Laboratory Pull-Out Test Study of Basalt Fiber Reinforced Polymer Bolt for Strengthening Mixed Soil

-

摘要:

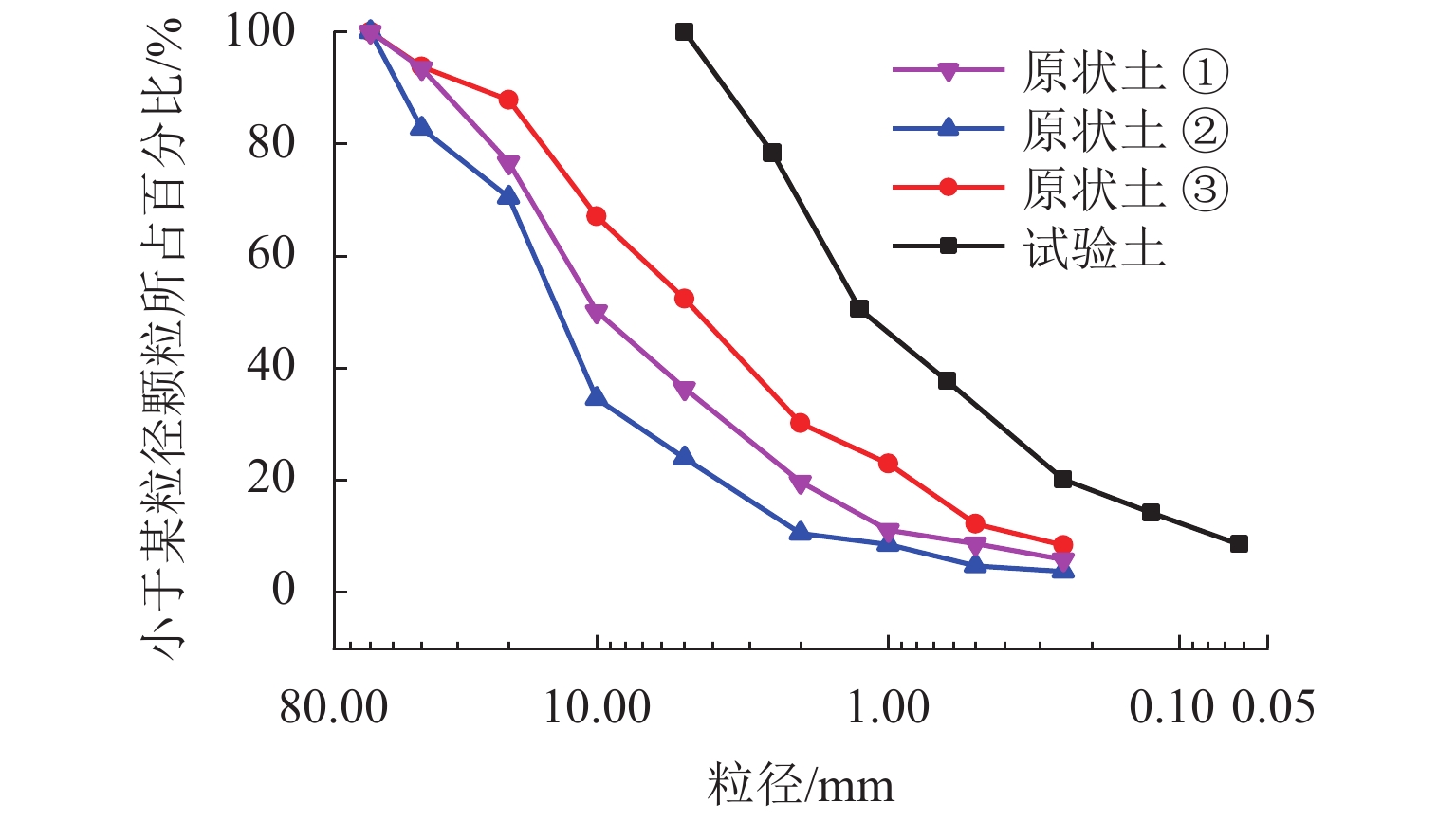

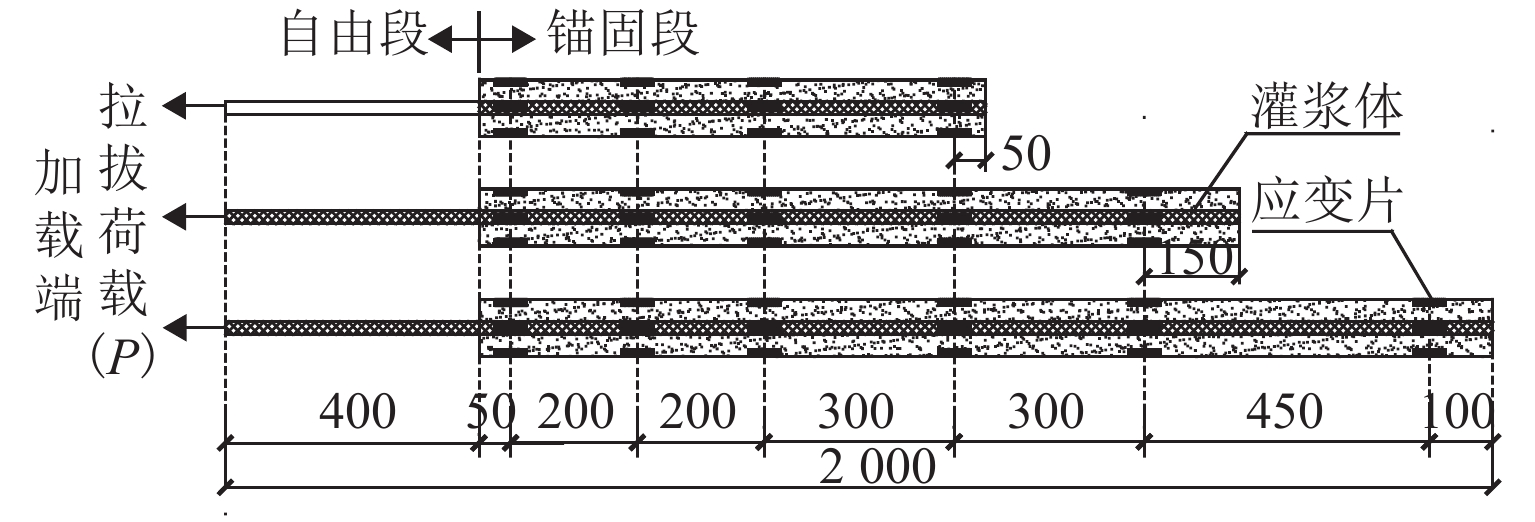

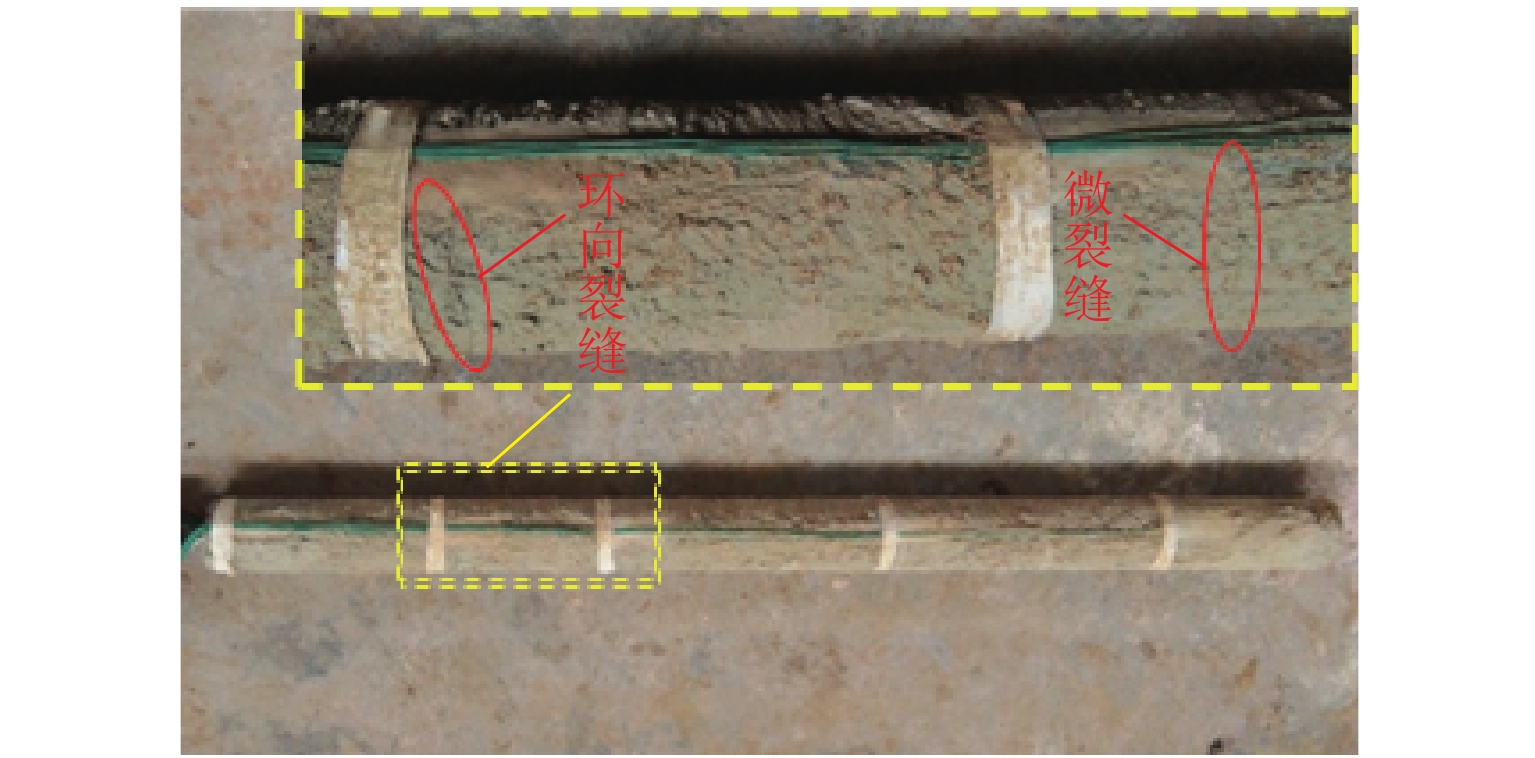

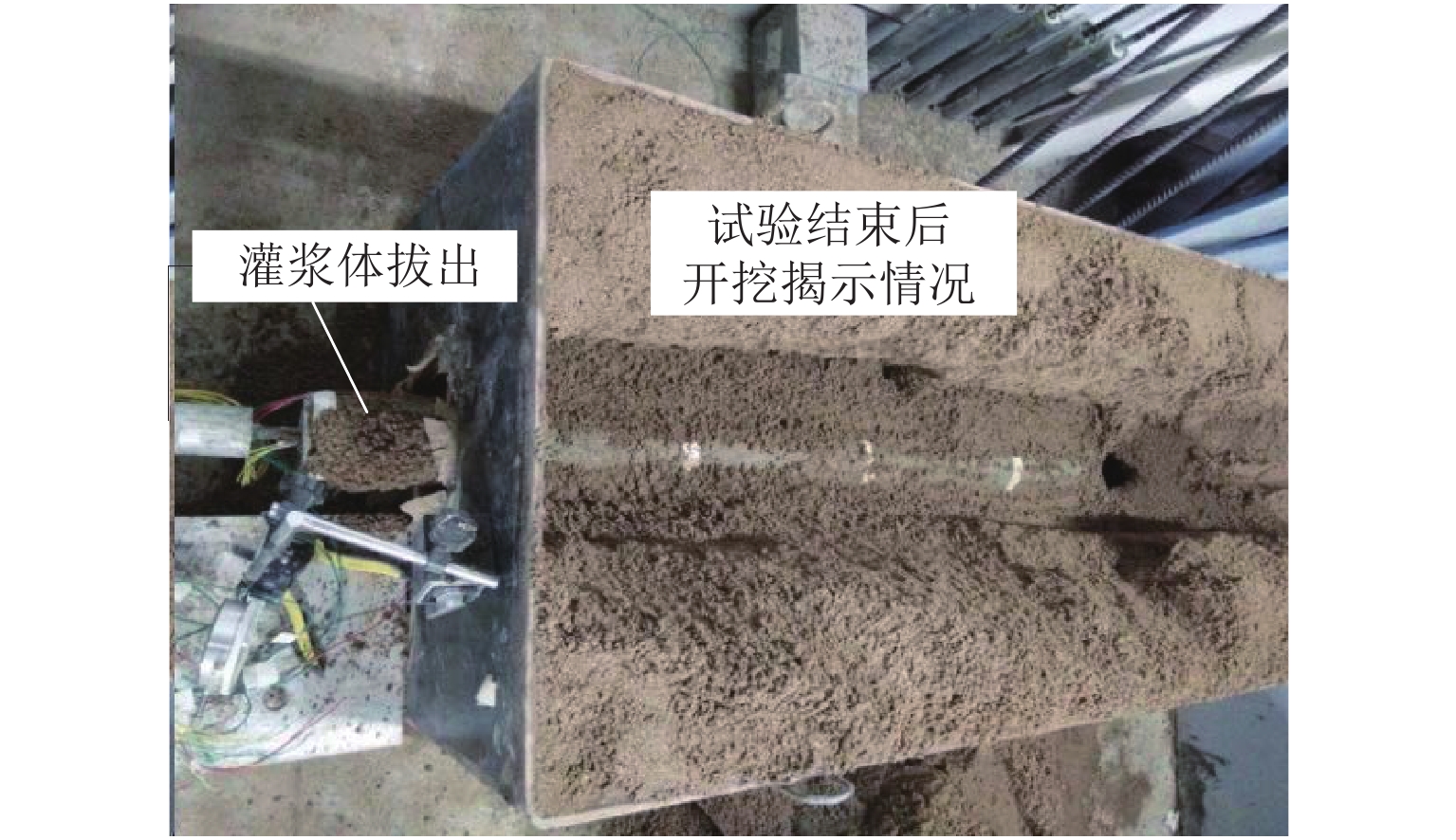

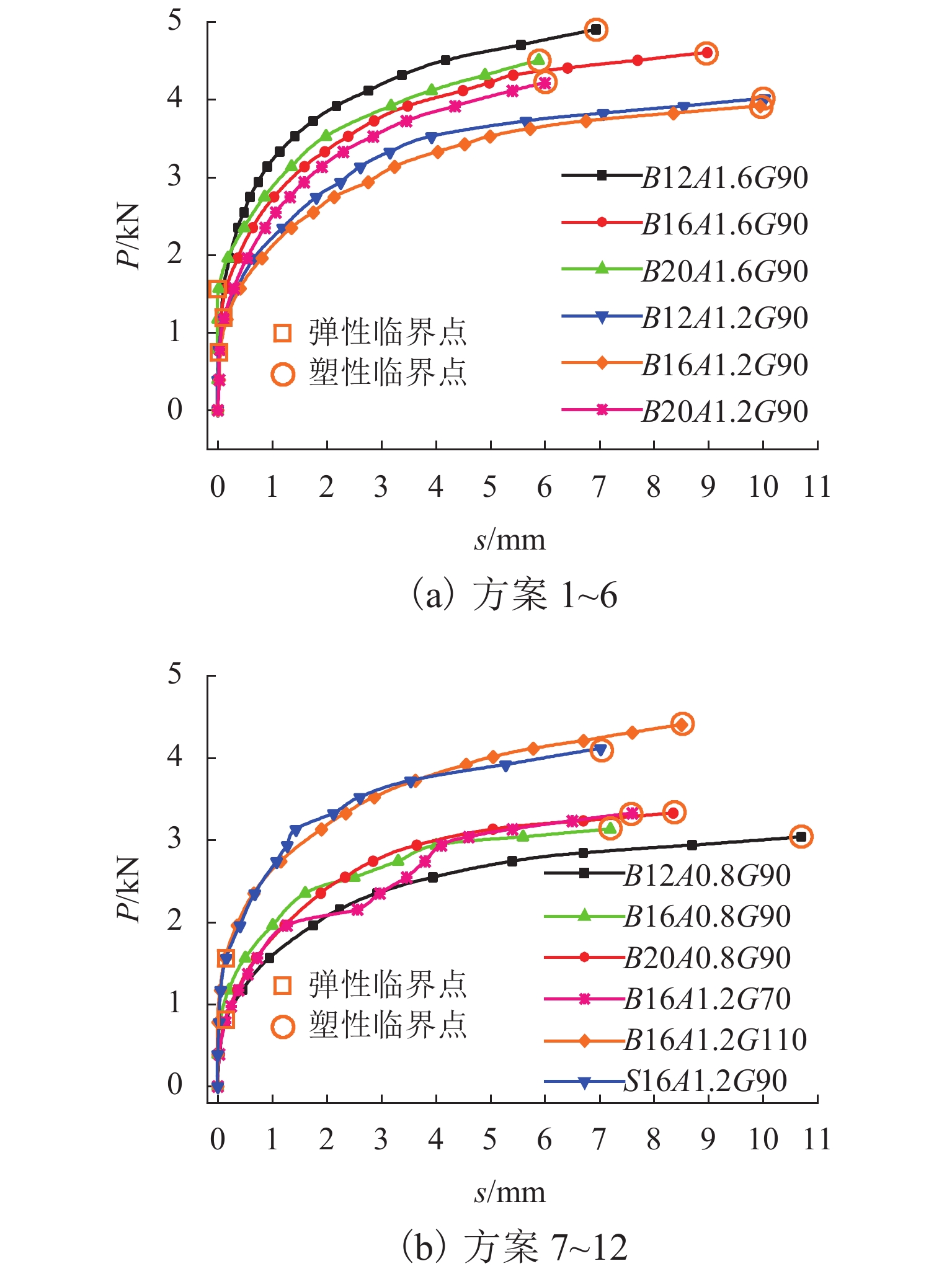

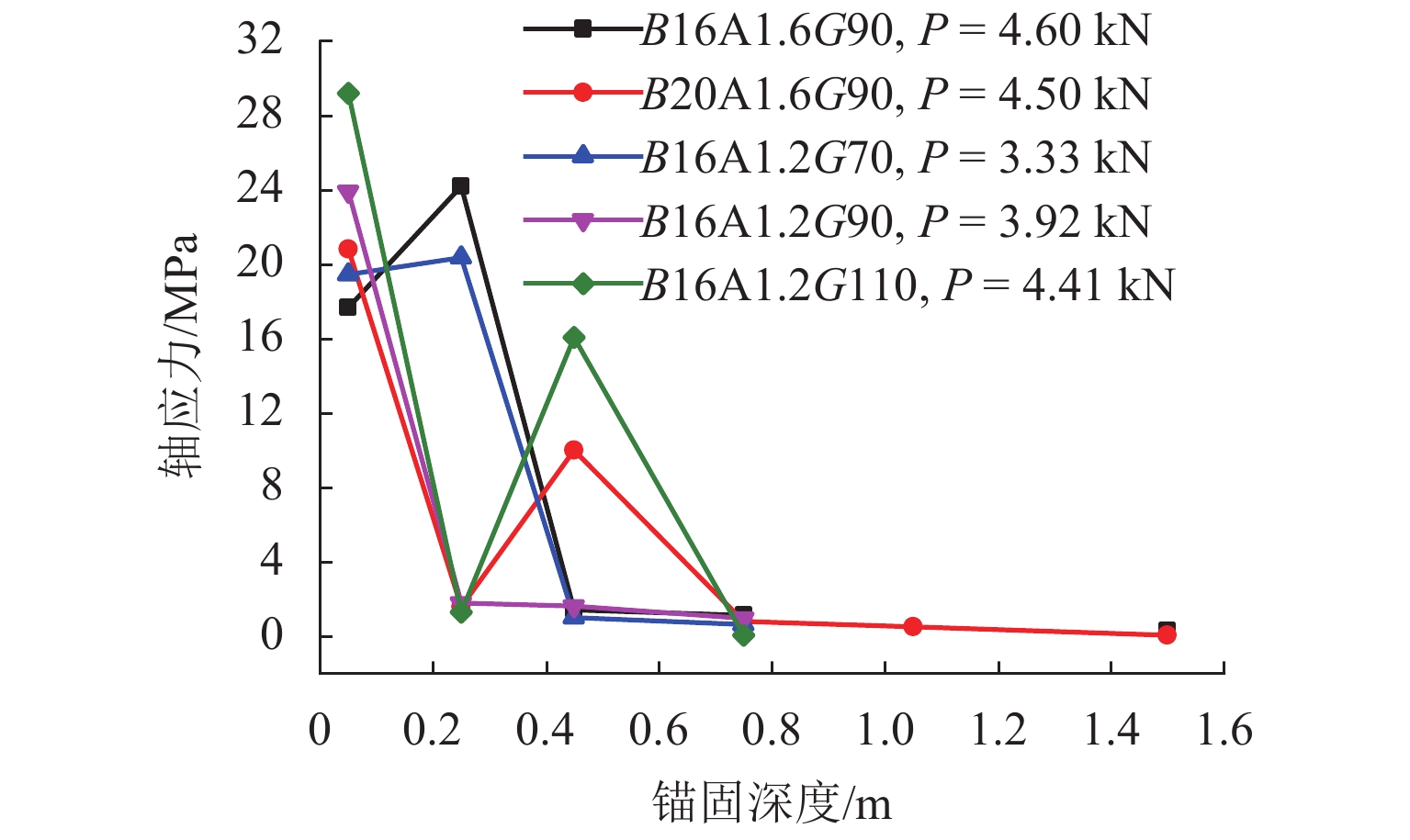

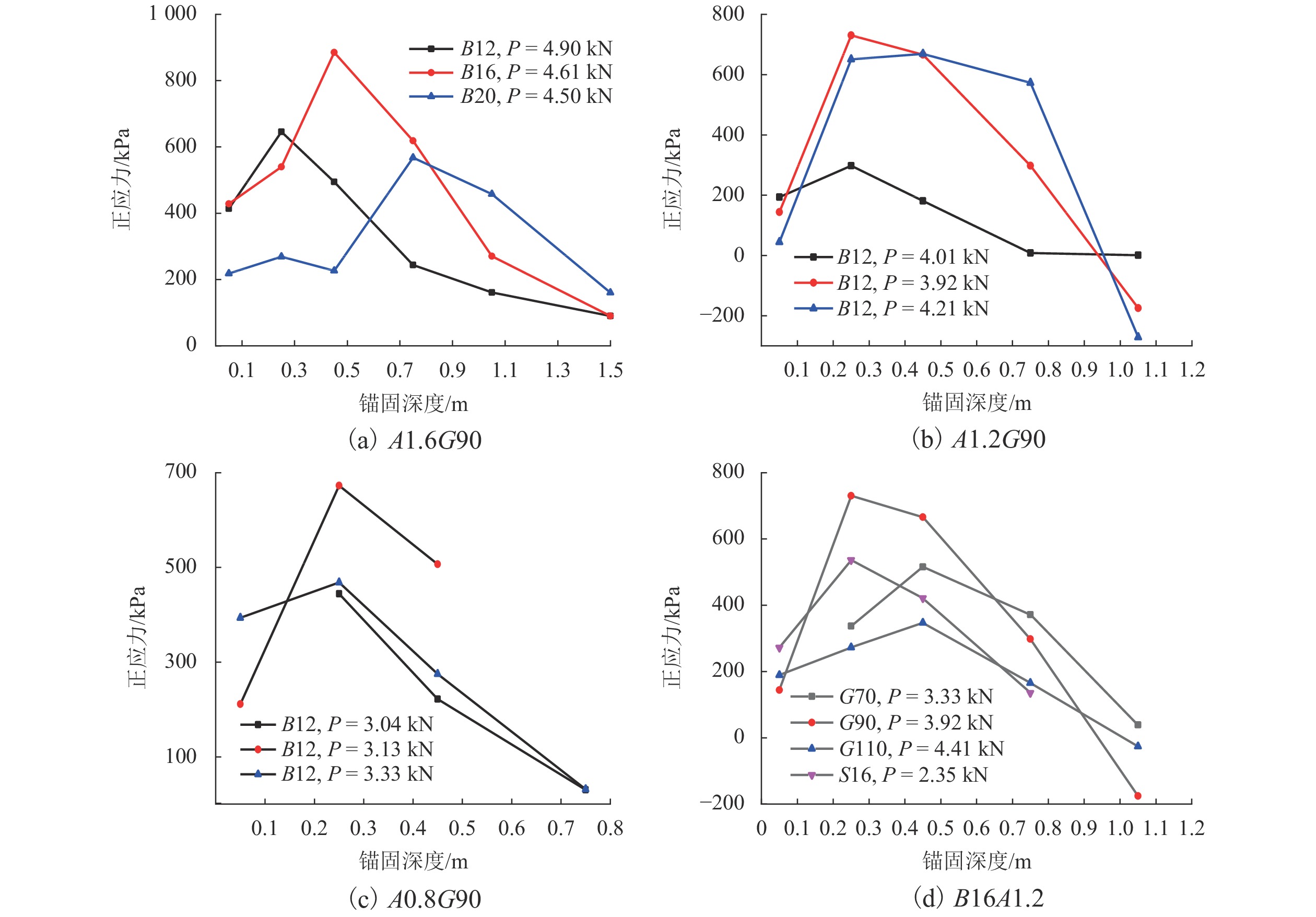

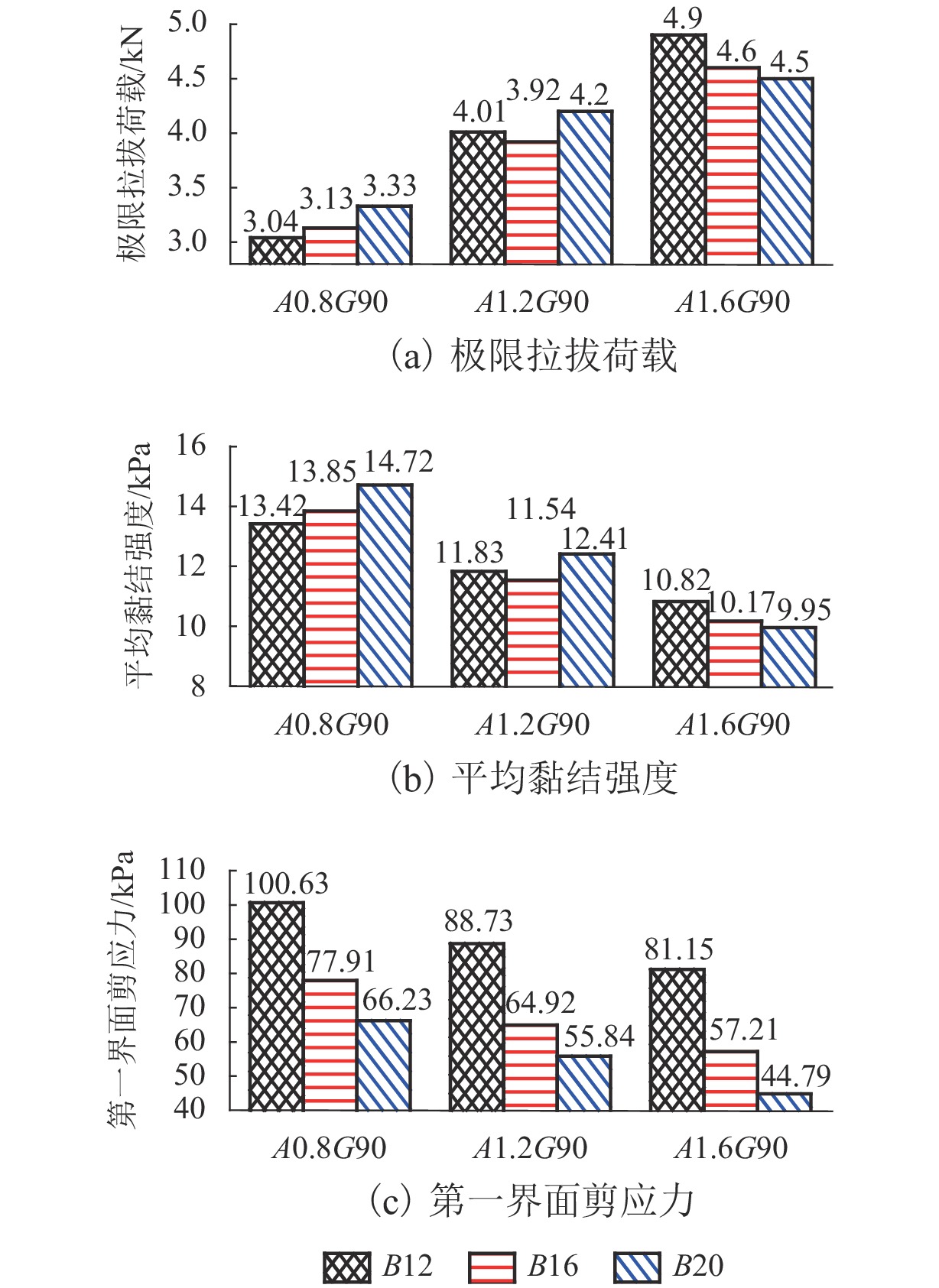

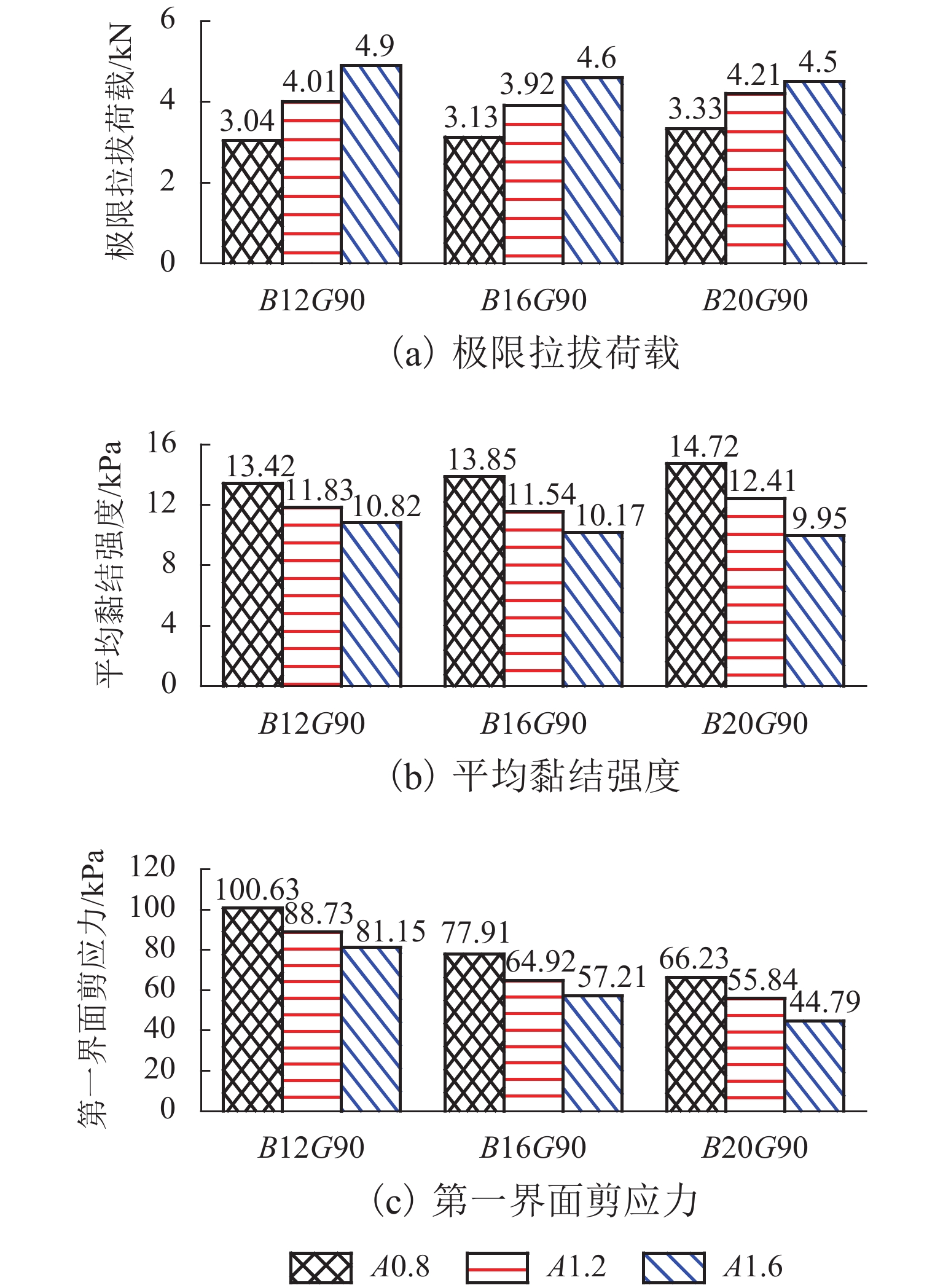

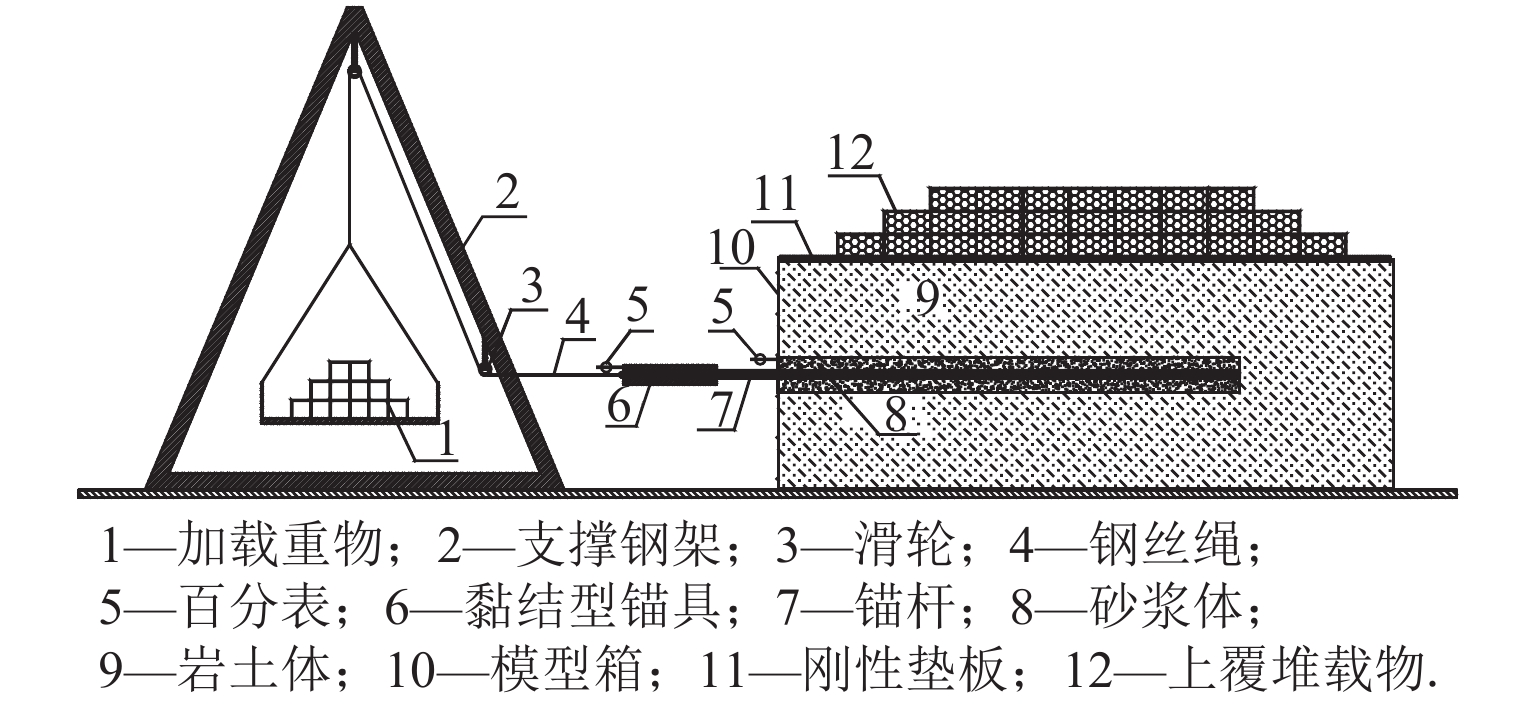

玄武岩纤维增强复合材料(BFRP)质量轻、强度高、耐久性好,将该材料用作锚杆可有效解决传统钢筋锚杆的腐蚀问题,在恶劣环境下的工程建设中具有广阔的应用前景. 本文以广泛存在于西南山区的崩坡积混合土为对象,通过室内拉拔试验研究了锚杆类型、锚杆直径、锚固长度以及灌浆体直径等因素对极限拉拔荷载和界面剪应力的影响,并对锚固体系的破坏模式以及应力分布规律进行了分析. 研究结果表明:混合土中BFRP锚杆破坏模式均为沿灌浆体与土体界面的剪切破坏,BFRP锚杆与钢筋锚杆的抗拔承载性能基本一致,实际工程可以使用BFRP锚杆直接替代钢筋锚杆;BFRP锚杆拉拔荷载位移曲线呈三阶段形式,弹性临界荷载为极限荷载的20% ~ 28%,试验条件下锚杆的极限承载力与锚固长度、灌浆体直径成正比关系;灌浆体环向裂缝使锚杆的轴向应力沿杆体呈单峰形式分布,同时使锚固段前部的应力集中程度降低;混合土中灌浆体直径越大则界面强度越低,直径从90 mm增大为110 mm,界面强度降低约8%.

Abstract:Basalt fiber reinforced polymer (BFRP) has the advantages of light weight, high strength and good durability. Using the material as anchor can effectively solve the corrosion problem of traditional steel bar anchor and has a broad application prospect in engineering construction in harsh environment. Taking the collapse alluvial mixed soil which widely exists in the southwest mountainous area as the object, through the indoor pull-out test, the effects of anchor type, anchor diameter, anchorage length and grouting diameter on the ultimate pullout load and interface shear stress are studied. The failure mode and stress distribution law of the anchoring system are analyzed. The results show that the failure mode of BFRP anchor in mixed soil is shear failure along the interface between grouting body and soil, and the pull-out bearing capacity of BFRP anchor is basically the same as that of reinforced anchor, so BFRP anchor can be used to replace reinforced anchor directly in practical engineering. The pullout load-displacement curve of BFRP anchor is in the form of three stages, and the elastic critical load is 20%−28% of the ultimate load. Under the test condition, the ultimate bearing capacity of the bolt is proportional to the anchoring length and the diameter of the grout. And the circumferential crack in the grouting body makes the axial stress of the bolt in the form of a single peak and reduces the stress concentration in the front of the anchoring section. The larger the diameter of the grouting body in the mixed soil is, the lower the interface strength is, the diameter increases from 90 mm to 110 mm, and the interface strength decreases by about 8%.

-

Key words:

- BFRP bolt /

- talus mixed soil /

- pull-out test /

- the interfacial mechanical behaviors

-

表 1 锚杆力学参数

Table 1. Mechanical parameters of bolts

类别 直径/

mm弹模/

GPa密度/

(kg·m−3)抗拉强度/

GPa极限

应变/%钢筋 16 200 7850 0.4 >10.0 BFRP 12 50 1940 1.1 2.20 BFRP 16 48 2050 1.0 2.08 BFRP 20 45 2020 0.9 2.08 表 2 物理力学参数

Table 2. Physical and mechanical parameters

类别 密度/

(kg·m−3)黏聚力/kPa 摩擦角/(º) 含水率/% 原状土 ① 1840 24.9 38.9 20.2 原状土 ② 1810 23.1 39.9 16.8 原状土 ③ 1800 31.8 35.0 16.6 试验土 1850 20.5 40.4 8.0 表 3 试件方案参数

Table 3. Specimen parameters

杆型 方案 杆名 锚杆

直径

/mm锚固

长度

/m锚杆

总长

/m灌浆体

直径

/mmBFRP 1 B12A0.8G90 12 0.8 1.2 90 2 B12A1.2G90 12 1.2 1.6 90 3 B12A1.6G90 12 1.6 2.0 90 4 B16A0.8G90 16 0.8 1.2 90 5 B16A1.2G70 16 1.2 1.6 70 6 B16A1.2G90 16 1.2 1.6 90 7 B16A1.2G110 16 1.2 1.6 110 8 B16A1.6G90 16 1.6 2.0 90 9 B20A0.8G90 20 0.8 1.2 90 10 B20A1.2G90 20 1.2 1.6 90 11 B20A1.6G90 20 1.6 2.0 90 钢 12 S16A1.2G90 16 1.2 1.6 90 表 4 拉拔试验结果

Table 4. Experimental results of pullout test

杆名 极限拉拔

荷载/kN第一界面平均

剪应力/kPa第二界面平均

黏结强度/kPaB12A0.8G90 3.0 100.6 13.4 B12A1.2G90 4.0 88.7 11.8 B12A1.6G90 4.9 81.2 10.8 B16A0.8G90 3.1 77.9 13.9 B16A1.2G90 3.9 64.9 11.5 B16A1.2G70 3.3 55.2 12.6 B16A1.2G110 4.4 73.1 10.6 B16A1.6G90 4.6 57.2 10.2 B20A0.8G90 3.3 66.2 14.7 B20A1.2G90 4.2 55.8 12.4 B20A1.6G90 4.5 44.8 10.0 S16A1.2G90 4.1 68.2 12.1 表 5 锚杆类型的影响

Table 5. Influence of anchor type

锚杆类型 平均黏结

强度/kPa极限拉拔

荷载/kN第一界面

剪应力/kPaB16 11.54 3.92 64.92 S16 12.12 4.11 68.17 表 6 极限拉拔荷载增幅

Table 6. Increasing range of ultimate pullout load

% 荷载 B12G90 B16G90 B20G90 A0.8 → A1.2 A1.2 → A1.6 A0.8 → A1.2 A1.2 → A1.6 A0.8 → A1.2 A1.2 → A1.6 增幅 32.3 21.9 25.0 17.5 26.5 7.0 表 7 灌浆体直径的影响

Table 7. Influence of grouting body diameter

灌浆体直径 平均黏结

强度/kPa极限拉拔

荷载/kN第一界面

剪应力/kPaG70 12.61 3.33 55.19 G90 11.54 3.92 64.92 G110 10.62 4.41 73.05 -

[1] 张景科,谌文武,和法国,等. 土遗址加固中GFRP锚杆锚固性能现场试验研究[J]. 工程地质学报,2014,22(5): 804-810. doi: 10.13544/j.cnki.jeg.2014.05.005ZHANG Jingke, CHEN Wenwu, HE Faguo, et al. Field experimental study on anchorage perfromance of gfrp at conservation earthen sites[J]. Journal of Engineering Geology, 2014, 22(5): 804-810. doi: 10.13544/j.cnki.jeg.2014.05.005 [2] 王洋,冯君,李珈瑶,等. FRP锚杆在岩土锚固中的研究进展[J]. 工程地质学报,2018,26(3): 776-784. doi: 10.13544/j.cnki.jeg.2017-139WANG Yang, FENG Jun, LI Jiayao, et al. Advance of frp anchor bolts in geotechnical anchoring[J]. Journal of Engineering Geology, 2018, 26(3): 776-784. doi: 10.13544/j.cnki.jeg.2017-139 [3] 吴刚,朱莹,董志强,等. 碱性环境中BFRP筋耐腐蚀性能试验研究[J]. 土木工程学报,2014,47(8): 32-41. doi: 10.15951/j.tmgcxb.2014.08.029WU Gang, ZHU Ying, DONG Zhiqiang, et al. Experimental study on the corrosion resistance performance of BFRP bars in the alkaline environment[J]. China Civil Engineering Journal, 2014, 47(8): 32-41. doi: 10.15951/j.tmgcxb.2014.08.029 [4] 朱颖,魏永幸,蒋登伟,等. 复杂艰险山区高速铁路减灾选线设计研究[J]. 高速铁路技术,2020,11(2): 7-11,26.ZHU Ying, WEI Yongxing, JIANG Dengwei, et al. Research on route selection design of high-speed railway for disaster reduction in complex and dangerous mountain[J]. High Speed Railway Technology, 2020, 11(2): 7-11,26. [5] 贾毅,赵人达,李福海. 高温及围岩粗糙度对锚杆灌浆料抗拔强度影响的试验研究[J]. 铁道学报,2017,39(6): 141-149. doi: 10.3969/j.issn.1001-8360.2017.06.019JIA Yi, ZHAO Renda, LI Fuhai. Experimental study on influence of high temperature and roughness of surrounding rock on tensile strength of bolt grouting material[J]. Journal of the China Railway Society, 2017, 39(6): 141-149. doi: 10.3969/j.issn.1001-8360.2017.06.019 [6] 崔凯,王东华,谌文武,等. 基于SH-(C + F)浆液锚杆锚固性能与机理研究[J]. 工程地质学报,2017,25(1): 19-26.CUI Kai, WANG Donghua, CHEN Wenwu, et al. Performance and mechanism of bolts fully grouted with SH-(C + F) slurry[J]. Journal of Engineering Geology, 2017, 25(1): 19-26. [7] 王洋. BFRP砂浆锚杆锚固机理现场试验研究[D]. 成都: 西南交通大学, 2018. [8] 吴芳. 玄武岩纤维筋与混凝土粘结性能试验研究[D]. 大连: 大连理工大学, 2009. [9] WANG H L, SUN X Y, PENG G Y, et al. Experimental study on bond behaviour between BFRP bar and engineered cementitious composite[J]. Construction and Building Materials, 2015, 95: 448-456. doi: 10.1016/j.conbuildmat.2015.07.135 [10] DONG Z Q, WU G, ZHAO X L, et al. A refined prediction method for the long-term performance of BFRP bars serviced in field environments[J]. Construction and Building Materials, 2017, 155: 1072-1080. doi: 10.1016/j.conbuildmat.2017.07.154 [11] 张绍逸. 玄武岩纤维筋与混凝土粘结锚固性能试验研究[D]. 哈尔滨: 东北林业大学, 2013. [12] 李国维,黄志怀,张丹,等. 玻璃纤维增强聚合物锚杆承载特征现场试验[J]. 岩石力学与工程学报,2006,25(11): 2240-2246. doi: 10.3321/j.issn:1000-6915.2006.11.012LI Guowei, HUANG Zhihuai, ZHANG Dan, et al. Field test on load-bearing character of glass fiber reinforced polymer bolt[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(11): 2240-2246. doi: 10.3321/j.issn:1000-6915.2006.11.012 [13] 曾宪明,林大路,李世民,等. 锚固类结构杆体临界锚固长度问题综合研究[J]. 岩石力学与工程学报,2009,28(增2): 3609-3625. doi: 10.3321/j.issn:1000-6915.2009.z2.046ZENG Xianming, LIN Dalu, LI Shimin, et al. Comprehensive research of critical anchorage length problem of rod of anchorage structure[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(S2): 3609-3625. doi: 10.3321/j.issn:1000-6915.2009.z2.046 [14] 张乐文,汪稔. 岩土锚固理论研究之现状[J]. 岩土力学,2002,23(5): 627-631. doi: 10.3969/j.issn.1000-7598.2002.05.022ZHANG Lewen, WANG Ren. Research on status quo of anchorage theory of rock and soil[J]. Rock and Soil Mechanics, 2002, 23(5): 627-631. doi: 10.3969/j.issn.1000-7598.2002.05.022 [15] 吕东. 粗颗粒含量对川西崩坡积混合土静、动强度特性的影响研究[D]. 成都: 西南交通大学, 2017. [16] 傅华,韩华强,凌华. 堆石料级配缩尺方法对其室内试验结果的影响[J]. 岩土力学,2012,33(9): 2645-2649. doi: 10.16285/j.rsm.2012.09.030FU Hua, HAN Huaqiang, LING Hua. Effect of grading scale method on results of laboratory tests on rockfill materials[J]. Rock and Soil Mechanics, 2012, 33(9): 2645-2649. doi: 10.16285/j.rsm.2012.09.030 [17] 郭万里,朱俊高,温彦锋. 对粗粒料4种级配缩尺方法的统一解释[J]. 岩土工程学报,2016,38(8): 1473-1480. doi: 10.11779/CJGE201608015GUO Wanli, ZHU Jungao, WEN Yanfeng. Unified description for four grading scale methods for coarse aggregate[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(8): 1473-1480. doi: 10.11779/CJGE201608015 -

下载:

下载: