Fatigue Life Assessment of Metro Carbody Based on Submodel Method

-

摘要:

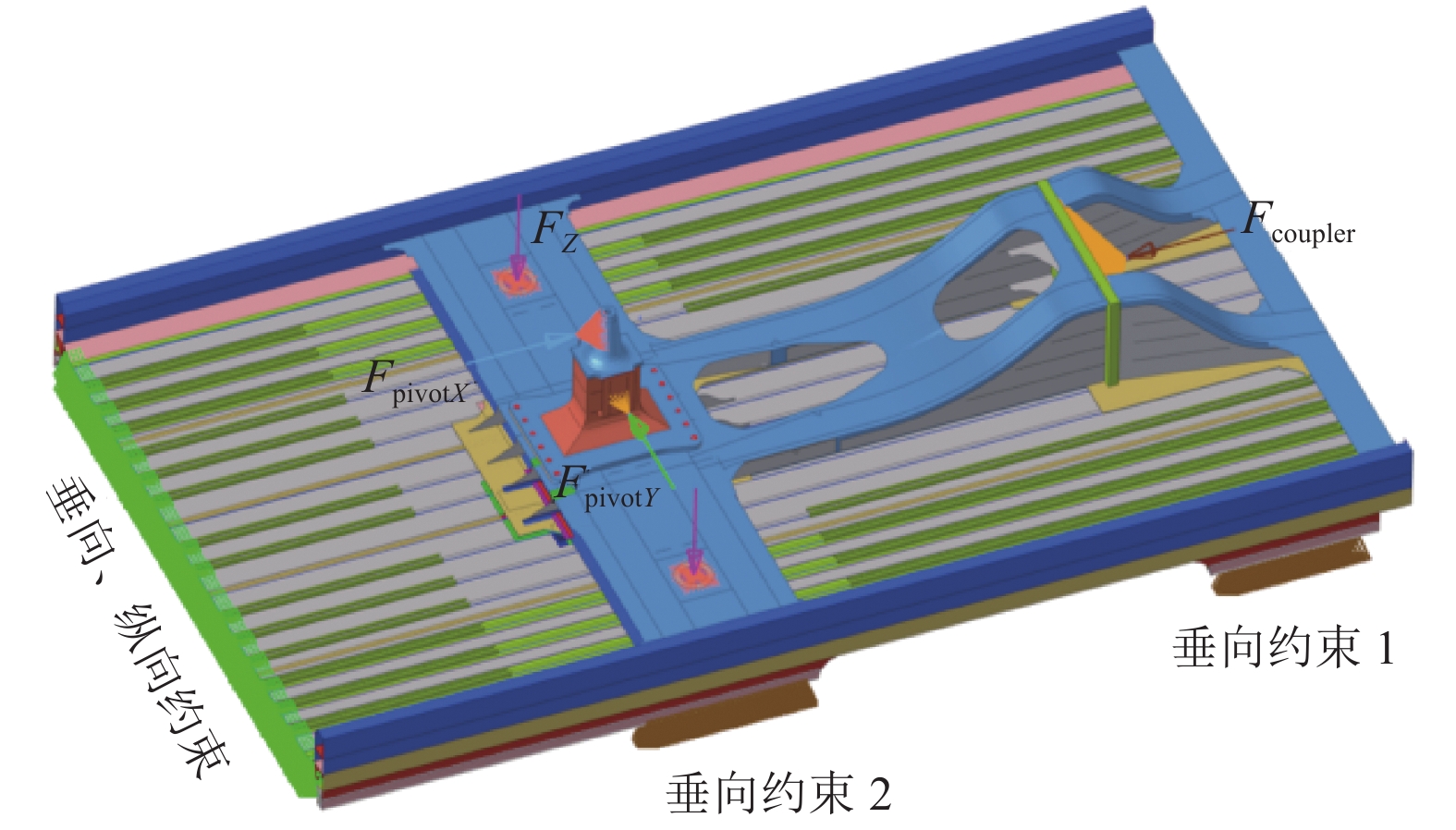

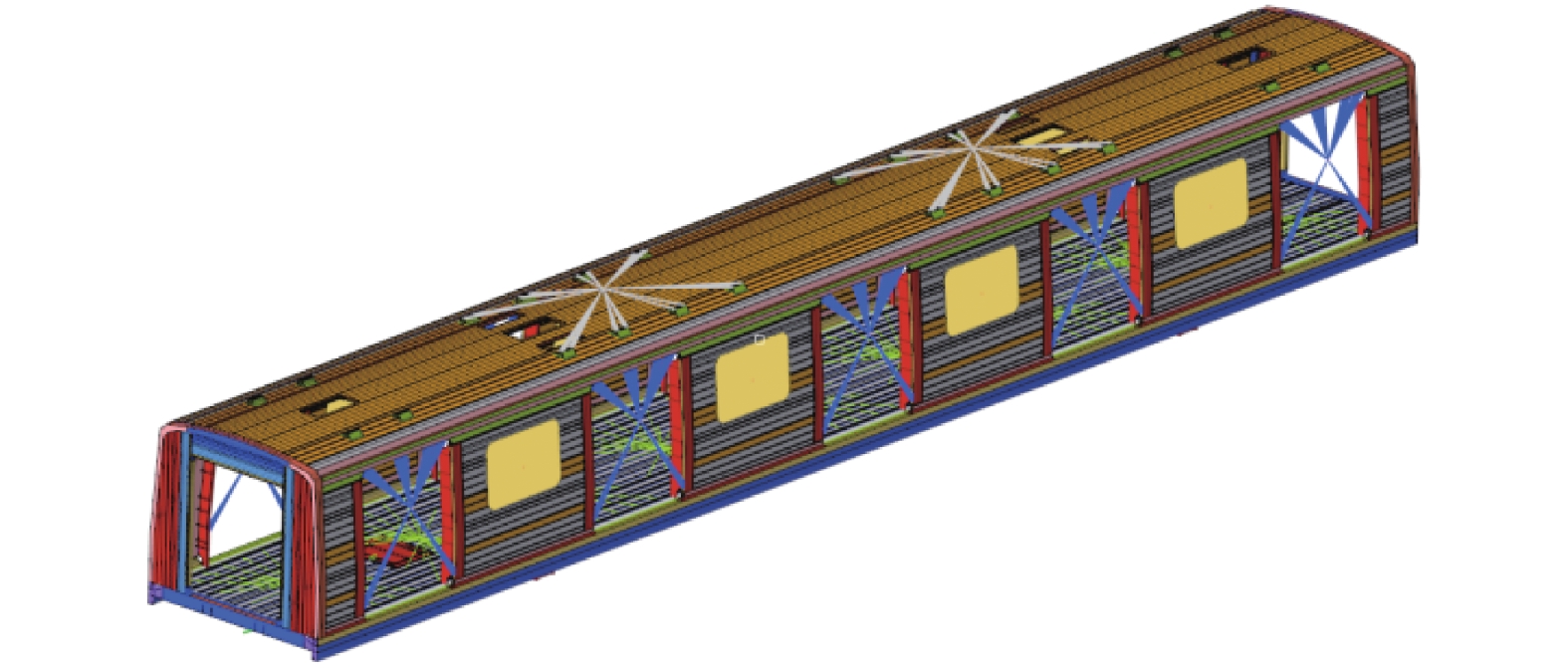

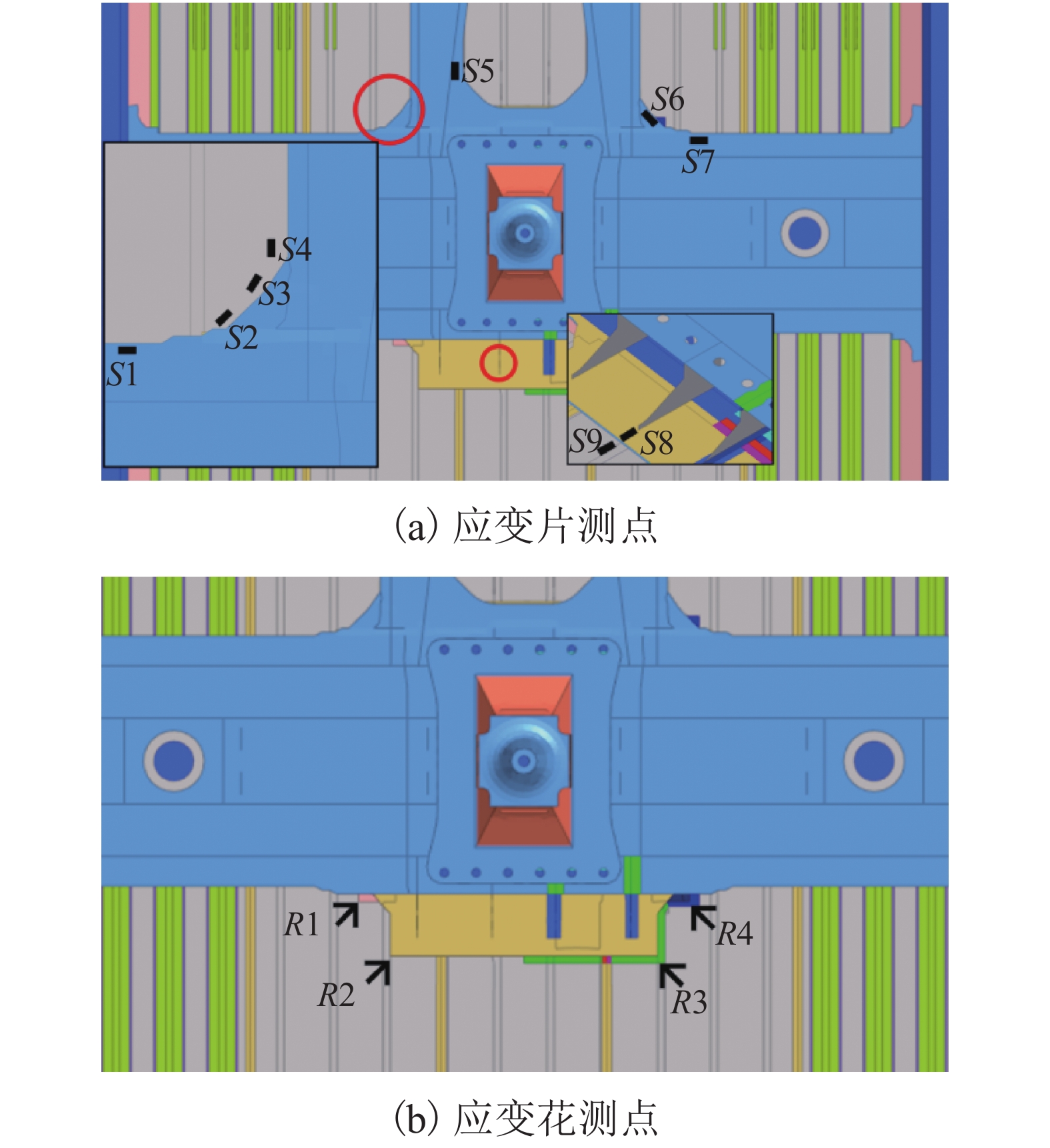

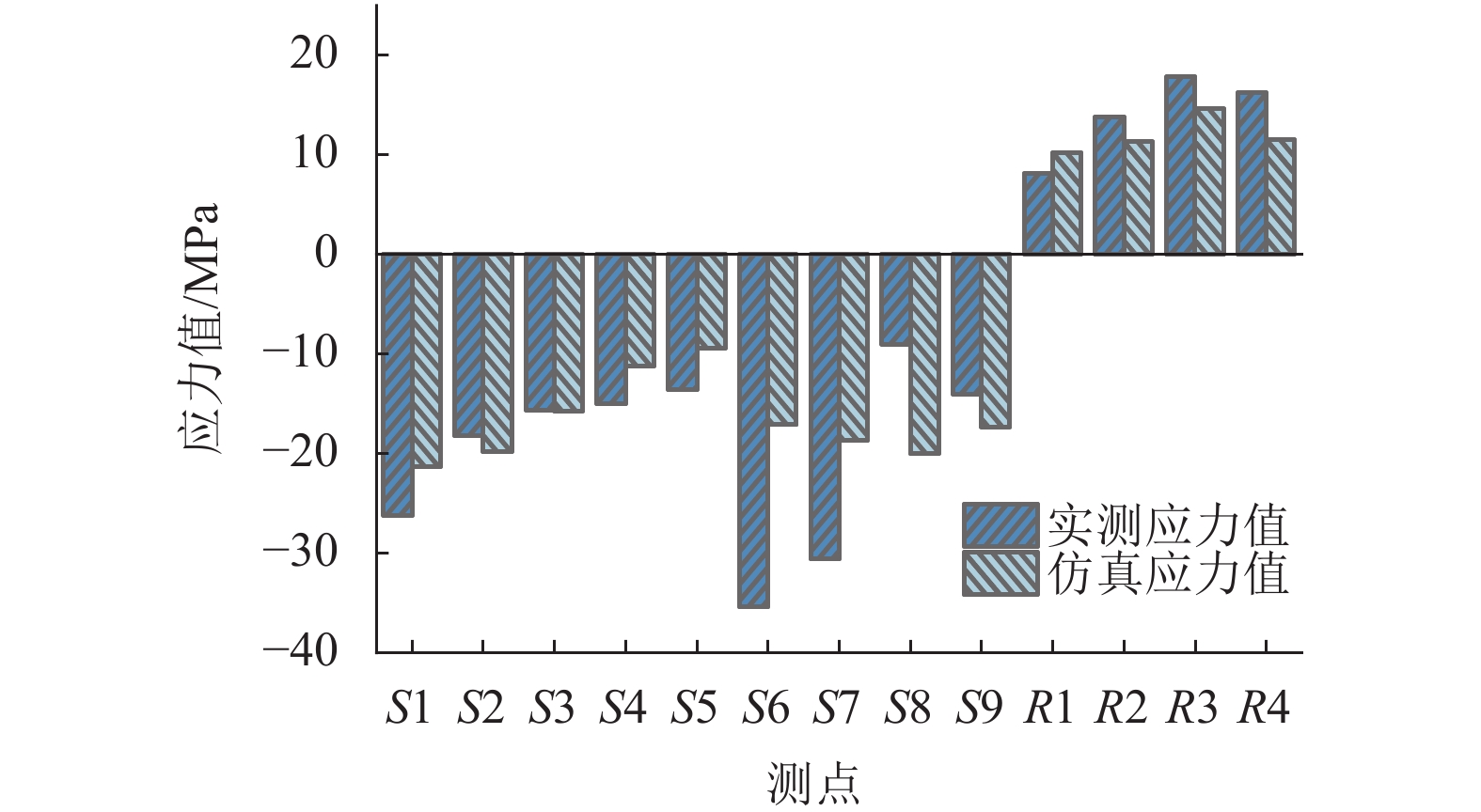

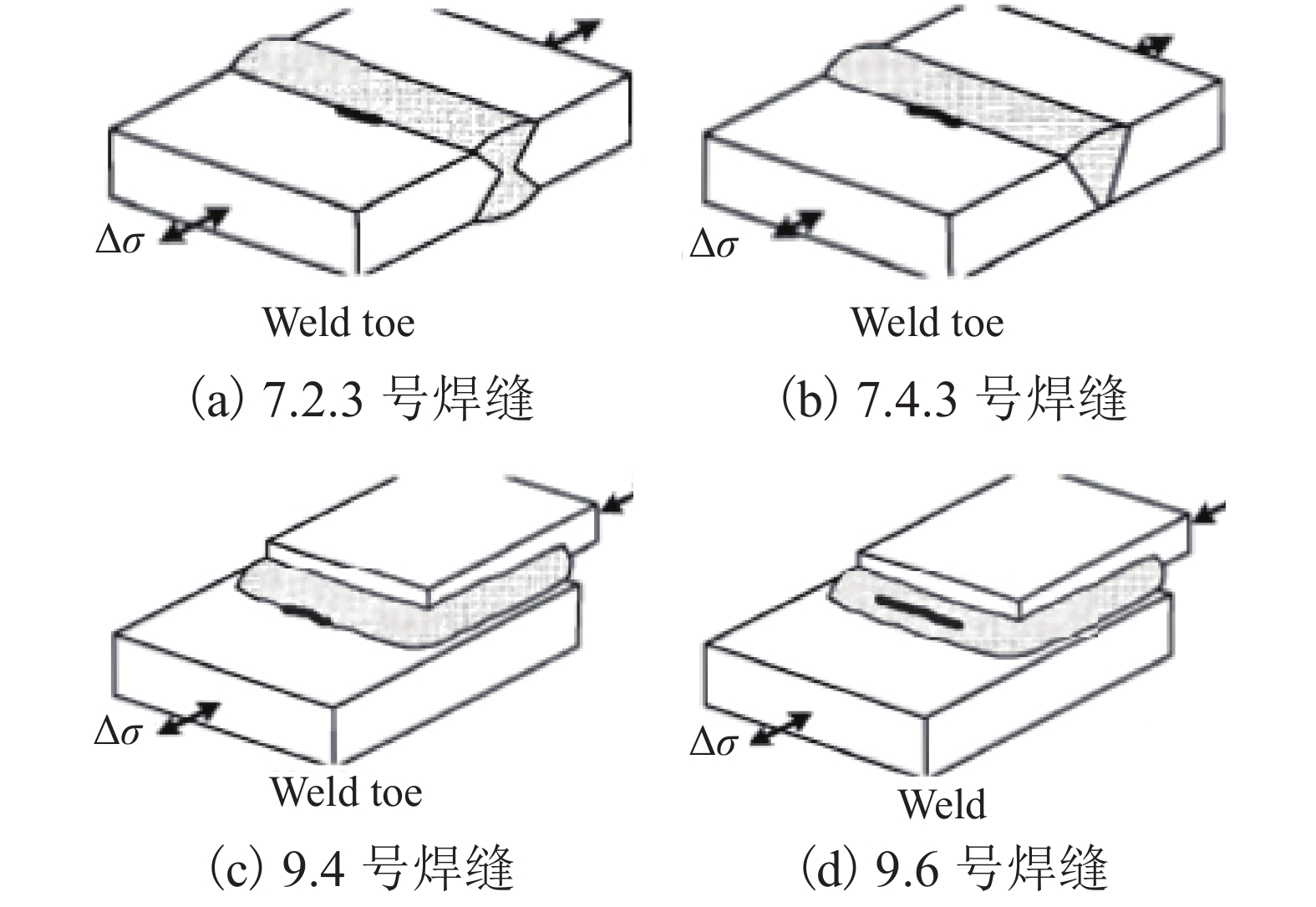

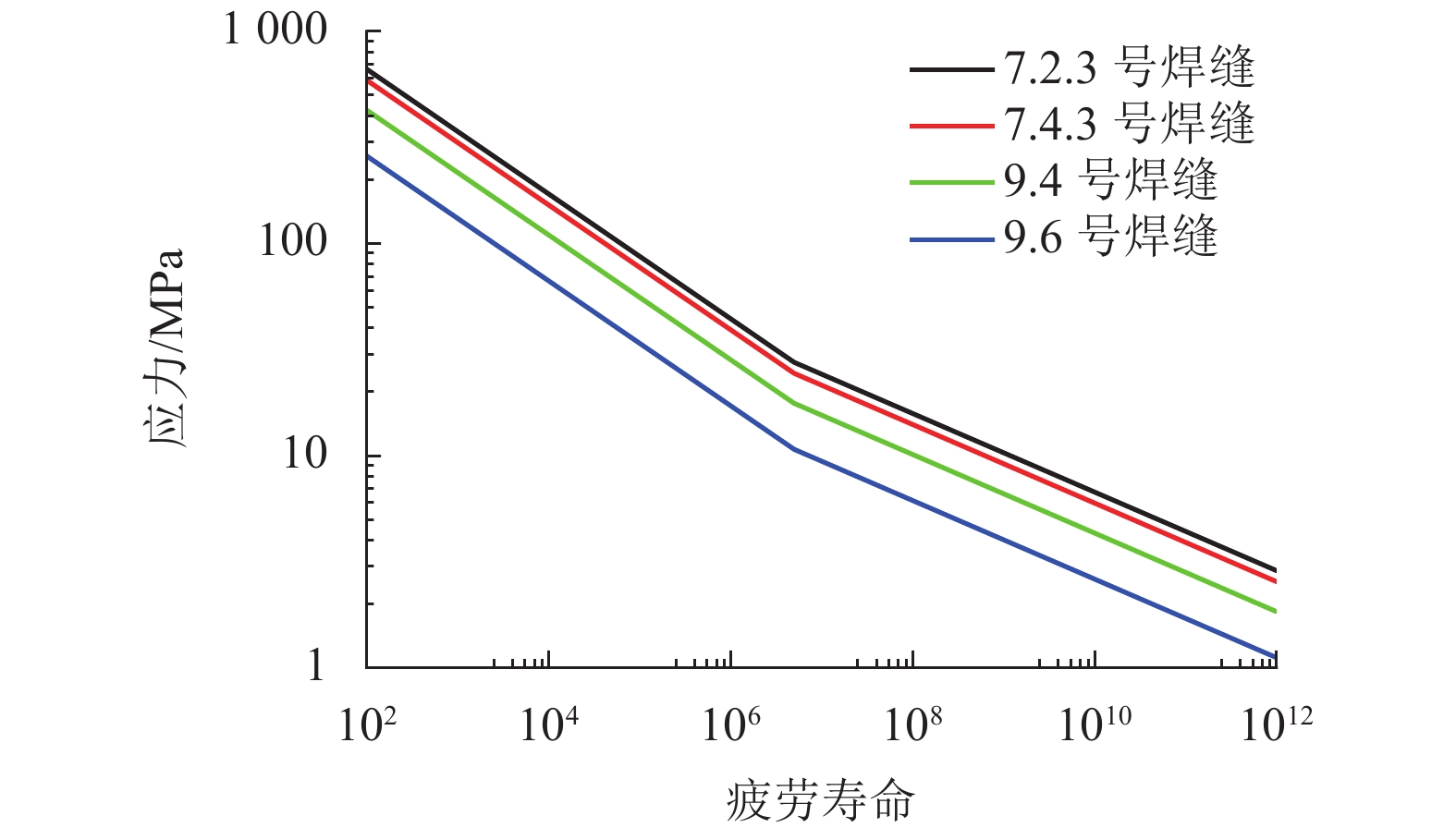

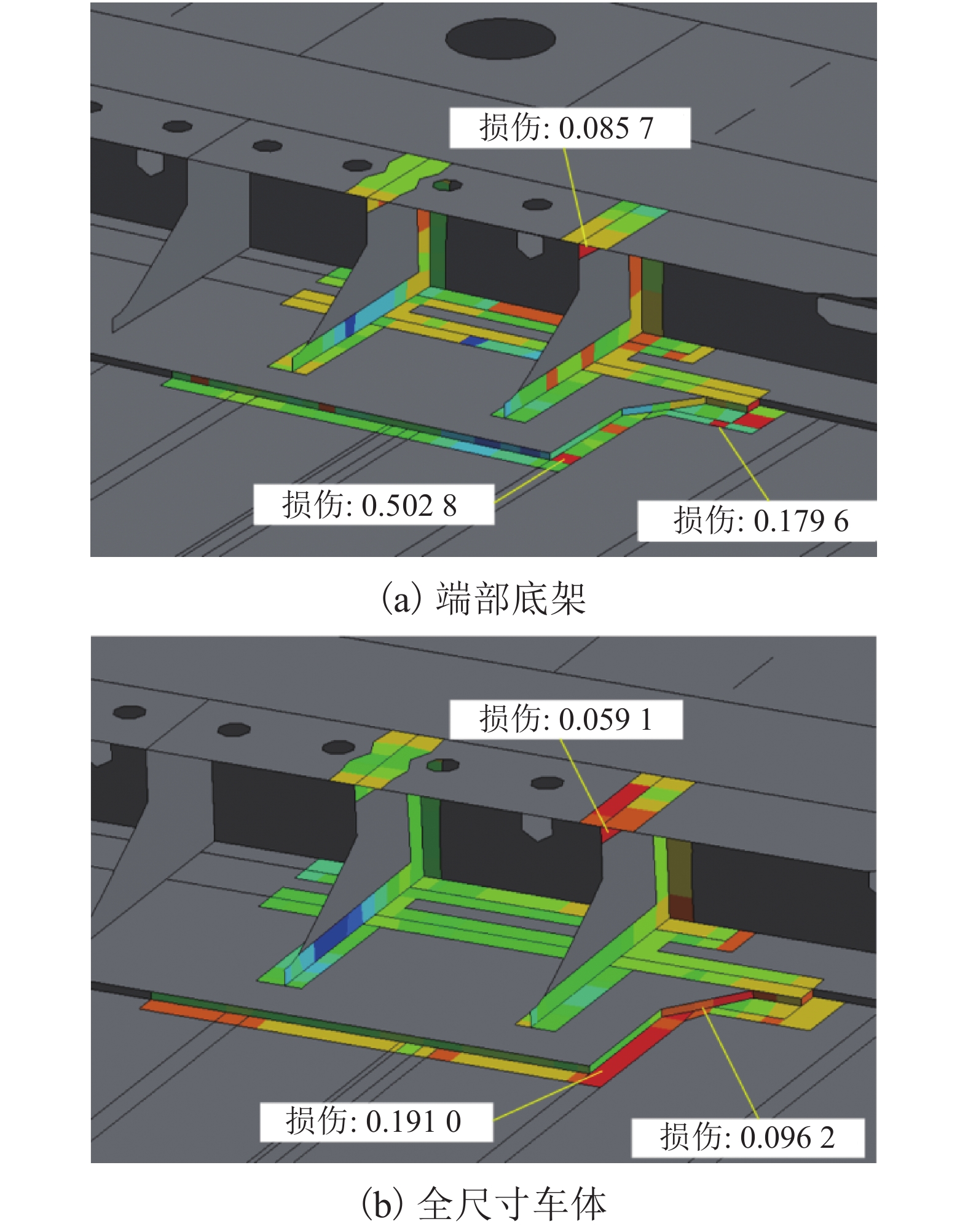

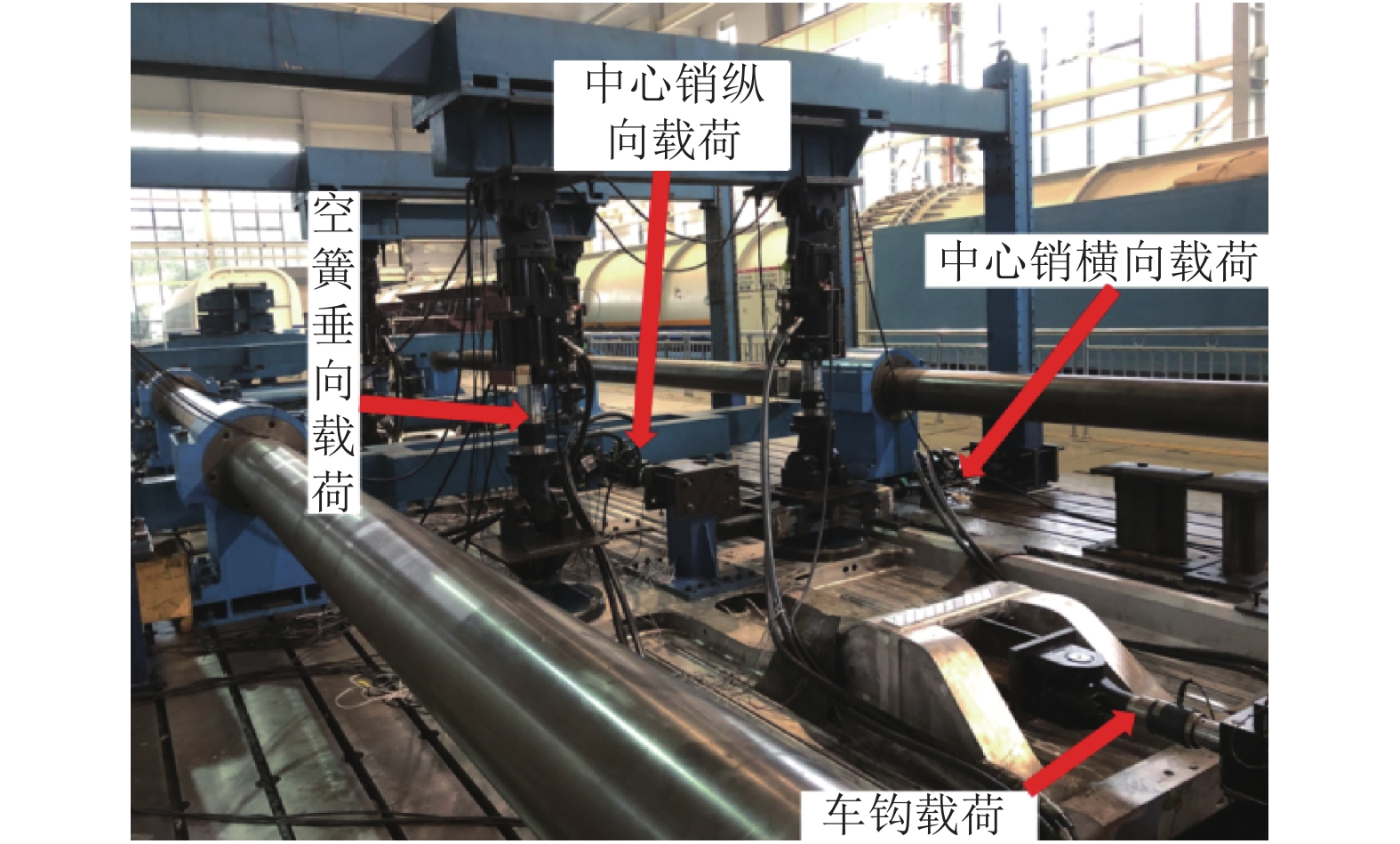

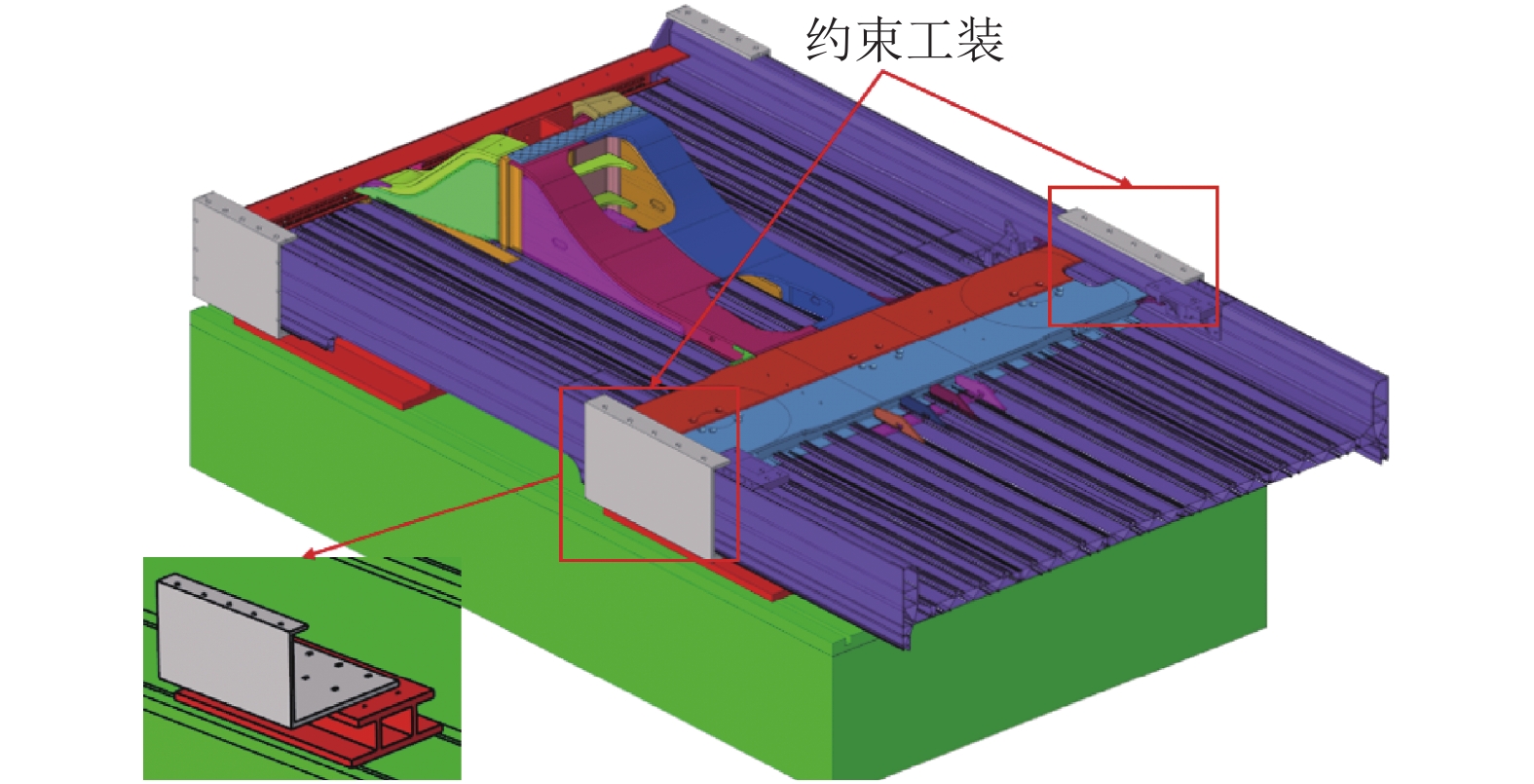

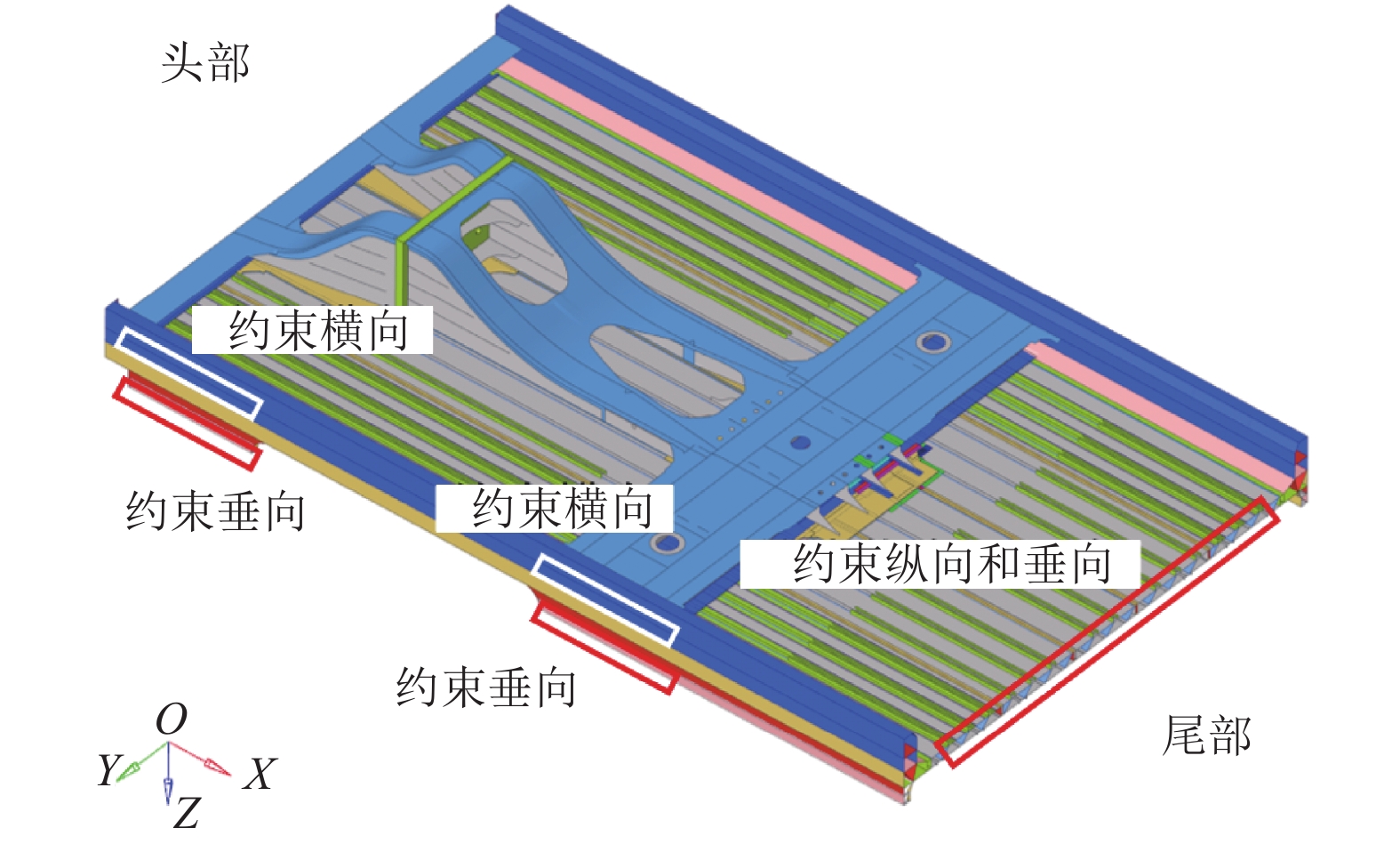

车体是地铁车辆的重要承载部件,针对全尺寸车体疲劳试验综合难度高的问题,基于端部底架子模型包含了牵枕缓等在车体中受力最严苛结构的特点,提出采用端部底架子模型代替全尺寸车体进行疲劳试验的方法;建立了端部底架子模型和全尺寸车体的有限元模型,并参照EN 12663标准所确定的疲劳载荷,通过设置合理的边界条件使得端部底架子模型与全尺寸车体关键位置应力分布一致;将试验测得端部底架关键位置的应力与仿真结果进行对比,验证了有限元模型的准确性,进而采用名义应力法和Eurocode 9标准规定的疲劳寿命-应力(

S -N )曲线对车体和底架焊缝部位进行了疲劳损伤计算. 结果表明:端部底架3个最大损伤位置与全尺寸车体一致,并且同一位置处端部底架的损伤值均大于车体损伤值,因此采用子模型法评估全尺寸车体的疲劳寿命易于获得相对保守的结果,针对地铁车体采用子模型法进行疲劳寿命评估是可行的.Abstract:The carbody is an important load-bearing component of metro vehicles. In view of the high comprehensive difficulty of the full-scale carbody fatigue test, on the basis of the characteristics of the end underframe model including the most severely stressed structures in the carbody (e.g., the draft, bolster and buffer), adoption of a fatigue test method using an end underframe submodel is proposed instead of the full-scale carbody. Finite element models of the end underframe and the full-size carbody are established, and the fatigue loads are determined according to the EN 12663 standard. The end underframe model and the stress distribution at key positions of the full-scale carbody are made consistent by setting reasonable boundary conditions. The stress at key positions of the end underframe is measured in a test, and a comparison is made with simulation results to verify the accuracy of the finite element model. The nominal stress method and the

S -N curve specified by Eurocode 9 are then used to calculate the fatigue damage to the carbody and underframe welding seams. The results show that the three positions of maximum damage for the end underframe are consistent with the full-scale carbody, and the damage to the end underframe at the same position is greater than the damage to the carbody. Therefore, the fatigue life evaluation of the full-scale carbody using the submodel method readily obtains conservative results, and it is feasible to use the submodel method to evaluate the fatigue life of a metro carbody.-

Key words:

- full-scale carbody /

- end underframe submodel /

- fatigue testing /

- finite element /

- damage

-

表 1 标准之间疲劳载荷工况对比

Table 1. Comparison of fatigue load cases between standards

标准 工况 X Y Z VDV 152 1 ± 1.20 m/s2 g ± 1.90 m/s2 2 ± 1.60 m/s2 g ± 1.00 m/s2 3 ± 1.50 m/s2 ± 0.60 m/s2 g ± 1.00 m/s2 EN 12663 1 ± 0.15g 2 ± 0.15g 3 ± 0.15g 表 2 端部底架与全尺寸车体损伤对比

Table 2. Damage comparison of the end underframe and the full-scale carbody

端部底架损伤 整车损伤 损伤部位 0.5028 0.1910 地板下表面与枕内加强筋底板焊缝直角拐角处 0.1796 0.0962 地板下表面与枕内加强筋底板135°拐角附近区域 0.0857 0.0591 外侧枕内加强筋与枕梁下盖板焊缝 -

[1] 王生华. 上海轨道交通1号线列车车体裂纹原因分析及解决措施[J]. 铁道车辆,2018,56(3): 41-43. doi: 10.3969/j.issn.1002-7602.2018.03.016WANG Shenghua. Analysis of causes to cracking in carbodies of trains for Shanghai rail traffic No. 1 line and measures for solution[J]. Rolling Stock, 2018, 56(3): 41-43. doi: 10.3969/j.issn.1002-7602.2018.03.016 [2] 胡杰鑫,谢里阳,喻海洋,等. 基于验证模型的枕梁疲劳寿命预测虚拟实验[J]. 西南交通大学学报,2019,54(1): 106-112.HU Jiexin, XIE Liyang, YU Haiyang, et al. Virtual experiments to predict bolster fatigue lifetime based on FEM model validated by static tests[J]. Journal of Southwest Jiaotong University, 2019, 54(1): 106-112. [3] 王玉伟. 基于实测载荷的CRH2型动车组车体枕梁疲劳强度研究[D]. 北京: 北京交通大学, 2015. [4] 李珊珊. CRH2046动车枕梁结构剩余寿命预测及补强方案分析[D]. 沈阳: 东北大学, 2015. [5] 臧伟锋,陈安,董登科. 机身壁板内压载荷试验研究[J]. 航空工程进展,2018,9(1): 69-76.ZANG Weifeng, CHEN An, DONG Dengke, et al. Test research on fuselage panel subjected to internal pressure load[J]. Advances in Aeronautical Science and Engineering, 2018, 9(1): 69-76. [6] 魏亚龙. 高速列车车体气密疲劳强度试验台气密载荷加载特性的仿真分析[D]. 北京: 北京交通大学, 2012. [7] GUTIÉRREZ-CARVAJAL R, BETANCUR GIRALDO G, BARBOSA J, et al. Full scale fatigue testing performed to the bolster beam of a railway vehicle[J]. International Journal on Interactive Design and Manufacturing (IJIDeM), 2016, 12(1): 253-261. [8] European Committee for Standardization. Railway applications—structural requirements of railway vehicle bodies, part 1: Locomotives and passenger rolling stock (and alternative method for freight wagons): EN 12663-1: 2010 + A1: 2014[S]. British: BSI Group, 2014. [9] Committee on Urban Rail Rolling Stock. Recommendation on the design for strength of urban rail rolling stock according to BOStrab: VDV 152-2016[S]. Germany: Verband Deutscher Verkehrsunternehmen, 2016. [10] Forschungskuratorium Maschinenbau. Analytical strength assessment of components : made of steel, cast iron and aluminum materials in mechanical engineering: FKM Guideline[S]. Frankfurt am Main: VDMA-Verl, 2013. [11] 李凡松. 服役环境下动车组车体振动与疲劳研究[D]. 成都: 西南交通大学, 2018. [12] European Committee for Standardization. Eurocode 9: Design of aluminium structures, part 1-3: structures susceptible to fatigue: EN 1999-1-3-2007+A1: 2011[S]. British: BSI Group, 2011. -

下载:

下载: