Moisture Susceptibility of SBS and Coarse Crumb Rubber Composite Modified Asphalt Permeable Mixture

-

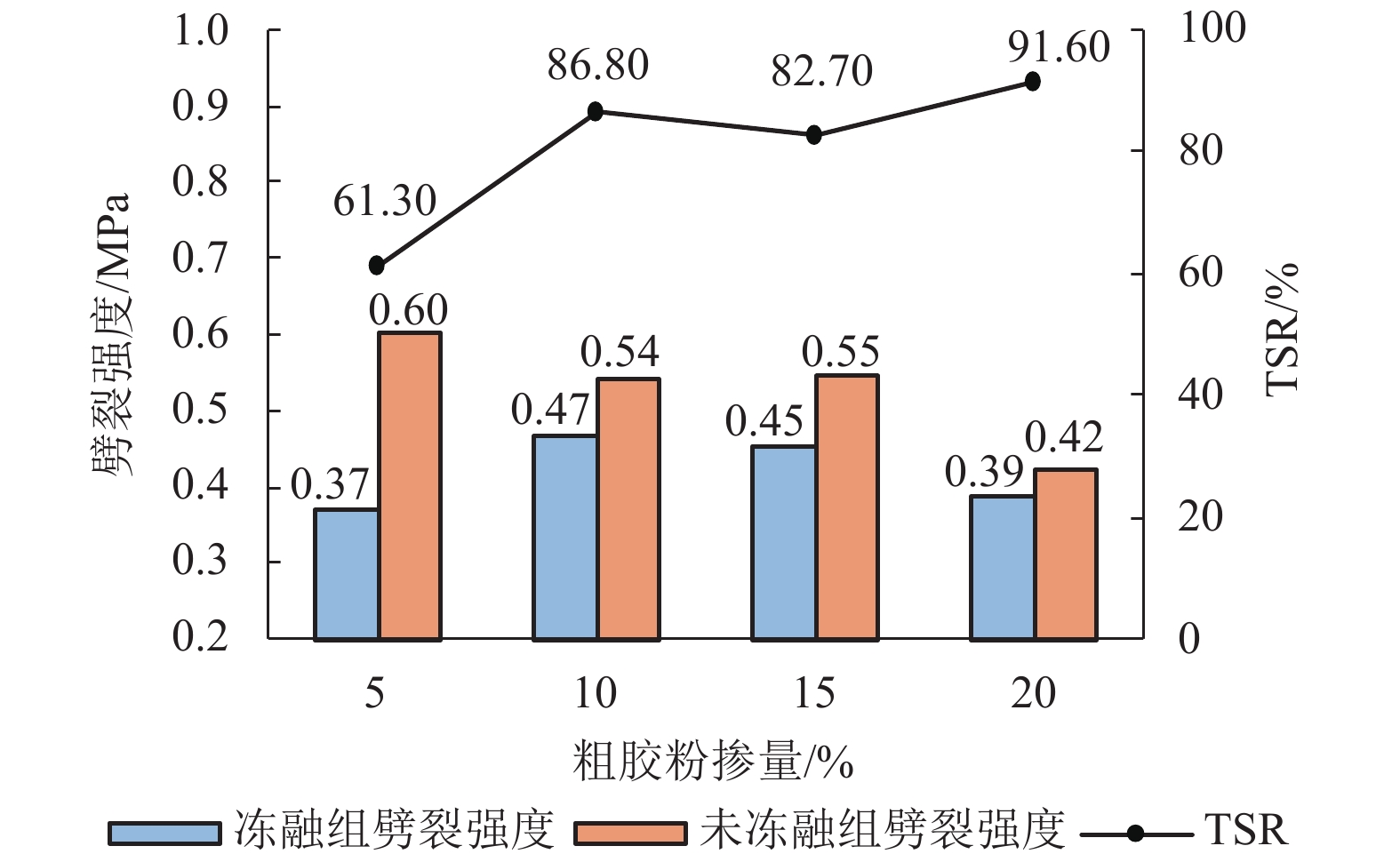

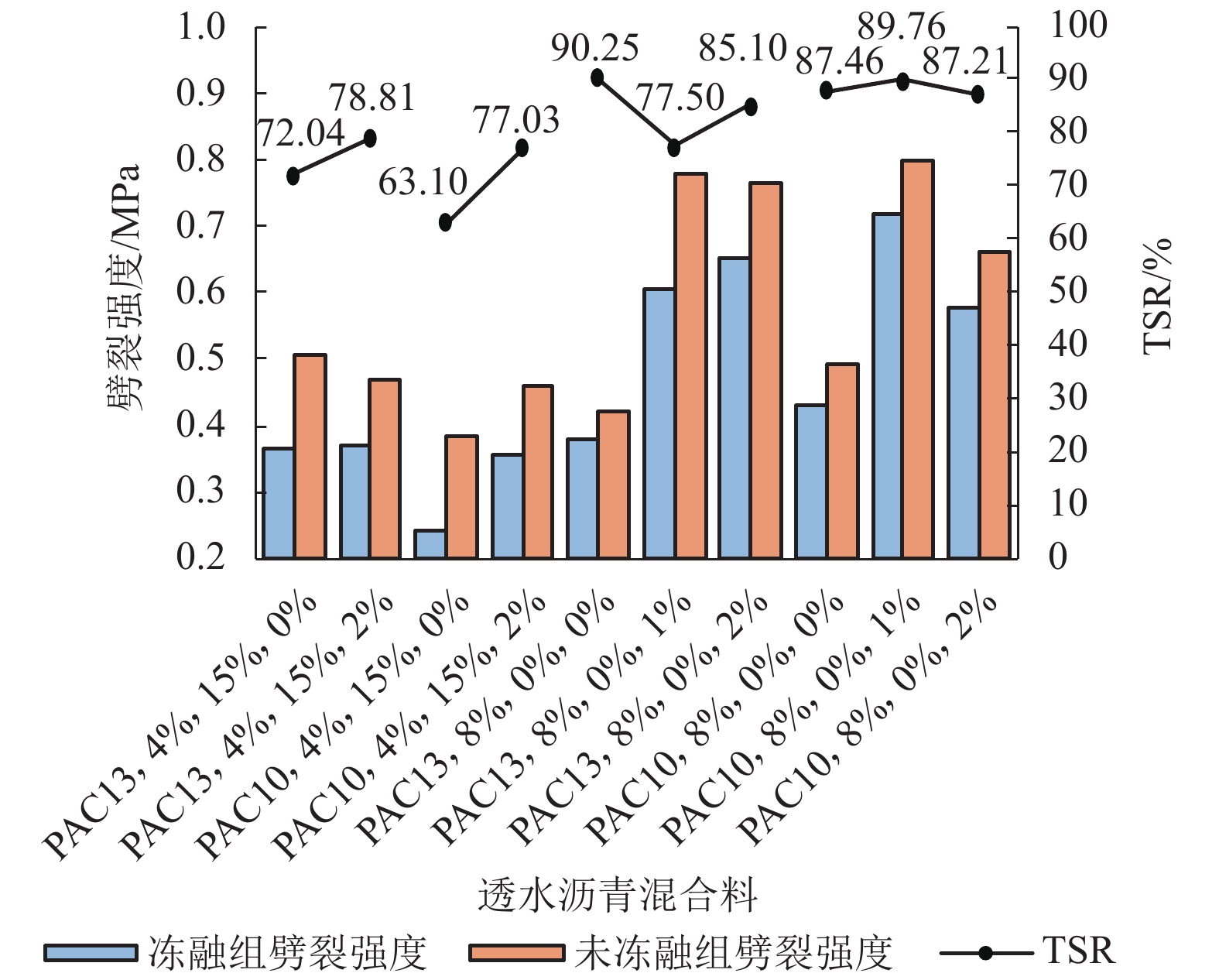

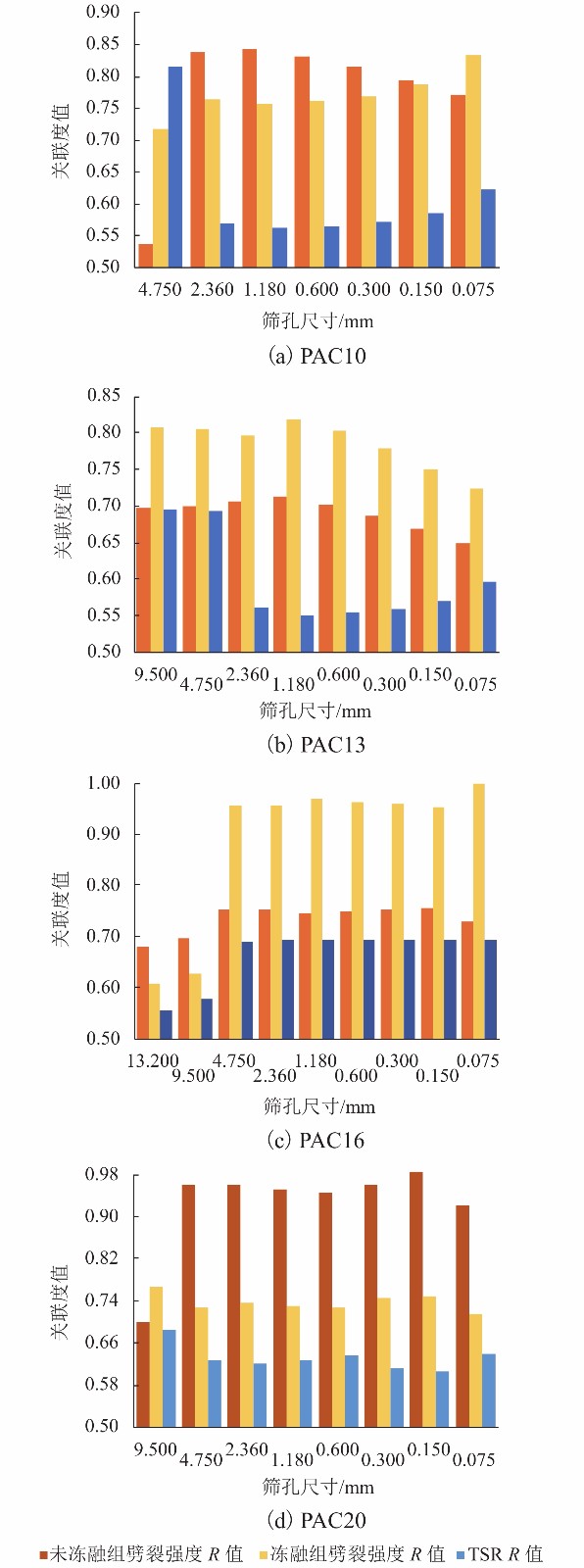

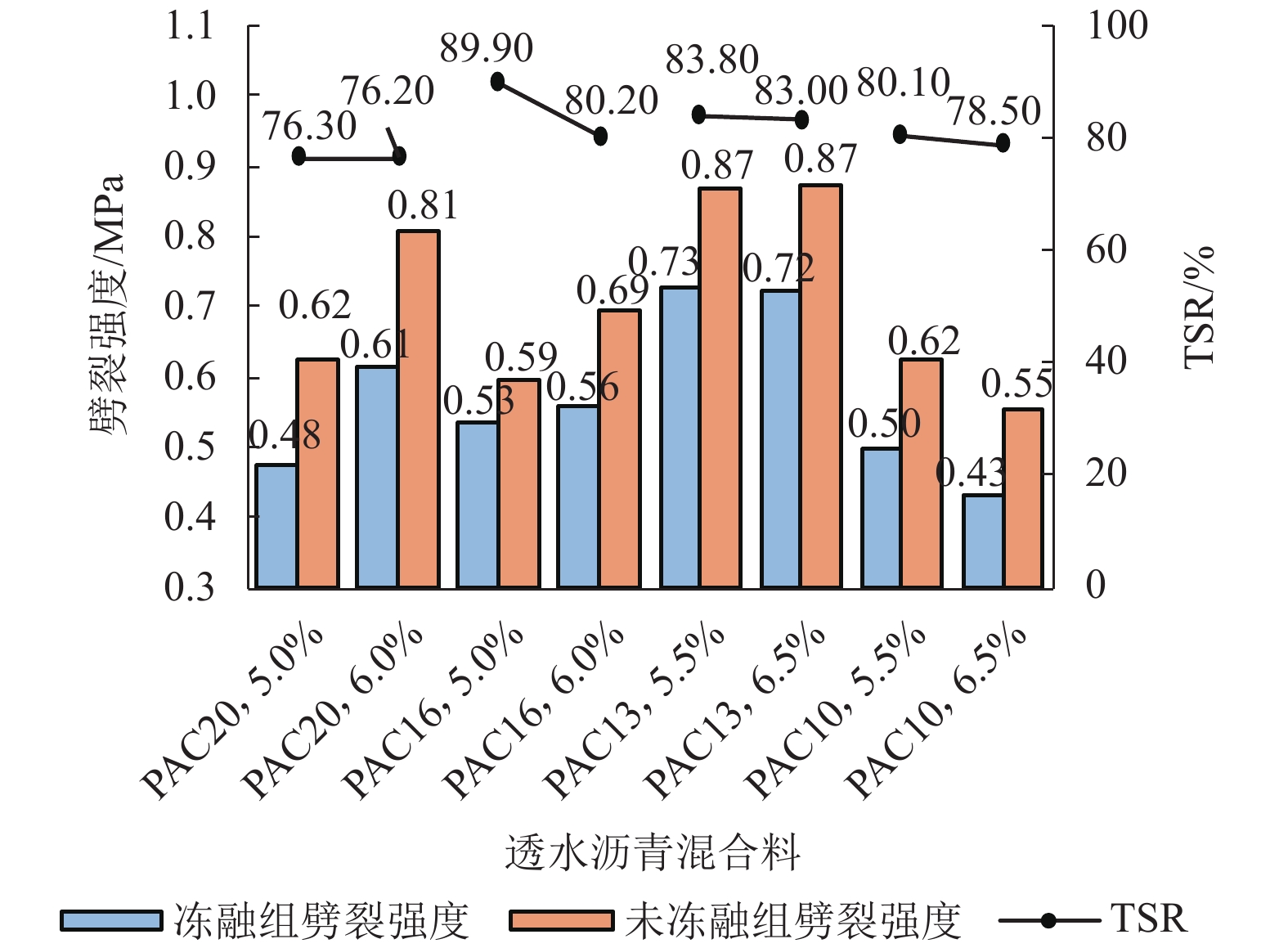

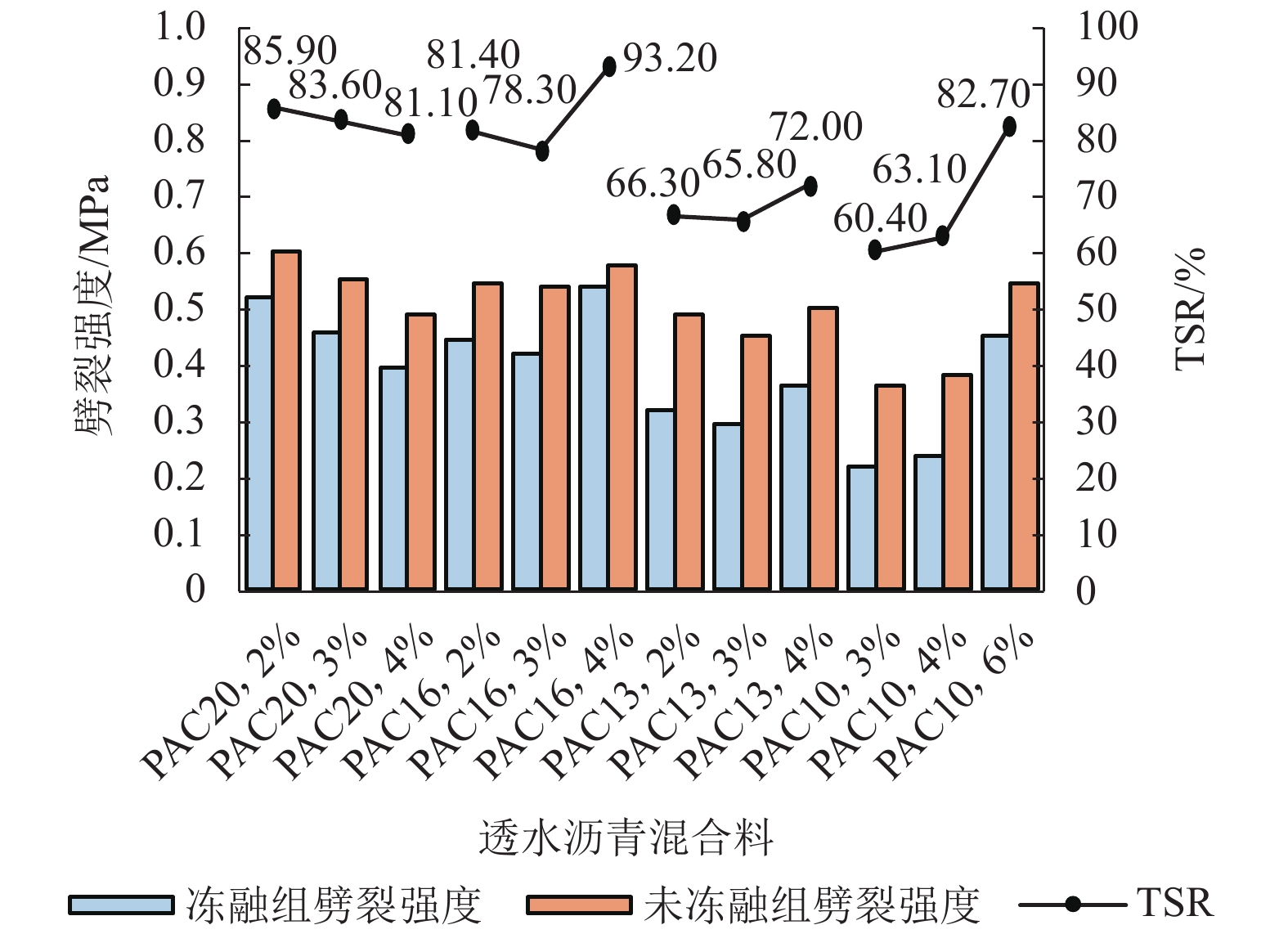

摘要: 排水沥青混凝土孔隙率大,具有良好的排水、降噪功能,但是易发生水损害. 使用粗橡胶粉和SBS(styrene-butadiene-styrene block copolymer)改性剂对基质沥青进行复合改性. 采用冻融劈裂强度比对透水沥青混合料的抗水损害性能进行评价. 研究SBS用量、最大公称粒径、粗橡胶粉用量、级配各筛孔通过率、消石灰用量和沥青用量6个影响因素对透水沥青混凝土抗水害损性能的影响,揭示粗橡胶粉SBS复配沥青混合料的抗水损害机理. 研究结果表明:SBS用量的增加、集料最大公称粒径的增大、消石灰的加入均能提高透水混合料的冻融劈裂强度比;为了获得最佳的水稳定性和良好的经济性,建议SBS与粗橡胶粉的最佳掺量分别为6%和10%,并且通过灰关联分析得出了影响各规格混合料抗水损害性能的关键筛孔.Abstract: Permeable asphalt concrete (PAC) possesses good capacity of drainage and noise reduction due to its large porosity. Nevertheless, it is prone to suffer water damage. Coarse crumb rubber (CCR) and styrene-butadiene-styrene block copolymer (SBS) were used to prepare composite modified asphalt. Freeze-thaw splitting tensile strength ratio (TSR) was employed to evaluate the moisture susceptibility of PAC. The influences of the contents of SBS, coarse crumb rubber, asphalt binder, and hydrated lime as well as the nominal maximum particle size (NMPS) and passing percentage of key sieve sizes on the moisture susceptibility of PAC were explored to reveal the moisture damage resistance mechanism of SBS and CCR composite modified asphalt (SBS/CRMA) mixture. The results indicate that the increases in SBS content, the NMPS of aggregates, and the addition of slaked lime can effectively increase the TSR value. To optimize moisture susceptibility and cost efficiency, it is recommended that the favorable contents of SBS and CCR are 6% and 10%, respectively. Moreover, through grey relational analysis, the key sieve sizes that affect the moisture susceptibility of permeable asphalt mixtures with various NMPS were presented as well.

-

表 1 不同透水沥青混合料级配各筛孔通过率

Table 1. Gradations of PAC with various nominal maximum particle sizes

% 级配编号 筛孔/mm 26.000 19.000 16.000 13.200 9.500 4.750 2.360 1.180 0.600 0.300 0.150 0.075 PAC10 #1 100.0 100.0 100.0 100.0 98.9 56.5 15.0 9.2 8.8 8.4 8.1 7.1 PAC10 #2 100.0 100.0 100.0 100.0 98.9 54.1 12.1 6.6 6.5 6.4 6.4 5.8 PAC10 #3 100.0 100.0 100.0 100.0 98.9 56.4 12.5 6.6 6.5 6.5 6.4 5.9 PAC10 #4 100.0 100.0 100.0 100.0 98.9 54.1 15.3 9.9 9.1 8.3 7.7 6.6 PAC10 #5 100.0 100.0 100.0 100.0 98.9 54.2 18.6 13.2 11.7 10.2 9.0 7.4 PAC13 #1 100.0 100.0 100.0 85.0 69.4 26.9 11.7 10.4 9.7 9.0 8.4 7.2 PAC13 #2 100.0 100.0 100.0 85.0 69.2 22.2 10.0 9.4 8.7 8.0 7.4 6.3 PAC13 #3 100.0 100.0 100.0 85.0 69.4 26.9 11.7 10.2 9.4 8.5 7.7 6.5 PAC13 #4 100.0 100.0 100.0 85.0 69.3 25.4 13.9 12.7 11.3 9.9 8.7 7.0 PAC13 #5 100.0 100.0 100.0 85.0 69.4 28.5 17.8 16.0 14.0 11.8 10.0 7.8 PAC16 #1 100.0 100.0 99.9 72.6 45.1 17.0 9.8 9.2 8.5 7.8 7.2 6.1 PAC16 #2 100.0 100.0 99.9 72.6 45.1 19.4 12.7 11.7 10.5 9.2 8.2 6.7 PAC16 #3 100.0 100.0 99.9 72.6 45.2 21.7 15.7 14.2 12.5 10.6 9.2 7.2 PAC16 #4 100.0 100.0 99.9 72.1 44.1 18.4 11.7 10.9 9.8 8.7 7.8 6.5 PAC20 #1 100.0 96.7 92.0 77.5 51.0 17.9 10.0 9.4 8.7 7.9 7.3 6.3 PAC20 #2 100.0 96.7 92.0 77.5 51.1 20.2 12.9 11.9 10.7 9.4 8.3 6.8 PAC20 #3 100.0 96.7 92.0 77.5 51.1 22.6 15.8 14.4 12.7 10.8 9.3 7.4 PAC20 #4 100.0 96.7 92.0 77.5 51.1 21.0 13.9 12.7 11.3 9.9 8.7 7.0 表 2 不同级配规格透水沥青混合料的性能试验结果

Table 2. Performance test results for different types of PAC

规格 劈裂强度/MPa TSR/% MS/kN γf γt 冻融组 未冻融组 PAC20 0.46 0.55 83.64 6.59 2.010 2.518 PAC16 0.42 0.54 78.35 6.36 2.020 2.511 PAC13 0.30 0.45 65.75 6.00 1.963 2.495 PAC10 0.22 0.36 60.42 5.71 1.888 2.469 -

XIAO F, HERNDON D A, AMIRKHANIAN S, et al. Aggregate gradations on moisture and rutting resistances of open graded friction course mixtures[J]. Construction and Building Materials, 2015, 85: 127-135. PAN Qinxue, QIAN Guoping, LIU Hongfu, et al. Applicability analysis on index values of water stability of asphalt mixture[C]//Proceedings of the 4th International Conference on GreenBuilding, Materials and Civil Engineering, GBMCE 2014. Florida: CRC Press, 2015: 377-381. 孙璐,辛宪涛,任皎龙. 纳米改性沥青混合料路用性能[J]. 东南大学学报(自然科学版),2013,43(4): 873-876.SUN Lu, XIN Xiantao, REN Jiaolong. Pavement performance of nanomaterial modified asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2013, 43(4): 873-876. YUAN Yuqing, GAO Danying, ZHAO Jun, et al. Experimental study on water stability of asphalt mixture[J]. Advonced Materials Research, 2011, 266: 135-138. LI Junxiao, FU Wei, ZANG Hechao. Performance on water stability of cement-foamed asphalt cold recycled mixture[C]//The 8th International Conference on Mechanical and Aerospace Engineering (ICMAE 2017). Prague: IEEE, 2018: 2005-2010. LIU Minghui. Experimental study on water stability of cold recycled mixture stabilized with emulsified asphalt[J]. Applied Mechanics and Materials, 2012, 204/205/206/207/208: 1914-1917. 郭平. Sasobit®温拌沥青混合料水稳定性能研究[J]. 郑州大学学报(工学版),2010,31(5): 36-39. doi: 10.3969/j.issn.1671-6833.2010.05.009GUO Ping. Study on water stability of Sasobit® warm mixture asphalt[J]. Journal of Zhengzhou University (Engineering Science), 2010, 31(5): 36-39. doi: 10.3969/j.issn.1671-6833.2010.05.009 HUANG Weirong, LIU Tao, YANG Donglai. Research of grading ’s influence on asphalt mixture ’s water stability[C]//Proceedings of the 2011 IEEE International Conference on Automation and Logistics (ICAL). Piscataway: IEEE, 2011: 456-460. GUO Xuedong, CAO Jian, FANG Xiangyang. Study of water stability of asphalt mixture based on residual water[J]. Frontiers of Green Building,Materials and Civil Engineering, 2011, 71/72/73/74/75/76/77/78: 1791-1794. GUO Xuedong, CAO Jian, FANG Xiangyang. Study of water stability of AC and SMA asphalt mixture based on water content[J]. Advanced Materials Research, 2012, 457/458: 435-438. doi: 10.4028/www.scientific.net/AMR.457-458.435 SHEN Guoyin. Common diseases and preventive measures during the asphalt concrete pavement construction[C]//Proceedings of the 2012 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring (CDCIEM 2012). Los Alamitos: IEEE Computer Society, 2012: 198-203. 丛林,郑晓光,吕伟民. 细集料泥土含量对沥青混合料水稳定性的影响[J]. 同济大学学报(自然科学版),2006,34(5): 619-623.CONG Lin, ZHENG Xiaoguang, LV Weimin. Effect of clay content in fine aggregate on water stability of asphalt mixture[J]. Journal of Tongji University (Natural Science), 2006, 34(5): 619-623. MA Tao, HUANG Xiaoming, ZHAO Yongli, et al. Aging behaviour and mechanism of SBS-modified asphalt[J]. Journal of Testing and Evaluation, 2012, 40(7): 1186-1191. WANG Tao, XIAO Feipeng, AMIRKHANIAN S, et al. A review on low temperature performances of rubberized asphalt materials[J]. Construction and Building Materials, 2017, 145: 483-505. KADLECEK S V, MODRY S, KADLECEK J V. Size effect of test specimens on tensile splitting strength of concrete:general relation[J]. Materials and Structures/Materiaux et Constructions, 2002, 34: 28-34. YANG Wenfeng. Effect and its mechanisms of hydrated lime on water stability of hot asphalt mixture[C]//Materials, Mechanical and Manufacturing Engineering. Zurich-Durnten: Trans Tech Publications Ltd., 2014: 22-26. 肖飞鹏,宗启迪,陈军,等. 等离子体微表处理胶粉改性沥青工艺条件优化分析[J]. 中国公路学报,2019,32(4): 170-176.XIAO Feipeng, ZONG Qidi, CHEN Jun, et al. Processing conditions optimization analysis of crumb rubber modified asphalt treated by plasma micrometer processing method[J]. China Journal of Highway and Transport, 2019, 32(4): 170-176. 张英,刘昌清,毛国军,等. LSPM沥青用量与水稳定性的关系探讨[J]. 建材技术与应用,2015(3): 8-9. doi: 10.3969/j.issn.1009-9441.2015.03.003ZHANG Ying, LIU Changqing, MAO Guojun, et al. Relationship between LSPM asphalt amount and water stability[J]. Research and Application of Building Materials, 2015(3): 8-9. doi: 10.3969/j.issn.1009-9441.2015.03.003 -

下载:

下载: