Experimental Investigation on Behavior of Rectangular Concrete-Filled Stainless Steel Tubular Stub Columns under Axial Loading

-

摘要:

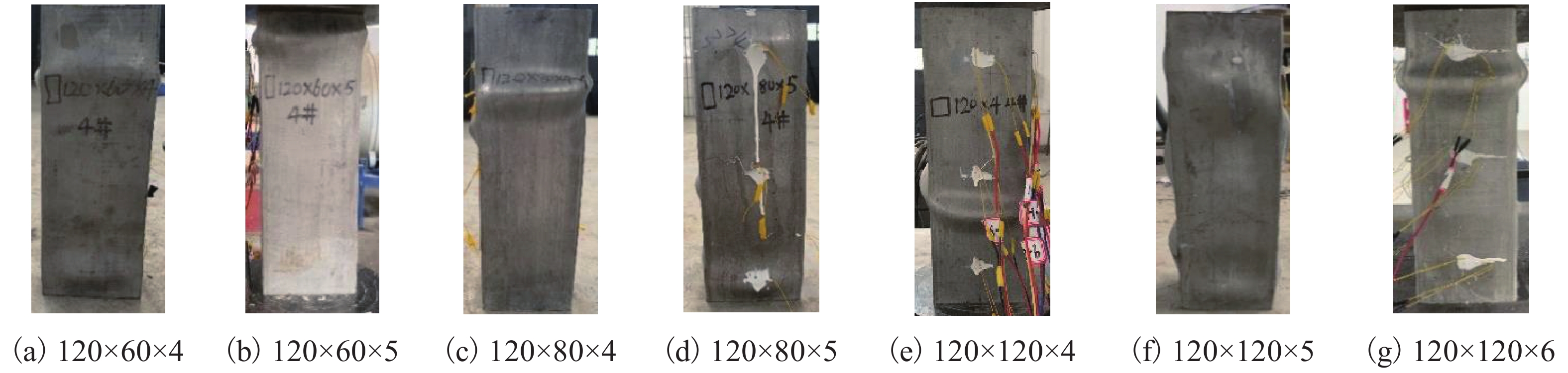

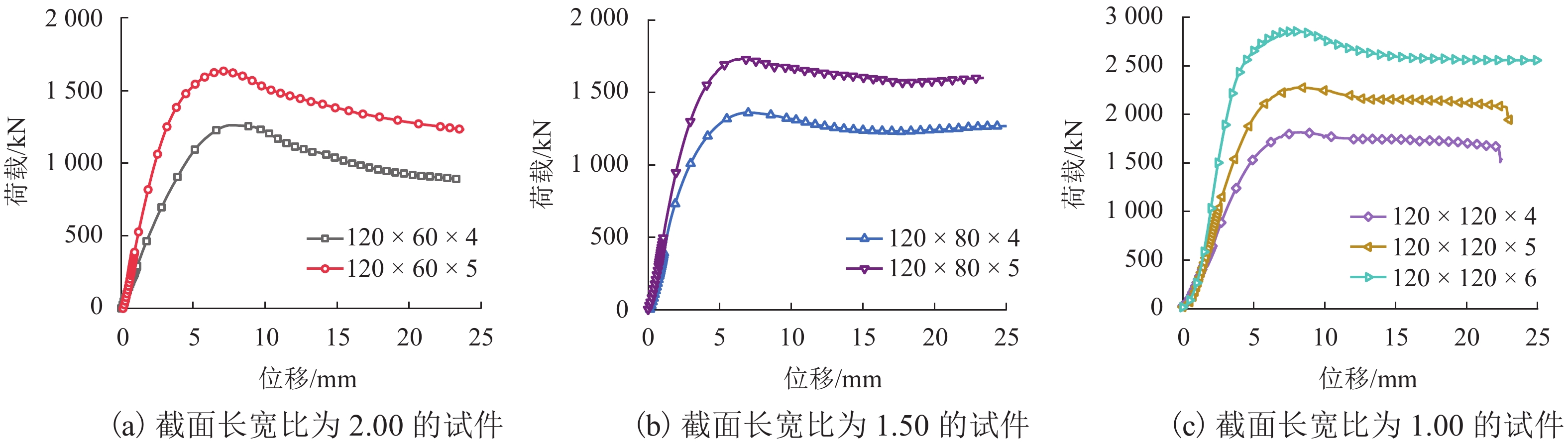

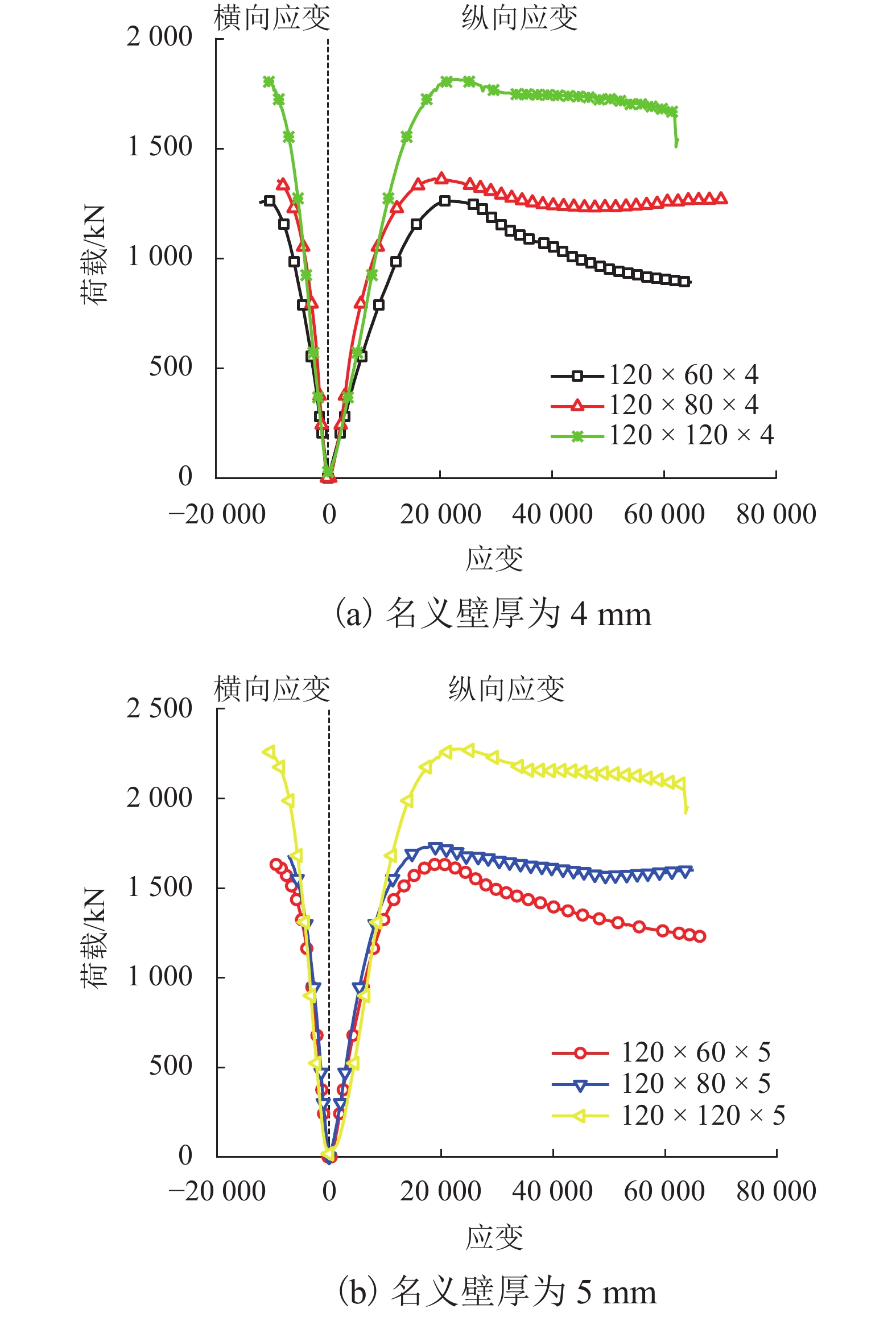

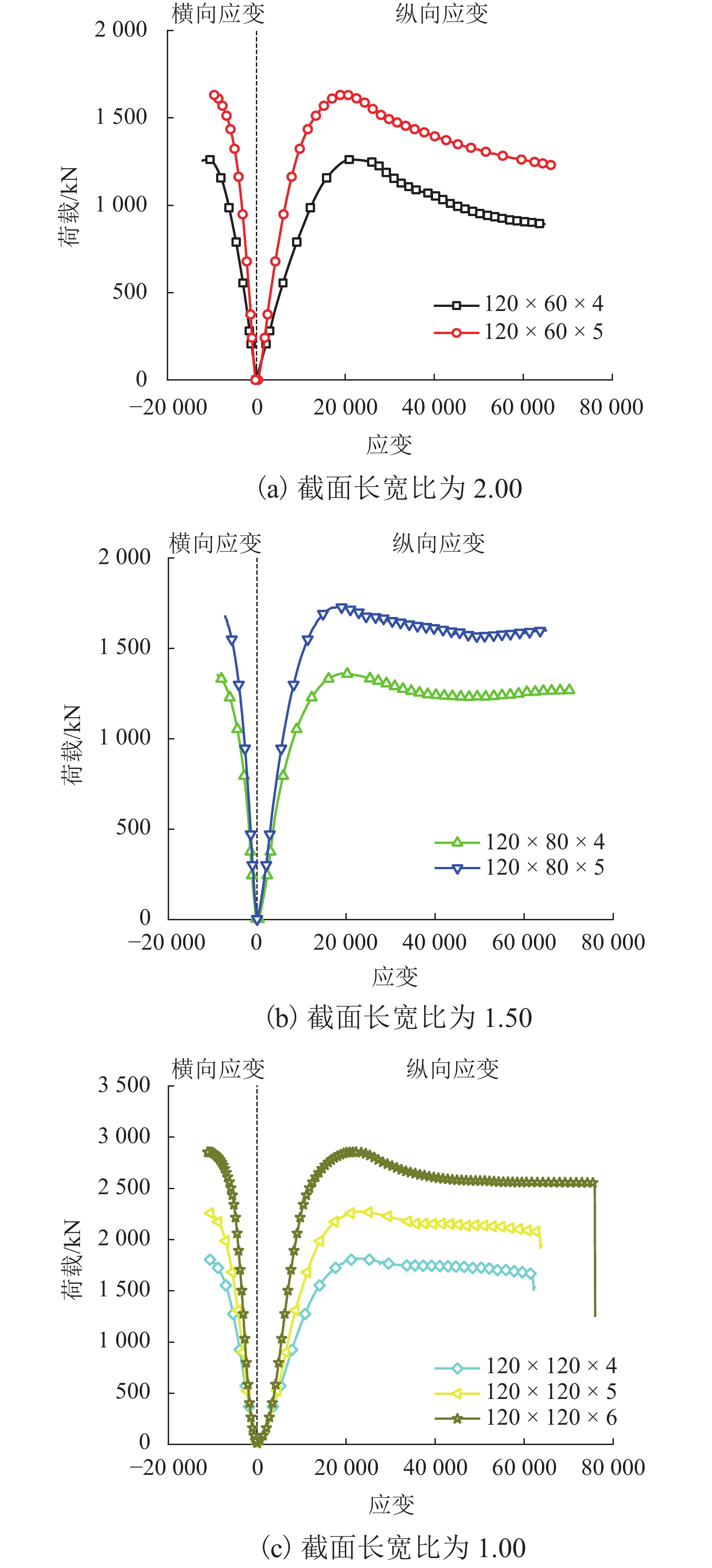

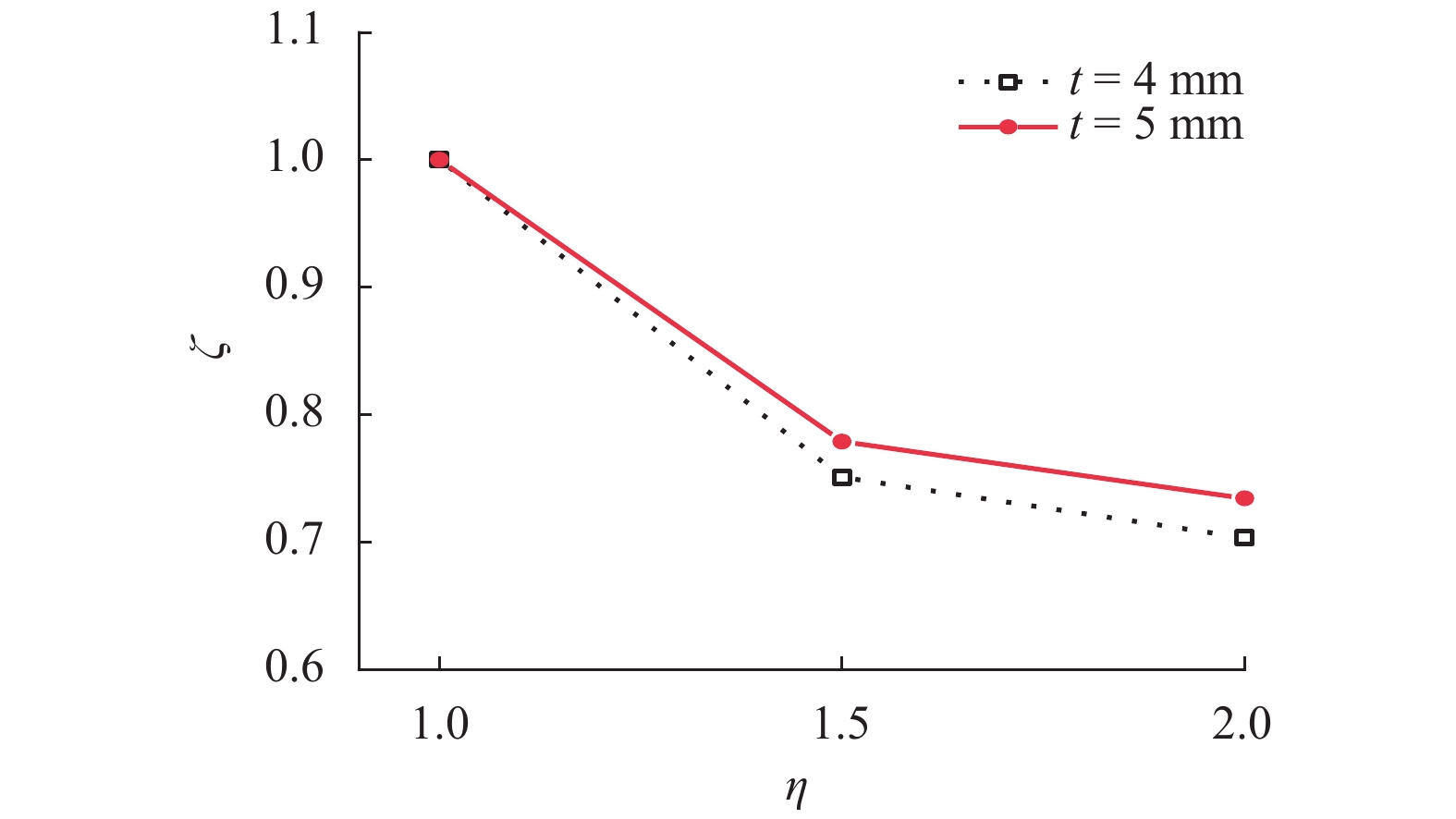

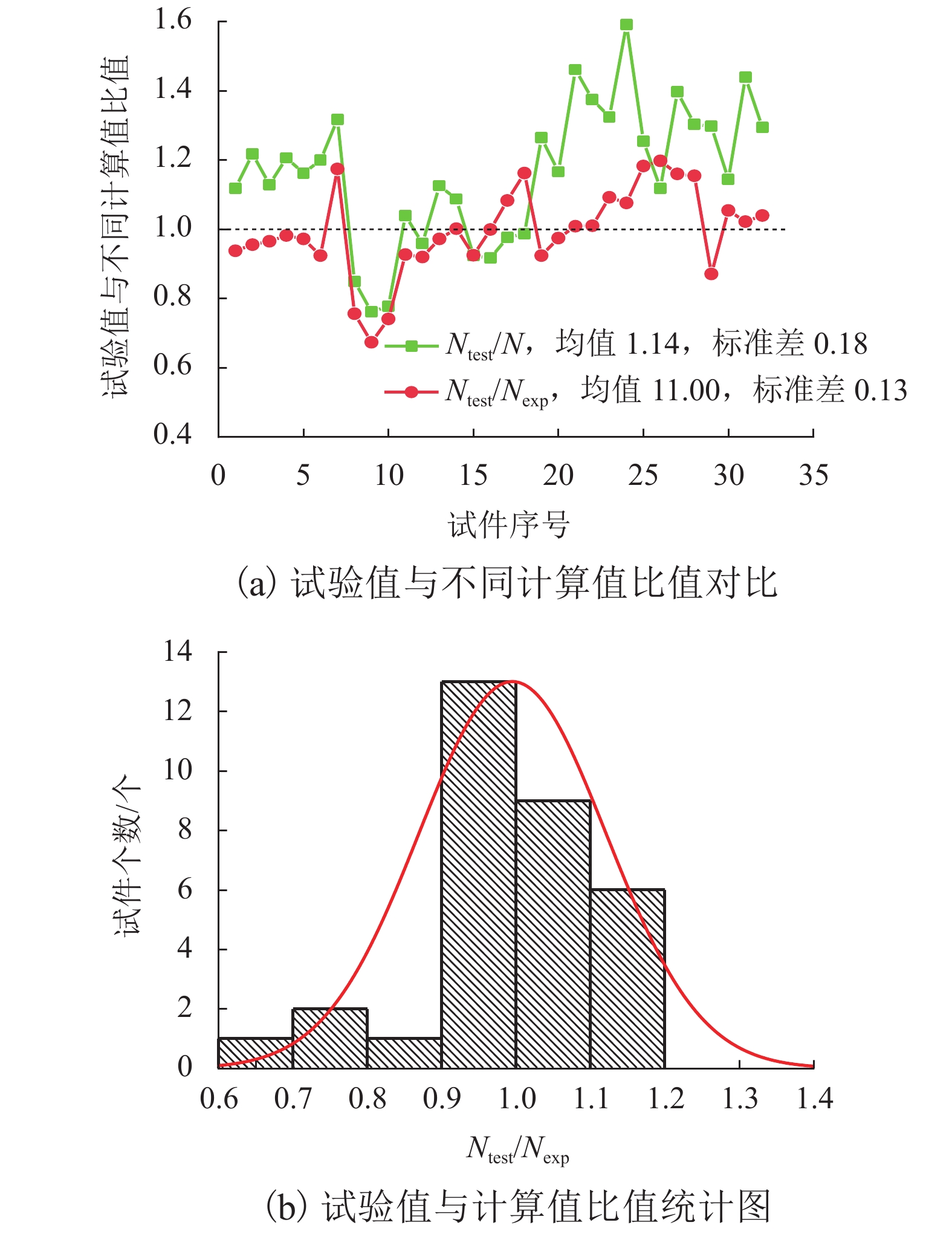

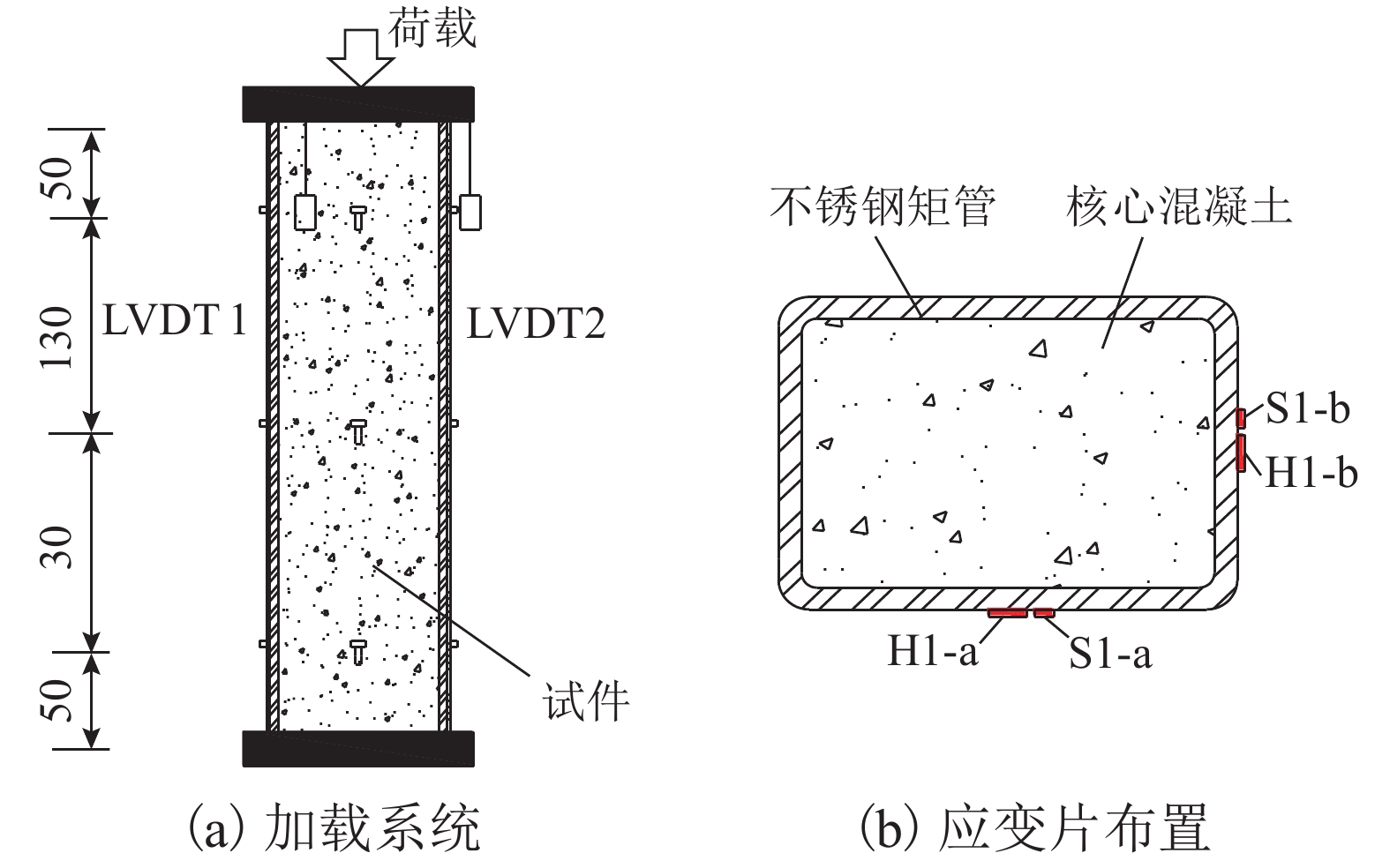

为了研究矩形不锈钢管混凝土短柱轴压承载力性能,对7组不同截面尺寸的矩形不锈钢管混凝土短柱进行轴压试验,得到了不同试件的破坏模式、荷载-位移曲线、荷载-横向应变曲线、荷载-纵向应变曲线、荷载-长宽比曲线,分析了矩形截面长宽比对试件承载力的影响. 研究结果表明:矩形不锈钢管混凝土短柱在轴向压力作用下,其典型破坏模式为试件局部向外屈曲破坏;在相同长宽比的情况下,壁厚由4 mm增加到6 mm时,试件承载力增加25%~57%;在相同壁厚的情况下,长宽比由1增加到2,试件承载力减小22%~30%;将本文试验数据与国内外普通碳钢钢管混凝土柱的相关规范和标准的计算结果进行对比分析,发现不锈钢管混凝土短柱轴压承载力较相同截面的普通碳钢钢管混凝土短柱承载力平均高出14%;通过数值拟合得到了轴压承载力计算公式,该计算公式能较好地预测矩形不锈钢管混凝土短柱轴压承载力.

Abstract:In order to study the axial compressive behavior of rectangular concrete-filled stainless steel tubular (CFSST) short columns, axial compression tests were conducted on seven groups of rectangular CFSST short columns with different cross-sectional sizes. The failure modes, load-displacement curves, load-circumferential strain curves, load-longitudinal strain curves, and load-cross-sectional aspect ratio curves of different specimens under axial compression were obtained. The influence of aspect ratio of the rectangular cross-section on the bearing capacity of the specimens was analyzed. The results show that the typical failure mode of rectangular CFSST short columns under axial compression was local outward buckling. Under the same aspect ratio, when the wall thickness of the specimens increases from 4 mm to 6 mm, the bearing capacity of the specimens increases by 25%–57%. With the fixed wall thickness, when the aspect ratio of specimens increases from 1 to 2, the bearing capacity decreases by 22%–30%. Comparison of the test results with the calculated results by relevant codes and standards indicates that the bearing capacity of CFSST stub columns is more than 14% higher than that of the concrete-filled conventional carbon steel tubular stub columns with the same section. Furthermore, a formula for calculating the axial compression bearing capacity is obtained by numerical fitting of the data obtained in this study and those from literature, which can well predict the bearing capacity of rectangular CFSST short columns.

-

表 1 试件参数

Table 1. Parameters of specimens

试件编号 a/mm b/mm t/mm L/mm fcu/MPa fck/MPa σ0.2/MPa 120 × 60 × 4 120.0 61.3 4.4 359.7 44.0 28.9 538 120 × 60 × 5 119.5 60.4 5.4 360.3 44.0 28.9 581 120 × 80 × 4 119.8 81.0 4.2 359.6 44.0 28.9 516 120 × 80 × 5 120.5 81.1 5.0 361.0 44.0 28.9 558 120 × 120 × 4 120.8 120.3 4.0 360.2 44.0 28.9 549 120 × 120 × 5 120.0 120.5 5.4 360.5 44.0 28.9 578 120 × 120 × 6 120.5 120.1 5.8 361.2 44.0 28.9 598 表 2 各试件的基本参数

Table 2. Basic parameters of all specimens

试件编号 As/mm2 Ac/mm2 σ0.2/MPa fck/MPa η 数据来源 120 × 60 × 4 1523 5836 538 29.48 2.00 本文 120 × 60 × 5 1824 5390 581 29.48 2.00 120 × 80 × 4 1606 8094 516 29.48 1.50 120 × 80 × 5 1921 7847 558 29.48 1.50 120 × 120 × 4 1857 12745 578 29.48 1.00 120 × 120 × 5 2462 11939 598 29.48 1.00 120 × 120 × 6 2680 11829 549 29.48 1.00 200 × 110 × 4C40 2346 19088 503 31.22 1.80 文献[24] 160 × 80 × 3C40 1339 11637 536 31.22 2.00 160 × 80 × 3C60 1328 11568 536 41.47 2.00 140 × 80 × 3C40 1282 9861 486 31.22 1.75 140 × 80 × 3C60 1282 9861 486 41.47 1.75 150 × 150 × 6C40 3292 19250 497 31.22 1.00 150 × 150 × 6C60 3293 19281 497 41.47 1.00 150 × 150 × 3C40 1615 20988 448 31.22 1.00 150 × 150 × 3C60 1614 20989 448 41.47 1.00 100 × 100 × 2C30 856 9308 385 20.10 1.00 文献[17] 100 × 100 × 2C60 776 9269 385 35.51 1.00 100 × 100 × 5C30 1841 8123 458 20.10 1.00 100 × 100 × 5C60 1806 8151 458 35.51 1.00 50 × 50 × 2C20 384 2116 353 14.41 1.00 文献[18] 50 × 50 × 2C30 384 2116 353 23.38 1.00 50 × 50 × 3C20 564 1936 440 14.41 1.00 50 × 50 × 3C30 564 1936 440 23.38 1.00 100 × 100 × 3C20 1164 8836 358 14.41 1.00 100 × 100 × 3C30 1164 8836 358 23.38 1.00 100 × 100 × 5C20 1900 8100 435 14.41 1.00 100 × 100 × 5C30 1900 8100 435 23.38 1.00 150 × 150 × 3C20 1764 20736 268 14.41 1.00 150 × 150 × 3C30 1764 20736 268 23.38 1.00 150 × 150 × 5C20 2900 19600 340 14.41 1.00 150 × 150 × 5C30 2900 19600 340 23.38 1.00 表 3 承载力计算与试验值

Table 3. Calculated and tested values of bearing capacity

序号 试件编号 规范计算值 N /kN Ntest/kN Nexp/kN 文献[28] 文献[29] 文献[30] 文献[31] 文献[32] 1 120 × 60 × 4 985.75 970.45 954.93 1127.31 925.15 1261 1344 2 120 × 60 × 5 1115.91 1101.78 971.97 1340.03 1059.94 1632 1708 3 120 × 80 × 4 1090.13 1068.95 1132.21 1206.18 1006.19 1362 1410 4 120 × 80 × 5 1268.14 1247.58 1251.20 1435.89 1186.61 1732 1764 5 120 × 120 × 4 1455.26 1421.92 1584.14 1560.61 1323.19 1814 1866 6 120 × 120 × 5 1710.51 1679.26 1755.92 1895.83 1586.73 2274 2460 7 120 × 120 × 6 1946.23 1915.16 1938.93 2166.75 1823.13 2854 2430 8 200 × 110 × 4C40 1775.96 1692.74 1974.76 1915.92 2069.53 1627 2151 9 160 × 80 × 3C40 1081.01 1030.27 1209.70 1158.21 1259.98 882 1308 10 160 × 80 × 3C60 1191.53 1177.88 1352.79 1305.55 1427.86 1015 1369 11 140 × 80 × 3C40 930.91 887.91 1030.11 1008.94 1082.57 1049 1131 12 140 × 80 × 3C60 1031.98 1020.35 1160.93 1143.72 1233.44 1097 1192 13 150 × 150 × 6C40 2237.10 2153.17 2398.18 2458.97 2533.17 2768 2847 14 150 × 150 × 6C60 2436.20 2413.45 2652.82 2733.36 2830.11 2972 2967 15 150 × 150 × 3C40 1378.76 1287.25 1577.12 1495.00 1701.56 1381 1492 16 150 × 150 × 3C60 1593.48 1568.71 1852.90 1767.94 1701.15 1620 1621 17 100 × 100 × 2C30 516.65 517.06 571.55 546.95 608.80 534 613 18 100 × 100 × 2C60 627.90 672.20 721.54 696.10 790.01 687 651 19 100 × 100 × 5C30 1006.45 1006.81 1037.03 1115.46 1086.86 1410 1379 20 100 × 100 × 5C60 1116.59 1155.55 1162.70 1276.07 1259.15 1488 1431 21 50 × 50 × 2C20 166.04 174.22 177.42 178.63 155.86 261 224 22 50 × 50 × 2C30 185.02 198.32 198.70 205.09 165.81 282 235 23 50 × 50 × 3C20 276.05 283.54 283.80 314.89 266.74 417 393 24 50 × 50 × 3C30 293.42 305.59 287.35 341.35 275.84 543 404 25 100 × 100 × 3C20 544.03 578.18 586.94 570.90 501.53 716 709 26 100 × 100 × 3C30 623.29 678.83 682.87 676.75 543.06 757 757 27 100 × 100 × 5C20 943.22 974.52 993.26 1037.35 904.26 1449 1326 28 100 × 100 × 5C30 1015.87 1066.78 1042.10 1143.19 942.33 1490 1369 29 150 × 150 × 3C20 771.55 851.70 840.98 818.60 671.81 1062 897 30 150 × 150 × 3C30 957.55 1087.88 1078.87 1056.76 769.27 1209 1009 31 150 × 150 × 5C20 1268.43 1344.19 1362.93 1344.69 1174.16 1935 1668 32 150 × 150 × 5C30 1444.24 1567.43 1574.79 1582.84 1266.28 2048 1773 -

[1] 韩林海. 钢管混凝土结构-理论与实践[M]. 3版. 北京: 科学出版社, 2016. [2] 韩林海,杨有福. 矩形钢管混凝土轴心受压构件强度承载力的试验研究[J]. 土木工程学报,2001,34(4): 22-31. doi: 10.3321/j.issn:1000-131X.2001.04.004HAN Linhai, YANG Youfu. Study on axial bearing capacity of concrete-filled-steel-tube columns with rectangular section[J]. China Civil Engineering Journal, 2001, 34(4): 22-31. doi: 10.3321/j.issn:1000-131X.2001.04.004 [3] 郭红香,赵均海,魏雪英. 方钢管混凝土轴压短柱承载力分析[J]. 工业建筑,2008,38(3): 4,9-11.GUO Hongxiang, ZHAO Junhai, WEI Xueying. Analysis of bearing capacity of concrete-filled square steel tube column under axial load[J]. Industrial Construction, 2008, 38(3): 4,9-11. [4] 龙跃凌,蔡健,黄炎生. 矩形钢管混凝土短柱轴压承载力[J]. 工业建筑,2010,40(7): 95-99.LONG Yueling, CAI Jian, HUANG Yansheng. Ultimate capacity of axially-loaded rectangular cft stub columns[J]. Industrial Construction, 2010, 40(7): 95-99. [5] LUO X Y, LIU W P. Mechanics behavior of concrete-filled square steel tube columns[J]. Applied Mechanics and Materials, 2012, 256/257/258/259: 662-665. doi: 10.4028/www.scientific.net/AMM.256-259.662 [6] 刘洁, 王正中. 方钢管混凝土短柱轴压极限承载力计算方法分析[J]. 建筑结构, 2015, 45(10): 21-25, 42.LIU Jie, WANG Zhengzhong. Analysis on calculating method of ultimate bearing capacity of concrete-filled square steel tube short columns under axial load[J], Building Structure, 2015, 45(10): 21-25, 42. [7] 胡红松,林康,刘阳,等. 方钢管混凝土中钢管和混凝土抗压强度研究[J]. 建筑结构学报,2019,40(2): 161-168.HU Hongsong, LIN Kang, LIU Yang, et al. Study on compressive strength of steel tube and concrete in square CFT columns[J]. Journal of Building Structures, 2019, 40(2): 161-168. [8] 王庆利,李瑞霖,李庆刚,等. 钢管高性能混凝土轴压短柱的静力性能(Ⅱ):机理分析及承载力[J]. 工业建筑,2013,43(3): 8-12.WANG Qingli, LI Ruilin, LI Qinggang, et al. Static performance of the high-performance concrete filled steel tubular stub column (Ⅱ):mechanism analysis and load bearing capacity[J]. Industrial Construction, 2013, 43(3): 8-12. [9] 史庆轩,蔡文哲,王斌. 轴向往复荷载作用下钢管混凝土柱抗震性能试验研究[J]. 建筑结构学报,2020,40(9): 88-97.SHI Qingxuan, CAI Wenzhe, WANG Bin. Experimental research on seismic behavior of concrete-filled steel tube columns under cyclic axial loading[J]. Journal of Building Structures, 2020, 40(9): 88-97. [10] JUNG H S, CHOI C S. An experimental study on the behavior of square concrete-filled high strength steel tube columns[J]. Journal of Iron and Steel Research, 2011, 18(S1): 878-882. [11] IBAÑEZ C, HERNÁNDEZ-FIGUEIRIDO D, PIQUER A. Shape effect on axially loaded high strength CFST stub columns[J]. Journal of Constructional Steel Research, 2018, 147: 247-256. doi: 10.1016/j.jcsr.2018.04.005 [12] ABHILASH M, JHANJHARI S, PARTHIBAN P, et al. Axial behaviour of semi-lightweight aggregate concrete-filled steel tube columns-A DOE approach[J]. Journal of Constructional Steel Research, 2019, 162(5): 105614.1-105614.16. [13] 余敏,李书磊,王圣松. 钢管混凝土构件轴压承载力设计公式的可靠度分析[J]. 建筑钢结构进展,2017,19(2): 45-52,67.YU Min, LI Shulei, WANG Shengsong. Reliability analysis of the bearing capacity of concrete-filled steel tube under axial compression[J]. Progress in Steel Building Structures, 2017, 19(2): 45-52,67. [14] 陈誉,李凤霞,王江. 热成型不锈钢圆管混凝土轴压短柱受力性能试验研究[J]. 建筑结构学报,2013,34(2): 106-112.CHEN Yu, LI Fengxia, WANG Jiang. Experimental study on axial compressive behavior of concrete-filled thermoforming stainless steel tubular stub columns[J]. Journal of Building Structures, 2013, 34(2): 106-112. [15] PATEL V I, LIANG Q Q, HADI M N S. Nonlinear analysis of axially loaded circular concrete-filled stainless steel tubular short columns[J]. Journal of Constructional Steel Research, 2014, 101: 9-18. doi: 10.1016/j.jcsr.2014.04.036 [16] 唐红元,范璐瑶,赵鑫,等. 圆不锈钢管混凝土短柱轴压承载力模型研究[J]. 工程科学与技术,2020,52(3): 10-20.TANG Hongyuan, FAN Luyao, ZHAO Xin, et al. Bearing capacity model of circular concrete-filled stainless steel stub columns under uniaxial compression[J]. Advanced Engineering Sciences, 2020, 52(3): 10-20. [17] 代鹏,杨璐,卫璇,等. 不锈钢管混凝土短柱轴压承载力试验研究[J]. 工程力学,2019,36(增刊1): 298-305.DAI Peng, YANG Lu, WEI Xuan, et al. Experimental studies on the behavior and capacity of concrete filled stainless steel tube short columns[J]. Engineering Mechanics, 2019, 36(S1): 298-305. [18] LAM D, GARDNER L. Structural design of stainless steel concrete filled columns[J]. Journal of Constructional Steel Research, 2008, 64(11): 1275-1282. doi: 10.1016/j.jcsr.2008.04.012 [19] BRIAN U, ZHONG T, HAN L H. Behaviour of short and slender concrete-filled stainless steel tubular columns[J]. Journal of Constructional Steel Research, 2011, 67(3): 360-378. doi: 10.1016/j.jcsr.2010.10.004 [20] 徐晨豪,赵俊亮,金国平. 圆不锈钢管混凝土轴压短柱三维有限元分析[J]. 混凝土,2017(7): 44-46,49. doi: 10.3969/j.issn.1002-3550.2017.07.011XU Chenhao, ZHAO Junliang, JIN Guoping. Three-dimensional finite element analysis of concrete filled circular stainless steel tubular stubs[J]. Concrete, 2017(7): 44-46,49. doi: 10.3969/j.issn.1002-3550.2017.07.011 [21] 纪官运. 不锈钢管混凝土构件承载力计算方法及应用[D]. 大连: 大连理工大学, 2018. [22] DING F X, YIN Y X, MAO J F, et. al. Analytical behaviors of concrete-filled circular stainless steel tubular (CFCSST) stub columns under axial loading[J]. Structures, 2019, 19: 277-285. doi: 10.1016/j.istruc.2019.01.013 [23] 廖飞宇. 圆不锈钢管混凝土轴压力学性能的有限元分析[J]. 福建农林大学学报(自然科学版), 2009, 38(6): 659-662.LIAO Feiyu. Finite element analysis for circular concrete-filled stainless steel tubular column under axial compression[J]. Journal of Fujian Agriculture and Forestry University (Natural Science Edition), 2009, 38(6): 659-662. [24] YOUNG B, ELLOBODY E. Experimental investigation of concrete-filled cold-formed high strength stainless steel tube columns[J]. Journal of Constructional Steel Research, 2006, 62(5): 484-492. doi: 10.1016/j.jcsr.2005.08.004 [25] DABAON M, EL-KHORIBY S, EL-BOGHDADI M, et al. Confinement effect of stiffened and unstiffened concrete-filled stainless steel tubular stub columns[J]. Journal of Constructional Steel Research, 2009, 65(8/9): 1846-1854. [26] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料拉伸试验第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011. [27] 中华人民共和国建设部, 国家质量监督检验检疫总局. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003 [28] European Committee for Standardization. Design of composite steel and concrete structures, part 1.1: general rules and rules for buildings: EC4[S]. Brussels: European Committee for Standardization, 2004. [29] Architectural Institute of Japan. Recommendations for design and construction of concrete filled steel tubular structures: AIJ-CFT[S]. Tokyo: Architectural Institute of Japan, 1997. [30] 国家能源局. 钢-混凝土组合结构设计规程: DL/T 5085—2021[S]. 北京: 中国计划出版社, 2021. [31] 福建省住房和城乡建设厅. 钢管混凝土结构技术规程: DBJ/T 13-51—2010[S]. 福州: 福建省住房和城乡建设厅, 2010. [32] 中国工程建设标准化协会. 矩形钢管混凝土结构技术规程: CECS 159—2004[S]. 北京: 中国计划出版社, 2004. -

下载:

下载: