Carbonation Resistance of Fly Ash-Slag Based Geopolymer Concrete

-

摘要:

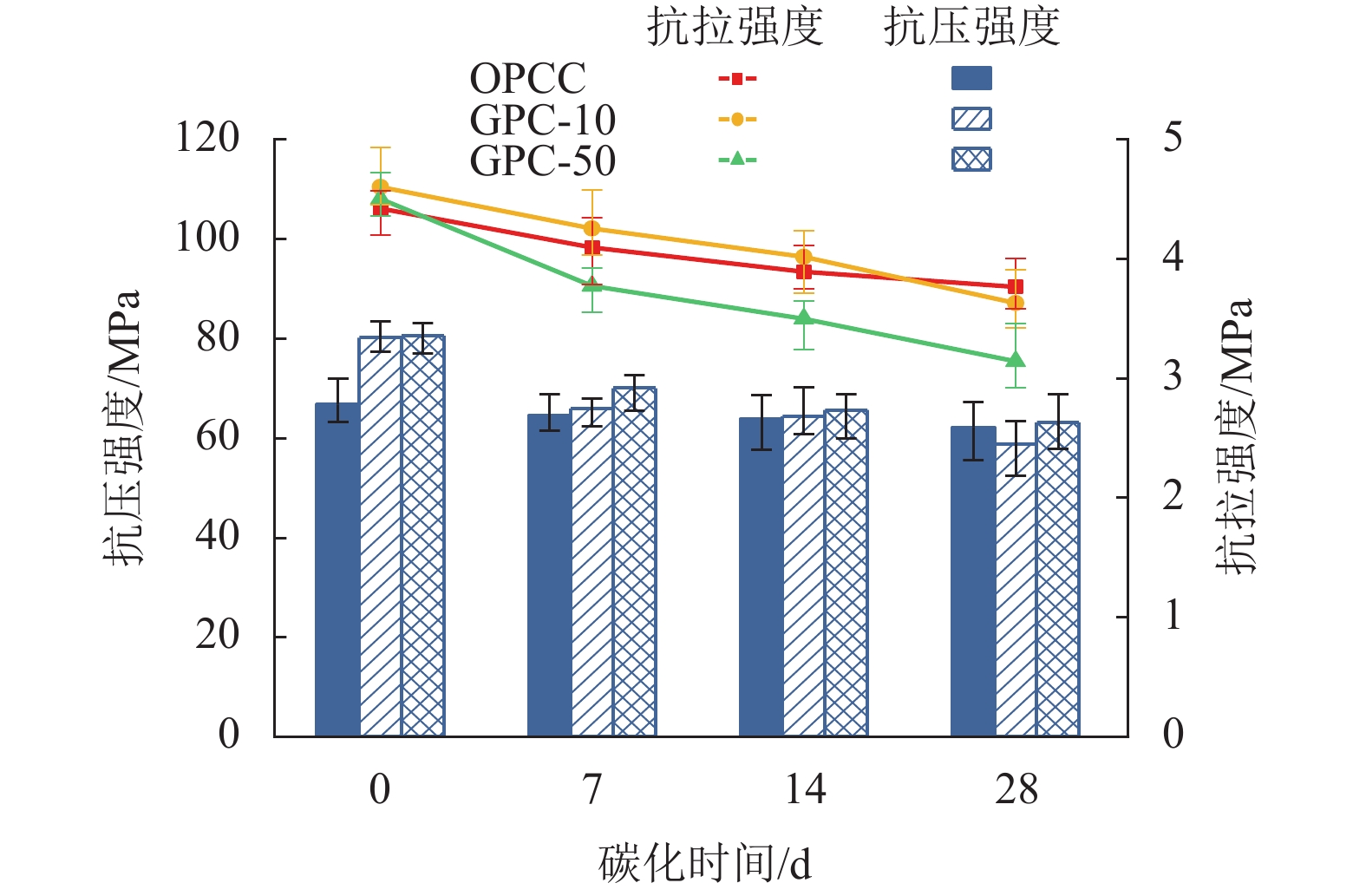

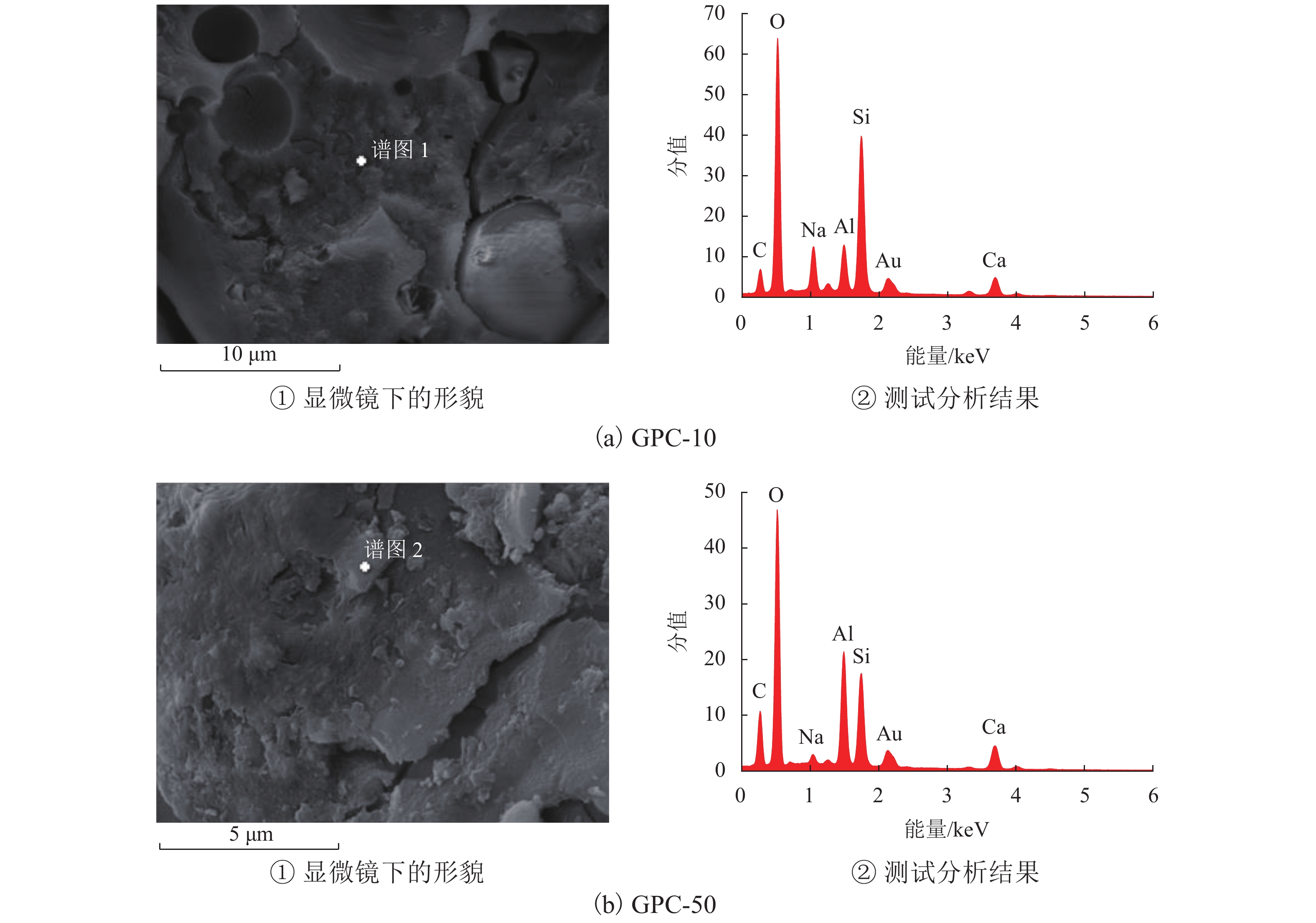

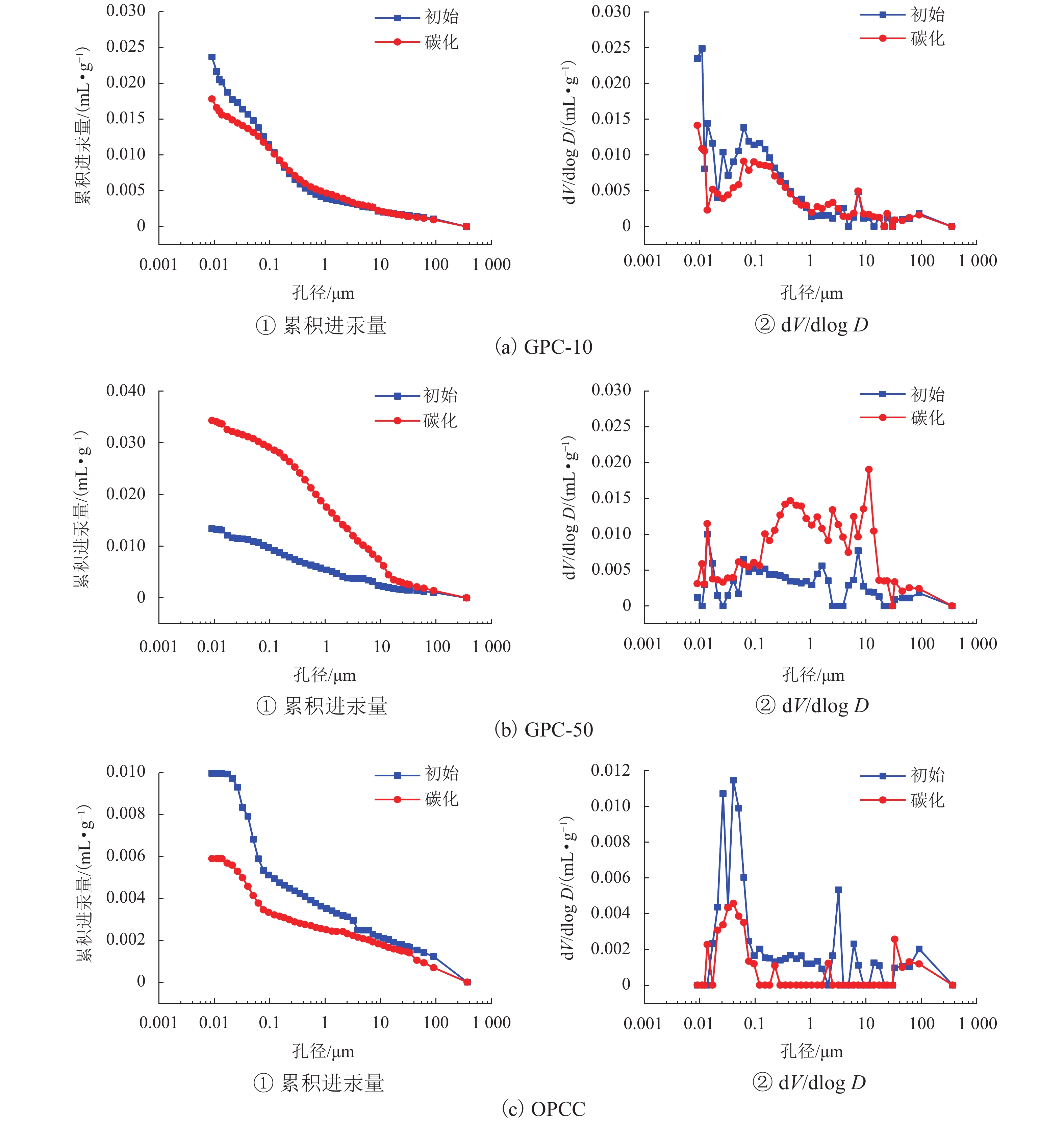

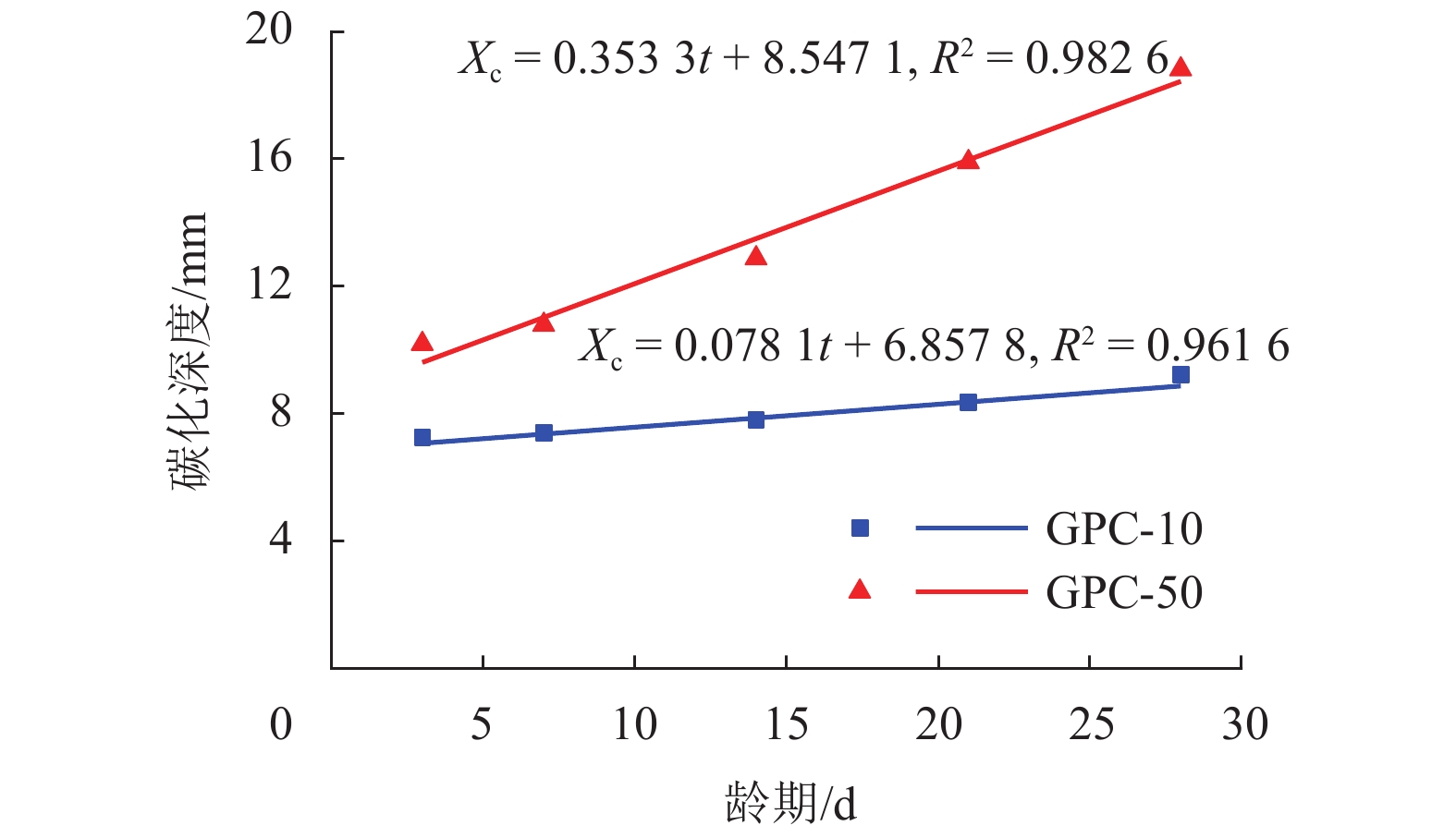

F级粉煤灰-矿渣基地聚物混凝土,即GPC-10(矿渣掺量10%,80 °C高温养护)和GPC-50(矿渣掺量50%,标准养护)力学性能良好,为进一步研究其抗碳化性能, 首先,对这两种地聚物混凝土进行了快速碳化试验,并与作为对照组的普通水泥混凝土(OPCC)进行了比较,通过抗压强度和劈裂抗拉强度评价了碳化对混凝土的损伤;其次,为分析损伤原因,分别通过X射线能谱分析(EDS)和压汞测试(MIP),对碳化后的成分和孔结构进行了研究;最后,建立了两种地聚物混凝土的碳化模型. 研究结果表明:相比OPCC,地聚物混凝土的抗碳化能力薄弱,尤其是钙含量较高的GPC-50,其主要产物C—A—S—H会与CO2反应而发生分解,导致孔隙率增大,进而加快了碳化速率,且碳化深度与时间呈线性关系;OPCC、GPC-10以及GPC-50的28 d碳化深度分别达到了2.0、9.2、18.8 mm.

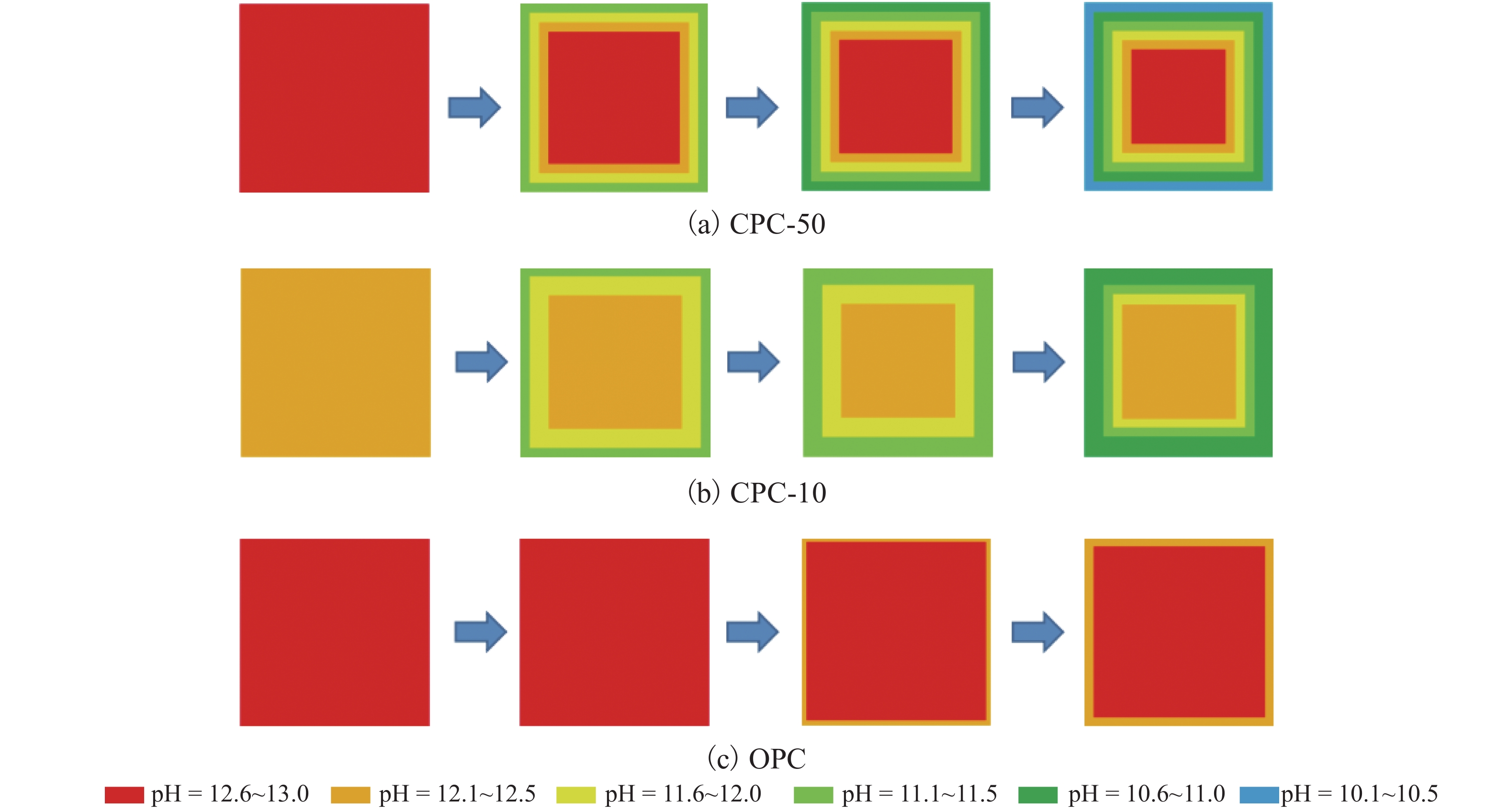

Abstract:Two kinds of Class F fly ash-slag based geopolymer concrete, namely GPC-10 (10% slag content, 80 °C high-temperature curing) and GPC-50 (50% slag content, standard curing), are characterized by good mechanical properties. To understand better their carbonation resistance, rapid carbonation tests were carried out on the two kinds of geopolymer concrete in comparison with the ordinary Portland cement concrete (OPCC). The damage of concrete was evaluated in terms of compressive strength and splitting tensile strength. To analyze the damage cause, the composition and pore structure of the carbonized materials were investigated using X-ray energy spectroscopy (EDS) and mercury intrusion test (MIP), respectively. On this basis, carbonation models of the two kinds of concrete were established. The results show that compared with the OPCC, the geopolymer concrete has a weak carbonation resistance, especially for GPC-50, the type with high calcium content, in which the main product C—A—S—H was decomposed during carbonation, leading to an increase in porosity and thus accelerating the carbonation rate, and the carbonation depth has a linear relation with time. The 28 d carbonization depth of OPCC, GPC-10 and GPC-50 reached 2.0, 9.2 and 18.8 mm, respectively.

-

Key words:

- class F fly ash /

- slag /

- geopolymer concrete /

- rapid carbonation test /

- pore structure /

- carbonation models

-

表 1 粉煤灰、矿渣及水泥化学成分

Table 1. Compositions ratios of fly ash,slag and cement

% 类型 SiO2 Al2O3 Fe2O3 CaO P2O5 Na2O K2O MnO MgO SO3 Tio2 SrO 粉煤灰 62.04 25.5 4.28 3.96 0.31 0.46 1.27 0.73 1.33 0.12 矿渣 34.11 15.36 0.83 35.99 0.40 0.62 1.07 6.58 2.50 2.41 0.12 水泥 20.01 5.68 3.20 65.89 0.08 0.09 1.17 0.19 0.81 2.00 表 2 混凝土配合比设计

Table 2. Mix proportion design and numbering of the concrete specimens

kg/m3 编号 粉煤灰 炉渣 水泥 沙 砾石 Na2SiO3 NaOH 水 减水剂 养护条件 GPC-10 346.7 38.5 601.7 1203.5 165.7 66.2 80 ℃ sealed GPC-50 192.6 192.6 601.7 1203.5 165.7 66.2 标准 OPCC 56.0 56.0 448.0 626.0 1022.0 174.7 2.5 标准 表 3 碳化对混凝土力学性能的影响

Table 3. Effect of carbonation on mechanical properties of concrete

编号 3 d 7 d 14 d 21 d 28 d GPC-50

GPC-10

OPCC

表 4 原子相对数量

Table 4. Relative number of atoms

% 编号 O C Si Al Na Ca Ca/Na Si/Al GPC-10 59.80 18.10 11.80 3.30 3.90 3.10 0.79 3.60 GPC-50 54.10 29.40 5.80 6.50 0.70 3.40 4.80 0.89 -

[1] 阿列克谢耶夫. 钢筋混凝土结构中钢筋腐蚀与保护[M]. 黄可信, 吴兴祖, 蒋仁敏, 等译. 北京: 中国建筑工业出版社, 1983: 19-35. [2] 金伟良, 赵羽习. 混凝土结构耐久性[M]. 北京: 科学出版社, 2002: 16-25. [3] MARQUES P F, CARLOS C, NUNES A. Carbonation service life modelling of RC structures for concrete with Portland and blended cements[J]. Cement and Concrete Composites, 2013, 37(3): 171-184. [4] JUENGER M C G, WINNEFELD F, PROVIS J L, et al. Advances in alternative cementitious binders[J]. Cement and Concrete Research, 2011, 41(12): 1232-1243. doi: 10.1016/j.cemconres.2010.11.012 [5] SHI C J, FERNÁNDEZ-JIMÉNEZ A, PALOMO A. New cements for the 21st century:the pursuit of an alternative to Portland cement[J]. Cement and Concrete Research, 2011, 41(7): 750-763. doi: 10.1016/j.cemconres.2011.03.016 [6] TENNAKOON C, SHAYAN A, SANJAYAN J G, et al. Chloride ingress and steel corrosion in geopolymer concrete based on long term tests[J]. Materials and Design, 2017, 116: 287-299. doi: 10.1016/j.matdes.2016.12.030 [7] BAKHAREV T. Resistance of geopolymer materials to acid attack[J]. Cement and Concrete Research, 2005, 32(4): 658-670. [8] BAKHAREV T. Durability of geopolymer materials in sodium and magnesium sulfate solutions[J]. Cement and Concrete Research, 2005, 35(6): 1233-1246. doi: 10.1016/j.cemconres.2004.09.002 [9] ZHUANG X Y, CHEN L, KOMARNENI S, et al. Fly ash-based geopolymer:clean production,properties and applications[J]. Journal of Cleaner Production, 2016, 125: 253-267. doi: 10.1016/j.jclepro.2016.03.019 [10] ZHANG J, SHI C J, ZHANG Z H, et al. Durability of alkali-activated materials in aggressive environments:a review on recent studies[J]. Construction and Building Materials, 2017, 152(2): 598-613. doi: 10.1016/j.conbuildmat.2017.07.027 [11] BERNAL S A, PROVIS J L, WALKLEY B, et al. Gel nanostructure in alkali-activated binders based on slag and fly ash,and effects of accelerated carbonation[J]. Cement and Concrete Research, 2013, 53: 127-144. doi: 10.1016/j.cemconres.2013.06.007 [12] LAW D W, ADAM A A, MOLYNEAUX T K, et al. Long term durability properties of class F fly ash geopolymer concrete[J]. Materials and Structures, 2015, 48(3): 721-731. doi: 10.1617/s11527-014-0268-9 [13] BAKHAREV T, SANJAYAN J G, CHENG Y B. Resistance of alkali-activated slag concrete to carbonation[J]. Cement and Concrete Research, 2001, 31(9): 1277-1283. doi: 10.1016/S0008-8846(01)00574-9 [14] BADAR M S, KUPWADE-PATIL K, BERNAL S A, et al. Corrosion of steel bars induced by accelerated carbonation in low and high calcium fly ash geopolymer concretes[J]. Construction and Building Materials, 2014, 61: 79-89. doi: 10.1016/j.conbuildmat.2014.03.015 [15] PASUPATHY K, BERNDT M, CASTEL A, et al. Carbonation of a blended slag-fly ash geopolymer concrete in field conditions after 8 years[J]. Construction and Building Materials, 2016, 125: 661-669. doi: 10.1016/j.conbuildmat.2016.08.078 [16] CRIADO M, PALOMO A, FERNÁNDEZ-JIMÉNEZ A. Alkali activation of fly ashes. part 1:effect of curing conditions on the carbonation of the reaction products[J]. Fuel, 2005, 84(16): 2048-2054. doi: 10.1016/j.fuel.2005.03.030 [17] 黄琪,石宵爽,王清远,等. 粉煤灰基地聚物混凝土的碳化性能研究[J]. 中国农村水利水电,2015(7): 121-125,130. doi: 10.3969/j.issn.1007-2284.2015.07.031HUANG Qi, SHI Xiaoshuang, WANG Qingyuan, et al. Research on carbonation of fly ash geopolymeric concrete[J]. China Rural Water and Hydropower, 2015(7): 121-125,130. doi: 10.3969/j.issn.1007-2284.2015.07.031 [18] 黄琪,石宵爽,王清远,等. 再生粗骨料对粉煤灰基地聚物混凝土碳化性能的影响[J]. 硅酸盐通报,2015,34(5): 1264-1269,1281.HUANG Qi, SHI Xiaoshuang, WANG Qingyuan, et al. Effect of recycled coarse aggregate on carbonation resistance of fly ash geopolymeric concrete[J]. Bulletin of the Chinese Ceramic Society, 2015, 34(5): 1264-1269,1281. [19] 陈晓星,曹海琳,翁履谦,等. 碱激发水泥砂浆碳化行为研究[J]. 武汉理工大学学报,2014,36(3): 18-22.CHEN Xiaoxing, CAO Hailin, WENG Lvqian, et al. Research on carbonation process of alkali-activated cement mortars[J]. Journal of Wuhan University of Technology, 2014, 36(3): 18-22. [20] 贺鹏飞. 混凝土碳化研究进展[C]//《工业建筑》2018年全国学术年会论文集(上册). 北京: 工业建筑杂志社, 2018: 316-321. [21] KUMAR S S, VASUGI J, AMBILY P S, et al. Development and determination of mechanical properties of fly ash and slag blended geopolymer concrete[J]. International Journal of Scientific and Engineering Research, 2013, 4(8): 1-5. [22] NATH P, SARKER P K. Effect of GGBFS on setting,workability and early strength properties of fly ash geopolymer concrete cured in ambient condition[J]. Construction and Building Materials, 2014, 66: 163-171. doi: 10.1016/j.conbuildmat.2014.05.080 [23] 杨世玉,赵人达,靳贺松,等. 单组分地聚物砂浆的力学性能和微观结构分析[J]. 西南交通大学学报,2021,56(1): 101-107.YANG Shiyu, ZHAO Renda, JIN Hesong, et al. Mechanical performance and microstructure of single component geopolymer mortar[J]. Journal of Southwest Jiaotong University, 2021, 56(1): 101-107. [24] ZHANG H E, SHI X S, WANG Q Y. Effect of curing condition on compressive strength of fly ash geopolymer concrete[J]. ACI Materials Journal, 2018, 115(2): 191-196. [25] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009. [26] 中华人民共和国建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003. [27] BAKHAREV T. Geopolymeric materials prepared using class F fly ash and elevated temperature curing[J]. Cement and Concrete Research, 2004, 35(6): 1224-1232. [28] ZHAO R D, YUAN Y, CHENG Z Q, et al. Freeze-thaw resistance of class F fly ash-based geopolymer concrete[J]. Construction and Building Materials, 2019, 222(3): 474-483. doi: 10.1016/j.conbuildmat.2019.06.166 [29] 杨绿峰,成荻,刘才勇,等. 矿物掺合料混凝土碳化分析的实用预测模型[J]. 混凝土,2016(7): 79-83. doi: 10.3969/j.issn.1002-3550.2016.07.019YANG Lufeng, CHENG Di, LIU Caiyong, et al. Practical prediction model of carbonation depth for concrete with mineral admixtures[J]. Concrete, 2016(7): 79-83. doi: 10.3969/j.issn.1002-3550.2016.07.019 [30] SAETTA A V, VITALIANI R V. Experimental investigation and numerical modeling of carbonation process in reinforced concrete structures part I:theoretical formulation[J]. Cement and Concrete Research, 2004, 34(4): 571-579. doi: 10.1016/j.cemconres.2003.09.009 -

下载:

下载: