Emission Characteristics of Successively Supercharged Diesel Engine Blended with Biodiesel

-

摘要:

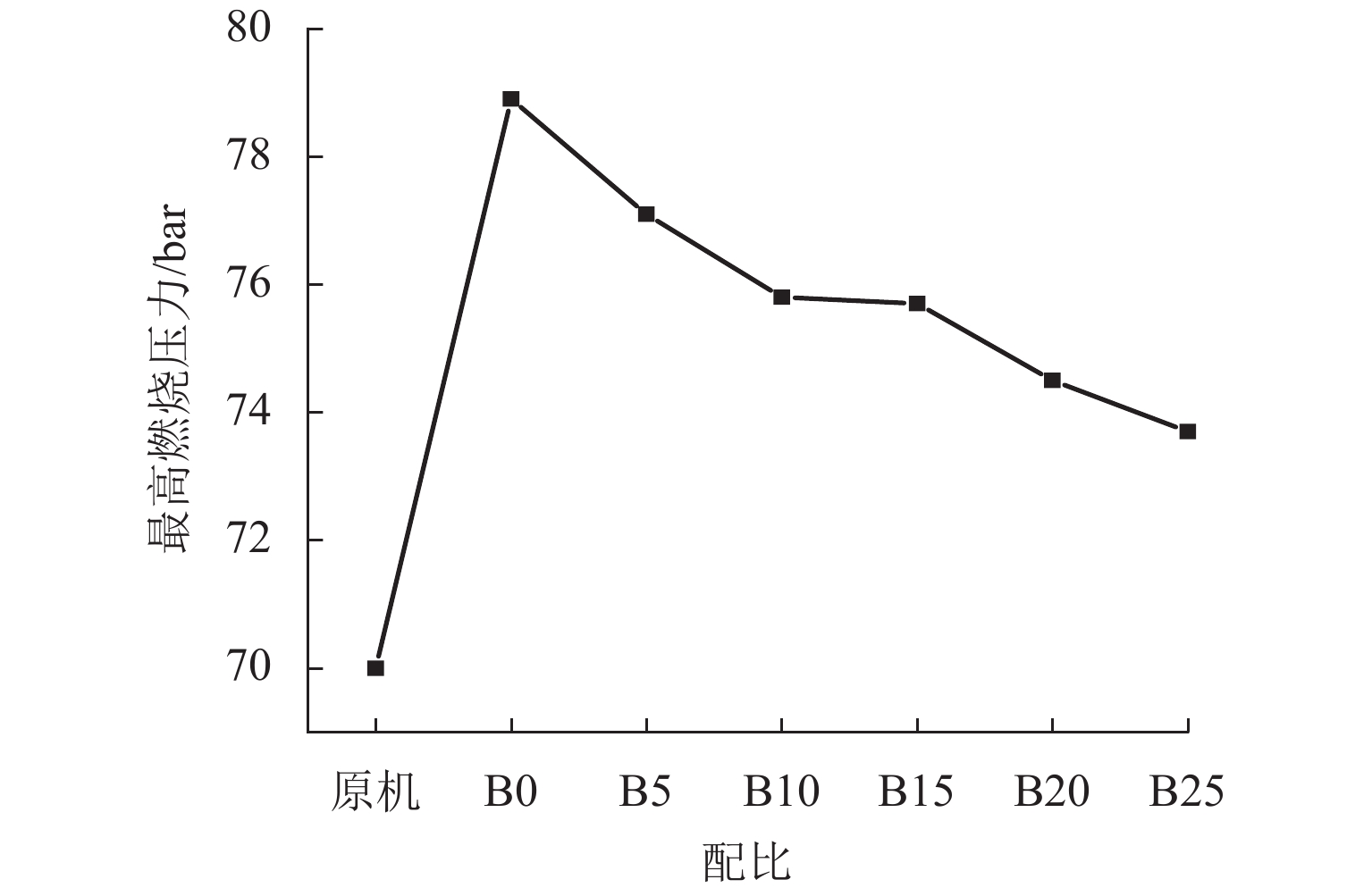

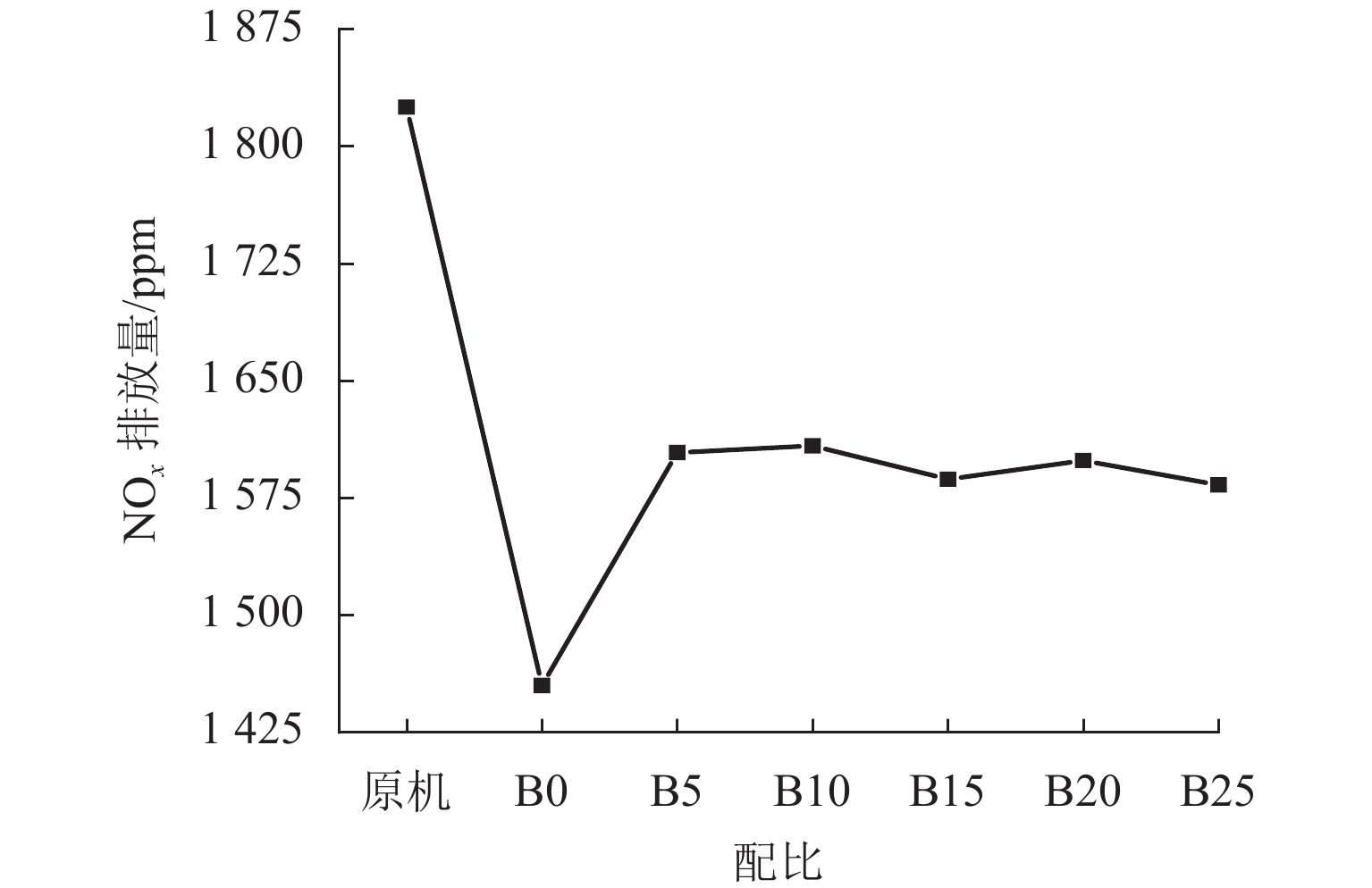

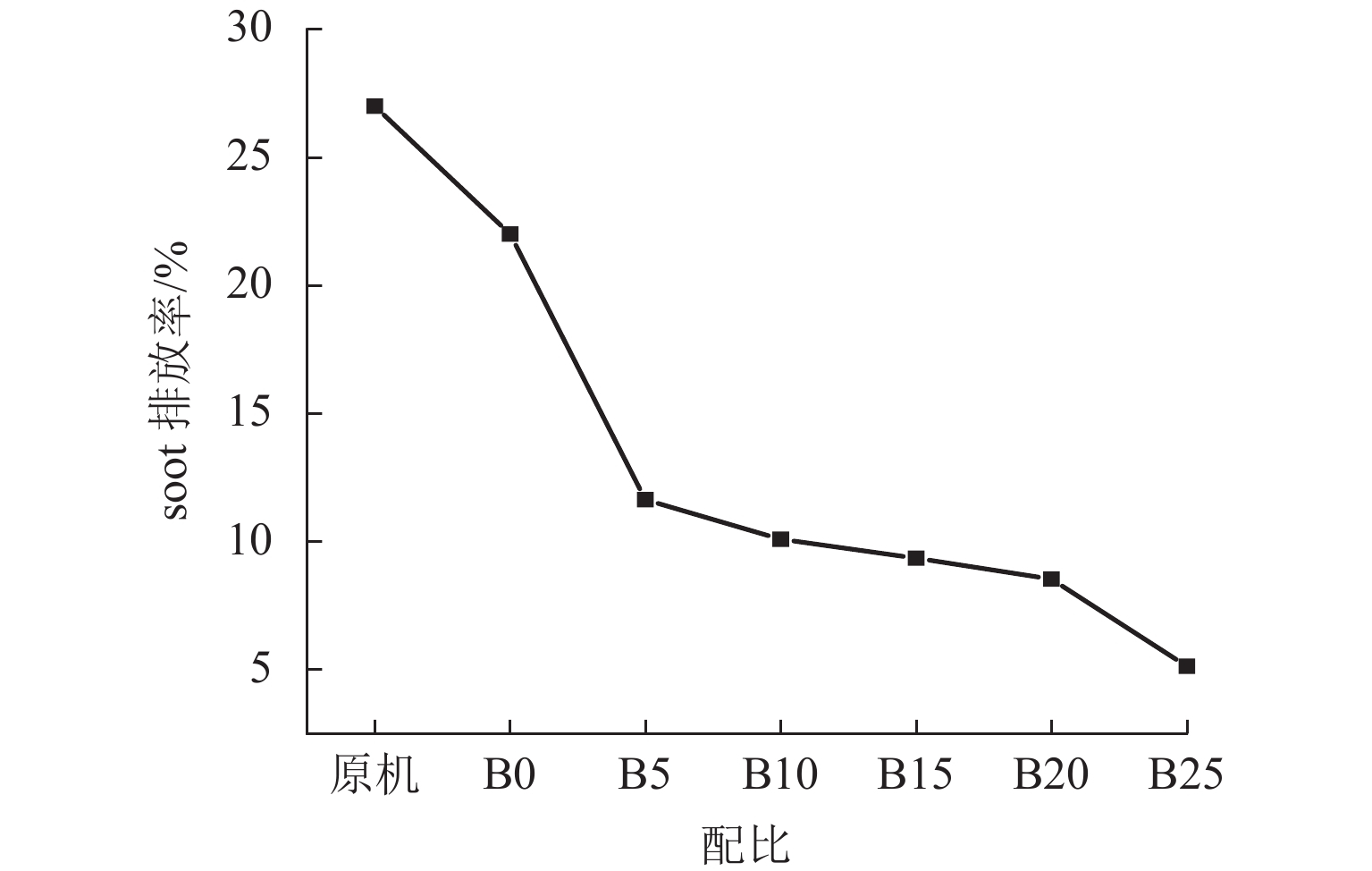

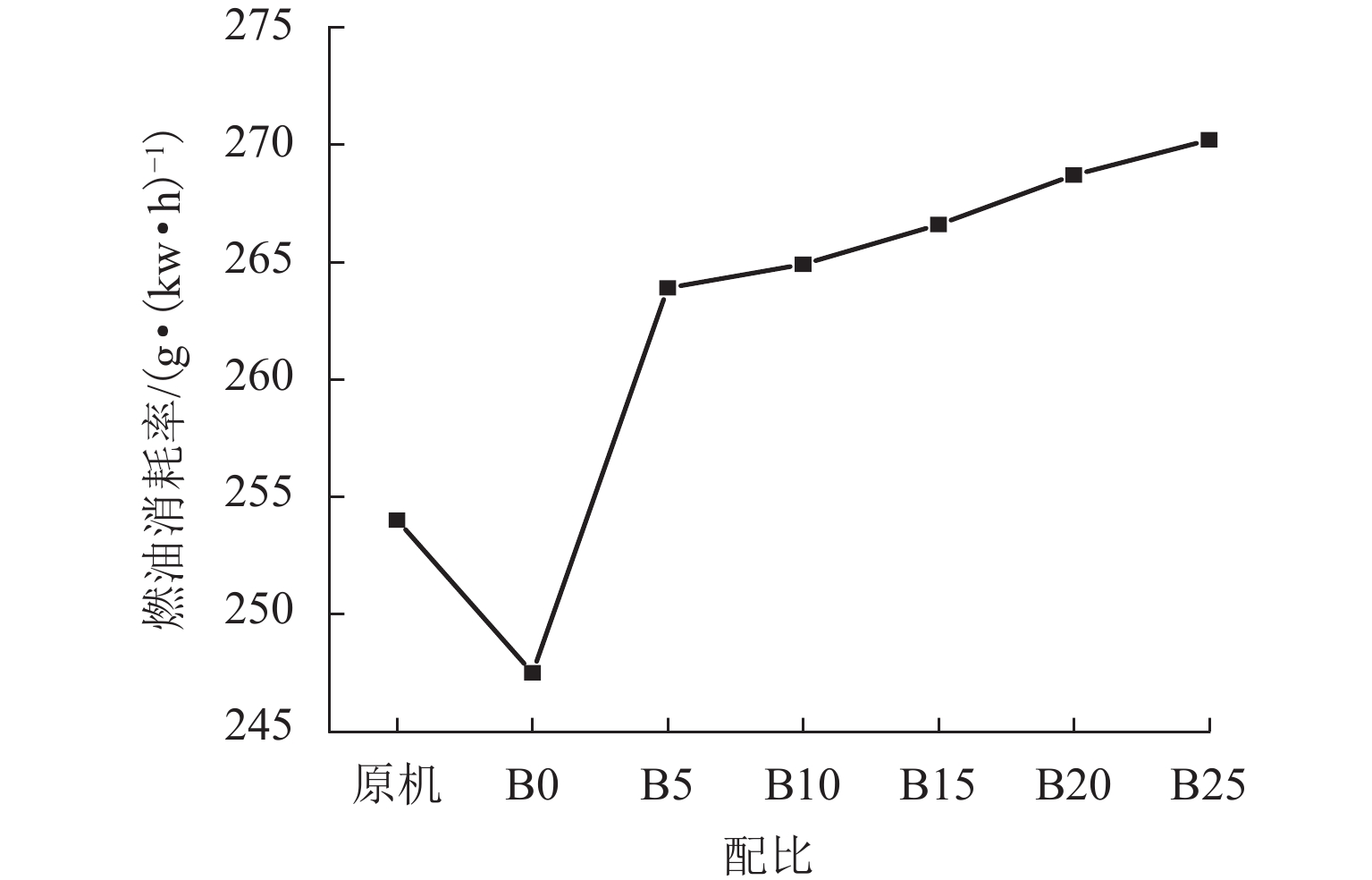

为促进生物质能源应用,减轻国家对于化石能源的依赖,以某船用增压柴油机为研究对象,将其改造为相继增压系统柴油机,进行掺混生物柴油燃烧试验,在推进特性25%负荷试验时,生物柴油设置5% ~ 25%共5组配比,研究不同生物柴油配比对柴油机动力性、经济性及排放性的影响. 研究结果表明:在25%负荷时,掺混生物柴油燃烧与纯柴油燃烧相比,相继增压柴油机的动力性下降约6.5%,燃油消耗率增长约9.2%,NO

x 排放量降低约9.8%,SOOT排放量降低约76.7%;相继增压柴油机掺混生物柴油燃烧时,其动力性及排放性均优于原机;在25%负荷时生物柴油最佳掺混率为25%,随着生物柴油配比增加其动力性与经济性下降较快,NOx 排放升高,掺混率不宜过高;改造为相继增压船用柴油机后,在一定程度上弥补了掺混生物柴油燃烧带来的不足.Abstract:To promote the application of biomass energy and reduce the country's dependence on fossil energy, a marine turbocharged diesel engine was transformed into a sequential turbocharged system diesel engine, and the combustion test of mixed biodiesel was carried out. When the propulsion characteristic is 25% load, biodiesel is set at 5% − 25% in total. Through experiments, the effects of different proportion of Biodiesel on the power, economy and emission of diesel were studied. The results show that at 25% load, compared with pure diesel combustion, the power performance of Sequential Turbocharged Diesel engine is reduced by about 6.5%, the fuel consumption rate is increased by about 9.2%, the NO

x emission is reduced by about 9.8%, and the soot emission is reduced by about 76.7%. When the sequential supercharged diesel engine is mixed with biodiesel for combustion, its power performance and emission are better than the original engine. Through the optimization analysis of grey decision theory, the comprehensive optimization shows that the optimal blending rate of biodiesel is 25% at 25% load. With the increase of biodiesel ratio, its power and economy decline rapidly and NOx emission increases, so the blending rate should not be too high. The transformation into a sequential turbocharged marine diesel engine makes up for the shortcomings brought by the combustion of mixed biodiesel to a certain extent.-

Key words:

- marine diesel engine /

- sequential turbocharing /

- biodiesel /

- optimize

-

表 1 TBD234柴油机技术参数

Table 1. Technical parameters of TBD234 diesel engine

项目名称 技术参数 机型 四冲程、直喷、水冷、废

气涡轮增压、进气中冷气缸直径、行程/mm 128、140 燃烧室型式 ω 型 总排量/L 10.8 压缩比 15∶1 标定转速/(r·min−1) 1500 标定功率/kW 186 表 2 主要实验设备

Table 2. Main test equipments

实验设备 名称 控制系统 NCK2010 自动测控系统 功率测量 DW440 电涡流测功器 烟度排放测试系统 不透光烟度计(AVL439) 废弃排放测试系统 HoribaMEXA-1600D/DSEGR

尾气分析仪燃油油耗测量系统 HZB2000 油耗仪 燃烧分析测试系统 DEWE—2010CA 型便携式

燃烧分析仪表 3 实验方案

Table 3. Experimental schemes

负荷/% 转速 r/min 掺混率/% 配比 25 945 0

5

10

15

20

25B0

B5

B10

B15

B20

B25 -

[1] 刘杰,魏立江,魏海军. 掺混生物柴油对6135Aca型柴油机NO x排放的影响机理[J]. 上海海事大学学报,2019,40(3): 111-115,126.LIU Jie, WEI Lijiang, WEI Haijun. Influence mechanism of biodiesel blending on NO x emission of 6135Aca diesel engine[J]. Journal of Shanghai Maritime University, 2019, 40(3): 111-115,126. [2] KALGHATGI G, LEVINSKY H, COLKET M. Future transportation fuels[J]. Progress in Energy and Combustion Science, 2018, 69: 103-105. doi: 10.1016/j.pecs.2018.06.003 [3] PERKINS G, BHASKAR T, KONAROVA M. Process development status of fast pyrolysis technologies for the manufacture of renewable transport fuels from biomass[J]. Renewable and Sustainable Energy Reviews, 2018, 90: 292-315. doi: 10.1016/j.rser.2018.03.048 [4] ÇELEBI Y, AYDIN H. An overview on the light alcohol fuels in diesel engines[J]. Fuel, 2019, 236: 890-911. doi: 10.1016/j.fuel.2018.08.138 [5] AWAD O I, MAMAT R, ALI O M, et al. Alcohol and ether as alternative fuels in spark ignition engine: a review[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 2586-2605. doi: 10.1016/j.rser.2017.09.074 [6] VENU H, VENKATARAMAN D, PURUSHOTHAMAN P, et al. Eichhornia crassipes biodiesel as a renewable green fuel for diesel engine applications: performance, combustion, and emission characteristics[J]. Environmental Science and Pollution Research, 2019, 26(18): 18084-18097. doi: 10.1007/s11356-019-04939-z [7] 黄文杰. 生物柴油喷雾特性的数值模拟和试验研究[D]. 太原: 中北大学, 2019. [8] 陈彦君. 柴油机燃用生物柴油低温燃烧性能的仿真研究[D]. 成都: 西南交通大学, 2019. [9] 杜家益,蒋胜,张登攀,等. 生物柴油颗粒表面含氧官能团及氧化活性研究[J]. 内燃机学报,2021,39(5): 395-401.DU Jiayi, JIANG Sheng, ZHANG Dengpan, et al. Study on oxygen-containing functional group and oxidation activity on the surface of biodiesel particles[J]. Transactions of CSICE, 2021, 39(5): 395-401. [10] 左磊. 柴油机燃用加氢生物柴油—乙醇—柴油的燃烧与排放特性研究[D]. 镇江: 江苏大学, 2020. [11] 曹合力. 相继增压结合EGR对某游艇发动机性能影响研究[D]. 厦门: 集美大学, 2019. [12] 吴子芳. 某型游艇发动机STC系统设计研究[D]. 厦门: 集美大学, 2017. [13] 段道申. 相继增压柴油机性能研究及排气系统优化分析[D]. 大连: 大连交通大学, 2018. [14] 赵金楼,康正. 基于灰色理论的项目多目标决策模型及在造船工程中的应用[J]. 中国管理科学,2008,16(增刊1): 187-191.ZHAO Jinlou, KANG Zheng. A model based on the grey system forMulti-objective decision-making and its appliaction in the shipbuilding project[J]. Chinese Journal of Management Science, 2008, 16(S1): 187-191. [15] 冯勇,何建新,侍克斌. 灰色系统理论在多目标施工方案决策中的应用研究[J]. 数学的实践与认识,2008,38(6): 47-51.FENG Yong, HE Jianxin, SHI Kebin. The application of grey theory of decision-making in management projects[J]. Mathematics in Practice and Theory, 2008, 38(6): 47-51. -

下载:

下载: