Numerical Simulation Method for Vertical Vibration of Heavy Vehicle-Expansion Joint Coupled System

-

摘要:

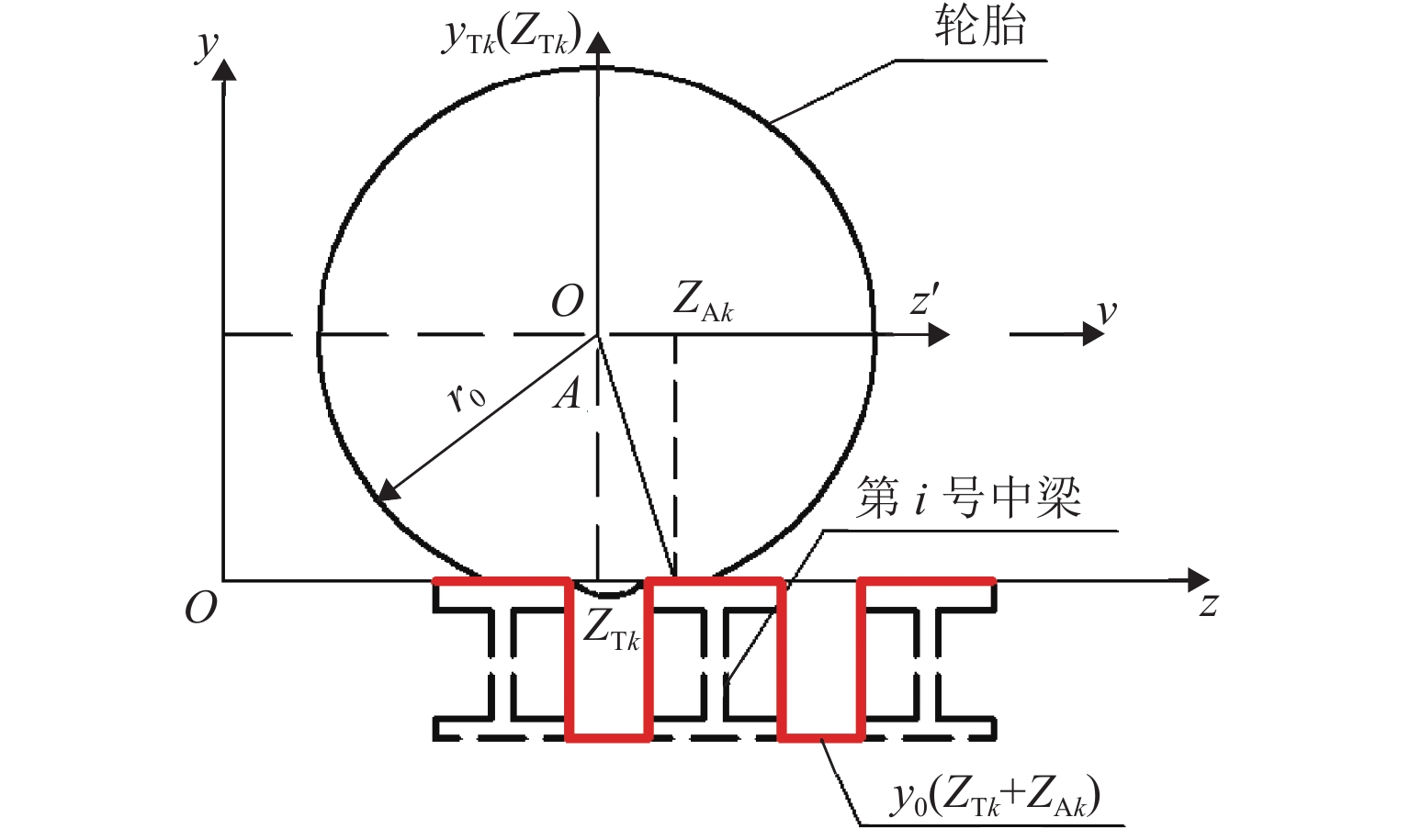

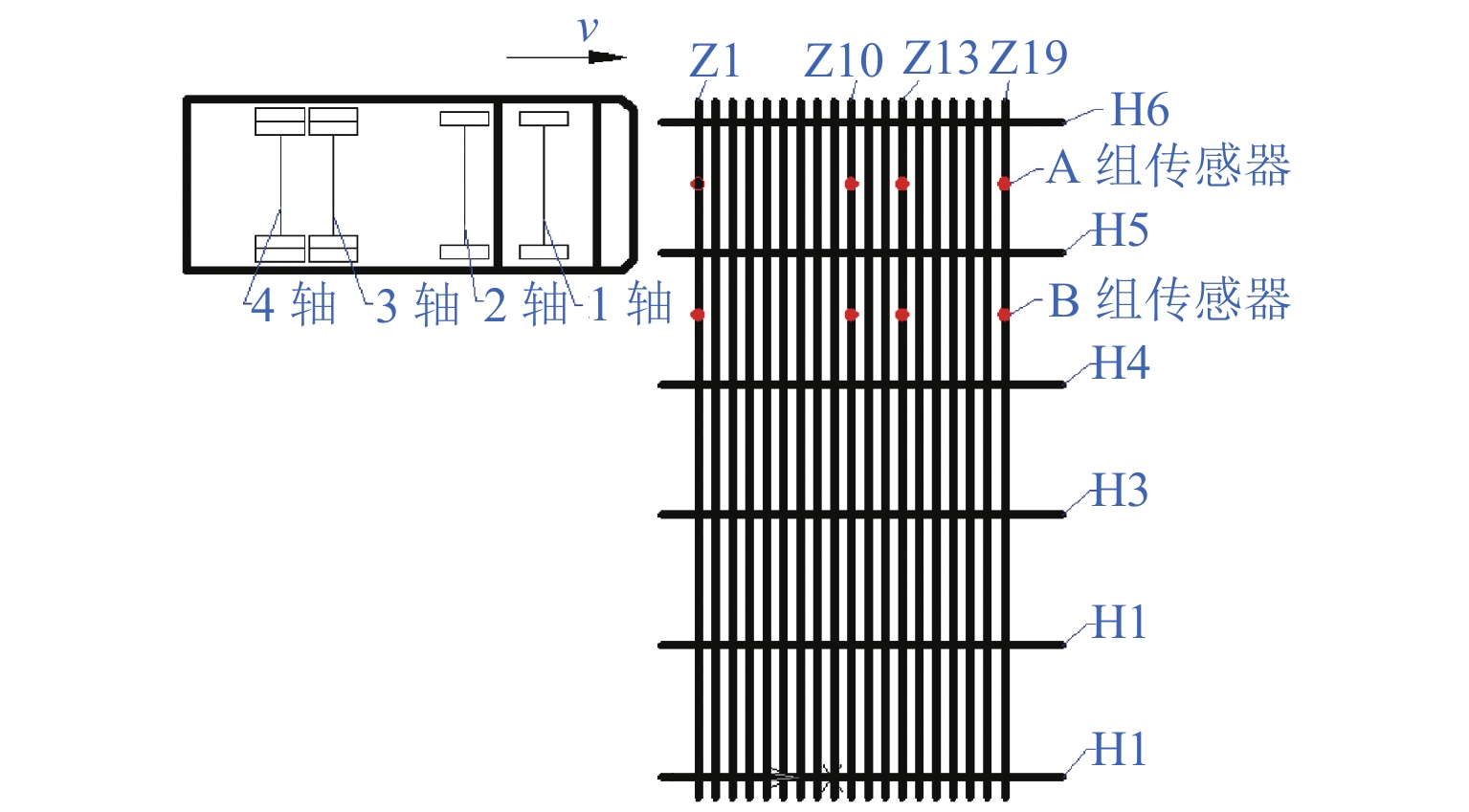

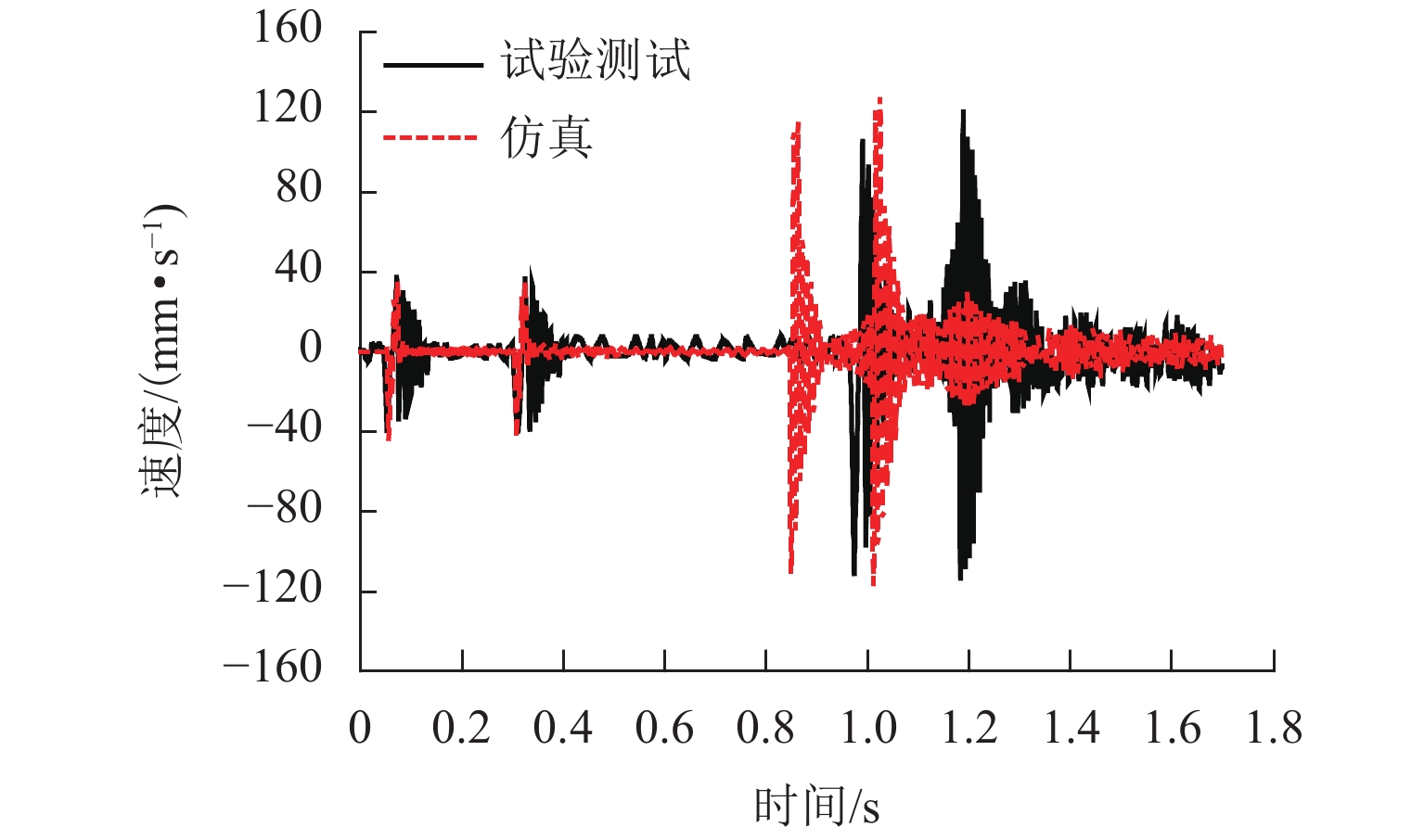

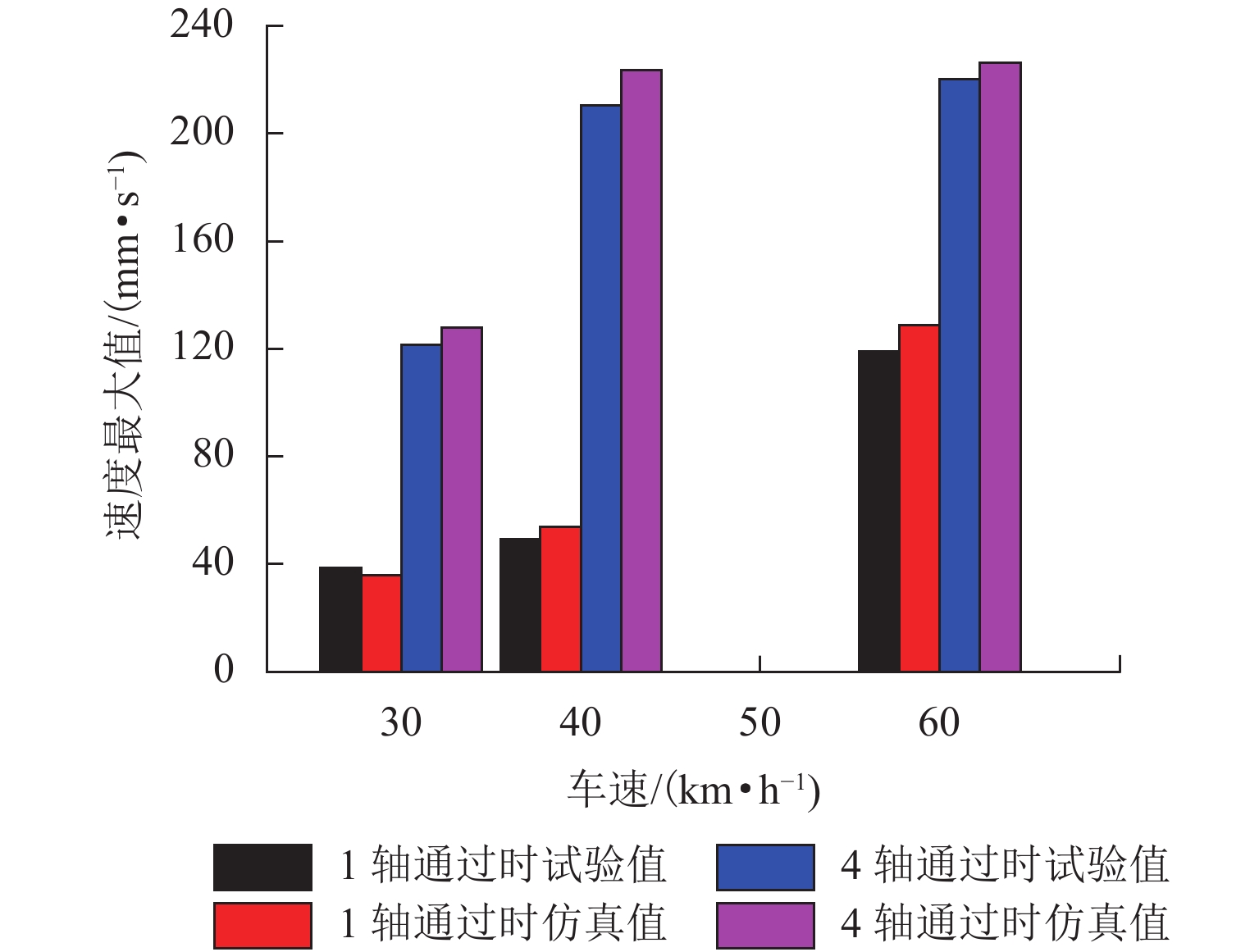

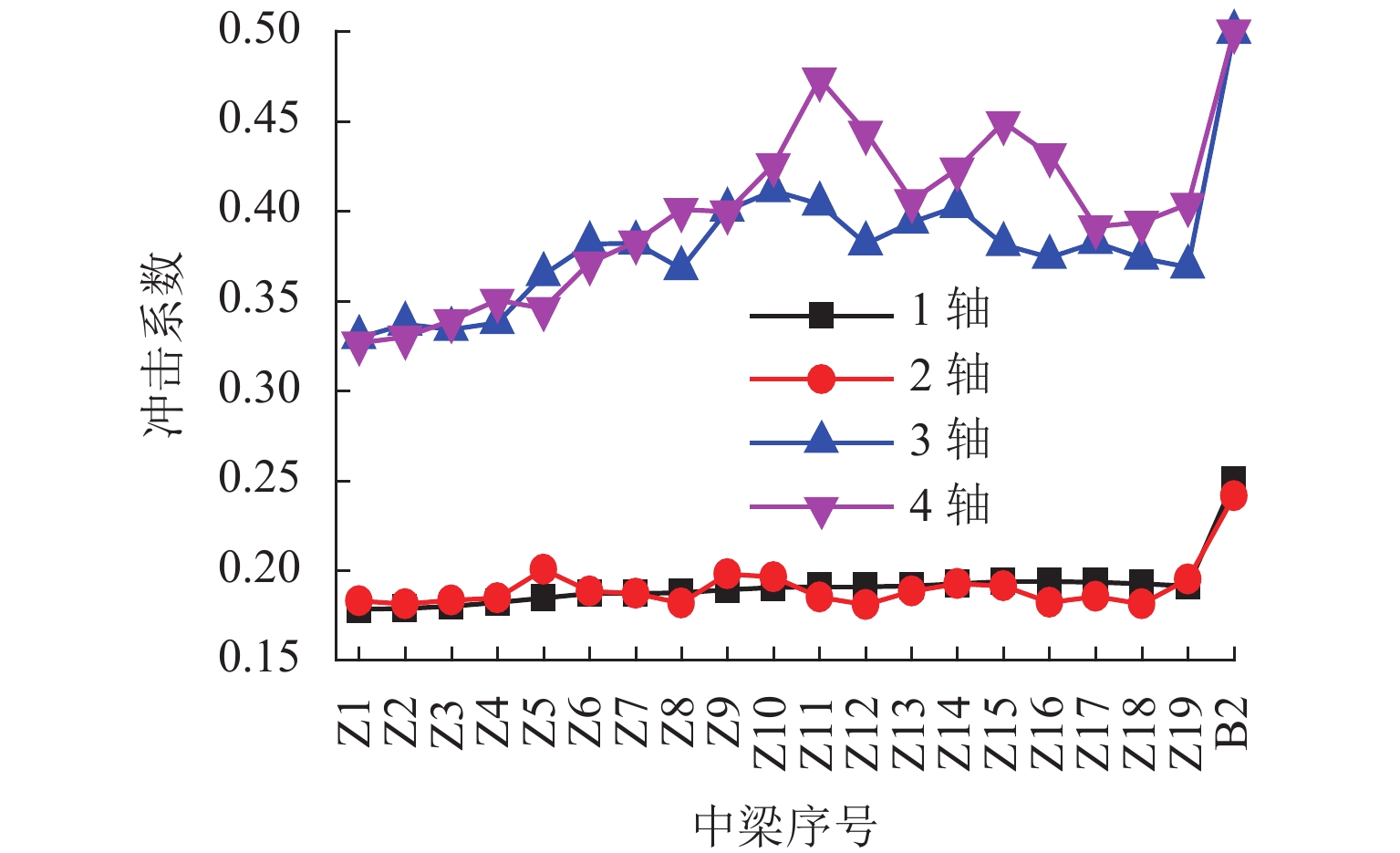

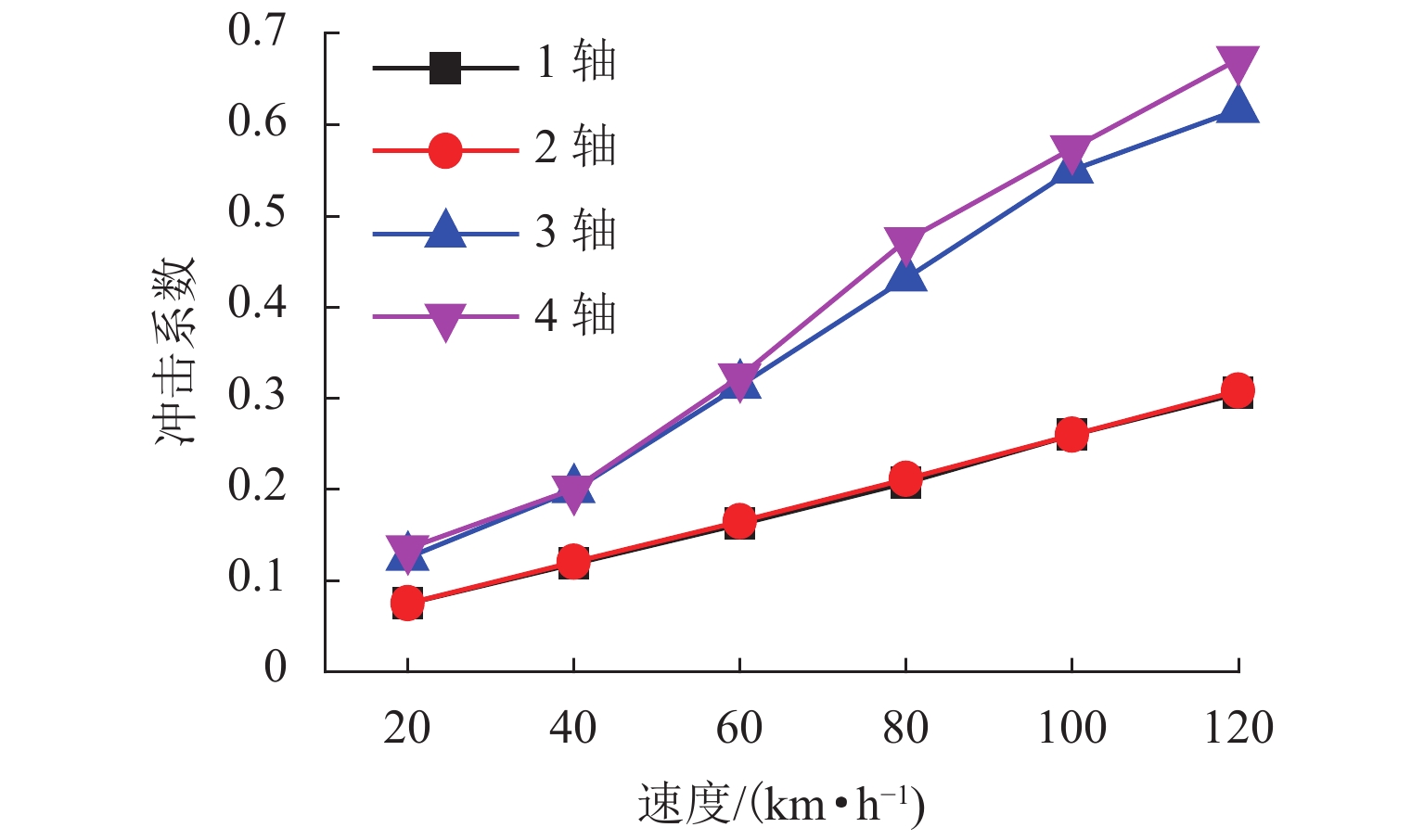

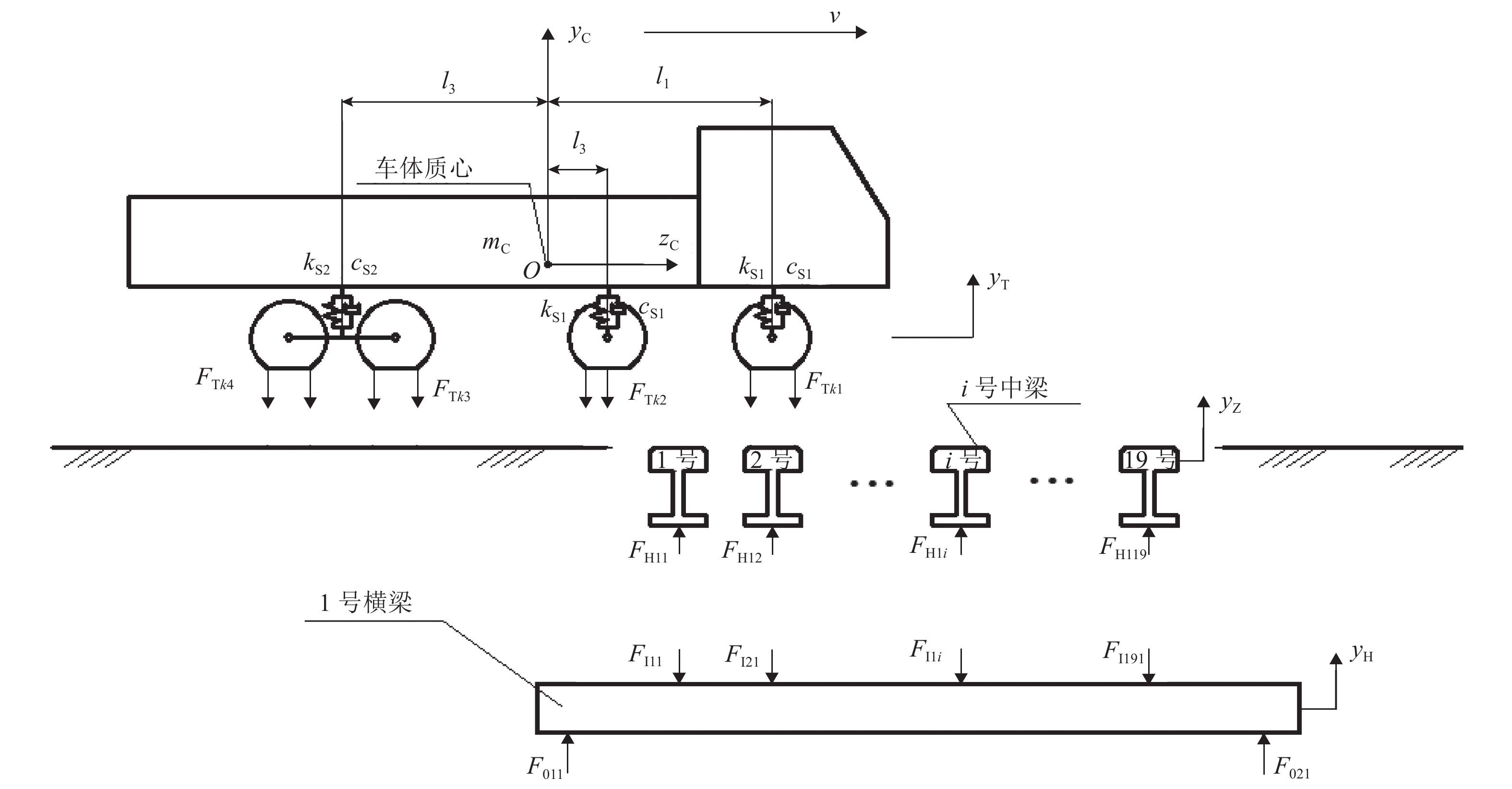

为研究车辆对大位移伸缩缝振动特性的影响,考虑轮胎载重车辆过大位移桥梁伸缩缝时的真实激励特性,提出了一种载重车辆-伸缩缝耦合系统垂向动力学模型,同时引入新型快速积分法对数值模型进行求解. 以ZL1600模数式大位移伸缩缝为研究对象,通过仿真结果与试验测试结果的对比验证模型有效性,并基于此模型分析了轮胎载重车辆对大位移伸缩缝的冲击效应. 研究结果表明:中梁测点垂向速度的动力学模型仿真结果能较好地匹配试验测试结果,仿真得到中梁测点最大下沉位移的偏差均小于10.0%,表明该模型具有较高的计算精度;车辆轮胎力的最大冲击系数出现在车轮驶上伸缩缝后方桥面时,需要考虑对此处结构进行加强;车辆轮胎对伸缩缝中梁和后方桥面的冲击系数均随车速的增大而增大,最大冲击系数分别为0.67和0.82,均超过了国内现行规范的推荐值0.45,应得到重视.

Abstract:To study the influence of vehicles on vibration characteristics of large displacement expansion joints, a vertical dynamic model of heavy vehicle-expansion joint coupled system is established, considering the real load characteristics of a wheeled heavy vehicle when passing a large displacement bridge expansion joint. The new fast integration method is introduced to solve the numerical model. Taking ZL1600 modular large displacement expansion joint as the research object, the validity of the model is verified by comparing simulation results with test results. Based on the model, the impact effect of wheeled heavy vehicle on expansion joint is analyzed. The results show that the dynamic model simulation results of vertical velocity at the center beam test points can be well matched with the test results. The deviations of center beam maximum sinking displacements between simulation results and test results are less than 10.0%, which indicates that the model has high calculation accuracy. The maximum impact factor of tire loads occurs when the wheel drives on the bridge deck behind the expansion joint. Therefore, it is necessary to strengthen the nearby structure. The impact factor of tire loads on the center beams and the rear bridge deck increases with speed. The maximum impact factors are 0.67 and 0.82 respectively, both exceeding the recommended value of 0.45 in the current Chinese standard. It should be given more attention.

-

Key words:

- vehicles /

- expansion joints /

- numerical simulation /

- experimental verification /

- coupled vibration

-

表 1 大位移伸缩缝主要结构参数

Table 1. Main structural parameters of large displacement expansion joint

项目 数值 项目 数值 弹性模量 E/GPa 205 泊松比 ν 0.3 材料密度 ρ/(kg·m−3) 7800 缝宽 B/mm 0~80 中梁单位长度质量 mZ/(kg·m−1) 49.33 横梁单位长度质量 mH/(kg·m−1) 315.9 中梁长度 LZ/m 10.2 横梁长度 LH/m 4.2 中梁截面惯性矩 IZ/m4 1.24 × 10−5 横梁截面惯性矩 IH/m4 2.46 × 10−4 中梁、横梁弹性元件刚度/(kN·mm−1) 80 中梁、横梁弹性元件阻尼/(N·s·mm−1) 5 表 2 四轴载重车辆动力学参数

Table 2. Dynamic parameters of four-axle vehicle

参数 数值 参数 数值 车体质量 mC/kg 6450 1 轴至车体质心

的距离 l1/m3.327 车体俯仰惯量JCx/(kg·m2) 88327 2 轴至车体质心

的距离 l2/m1.227 车体侧滚惯量JCz/(kg·m2) 17665 后悬架中心至车体质心的距离 l3/m 3.948 后悬架平衡

杆质量 mS/kg200 3、4 轴之间的

距离 l4/m1.35 后悬架平衡杆俯仰惯量 JS/(kg·m2) 380 1、2 轴的轮距

一半 b1/m1.0135 1、2 轴非簧载

的质量 mT1 /kg500 3、4 轴的轮距

一半 b2/m0.93 3、4 轴非簧载

的质量 mT2/kg800 1、2 悬架阻尼

cS1/(kN·s·m−1)25.32 1、2 轴悬架刚

度 kS1 /(kN·m−1)284 后悬架阻尼cS2/(kN·s·m−1) 50.636 后悬架刚度kS2/(kN·m−1) 2064 1、2 轴轮胎阻尼

cT1/(kN·s·m−1)3.5 1、2 轴轮胎刚

度 kT1 /(kN·m−1)1402 3、4 轴轮胎阻尼 cT2/(kN·s·m−1) 7 3、4 轴轮胎刚

度 kT2 /(kN·m−1)2804 轮胎型号 11.00R20-18RP 表 3 中梁测点最大下沉量对比结果

Table 3. Comparison results of maximum sinking displacement of center beam test points

传感器

位置车速/

(km·h−1)1 号中梁 10 号中梁 13 号中梁 19 号中梁 试验

值/mm仿真

值/mm偏差/

%试验

值/mm仿真

值/mm偏差/

%试验

值/mm仿真

值/mm偏差/

%试验

值/mm仿真

值/mm偏差/

%A 组 30 0.42 0.41 2.4 0.49 0.51 4.1 0.54 0.56 3.7 0.55 0.58 5.5 40 0.50 0.48 4.0 0.56 0.60 7.1 0.58 0.61 5.2 0.64 0.69 7.8 60 0.54 0.51 5.6 0.58 0.59 1.7 0.62 0.65 4.8 0.60 0.64 6.7 B 组 30 0.14 0.13 7.1 0.23 0.24 4.3 0.20 0.21 5.0 0.22 0.21 4.5 40 0.18 0.17 5.6 0.25 0.27 8.0 0.29 0.31 6.9 0.26 0.28 7.7 60 0.20 0.19 5.0 0.29 0.31 6.9 0.31 0.30 3.2 0.23 0.25 8.7 -

[1] 赵健. 高速公路桥梁伸缩缝病害的成因及防治[J]. 公路交通科技(应用技术版),2007,3(12): 128-129, 133.ZHAO Jian. Causes and prevention of expansion joint disease for expressway bridge[J]. Highway Transportation Technology (Application Technology Edition), 2007, 3(12): 128-129, 133. [2] XIA Q, XIA Y, WAN H P, et al. Condition analysis of expansion joints of a long-span suspension bridge through metamodel-based model updating considering thermal effect[J]. Structural Control and Health Monitoring, 2020, 27(5): 1-16. [3] HU J H, WANG L H, SONG X P, et al. Field monitoring and response characteristics of longitudinal movements of expansion joints in long-span suspension bridges[J]. Measurement: Journal of the International Measurement Confederation, 2020, 162: 1-13. [4] 孙正峰,王少华,吴昊,等. 大位移桥梁伸缩缝耦合动力学研究[J]. 公路工程,2014,39(2): 59-62,104.SUN Zhengfeng, WANG Shaohua, WU Hao, et al. Coupling dynamic research of the large displacement bridge expansion joints[J]. Highway Engineering, 2014, 39(2): 59-62,104. [5] 严情木,王少华,杨刚,等. 大位移桥梁伸缩缝的垂向动力学响应研究[J]. 机械设计与制造,2013(7): 41-43,46. doi: 10.3969/j.issn.1001-3997.2013.07.014YAN Qingmu, WANG Shaohua, YANG Gang, et al. Research of vertical dynamic response of the large displacement bridge expansion joint[J]. Machinery Design & Manufacture, 2013(7): 41-43,46. doi: 10.3969/j.issn.1001-3997.2013.07.014 [6] LI B, WANG S H, WU X, et al. Dynamic response of continuous beams with discrete viscoelastic supports under sinusoidal loading[J]. International Journal of Mechanical Sciences, 2014, 86: 76-82. doi: 10.1016/j.ijmecsci.2014.02.005 [7] 谢旭,吴冬雁,王建峰,等. 伸缩缝车辆冲击引起的钢箱梁桥振动特性[J]. 浙江大学学报(工学版),2009,43(10): 1923-1930. doi: 10.3785/j.issn.1008-973X.2009.10.030XIE Xu, WU Dongyan, WANG Jianfeng, et al. Dynamical behavior of steel box girder bridges due to vehicle-induced vibration at expansion joint[J]. Journal of Zhejiang University (Engineering Science), 2009, 43(10): 1923-1930. doi: 10.3785/j.issn.1008-973X.2009.10.030 [8] SUN Z, ZHANG Y F. Vehicle-induced dynamic response of expansion joints in long span bridges[J]. Applied Mechanics and Materials, 2014, 584/585/586: 2117-2120. [9] FRIEDL R, MANGERIG I. Dynamic amplification of bridge-expansion-joints considering roughness induced vehicle vibrations[J]. Procedia Engineering, 2017, 199: 2651-2656. doi: 10.1016/j.proeng.2017.09.515 [10] MANGERIG I, FRIEDL R. Dynamic interaction between vehicles and bridge expansion joints[C]// Proceedings of the International Conference on Structural Dynamic Porto. [S.l.]: European Association for Structural Dynamics, 2014: 1153-1160. [11] 丁勇,谢旭,区达光,等. 基于分布式弹簧-阻尼单元的桥头跳车动力荷载分析[J]. 土木工程学报,2012,45(12): 127-135.DING Yong, XIE Xu, AU FRANCIS T K, et al. Analysis of dynamic load of vehicle bumping at bridge-head using distributed spring-damper element[J]. China Civil Engineering Journal, 2012, 45(12): 127-135. [12] DING Y, ZHANG W, AU F T K. Effect of dynamic impact at modular bridge expansion joints on bridge design[J]. Engineering Structures, 2016, 127: 645-662. doi: 10.1016/j.engstruct.2016.09.007 [13] 张纬. 车辆荷载作用下桥梁伸缩缝强度与疲劳问题研究[D]. 宁波: 宁波大学, 2017. [14] 吴延平,吴冬雁,谢旭,等. 车辆通过钢箱梁桥伸缩缝的振动响应及减振[J]. 噪声与振动控制,2013,33(2): 95-100.WU Yanping, WU Dongyan, XIE Xu, et al. Response and vibration control of steel box-girder bridge when vehicles passing through the expansion joint[J]. Noise and Vibration Control, 2013, 33(2): 95-100. [15] 张锋. 深季节冻土区重载汽车荷载下路基动力响应与永久变形[D]. 哈尔滨: 哈尔滨工业大学, 2012. [16] 翟婉明. 车辆-轨道耦合动力学[M]. 4版. 北京: 科学出版社, 2015. [17] 郭孔辉,刘青,丁国峰. 轮胎包容特性分析及其在汽车振动系统建模中的应用[J]. 汽车工程,1999,21(2): 65-71,80.GUO Konghui, LIU Qing, DING Guofeng. Analysis of tire enveloping properties and its application in modeling of vehicle vibration systems[J]. Automotive Engineering, 1999, 21(2): 65-71,80. [18] YANG S P, LI S H, LU Y J. Dynamics of vehicle-pavement coupled system based on a revised flexible roller contact tire model[J]. Science in China Series E:Technological Sciences, 2009, 52(3): 721-730. doi: 10.1007/s11431-009-0053-0 [19] 崔志博. 子午线轮胎接地特性可控设计理论及实验研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. [20] 林楠,李东升,李宏男. 基于零初值的测试加速度积分速度与位移的方法[J]. 中国科学:技术科学,2016,46(6): 602-614. doi: 10.1360/N092015-00282LIN Nan, LI Dongsheng, LI Hongnan. Novel integration method of measured acceleration to velocity and displacement based on zero initial condition[J]. Scientia Sinica (Technologica), 2016, 46(6): 602-614. doi: 10.1360/N092015-00282 [21] 中华人民共和国交通运输部. 公路桥涵设计通用规范: JTG D60—2015[S]. 北京: 人民交通出版社, 2015 -

下载:

下载: