Dynamic Response Characteristics of Bridge-Tunnel Transition Section with Deep Buried Pile-Plank Structures

-

摘要:

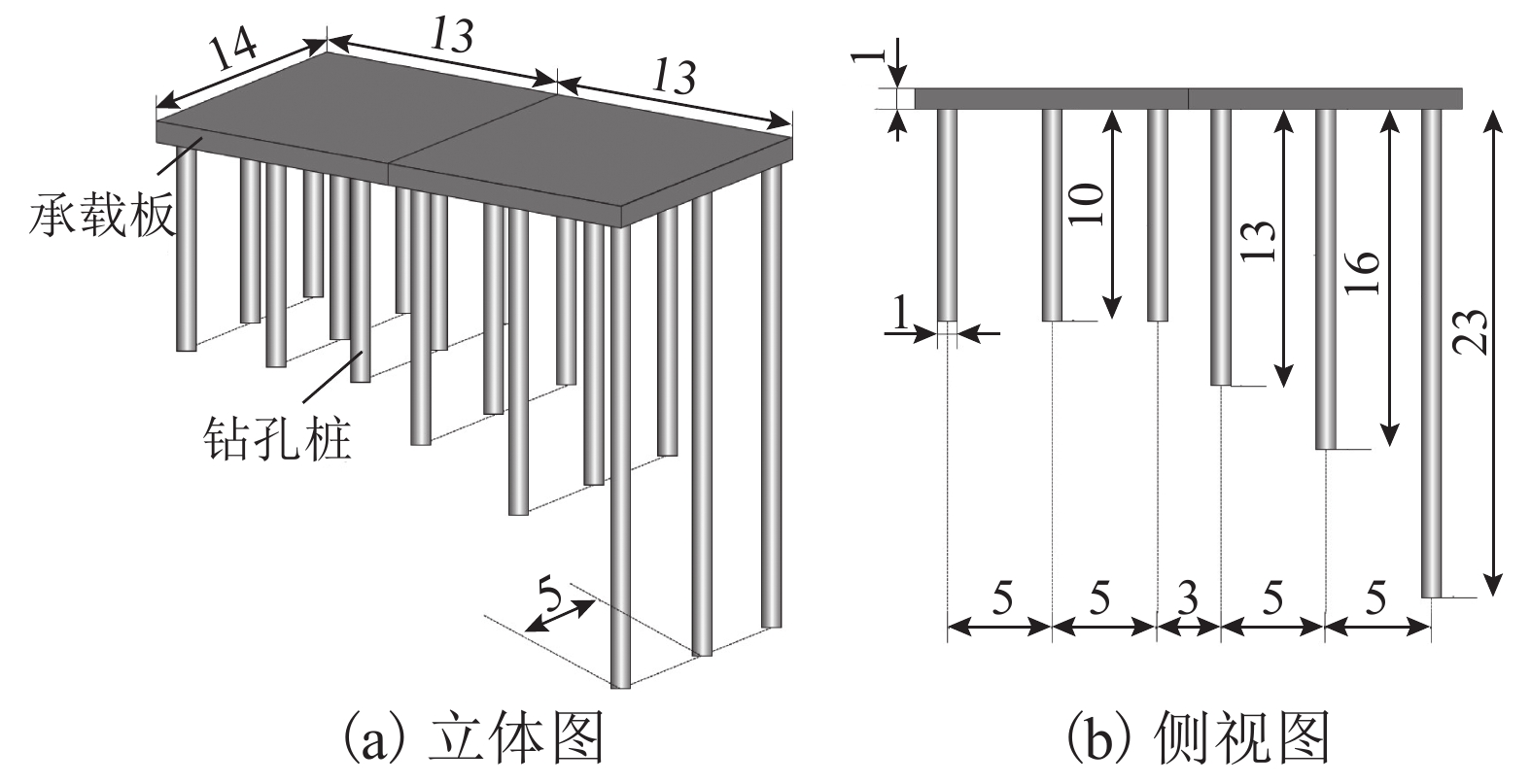

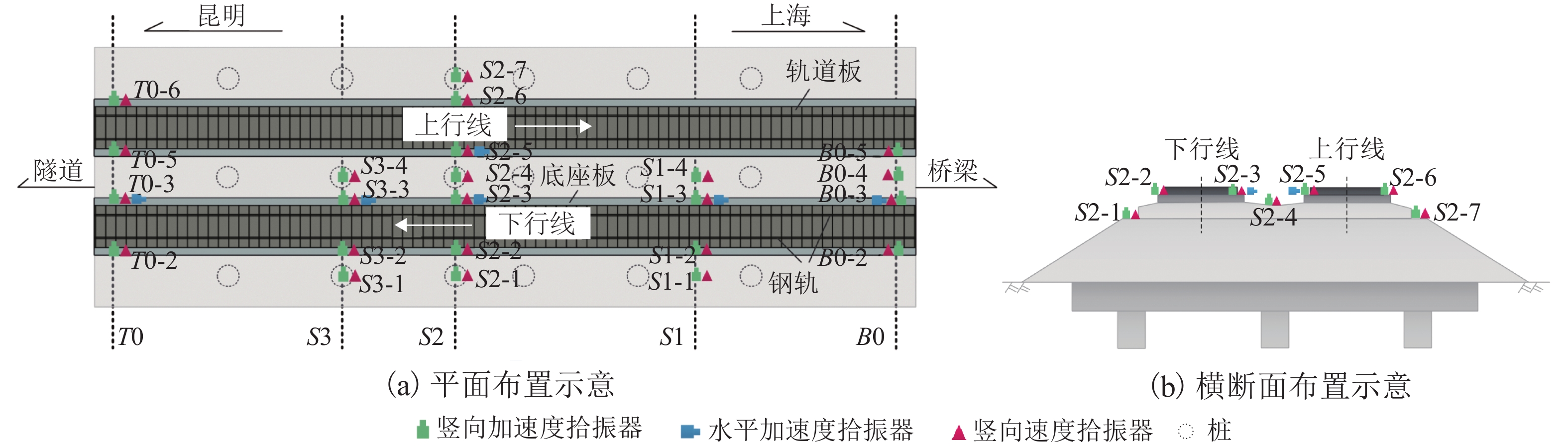

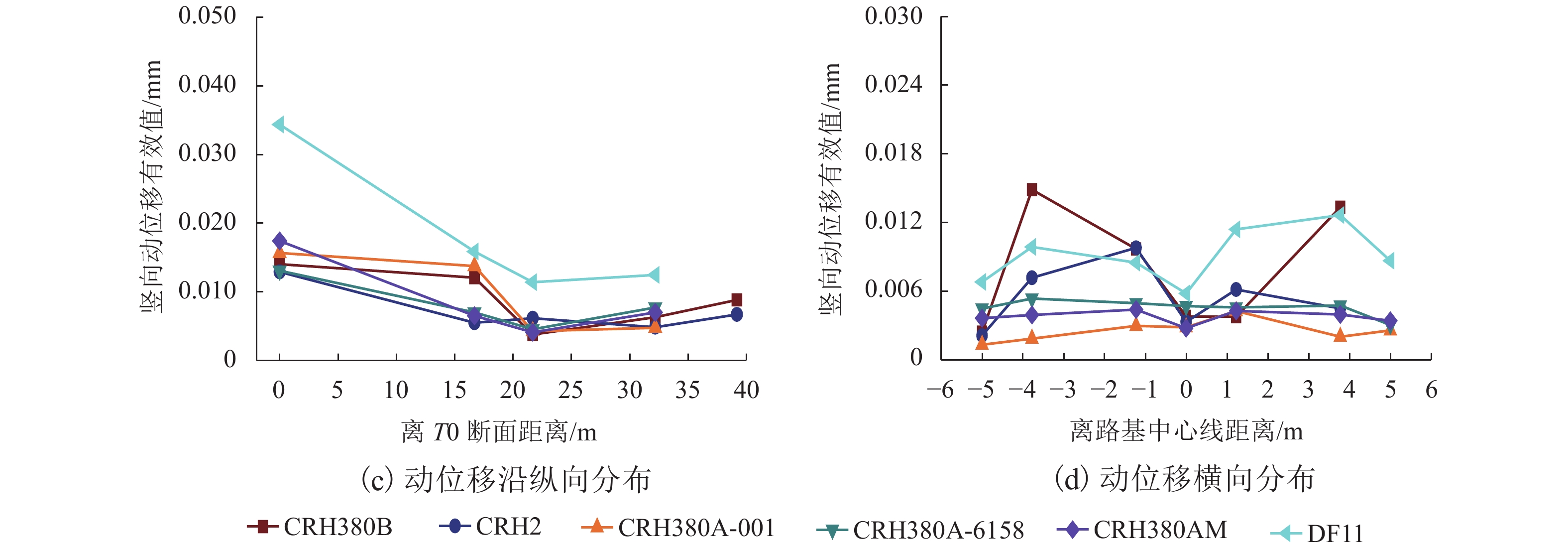

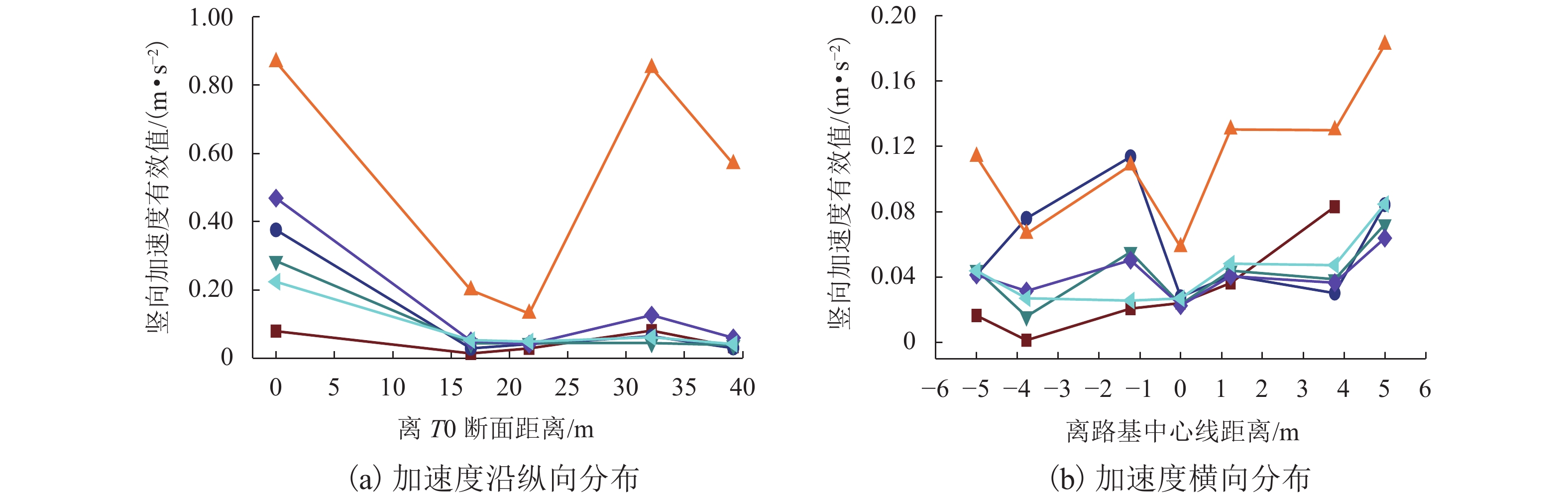

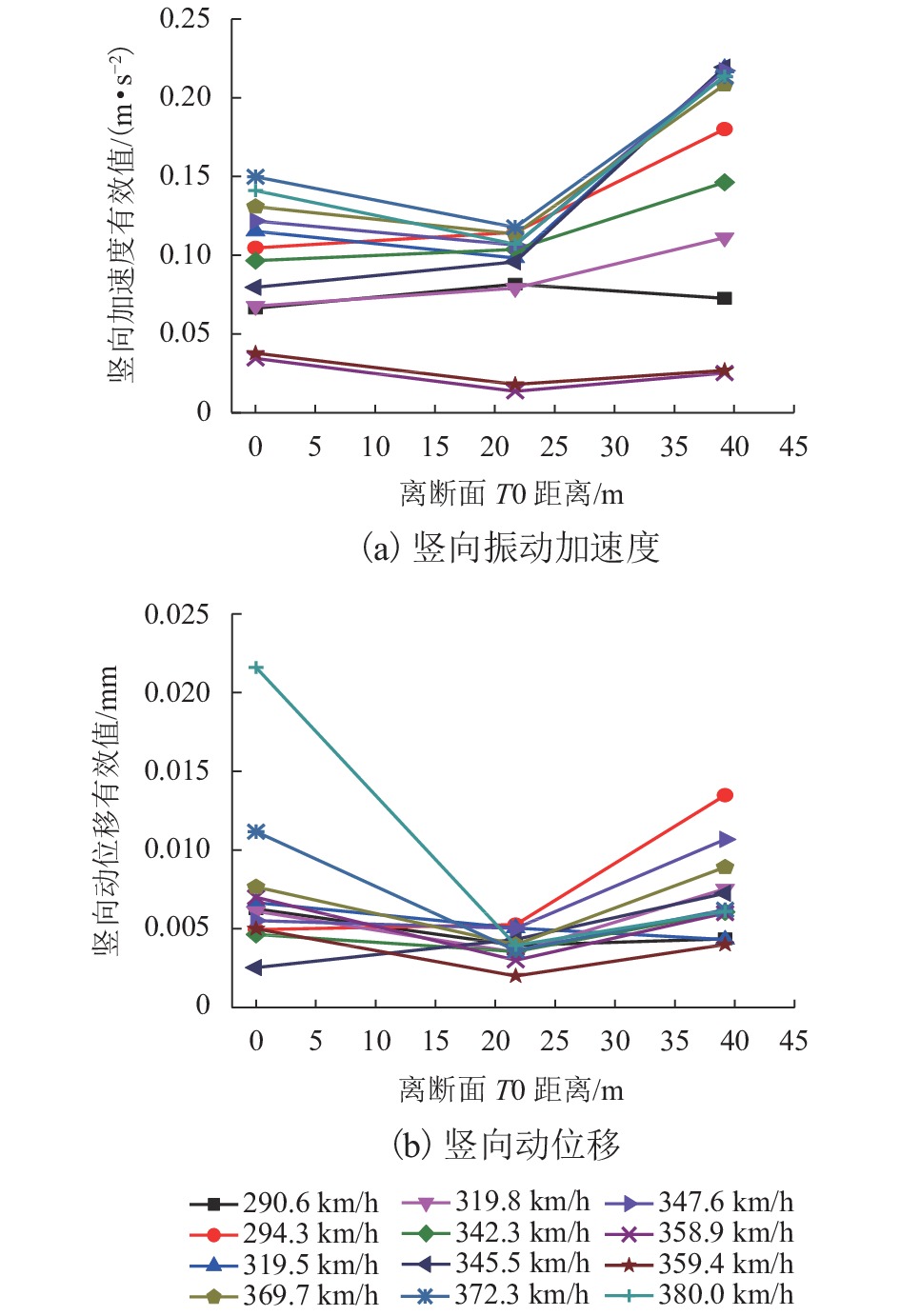

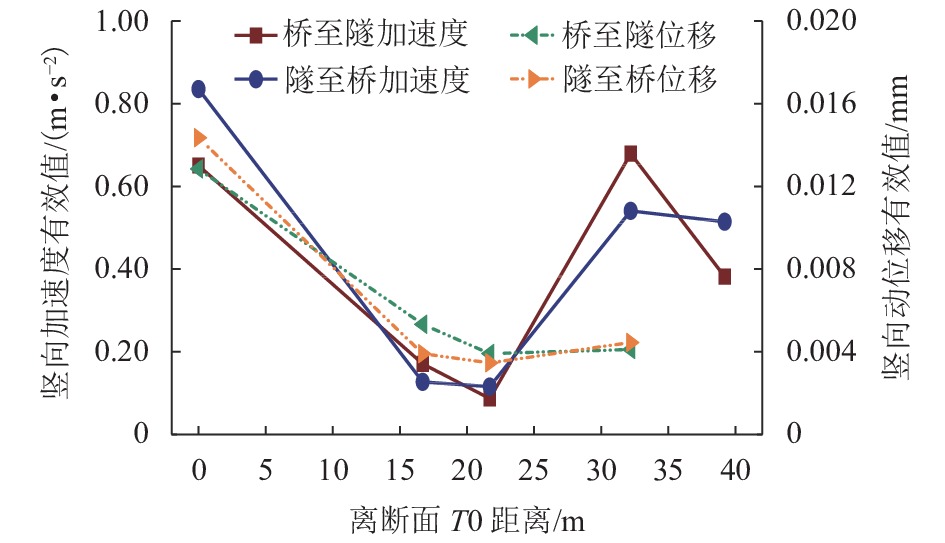

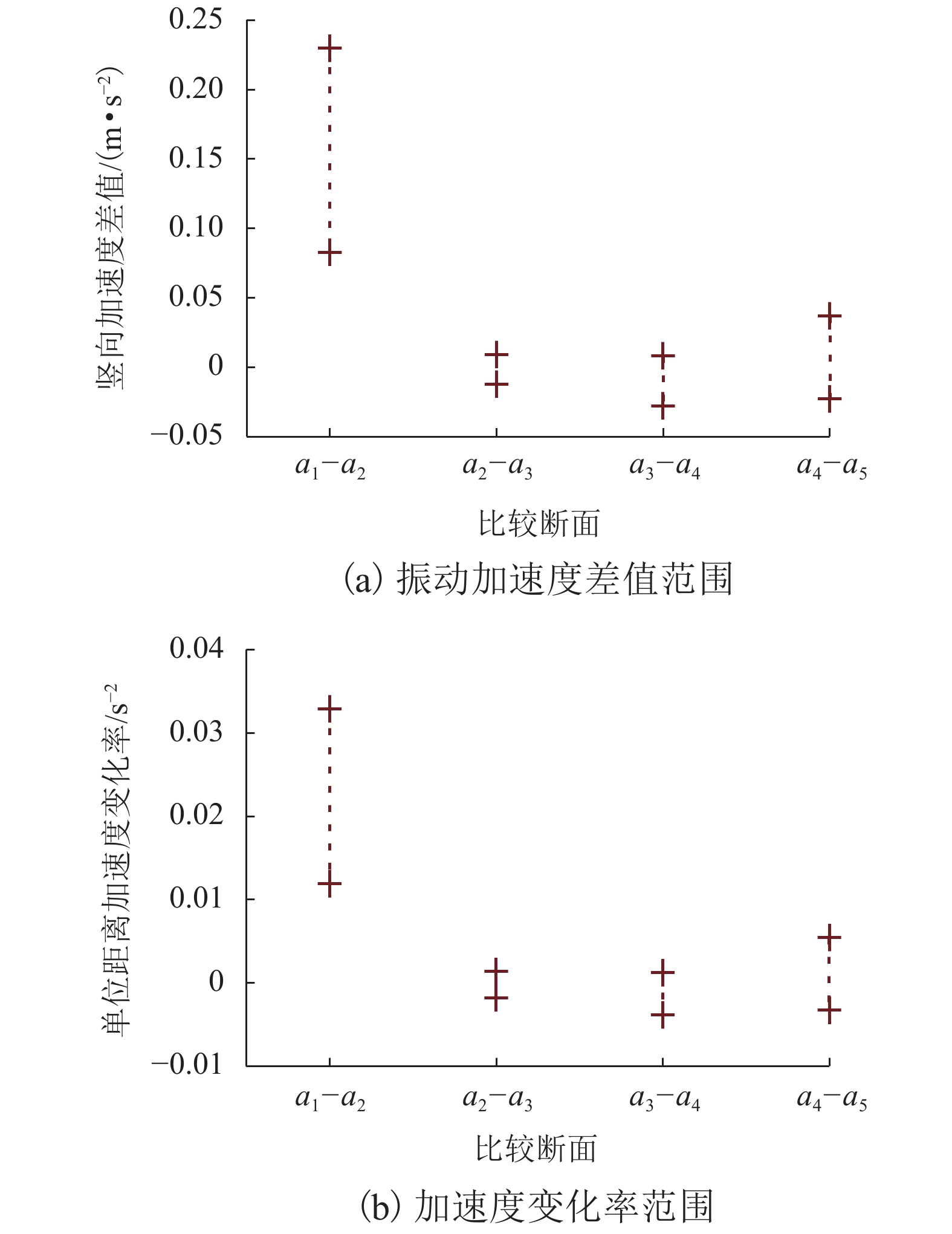

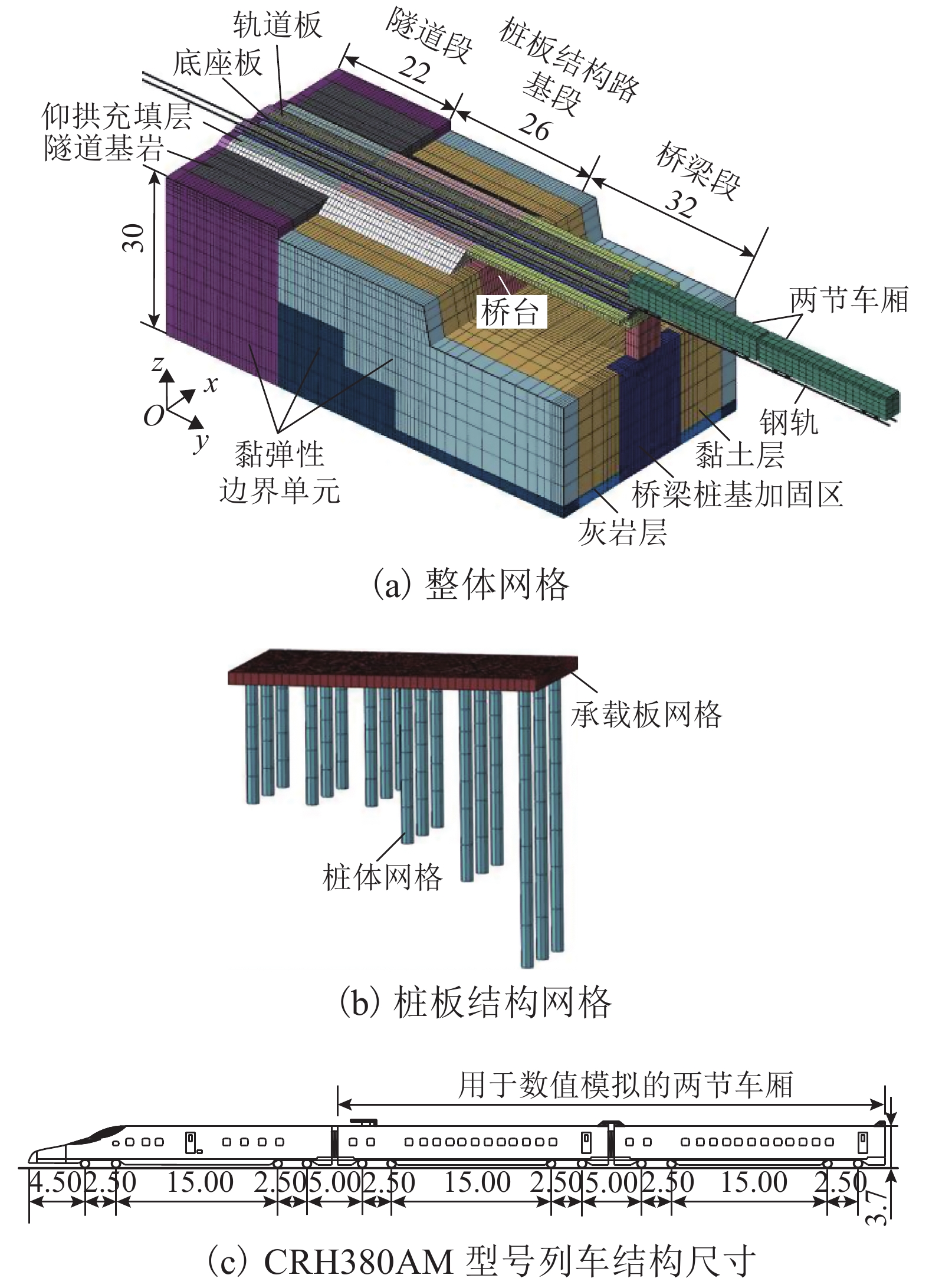

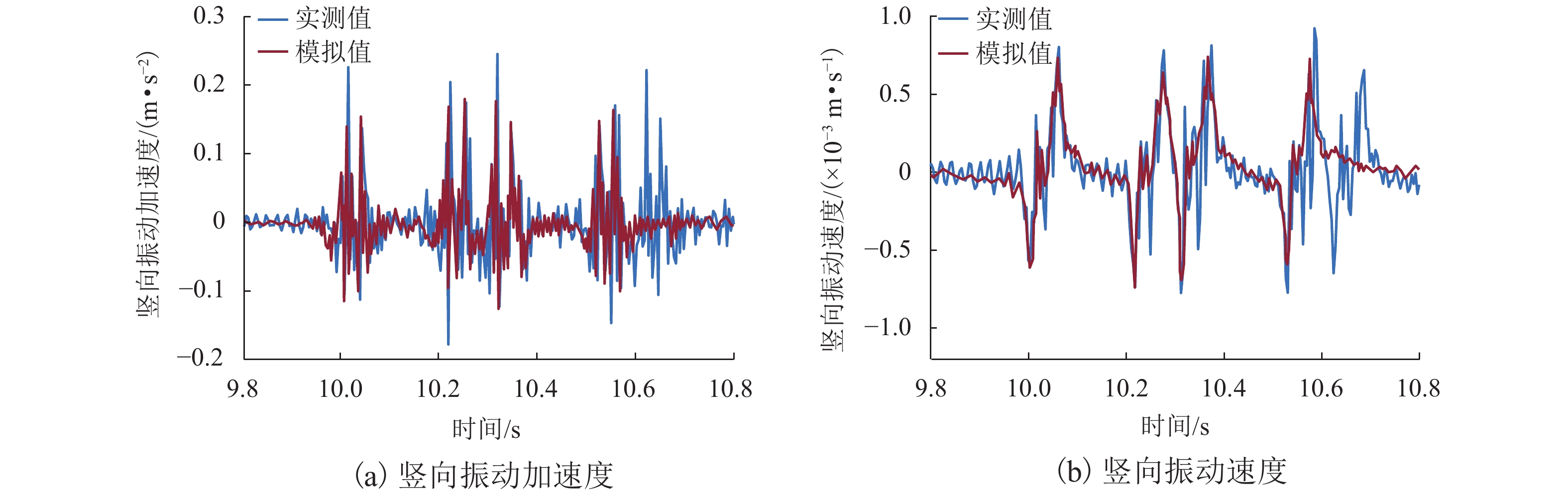

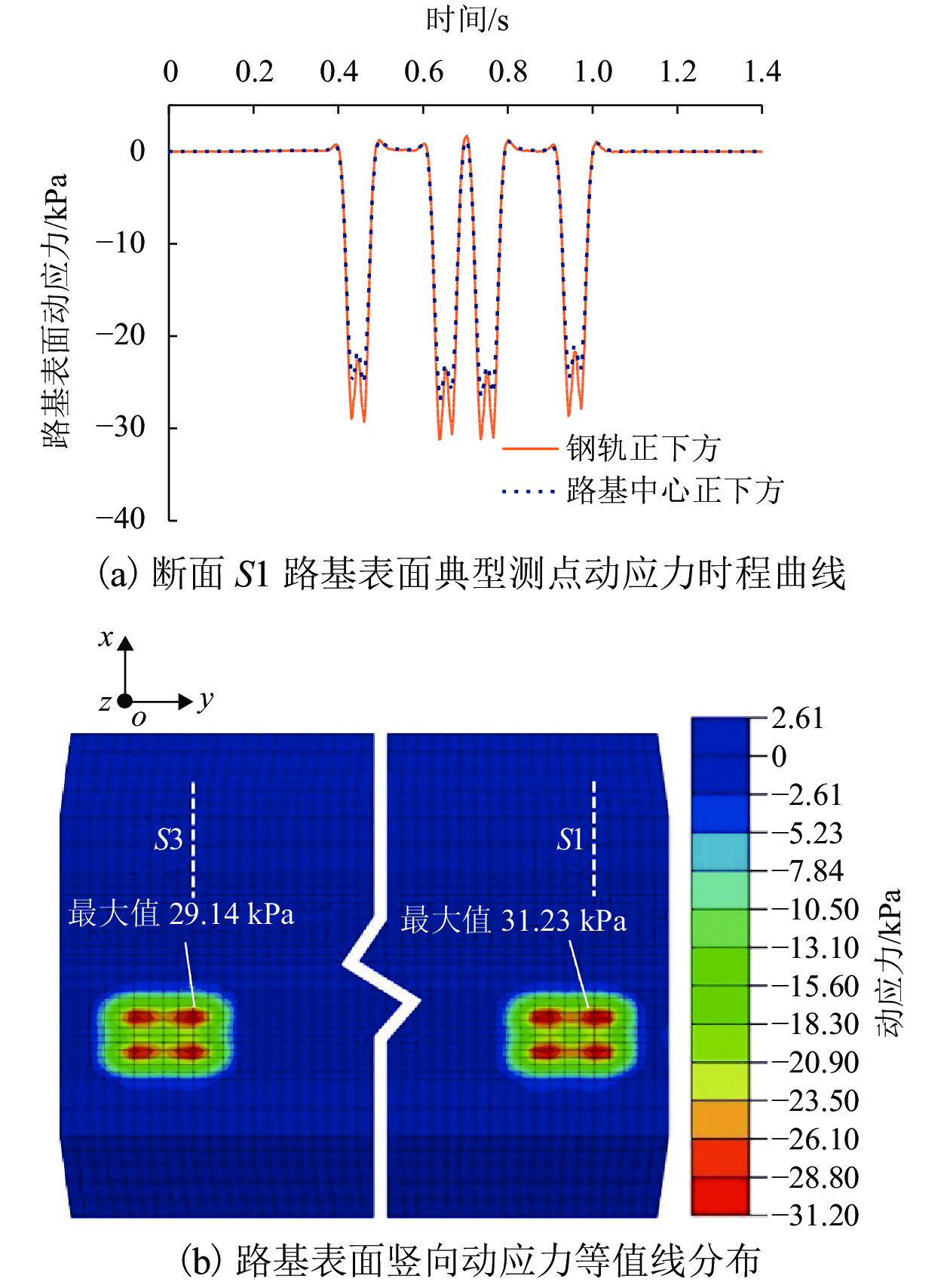

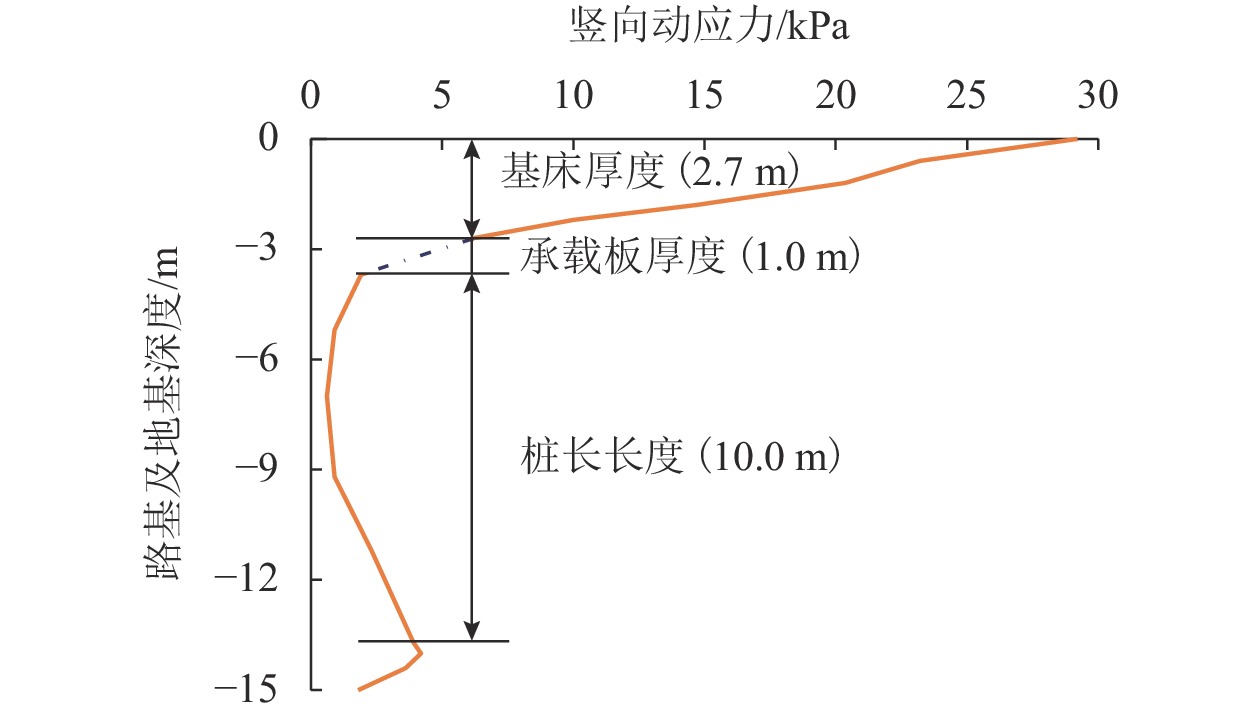

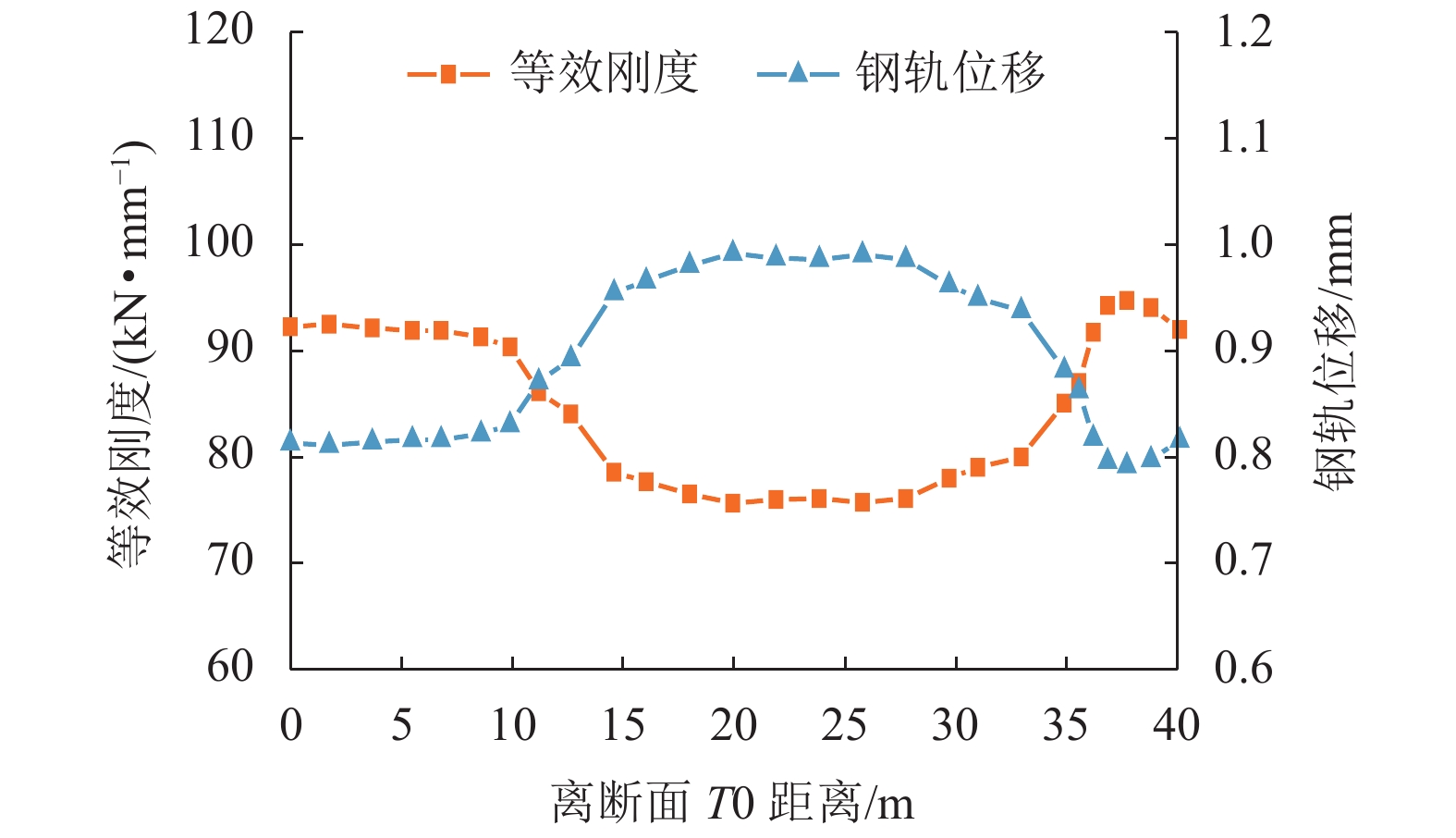

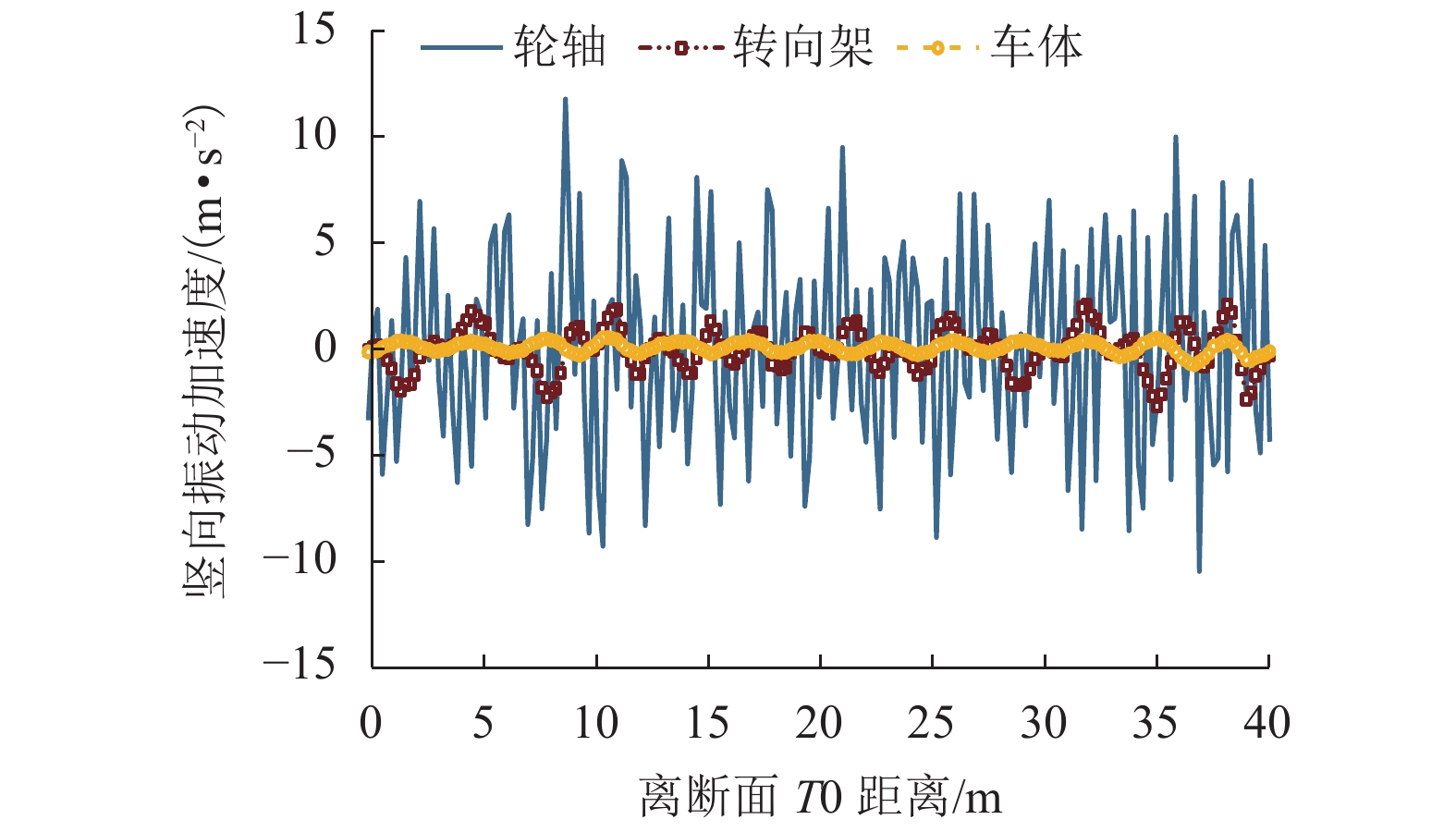

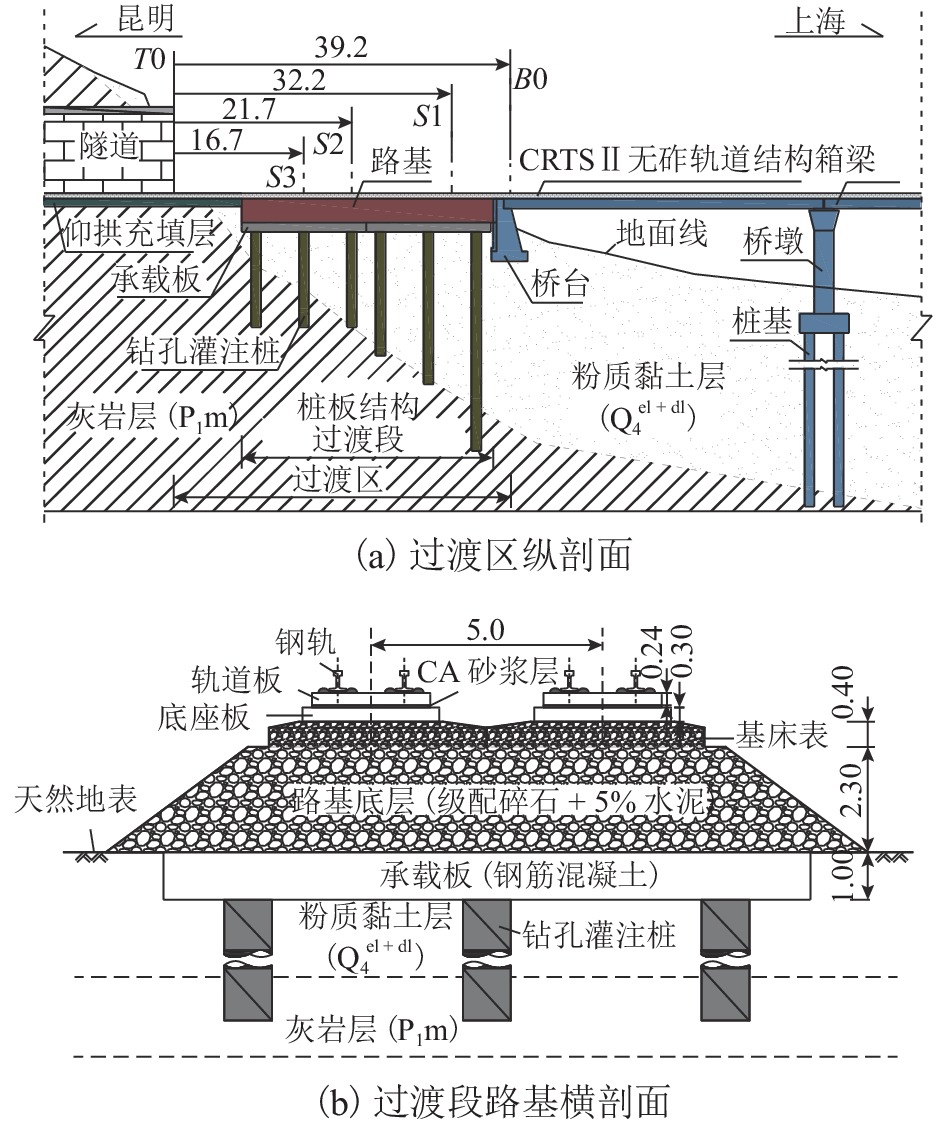

为了解深埋式桩板结构桥-隧过渡段的动力特性及过渡性能,在沪昆高铁某工点过渡区(含隧道口、过渡段及桥台)开展现场动力响应测试,分析不同车型、车速及行车方向等工况下过渡区的动力响应分布规律;并建立考虑车辆-轨道-路基耦合振动数值模型,研究过渡区的线路平顺性及桩板结构过渡段的动应力分布. 研究结果表明:不同车型列车激励下,过渡区振动加速度及动位移有效值的最大值分别为0.85 m/s2、0.034 mm,过渡段的振动水平要比隧道及桥台的更低;过渡段动力响应有效值随车速增大而增大,其增幅比隧道与桥台的更小;行车方向对过渡段与桥台连接区域的动力响应影响较大,对其他断面影响微弱;列车以300 km/h车速经过该过渡区时,过渡区钢轨挠度最大变化率约为0.149 mm/m,车体竖向加速度最大值为0.74 m/s2;桩板结构的存在能够将列车荷载传递至深部地基,使浅层地基土体承受的动力作用降低.

Abstract:To understand the dynamic characteristics and performances of bridge-tunnel transition sections with deep buried pile-plank structures (DBPPS), dynamic field tests were performed on a transition zone including a tunnel entrance, a transition section and a abutment in the Shanghai—Kunming high-speed railway to investigate its dynamic response distributions under running trains with different train types, speeds and driving directions. A numerical model considering vehicle-track-subgrade coupled interaction was then established to study the railway line smoothness along the transition zone and the vertical dynamic stress distribution of the DBPPS subgrade. Results show that under the train loads with different train types, the maximum effective values of acceleration and displacement along the transition zone are 0.85 m/s2 and 0.034 mm, respectively. The vibration level of the transition section is lower than that of the tunnel and the abutment. The effective values of dynamic response in the transition section increase with the increasing train speed, and its increase rate is smaller than that of the tunnel and the abutment. The driving directions have a significant influence on the dynamic responses in the connection between the transition section and the abutment, but have a weak influence on other sections. When the train passes through the transition zone at a speed of 300 km/h, the maximum change rate of rail deflection is approximately 0.149 mm/m, and the maximum vertical acceleration of the carbody is 0.74 m/s2. The pile-plank structure can transfer the train load to the deep foundation and reduce the dynamic effect on shallow soil of the foundation.

-

表 1 车辆参数与扣件参数

Table 1. Vehicle parameters and fastener parameters

车体及扣件参数 数值 车体质量 Mv/kg 44 320 转向架质量 Mb/kg 3 136 轮对质量 Mw/kg 2 352 一系悬挂刚度 Kpz/(kN•m−1) 1 040 二系悬挂刚度 Ksz/(kN•m−1) 400 扣件刚度 Krz/(MN•m−1) 60 一系悬挂阻尼 Cpz/(kN•s•m−1) 40 二系悬挂阻尼 Csz/(kN•s•m−1) 60 扣件阻尼 Crz/(kN•s•m−1) 60 表 2 过渡区各结构层材料属性

Table 2. Material properties of components in the transition zone

结构层 弹性模量/GPa 泊松比 密度/(kg•m−3) 黏聚力/kPa 内摩擦角/(°) 阻尼比 钢轨 205.900 0.30 7830 0.01 轨道板 32.500 0.16 2500 0.03 底座板 25.500 0.16 2500 0.03 基床表层 0.5400 0.30 2000 34 58 0.08 基床底层 0.920 0.25 2100 29 27 0.07 承载板 56.000 0.20 2500 0.02 钻孔桩 38.000 0.20 2500 0.03 粉质黏土 0.035 0.30 1930 24 16 0.10 灰岩 0.600 0.29 2090 0.09 桥台 30.000 0.20 2300 0.02 简支梁 22.000 0.18 2550 0.03 隧道基岩 12.000 0.20 2300 0.04 表 3 模拟值与实测值对比

Table 3. Comparison between the numerical results and the field measurements

项目名称 加速度 速度 实测值/(m•s−2) 模拟值/(m•s−2) 差异/% 实测值/

(× 10−3 m•s−1)模拟值/

(× 10−3 m•s−1)差异/% 底座板内侧测点 B0-3 0.190 0.170 10.5 0.940 0.89 5.3 S1-3 0.250 0.270 8.0 0.860 0.820 4.7 S2-3 0.170 0.160 5.9 0.800 0.690 13.8 S3-3 0.150 0.110 26.7 0.470 0.460 2.1 T0-3 0.460 0.250 45.6 1.420 0.930 34.5 路基中心线测点 B0-4 0.127 0.121 4.1 0.723 0.636 12.1 S1-4 0.114 0.129 13.1 0.391 0.357 8.8 S2-4 0.077 0.070 10.0 0.320 0.288 10.2 S3-4 0.071 0.055 23.0 0.247 0.209 15.5 -

[1] 苏谦, 罗照新, 王迅. 高速铁路路基非埋式桩板结构理论与实践[M]. 北京: 中国铁道出版社, 2011: 12-13. [2] 张树明,蒋关鲁,杜登峰,等. 新型桩板结构路基在季节冻土区的适用性[J]. 西南交通大学学报,2021,56(3): 541-549.ZHANG Shuming, JIANG Guanlu, DU Dengfeng, et al. Applicability of novel pile-plank embankment in seasonally frozen regions[J]. Journal of Southwest Jiaotong University, 2021, 56(3): 541-549. [3] 中华人民共和国铁道部. 铁路工程地基处理技术规程: TB 10106—2010[S]. 北京: 中国铁道出版社, 2010. [4] 詹永祥,蒋关鲁,牛国辉,等. 桩板结构路基动力模型试验研究[J]. 岩土力学,2008,29(8): 2097-2101,2110.ZHAN Yongxiang, JIANG Guanlu, NIU Guohui, et al. Model experimental research on dynamic performance of pile-plank embankment[J]. Rock and Soil Mechanics, 2008, 29(8): 2097-2101,2110. [5] 苏谦,王武斌,白皓,等. 非埋式桩板结构路基承载机制[J]. 交通运输工程学报,2012,12(1): 19-24.SU Qian, WANG Wubin, BAI Hao, et al. Bearing capacity mechanism of non-embedded pile-plank structure subgrade[J]. Journal of Traffic and Transportation Engineering, 2012, 12(1): 19-24. [6] 梁波,邓剑辰. 桩板结构路基的动力响应分析[J]. 铁道学报,2008,30(5): 80-84.LIANG Bo, DENG Jianchen. Analysis on dynamic responses of subgrade with the pile-plank structure[J]. Journal of the China Railway Society, 2008, 30(5): 80-84. [7] 马坤全. 高速行车条件下桩板结构-地基土系统的空间振动性能分析[J]. 铁道学报,2013,35(1): 93-100.MA Kunquan. Analysis on space vibration performance of pile-plank structure-foundation soil system under the condition of high-speed trains running[J]. Journal of the China Railway Society, 2013, 35(1): 93-100. [8] 苏谦,白皓,黄俊杰,等. 埋入式连续桩板结构温度效应计算方法[J]. 西南交通大学学报,2012,47(2): 181-186.SU Qian, BAI Hao, HUANG Junjie, et al. Calculation method for embedded continuous pile-board structure under thermal stresses[J]. Journal of Southwest Jiaotong University, 2012, 47(2): 181-186. [9] 国家铁路局. 高速铁路设计规范: TB 10621—2014[S]. 北京: 中国铁道出版社, 2014. [10] 魏丽敏, 何重阳, 杨哲. 沪昆铁路客运专线南昌西至宜春东段高速综合试验研究报告[R]. 长沙: 中南大学, 2014. [11] PAIXAO A, FORTUNATO E, CALCADA R. Transition zones to railway bridges:track measurements and numerical modelling[J]. Engineering Structures, 2014, 80: 435-443. doi: 10.1016/j.engstruct.2014.09.024 [12] 瀚邦. 峰值、有效值和平均值的使用[J]. 噪声与振动控制,1984(3): 26. [13] ANG K K, DAI J. Response analysis of high-speed rail system accounting for abrupt change of foundation stiffness[J]. Journal of Sound and Vibration, 2013, 332(12): 2954-2970. [14] SANUDO R, CERRADA M, ALONSO B, et al. Analysis of the influence of support positions in transition zones. a numerical analysis[J]. Construction and Building Materials, 2017, 145: 207-217. doi: 10.1016/j.conbuildmat.2017.03.204 [15] LI D, SELIG E T. Method for railroad track foundation design. I:development[J]. Journal of Geotechnical and Geoenvironmental Engineering, 1998, 124(4): 316-322. doi: 10.1061/(ASCE)1090-0241(1998)124:4(316) [16] ZHAI W M, SUN X. A detailed model for investigating vertical interactions between railway vehicle and track[J]. Vehicle System Dynamics, 1994, 23: 603-615. doi: 10.1080/00423119308969544 [17] 刘文劼,梅慧浩,冷伍明,等. 路基基床动应力响应特征的数值模拟研究[J]. 铁道学报,2017,39(12): 108-1.LIU Wenjie, MEI Huihao, LENG Wuming, et al. Numerical analysis of dynamic stress response characteristics of subgrade bed[J]. Journal of the China Railway Society, 2017, 39(12): 108-1. [18] 薛富春,张建民. 移动荷载下高铁路基段振动加速度频谱衰减特性[J]. 岩土力学,2015,36(增刊1): 445-451.XUE Fuchun, ZHANG Jianming. Attenuations of acceleration spectra of high-speed railway embankment subjected to moving loads[J]. Rock and Soil Mechanics, 2015, 36(S1): 445-451. [19] HU P, ZHANG C, WEN S, et al. Dynamic responses of high-speed railway transition zone with various subgrade fillings[J]. Computers and Geotechnics, 2019, 108: 17-26. doi: 10.1016/j.compgeo.2018.12.011 [20] 聂志红,阮波,李亮. 秦沈客运专线路堑段基床结构动态测试分析[J]. 振动与冲击,2005,24(2): 30-32,146.NIE Zhihong, RUAN Bo, LI Liang. Testing and analysis on dynamic performance of subgrade of QingShen Railway[J]. Journal of Vibration and Shock, 2005, 24(2): 30-32,146. [21] 郭志广,魏丽敏,何群,等. 武广高速铁路无砟轨道路基动力响应试验研究[J]. 振动与冲击,2013,32(14): 148-152,163.GUO Zhiguang, WEI Limin, HE Qun, et al. Tests for dynamic response of ballastless track subgrade of wu-guang high-speed railway[J]. Journal of Vibration and Shock, 2013, 32(14): 148-152,163. [22] ESVELD C. Modern railway track[M]. Zaltbommel: MRT-Production, 2001: 480-481. [23] 陈小平,王平. 时速350 km客运专线无砟道岔的合理轨道刚度研究[J]. 铁道标准设计,2010(3): 1-3.CHEN Xiaoping, WANG Ping. Study on reasonable orbital stiffness of ballastless turnouts in passenger dedicated lines with a speed of 350km/h[J]. Railway Standard Design, 2010(3): 1-3. [24] 蔡成标,徐鹏. 弹性支承块式无砟轨道结构参数动力学优化设计[J]. 铁道学报,2011,33(1): 69-75.CAI Chengbiao, XU Peng. Dynamic optimization design of the structural parameters of low vibration track[J]. Journal of the China Railway Society, 2011, 33(1): 69-75. [25] 铁道部标准计量研究所. 铁道机车动力学性能试验鉴定方法及评定标准: TBT 2360—1993[S]. 北京: 中华人民共和国铁道部, 1993. -

下载:

下载: