Service Performance of ER8C and ER8 Wheels for High-Speed Electric Multiple Unit

-

摘要:

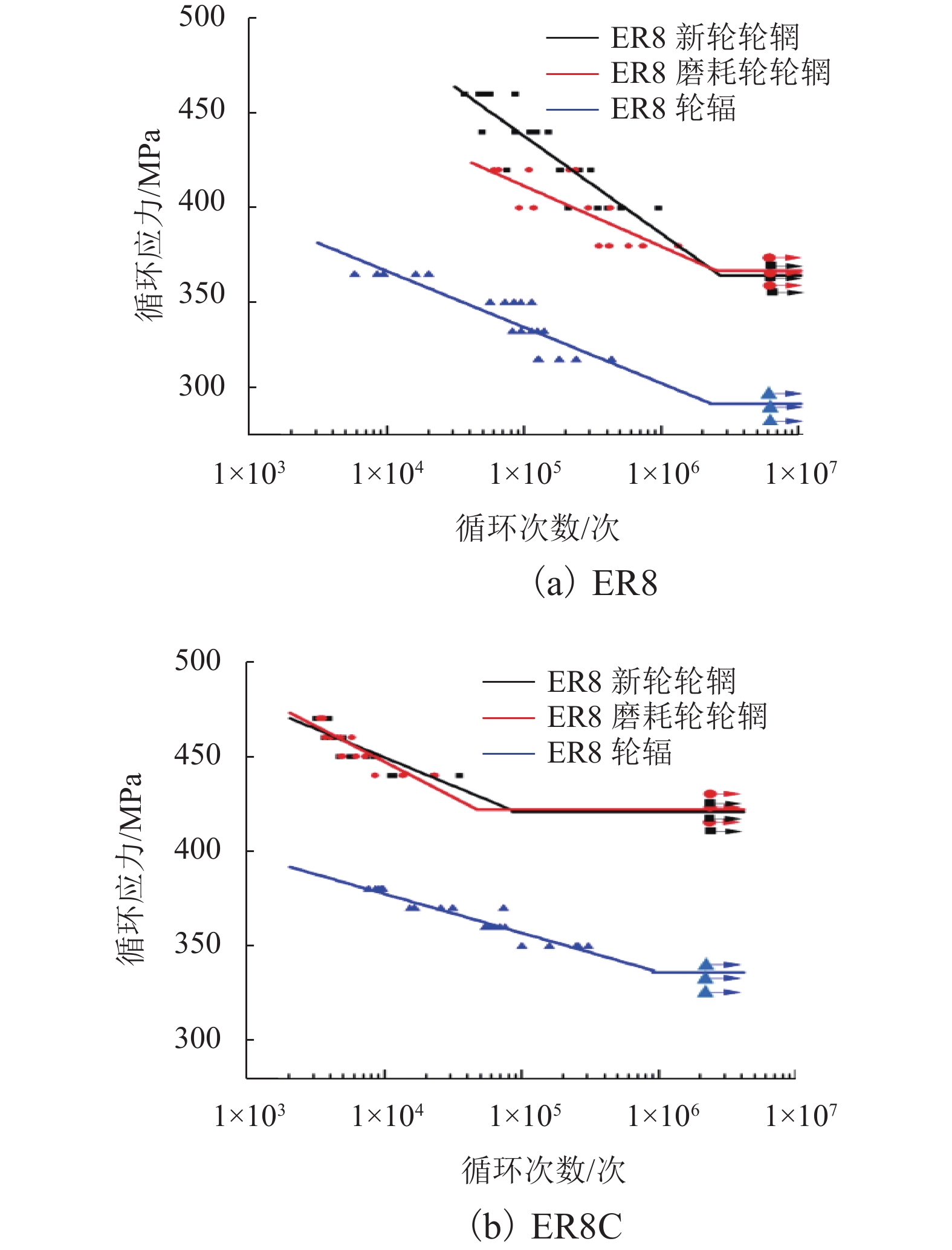

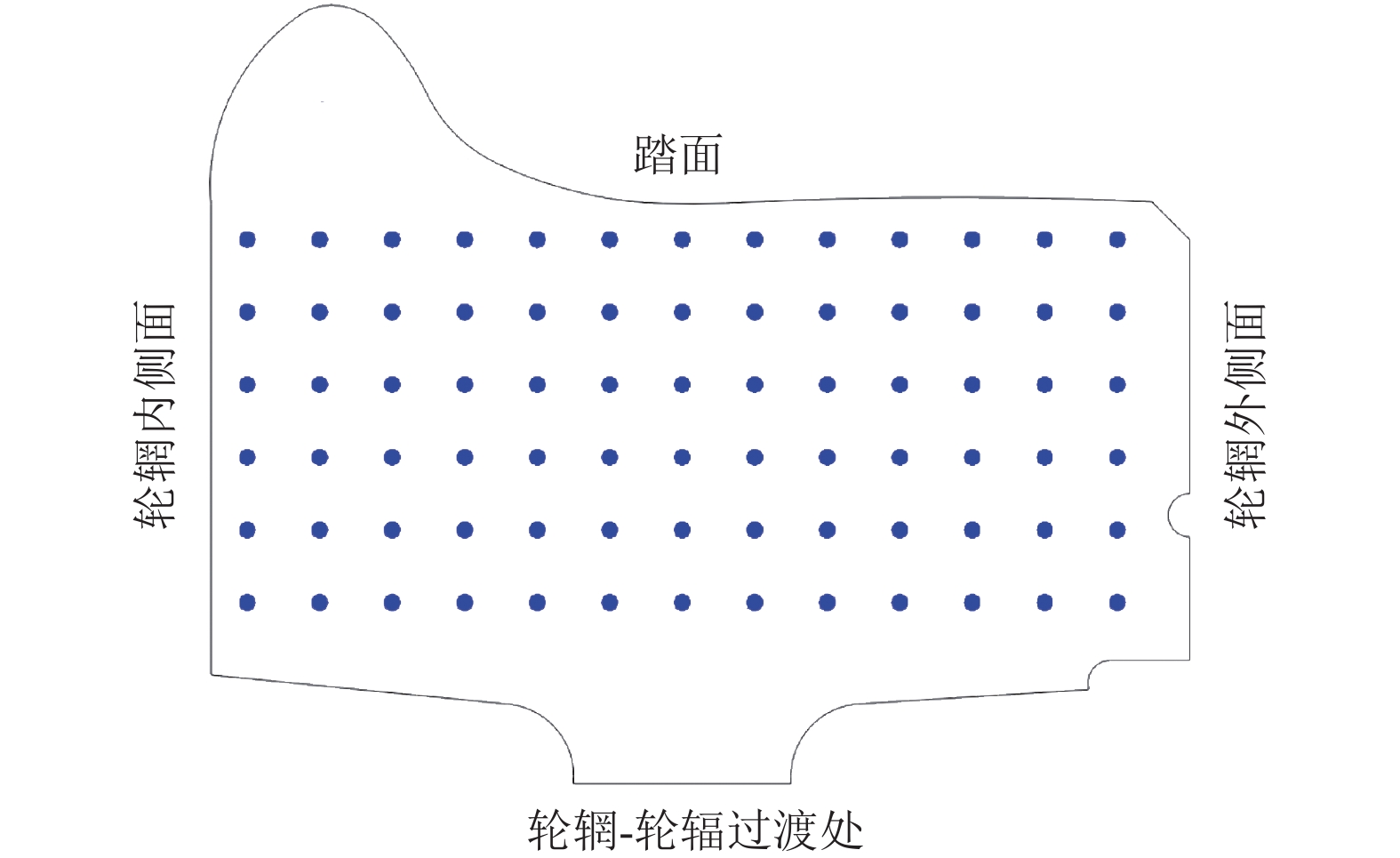

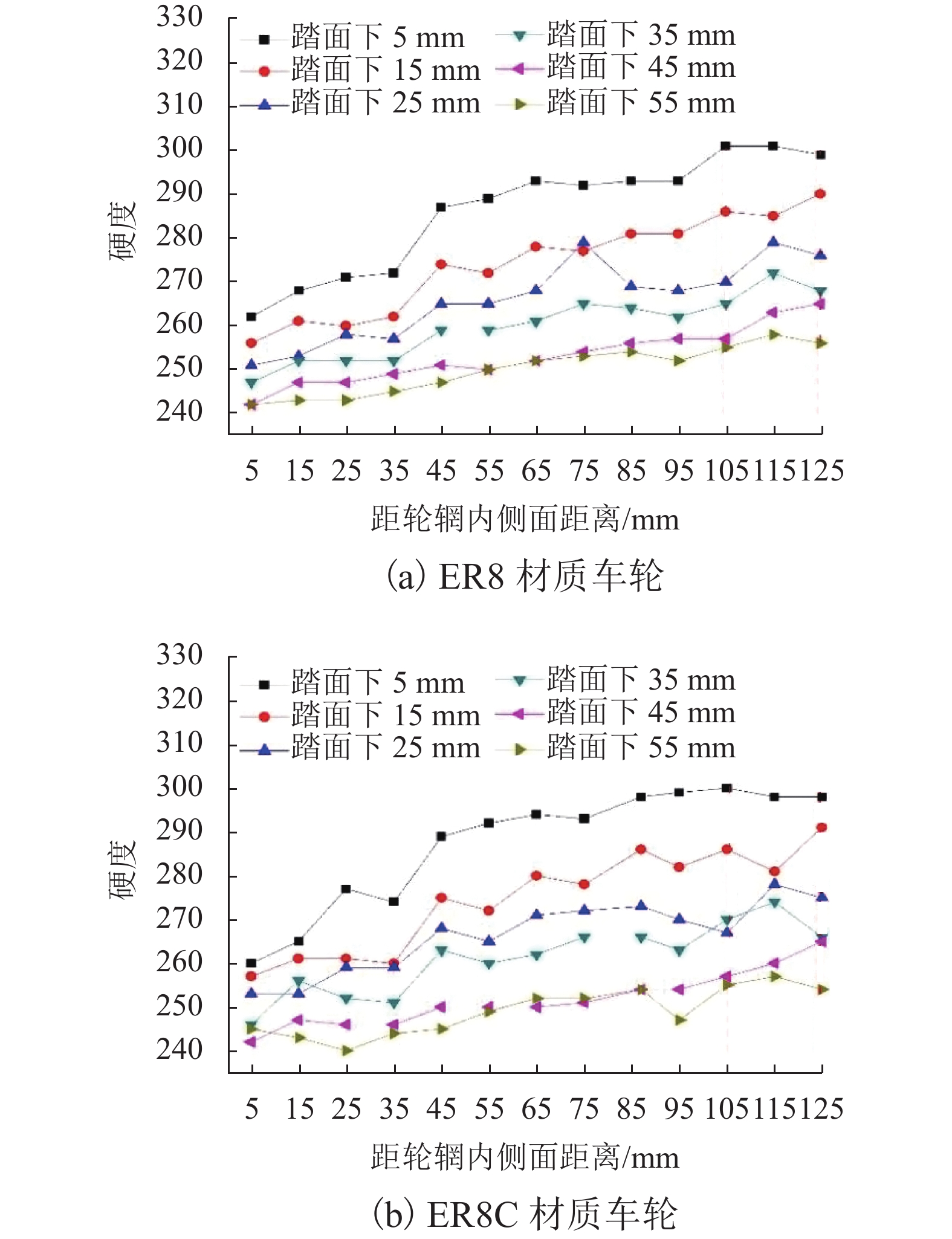

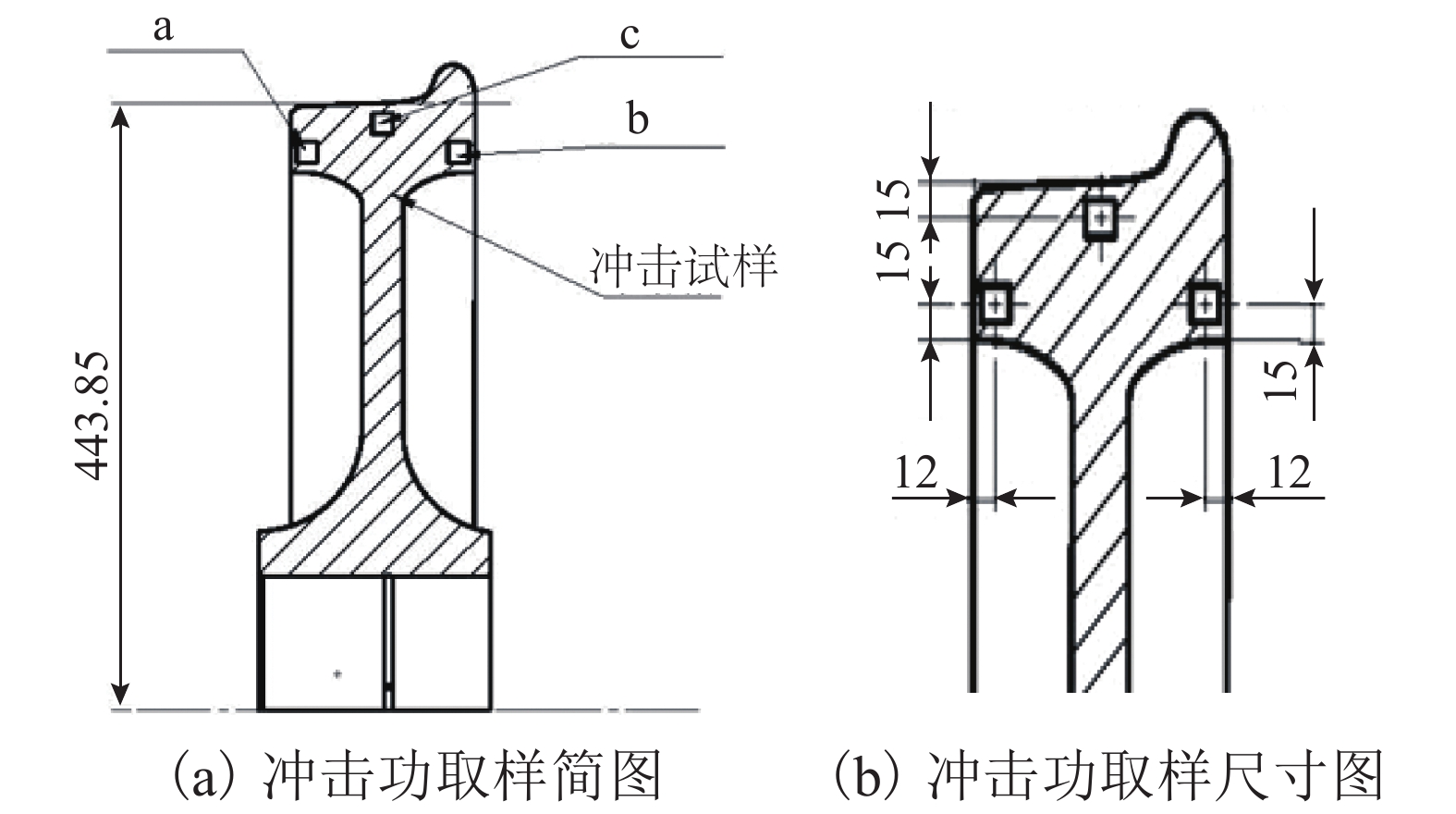

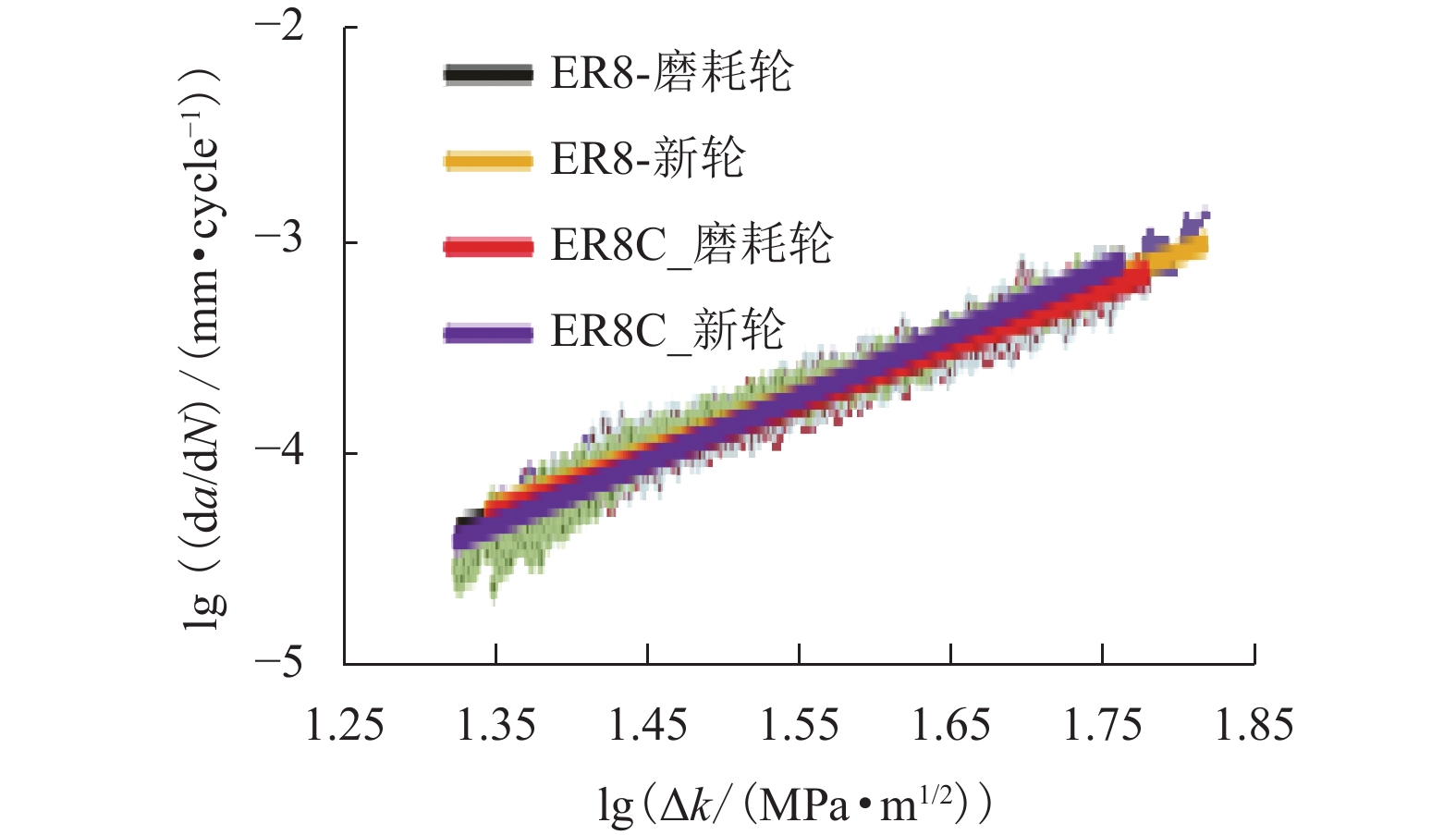

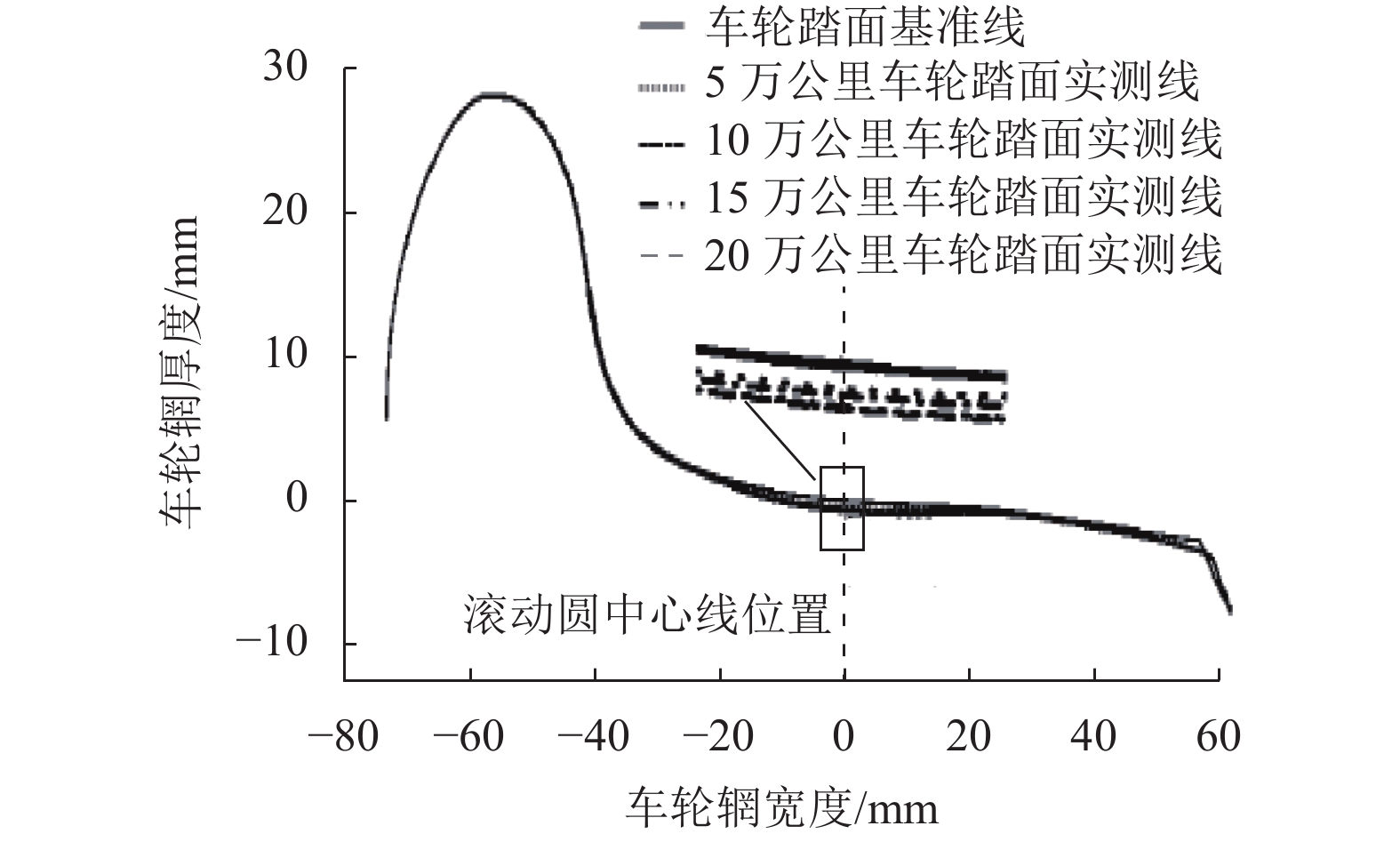

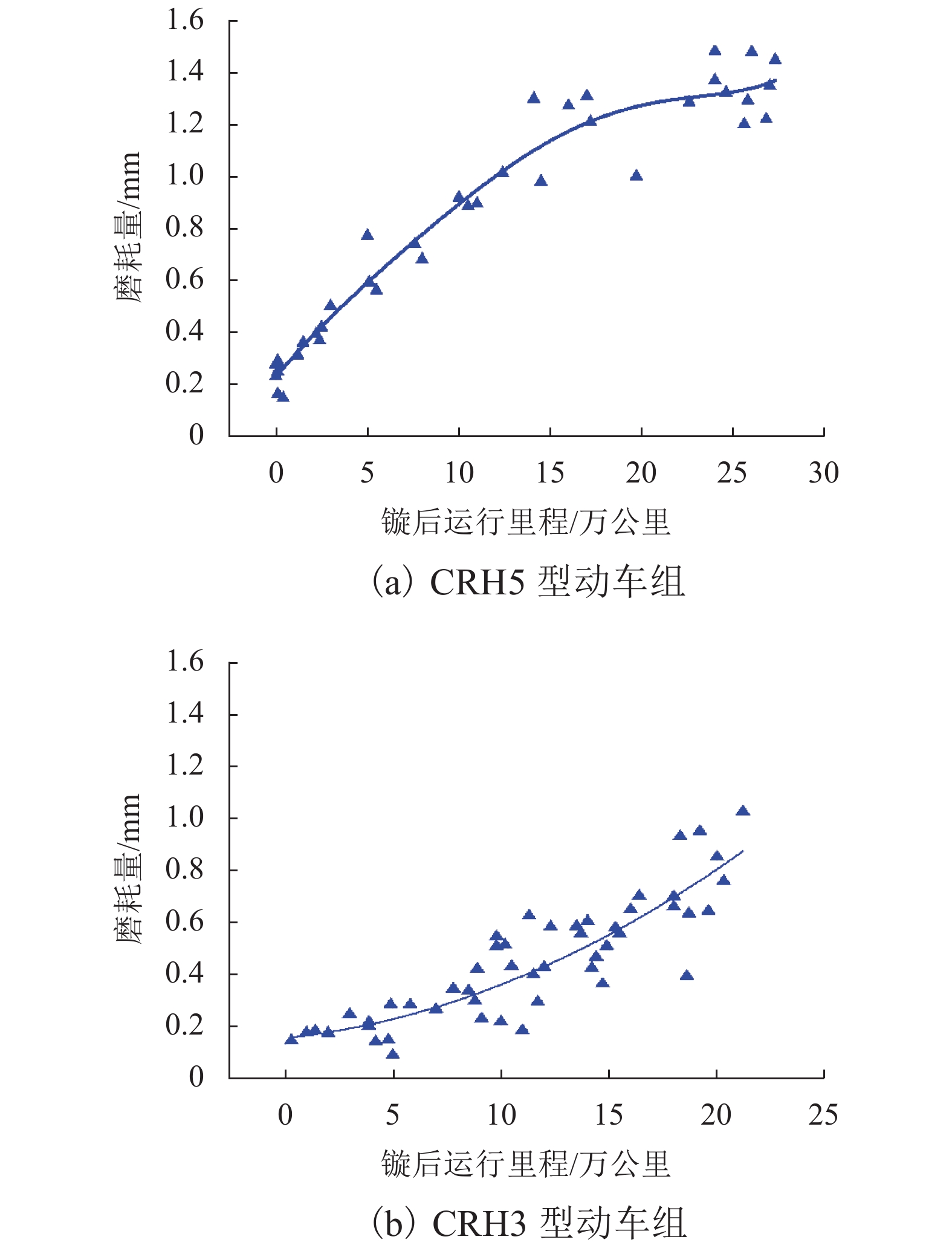

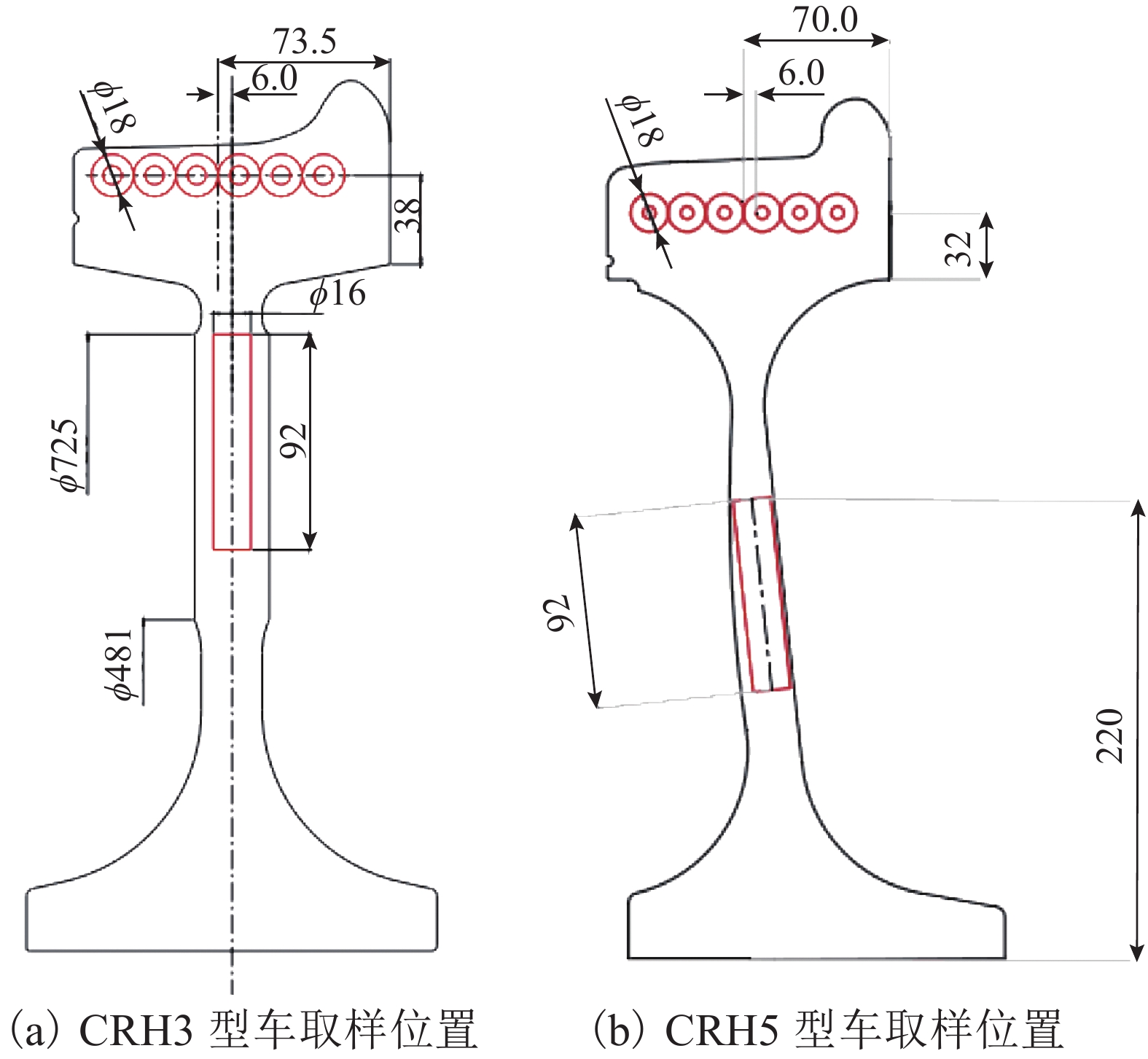

为全面掌握高速动车组用ER8C和ER8车轮服役性能,使用OBLFQSN750型电火花直读光谱仪等设备分别实测了新旧车轮材料的化学成分、常规力学性能、疲劳特性、冲击性能及韧脆转变温度、断裂韧性、疲劳裂纹扩展门槛值和疲劳裂纹扩展速率等,并进行了金相组织观测,综合评价分析了两种材质车轮服役性能. 结果表明:1) ER8C材质车轮比ER8材质车轮中Si含量高2.74倍,Mn含量高1.29倍,Cr+Mo+Ni总含量低45%,C含量略低,其抗拉强度和屈服强度提高5%,疲劳强度提高15%. 2) 车轮显微组织为珠光体+少量铁素体,踏面下相同深度,ER8C材质车轮中铁素体更均匀细小,晶粒度大于8.5级,ER8材质车轮铁素体粗大,晶粒度为8级. 3) ER8C材质车轮韧脆转变温度为84.30 ℃,ER8材质车轮韧脆转变温度为71.97 ℃,车轮运用工况处于两种材质的脆性区. 4) ER8C材质车轮断裂韧性比ER8材质车轮高约6%,其阻止裂纹产生的能力优于ER8材质车轮;ER8材质车轮裂纹扩展门槛值比ER8C材质高17%,其阻止裂纹扩展的能力优于ER8C材质车轮;两种材质车轮的裂纹扩展速率相当. 5) 服役过程中ER8C材质车轮踏面垂直磨耗速率略大于ER8材质车轮.

Abstract:In order to fully understand the service performance of ER8C and ER8 wheels for high-speed electric multiple units (EMUs), the chemical composition, the conventional mechanical properties, the fatigue properties, the impact properties, the ductile-brittle transition temperature, the fracture toughness, the fatigue crack growth threshold, the fatigue crack growth rate and etc of in-serving and over-served wheels materials were measured by electric spark direct reading spectrometer(OBLFQSN 750). The metallographic structure of the both wheels materials was analyzed,and the service performance of the both wheels were assessed. The results show as follows: 1) Compared with the ER8 wheel, the ER8C wheel has 2.74 times higher Si content, 1.29 times higher Mn content, 45% lower total Cr + Mo + Ni content and slightly lower C content; their tensile and yield strengths have increased by 5%, and their fatigue strength has increased by 15%. 2)The microstructure of the wheels contains pearlite and a small amount of ferrite, the same depth under the tread, the ferrite in the ER8C wheel is more uniform and fine, the grain size is greater than 8.5, and the ferrite wheel in the ER8 material is coarse and the grain size is grade 8. 3) The ductile-brittle transition temperature of the ER8C wheel is 84.30 ℃ and that of the ER8 wheel is 71.97 ℃. The working condition of wheels is in the brittle zone of two materials. 4) The fracture toughness of the ER8C wheel is about 6% higher than that of the ER8 wheel. However, the crack propagation threshold of the ER8 wheel is 17% higher than that of the ER8C wheel, where their crack growth rates are almost the same. 5) During service, the vertical wear rate of the ER8C wheel is slightly higher than that of the ER8 wheel.

-

Key words:

- high-speed EMU wheel /

- mechanical performance /

- microstructure

-

表 1 化学成分的质量分数

Table 1. Mass fraction of chemical components

% 车轮材质 C Si Mn P S Cr Cu Mo Ni V Al Cr+Mo+Ni ER8C 0.533 0.959 0.907 0.009 0.001 0.089 0.089 0.025 0.068 0.001 0.014 0.182 ER8 0.547 0.350 0.700 0.0085 0.001 0.174 0.199 0.038 0.120 0.001 0.016 0.332 表 2 两种材质金相组织对比

Table 2. Comparison of crack growth rate of two kinds of material axles

材质 名义滚动圆处 滚动圆下15 mm 滚动圆下 35 mm ER8C

ER8

表 3 ER8和ER8C两种材质常规力学性能对比

Table 3. Comparison of conventional mechanical properties between ER8 and ER8C

车轮材质 抗拉强度/MPa 屈服强度/MPa 延伸率/% 断面收缩率/% 轮辋 轮幅 轮辋 轮幅 轮辋 轮幅 轮辋 轮幅 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 新轮 磨耗轮 ER8 869 869 741 743 542 543 408 403 20.56 20.13 20.48 20.95 51.31 50.72 39.42 43.20 ER8C 913 926 787 779 595 589 428 427 19.17 19.92 22.28 22.26 54.66 54.03 45.14 44.83 表 4 车轮断裂韧性试验值

Table 4. Wheel fracture toughness test value

MPa•m1/2 材质 试样编号 新轮 磨耗轮 ER8C C1 83.1 71.0 C2 71.9 89.3 C3 85.5 77.3 C4 87.7 79.0 平均值 82.1 79.15 ER8 R1 74.0 73.4 R2 79.7 74.9 R3 76.0 82.4 R4 79.7 68.7 平均值 77.35 74.85 表 5 车轮疲劳裂纹扩展门槛值

Table 5. Fatigue crack growth threshold

MPa•m1/2 材质 车轮类型 试样编号 门槛值 ΔKth 平均门槛值 ER8C 新轮 CN1 7.7949 7.55 CN2 6.9228 CN3 7.8247 CN4 7.8500 CN5 7.3400 磨耗轮 CW1 8.9815 8.61 CW2 8.6810 CW3 9.0462 CW4 7.5393 CW5 8.7782 ER8 新轮 RN1 8.9700 8.88 RN2 8.7500 RN3 9.0600 RN4 8.7300 磨耗轮 RW1 8.9700 9.02 RW2 9.4800 RW3 8.5060 RW4 9.1393 -

[1] 张峰. 车轮钢动态断裂韧性研究[J]. 理化检验-物理分册,2006,42: 177-179.ZHANG Feng. Research on dynamic fracture toughness of wheel steel[J]. Physical and Chemical Inspection-Physical Volume, 2006,42: 177-179. [2] 崔银会,张建平,苏航,等. 高速列车车轮用钢研究和应用的进展[J]. 钢铁研究,2005(3): 53-57. doi: 10.3969/j.issn.1001-1447.2005.03.015CUI Yinhui, ZHANG Jianping, SU Hang, et al. Research and application of steel for high-speed train wheels[J]. Steel Research, 2005(3): 53-57. doi: 10.3969/j.issn.1001-1447.2005.03.015 [3] 苏世怀,赵海,江波,等. 中国高速车轮产品质量性能研发应用进展[J]. 钢铁,2018,53(11): 1-7.SU Shihuai, ZHAO Hai, JIANG Bo, et al. Development and application of high-speed wheel product quality performance in China[J]. Steel, 2018, 53(11): 1-7. [4] 史建平,刘忠侠,肖乾. 车轮钢的化学成分、微观组织对车轮钢力学性能的影响[J]. 中国铁道科学,2012,33(6): 44-50. doi: 10.3969/j.issn.1001-4632.2012.06.08SHI Jianping, LIU Zhongxia, XIAO Qian. Effect of chemical composition and microstructure of wheel steel on mechanical properties of wheel steel.[J]. China Railway Science, 2012, 33(6): 44-50. doi: 10.3969/j.issn.1001-4632.2012.06.08 [5] 肖蔚荣,任学冲,陈刚,等. 显微组织对高速车轮钢不同温度下断裂韧性的影响[J]. 材料热处理学报,2016,37(4): 141-148.XIAO Weirong, REN Xuechong, CHEN Gang, et al. Effect of microstructure on fracture toughness of high-speed wheel steel at different temperatures[J]. Journal of Materials Heat Treatment, 2016, 37(4): 141-148. [6] 任学冲,李胜军,高克玮,等. 热处理工艺对CL50D车轮钢晶粒度的影响[J]. 金属热处理,2012,37(7): 7-12.REN Xuechong, LI Shengjun, GAO Kewei. et al. Effect of heat treatment process on grain size of CL50D wheel steel[J]. Metal Heat Treatment, 2012, 37(7): 7-12. [7] 龚 帅,任学冲,马英霞,等. 热处理对高速车轮钢显微组织和断裂韧性的影响[J]. 材料热处理学报,2015,36(4): 150-155.GONH Shuai, REN Xuechong, MA Yingxia, et al. Effect of heat-reatment on microstructure and fracture toughness of high-speed railway wheel steel[J]. Transactions of Materials and Heat Treatment, 2015, 36(4): 150-155. [8] 李胜军,任学冲,高克玮,等. 晶粒尺寸对车轮钢解理断裂韧性的影响[J]. 北京科技大学学报,2011,33(9): 1105-1110.LI Shengjun, REN Xuechong, GAO Kewei, et al. Effects of grain size on the cleavage fracture toughness of wheel steel[J]. Journal of University of Science and Technology Beijing, 2011, 33(9): 1105-1110. [9] 王丽英,李伟. ER7车轮钢的KQ值试验结果与分析[J]. 物理测试,2010,8(4): 33-36.WANG Liying, LI Wei. KQ test result and analysis of ER7 railway wheel steel[J]. Physics Examination and Testing, 2010, 8(4): 33-36. [10] 任学冲,马英霞,高克玮,等. 温度对高速车轮钢断裂韧性的影响[J]. 中国铁道科学,2013,34(5): 93-99. doi: 10.3969/j.issn.1001-4632.2013.05.14REN Xuechong, MA Yingxia, GAO Kewei, et al. Effects of temperature on the fracture toughness of high-speed wheel steel[J]. China Railway Science, 2013, 34(5): 93-99. doi: 10.3969/j.issn.1001-4632.2013.05.14 [11] 张志明,李余德,牛延军,等. 金属材料断裂韧度随温度变化的研究[J]. 力学与实践,2010,32(6): 43-48.ZHANG Zhiming, LI Yude, NIU Yanjun, et al. Variation of fracture toughness of metallic materials with temperature[J]. Mechanics in Engineering, 2010, 32(6): 43-48. [12] 张关震, 任瑞铭, 丛韬, 等. 时速250 km等级动车组自主化车轮的耐磨性能试验研究[J]. 中国铁道科学, 2017, 38(1): 117-122.ZHANG Guanzhen, REN Ruiming, CONG Tao, et al. Experimental study on wear resistance of autonomous wheels of 250 km/h EMU[J]. China Railway Science, 2017, 38 (1): 117-122. -

下载:

下载: