Fault Detection of Axle Box Bearing Based on Matter-Element and Negative Selection Algorithm

-

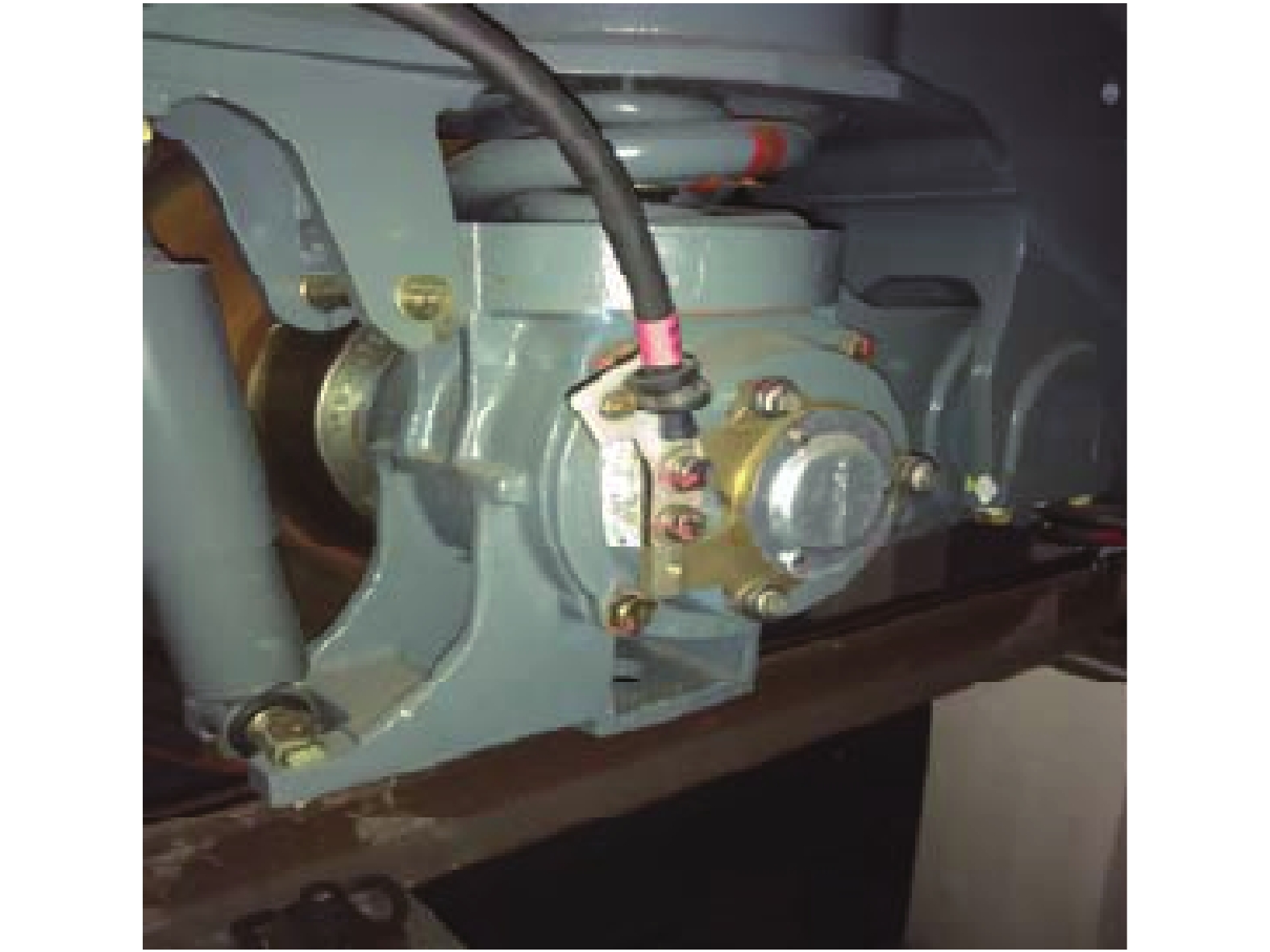

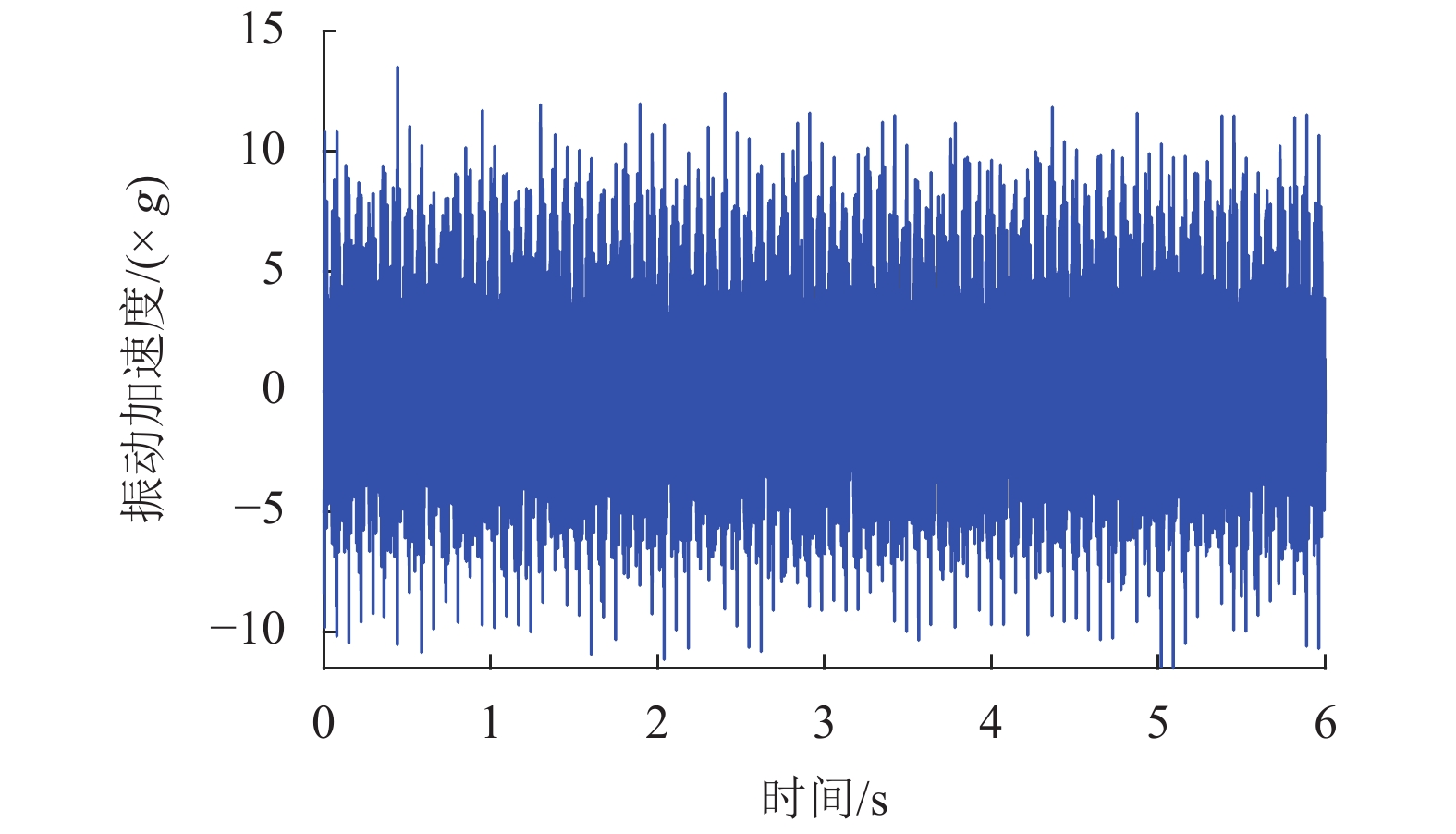

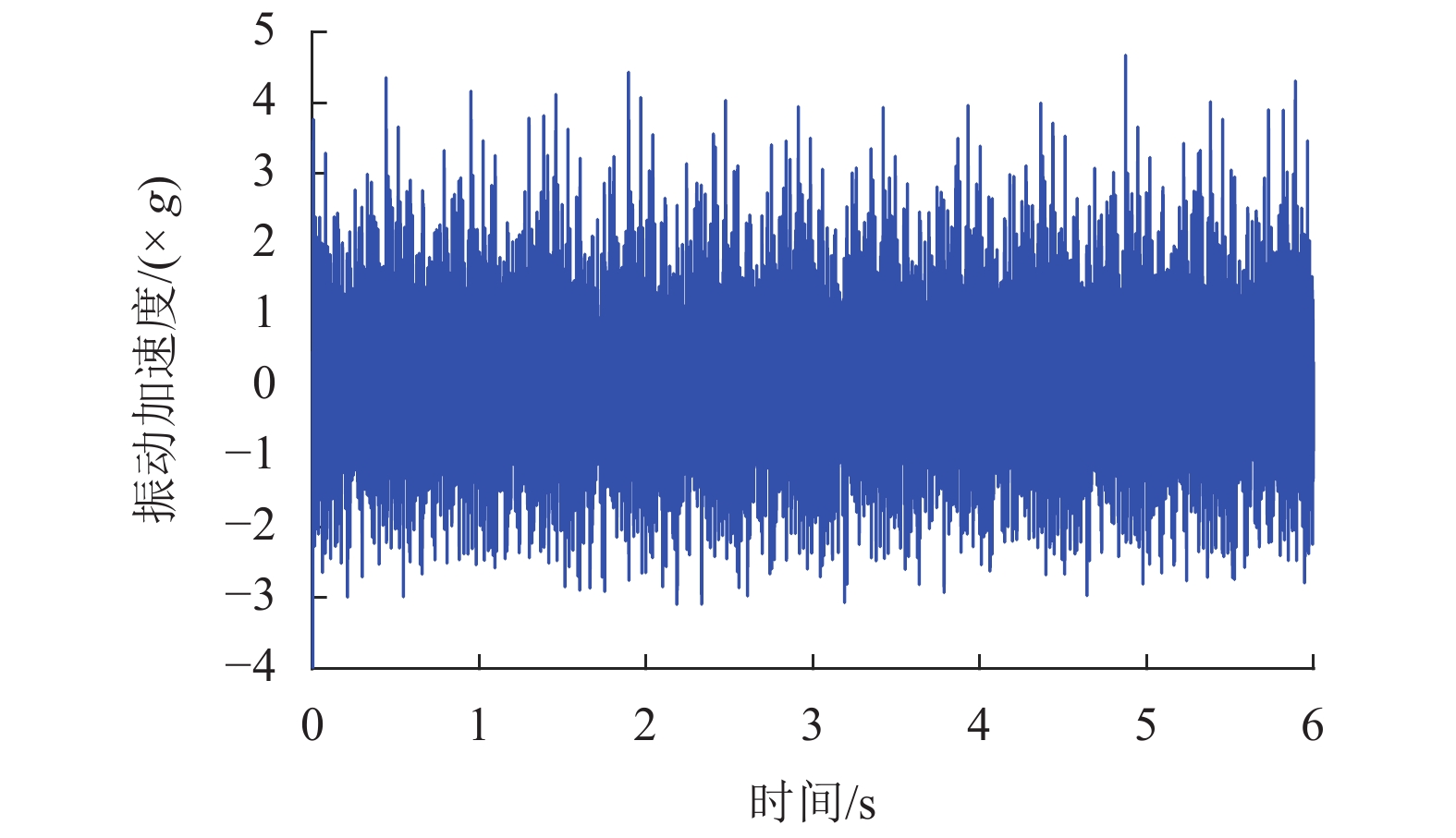

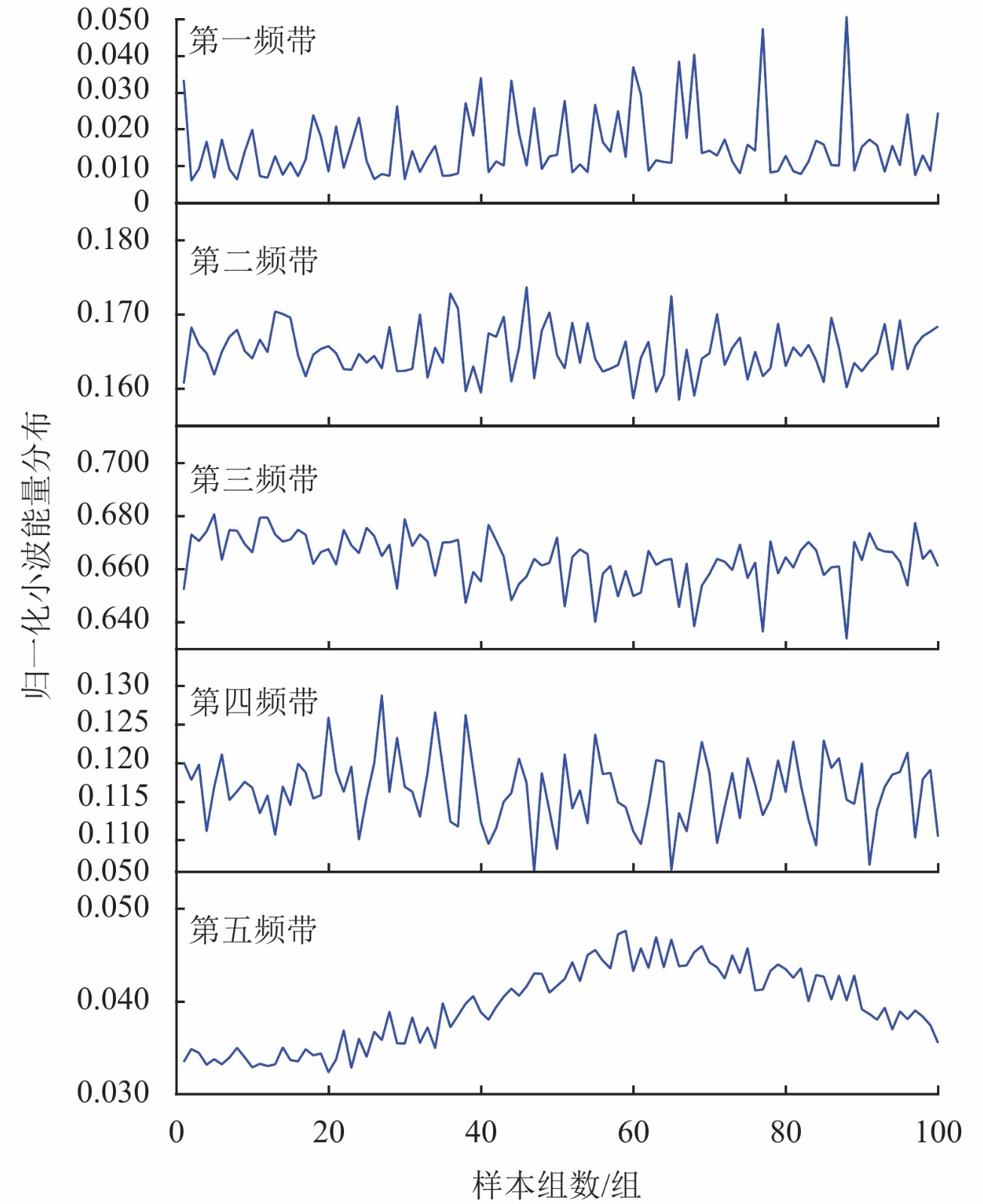

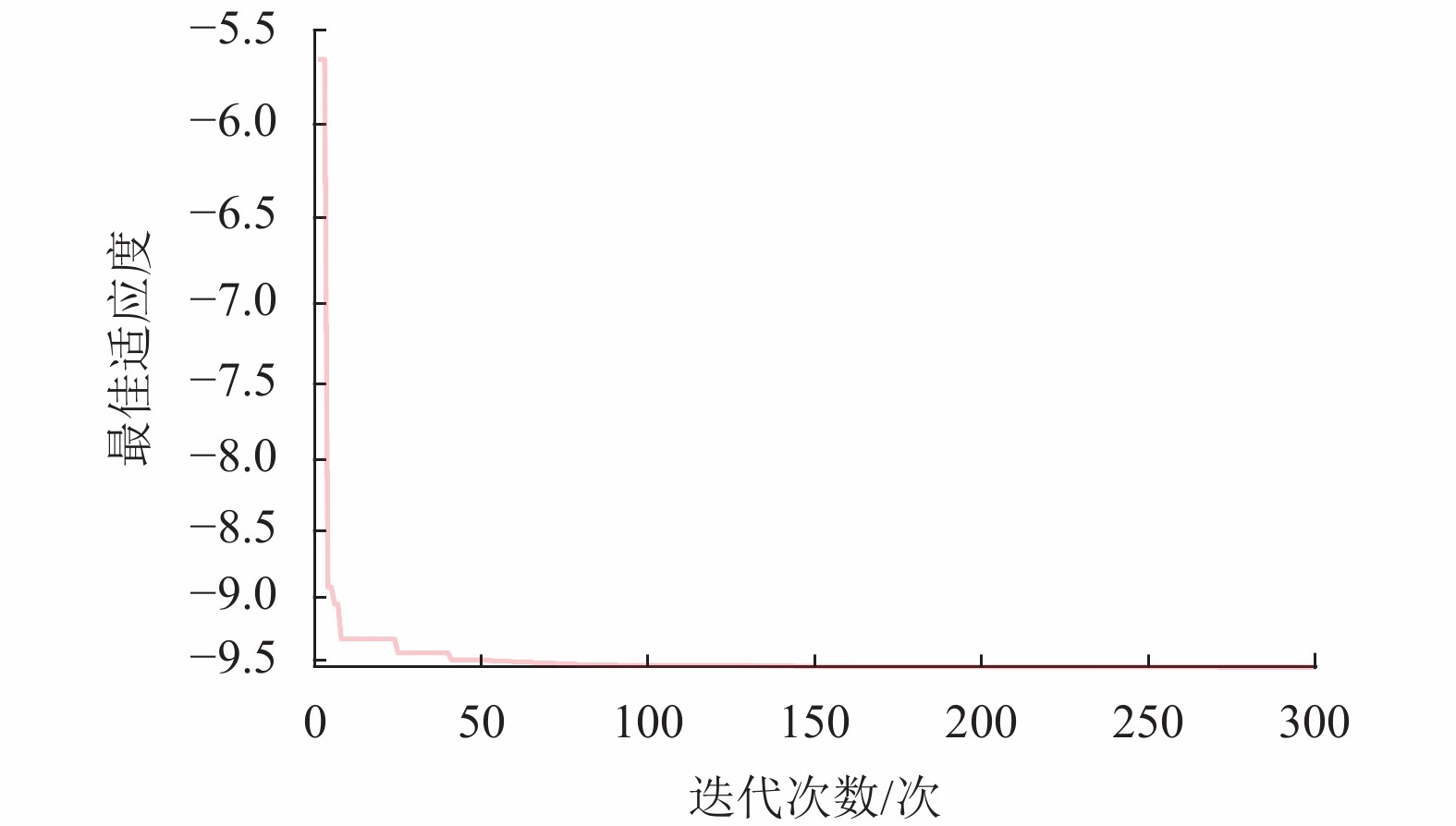

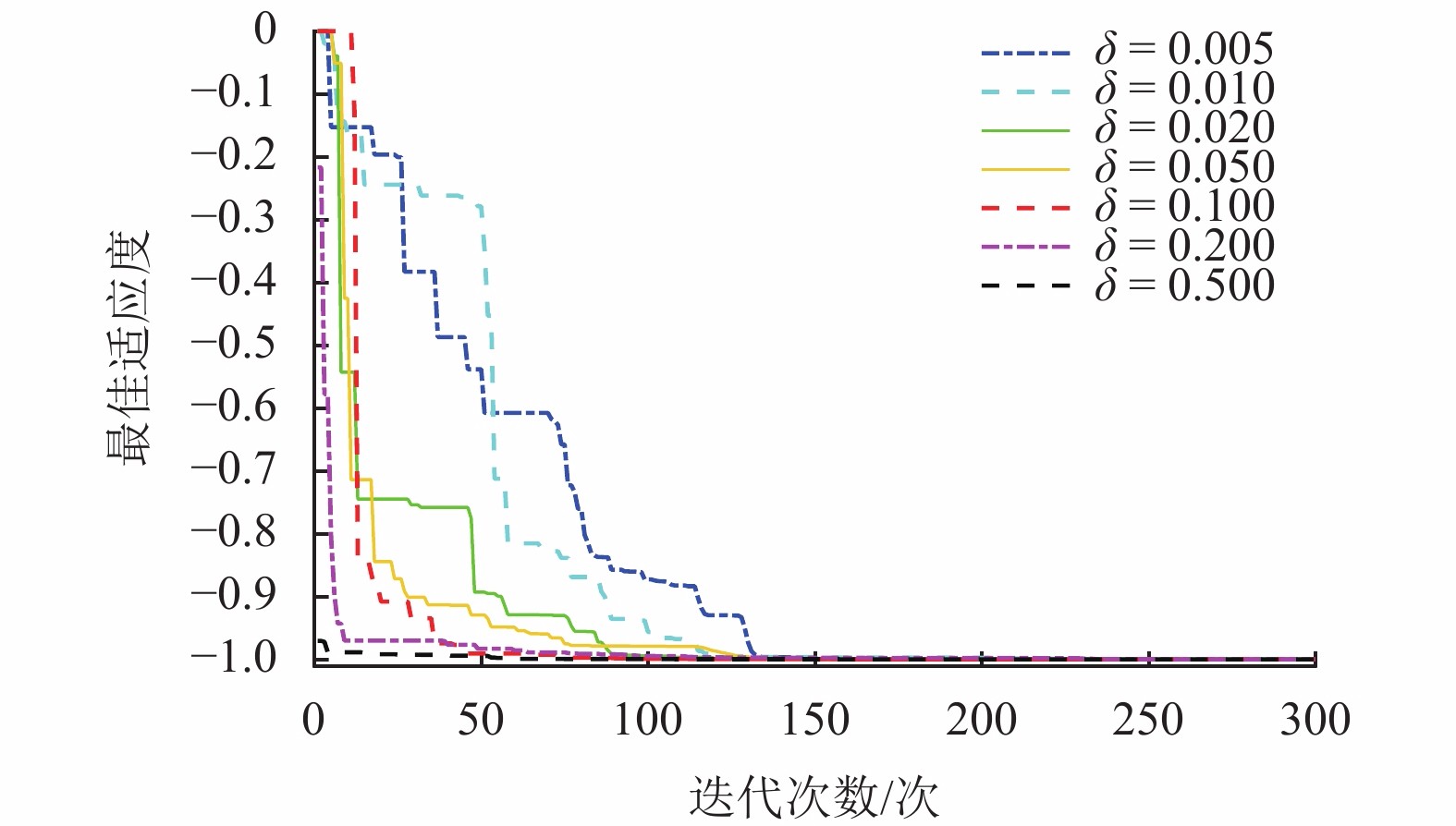

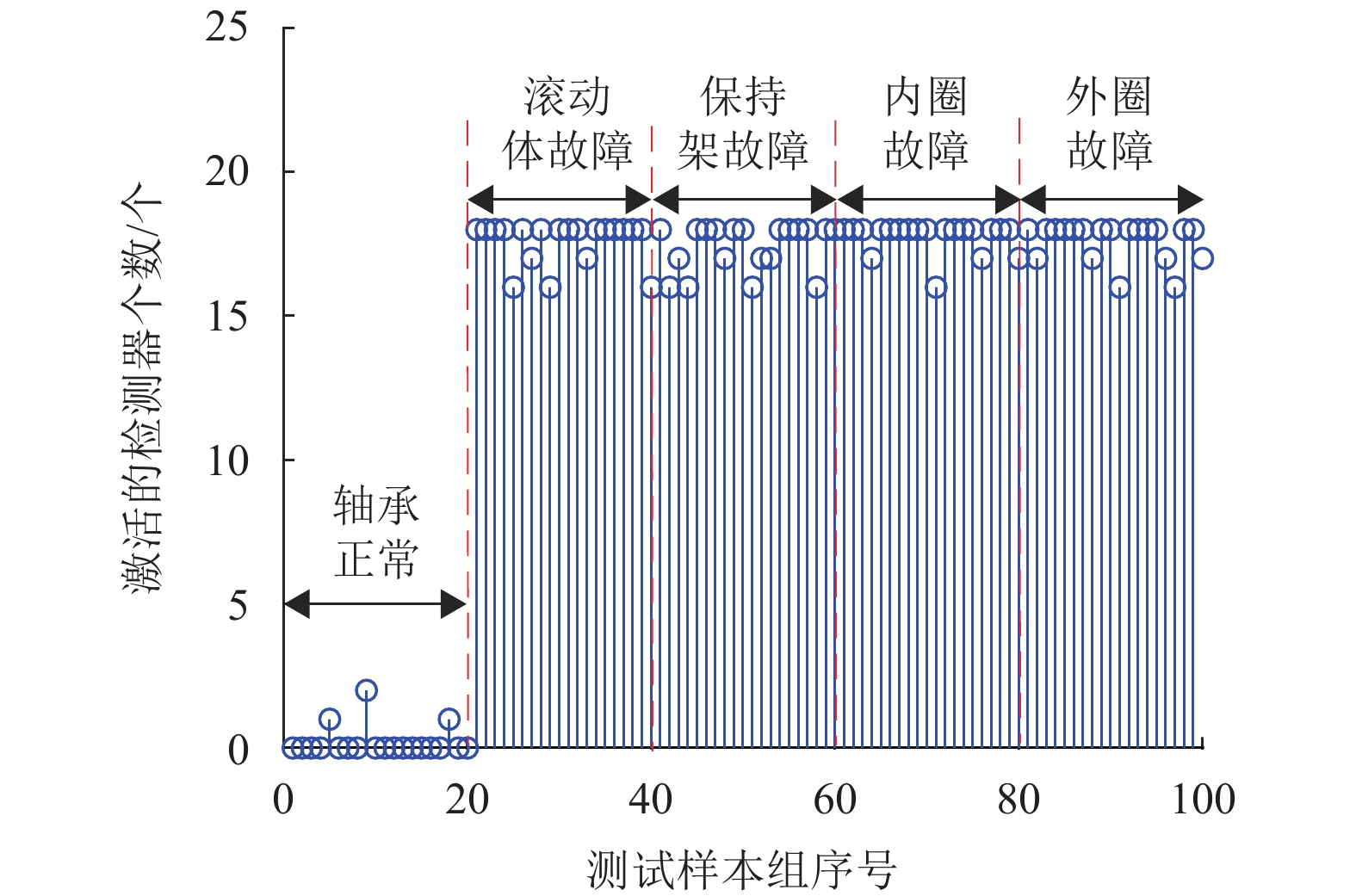

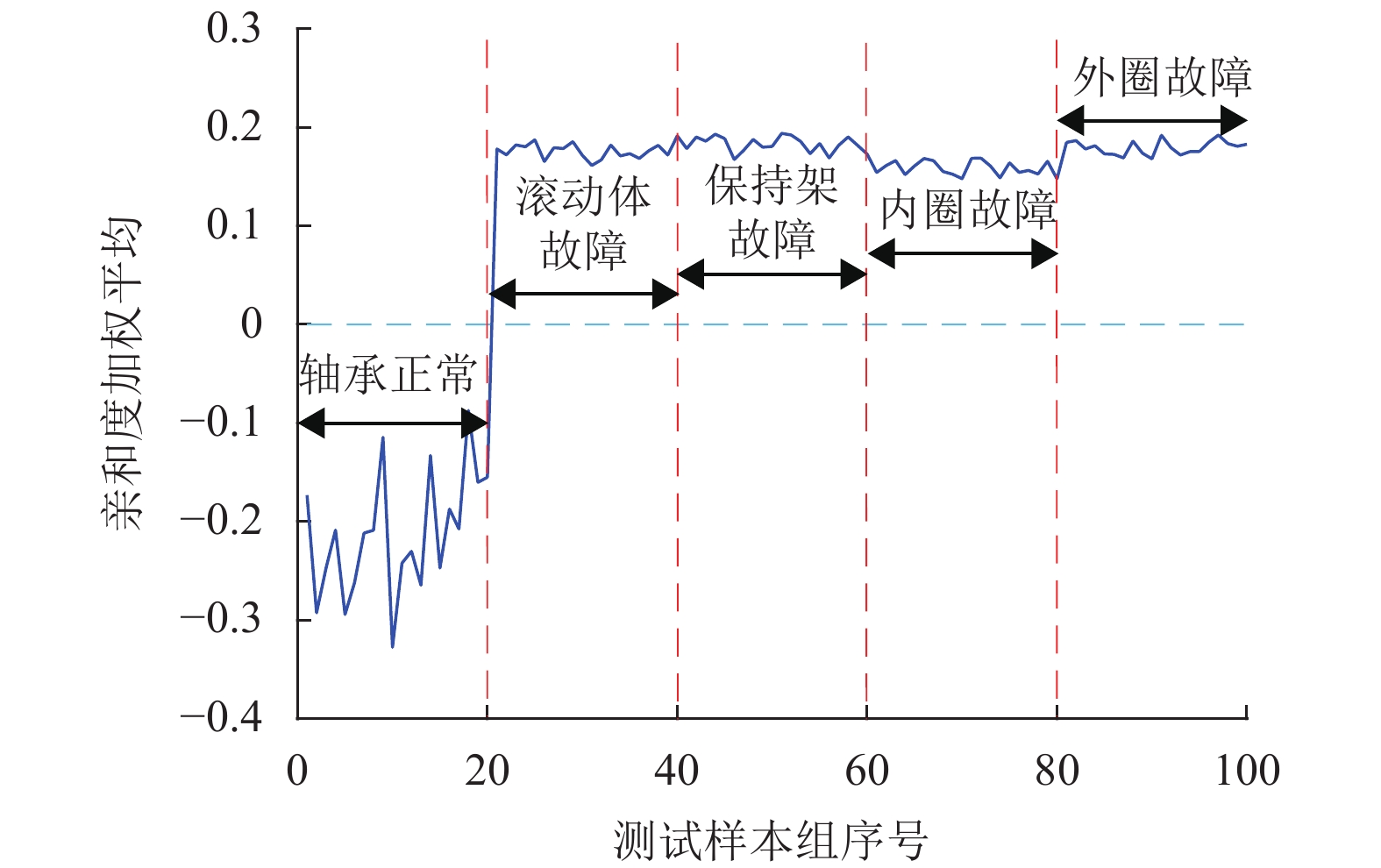

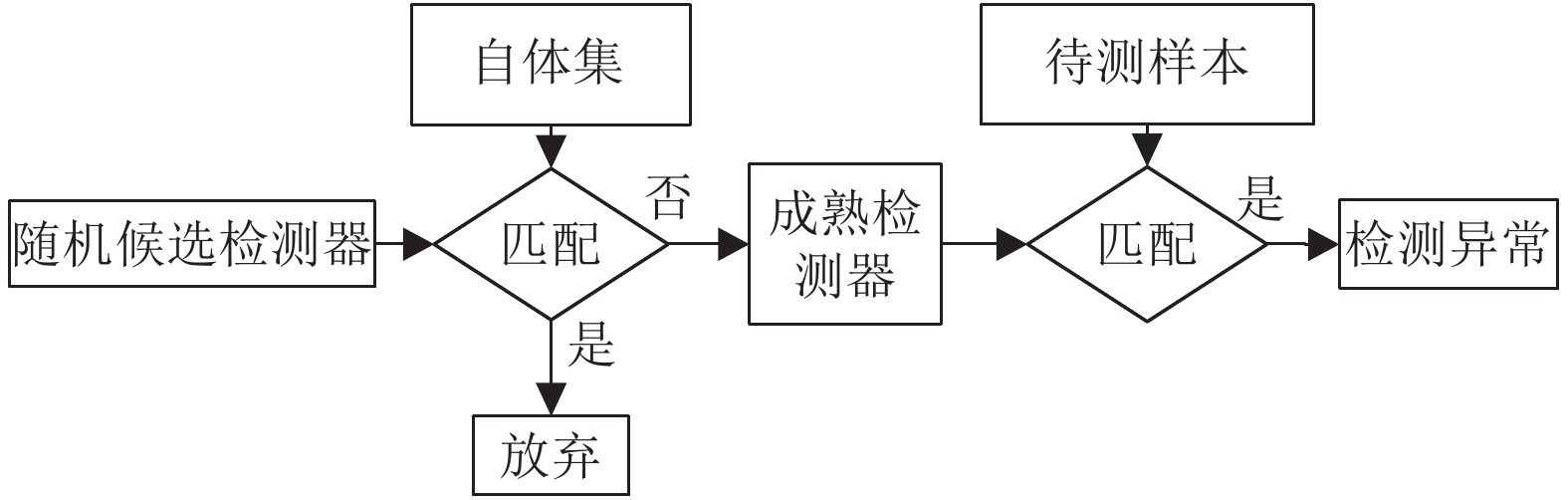

摘要: 针对高速列车轴箱轴承故障数据获取困难的问题,提出了一种无需先验知识的利用物元和阴性选择算法进行轴承故障检测的方法. 首先利用多维物元构建阴性选择算法的检测器模型,以检测器与训练样本之间的综合关联度作为匹配规则,并在综合关联度约束范围内引入控制参数,实现检测器对非己空间的更大覆盖;其次,根据匹配规则和控制参数构建适应度函数,采用粒子群优化算法生成候选检测器,分析控制参数对检测器生成和粒子群优化算法收敛速度的影响;此外,为降低候选检测器集合的冗余度,基于关联度提出了检测器特征参数区间的合并规则,将成熟检测器个数降低至18个;最后,通过信号模拟方法生成轴箱轴承的各类故障信号,建立100组测试样本,并利用18个成熟检测器进行故障检测. 研究结果表明:成熟检测器对不同类轴承故障均具有较好的检测性能,正常样本的检测器激活率为1.11%,故障样本的检测器激活率不低于96.67%.Abstract: In view of the difficulty in obtaining the fault data of high-speed train axle box bearings, a fault detection method combined matter-element model and negative selection algorithm (NSA) was proposed, which did not need prior knowledge. Firstly, detectors of NSA were constructed by means of multi-dimensional matter-element model, and the comprehensive correlation degree (CCD) between detectors and training samples was used as the matching rule. In order to achieve greater coverage of the non-self space by the detector, a control parameter was introduced within the constraint range of CCD. Then, the fitness function was constructed according to the matching rule and the control parameter, and the particle swarm optimization (PSO) algorithm was utilized to generate candidate detectors. The influence of control parameter on detector generation and convergence speed of particle swarm optimization algorithm was analyzed. In order to reduce the redundancy of the candidate detector set, the merging rules of characteristic parameters intervals of candidate detectors were proposed based on the correlation function, and the number of mature detectors was reduced to 18. Various fault signals of axle box bearings were generated by signal simulation method, 100 sets of test samples were established, and 18 mature detectors were used for fault detection. The results show that the mature detectors have good detection performance for different types of bearing fault, and the detector activation rate of normal sample is 1.11%, while its minimum value of fault samples is 96.67%.

-

表 1 各频带的频率范围

Table 1. Frequency range of each frequency band

Hz 频带 第一频带 第二频带 第三频带 第四频带 第五频带 频率 0~128 128~256 256~512 512~1024 1024~2048 表 2 成熟检测器分布

Table 2. Mature detector distribution

检测器 c1 c2 c3 c4 c5 D1 <0,0.994> <0,0.884> <0.016,0.994> <0,0.987> <0,0.913> D2 <0.449,0.917> <0.693,0.961> <0.526,0.963> <0.570,0.577> <0.429,0.995> D3 <0,0.399> <0.072,0.344> <0.526,0.963> <0.067,0.554> <0,0.913> D4 <0,0.399> <0.072,0.344> <0.526,0.963> <0,0.987> <0.429,0.995> D5 <0,0.399> <0,0.884> <0.526,0.963> <0,0.987> <0.429,0.995> D6 <0,0.993> <0,0.884> <0.526,0.963> <0.067,0.554> <0.429,0.995> D7 <0,0.399> <0.374,0.667> <0.526,0.963> <0,0.987> <0,0.913> D8 <0.449,0.917> <0.509,0.643> <0.016,0.994> <0,0.987> <0.563,0.679> D9 <0,0.994> <0.374,0.667> <0.526,0.963> <0,0.987> <0.028,0.353> D10 <0,0.994> <0,0.884> <0.016,0.994> <0.622,0.999> <0.028,0.353> D11 <0,0.994> <0.072,0.344> <0.526,0.963> <0,0.987> <0,0.913> D12 <0,0.399> <0,0.884> <0.016,0.994> <0,0.987> <0.430,0.995> D13 <0.449,0.917> <0,0.884> <0.016,0.994> <0.067,0.554> <0,0.913> D14 <0,0.994> <0,0.884> <0.526,0.963> <0,0.987> <0.028,0.353> D15 <0,0.994> <0,0.884> <0.016,0.994> <0.622,0.999> <0,0.913> D16 <0,0.994> <0,0.884> <0.016,0.994> <0,0.987> <0.430,0.995> D17 <0,0.994> <0,0.884> <0.526,0.963> <0,0.987> <0,0.913> D18 <0,0.994> <0.374,0.667> <0.016,0.994> <0,0.987> <0,0.913> 表 3 轴箱轴承基本参数

Table 3. Basic parameters of axle box bearing

项目 参数 数值 基本参数 滚动体直径/mm 23 滚动轴承节径/mm 180.5 单列滚子数 21 接触角/(°) 7.75 主轴转频/Hz 30.84 车辆运行速度 300 km/h 外圈故障特征频率/Hz 282.82 内圈故障特征频率/Hz 364.82 滚动体故障特征频率/Hz 118.74 保持架故障特征频率/Hz 13.47 表 4 检测器激活率

Table 4. Detector activation rate

% 轴承状态 检测器激活率 轴承正常 1.11 轴承滚动体故障 97.78 轴承保持架故障 96.67 轴承内圈故障 98.61 轴承外圈故障 97.78 -

刘国云,曾京,罗仁,等. 轴箱轴承缺陷状态下的高速车辆振动特性分析[J]. 振动与冲击,2016,35(9): 37-42,51.LIU Guoyun, CENG Jing, LUO Ren, et al. Vibration performance of high-speed vehicles with axle box bearing defects[J]. Journal of Vibration and Shock, 2016, 35(9): 37-42,51. 赵聪聪,白杨,刘玉梅,等. 基于改进安全域的轴箱轴承状态监测[J]. 西南交通大学学报,2020,55(4): 889-895.ZHAO Congcong, BAI Yang, LIU Yumei, et al. Combining boundary values of safety region and correlation function for condition monitoring of axle box bearing[J]. Journal of Southwest Jiaotong University, 2020, 55(4): 889-895. 熊庆. 列车滚动轴承振动信号的特征提取及诊断方法研究[D]. 成都: 西南交通大学, 2015. DONG S J, LUO T H. Bearing degradation process prediction based on the PCA and optimized LS-SVM model[J]. Measurement, 2013, 46(9): 3143-3152. doi: 10.1016/j.measurement.2013.06.038 FORREST S, PERELSON A S, ALLEN L, et al. Self-nonself discrimination in a computer[C]//Proceedings of the 1994 IEEE Symposium on Research in Security and Privacy IEEE. Los Alamitos: [s.n.], 1994, 221-231. GAO X Z, WANG X, ZENGER K. Motor fault diagnosis using negative selection algorithm[J]. Neural Computing and Applications, 2013, 25(1): 55-65. LIU Yumei, ZHAO Congcong, XIONG Mingye, et al. Assessment of bearing performance degradation via extension and EEMD combined approach[J]. Journal of Central South University, 2017, 24(5): 1155-1163. doi: 10.1007/s11771-017-3518-5 刘玉梅,赵聪聪,熊明烨,等. 高速列车传动系统特征参数经典域优化[J]. 西南交通大学学报,2016,51(1): 85-90,120. doi: 10.3969/j.issn.0258-2724.2016.01.013LIU Yumei, ZHAO congcong, XIONG Mingye, et al. Optimization of classical domains for high-speed train transmission system[J]. Journal of Southwest Jiaotong University, 2016, 51(1): 85-90,120. doi: 10.3969/j.issn.0258-2724.2016.01.013 金章赞,廖明宏,肖刚. 否定选择算法综述[J]. 通信学报,2013,34(1): 159-170.JIN Zhangzan, LIAO Minghong, XIAO Gang. Survey of negative selection algorithms[J]. Journal on Communications, 2013, 34(1): 159-170. LIU Z W, CAO H R, CHEN X F, et al. Multi-fault classification based on wavelet SVM with PSO algorithm to analyze vibration signals from rolling element bearings[J]. Neurocomputing, 2013, 99(1): 399-410. YU K, LIN T, TAN J W. An adaptive sensitive frequency band selection method for empirical wavelet transform and its application in bearing fault diagnosis[J]. Measurement, 2019, 134: 375-384. doi: 10.1016/j.measurement.2018.10.086 李永波. 滚动轴承故障特征提取与早期诊断方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. -

下载:

下载: