Service Performance of High-Speed EMU Axles Made of 30NiCrMoV12 and EA4T

-

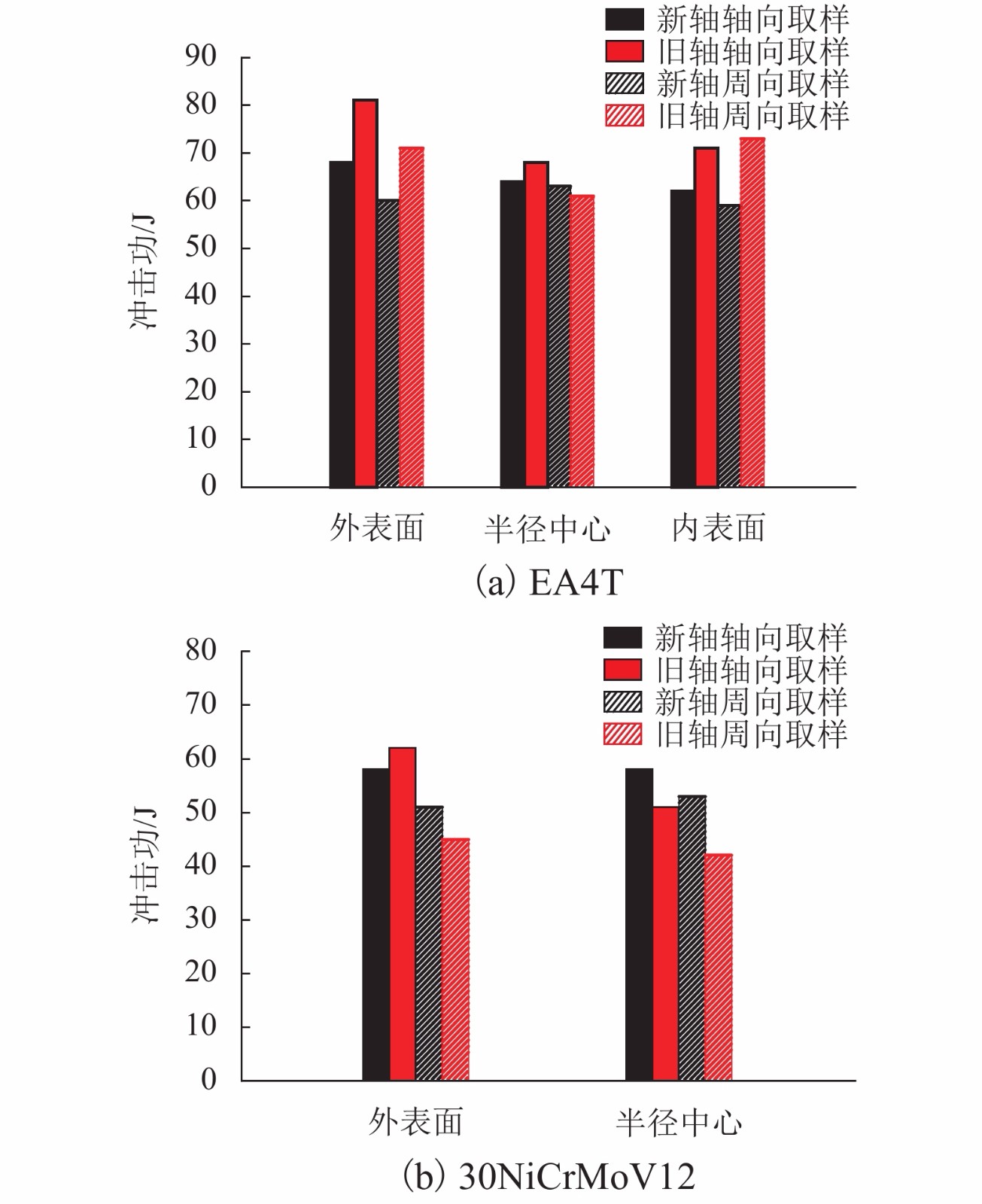

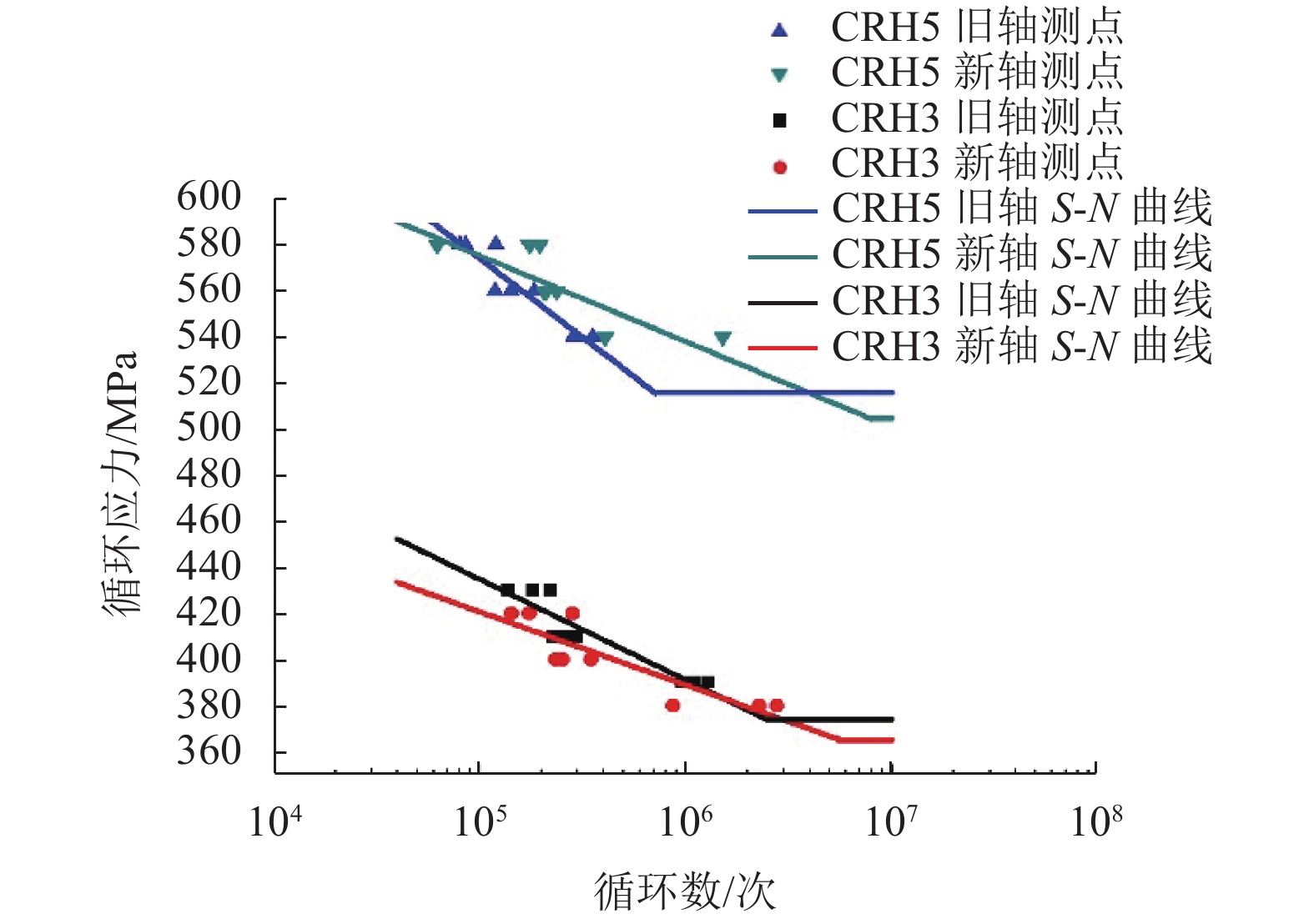

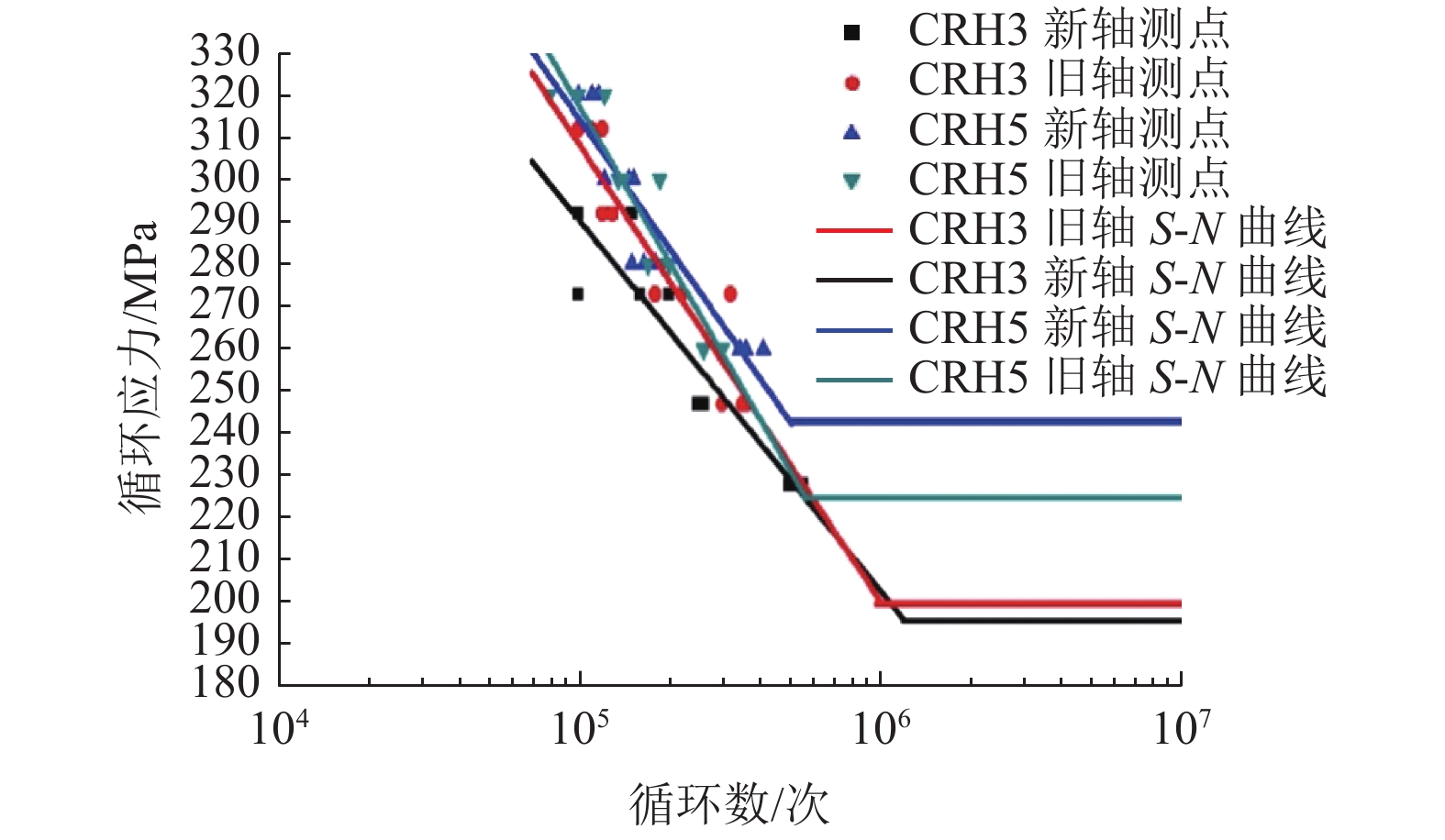

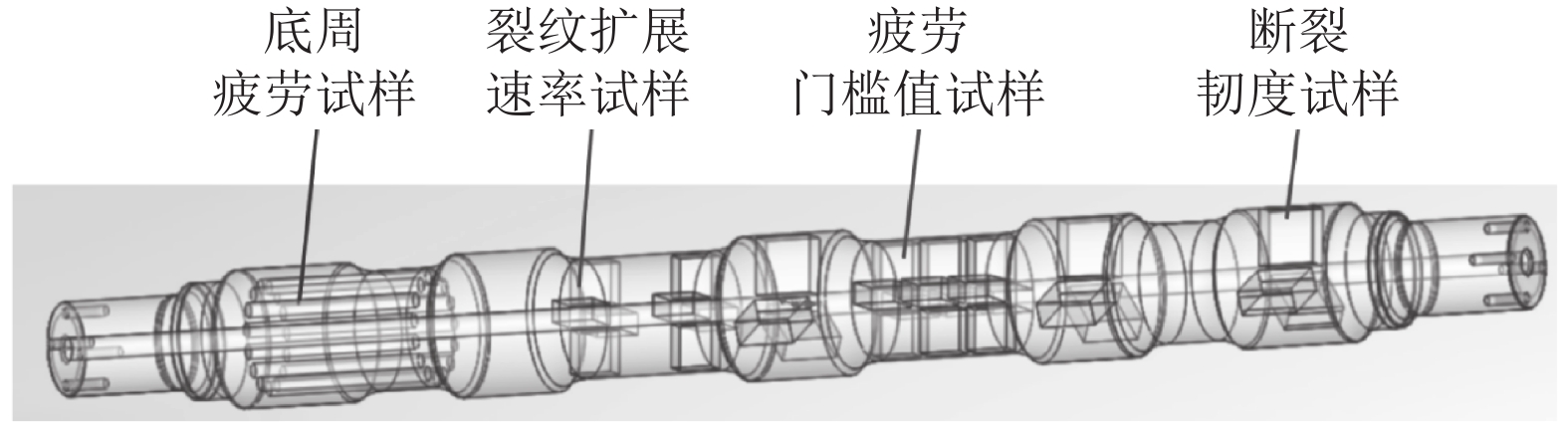

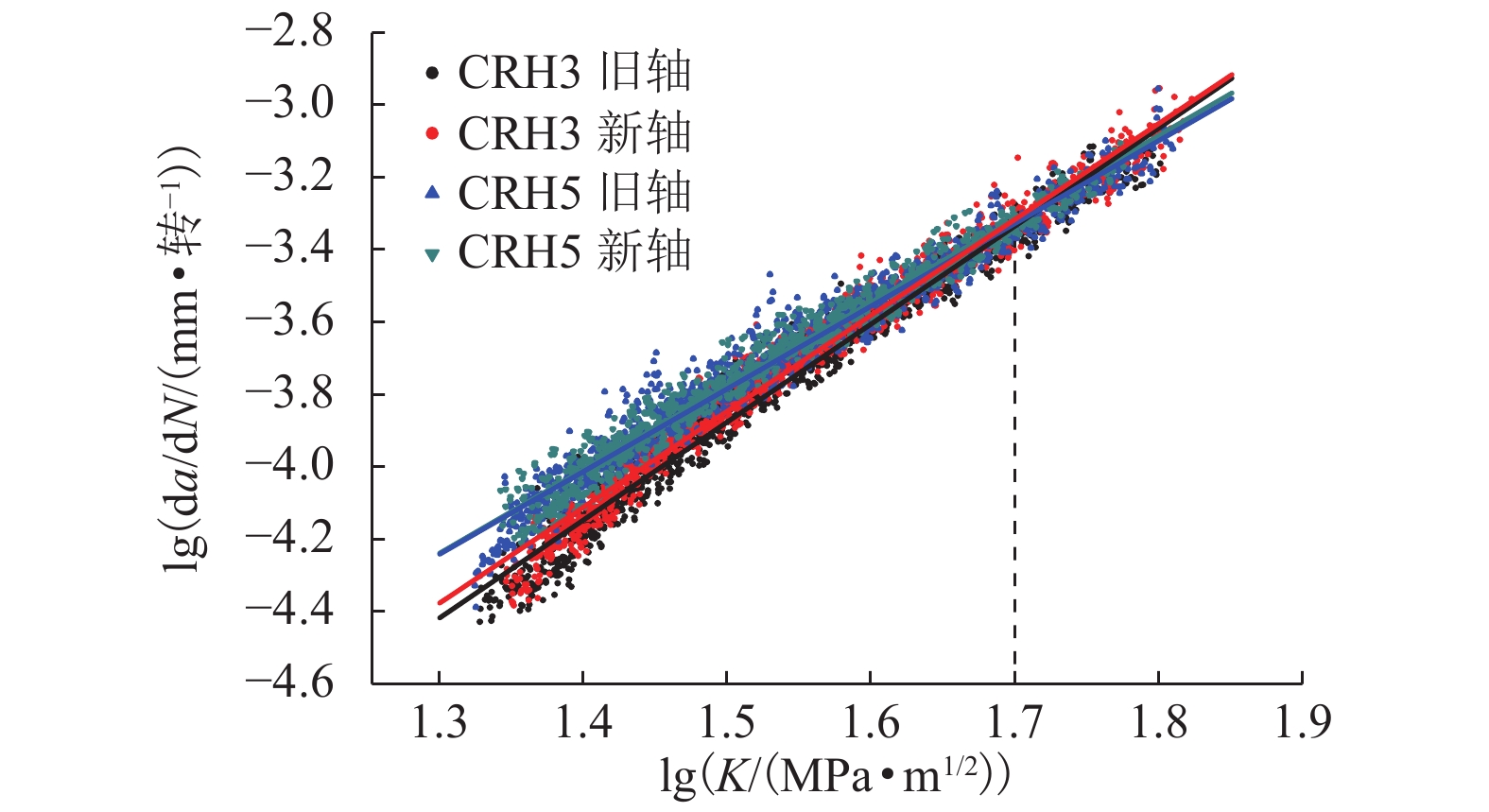

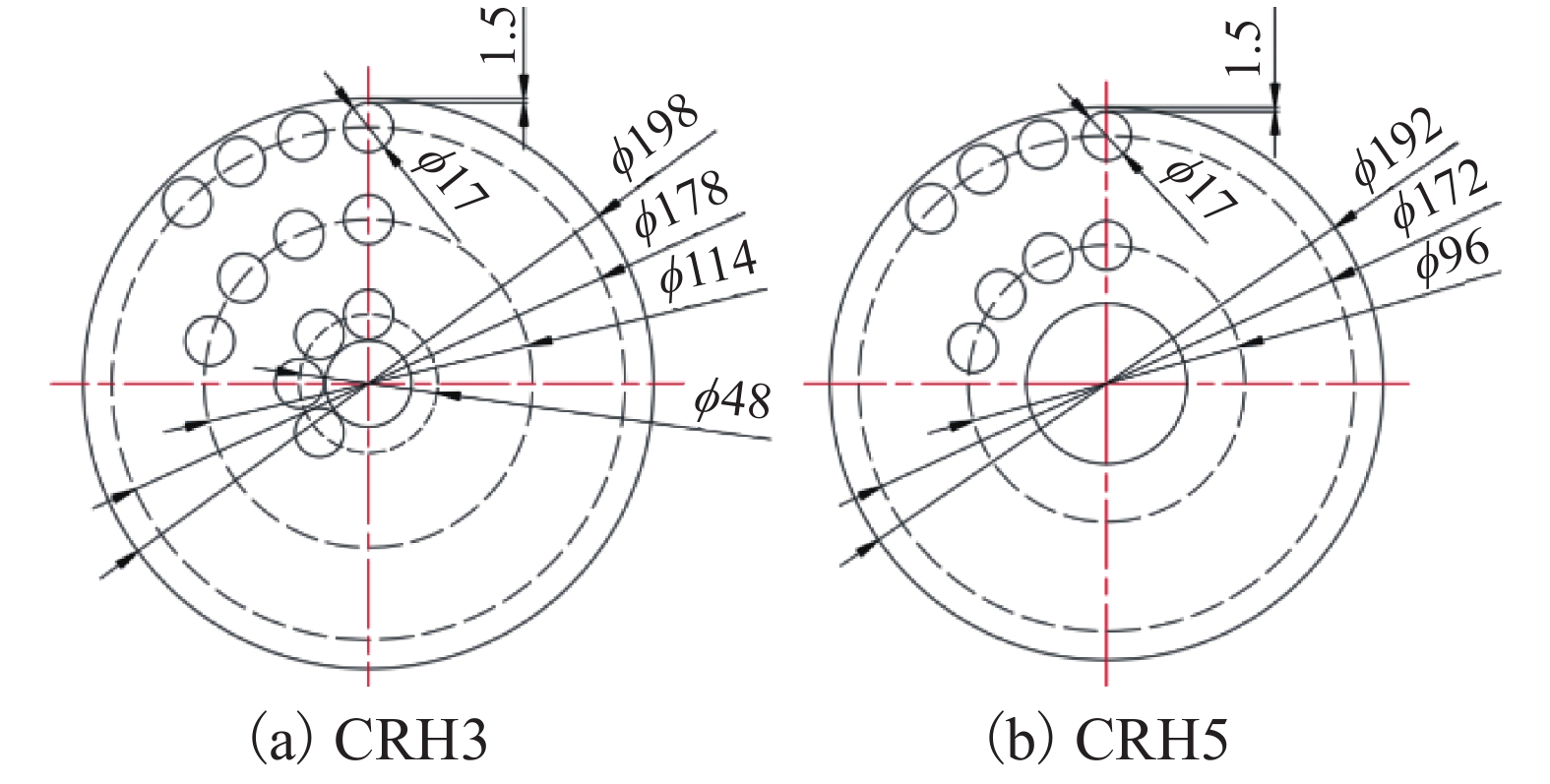

摘要: 为全面掌握高速动车组30NiCrMoV12和EA4T两种车轴材质的服役性能,分别实测了新、旧车轴的化学成分、常规力学性能、标样疲劳特性、冲击性能、断裂韧性、疲劳裂纹扩展门槛值和疲劳裂纹扩展速率等,并对其金相组织进行观测,综合评价分析两种材质车轴服役性能. 结果表明:(1) 与EA4T材质相比,30NiCrMoV12材质车轴中Ni含量高10倍,Mo、V含量高2倍,C含量略高,抗拉强度高34%,屈服强度高54%,疲劳强度高30%;(2) 断裂损伤性能对比中,30NiCrMoV12材质车轴比EA4T材质车轴的常温冲击功约低12%,断裂韧性约高34%,EA4T材质新轴疲劳裂纹扩展门槛值比30NiCrMoV12新轴的高21%,旧轴时两者相当;(3) 当应力强度因子幅度小于50 MPa•m1/2时,30NiCrMoV12材质车轴裂纹扩展速率大于EA4T材质车轴,反之,30NiCrMoV12材质车轴裂纹扩展速率小于EA4T材质车轴;(4) 30NiCrMoV12材质车轴整个截面组织均为晶粒细小的贝氏体和回火马氏体,淬透性较好,制造工艺性能好;EA4T车轴在表面约30 mm深度范围为均匀的贝氏体和回火马氏体,后随深度增加逐渐出现铁素体,距表面60 mm为珠光体和铁素体,并以铁素体为主.Abstract: In order to gain insight into the mechanical behaviors of China’s high-speed EMU (electric multiple unit) axles made of 30NiCrMoV12 and EA4T, both the in-serving and over-served axles were examined in their chemical composition, conventional tensile strength, fatigue, impact toughness, fracture toughness, the threshold value and rate of fatigue crack growth and the metallographic structure. The final results are shown as follows: (1) The 30NiCrMoV12 axles had 10 times higher Ni element content, 2 times higher Mo and V elements content, and slightly higher C element content than the EA4T axle. The conventional tensile strength, yield strength and fatigue strength were increased by 34%, 54%, and 30%, respectively. (2) Compared with the EA4T axle, the conventional impact energy of the 30NiCrMoV12 axle at room temperature decreased by 12%; however, its fracture toughness increased by 34%. The EA4T axle had a 12% higher threshold value of fatigue crack growth than the 30NiCrMoV12 axle, and as for the two types of the old axis, this feature are quite similar. (3) When the stress intensity factor was less than 50 MPa•m1/2, the crack growth rate was greater than the EA4T axle; However, when it was larger than 50 MPa•m1/2, it was on the contrary. (4) The grain size of the full section microstructure of the 30NiCrMoV12 axle was fine bainite and tempered martensite with good hardenability and manufacturing performance. However, the section of the EA4T axle was composed of uniform bainite and tempered martensite within the depth of 30 mm from surface, and the ferrite gradually appeared with depth increasing. When the depth increased to 60 mm, the microstructure consisted of pearlite and ferrite, meanwhile the volume fraction of ferrite was significantly higher than that of pearlite.

-

Key words:

- high-speed emu axle /

- service performance /

- metallographic structure

-

表 1 化学成分的质量分数

Table 1. Mass fraction of chemical components

材质 试样/标准 C Si Mn P S Cr Ni Mo Cu V EA4T 新轴 0.277 0.287 0.726 0.005 0.002 1.063 0.215 0.230 0.130 0.040 旧轴 0.276 0.302 0.703 0.004 0.001 1.059 0.217 0.233 0.139 0.045 EN 13261: 2009[7] 0.220~

0.2900.150~

0.4000.500~

0.800≤ 0.020 ≤ 0.015 0.900~

1.200≤ 0.300 0.150~

0.300≤ 0.300 ≤ 0.060 30NiCr-MoV12 新轴 0.306 0.318 0.621 0.006 0.001 0.778 2.935 0.480 0.108 0.092 旧轴 0.301 0.255 0.608 0.006 0.001 0.815 2.992 0.506 0.095 0.102 UNI 6787-

71[8]0.260~

0.320≤ 0.400 0.400~

0.700≤ 0.020 ≤ 0.020 0.60~

1.002.700~

3.3000.400~

0.600≤ 0.200 0.080~

0.130表 2 强度试验

Table 2. Strength test results

MPa 项目 EA4T 30NiCrMoV12 外表面 半径中心 内表面 外表面 半径中心 新轴 旧轴 新轴 旧轴 新轴 旧轴 新轴 旧轴 新轴 旧轴 抗拉强度 725 745 715 750 670 723 965 979 966 967 屈服强度 586 603 560 590 493 559 881 888 867 865 表 3 延伸率与断面收缩率试验

Table 3. Test results in elongation and section shrinkage ratio

% 项目 EA4T 30NiCrMoV12 外表面 半径中心 内表面 外表面 半径中心 新轴 旧轴 新轴 旧轴 新轴 旧轴 新轴 旧轴 新轴 旧轴 延伸率 23.2 24.5 22.9 24.9 23.8 25.6 20.1 19.8 19.6 19.7 断面收缩率 46.2 46.9 44.2 44.5 43.7 45.8 63.0 61.6 60.8 63.3 表 4 车轴断裂韧性试验值

Table 4. Test fracture toughness values of axle shaft

MPa•m1/2 试样编号 EA4T 30NiCrMoV12 新轴 旧轴 新轴 旧轴 1 92.4 88.8 125.7 114.9 2 89.9 91.2 123.1 122.6 3 90.2 89.7 125.2 114.7 4 90.2 92.2 128.5 119.6 平均值 90.7 90.5 125.6 118.0 表 5 疲劳裂纹扩展门槛值

Table 5. Threshold values of EA4T axle fatigue crack growth

MPa•m1/2 试样编号 EA4T 30NiCrMoV12 新轴 旧轴 新轴 旧轴 1 8.39 8.27 7.07 8.36 2 8.58 8.55 6.96 8.66 平均值 8.49 8.41 6.99 8.60 表 6 金相组织试验

Table 6. Metallographic structure test results

材质 表面下 10 mm 表面下 30 mm 表面下 60 mm EA4T

30NiCrMoV12

-

张永生. 东风4、7型机车车轴使用寿命的探讨[J]. 内燃机车,2002(12): 24-25,19. 杨广雪,李强,谢基龙,等. 微动对车轴钢疲劳性能的影响[J]. 北京交通大学学报,2012,36(1): 127-131. doi: 10.3969/j.issn.1673-0291.2012.01.025YANG Guangxue, LI Qiang, XIE Jilong, et al. Influence of fretting on the fatigue behavior of axle steel[J]. Journal of Beijing Jiaotong University, 2012, 36(1): 127-131. doi: 10.3969/j.issn.1673-0291.2012.01.025 杨广雪. 高速列车车轴旋转弯曲作用下微动疲劳损伤研究[D]. 北京: 北京交通大学, 2010. 伍颖. 断裂与疲劳[M]. 武汉: 中国地质大学出版社, 2008. CANTINI S, BERETTA S. Structural reliability assessment of railway axles[M]. Lovere: Lucchini RS, 2011. 吴毅,赵雷. 中国标准动车组车轴研制与应用[J]. 铁道车辆,2017,55(12): 26-30,56. doi: 10.3969/j.issn.1002-7602.2017.12.007WU Yi, ZHAO Lei. Development and application of axles for Chinese standard EMUs[J]. Railway Vehicle, 2017, 55(12): 26-30,56. doi: 10.3969/j.issn.1002-7602.2017.12.007 European Committee for Standardization. Railway applications—wheelsets and bogies-axles-product requirements: EN 13261: 2009[S]. Brussels: European Committee for Standardization, 2009. IT-UNI. Assi fucinati di acciaio speciale legato, bonificati, ad elevate caratteristiche di fatica e di tenacita per sale montate di rotabili ferroviari: UNI 6787-71[S]. Associazione Italiana di Normazione, 1971. US-ASTM. Standard test method for atomic emission vacuum spectrometric analysis of carbon and low-alloy steel: E415-08[S]. West Conshohocken: ASTM, 2008 潘小强. 合金元素Mo、V对耐火钢组织及性能的影响[D]. 重庆: 重庆大学, 2007. 史建平,刘忠侠,肖乾. 车轮钢的化学成分、微观组织对车轮钢力学性能的影响[J]. 中国铁道科学,2012,33(6): 44-50. doi: 10.3969/j.issn.1001-4632.2012.06.08SHI Jianping, LIU Zhongxia, QIAN Kun. The effect of chemical composition,microstructure on the mechanical properties of wheel steels[J]. China Railway Science, 2012, 33(6): 44-50. doi: 10.3969/j.issn.1001-4632.2012.06.08 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料拉伸试验第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011. US-ASTM. Standard test methods for notched bar inpact testing of metallic materials: E23-16b[S]. West Conshohocken: ASTM, 2016. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 夏比摆锤冲击试验方法: GB/T 229—2007[S]. 北京: 中国标准出版社, 2008. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 疲劳试验 轴向力控制方法: GB/T 3075—2008[S]. 北京: 中国标准出版社, 2009. 吴圣川,徐忠伟,康国政,等. 外物损伤对25CrMo4合金车轴钢疲劳性能的影响[J]. 西南交通大学学报,2020,55(3): 658-663.WU Shengchuang, XU Zhongwei, KANG Guozheng, et al. Influences of foreign object damage on fatigue strength of 25CrMo4 axle alloy steel[J]. Journal of Southwest Jiaotong University, 2020, 55(3): 658-663. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 疲劳试验 数据统计方案与分析方法: GB/T 24176—2009[S]. 北京: 中国标准出版社, 2010. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 疲劳试验 旋转弯曲方法: GB/T 4337—2015[S]. 北京: 中国标准出版社, 2016. US-ASTM. Standard test method for plane-strain fracture toughness of metallic materials: E399-90[S]. West Conshohocken: ASTM, 1990. US-ASTM. Standard test method for linear-elastic plane-strain fracture toughness KIC of metallic materials: E399-17[S]. West Conshohocken: ASTM, 2017. US-ASTM. Standard test method for measurement of fatigue crack growth rates: E647-15[S]. West Conshohocken: ASTM, 2017. 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属显微组织检验方法: GB/T 13298—2015[S]. 北京: 中国标准出版社, 2015. 龚帅,任学冲,马英霞. 热处理对高速车轮钢显微组织和断裂韧性的影响[J]. 材料热处理学报,2015,6(4): 150-155.GONG Shuai, REN Xuechong, MA Yingxia. Effect of heat-treatment on microstructure and fracture toughness of high-speed railway wheel steel[J]. Transactions of Materials and Heat Treatment, 2015, 6(4): 150-155. 杜松林,汪开忠,胡芳忠. 国内外高速列车车轴技术综述及展望[J]. 中国材料进展,2019,38(7): 641-650.DU Songling, WANG Kaizhong, HU Fangzhong. Summary and prospect of high speed train axle technology at home and Abroad[J]. Progress in China's Materials, 2019, 38(7): 641-650. 冉旭,姜明坤,韩英. 高铁用进EA4钢车轴的组织和力学性能[J]. 机械工程材料,2019,43(8): 41-45,74. doi: 10.11973/jxgccl201908008RAN Xu, JIANG Mingkun, HAN Ying. Microstructure and mechanical properties of high-speed rail into EA4T steel axle[J]. Mechanical Engineering Materials, 2019, 43(8): 41-45,74. doi: 10.11973/jxgccl201908008 -

下载:

下载: