Self-Healing Performance of Cement-Based Materials Mixed with Magnesium Acrylate

-

摘要:

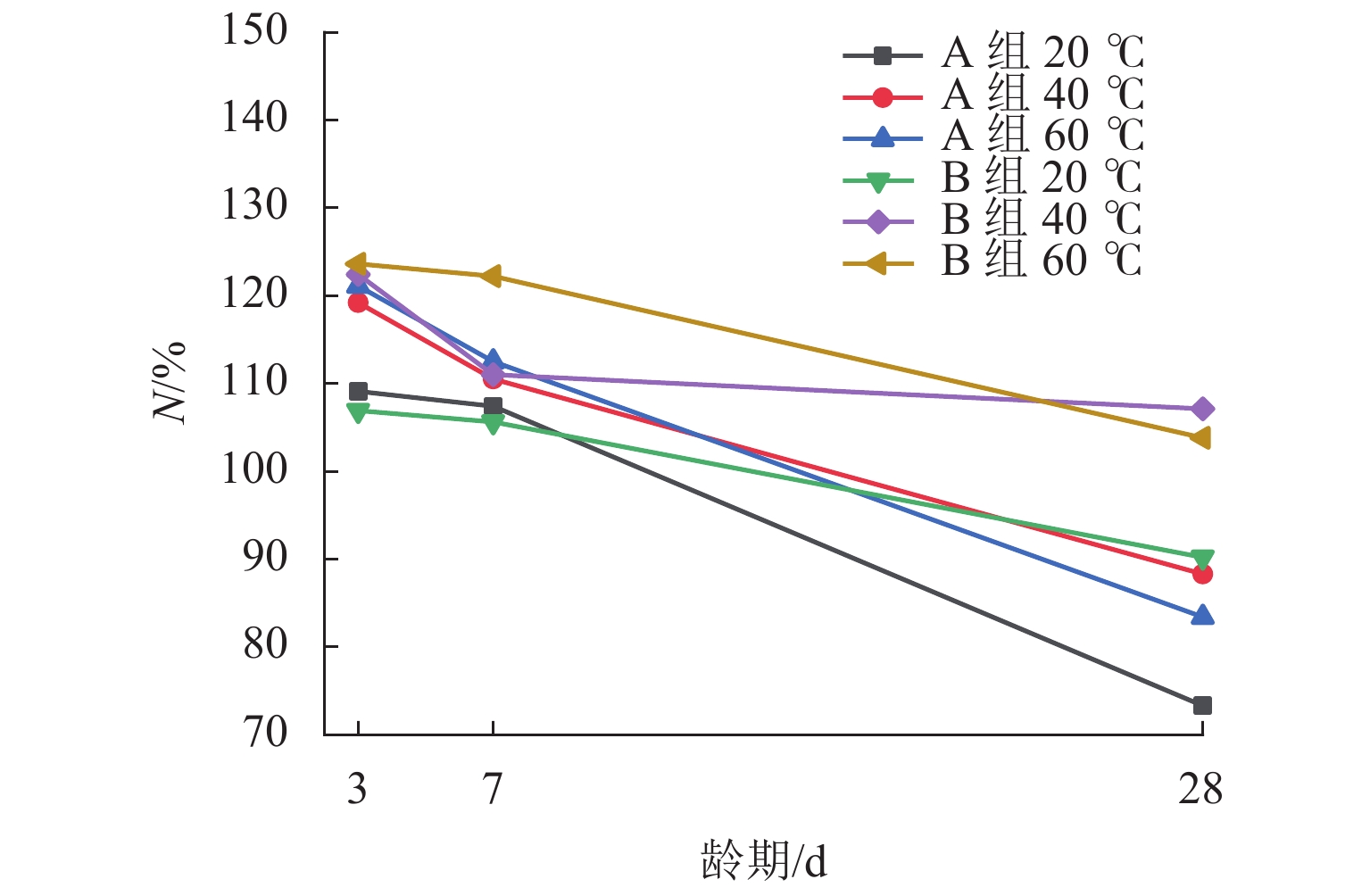

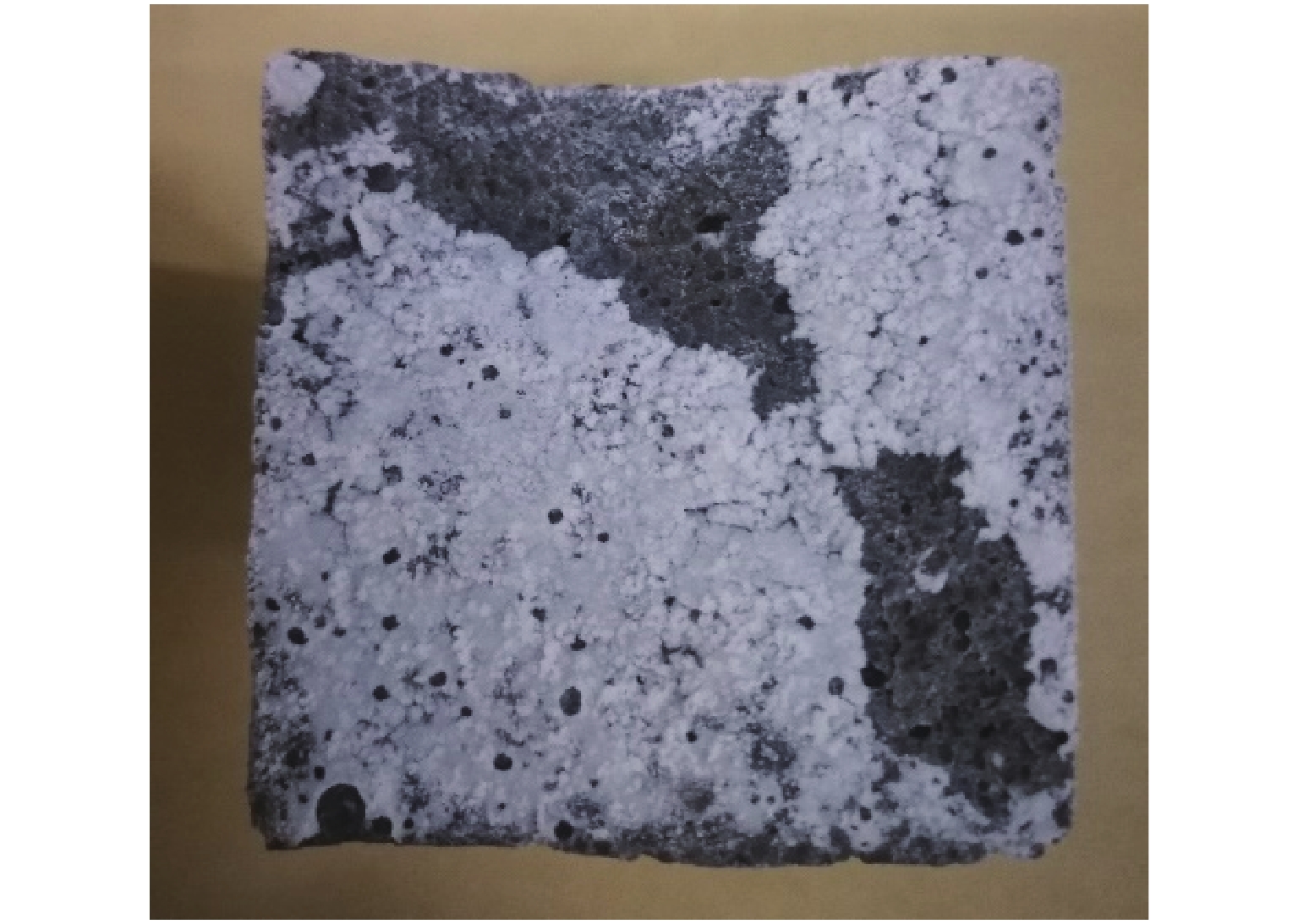

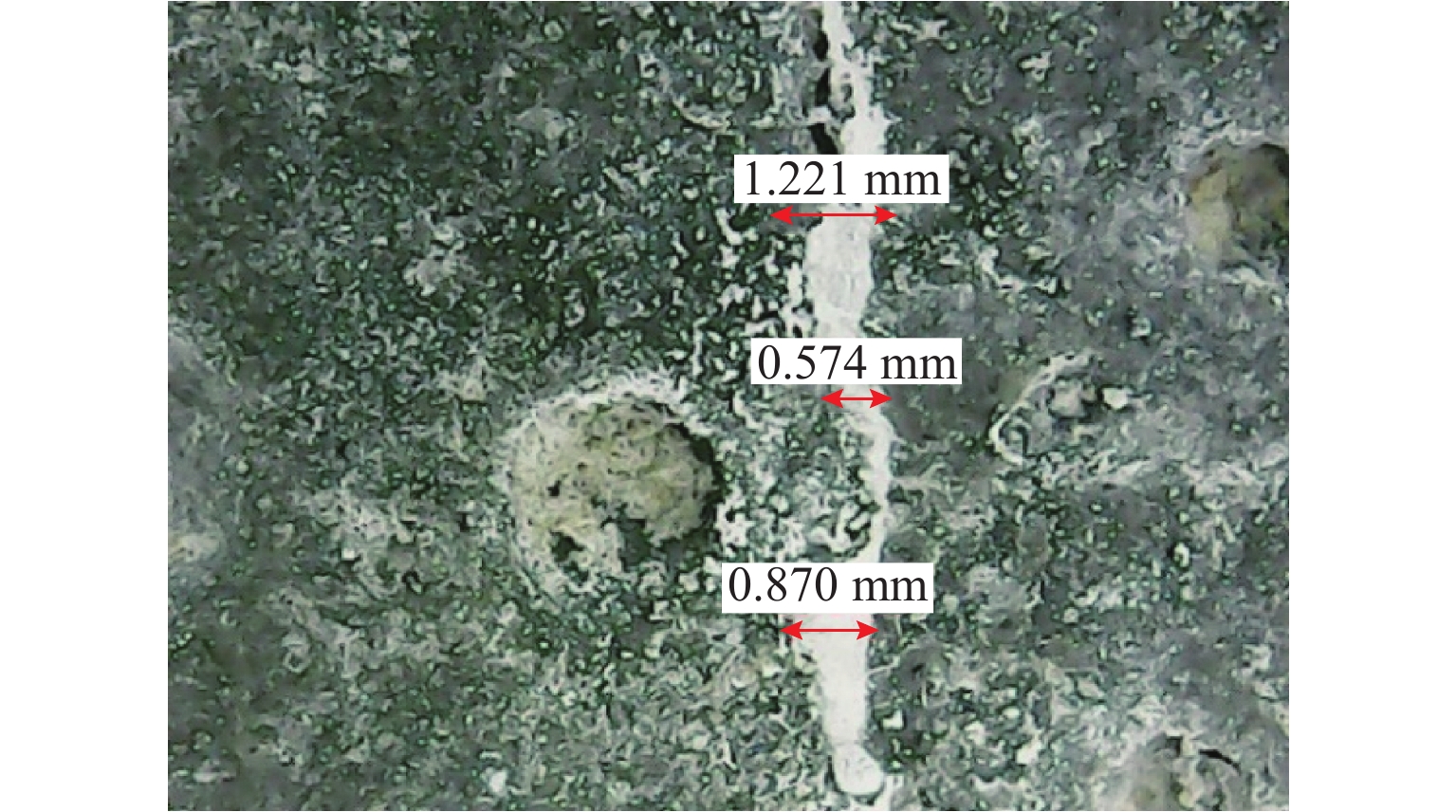

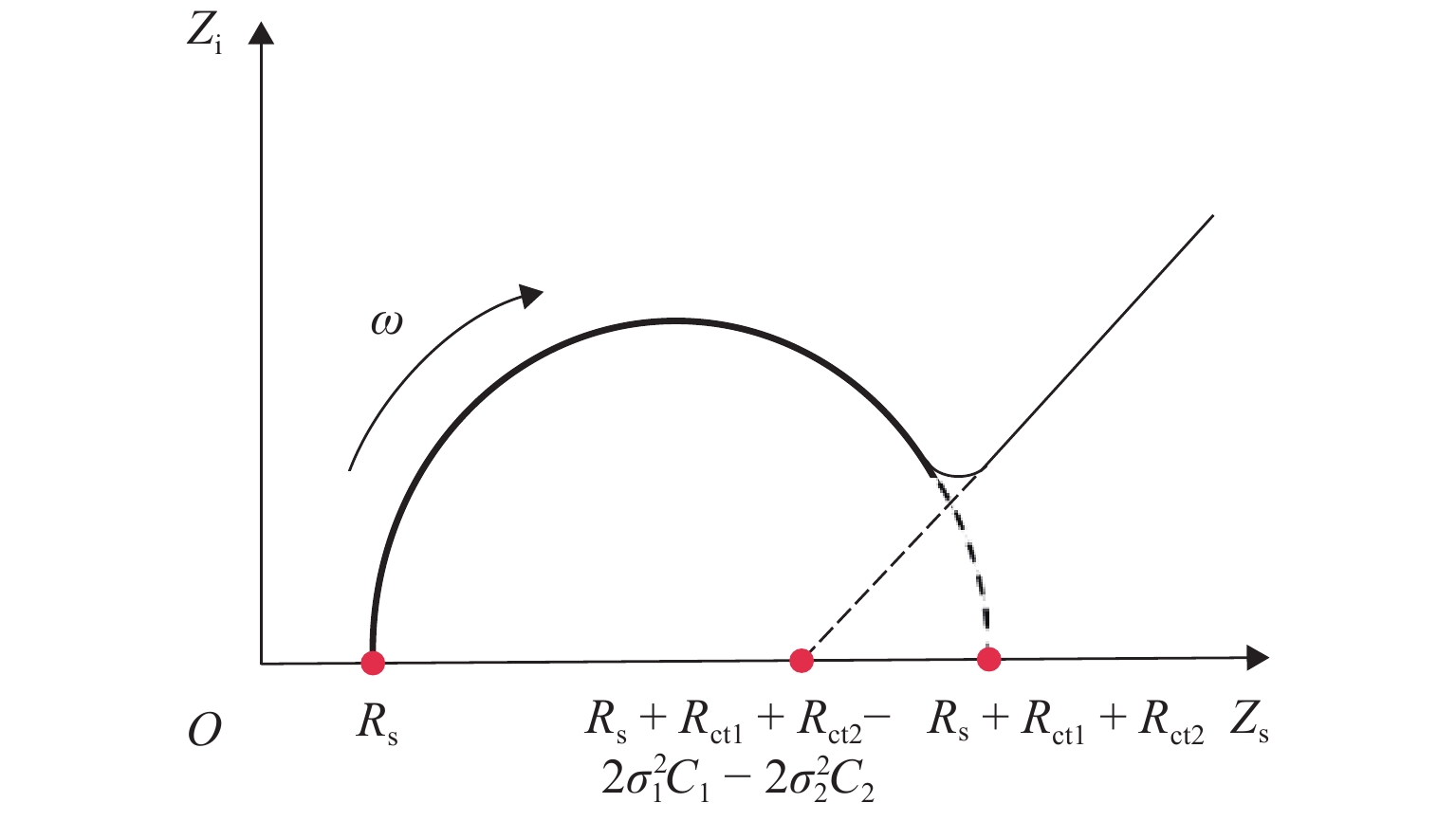

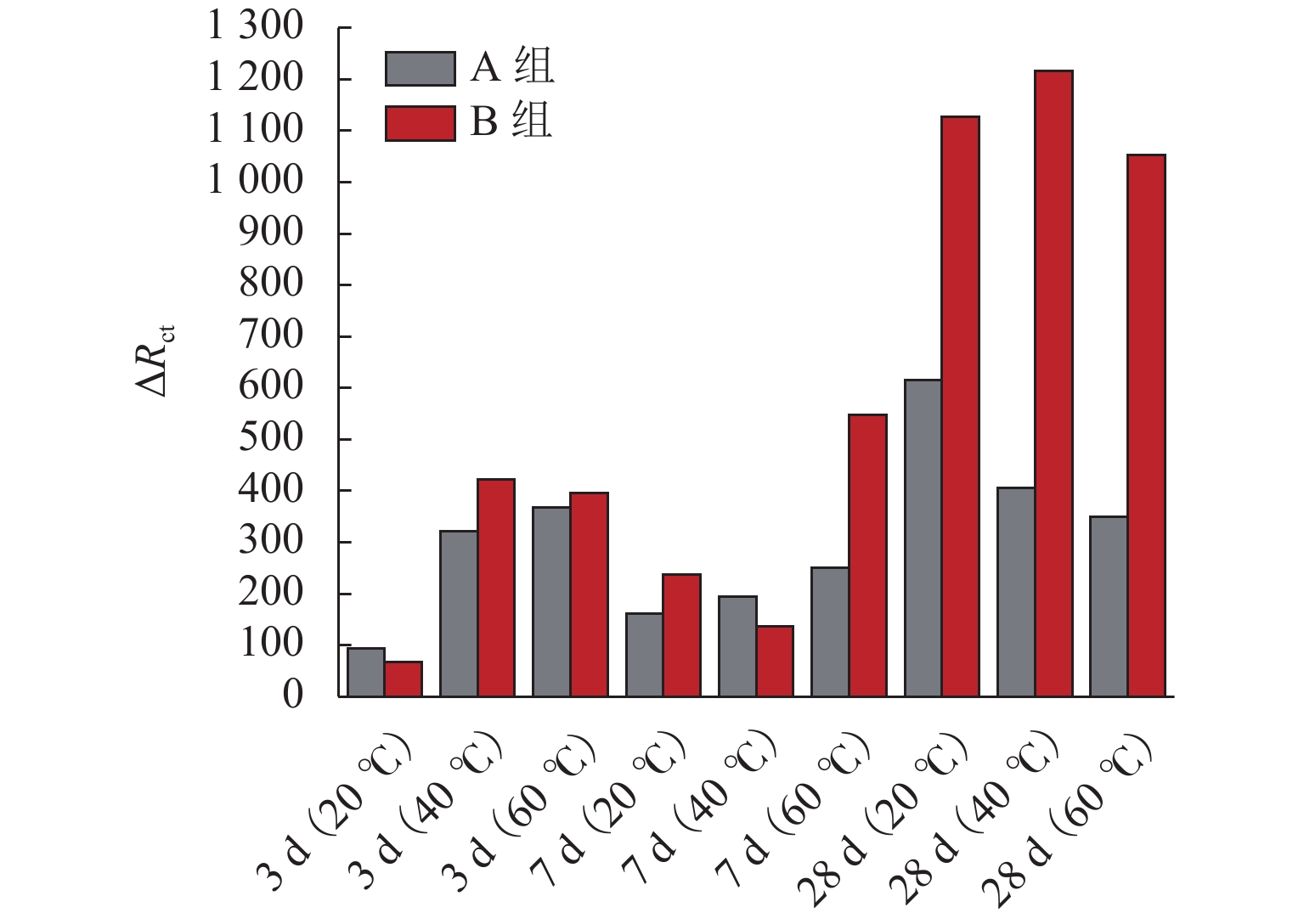

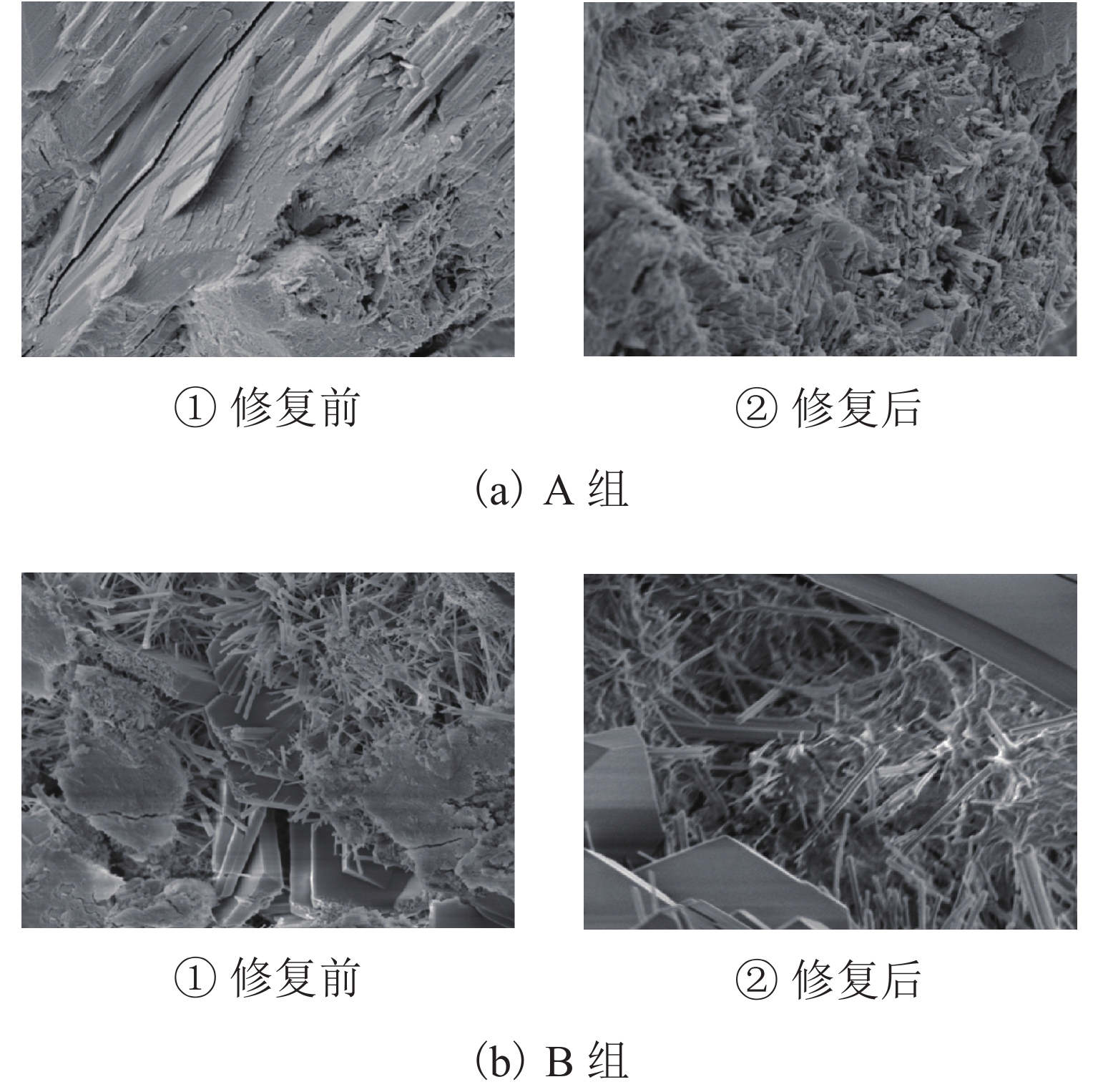

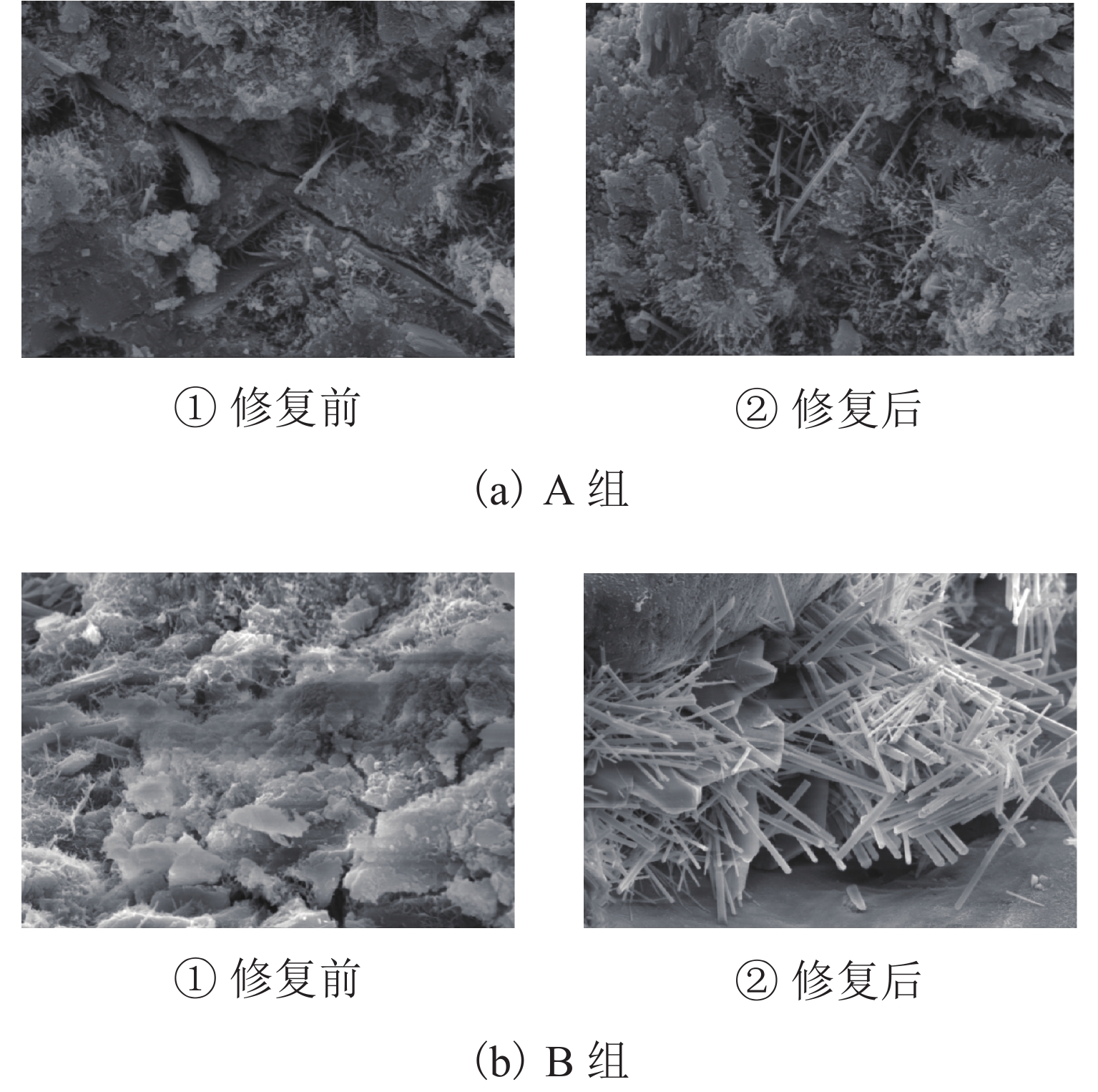

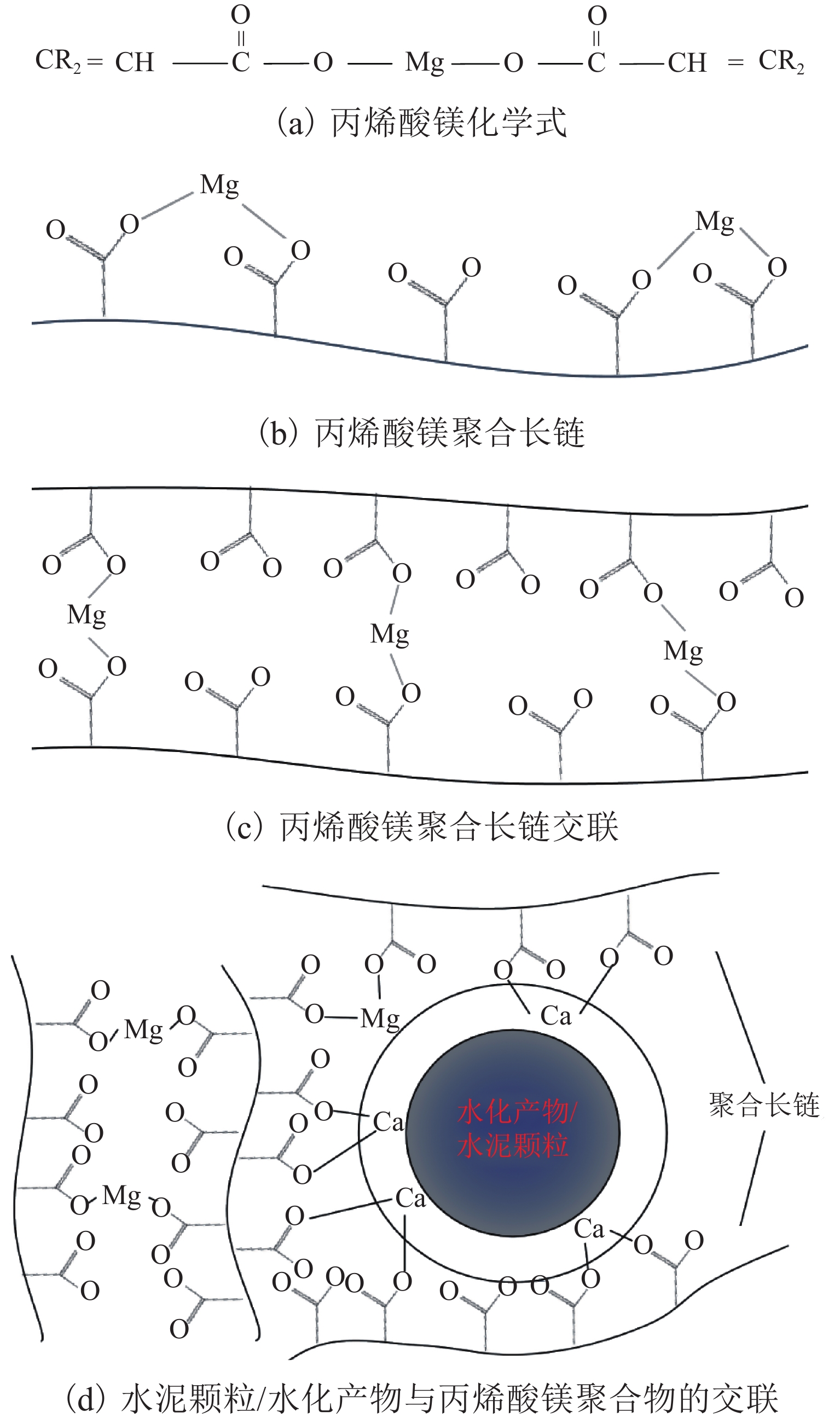

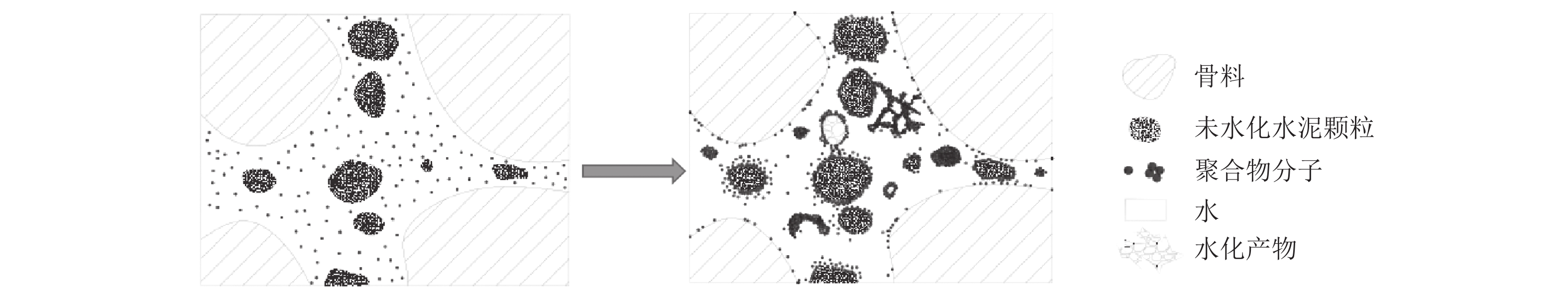

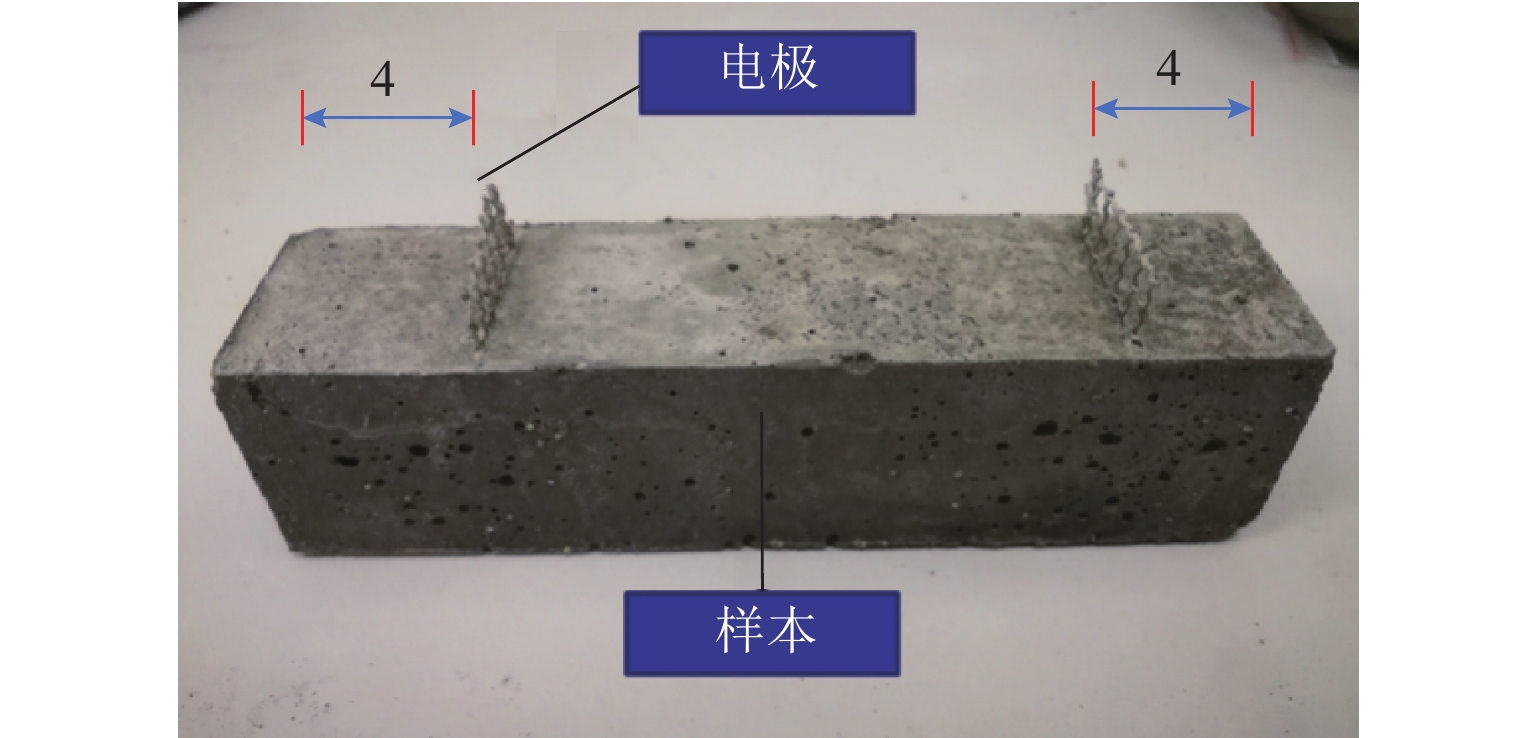

以抗压强度修复率、裂缝修复率、电化学阻抗谱(EIS)为表征手段,对不同龄期、修复温度的水泥砂浆试件进行自修复性能试验,同时,结合SEM (scanning electronic microscope)探究了丙烯酸镁水泥基材料的自修复性能及微观机理. 试验结果表明:早龄期时丙烯酸镁修复体系对砂浆试件抗压强度修复及表观修复效果不明显,随着龄期增长,抗压强度修复效果逐渐显著,且7 d龄期试件表观裂缝修复率达100.0%;中高温有利于丙烯酸镁修复体系的自修复效果,但40 ℃ 以上提高温度对修复效果提升不再明显;电化学阻抗谱测试表明,28 d龄期时试验组的等效电路参数全面优于对照组;高龄期下丙烯酸镁修复体系的修复效果显著优于水泥基材料水化反应带来的修复效果.

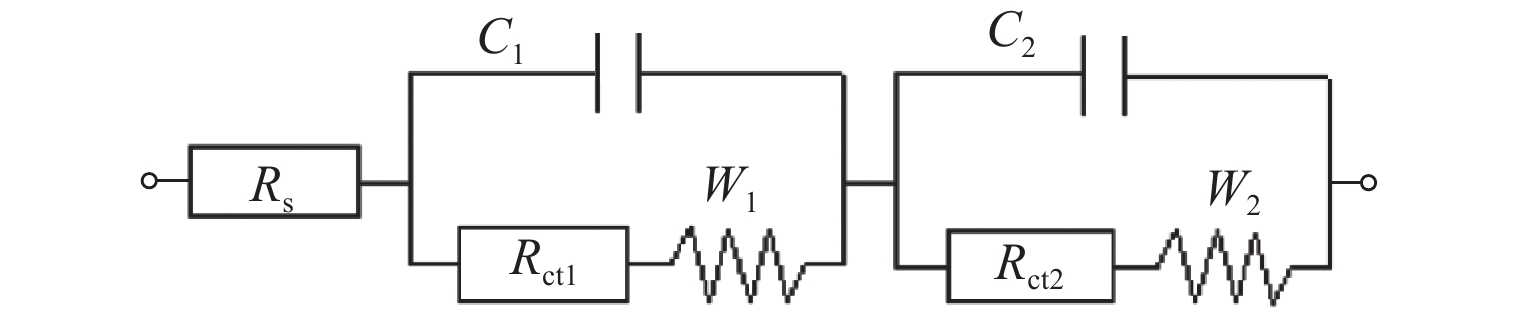

Abstract:The self-healing performance of cement mortar specimens at different ages and temperatures was tested by compressive strength repair rate, crack repair rate, and electrochemical impedance spectroscopy (EIS), and then was analyzed using the scanning electronic microscope (SEM) to study the microscopic self-healing mechanism of magnesium acrylate cement-based materials. The test results showed that the effect of magnesium acrylate on the compressive strength repair and apparent repair of the mortar specimens was not obvious at the early age. The effect on compressive strength repair intensifies gradually with the increasing age, and the apparent crack repair rate at 7 d reached 100.0%. Meanwhile, medium-high temperature was beneficial to self-healing effect, but the effect above 40 ℃ was no longer significant. EIS showed that the equivalent circuit parameters of the test group at the age of 28 d were better than those of the control group; the repair effect of the magnesium acrylate at old age is significantly better than the "healing" effect brought by the hydration reaction of cement-based materials.

-

Key words:

- magnesium acrylate /

- cement-based materials /

- self-healing /

- EIS /

- SEM

-

表 1 基础砂浆配合比

Table 1. Mix proportion of the mortar matrix

材料 水泥 砂 水 配合比/(kg•m−3) 450 1 350 225 表 2 试验分组

Table 2. Test group

% 组别 修复剂 引发剂 促进剂 交联剂 A 0 0 0 0 B 0.5 2 2 1 表 3 表观裂缝修复率

Table 3. Repair rate of apparent cracks

组别 龄期/d 温度/℃ 裂缝修复率/% A 3 20 8.3 40 0 60 0 7 20 2.0 40 6.2 60 0 28 20 7.5 40 0 60 67.6 B 3 20 18.3 40 72.3 60 94.2 7 20 100.0 40 100.0 60 100.0 28 20 96.0 40 96.1 60 95.7 -

[1] 张鹏,冯竟竟,陈伟,等. 混凝土损伤自修复技术的研究与进展[J]. 材料导报,2018,32(19): 3375-3386. doi: 10.11896/j.issn.1005-023X.2018.19.012ZHANG Peng, FENG Jingjing, CHEN Wei, et al. Self-healing performance of concrete: a technological review[J]. Materials Review, 2018, 32(19): 3375-3386. doi: 10.11896/j.issn.1005-023X.2018.19.012 [2] 李银连. 建筑工程中混凝土裂缝防治对策探究[J]. 建材与装饰,2018(11): 18-19. doi: 10.3969/j.issn.1673-0038.2018.11.013 [3] 薛徐. 裂缝修复剂的修复性能及其对水泥基材料的性能影响[D]. 合肥: 安徽建筑大学, 2018. [4] 蒋正武. 水泥基自修复材料: 理论与方法[M]. 上海: 同济大学出版社, 2018. [5] 周凤梅. 水泥混凝土微胶囊自修复技术研究[D]. 重庆: 重庆交通大学, 2015. [6] 邢锋,倪卓,汤皎宁,等. 自修复混凝土系统的研究进展[J]. 深圳大学学报(理工版),2013,30(5): 486-494. doi: 10.3724/SP.J.1249.2013.05486XING Feng, NI Zhuo, TANG Jiaoning, et al. State-of-the-art for self-healing concrete[J]. Journal of Shenzhen University (Science and Engineering), 2013, 30(5): 486-494. doi: 10.3724/SP.J.1249.2013.05486 [7] DRY C. Alteration of matrix permeability and associated pore and crack structure by the time release of internal chemicals [C]//Proceedings of Advance in Cementitious Materials. Maryland: American Ceramic Society, 1990: 729-68. [8] DRY C. Matrix cracking repair and filling using active and passive modes for smart timed release of chemicals from fibers into cement matrices[J]. Smart Materials and Structures, 1994, 3(2): 118-123. doi: 10.1088/0964-1726/3/2/006 [9] DRY C, MCMILLAN W. Three-part methylmethacrylate adhesive system as an internal delivery system for smart responsive concrete[J]. Smart Materials and Structures, 1996, 5(3): 297-300. doi: 10.1088/0964-1726/5/3/007 [10] DRY C M. Three designs for the internal release of sealants, adhesives, and waterproofing chemicals into concrete to reduce permeability[J]. Cement and Concrete Research, 2000, 30(12): 1969-1977. doi: 10.1016/S0008-8846(00)00415-4 [11] 胡宝云,管婧超. 自修复混凝土的国内研究现状与发展趋势[J]. 广东化工,2018,45(8): 170-171. doi: 10.3969/j.issn.1007-1865.2018.08.080HU Baoyun, GUAN Jingchao. Domestic research status and progress trend of self-repairing concrete[J]. Guangdong Chemical Industry, 2018, 45(8): 170-171. doi: 10.3969/j.issn.1007-1865.2018.08.080 [12] 李冰,郭荣鑫,万夫雄,等. 不同条件下内掺水泥基渗透结晶型防水材料混凝土自愈合性能研究[J]. 硅酸盐通报,2019,38(7): 2208-2212.LI Bing, GUO Rongxin, WAN Fuxiong, et al. Research on self-healing performance of concrete with cement-based permeable crystalline waterproof material under different conditions[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7): 2208-2212. [13] 魏玉伟,程培峰,刘满,等. 自修复混凝土修复效果影响因素的试验研究[J]. 建筑材料学报,2018,21(4): 588-594. doi: 10.3969/j.issn.1007-9629.2018.04.010WEI Yuwei, CHENG Peifeng, LIU Man, et al. Influencing factors of self-healing performance of concrete[J]. Journal of Building Materials, 2018, 21(4): 588-594. doi: 10.3969/j.issn.1007-9629.2018.04.010 [14] 逄锦伟. 渗透结晶型混凝土裂缝自修复材料试验研究[J]. 隧道建设,2015(增刊2): 32-36. doi: 10.3973/j.issn.1672-741X.2015.S2.007PANG Jinwei. Experiment and research on permeable crystallization self-healing materials of concrete[J]. Tunnel Construction, 2015(S2): 32-36. doi: 10.3973/j.issn.1672-741X.2015.S2.007 [15] 谷亚新,刘微,梁丽珠,等. 固化剂种类和用量对丙烯酸镁防水材料固化的影响[J]. 新型建筑材料,2020,47(1): 108-111.GU Yaxin, LIU Wei, LIANG Lizhu, et al. Effect of type and dosage of curing agent on curing of magnesium acrylate waterproof material[J]. New Building Materials, 2020, 47(1): 108-111. [16] 姜浩,杨其新,蒋雅君. 硅酸钙对丙烯酸盐喷膜防水材料耐碱性改善作用研究[J]. 新型建筑材料,2014,41(8): 35-38,46. doi: 10.3969/j.issn.1001-702X.2014.08.011JIANG Hao, YANG Qixin, JIANG Yajun. Research of calcium silicate’s improving effect on alkaline corrosion resistance of the acrylate spraying waterproof material[J]. New Building Materials, 2014, 41(8): 35-38,46. doi: 10.3969/j.issn.1001-702X.2014.08.011 [17] 王付兰,王琦,黄丹. 丙烯酸钙/镁对水泥水化进程的影响[J]. 四川水泥,2014(3): 113-117. doi: 10.3969/j.issn.1007-6344.2014.03.039 [18] 刘艳丽,黄先威,龚习. 丙烯酸接枝共聚改性聚氨酯的研究[J]. 湖南工程学院学报(自然科学版),2011,21(2): 79-81.LIU Yanli, HUANG Xianwei, GONG Xi. Study on polyurethane modified with acrylic acid grafting copolymerization[J]. Journal of Hunan Institute of Engineering (Natural Science Edition), 2011, 21(2): 79-81. [19] 姜凤娇,贡金鑫,王幻. 基于电化学阻抗谱的氯离子侵蚀混凝土研究[J]. 西安建筑科技大学学报(自然科学版),2019,51(5): 682-687.JIANG Fengjiao, GONG Jinxin, WANG Huan. Study on chloride ion erosion of concrete based on electrochemicalimpedance spectroscopy[J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 2019, 51(5): 682-687. [20] HE H T, ZHU Y, ZHOU A G. Electrochemical impedance spectroscopy (EIS) used to evaluate influence of different external pressures, curing ages and self-healing environments on the self-healing behavior of engineered cementitious composites (ECC)[J]. Construction and Building Materials, 2018, 188: 153-160. doi: 10.1016/j.conbuildmat.2018.08.104 [21] ZHU Y, ZHANG Z C, YANG Y Z, et al. Measurement and correlation of ductility and compressive strength for engineered cementitious composites (ECC) produced by binary and ternary systems of binder materials: fly ash, slag, silica fume and cement[J]. Construction and Building Materials, 2014, 68: 192-198. doi: 10.1016/j.conbuildmat.2014.06.080 [22] ATAHAN H N, CARLOS C J, CHAE S, et al. The morphology of entrained air voids in hardened cement paste generated with different anionic surfactants[J]. Cement and Concrete Composites, 2008, 30(7): 566-575. doi: 10.1016/j.cemconcomp.2008.02.003 [23] 杨其新,盛草樱,刘东民. 丙烯酸喷膜防水材料的研究及其工程应用[J]. 新型建筑材料,2002(6): 1-4. doi: 10.3969/j.issn.1001-702X.2002.06.001 [24] TIAN Y, JIN X Y, JIN N G, et al. Research on the microstructure formation of polyacrylate latex modified mortars[J]. Construction and Building Materials, 2013, 47: 1381-1394. doi: 10.1016/j.conbuildmat.2013.06.016 -

下载:

下载: