specimens subjected to freeze-thaw cycles[J]. Structure and Infrastructure Engineering, 2016, 12(2): 159-170. doi: 10.1080/15732479.2014.998241 [11] 邰爽. 冻融循环作用下预应力筋对预应力损失的影响[D]. 长春: 吉林建筑大学, 2016. [12] 周影. 预应力混凝土构件在冻融循环作用下的预应力损失研究[D]. 长春: 吉林建筑大学, 2015. [13] GUO R, ZHEN Z C, ZHAO S W, et al. Effects of grouting defects in a duct on the bonding of prestressing strands[J]. KSCE Journal of Civil Engineering, 2020, 24(4): 1268-1275. doi: 10.1007/s12205-020-0892-6 [14] 杨辉,吴文选,陈冬冬,等. 膨胀剂对孔道压浆料限制膨胀率的影响[J]. 新型建筑材料,2019,46(7): 56-59. doi: 10.3969/j.issn.1001-702X.2019.07.014YANG Hui, WU Wenxuan, CHEN Dongdong, et al. Effect of expansive agent on the restrained expansion rate of duct grouting material[J]. New Building Materials, 2019, 46(7): 56-59. doi: 10.3969/j.issn.1001-702X.2019.07.014 [15] 康勇. 复合膨胀剂在预应力孔道压浆材料中的应用试验研究[J]. 低温建筑技术,2020,42(5): 34-36,40. doi: 10.13905/j.cnki.dwjz.2020.05.009KANG Yong. Experimental study on application of the compound expansion agent in grouting material for prestressed duct[J]. Low Temperature Architecture Technology, 2020, 42(5): 34-36,40. doi: 10.13905/j.cnki.dwjz.2020.05.009 [16] ZHOU Y Z, ZHU E Y. Experimental study of bleed countermeasures for post-tensioning[J]. Advances in Structural Engineering, 2015, 18(8): 1273-1285. doi: 10.1260/1369-4332.18.8.1273 [17] 刘廷滨,贾汝波,张晨宇,等. 锈蚀RC梁抗弯承载力计算方法研究[J]. 西南交通大学学报,2020,55(4): 789-798. doi: 10.3969/j.issn.0258-2724.20190277LIU Tingbin, JIA Rubo, ZHANG Chenyu, et al. Bending capacity calculation method for corroded reinforced concrete beams[J]. Journal of Southwest Jiaotong University, 2020, 55(4): 789-798. doi: 10.3969/j.issn.0258-2724.20190277 [18] 过镇海. 钢筋混凝土原理[M]. 3版. 北京: 清华大学出版社, 2013: 6-34. [19] LEE J H, FENVES G L. Plastic-damage model for cyclic loading of concrete structures[J]. Journal of Engineering Mechanics, 1998, 124(8): 892-900. doi: 10.1061/(ASCE)0733-9399(1998)124:8(892) [20] 田连波,侯建国. ABAQUS中混凝土塑性损伤因子的合理取值研究[J]. 湖北大学学报(自然科学版),2015,37(4): 340-345,358.TIAN Lianbo, HOU Jianguo. Reasonable plastic damaged factor of concrete damaged plastic model of ABAQUS[J]. Journal of Hubei University (Natural Science), 2015, 37(4): 340-345,358. [21] 廖显东,胡翔,张士前,等. 后张预应力预制混凝土框架中节点的数值模拟[J]. 西南交通大学学报,2020,55(6): 1287-1296.LIAO Xiandong, HU Xiang, ZHANG Shiqian, et al. Numerical simulation of interior connections of precast concrete frame with post-tensioned tendons[J]. Journal of Southwest Jiaotong University, 2020, 55(6): 1287-1296. -

下载:

下载: