Seismic Performance Test and FEM Analysis of Assembled Concrete Pier with Sleeve and Steel Tube Shear Connector

-

摘要:

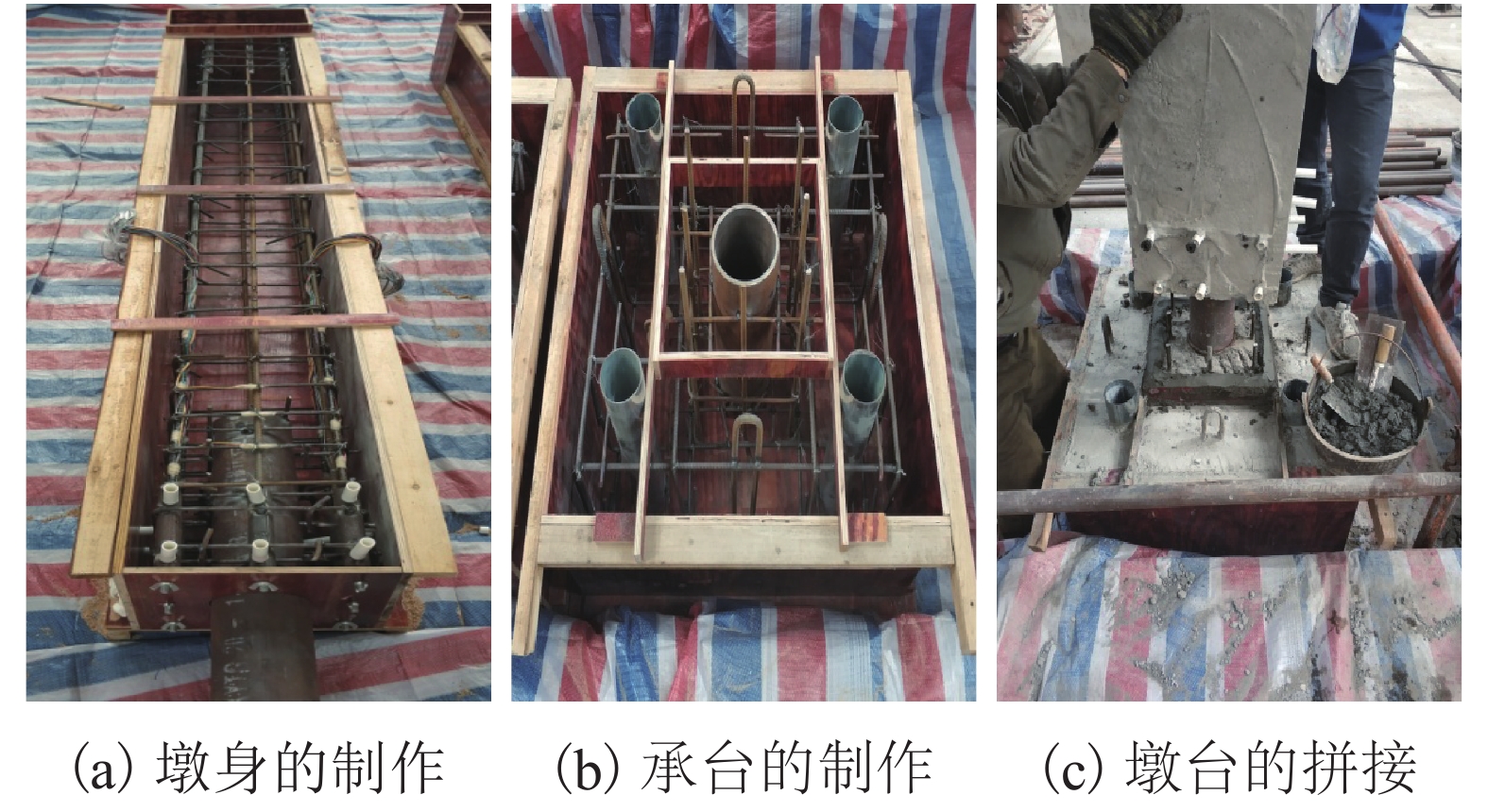

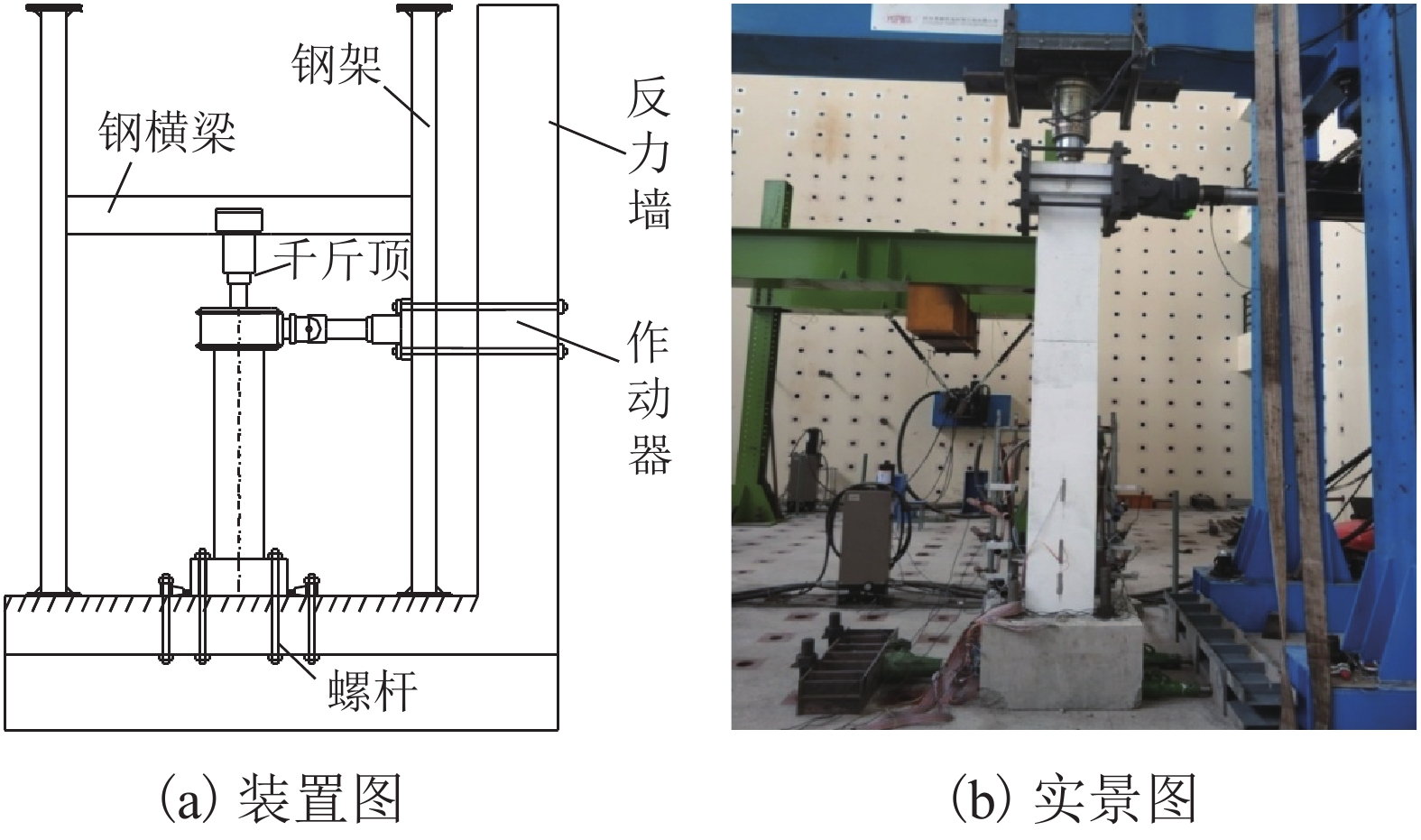

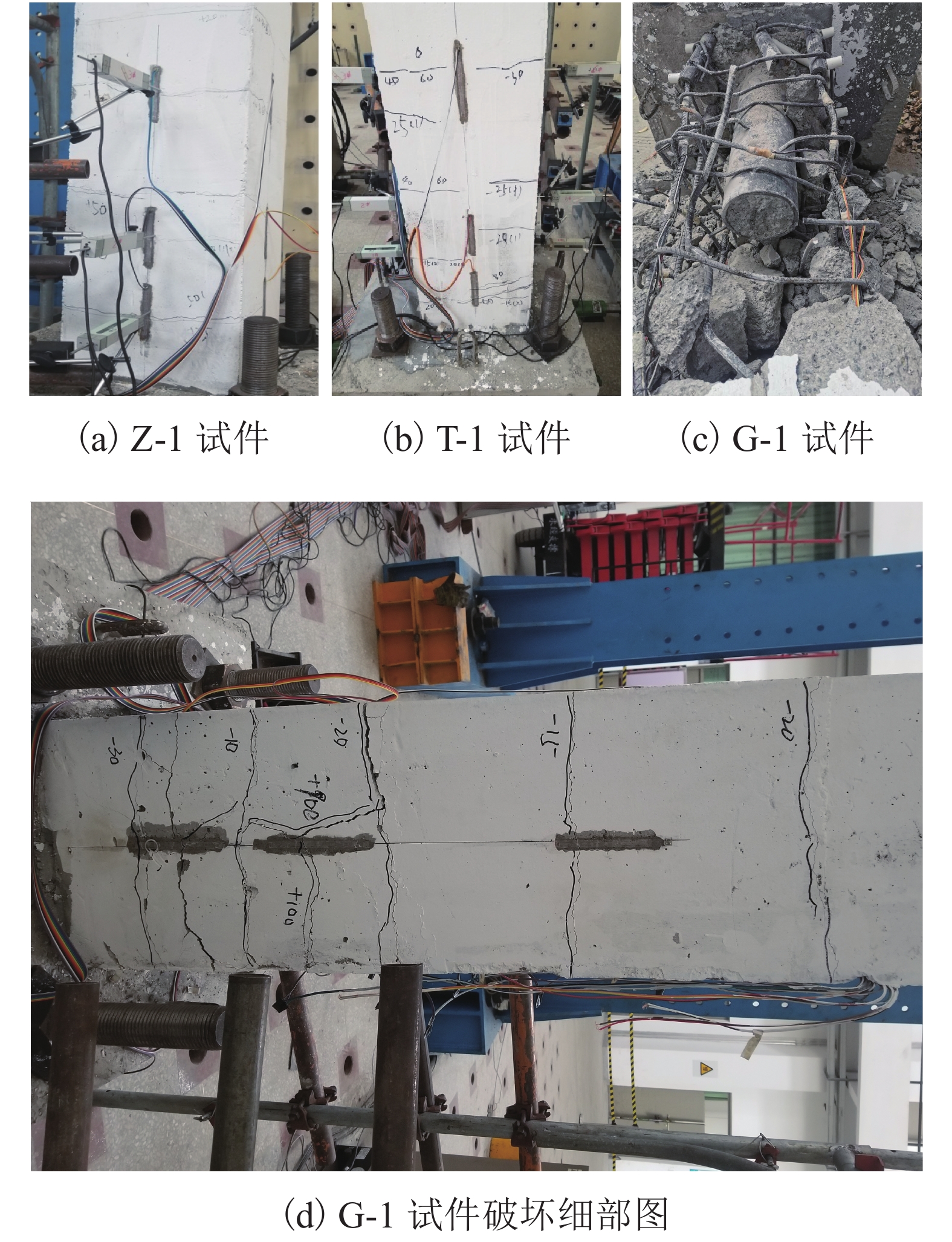

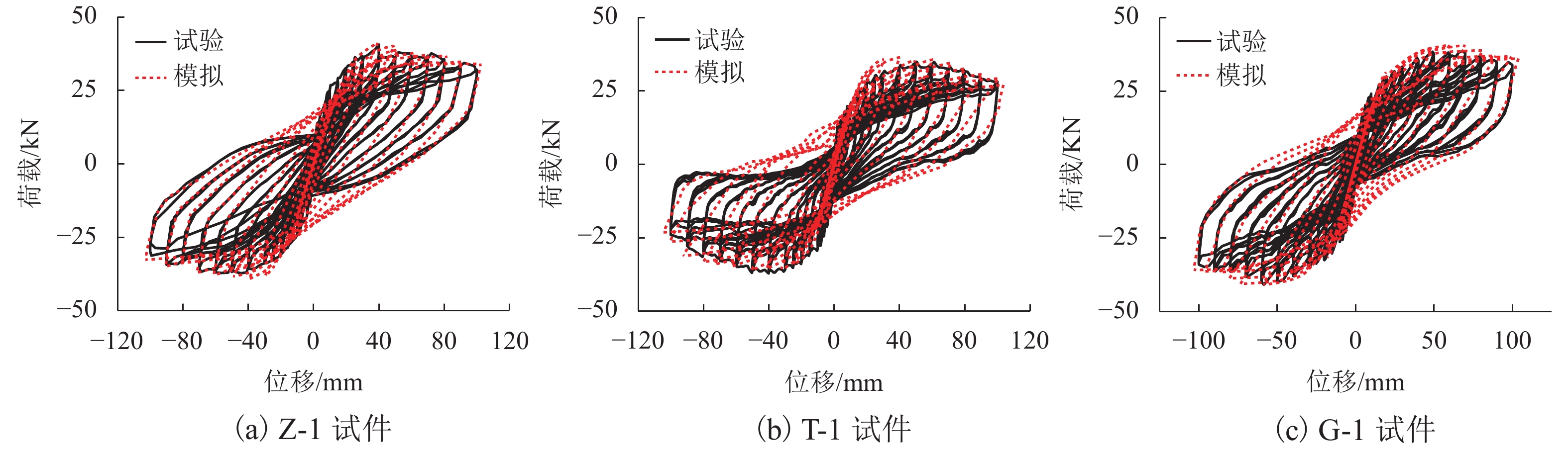

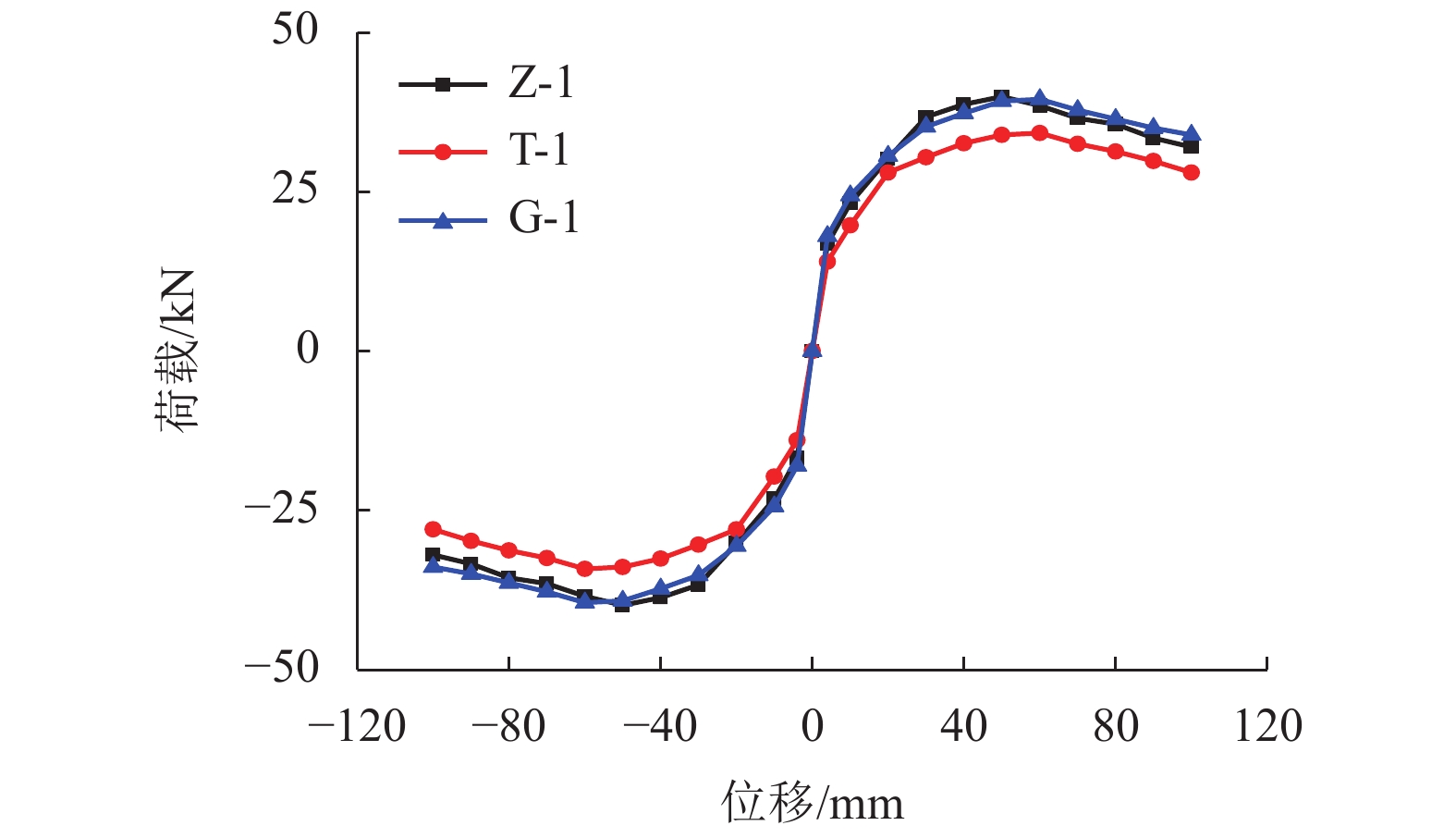

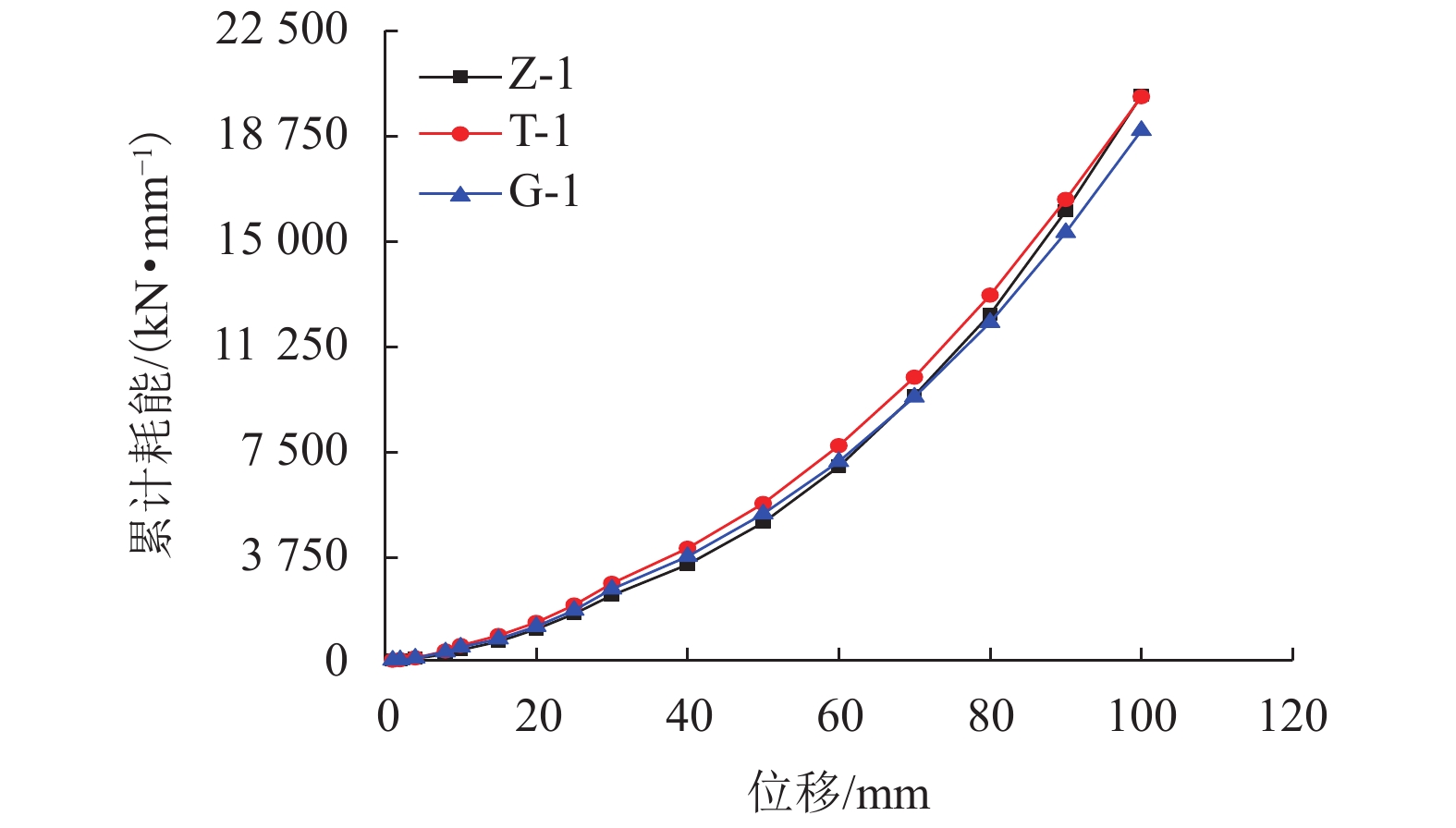

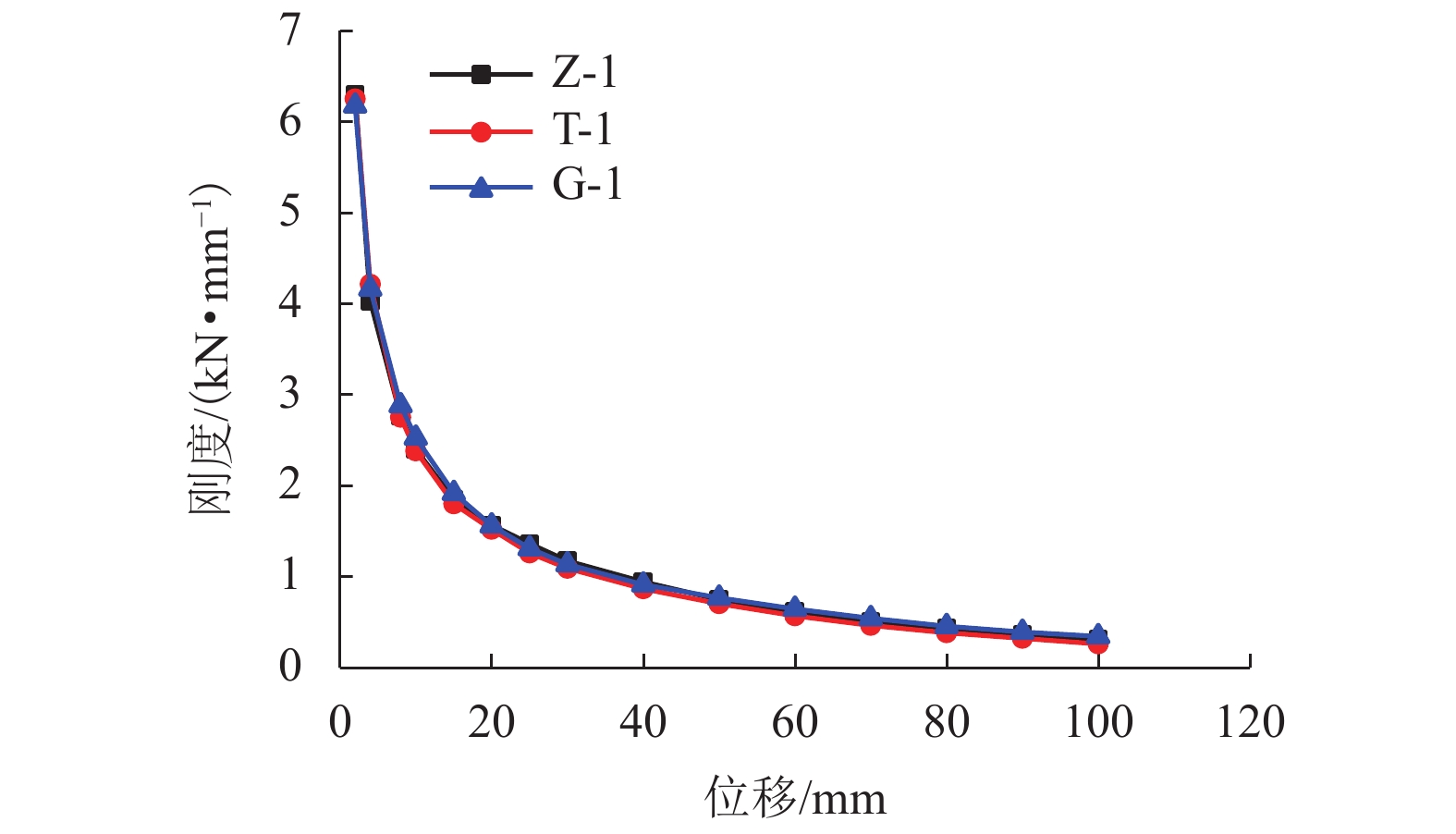

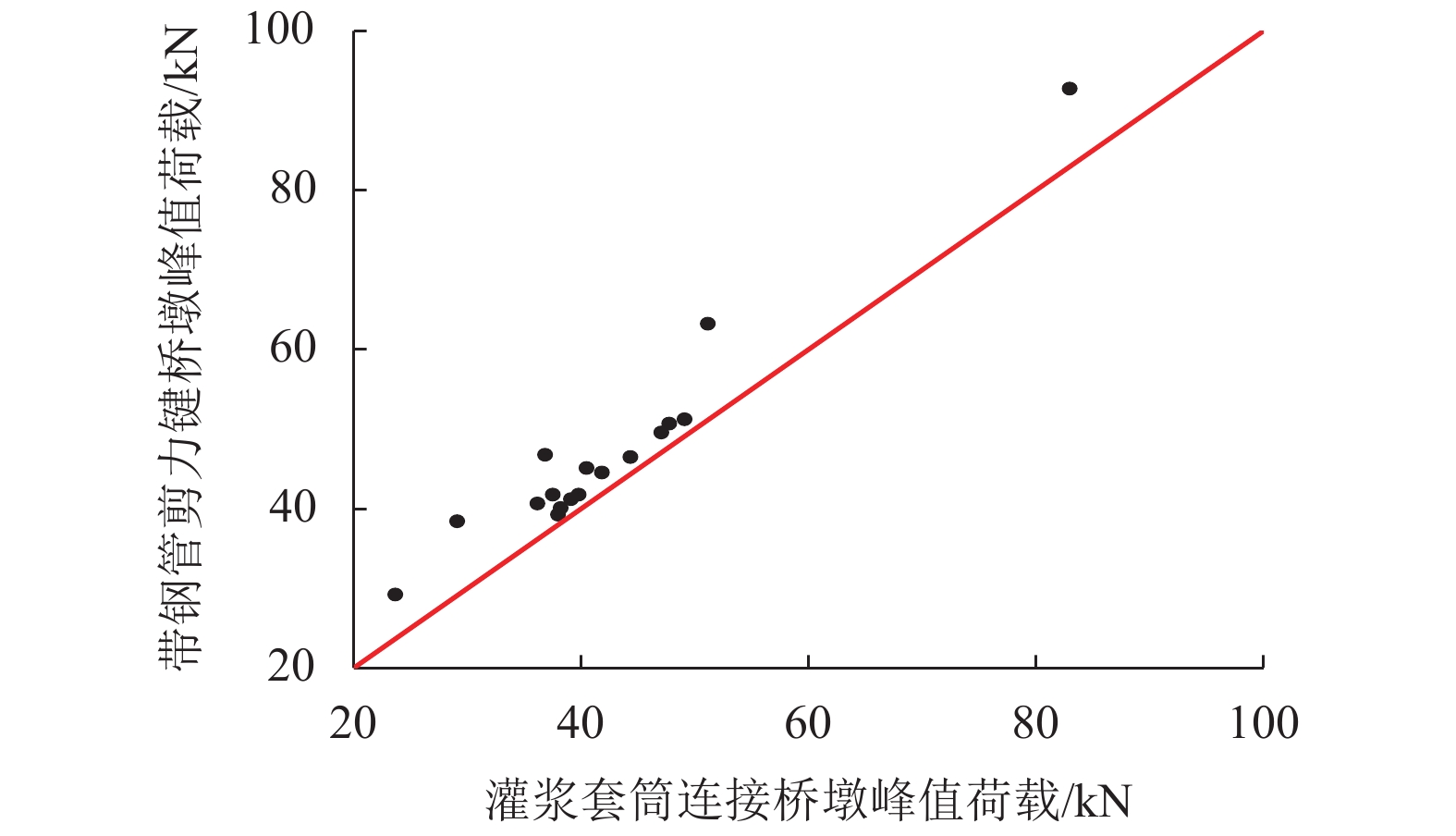

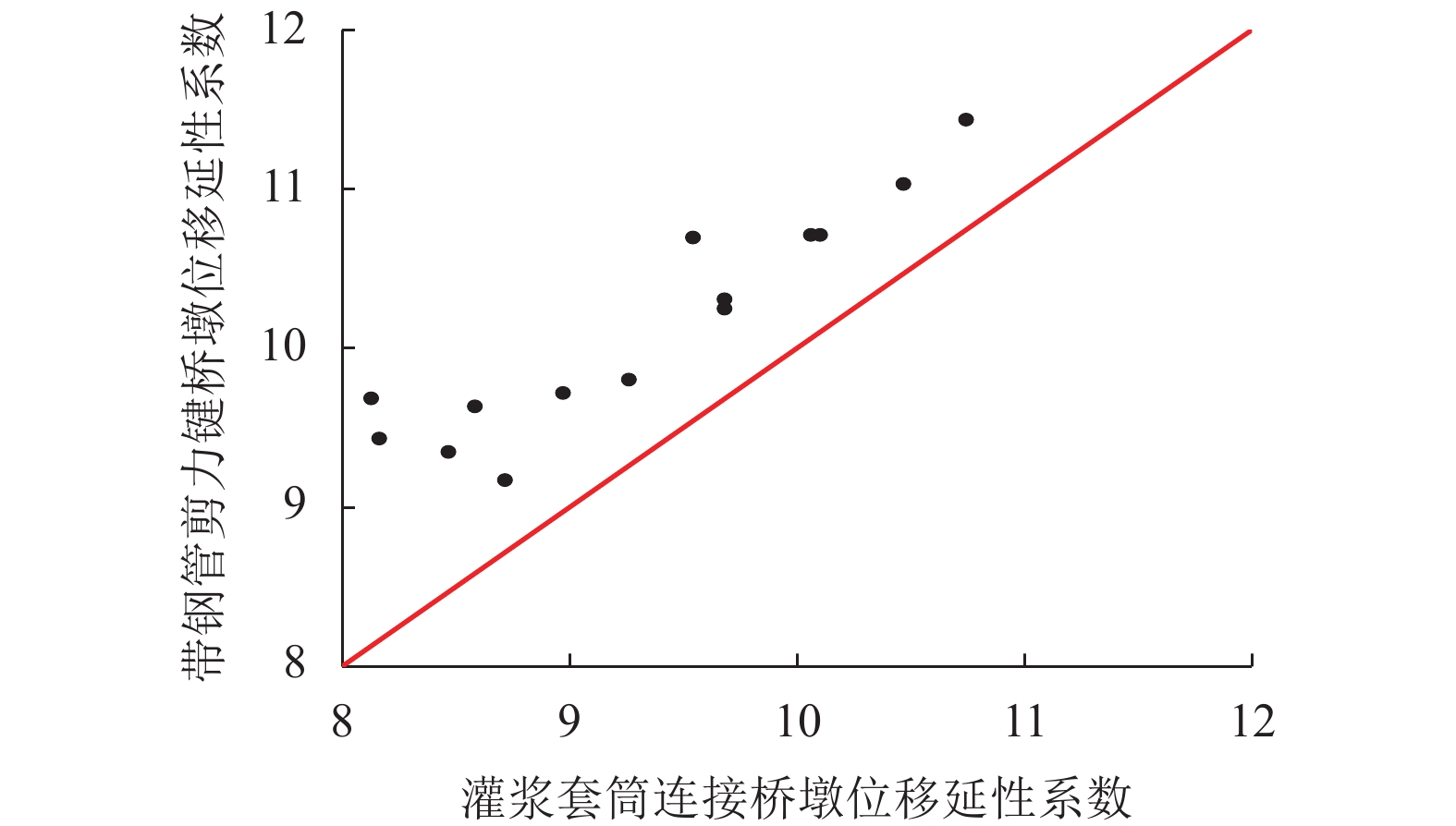

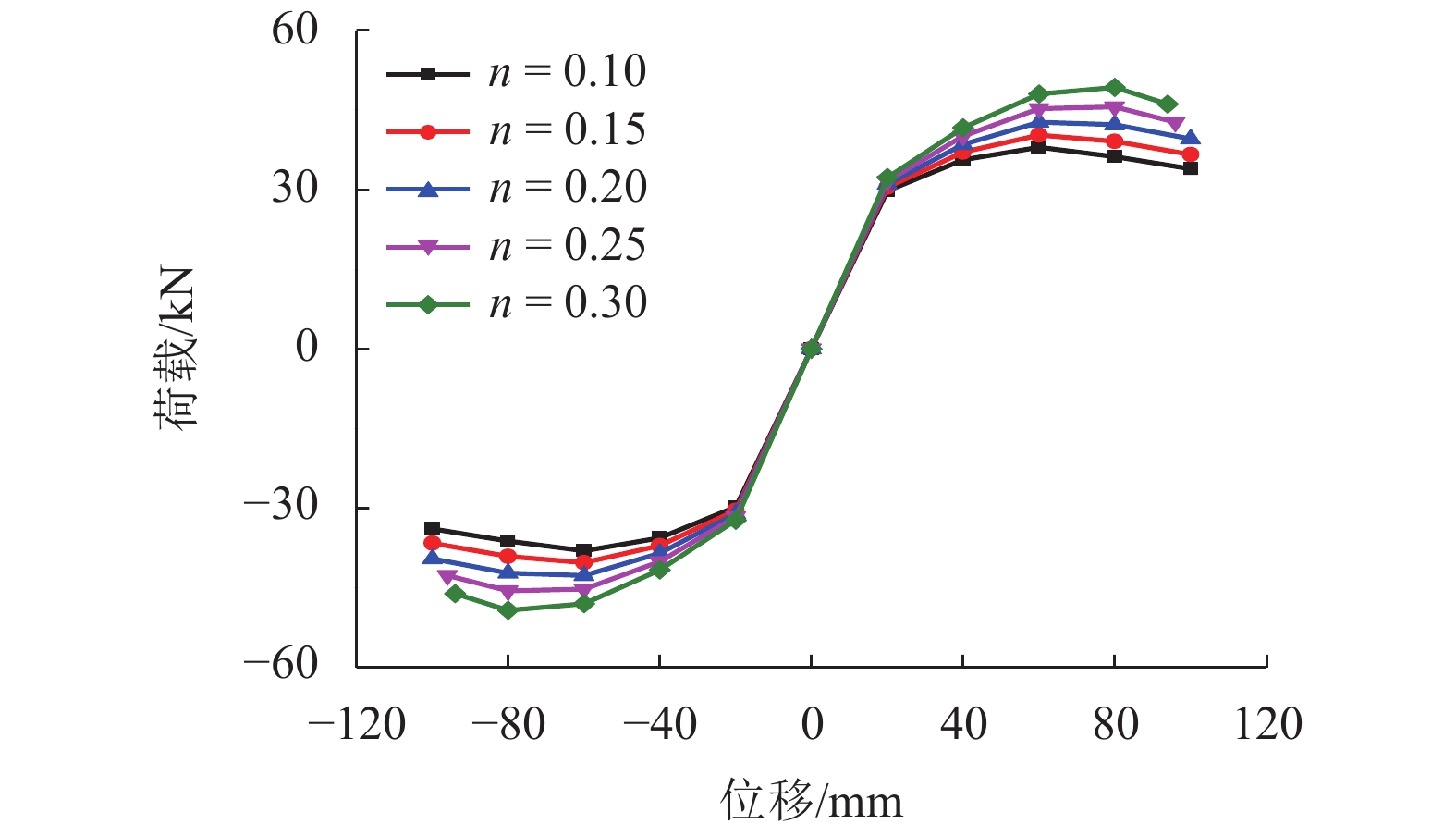

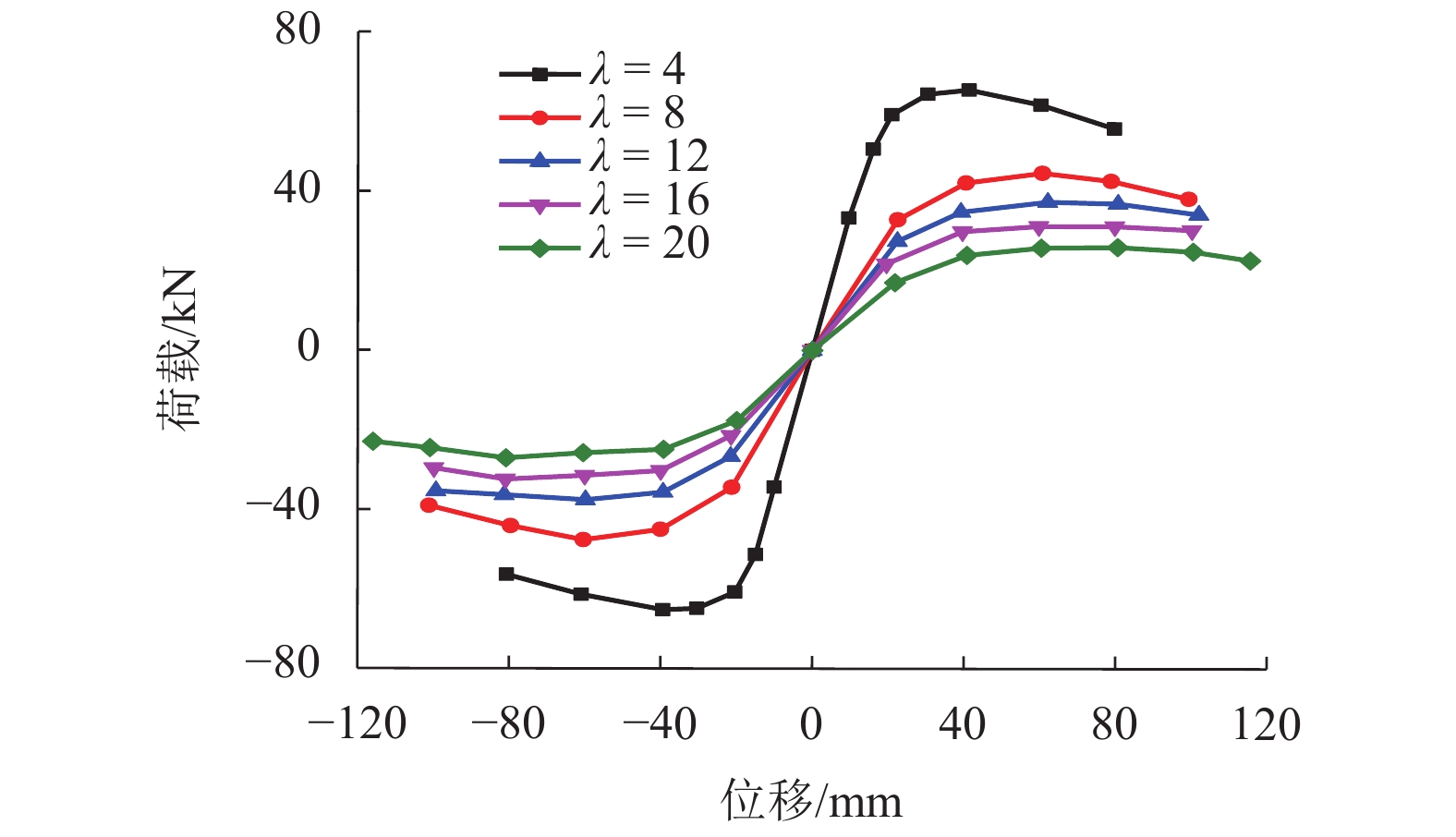

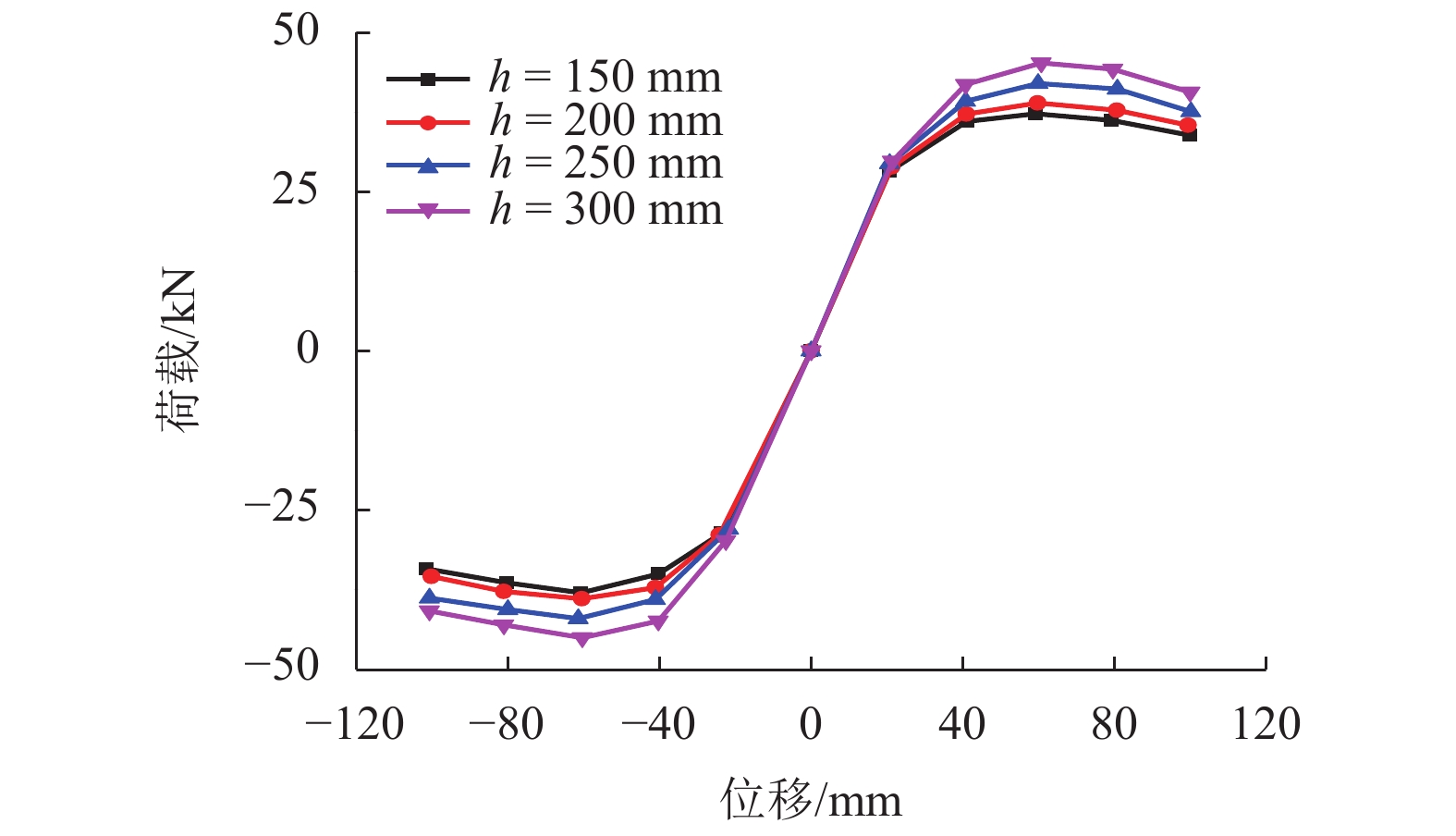

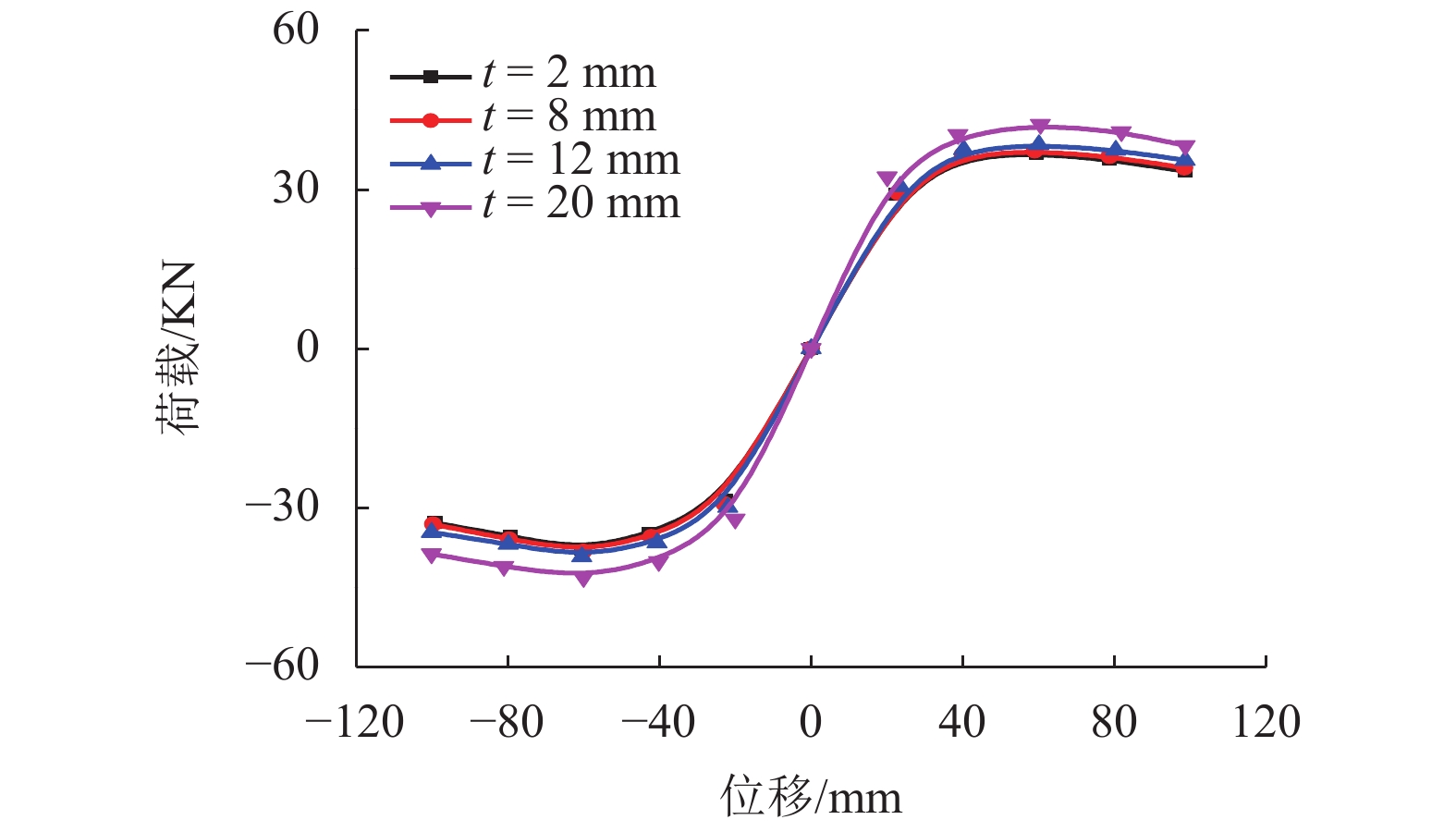

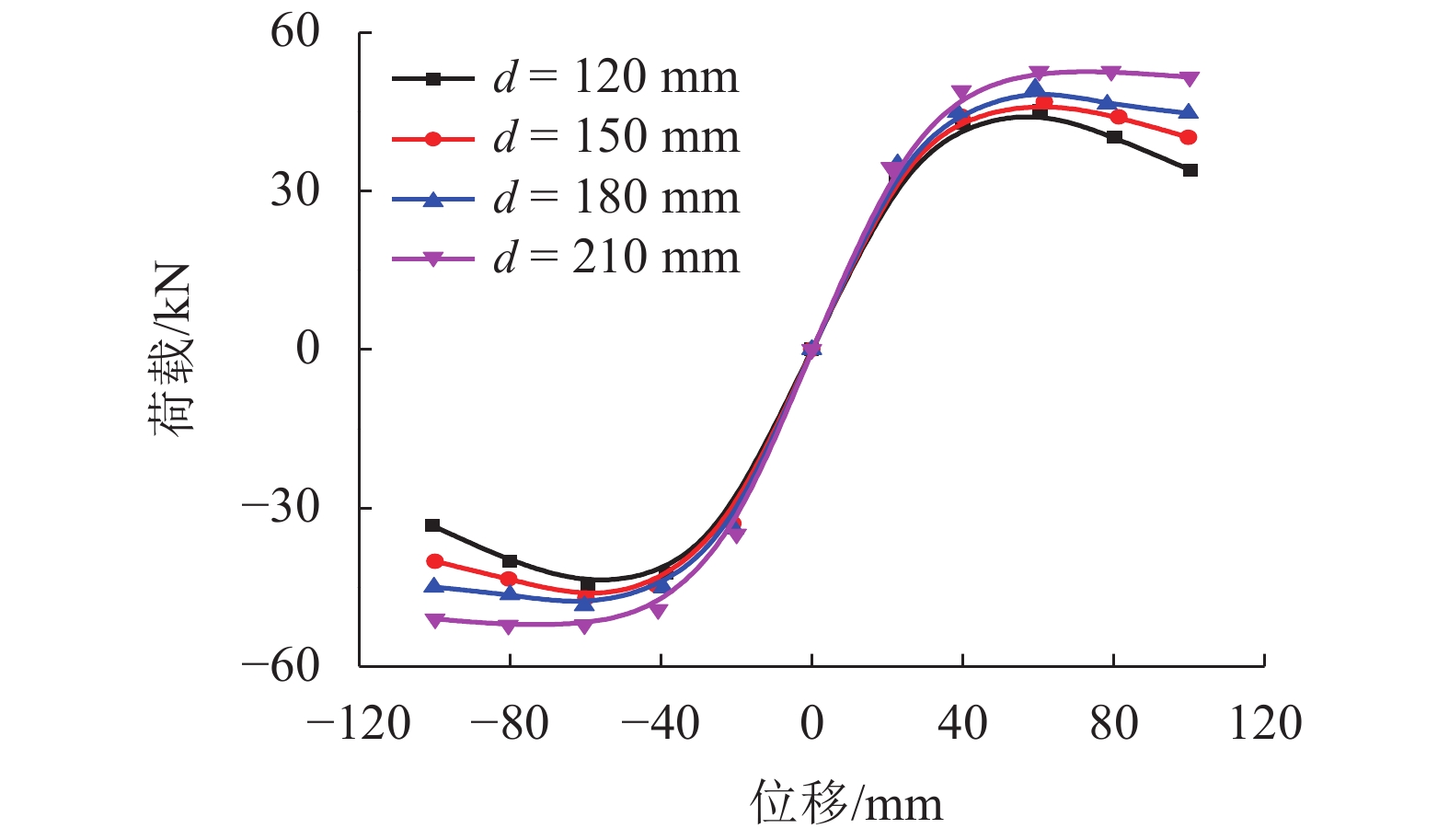

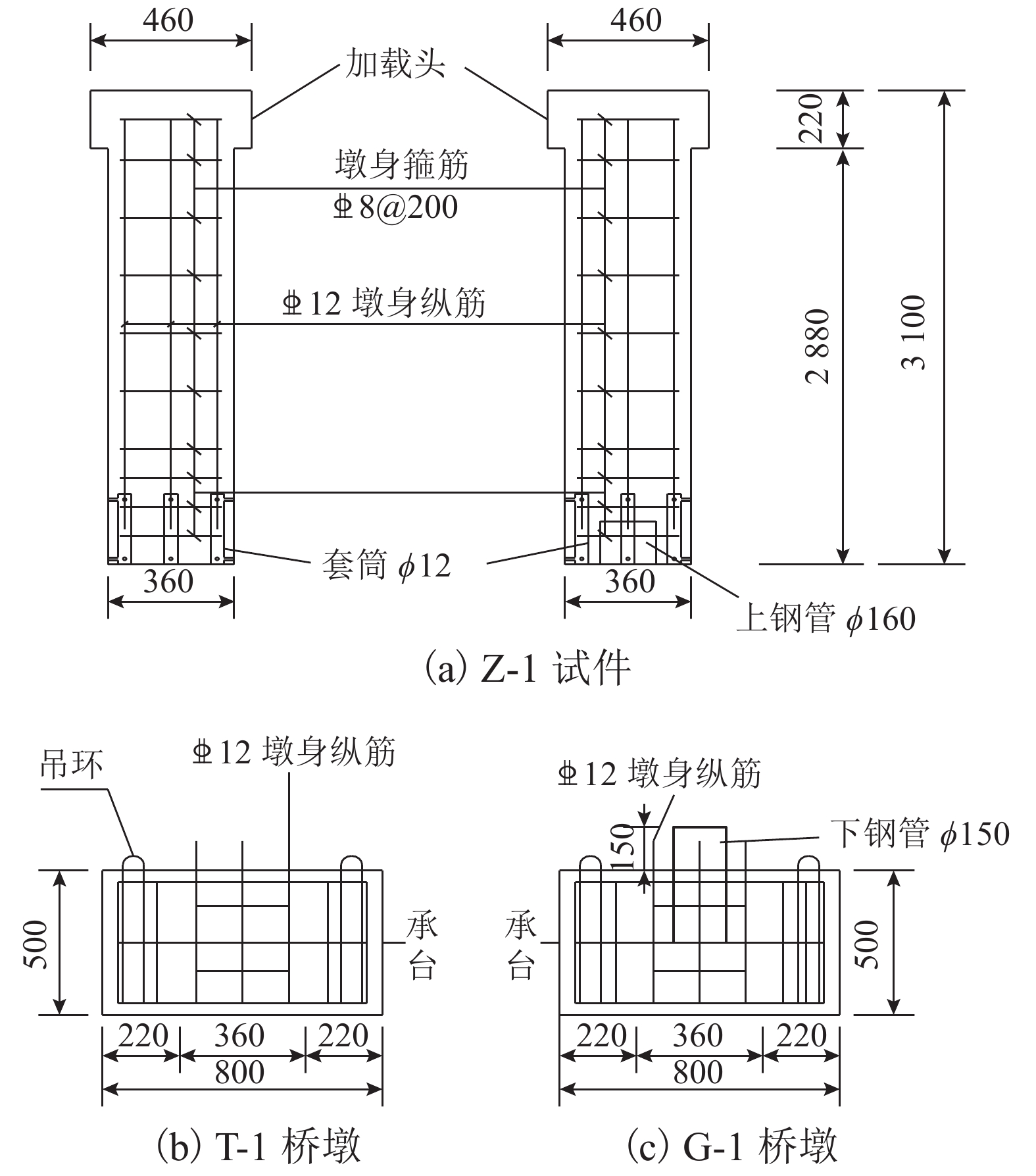

为研究不同连接方式装配式混凝土桥墩的抗震性能,进行了2根装配式混凝土桥墩(连接构造分别为钢管剪力键和灌浆套筒)和1根现浇整体式混凝土桥墩的拟静力试验,分析对比试件的滞回曲线、骨架曲线、延性、刚度退化和耗能能力,采用ABAQUS通用程序建立有限元模型,并开展了有限元参数分析. 研究结果表明:3类桥墩试件水平荷载-位移滞回曲线较饱满,具有良好的抗震性能,均为整体压弯破坏,无明显的强度退化,累积耗能能力相近;在不同轴压比、长细比、混凝土强度和钢筋强度条件下,带钢管剪力键的装配式混凝土桥墩的水平峰值荷载和位移延性系数均优于传统灌浆套筒连接的装配式桥墩,提高幅值分别为4%~32%和8%~36%;轴压比、长细比、钢管剪力键嵌入深度和钢管直径是影响钢管剪力键连接的装配式混凝土桥墩抗震性能的重要参数.

Abstract:In order to study the seismic performance of assembled concrete piers in different connection modes, the quasi-static test of two assembled concrete piers (using steel tube shear connector and grouting sleeve connection, respectively) and a cast-in-place integral concrete pier was conducted, the hysteresis curve, skeleton curve, ductility, stiffness degradation and energy consumption capacity of the comparison test specimens were analyzed, the finite element model was established by ABAQUS general procedure ,and the finite element parameters were analyzed. The results show that the hysteretic loops of the three types of piers are full and have good seismic performance, the failure mode of specimens is integral bending failure, there is no obvious strength degradation, and the piers have similar energy dissipation capabilities. Under the conditions of different axial compression ratio, slenderness ratio, concrete strength and steel strength, the horizontal peak load and displacement ductility coefficients of assembled concrete piers with steel tube shear connector are better than that connected with traditional grouting sleeves, and the increase amplitude is 4%−32% and 8%−36%, respectively. Axial compression ratio, slenderness ratio, embedding depth of steel tube shear connector and steel tube diameter are important parameters that affect the seismic performance of assembled concrete piers connected by steel tube shear connector.

-

Key words:

- prefabricated pier /

- steel tube shear connector /

- quasi-static /

- seismic performance /

- skeleton curve

-

表 1 材料性能参数

Table 1. Mechanical property parameters of material

材料类型 弹性模

量/MPa屈服强度/MPa 极限强

度/MPa泊松比 C40 混凝土 32500 44.2 灌浆料 38600 121.8 HRB400

钢筋206000 424.2 604.3 0.30 钢套筒 206000 202.5 302.1 0.30 钢管 206000 365.0 433.5 0.29 表 2 骨架曲线主要参数对比

Table 2. Comparison of main parameters of skeleton curves

试件 Py/kN Δy/mm Pmax/kN Pu/kN Δu/mm µu Z-1 23.74 9.42 39.60 33.66 88.82 9.43 T-1 20.07 9.34 34.20 29.07 94.06 10.07 G-1 23.29 9.35 39.50 33.58 100.00 10.70 注:Py为屈服荷载;Δy为屈服位移;Pmax为水平峰值荷载;Pu为极限荷载;Δu为极限位移;µu为位移延性系数. 表 3 骨架曲线特征值对比

Table 3. Comparison of skeleton curve characteristics

试件

编号弹性刚度 屈服荷载 峰值荷载 峰值荷载位移 下降段刚度 试验/

(kN•mm−1)模拟/

(kN•mm−1)误差/

%试验/

kN模拟/

kN误差/

%试验/

kN模拟/

kN误差/

%试验/

mm模拟/

mm误差/

%试验/

(kN•mm−1)模拟/

(kN•mm−1)误差/

%Z-1 2.47 2.37 −4.20 23.74 25.20 5.80 39.60 41.69 5.00 40.01 39.95 −0.20 −0.17 −0.16 −6.30 T-1 2.15 2.19 1.80 18.07 19.34 6.60 34.20 35.67 4.10 50.00 50.10 0.20 −0.14 −0.13 −7.70 G-1 2.41 2.49 3.20 23.29 24.15 3.60 39.50 40.67 2.90 49.20 48.63 −1.20 −0.98 −0.96 2.10 -

[1] 陈建华. 城市高架桥结构方案关键因素分析及发展构[J]. 桥梁建设,2013,43(4): 99-104.CHEN Jianhua. Critical factor analysis and development conceiving of structural schemes for urban viaducts[J]. Bridge Construction, 2013, 43(4): 99-104. [2] 曹兵,陈俊达,杜怡韩,等. 装配式圆钢管约束混凝土柱的轴压性能[J]. 西南交通大学学报,2020,55(5): 1017-1027.CAO Bing, CHEN Junda, DU Yihan, et al. Axial compressive properties of prefabricated circular steel tube confined concrete columns [J]. Journal of Southwest Jiaotong University, 2020, 55(5): 1017-1027. [3] CORY R B, FIORE S J D, KELLY D J, et al. Design and fabrication of precast segmental concrete foundations in the US and erection in the remote arctic[C]//Structures Congress 2013. Pittsburgh: [s.n.], 2013: 991-1001. [4] MO Y L, WONG D C, MAEKAWA K. Seismic performance of hollow bridge columns[J]. ACI Structural Journal, 2003, 100(3): 337-348. [5] 黄宜. 单节段装配式桥墩抗震性能试验研究[J]. 大连理工大学学报,2016,56(5): 481-487. doi: 10.7511/dllgxb201605007HUANG Yi. Experimental study on seismic performance of single segmental precast bridge piers[J]. Journal of Dalian University of Technology, 2016, 56(5): 481-487. doi: 10.7511/dllgxb201605007 [6] 杜青,高松松,卿龙邦. 内嵌钢管预应力装配式桥墩抗震性能研究[J]. 重庆交通大学学报(自然科学版),2017,36(9): 6-11. doi: 10.3969/j.issn.1674-0696.2017.09.02DU Qing, GAO Songsong, QING Longbang. Study on Seismic behavior of prestressed prefabricated bridge piers with embedded steel tubes[J]. Journal of Chongqing Jiaotong University (Natural Science), 2017, 36(9): 6-11. doi: 10.3969/j.issn.1674-0696.2017.09.02 [7] 葛继平,夏樟华,江恒. 灌浆波纹管装配式桥墩双向拟静力试验[J]. 中国公路学报,2018,31(12): 221-230,266. doi: 10.3969/j.issn.1001-7372.2018.12.022GE Jiping, XIA Zhanghua, JIANG Heng. Two-way quasi-static test of grouted bellows assembled bridge piers[J]. China Journal of Highway and Transport, 2018, 31(12): 221-230,266. doi: 10.3969/j.issn.1001-7372.2018.12.022 [8] ELSAYED M, NEHDI M L. Experimental and analytical study on grouted duct connections in precast concrete construction[J]. Materials and Structures, 2017, 50(4): 198-212. [9] HENIN E, MORCOUS G. Non-proprietary bar splice sleeve for precast concrete construction[J]. Engineering Structures, 2015, 83: 154-162. [10] 葛继平,闫兴非,王志强. 灌浆套筒和预应力筋连接的预制拼装桥墩的抗震性能[J]. 交通运输工程学报,2018,18(2): 42-52. doi: 10.3969/j.issn.1671-1637.2018.02.005GE Jiping, YAN Xingfei, WANG Zhiqiang. Seismic behavior of prefabricated bridge piers connected by grouting sleeve and prestressed tendons[J]. Journal of Traffic and Transportation Engineering, 2018, 18(2): 42-52. doi: 10.3969/j.issn.1671-1637.2018.02.005 [11] 李田田. 城市高架节段拼装桥墩构造及抗震性能研究[D]. 上海: 同济大学, 2013. [12] 中华人民共和国住房和城乡建设部. 钢管混凝土结构技术规范: GB 50936—2014[S]. 北京: 中国建筑工业出版社, 2014. [13] CHANG G A,MANDER J B. Seismic energy based fatigue damage analysis of bridge columns: part II−evaluation of seismic demand[M]. New York: [s.n.], 1994: 1-194. [14] MENEGOTTO M, PINTO P E. Method of analysis for cyclically loaded reinforced concrete plane frames including changes in geometry and non-elastic behavior of elements under combined normal force and bending[C]//Resistance and Ultimate Deformability of Structures Acted on by Well Defined Repeated Loads. Lisbon: [s.n.], 1973: 15-22. -

下载:

下载: