Numerical Modeling of Dynamic Temperature Field for Air-Cooling Traction Transformers with Forced Oil Circulation

-

摘要:

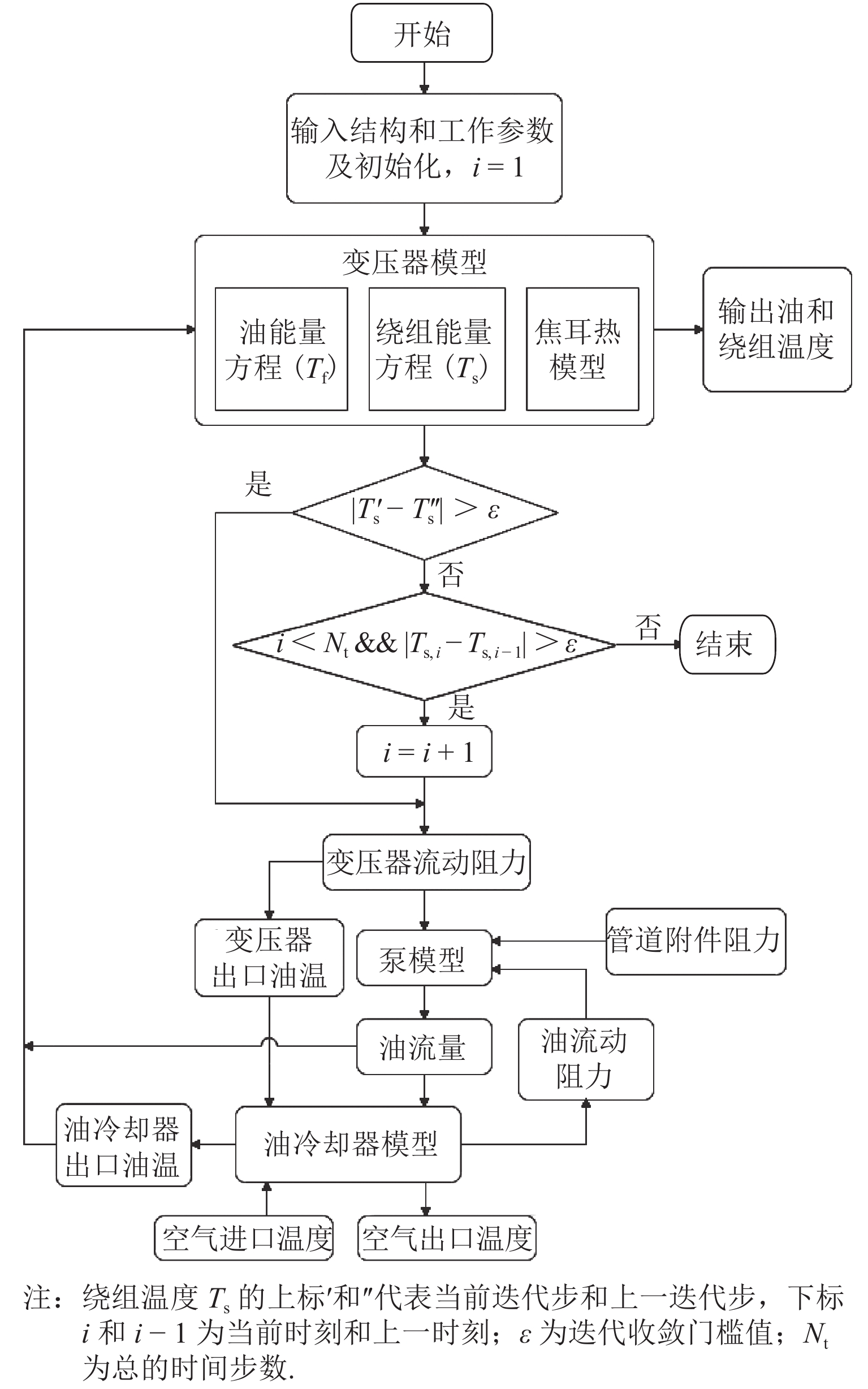

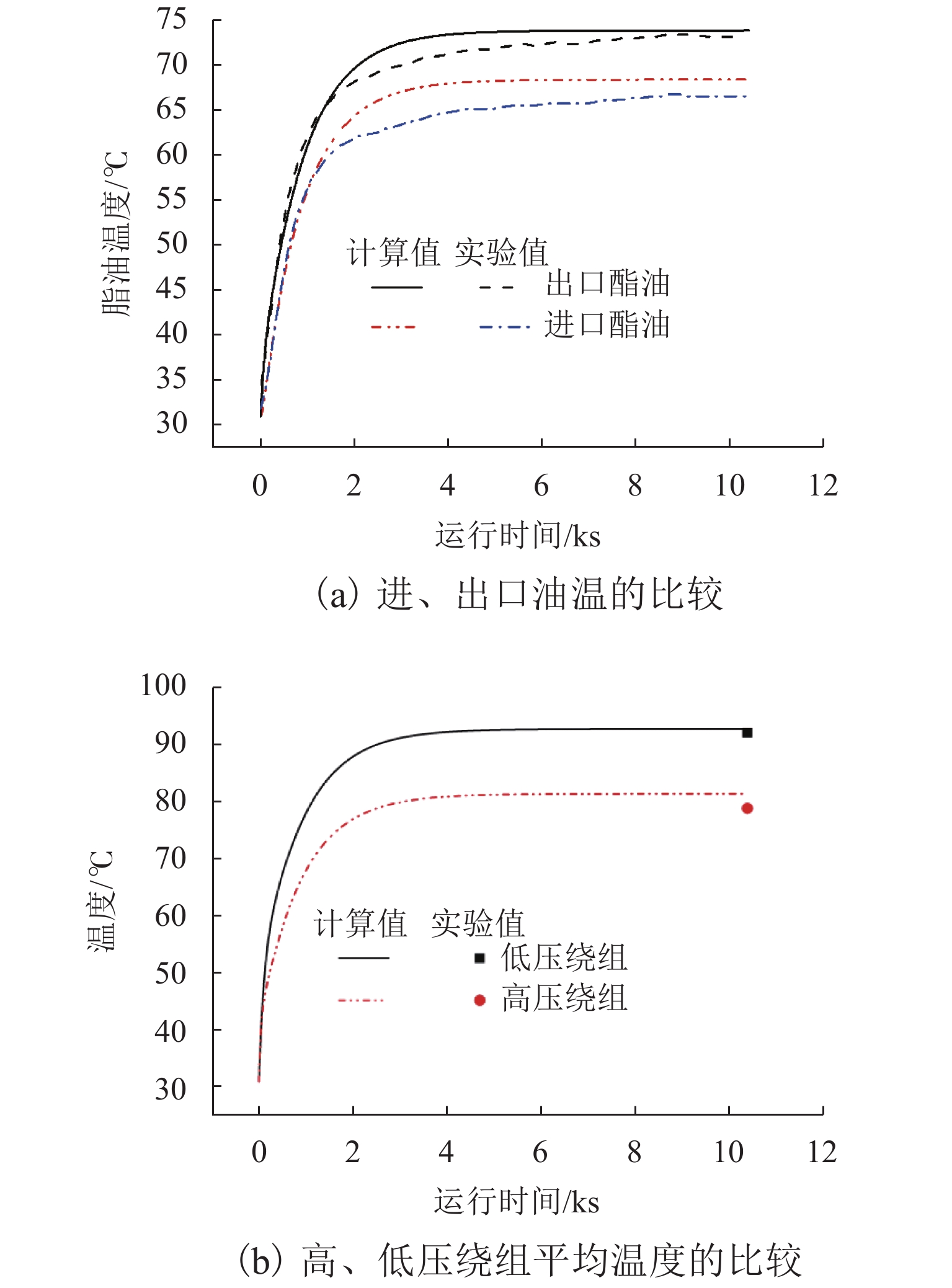

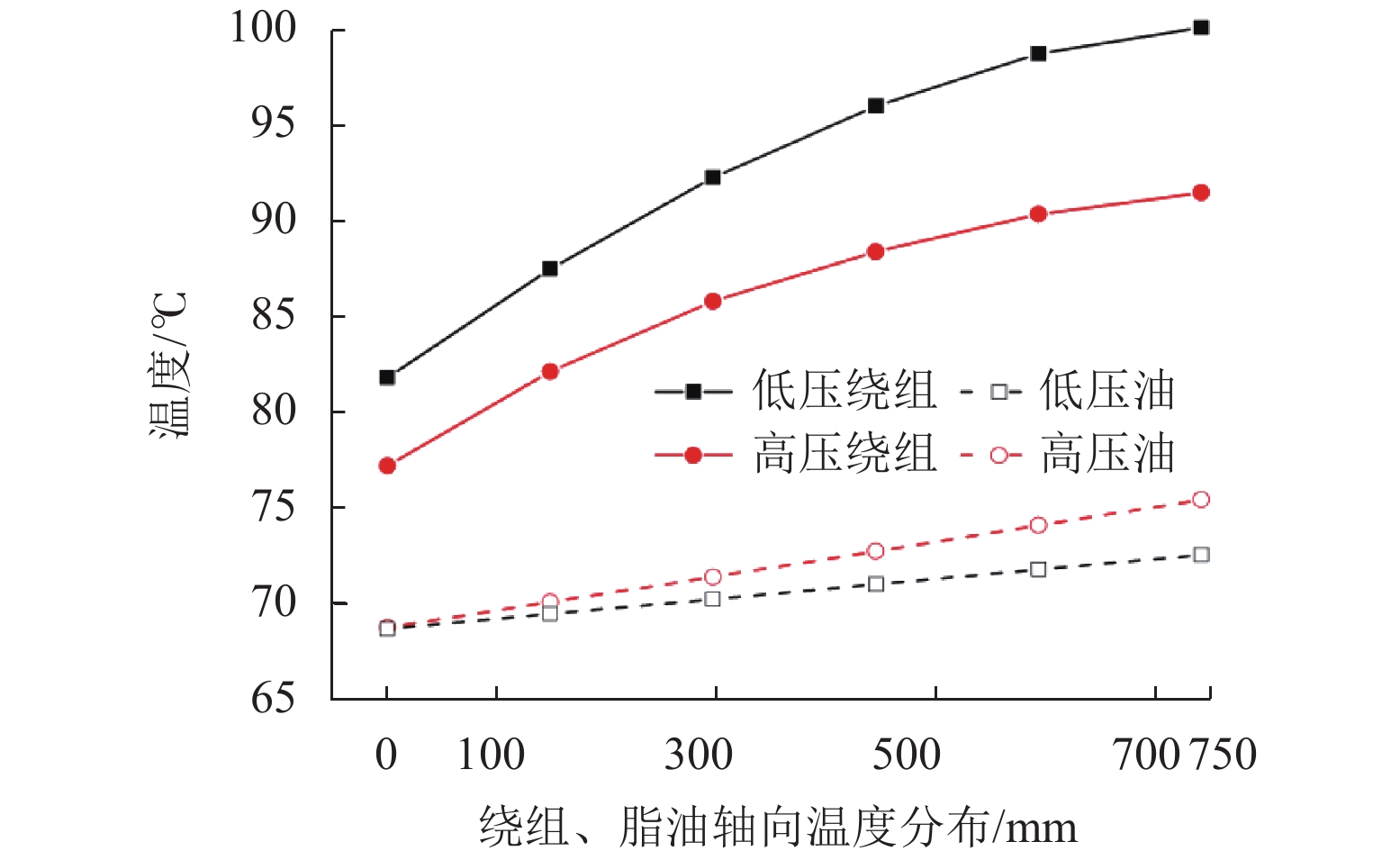

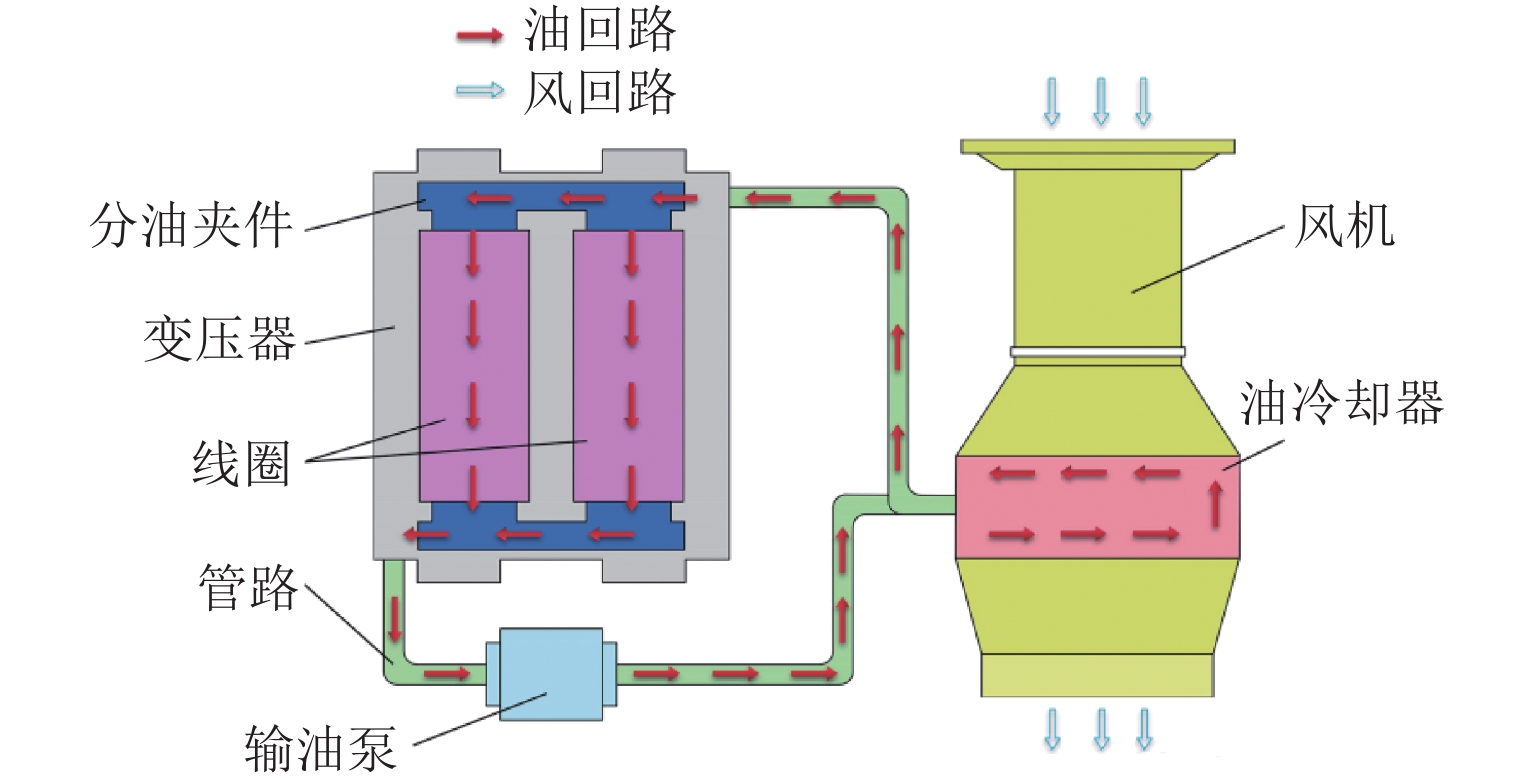

牵引变压器散热涉及冷却油与绕组的共轭传热和热油在油冷却器的二次散热. 为准确模拟其温度场随时间和空间的变化规律,在一维假设基础上,建立了牵引变压器(含绕组和冷却油)和油冷却器的分布参数模型,并与油泵和管道等集中参数模型耦合,建立了牵引变压器动态温度场数学模型,同时提出了一套数值求解算法;对一台牵引变压器及其散热系统进行动态温升实验,以此检验了模型预测精度. 研究结果表明:模型预测的牵引变压器冷却油温过渡时间(58 min)与实验值(61 min)吻合良好,稳定工作的冷却油和绕组温度与实验值的偏差分别为1.3 ℃和2.5 ℃,可以用于指导牵引变压器散热系统的工程设计及优化.

Abstract:The thermal dissipation of traction transformers is involved in the conjugate heat transfer between the cooling oil and windings along with the secondary heat release of the heated oil delivered to an oil cooler. To simulate the temporal and spatial temperature variations of traction transformers accurately, the distributed parameter models of traction transformer (including windings and oil) and oil cooler are set up based on the one-dimensional assumption, respectively. The two models are integrated with the lumped parameter ones of oil pump and pipelines. A mathematical model of dynamic temperature field is obtained for the traction transformers. Besides, an iteration algorithm is proposed for the numerical solution. For model validation, a temperature rise experiment is performed on a traction transformer and its cooling system. The results show that the transition time for a stable transformer oil temperature obtained by current model (58 min) meets well with experimental measurement (61 min). The predicted average temperatures of oil and windings under the stable running condition take the discrepancies of 1.3 ℃ and 2.5 ℃ against experimental counterparts, respectively. The current work can be used for the optimal design of traction transformers.

-

表 1 油和绕组稳态温度预测值与实验值的对比

Table 1. Comparison of oil and winding temperatures of current model against experimental counterparts

参数 进口油温/℃ 出口油温/℃ 稳定时间/min 高压绕组温度/℃ 低压绕组温度/℃ 模型预测值 68.5 73.9 58 81.4 92.7 实验值 66.7 73.2 61 78.9 92.1 偏差 1.8 0.7 −3 2.5 0.6 -

[1] 兰云飞, 仝泽柳, 石瑛. 高速铁路概论[M]. 北京: 北京交通大学出版社, 2016. [2] 杨斯泐,郭晨曦,李强. 动车组牵引变压器绕组变形测试技术研究[J]. 铁道机车车辆,2018,38(5): 61-65,76. doi: 10.3969/j.issn.1008-7842.2018.05.15YANG Sile, GUO Chenxi, LI Qiang. Research on test technology of the winding deformation of EMU traction transformers[J]. Railway Locomotive & Car, 2018, 38(5): 61-65,76. doi: 10.3969/j.issn.1008-7842.2018.05.15 [3] 高波,许竟,杨雁,等. 车载牵引变压器油纸绝缘热老化特性及机理研究[J]. 铁道学报,2020,42(7): 80-86.GAO Bo, XU Jing, YANG Yan, et al. Thermal aging characteristics and mechanism analysis of oil-paper insulation in on-board traction transformer[J]. Journal of the China Railway Society, 2020, 42(7): 80-86. [4] IEEE S A.IEEE guide for loading mineral-oil-immersed transformers and step-voltage regulators: IEEE Std C57.91—2011[S]. New York: IEEE, 2011. [5] SWIFT G, MOLINSKI T S, LEHN W. A fundamental approach to transformer thermal modeling—part I: theory and equivalent circuit[J]. IEEE Transactions on Power Delivery, 2001, 16(2): 171-175. doi: 10.1109/61.915478 [6] SWIFT G, MOLINSKI T S, BRAY R, et al. A fundamental approach to transformer thermal modeling—part II:field verification[J]. IEEE Transactions on Power Delivery, 2001, 16(2): 176-180. doi: 10.1109/61.915479 [7] 滕黎,陈伟根,孙才新. 油浸式电力变压器动态热路改进模型[J]. 电网技术,2012,36(4): 236-241.TENG Li, CHEN Weigen, SUN Caixin. An improved dynamic thermal circuit model of oil-immersed power transformer[J]. Power System Technology, 2012, 36(4): 236-241. [8] 陈伟根,苏小平,孙才新,等. 基于有限体积法的油浸式变压器绕组温度分布计算[J]. 电力自动化设备,2011,31(6): 23-27. doi: 10.3969/j.issn.1006-6047.2011.06.006CHEN Weigen, SU Xiaoping, SUN Caixin, et al. Temperature distribution calculation based on FVM for oil-immersed power transformer windings[J]. Electric Power Automation Equipment, 2011, 31(6): 23-27. doi: 10.3969/j.issn.1006-6047.2011.06.006 [9] 苏小平,陈伟根,胡启元,等. 基于解析-数值技术的变压器绕组温度分布计算[J]. 高电压技术,2014,40(10): 3164-3170.SU Xiaoping, CHEN Weigen, HU Qiyuan, et al. Calculation for transformer winding temperature distribution by numerical analytical technology[J]. High Voltage Engineering, 2014, 40(10): 3164-3170. [10] 谢蓉,张星,关亮,等. 强迫油循环冷却变压器内部温度场数值模拟[J]. 电力科学与工程,2012,28(10): 47-52.XIE Rong, ZHANG Xing, GUAN Liang, et al. Numerical simulation on temperature field in forced-directed oil cooling transformer[J]. Electric Power Science and Engineering, 2012, 28(10): 47-52. [11] TORRIANO F, CHAABAN M, PICHER P. Numerical study of parameters affecting the temperature distribution in a disc-type transformer winding[J]. Applied Thermal Engineering, 2010, 30(14/15): 2034-2044. [12] WAKIL N E, CHERECHES N C, PADET J. Numerical study of heat transfer and fluid flow in a power transformer[J]. International Journal of Thermal Sciences, 2006, 45(6): 615-626. doi: 10.1016/j.ijthermalsci.2005.09.002 [13] YOU Y H, YU S, TIAN Y Q, et al. A numerical study on the unsteady heat transfer in active regenerator with multi-layer refrigerants of rotary magnetic refrigerator near room temperature[J]. International Journal of Refrigeration, 2016, 65: 238-249. doi: 10.1016/j.ijrefrig.2016.02.002 [14] ZHANG J H, LI X G. Oil cooling for disk-type transformer windings—part 1: theory and model development[J]. IEEE Transactions on Power Delivery, 2006, 21(3): 1318-1325. doi: 10.1109/TPWRD.2006.871019 [15] ISMAIL L S, VELRAJ R. Studies on Fanning friction (f) and colburn (j) factors of offset and wavy fins compact plate fin heat exchanger—a CFD approach[J]. Numerical Heat Transfer, Part A: Applications, 2009, 56(12): 987-1005. doi: 10.1080/10407780903507957 [16] KAYS W M, LONDON A L. 紧凑式热交换器[M]. 宣益民, 张后雷, 译. 北京: 科学出版社, 1997. [17] 史美中, 王中铮. 热交换器原理与设计[M]. 4版. 南京: 东南大学出版社, 2009. [18] TSILI M A, AMOIRALIS E I, KLADAS A G, et al. Power transformer thermal analysis by using an advanced coupled 3D heat transfer and fluid flow FEM model[J]. International Journal of Thermal Sciences, 2012, 53: 188-201. doi: 10.1016/j.ijthermalsci.2011.10.010 -

下载:

下载: