Experimental Study on Pipeline Transport Characteristics of High-Concentration Mixed Aggregate Filling Slurry

-

摘要:

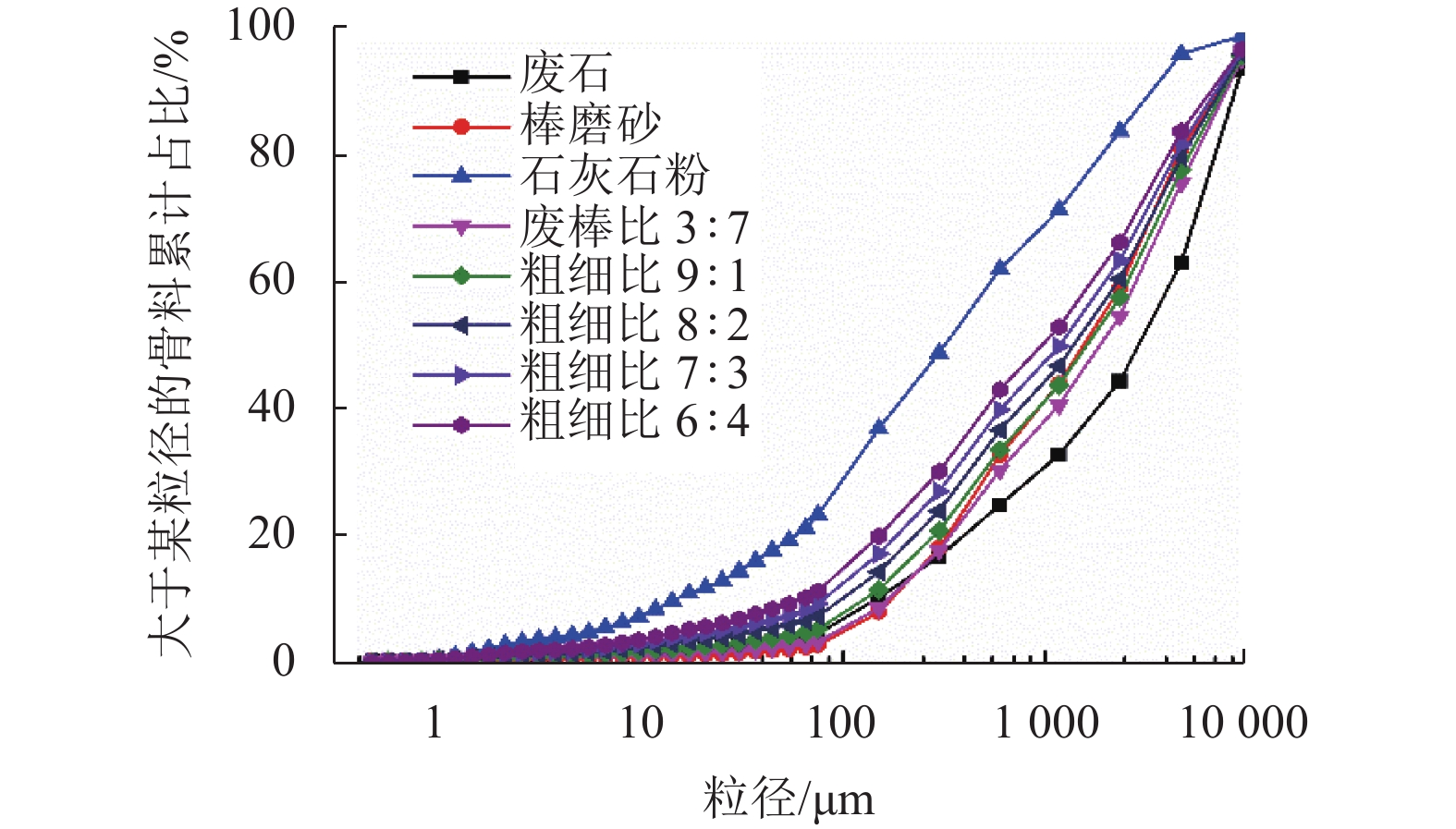

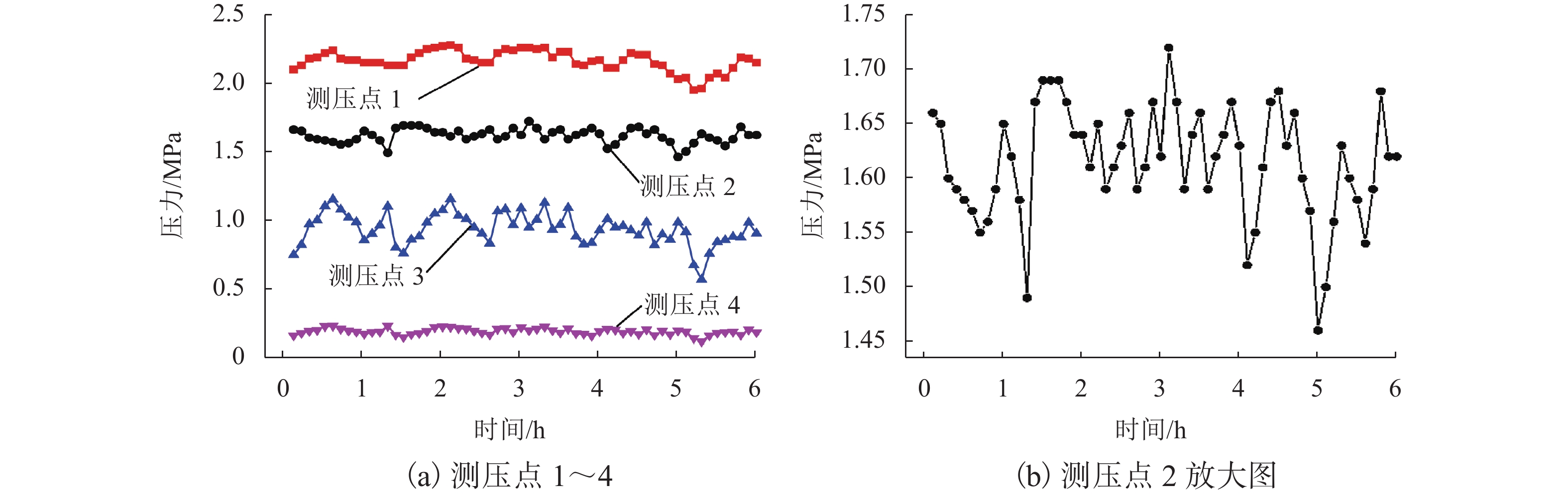

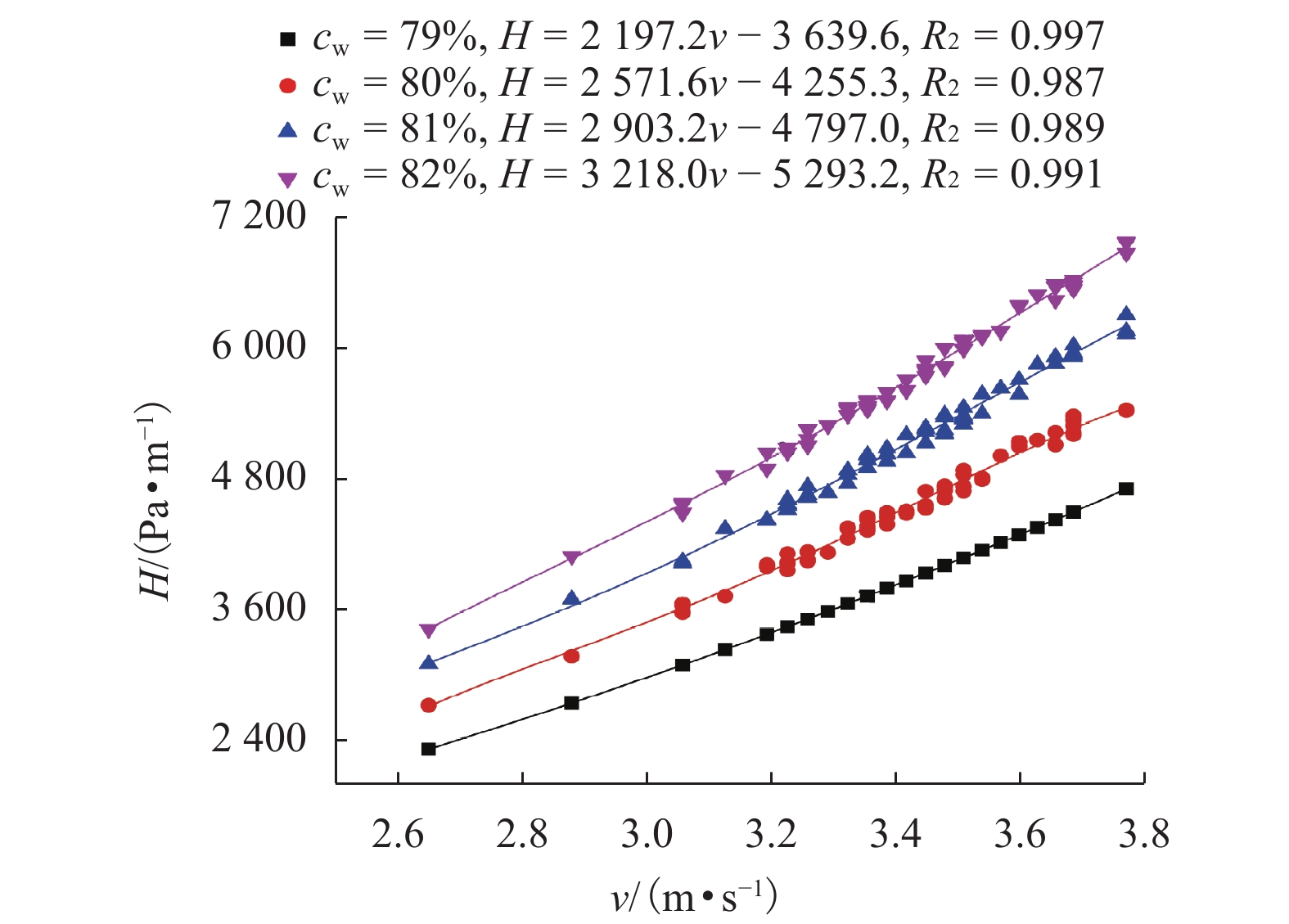

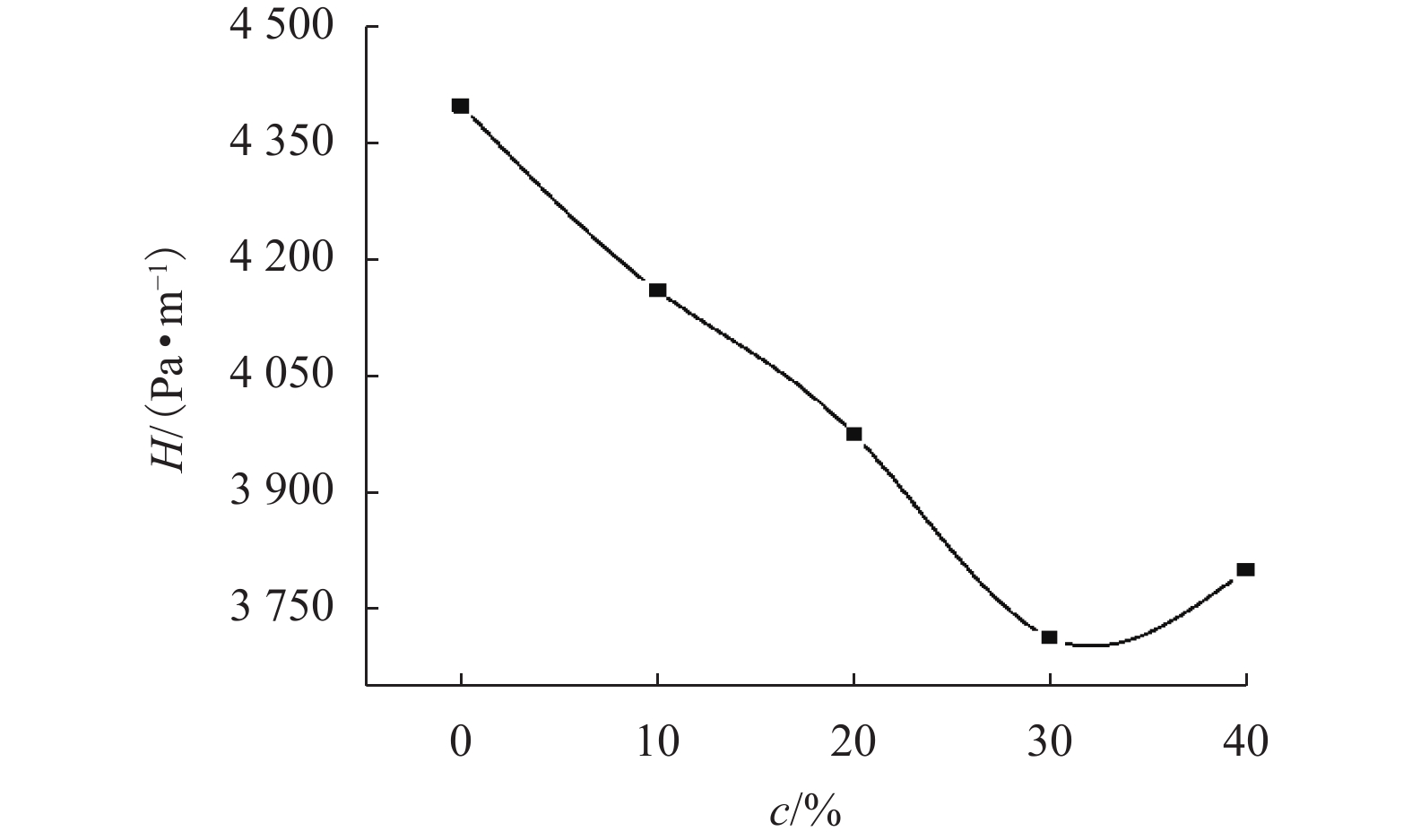

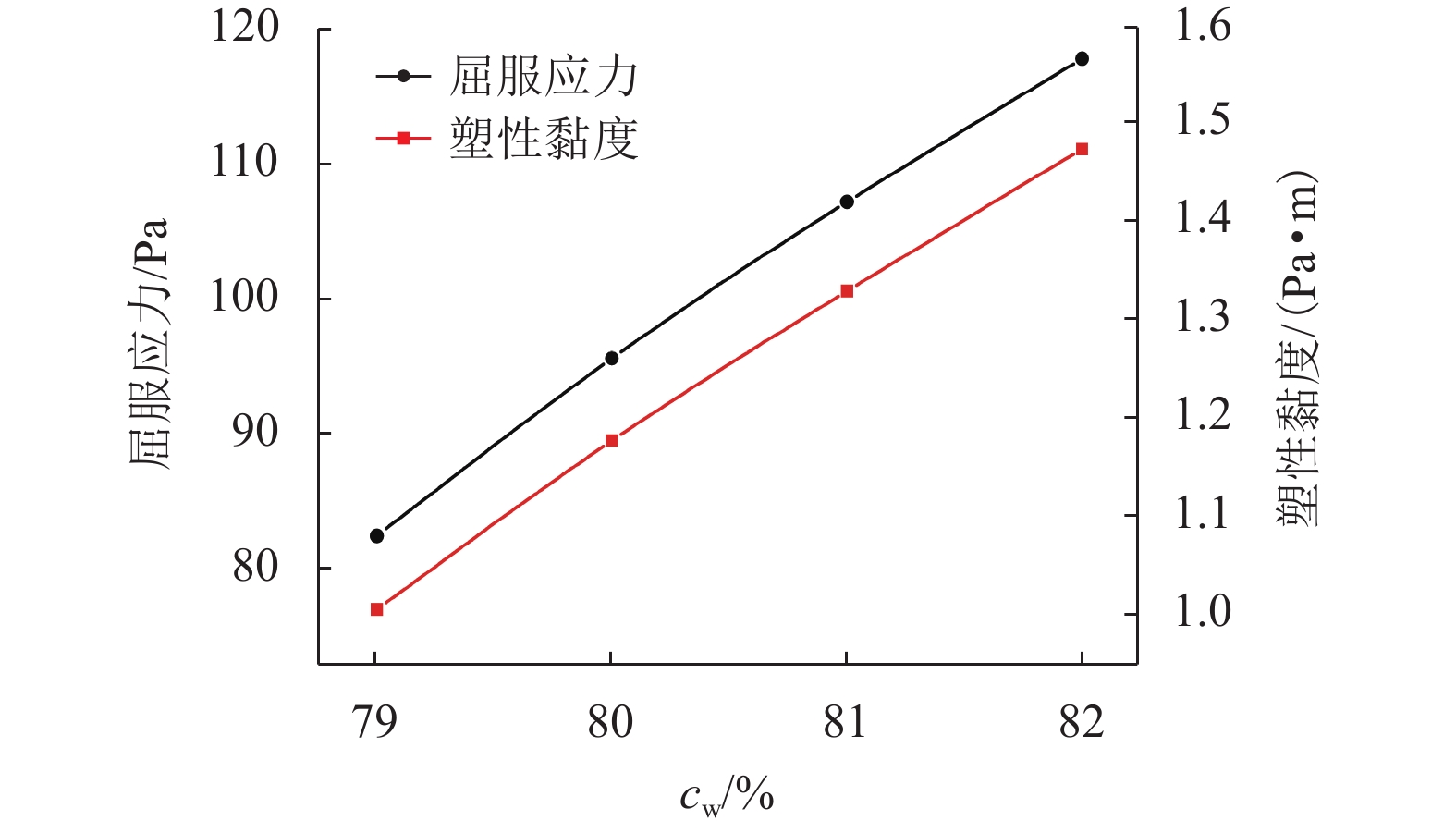

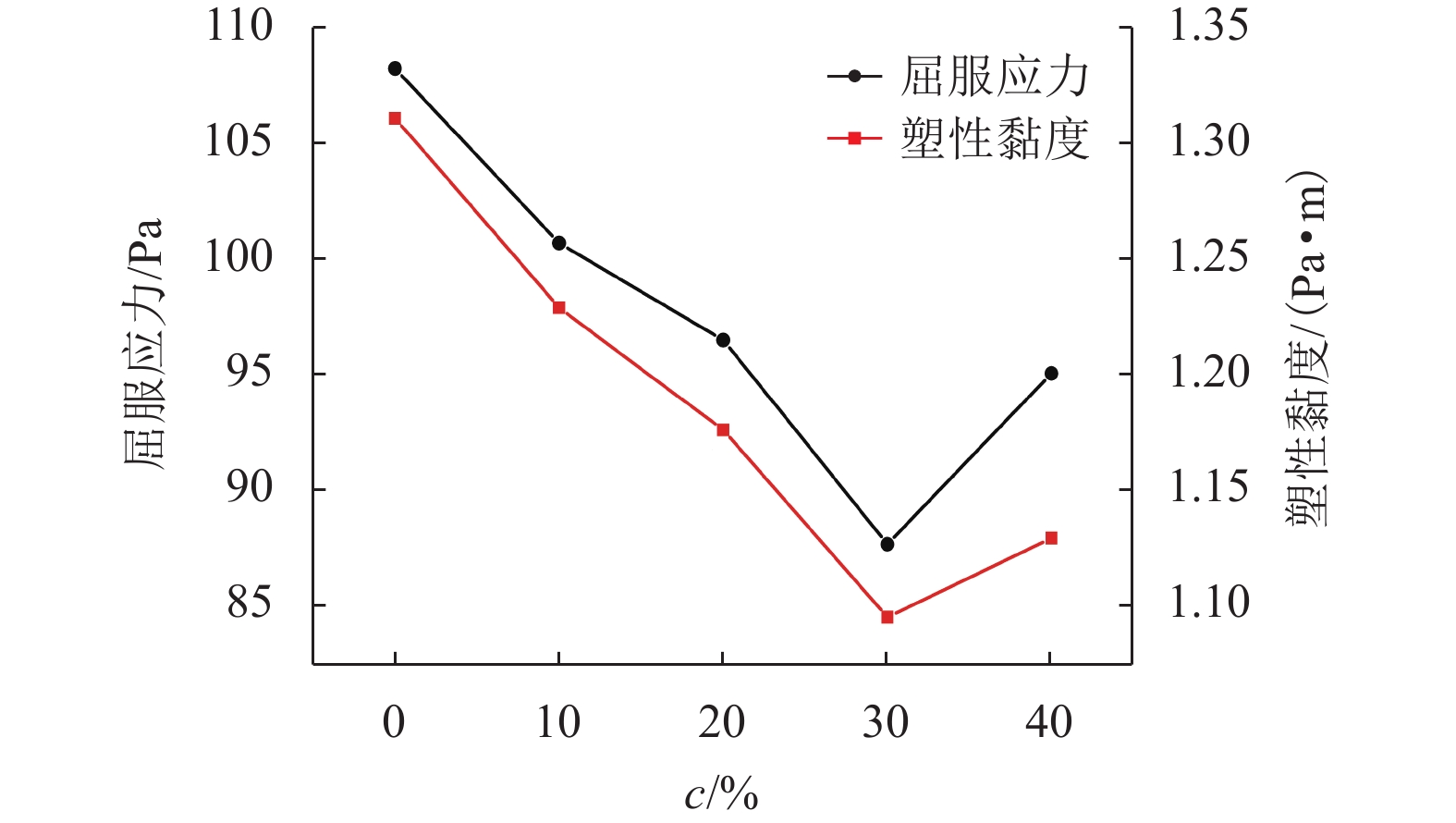

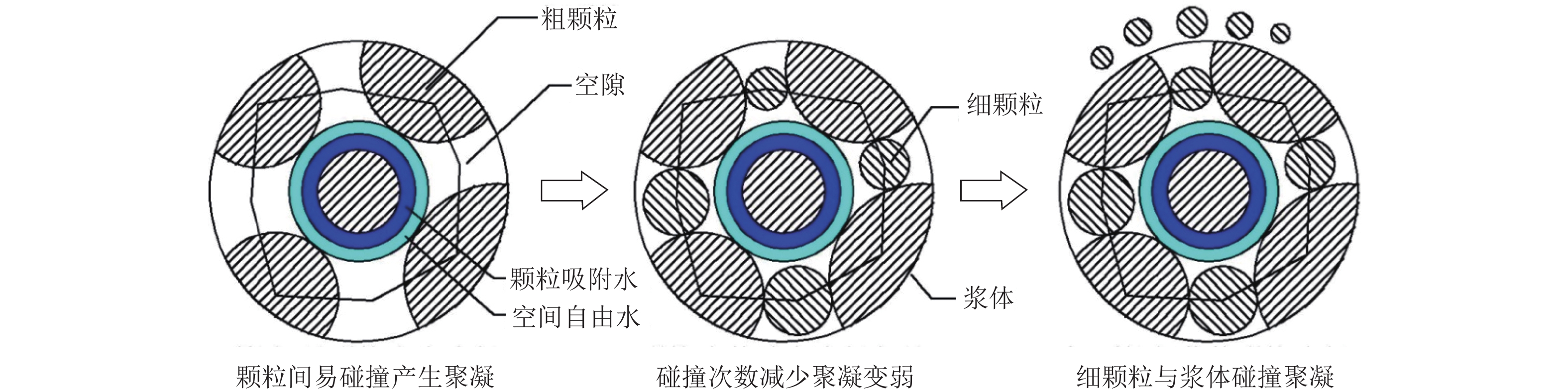

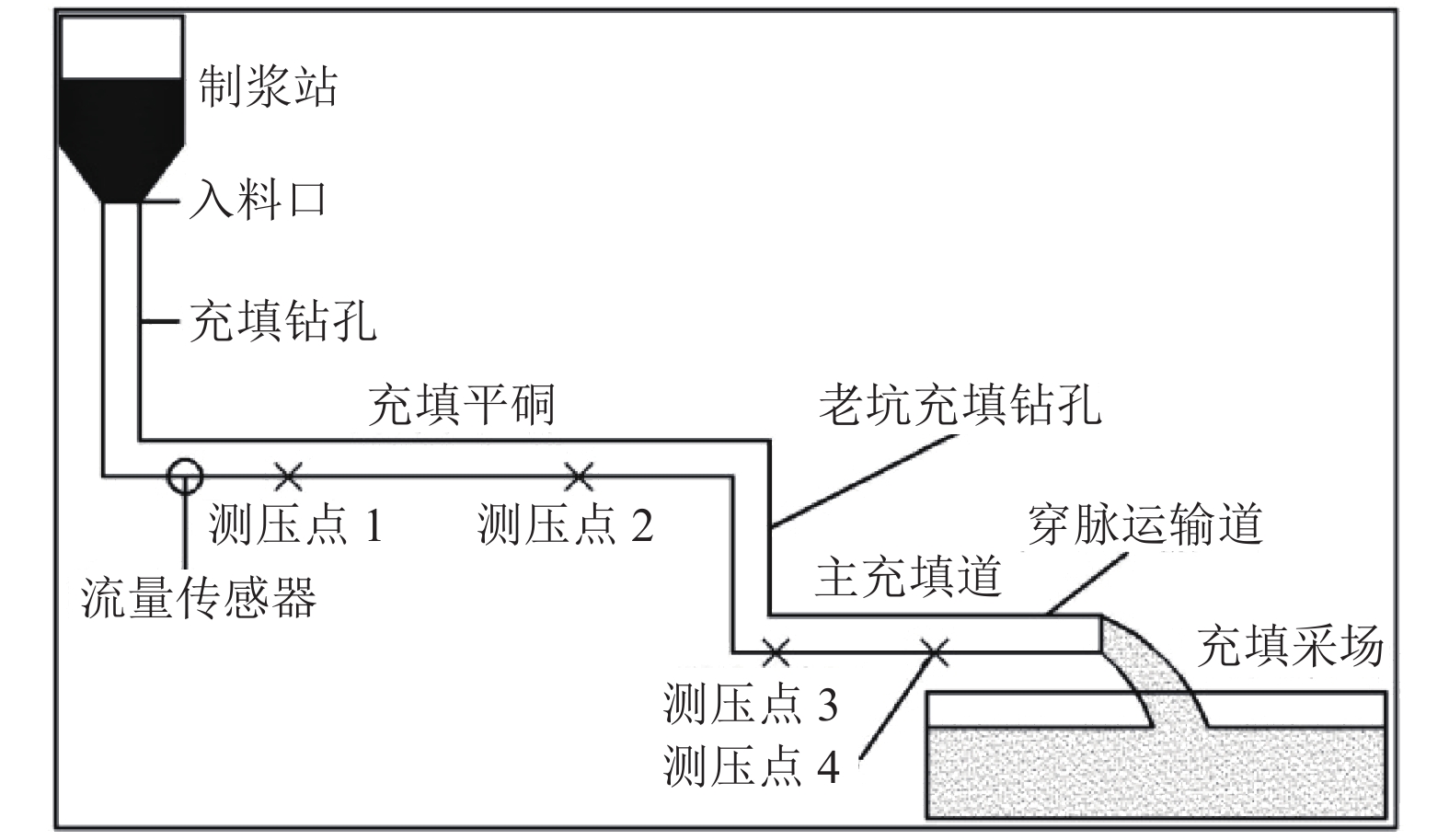

为研究高浓度混合骨料充填料浆管道自流输送规律,利用甘肃某镍矿充填管道输送系统进行工业试验. 首先,通过工业试验获取不同条件下的料浆管输阻力,并分析了管输阻力与料浆流速、料浆浓度与石粉掺加量的关系;然后,基于变量相互独立的性质假设建立了管输阻力数学模型,同时探讨了管输阻力影响因素的交互作用大小;最后,通过流变试验及机理研究对管输阻力结果进行验证分析. 研究结果表明:管输阻力随料浆流速与浓度增加分别呈线性与幂函数增长趋势,与石粉掺加量呈现先减小后增大的抛物线变化规律,石粉掺加量为30%时对应的管输阻力最小;管输阻力影响因素的交互作用从大到小依次为料浆浓度与流速、石粉掺加量与流速、石粉掺加量与料浆浓度,管输阻力变化范围分别为2070~6920、2180~5970、3140~5530 Pa/m;流变参数随料浆浓度与石粉掺加量的增加分别呈增加和先减小后增大的变化趋势,验证了管输阻力的变化规律;流速的振动效应、浓度的黏稠作用与石粉的絮网理论是改变浆体流变特性与管道输送阻力的原因.

Abstract:In order to study the pipeline gravity transport law of high-concentration mixed aggregate filling slurry, an industrial test was carried out using the filling pipeline transport system of a nickel mine in Gansu Province. Firstly, the pipeline resistance of slurry under different conditions was obtained through industrial test, and the relationships between pipeline resistance and slurry velocity, slurry concentration and content of stone powder were analyzed. Then, based on the assumed independent nature of variables, a mathematical model of pipeline resistance was established, and the interaction of influencing factors of pipeline resistance was discussed. Finally, the results of pipeline resistance were verified and analyzed by rheological test and mechanism research. The results show that the pipeline resistance increases linearly with the slurry velocity, increase as a power function with the slurry concentration, and decreases first and then increases, namely in parabolic fashion, with the addition of stone powder. When the stone powder content is 30%, the pipeline resistance is the minimum. Interacted influencing factor pairs of pipeline resistance, ranked by interaction from large to small, are slurry concentration and flow velocity, stone powder content and flow velocity, and stone powder content and slurry concentration, resulting in the pipeline resistance varies in range of 2070−6920, 2180−5970, and 3140−5530 Pa/m, respectively. In addition, the rheological parameters increase with the increased slurry concentration, and decrease first and then increase with the increase of stone powder content, which verifies the variation law of pipeline resistance. The reasons for the change of slurry rheological characteristics and pipeline resistance include the vibration effect of flow velocity, the viscous effect of concentration and the flocculation theory of stone powder.

-

Key words:

- high concentration /

- mixed aggregate /

- pipeline resistance /

- flow velocity /

- rheological properties

-

表 1 工业试验方案

Table 1. Industrial test plans

试验

编号水泥添

加量/(kg•m−3)料浆

浓度/%c/% A1 310 79 20 A2 310 80 20 A3 310 81 20 A4 310 82 20 B1 310 80 0 B2 310 80 10 B3 310 80 30 B4 310 80 40 -

[1] NASIR O, FALL M. Coupling binder hydration,temperature and compressive strength development of underground cemented paste backfill at early ages[J]. Tunnelling and Underground Space Technology, 2010, 25(1): 9-20. doi: 10.1016/j.tust.2009.07.008 [2] 杨志强,高谦,王永前,等. 金川高应力矿床充填采矿技术研究进展与亟待解决的技术难题[J]. 中国工程科学,2015,17(1): 42-50. doi: 10.3969/j.issn.1009-1742.2015.01.006YANG Zhiqiang, GAO Qian, WANG Yongqian, et al. Research development of filling mining technique and technical problems to solve in Jinchuan Nickel Mine with high stress[J]. Strategic Study of CAE, 2015, 17(1): 42-50. doi: 10.3969/j.issn.1009-1742.2015.01.006 [3] 李公成,王洪江,吴爱祥,等. 基于倾斜管实验的膏体自流输送规律[J]. 中国有色金属学报,2014,24(12): 3162-3164.LI Gongcheng, WANG Hongjiang, WU Aixiang, et al. Gravity transport law of paste based on inclined pipe experiment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3162-3164. [4] WANG X, ZHAO J, XUE J, et al. Features of pipe transportation of paste-like backfilling in deep mine[J]. Journal of Central South University, 2011, 18(5): 1413-1417. doi: 10.1007/s11771-011-0855-7 [5] 吴爱祥,刘晓辉,王洪江,等. 结构流充填料浆管道输送阻力特性[J]. 中南大学学报(自然科学版),2014,45(12): 4325-4330.WU Aixiang, LIU Xiaohui, WANG Hongjiang, et al. Resistance characteristics of structure fluid backfilling slurry in pipeline transport[J]. Journal of Central South University (Science and Technology), 2014, 45(12): 4325-4330. [6] BHARATHAN B, MCGUINNESS M, KUHAR S, et al. Pressure loss and friction factor in non-Newtonian mine paste backfill:modelling,loop test and mine field data[J]. Powder Technology, 2019, 344: 443-453. doi: 10.1016/j.powtec.2018.12.029 [7] 刘志祥,肖思友,王卫华,等. 海底开采高倍线强阻力充填料浆的输送[J]. 中国有色金属学报,2016,26(8): 1802-1810.LIU Zhixiang, XIAO Siyou, WANG Weihua, et al. Pipeline transportation of backfilling slurry with high filling times line and strong resistance in undersea mining[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1802-1810. [8] 董慧珍,冯国瑞,郭育霞,等. 新阳矿充填料浆管道输送特性的试验研究[J]. 采矿与安全工程学报,2013,30(6): 880-885.DONG Huizhen, FENG Guorui, GUO Yuxia, et al. Pipe transportation characteristics of filling slurry in Xinyang mine[J]. Journal of Mining & Safety Engineering, 2013, 30(6): 880-885. [9] KUMAR U, MISHRA R, SINGH S N, et al. Effect of particle gradation on flow characteristics of ash disposal pipelines[J]. Powder Technology, 2003, 132(1): 39-51. doi: 10.1016/S0032-5910(03)00045-7 [10] 吴迪,蔡嗣经,杨威,等. 基于CFD的充填管道固液两相流输送模拟及试验[J]. 中国有色金属学报,2012,22(7): 2133-2140.WU Di, CAI Sijing, YANG Wei, et al. Simulation and experiment of backfilling pipeline transportation of solid-liquid two-phase flow based on CFD[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2133-2140. [11] 王有团. 金川低成本充填胶凝材料及高浓度料浆管输特性研究[D]. 北京: 北京科技大学, 2016. [12] 杨志强,姚维信,高谦,等. 棒磨砂充填料浆管道自流输送充填工艺与关键技术[J]. 新疆大学学报(自然科学版),2016,33(2): 221-228.YANG Zhiqiang, YAO Weixin, GAO Qian, et al. Filling process and key technology of pipeline gravity transport for rod mill sand filing slurry[J]. Journal of Xinjiang University (Natural Science Edition), 2016, 33(2): 221-228. [13] 张修香,乔登攀. 粗骨料高浓度充填料浆的管道输送模拟及试验[J]. 中国有色金属学报,2015,25(1): 258-266.ZHANG Xiuxiang, QIAO Dengpan. Simulation and experiment of pipeline transportation of high density filling slurry with coarse aggregates[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 258-266. [14] 邓代强,高永涛,吴顺川. 基于坍落度测试的粗骨料充填料浆流动性检验[J]. 北京建筑工程学院学报,2009,25(1): 30-33.DENG Daiqiang, GAO Yongtao, WU Shunchuan. Liquidity detection based on the slump testing of coarse aggregate fill ing material[J]. Journal of Beijing University of Civil Engineering and Architecture, 2009, 25(1): 30-33. [15] 陈广文,古德生,高泉. 高浓度浆体的浓度判据及其层流输送特性[J]. 中国有色金属学报,1995,5(4): 35-39. doi: 10.3321/j.issn:1004-0609.1995.04.019CHEN Guangwen, GU Desheng, GAO Quan. Concentration criterion of high concentration slurry and its laminar flow transport characteristics[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(4): 35-39. doi: 10.3321/j.issn:1004-0609.1995.04.019 [16] WU D, YANG B, LIU Y. Transportability and pressure drop of fresh cemented coal gangue-fly ash backfill (CGFB) slurry in pipe loop[J]. Powder Technology, 2015, 284: 218-224. doi: 10.1016/j.powtec.2015.06.072 [17] 刘竹青. 流体力学[M]. 北京: 中国水利水电出版社, 2012. [18] 郝雪弟,张鹏程,郭吉昌,等. 煤泥管道输送压力损失特性的试验研究[J]. 煤炭工程,2009(12): 86-88. doi: 10.3969/j.issn.1671-0959.2009.12.031HAO Xuedi, ZHANG Pengcheng, GUO Jichang, et al. Experimental study on pressure loss feature of coal slurry pipeline transportation[J]. Coal Engineering, 2009(12): 86-88. doi: 10.3969/j.issn.1671-0959.2009.12.031 [19] 陈秋松,张钦礼,王新民,等. 全尾砂似膏体管输水力坡度计算模型研究[J]. 中国矿业大学学报,2016,45(5): 901-906.CHEN Qiusong, ZHANG Qinli, WANG Xinmin, et al. Pipeline hydraulic gradient model of paste-like unclassified tailings backfill slurry[J]. Journal of China University of Mining and Technology, 2016, 45(5): 901-906. -

下载:

下载: