|

王树国, 王平, 肖俊恒, 等. 高速铁路道岔区段轮轨关系深化研究报告[R]. 北京: 中国铁道科学研究院, 2016.

|

|

王平,陈嵘,徐井芒,等. 高速铁路道岔系统理论与工程实践研究综述[J]. 西南交通大学学报,2016,51(2): 357-372. doi: 10.3969/j.issn.0258-2724.2016.02.015WANG Ping, CHEN Rong, XU Jingmang, et al. Theories and engineering practices of high-speed railway turnout system:survey and review[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 357-372. doi: 10.3969/j.issn.0258-2724.2016.02.015

|

|

王树国, 张玉林, 方杭玮, 等. 高速铁路道岔设计技术[R]. 北京: 中国铁道科学研究院, 2009.

|

|

张东风. 时速350 km客运专线铁路60 kg/m钢轨42号单开道岔结构设计[J]. 铁道标准设计,2009(5): 6-9. doi: 10.3969/j.issn.1004-2954.2009.05.003ZHANG Dongfeng. Design on No.42 single slit turnout structure on 60 kg/m steel rail of passenger dedicated lines with a speed of 350 km/h[J]. Railway Standard Design, 2009(5): 6-9. doi: 10.3969/j.issn.1004-2954.2009.05.003

|

|

JENDEL T. Prediction of wheel profile wear-comparisons with field measurements[J]. Wear, 2002, 253(1/2): 89-99.

|

|

IGNESTI M, INNOCENTI A, MARINI L, et al. Development of a model for the simultaneous analysis of wheel and rail wear in railway systems[J]. Multibody System Dynamics, 2014, 31(2): 191-240. doi: 10.1007/s11044-013-9360-0

|

|

许玉德,魏恺,孙小辉,等. 钢轨磨耗预测模型及其算法的优化[J]. 中国铁道科学,2016,37(4): 48-53. doi: 10.3969/j.issn.1001-4632.2016.04.08XU Yude, WEI Kai, SUN Xiaohui, et al. Prediction model and algorithm optimization for rail wear[J]. China Railway Science, 2016, 37(4): 48-53. doi: 10.3969/j.issn.1001-4632.2016.04.08

|

|

APEZETXEA I S, PEREZ X, CASANUEVA C, et al. New methodology for fast prediction of wheel wear evolution[J]. Vehicle System Dynamics, 2017, 55(7): 1071-1097. doi: 10.1080/00423114.2017.1299870

|

|

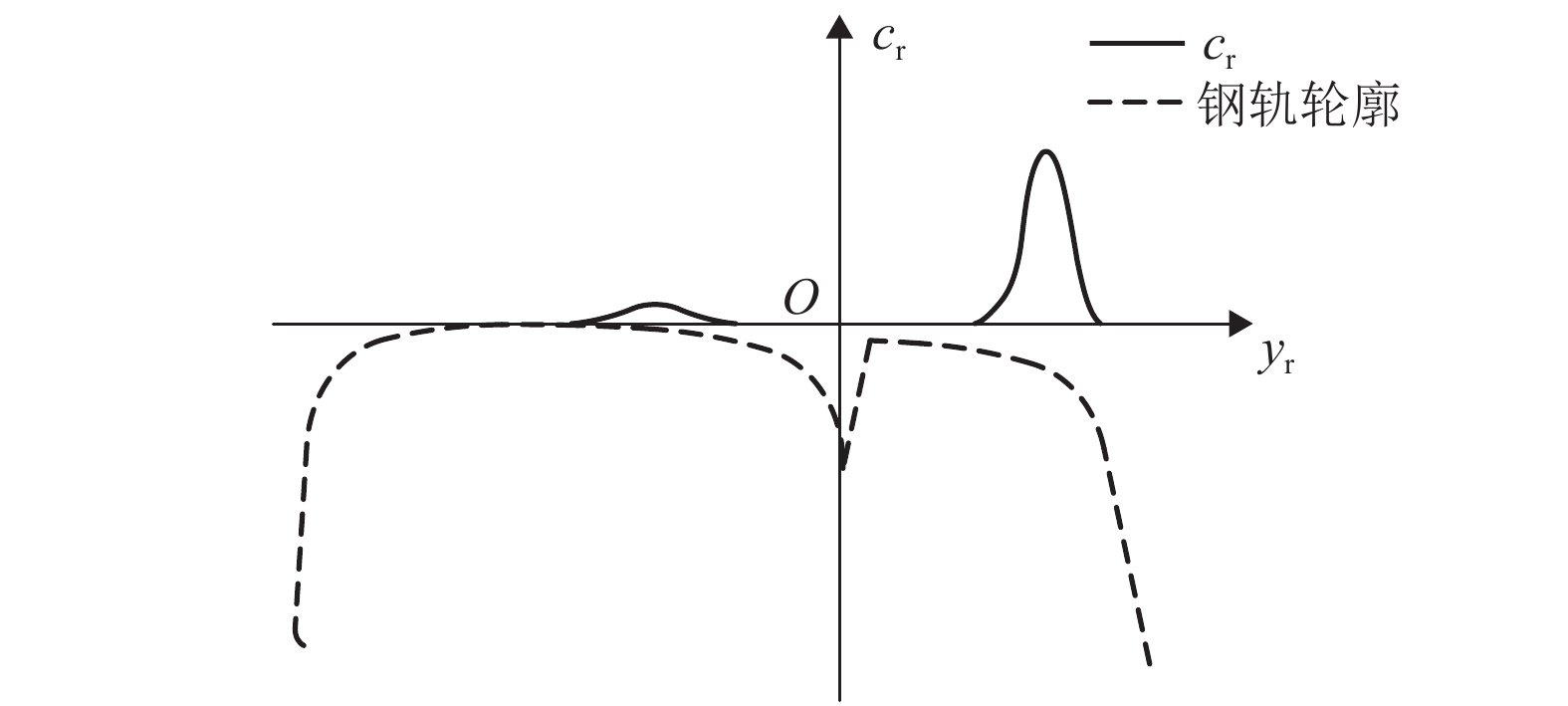

孙宇,翟婉明. 钢轨磨耗演变预测模型研究[J]. 铁道学报,2017,39(8): 1-9. doi: 10.3969/j.issn.1001-8360.2017.08.001SUN Yu, ZHAI Wanming. A prediction model for rail wear evolution[J]. Journal of the China Railway Society, 2017, 39(8): 1-9. doi: 10.3969/j.issn.1001-8360.2017.08.001

|

|

LUO R, SHI H, TENG W, et al. Prediction of wheel profile wear and vehicle dynamics evolution considering stochastic parameters for high-speed train[J]. Wear, 2017, 392/393: 126-138.

|

|

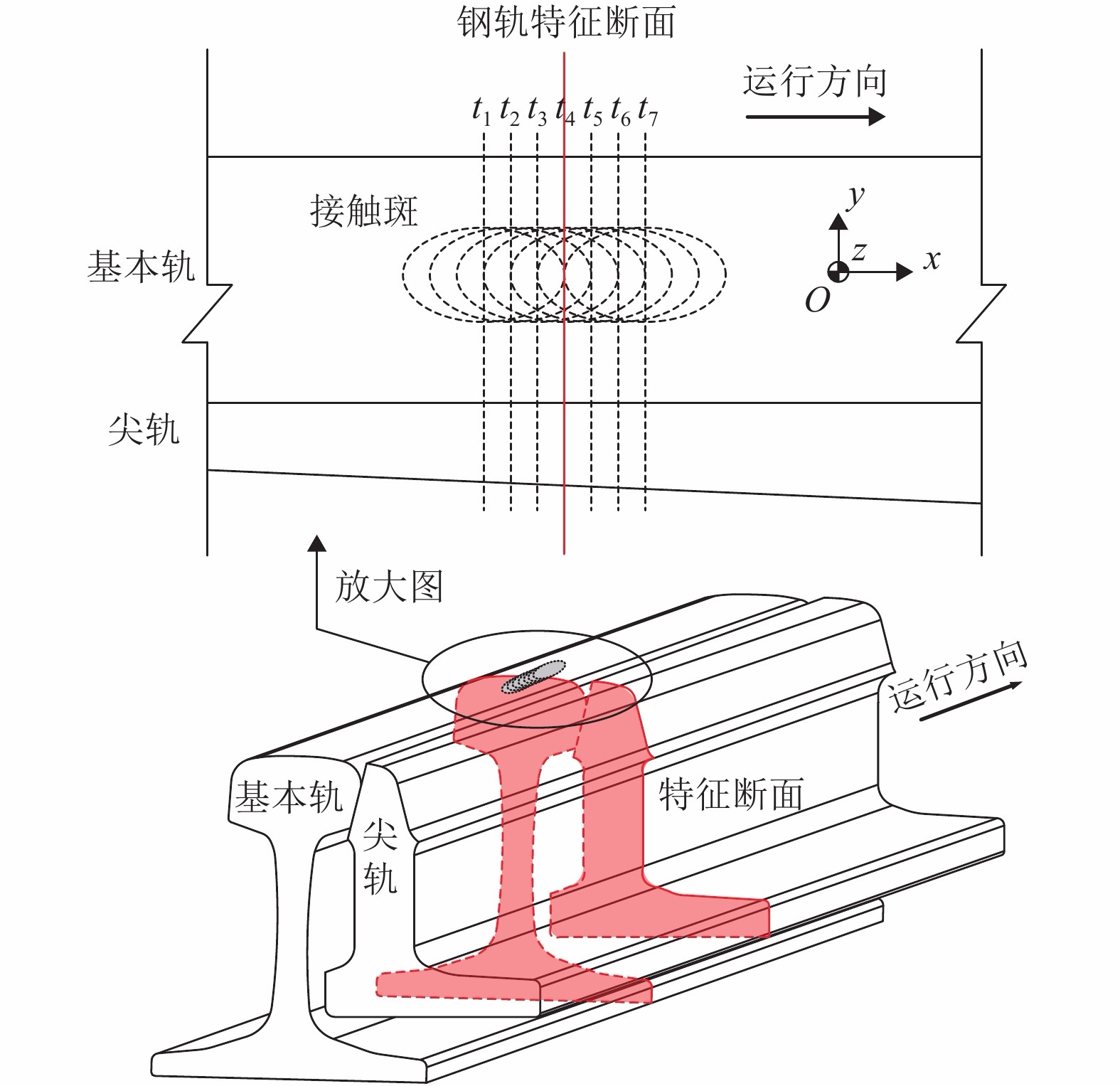

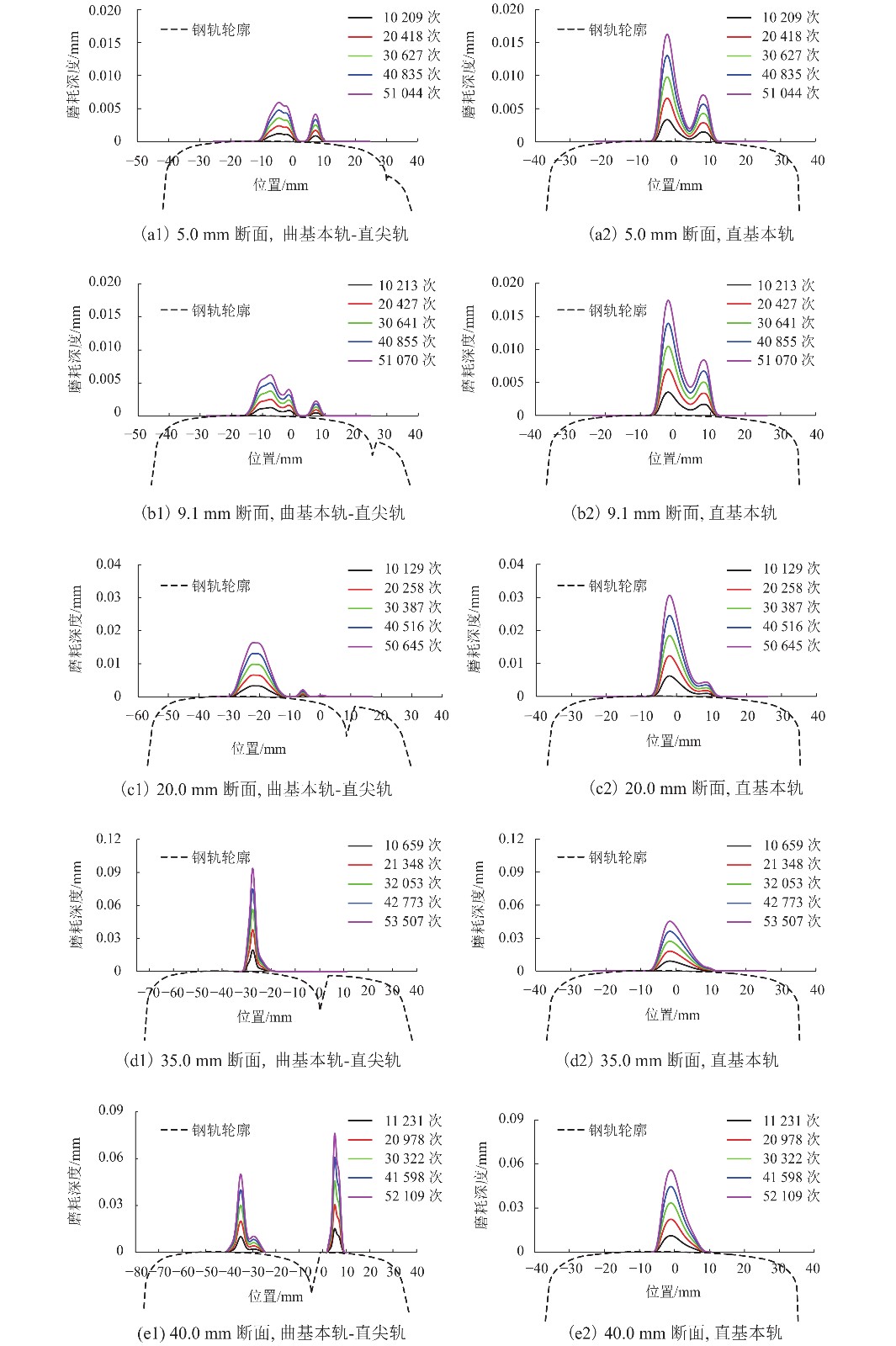

XU J M, WANG P, WANG J, et al. Numerical analysis of the effect of track parameters on turnout rails wear for high-speed railways[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2018, 232(3): 709-721. doi: 10.1177/0954409716685188

|

|

HAN P, ZHANG W H. A new binary wheel wear prediction model based on statistical method and the demonstration. Wear, 2015, 324/325: 90-99.

|

|

徐凯,李芾,安琪,等. 高速动车组车轮踏面磨耗特征分析[J]. 西南交通大学学报,2021,56(1): 92-100. doi: 10.3969/j.issn.0258-2724.20190266XU Kai, LI Fu, AN Qi, et al. Wheel tread wear characteristics of high-speed electric multi-units[J]. Journal of Southwest Jiaotong University, 2021, 56(1): 92-100. doi: 10.3969/j.issn.0258-2724.20190266

|

|

HERTZ H. Über die berührung fester elastische Körper[J]. Journal für die Reine und Angewandte Mathematik, 1882, 92: 156-171.

|

|

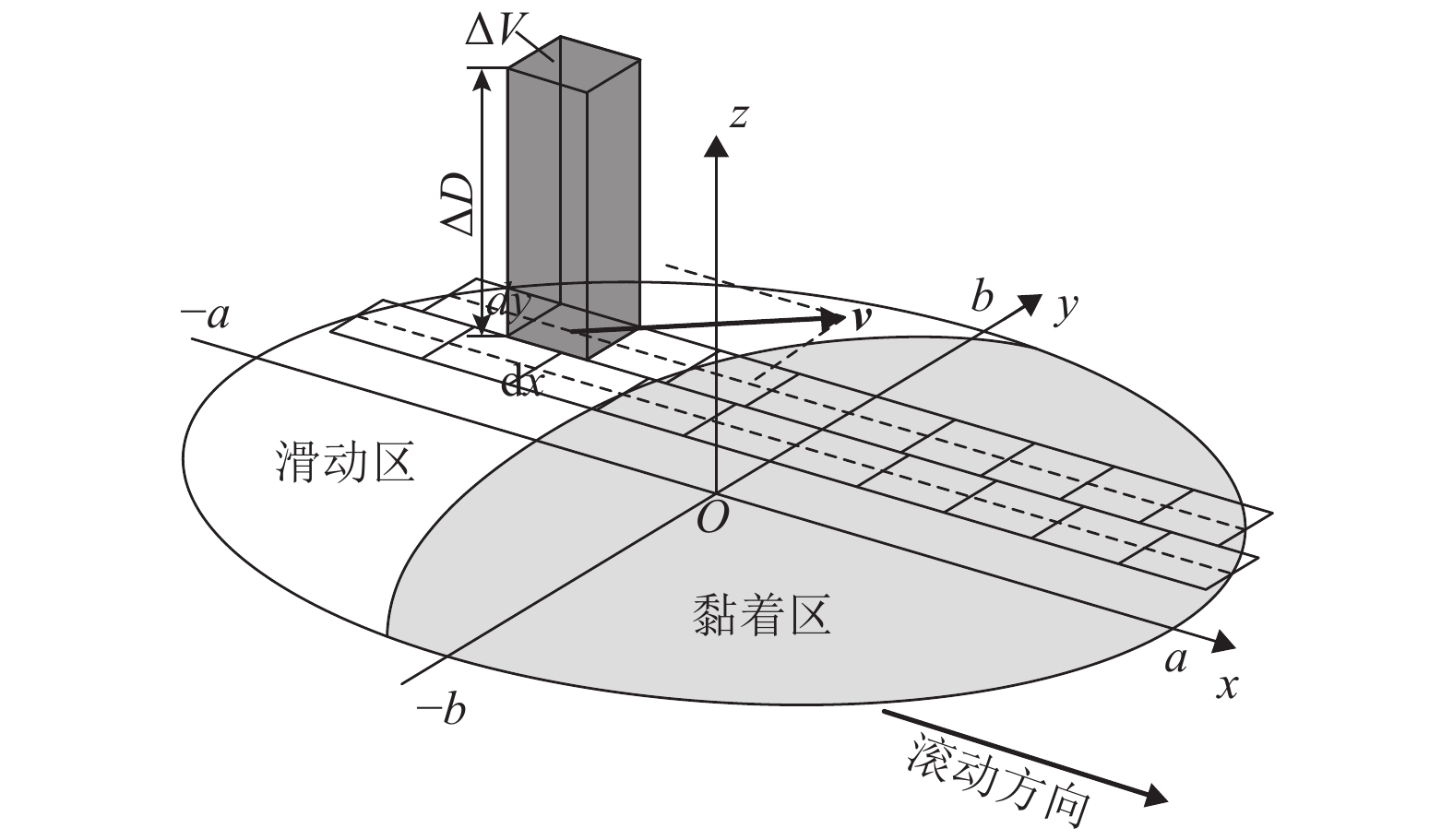

KALKER J J. A fast algorithm for the simplified theory of rolling contact[J]. Vehicle System Dynamics, 1982, 11(1): 1-13. doi: 10.1080/00423118208968684

|

|

ARCHARD J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953(24): 981-988.

|

|

中铁宝桥集团有限公司. 铁路道岔参数手册[M]. 北京: 中国铁道出版社, 2009.

|

|

胡晓依, 侯茂锐, 孙加林, 等. 车辆-轨道耦合动力学仿真模型验证方案[R]. 北京: 中国铁道科学研究院, 2016.

|

下载:

下载: