Master-Slave Interpolation Modeling of Compressor Healthy Parameters Based on Kriging Algorithm

-

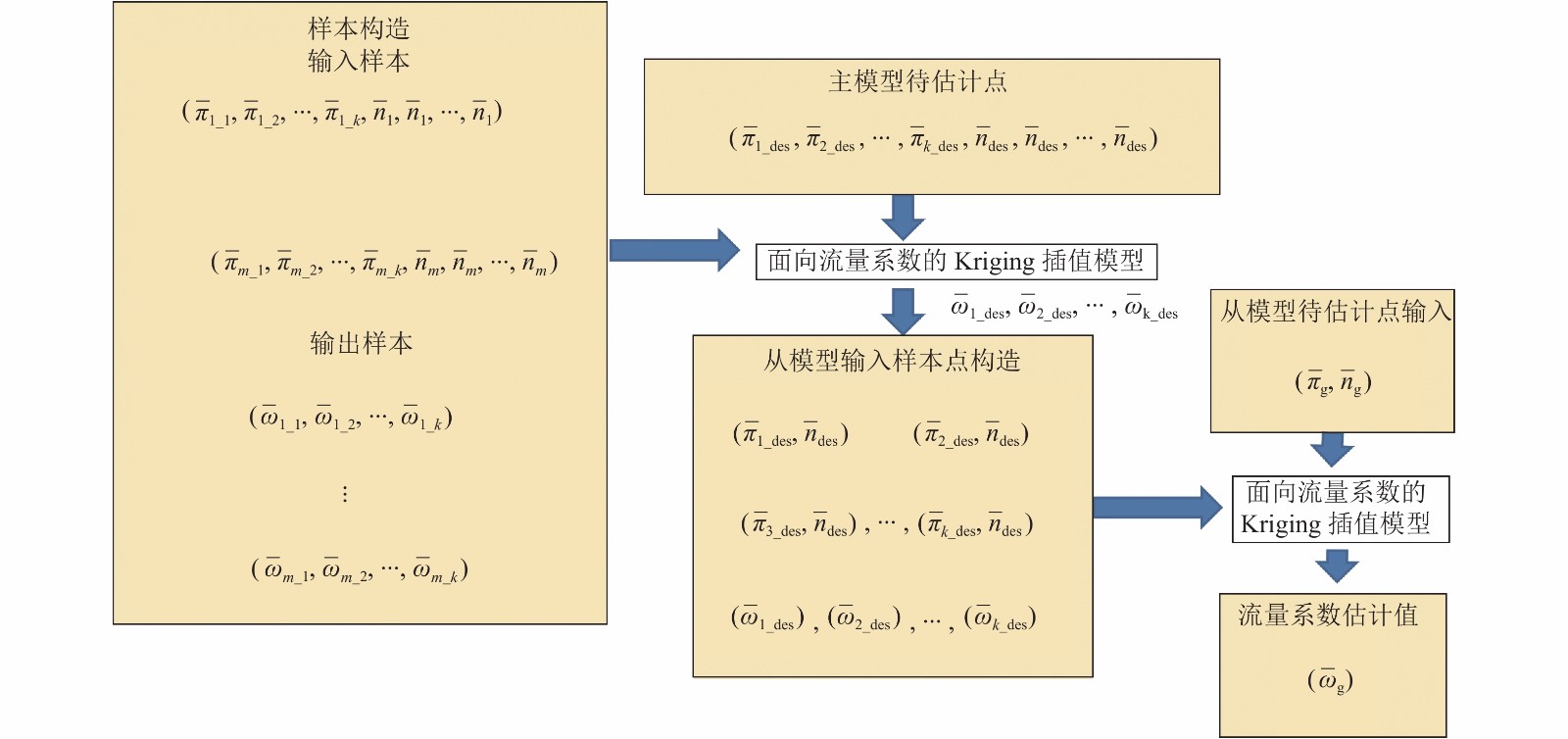

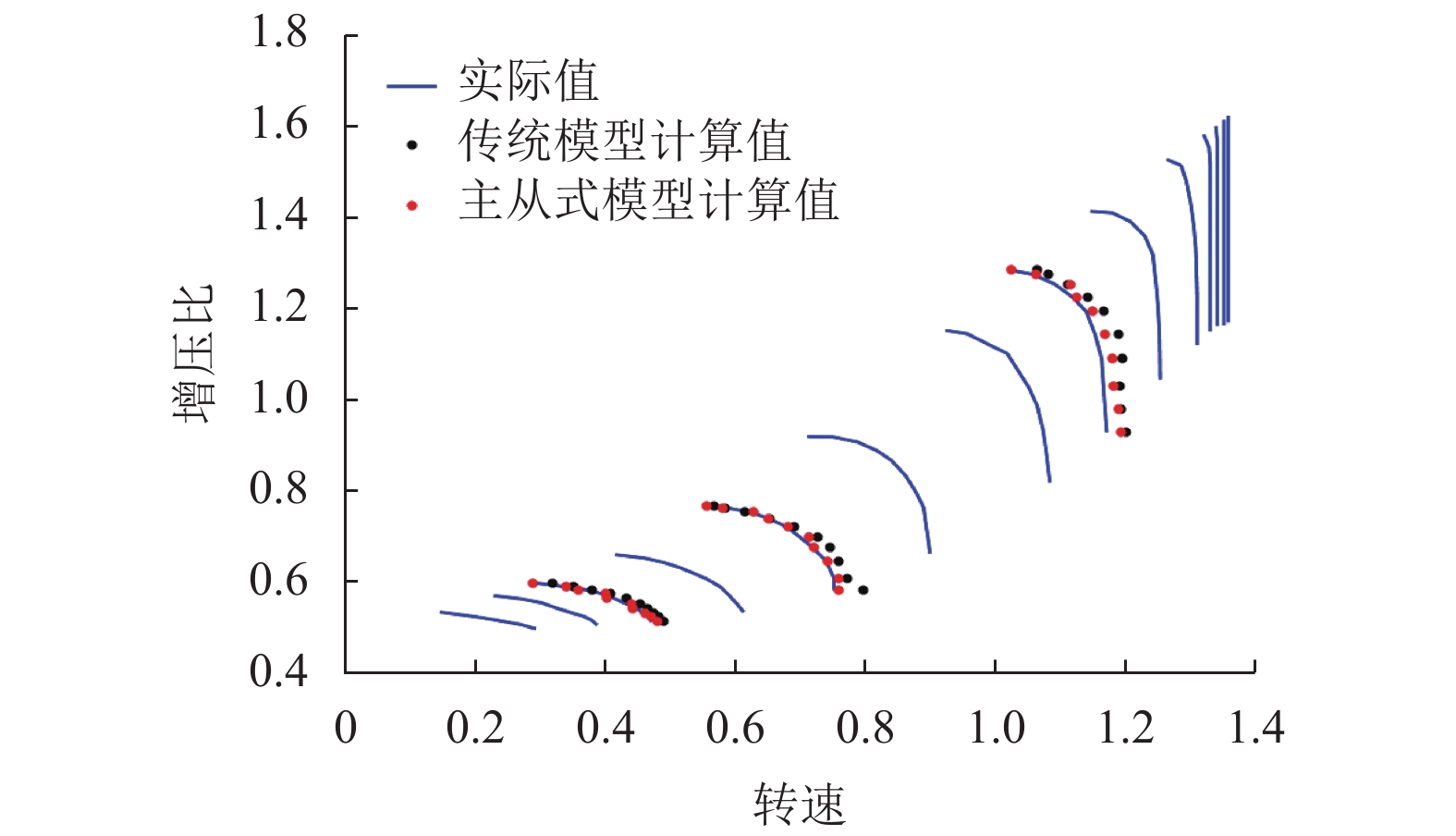

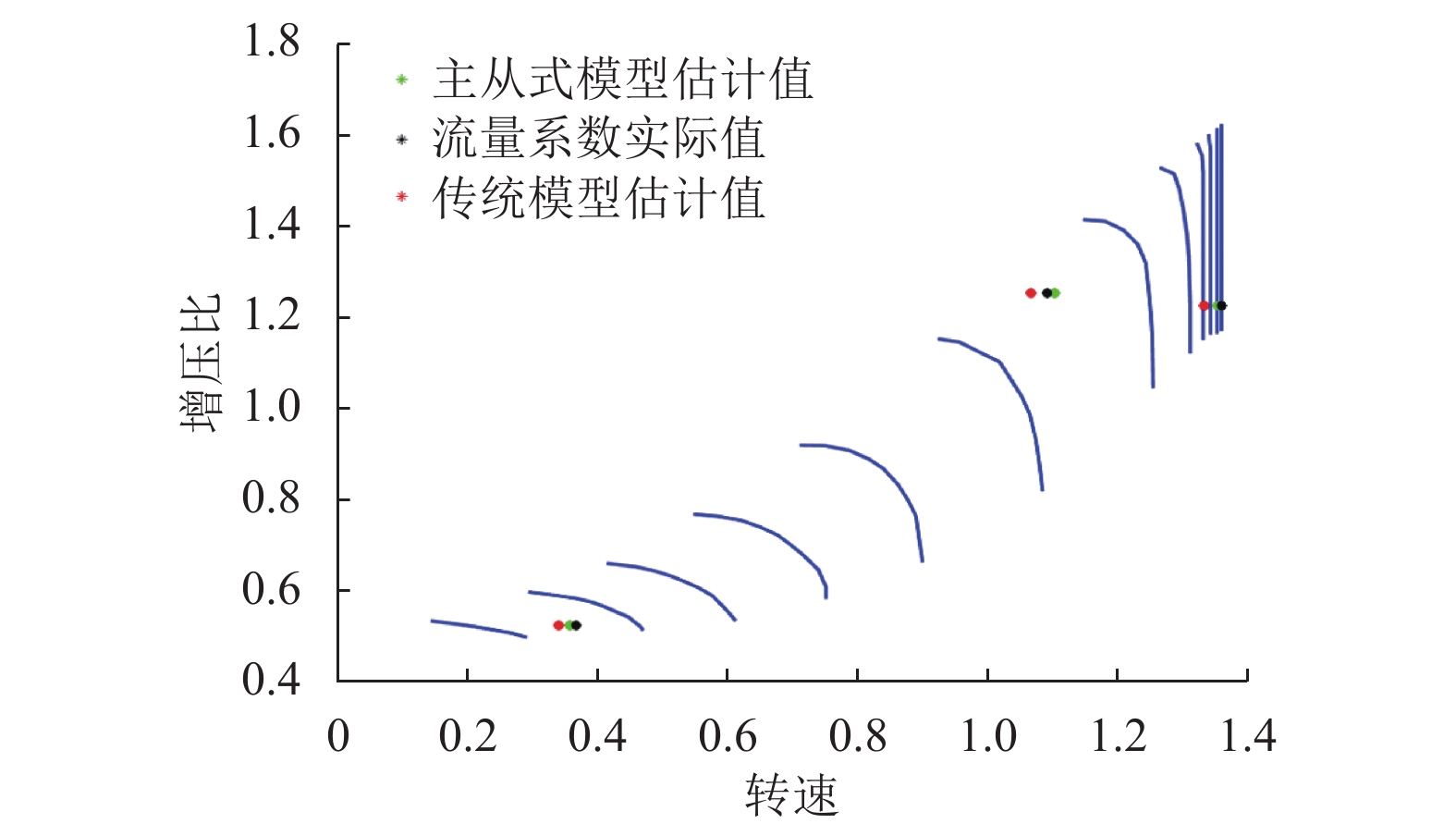

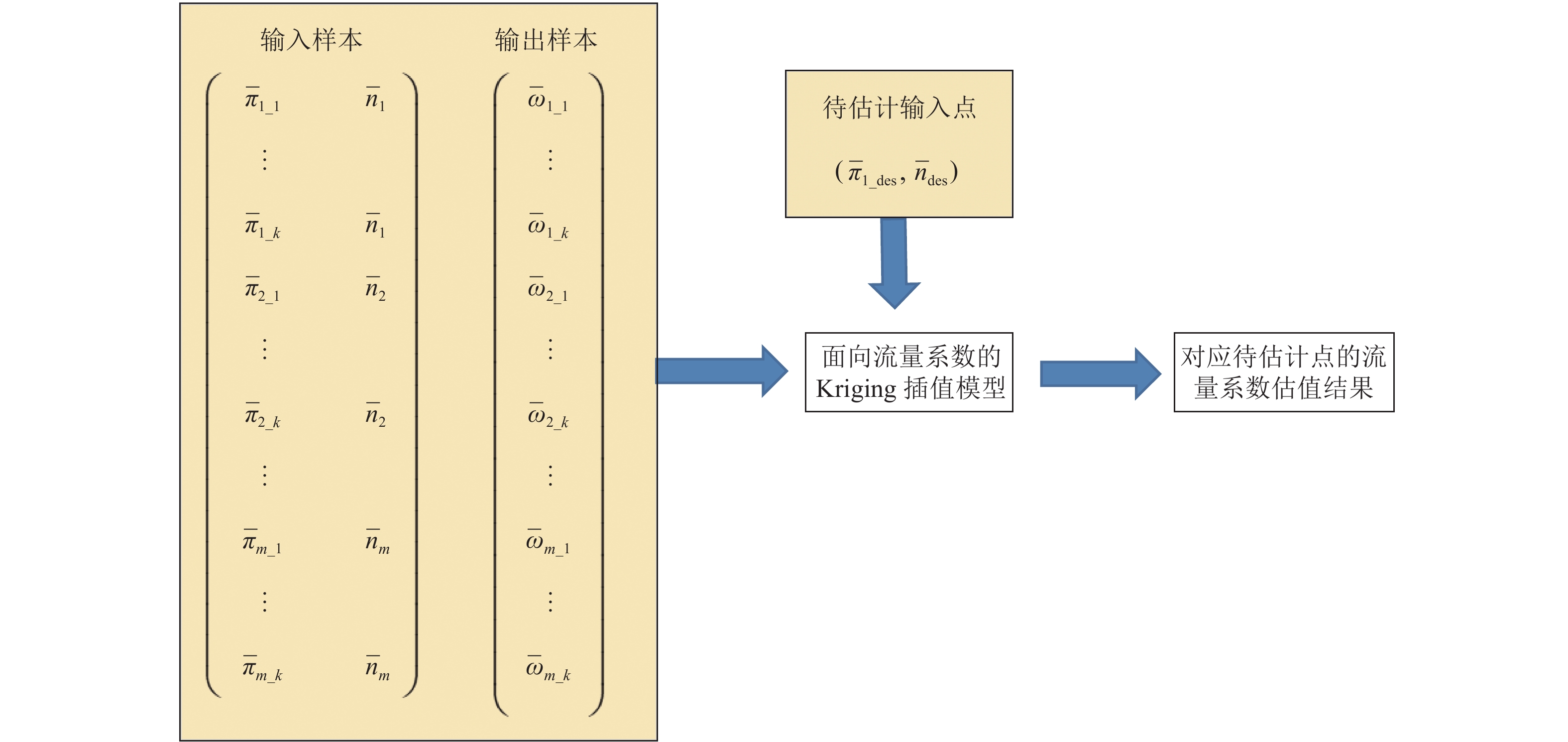

摘要: 针对航空燃气轮机压气机数字化建模过程中由于缺少压气机流量系数导致模型精度偏低的问题,基于Kriging插值算法构造了面向压气机流量系数估计的主从式建模方法,分析了高维空间下对应于不同压气机换算转速的流量系数分布特征;基于流量系数的特征提取方法探索了流量系数、换算转速、增压比之间的映射关系,并提出了关于这三类参数的多维样本向量构造方法;基于Kriging算法建立了适用于燃气轮机过渡工况下压气机流量系数主从式插值模型. 研究结果表明:与传统的Kriging插值方法及牛顿插值法相比,基于主从式模型的流量系数计算结果更接近实际值,计算精度提高了近10%;主模型可输出流量系数的估值向量,插值效率相比传统Kriging模型提高了近15%.Abstract: In order to solve the problem that the accuracy of the model is low due to the lack of compressor flow coefficient in the process of digital modeling of gas turbine compressor, a master-slave interpolation model for flow coefficient is constructed based on the Kriging interpolation algorithm. The distribution characteristics of flow coefficient in high-dimensional space are studied. The mapping relationship among flow coefficient, conversion speed and pressure ratio are explored, and a high-dimensional sample construction method for these three parameters is proposed. A high-precision flow coefficient master-slave interpolation model of gas turbine under transient conditions is established based on the Kriging algorithm. The results show that compared with the traditional Kriging interpolation method and the Newton interpolation method, the calculation result of flow coefficient based on master-slave model is closer to the actual value, and the calculation accuracy is improved by nearly 10%. In addition, the master model can output the estimated vector. Compared with the traditional Kriging model, the interpolation efficiency is improved by nearly 15%.

-

Key words:

- compressor /

- flow coefficient /

- Kriging algorithm /

- master-slave mode

-

表 1 待估计流量系数

Table 1. Flow coefficients to be estimated

${ {\overline n} _{\rm{des} } }$ ${\overline \pi } _{1\_{\rm{des} } }$ ${\overline \pi } _{2\_{\rm{des} } }$ ${\overline \pi } _{3\_{\rm{des} } }$ ${\overline \pi } _{4\_{\rm{des} } }$ ${\overline \pi } _{5\_{\rm{des} } }$ ${\overline \pi } _{6\_{\rm{des} } }$ ${\overline \pi } _{7\_{\rm{des} } }$ ${\overline \pi } _{8\_{\rm{des} } }$ ${\overline \pi } _{9\_{\rm{des} } }$ ${\overline \pi } _{10\_{\rm{des} } }$ 0.3315 0.600 0 0.593 0 0.586 0 0.577 0 0.5675 0.555 0 0.545 0 0.534 9 0.525 9 0.516 0 0.8478 0.4125 0.409 0 1.390 0 1.3583 1.3178 1.260 0 1.205 0 1.150 0 1.100 0 1.045 0 1.1268 1.620 0 1.577 0 1.532 5 1.485 0 1.4375 1.389 5 1.332 5 1.280 0 1.225 5 1.170 0 表 2 流量系数精度比较

Table 2. Accuracy comparison of flow coefficients

换算

转速传统 Kriging

算法主从插

值模型流量系数

实际值0.331 5 0.302 7 0.296 3 0.296 3 0.333 5 0.343 5 0.336 3 0.359 5 0.372 2 0.369 8 0.386 7 0.396 1 0.395 8 0.408 8 0.421 8 0.413 9 0.430 0 0.438 8 0.433 3 0.442 1 0.451 2 0.450 0 0.451 9 0.457 2 0.458 3 0.459 7 0.462 1 0.466 7 0.468 6 0.469 0 0.472 2 0.847 8 1.146 7 1.140 6 1.144 4 1.150 6 1.181 0 1.177 8 1.171 1 1.203 0 1.205 6 1.201 6 1.223 5 1.227 8 1.232 2 1.239 4 1.240 0 1.257 6 1.248 5 1.244 4 1.263 9 1.254 1 1.247 8 1.259 8 1.254 6 1.250 0 1.254 5 1.254 6 1.250 6 1.253 1 1.256 6 1.251 1 1.126 8 1.365 3 1.355 1 1.355 6 1.3593 1.3551 1.3556 1.3614 1.3552 1.3556 1.3646 1.3552 1.3556 1.3648 1.3553 1.3556 1.3620 1.3553 1.3556 1.3589 1.3553 1.3556 1.3595 1.3553 1.3556 1.3622 1.3553 1.3556 1.3575 1.3553 1.3556 表 3 流量系数目标点估值

Table 3. Estimation of target point of flow coefficients

换算

转速牛顿

插值传统 Kriging

算法主从插值

模型流量系数

实际值0.218 2 0.357 6 0.356 7 0.379 3 0.385 2 0.901 8 1.069 8 1.062 3 1.108 7 1.096 7 1.062 0 1.312 7 1.292 8 1.332 5 1.348 9 -

KULKTLA, RDEDDY P, PRASAD B. Numerical study on the secondary air performance of the film holes for the combined impingement and film cooled first stage of high pressure gas turbine nozzle guide vane[J]. International Journal of Turbo and Jet Engines, 2020, 37(3): 221-240. doi: 10.1515/tjj-2017-0022 谭治学,钟诗胜,林琳. 民航发动机性能诊断方法[J]. 哈尔滨工业大学学报,2019,51(1): 22-26. doi: 10.11918/j.issn.0367-6234.201801117TAN Zhixue, ZHONG Shisheng, LIN Lin. Method for performance diagnosis of commercial aero-engine[J]. Journal of Harbin Institute of Technology, 2019, 51(1): 22-26. doi: 10.11918/j.issn.0367-6234.201801117 潘率诚,李刚团,丁朝霞,等. 基于部件特性的航空发动机性能模型修正[J]. 燃气涡轮试验与研究,2016,29(6): 26-29. doi: 10.3969/j.issn.1672-2620.2016.06.006PAN Shuaicheng, LI Gangtuan, DING Zhaoxia, et al. Aero-engine performance model correction based on component performance map[J]. Gas Turbine Experiment and Research, 2016, 29(6): 26-29. doi: 10.3969/j.issn.1672-2620.2016.06.006 涂环,陈辉. 基于Kriging算法的压气机特性建模[J]. 内燃机学报,2014,32(4): 377-383.TU Huan, CHEN Hui. Modeling of compressor characteristica using Kriging method[J]. Transactions of CSICE, 2014, 32(4): 377-383. 尹大伟,李本威. 基于Kriging方法的航空发动机压气机特性元建模[J]. 航空学报,2011,32(1): 99-106.YIN Dawei, LI Benwei. Aeroengine compressor characteristics metamodeling using Kriging method[J]. Acta Aeronautia et Astronautica Sinica, 2011, 32(1): 99-106. 赵勇,李本威. 基于QPSO算法的压气机特性代理模型优化[J]. 推进技术,2014,35(11): 1538-1543.ZHAO Yong, LI Benwei. Surrogate model optimization of compressor characteristics based on QPSO algorithm[J]. Journal of Propulsion Technology, 2014, 35(11): 1538-1543. GHOLAMREZAEI M, GHORBANIAN K. Compressor map generation using a feed-forward neural network and rig data[J]. Power and Engine, 2009, 224(A): 97-106. MAREK O, SLAWOMIR S. Modeling of turbine engine axial-flow compressor and turbine characteristics[J]. Journal of Propolsion and Power, 2000, 16(2): 336-347. doi: 10.2514/2.5574 柳强,王成恩. 基于Kringing模型的复杂产品管线敷设顺序粒子群优化[J]. 机械工程学报,2011,47(13): 140-145. doi: 10.3901/JME.2011.13.140LIU Qiang, WANG Chengen. Kriging mode-based routing sequence planning for complex products by particle swarm optimization[J]. Journal of Mechanical Engineering, 2011, 47(13): 140-145. doi: 10.3901/JME.2011.13.140 赵海龙,岳珠峰,刘伟. 矩独立重要性分析的Kriging代理模型方法[J]. 航空学报,2016,37(7): 2234-2241.ZHAO Hailong, YUE Zhufeng, LIU Wei. A Kriging surrogatemodel method for moment-independent importanceanalysis[J]. Acta Aeronautics et Astronautica Sinica, 2016, 37(7): 2234-2241. 申静,苏天赟,王国宇. 基于Kriging算法的海底地形插值设计与实现[J]. 海洋科学,2012,36(5): 24-28.SHEN Jing, SU Tianyun, WANG Guoyu. Submarine topography visualization based on Kriging algorithm[J]. Marine Sciences, 2012, 36(5): 24-28. TIMOTHY W S, JOHN J K. Kriging models for global approximation in simulation-based multidisciplinary design optimization[J]. AIAA Journal, 2001, 39(12): 2233-2240. doi: 10.2514/2.1234 杨永存,辛庆伟. 一种基于试验数据的发动机特性曲线拟合[J]. 海军航空工程学院学报,2016,31(3): 312-316. doi: 10.7682/j.issn.1673-1522.2016.03.003YANG Yongcun, XIN Qingwei. A Fitting on engine characteristic map based on text data[J]. Journal of Naval Aeronautical and Astronautical University, 2016, 31(3): 312-316. doi: 10.7682/j.issn.1673-1522.2016.03.003 宋文艳,孟乒乒,柴政. 基于飞机/发动机性能一体化的发动机控制规律优化设计方法研究[J]. 推进技术,2018,39(12): 2661-2668.SONG Wenyan, MENG Pingping, CHAI Zheng. Research on aero-engine control law optimization design based on integrated fighter/aero-engine performance[J]. Journal of Propulsion Technology, 2018, 39(12): 2661-2668. 曾力,龙伟. 基于SVR的航空发动机滑油金属含量预测方法[J]. 四川大学学报(工程科学版),2016,48(增刊2): 161-164.ZENG Li, LONG Wei. Prediction method of metal content of aero engine lubricating oil based on SVR[J]. Journal of Sichuan University (Engineering Science Edition), 2016, 48(S2): 161-164. 骆广琦, 桑增产. 航空燃气涡轮发动机数值仿真[M]. 北京: 国防工业出版社, 2007. -

下载:

下载: