Dynamic Characteristics Analysis of Hardening Railway Ballast Bed Based on Discrete Element Method

-

摘要:

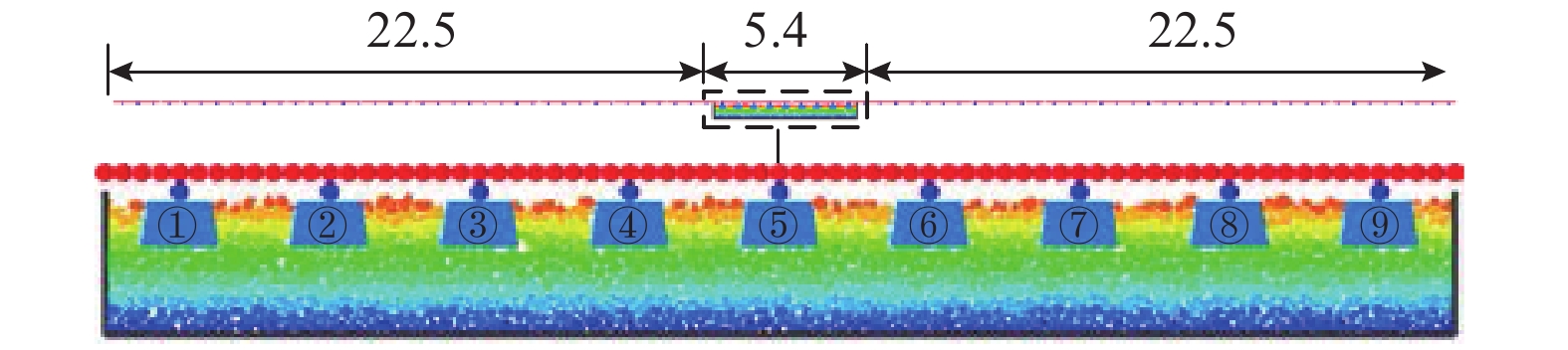

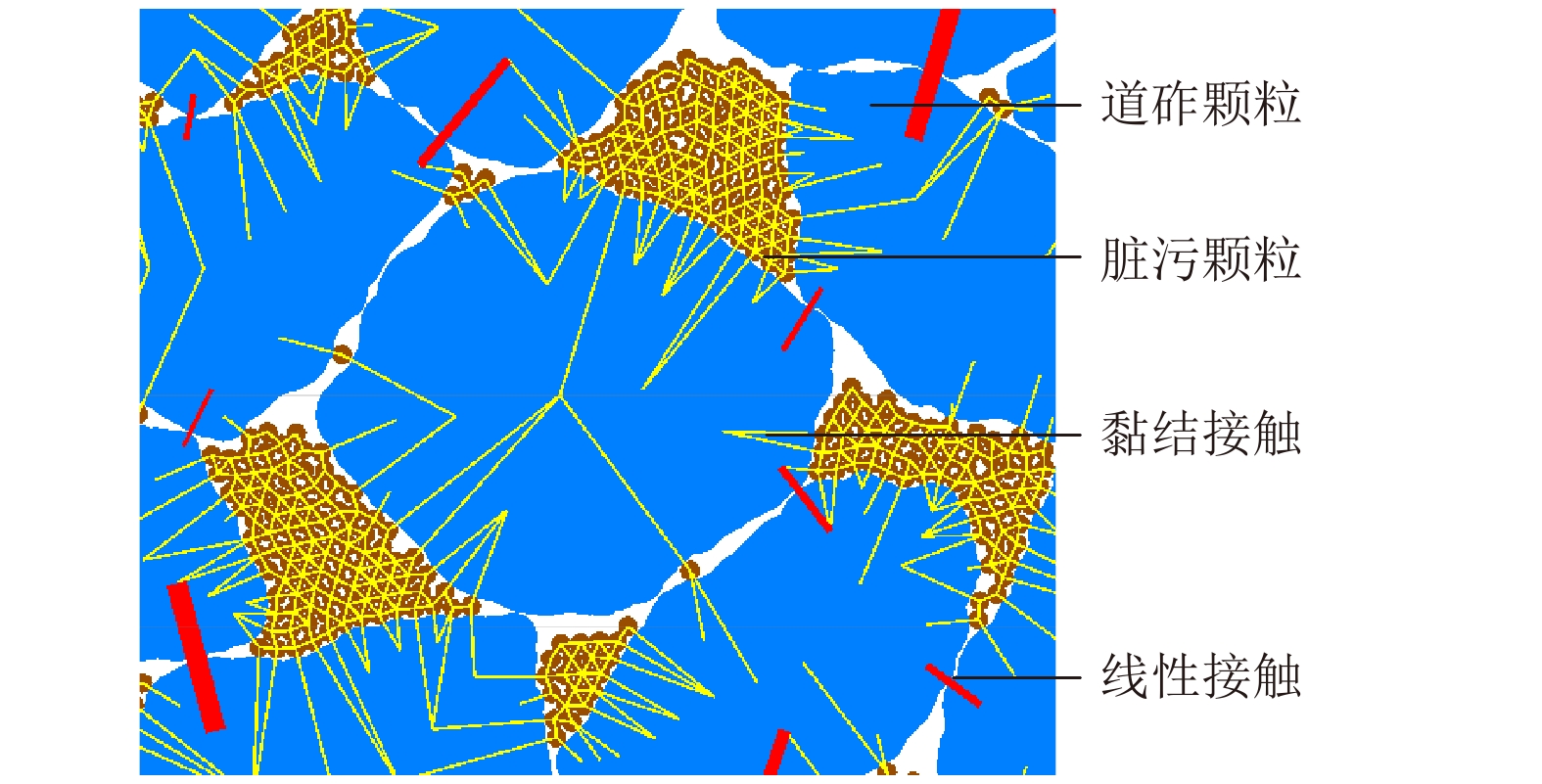

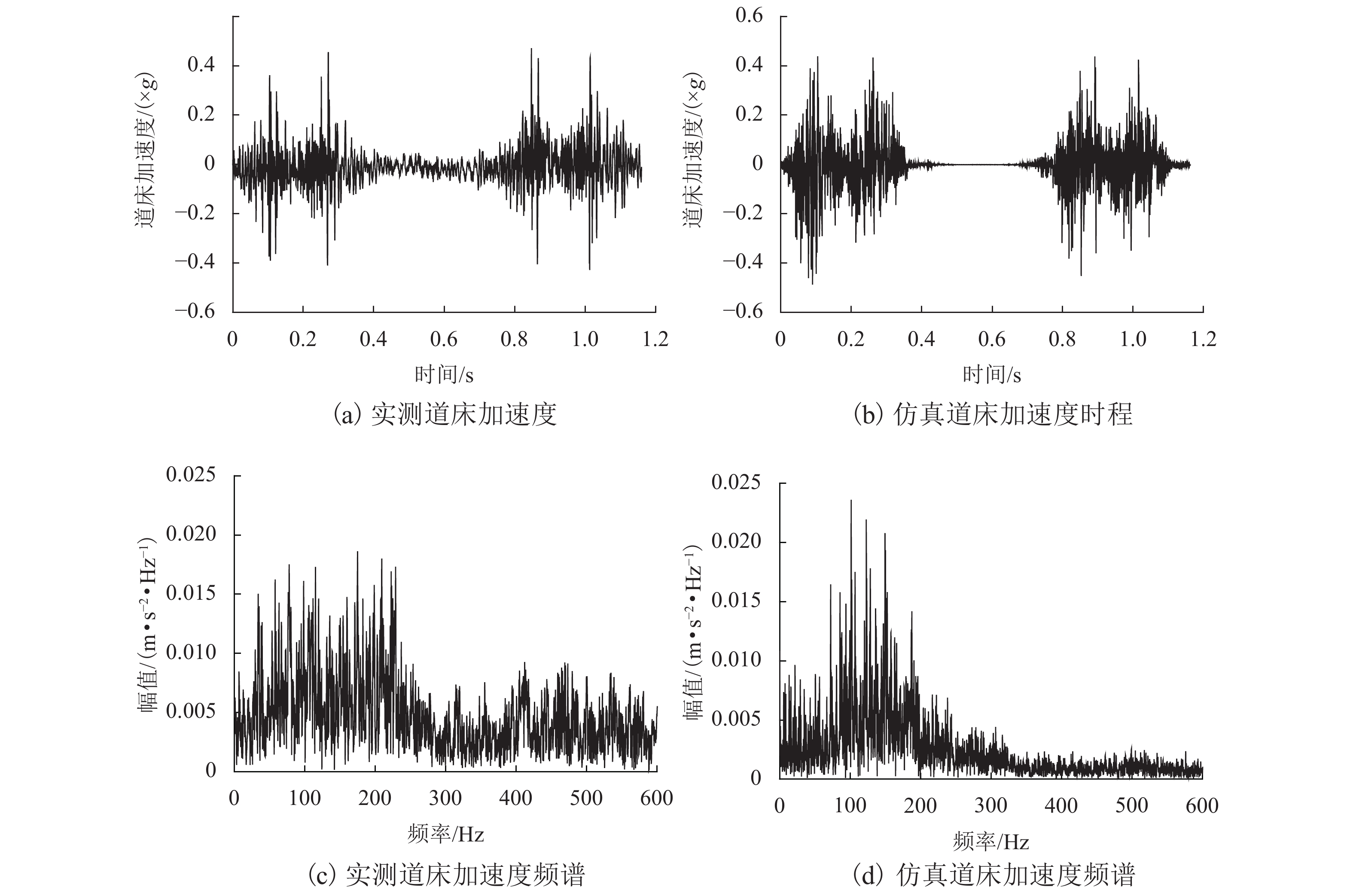

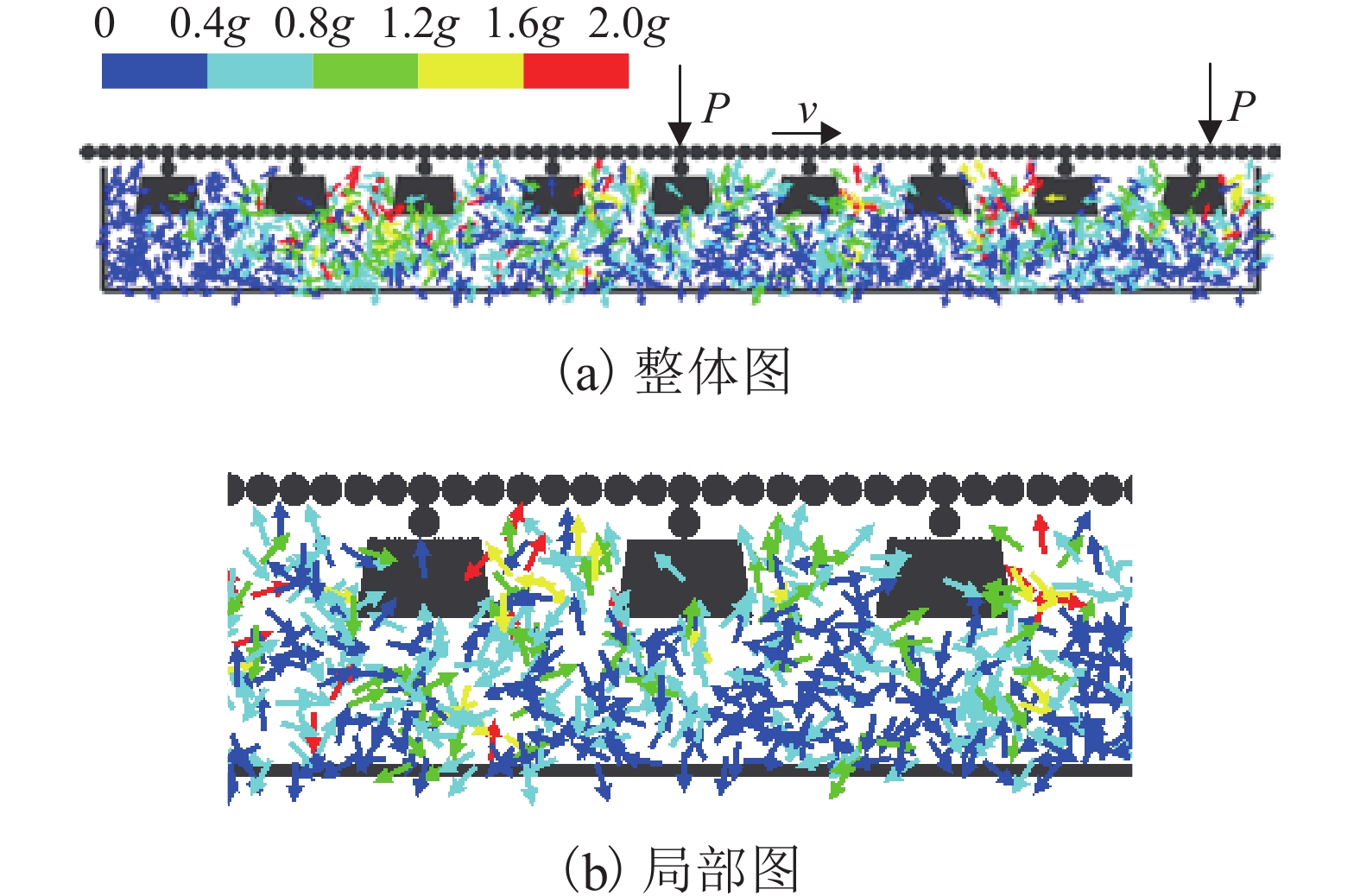

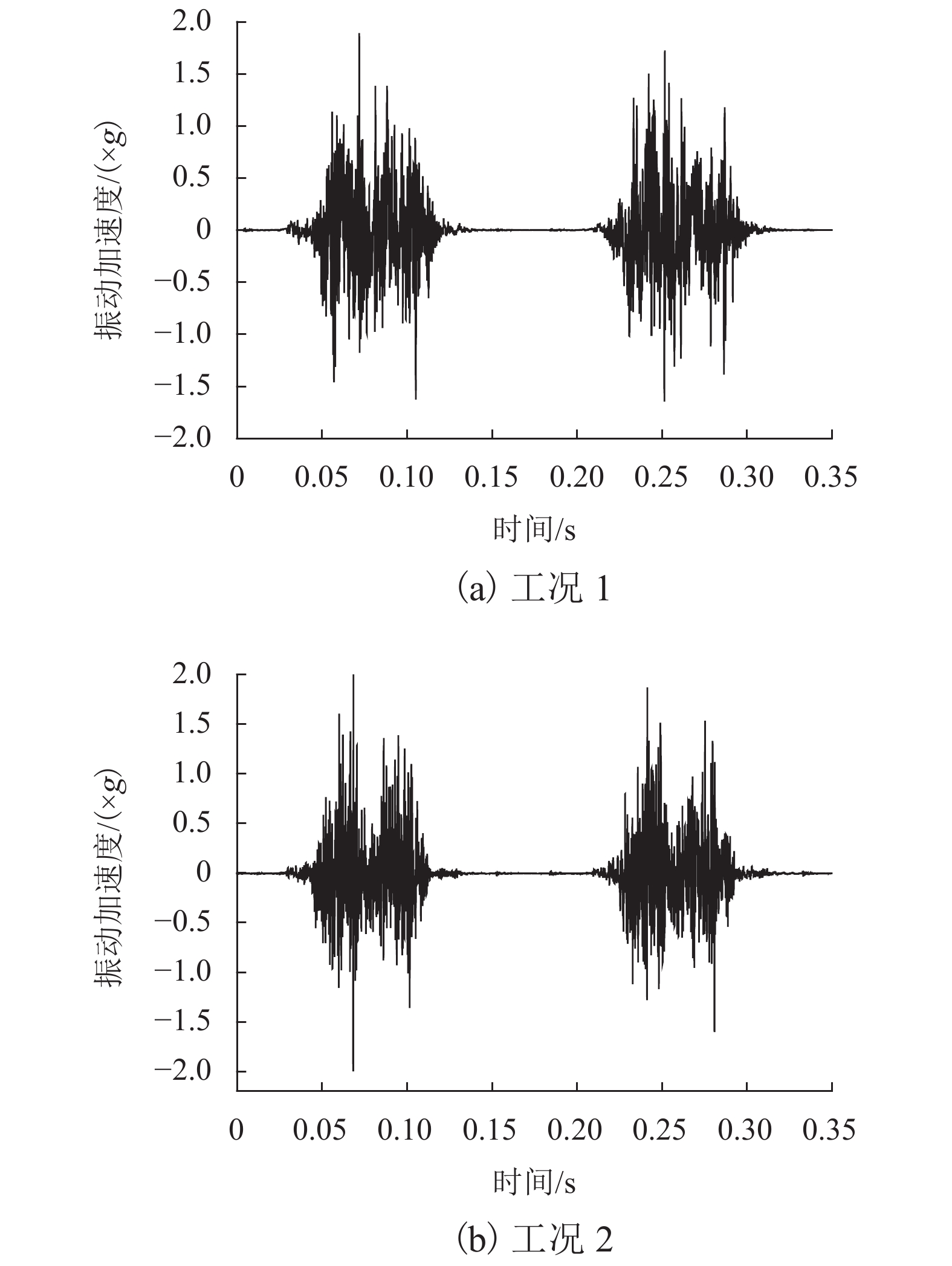

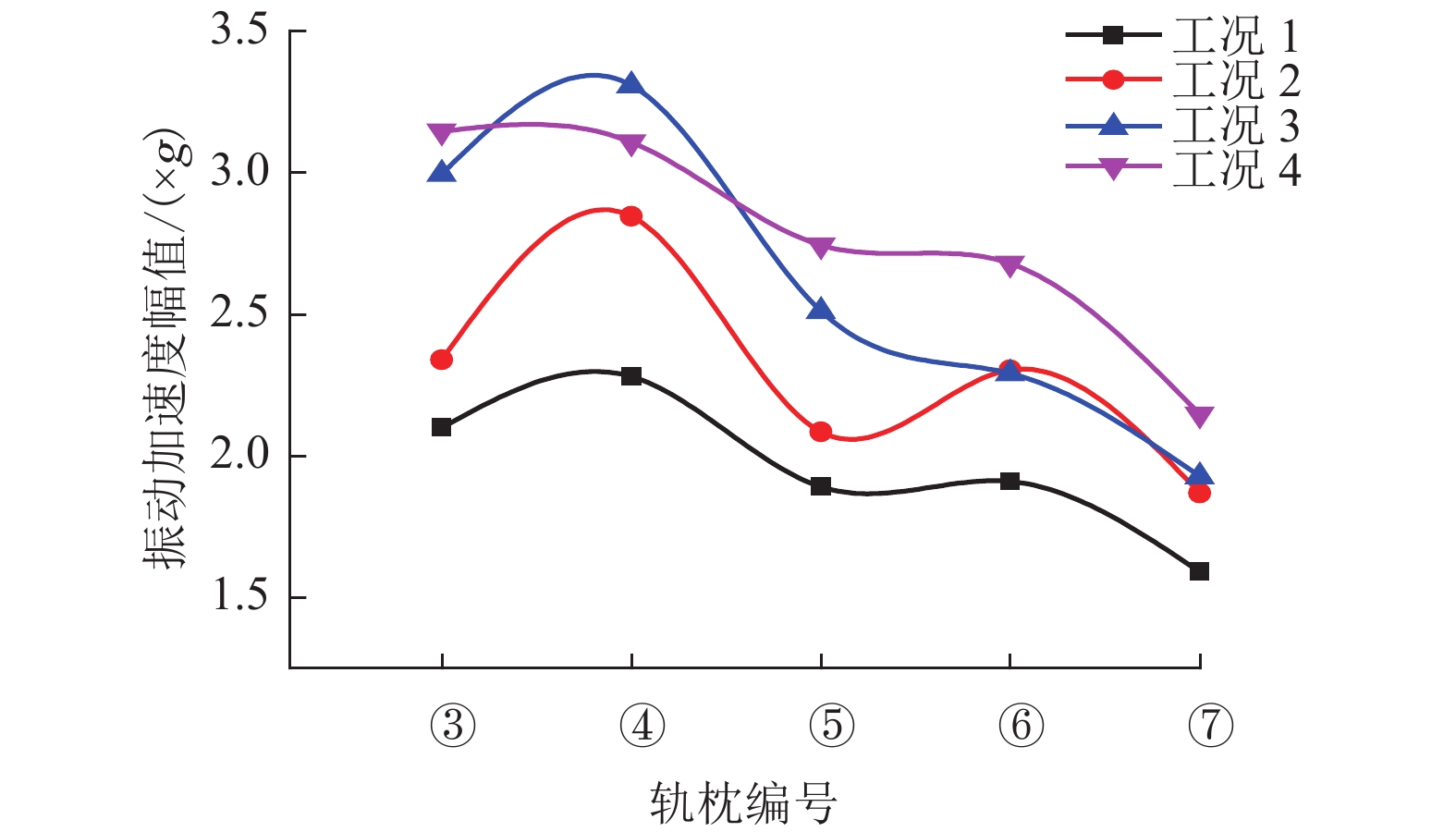

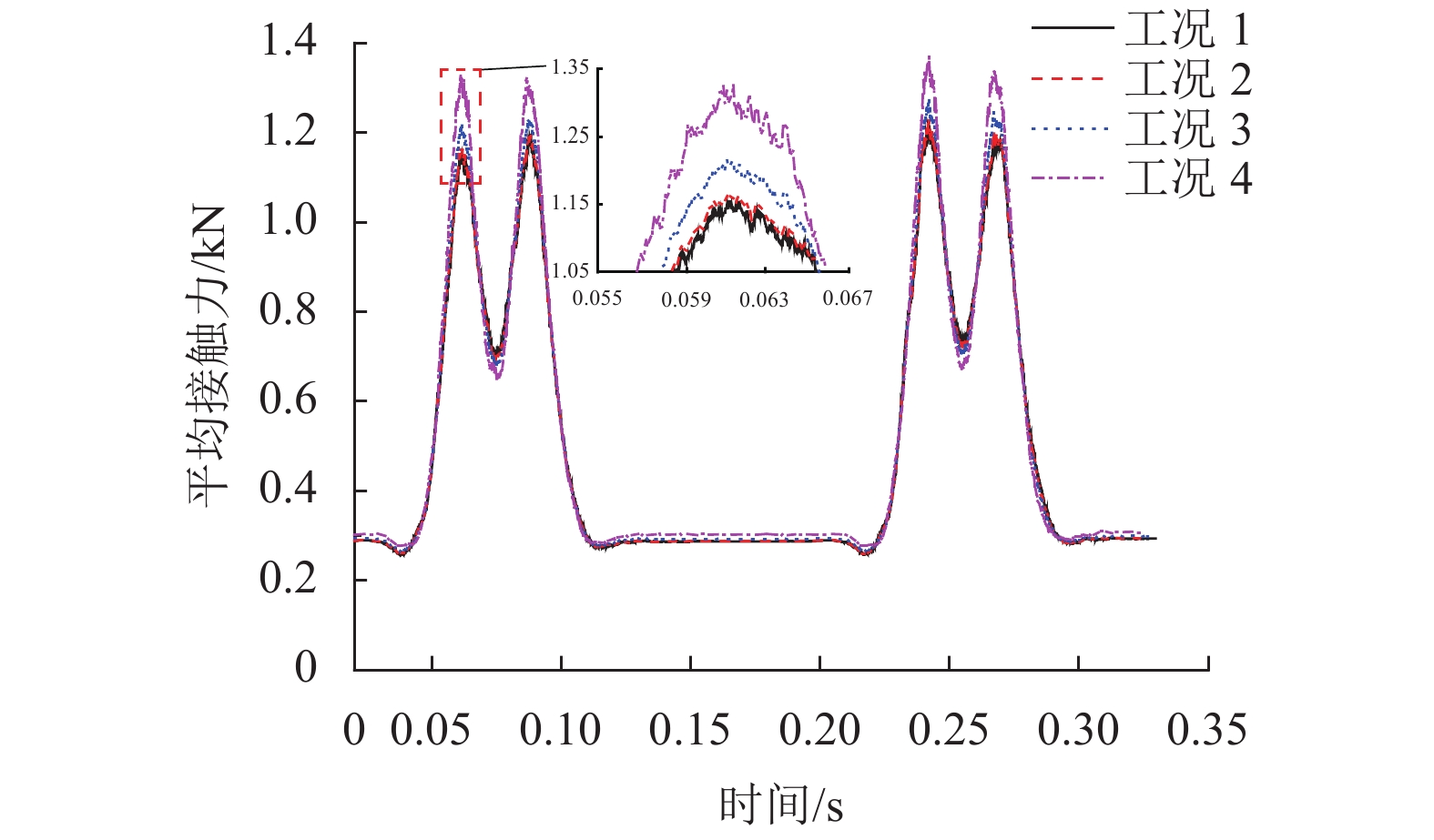

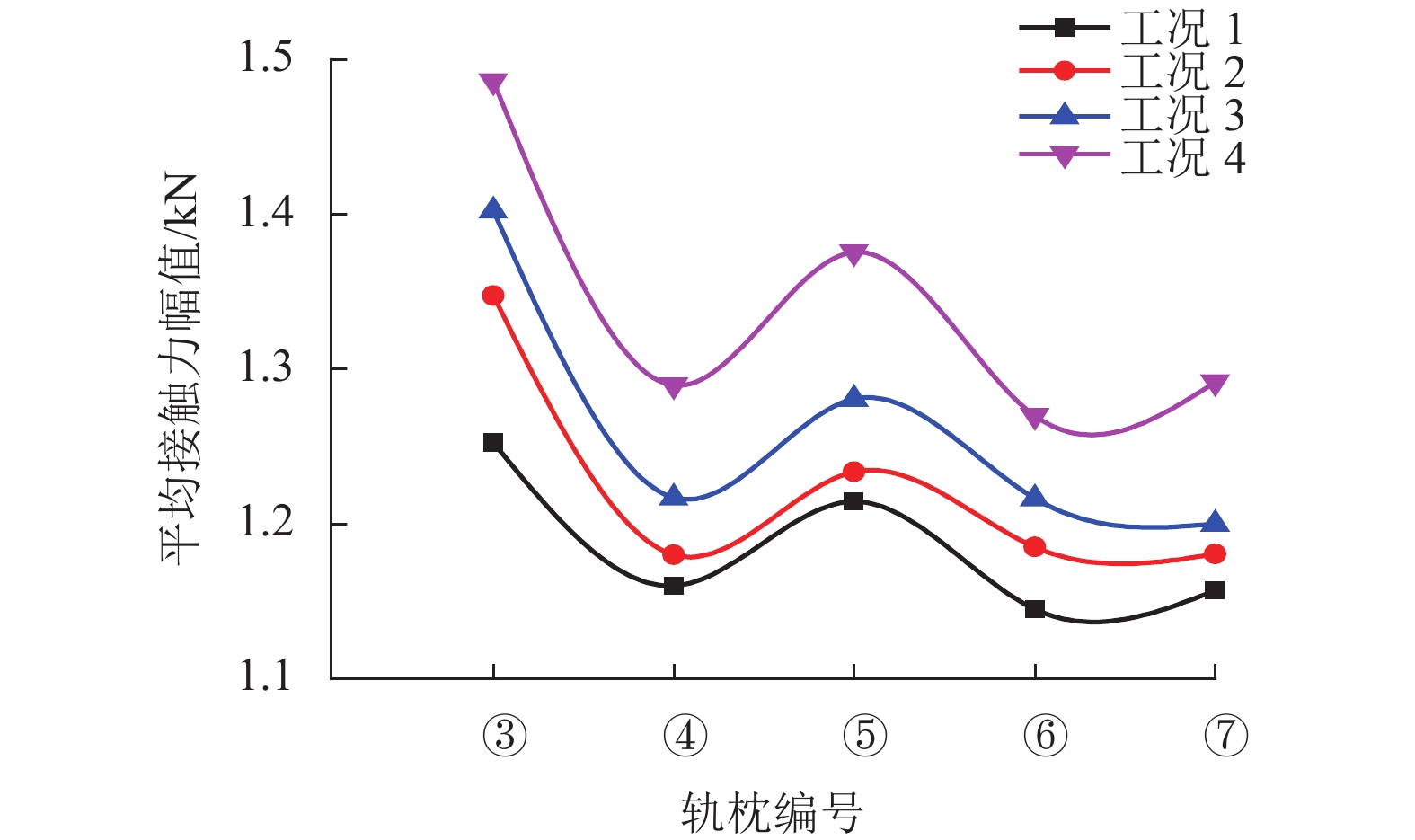

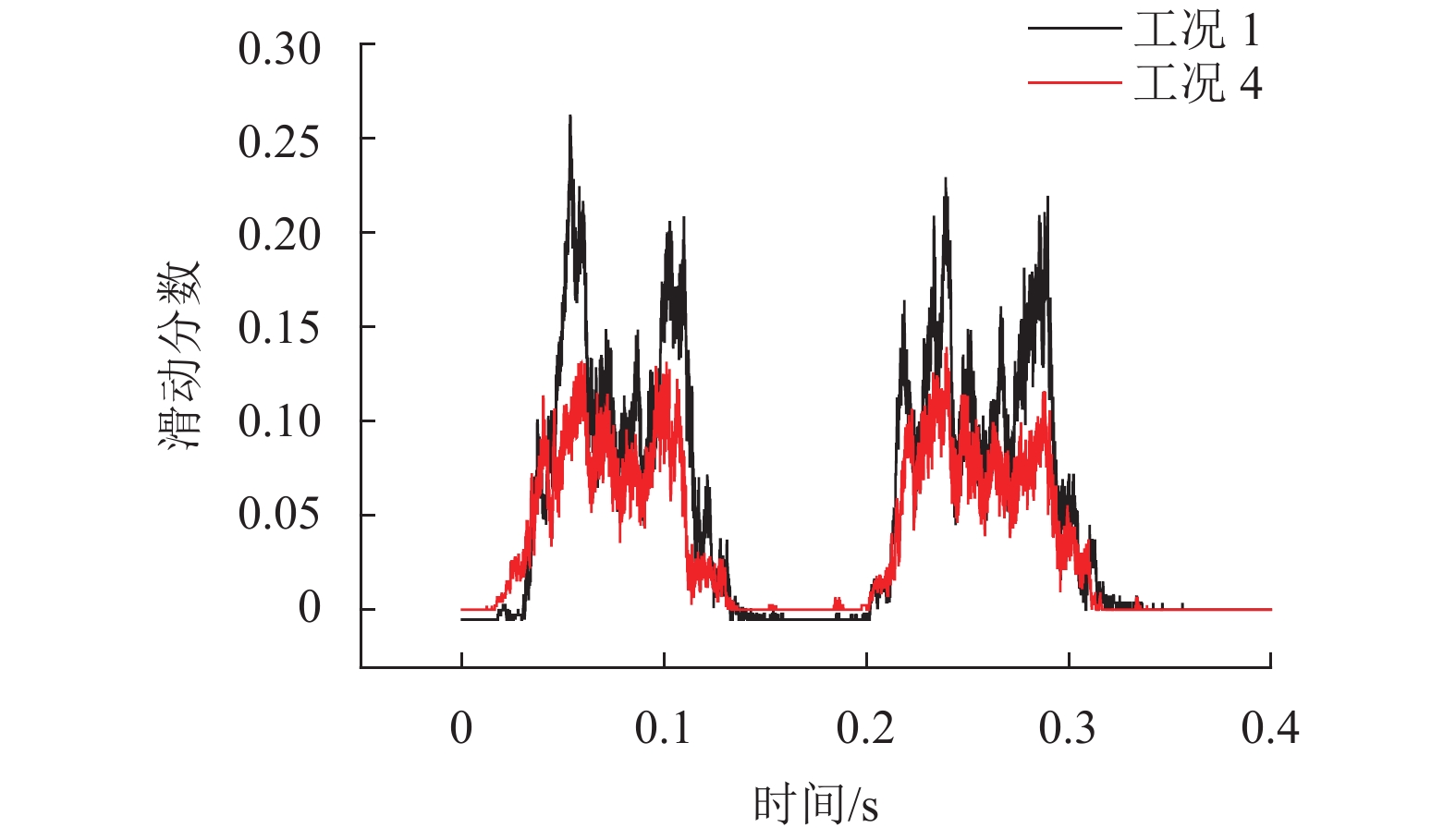

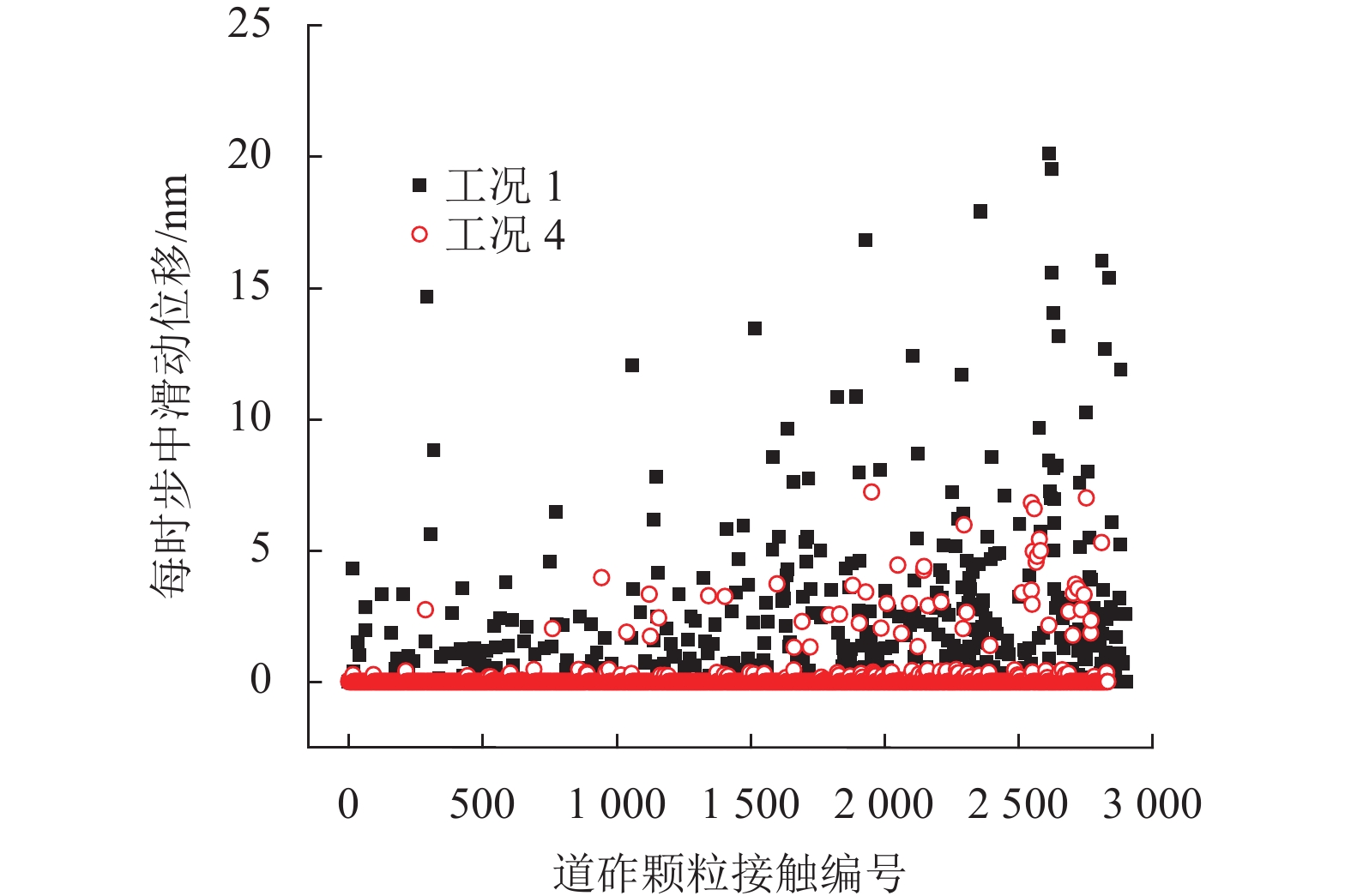

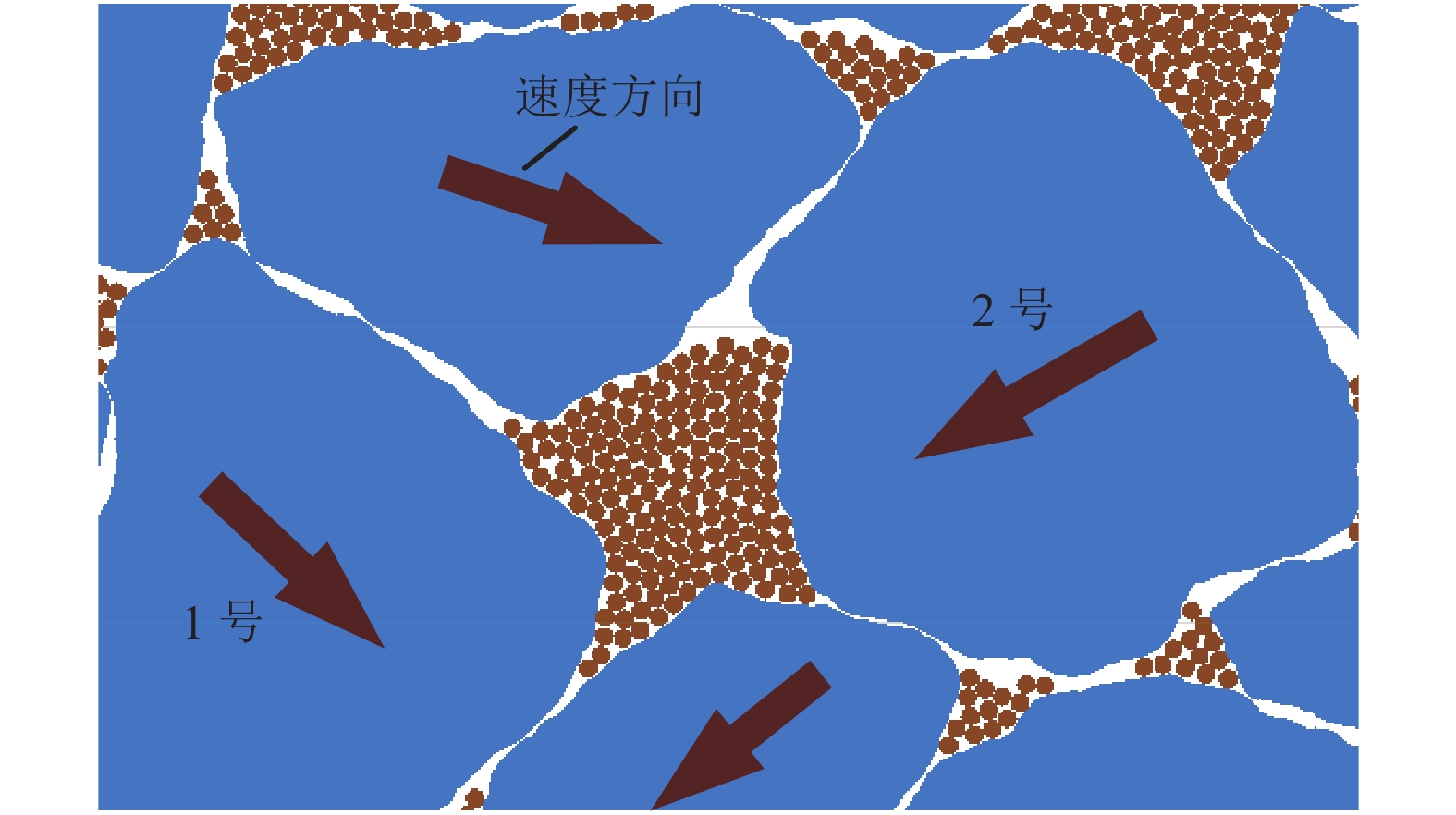

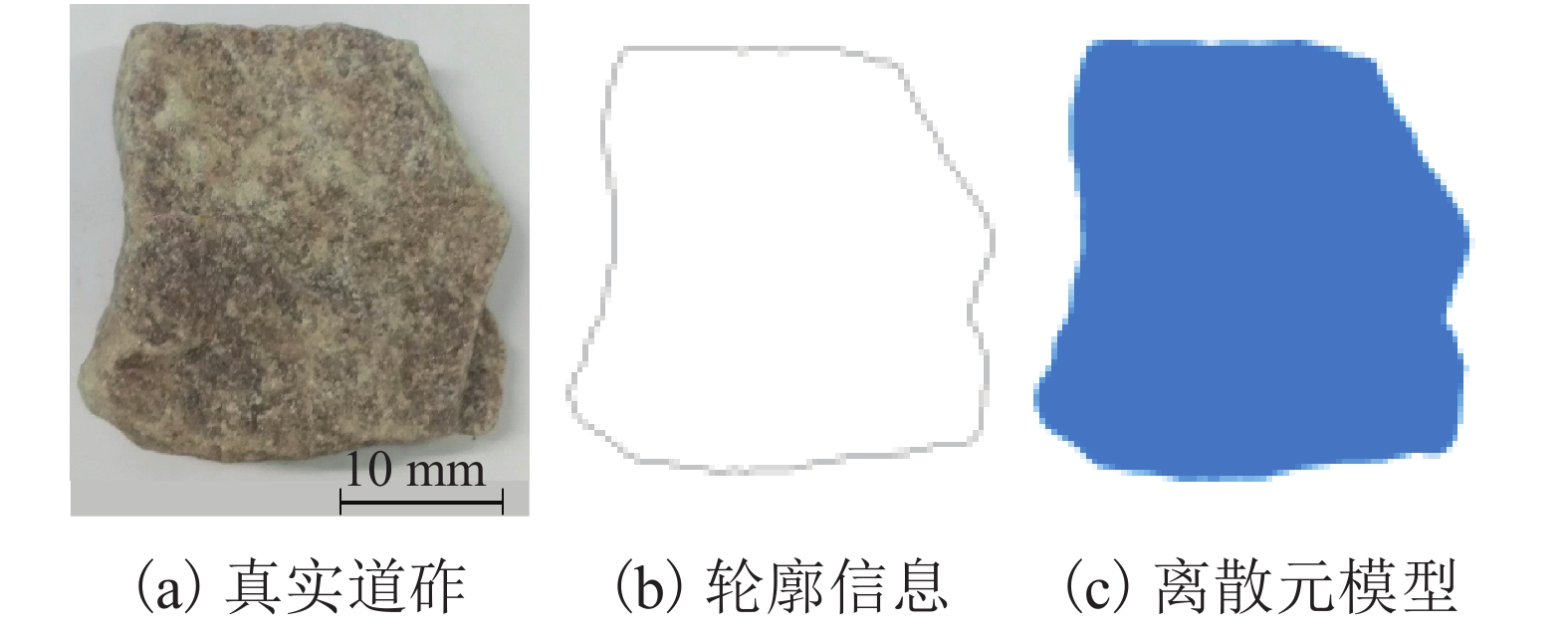

为研究铁路有砟道床板结对其自身动力特性的影响,利用离散单元法并考虑道砟颗粒的真实外形建立了板结道床的仿真分析模型,分析了脏污板结及板结程度对有砟道床动态响应的影响,并探讨了板结引起道床弹性损失、刚度变大的细观机理. 研究结果表明:道床板结会增大道床中道砟颗粒的振动水平,并且板结越严重影响越明显,板结可将道砟颗粒的振动加速度增大20%~30%;板结会加强列车荷载对道床的冲击作用,增大道砟颗粒之间的接触力容易引起道砟颗粒破碎劣化;板结会放大不同位置处道床工作性能的差异,增大道床刚度的不均匀性;道砟颗粒之间的脏污板结材质会抑制道砟颗粒的相对移动,可将道砟颗粒的滑动分数降低至正常的50%左右,减小列车荷载作用下道床整体的宏观变形,从而呈现出刚度增大的特性.

Abstract:In order to study the influence of hardening railway ballast bed on its own dynamic characteristics, considering the real shape of ballast particles, a simulation analysis model of hardening ballast bed was established by using discrete element method. The influences of dirty hardening and hardening degree on the dynamic response of ballast bed was analyzed, and the meso-mechanism of elastic loss and stiffness increase of ballast bed caused by hardening was discussed. The results show that the hardening will increase the vibration level of ballast particles, and the more serious the hardening is, the more obvious the influence will be, and the hardening can increase the vibration acceleration of ballast particles by 20%−30%. The compaction will strengthen the impact of the train load on the ballast bed, increase the contact force between the ballast particles, which easily causes the ballast particles to break. The working performance of the track bed at different positions was amplified and the unevenness of the ballast bed stiffness was increased by the hardening. Dirty hardening materials between ballast particles can inhibit the relative movement of ballast particles, reduce the sliding fraction of ballast particles to about 50% of the normal value, and reduce the overall macroscopic deformation of the ballast bed under train load, thus showing the characteristics of increased stiffness.

-

Key words:

- ballast bed /

- hardening /

- discrete element method /

- dynamic response

-

表 1 计算工况

Table 1. Calculation conditions

工况编号 道床 板结程度/% 脏污颗粒数量/粒 1 洁净道床 0 0 2 板结道床 25 17605 3 板结道床 50 35213 4 板结道床 100 70427 表 2 离散元模型计算参数

Table 2. Parameters of DE model

参数 取值 道砟颗粒法向刚度/(N•m−1) 5.0 × 108 道砟颗粒切向刚度/(N•m−1) 5.0 × 108 道砟颗粒摩擦系数 0.55 道砟颗粒密度/(kg•m−3) 2 500 脏污颗粒密度/(kg•m−3) 2500 钢轨密度/(kg•m−3) 1029.5 轨枕密度/(kg•m−3) 3025.8 脏污颗粒黏结强度/MPa 0.5 黏结半径比例系数 1.0 -

[1] 王青波. 大秦线人工更换桥梁道砟施工技术[J]. 铁道建筑技术,2015(2): 66-69. doi: 10.3969/j.issn.1009-4539.2015.02.016WANG Qingbo. Construction technology of artificial replacement of bridge ballast for datong-qinhuangdao railway[J]. Railway Construction Technology, 2015(2): 66-69. doi: 10.3969/j.issn.1009-4539.2015.02.016 [2] 郭善辛. 道床板结的形成及其分析[J]. 铁道工程学报,1985(2): 156-164.GUO Shanxin. Formation and analysis of ballast hardening[J]. Journal of Railway Engineering Society, 1985(2): 156-164. [3] 赵成江,王晓荣,夏琼,等. 不同含泥量与含水率下铁路板结道床的冻胀特性[J]. 铁道工程学报,2011,28(9): 36-39,96. doi: 10.3969/j.issn.1006-2106.2011.09.007ZHAO Chengjiang, WANG Xiaorong, XIA Qiong, et al. Frost heaving behaviors of hardened ballast beds under different content of clay and water[J]. Journal of Railway Engineering Society, 2011, 28(9): 36-39,96. doi: 10.3969/j.issn.1006-2106.2011.09.007 [4] FORTUNATO E, PINELO A, FERNANDES M M. Characterization of the fouled ballast layer in the substructure of a 19th century railway track under renewal[J]. Soils and Foundations, 2010, 50(1): 55-62. doi: 10.3208/sandf.50.55 [5] TANG A M, CUI Y J, DUPLA J C, et al. Mechanical characterisation of the fouled ballast in ancient railway track substructure by large-scale triaxial tests[J]. Soils and Foundations, 2012, 52(3): 511-523. doi: 10.1016/j.sandf.2012.05.009 [6] PAIVA C, FERREIRA M, FERREIRA A. Ballast drainage in Brazilian railway infrastructures[J]. Construction and Building Materials, 2015, 92: 58-63. doi: 10.1016/j.conbuildmat.2014.06.006 [7] ISHIKAWA T, FUKU S, NAKAMURA T, et al. Influence of water content on shear behavior of unsaturated fouled ballast[J]. Procedia Engineering, 2016, 143: 268-275. doi: 10.1016/j.proeng.2016.06.034 [8] 金寿延,谭复兴,王午生. 道床板结对轨道振动的影响[J]. 同济大学学报(自然科学版),2001,29(10): 1162-1168. doi: 10.3321/j.issn:0253-374X.2001.10.006JIN Shouyan, TAN Fuxing, WANG Wusheng. Researching for the influence of cement hardening on the rail track vibration[J]. Journal of Tongji University (Natural Science), 2001, 29(10): 1162-1168. doi: 10.3321/j.issn:0253-374X.2001.10.006 [9] 赵宁. TLV加载参数优化及轨道结构动态特征识别方法研究[D]. 北京: 北京交通大学, 2015. [10] 肖军华,张德,王延海,等. 基于DEM-FDM耦合的普通铁路碎石道床-土质基床界面接触应力分析[J]. 工程力学,2018,35(9): 170-179. doi: 10.6052/j.issn.1000-4750.2017.06.0422XIAO Junhua, ZHANG De, WANG Yanhai, et al. Study on interface stress between ballast and subgrade for traditional railway based on coupled DEM-FDM.[J]. Engineering Mechanics, 2018, 35(9): 170-179. doi: 10.6052/j.issn.1000-4750.2017.06.0422 [11] ZHANG X, ZHAO C, ZHAI W. Dynamic behavior analysis of high-speed railway ballast under moving vehicle loads using discrete element method[J]. International Journal of Geomechanics, 2017, 17(7): 04016157.1-04016157.14. [12] 井国庆,强伟乐,常锦秀,等. 针片状指数对道砟直剪力学特性的影响[J]. 西南交通大学学报,2020,55(4): 688-694.JING Guoqing, QIANG Weile, CHANG Jinxiu, et al. Effect of flakiness-elongation index on shear behavior of railway ballast[J]. Journal of Southwest Jiaotong University, 2020, 55(4): 688-694. [13] 中华人民共和国铁道部. 铁路碎石道砟: TB/T 2140—2018[S]. 北京: 中国铁道出版社, 2018. [14] 付龙龙,宫全美,周顺华,等. 列车荷载作用下有砟轨道轨面沉降与路基不均匀沉降间的相关关系[J]. 振动与冲击,2013,32(14): 23-28. doi: 10.3969/j.issn.1000-3835.2013.14.004FU Longlong, GONG Quanmei, ZHOU Shunhua, et al. Relationships between ballasted track settlement and differential subgrade settlement under train load[J]. Journal of Vibration and Shock, 2013, 32(14): 23-28. doi: 10.3969/j.issn.1000-3835.2013.14.004 [15] Itasca Consulting Group. Inc. PFC2D (particle flow code in 2 dimensions) theory and background[M]. Minneapolis : Itasca Consulting Group, 2002. [16] 伍超. 铁路板结道床捣固作业机理研究[D]. 成都: 西南交通大学, 2016. [17] 徐旸,高亮,井国庆,等. 脏污对道床剪切性能影响及评估指标的离散元分析[J]. 工程力学,2015,32(8): 96-102. doi: 10.6052/j.issn.1000-4750.2014.01.0051XU Yang, GAO Liang, JING Guoqing, et al. Shear behavior analysis of fouled railroad ballast by dem and its evaluation index[J]. Engineering Mechanics, 2015, 32(8): 96-102. doi: 10.6052/j.issn.1000-4750.2014.01.0051 [18] 国家铁路局. 轨道检测道床应变、振动测试方法: TB/T 2488—2017[S]. 北京: 中国铁道出版社, 2017. [19] 郑 建. 增加有砟轨道弹性的措施及其对轨道力学性能影响[D]. 成都: 西南交通大学, 2017. -

下载:

下载: