Construction Risk Assessment of Super-Large Open Caisson Foundation

-

摘要:

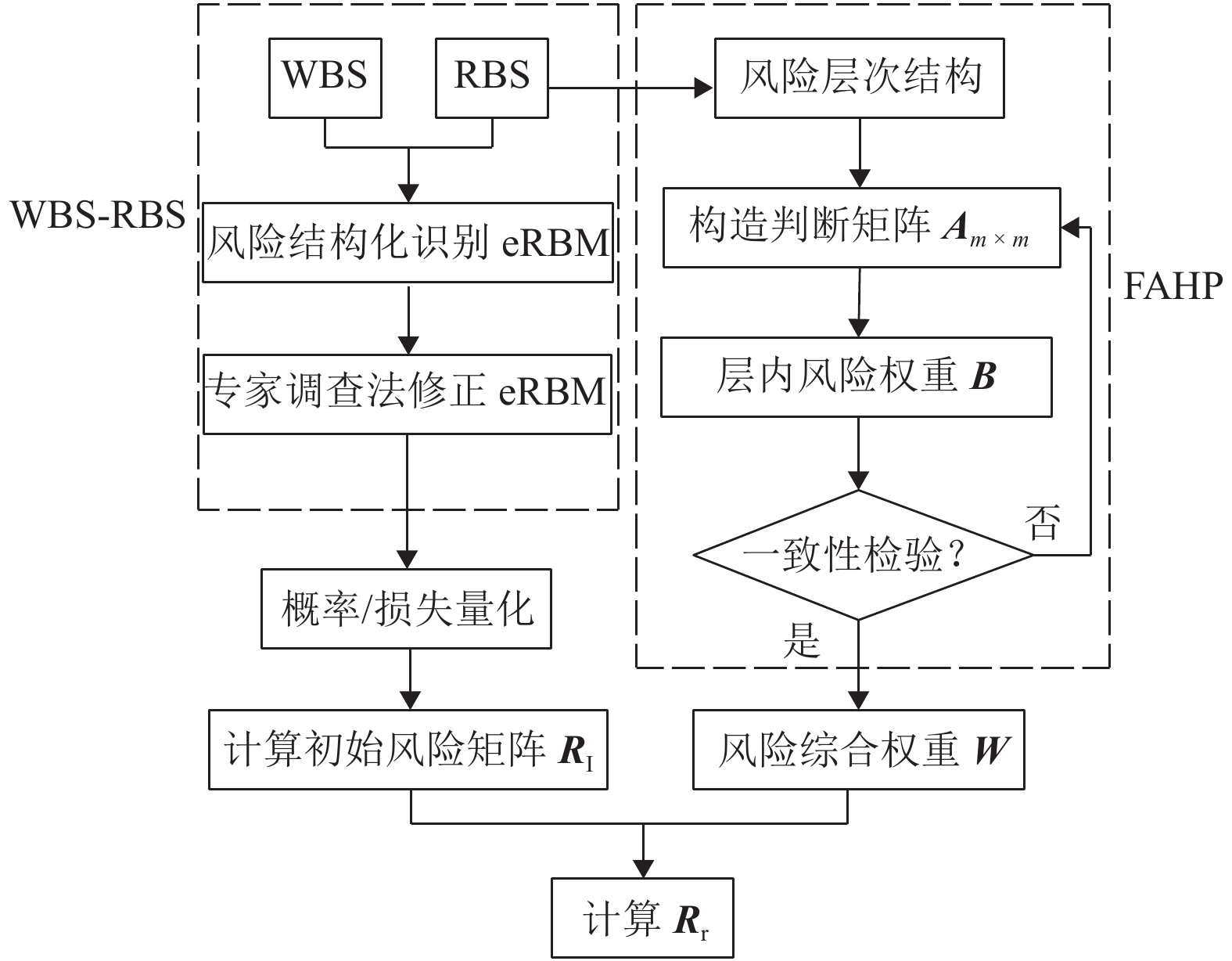

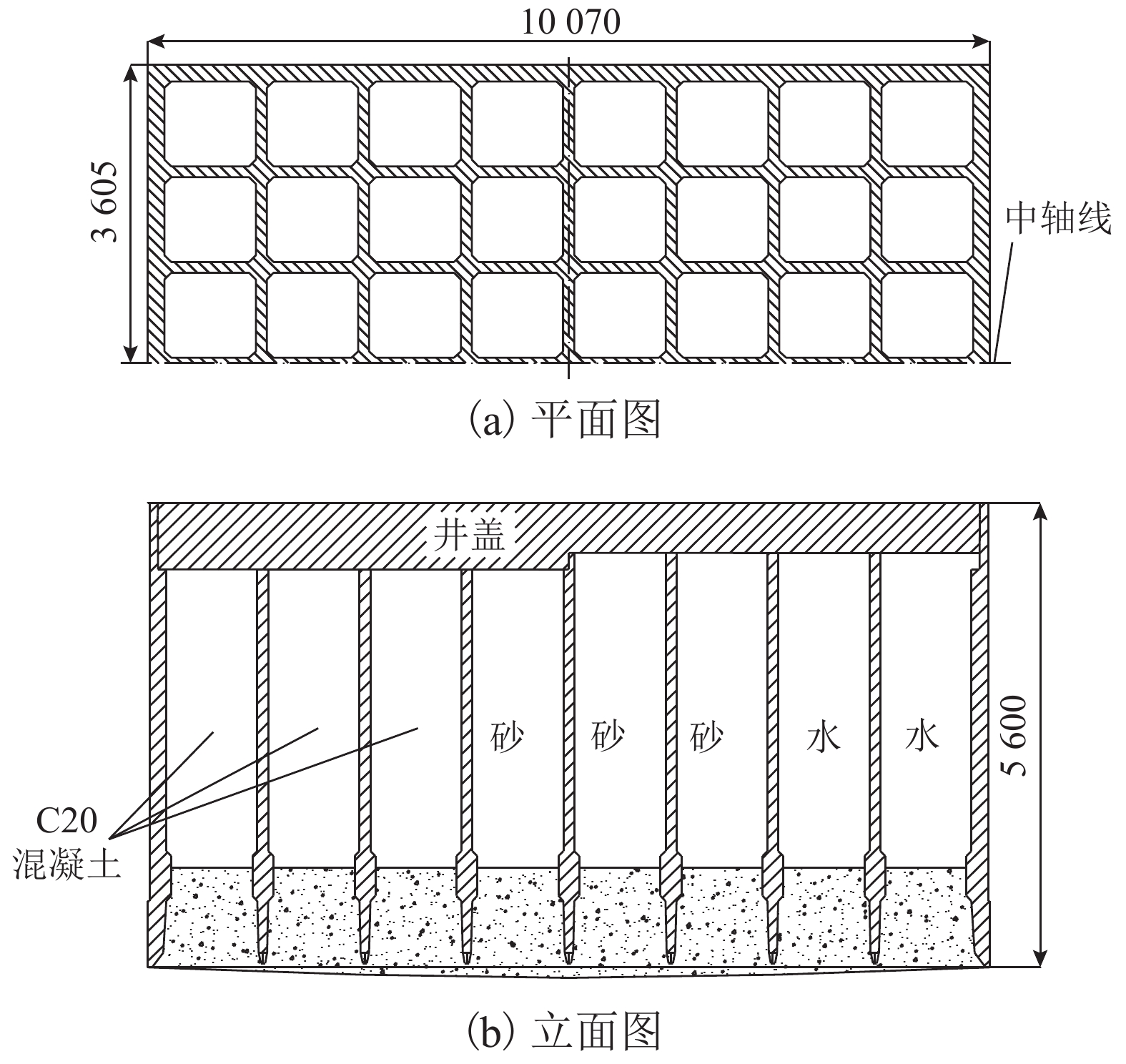

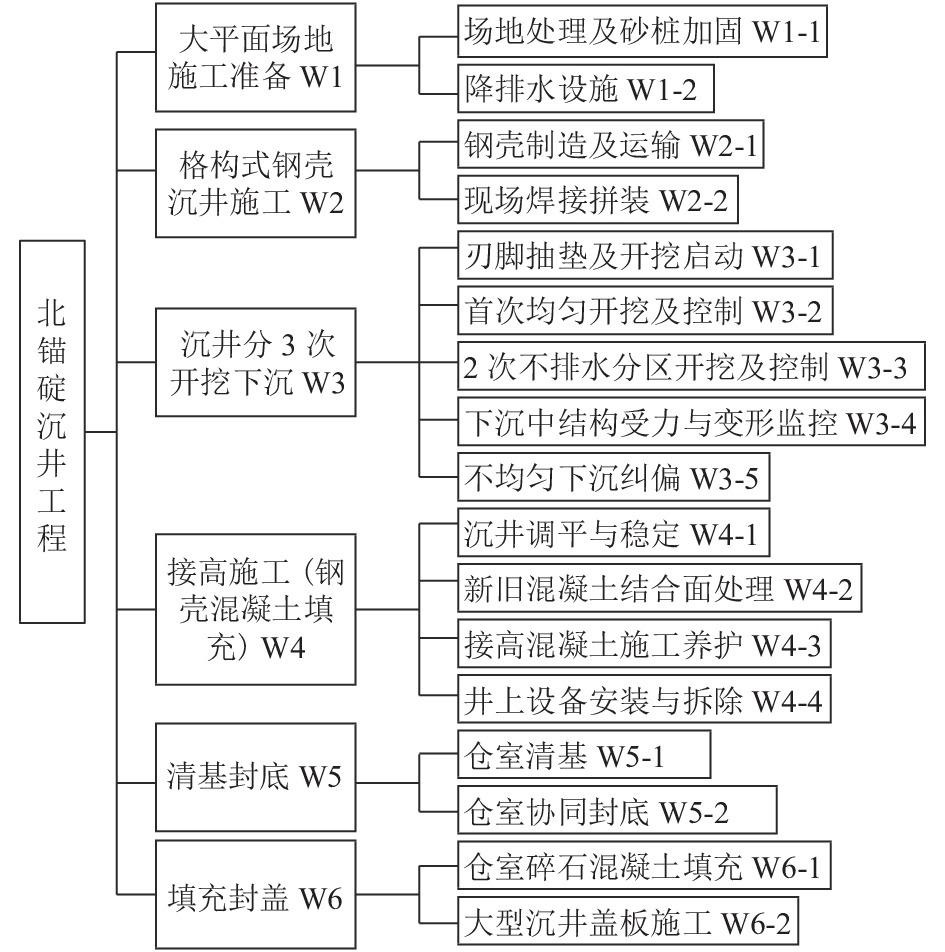

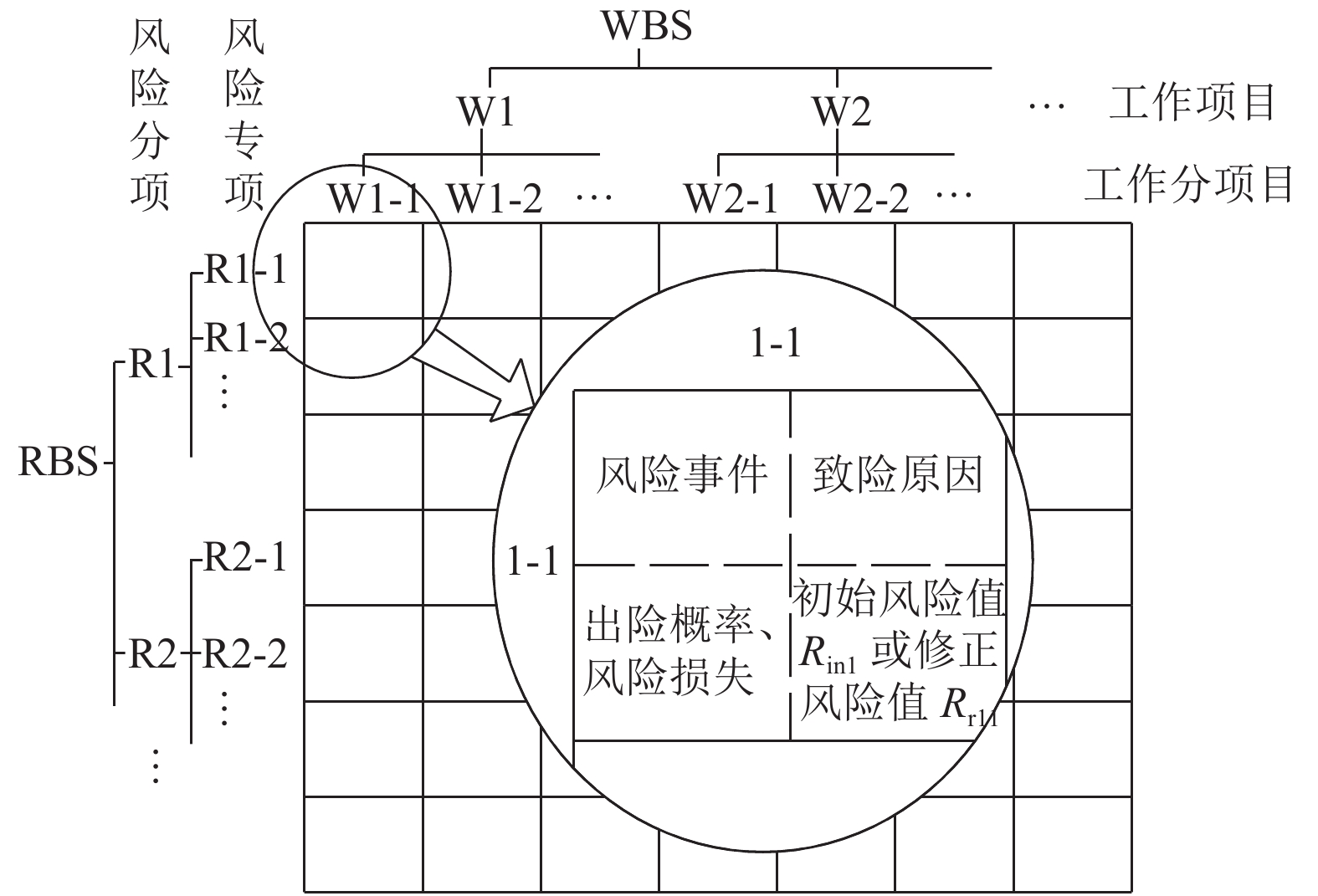

超大型沉井基础受尺寸巨大、地质条件复杂等因素影响,在施工阶段具有较高的安全及质量风险. 为准确有效地实现大型锚碇沉井基础施工过程的风险评估,采用工作分解结构-风险分解结构(WBS-RBS),并结合专家调查法进行施工全过程风险识别;基于分解结构估测风险事件概率及损失等级从而确定初始风险分解矩阵,通过模糊层次分析(FAHP)法分析各类风险权重对其加权修正,并以修正风险矩阵值评估风险等级;采用该风险评估方法开展连镇铁路五峰山长江大桥北锚碇沉井基础施工风险评估. 研究结果表明:基于WBS-RBS法及专家调查法识别出“井壁开裂”等158项风险源;逐项计算初始风险值、综合风险值权重,并按等级划分标准评估出修正风险值大于1.696的“沉井突沉”“几何偏斜”等重大风险源共16项;针对重大风险源提出施工专项方案、实时施工监控及风险预案等措施控制. 为该沉井基础工程施工风险控制提供了依据,并为类似工程风险评估与控制提供借鉴.

Abstract:Affected by factors such as huge size and complex geological conditions, the super-large anchorage caisson foundation has high quality and safety risks in the construction stage. In order to assess these risks accurately, the work breakdown structure-risk breakdown structure (WBS-RBS) method, combined with expert investigation, was used to identify risks in the whole construction process. Based on the breakdown structure, an initial risk breakdown matrix was determined by estimating probabilities and corresponding loss levels of risk events. By analyzing weights of all kinds of risks through fuzzy analytical hierarchy process (FAHP), the result of the risk breakdown matrix was revised. Finally, the risk levels were divided according to the revised risk matrix values. As a case study, the proposed method was applied to construction risk assessment of the north anchorage caisson foundation of Wufengshan Yangtze River Bridge in Lianyungang−Zhenjiang high-speed railway. The results reveal that 158 risk sources were identified by the WBS-RBS and expert investigation method. Based on calculation of initial risk values and comprehensive weights, 16 major risk sources with the revised risk value larger than 1.696, such as caisson sudden sinking and attitude deviation were obtained according to the risk classification criterion. Besides, countermeasures such as special construction scheme, real-time construction monitoring, and reserved risk plan were provided. The research work provides a basis for the construction risk control of the open caisson foundation project and also provides a reference for the risk assessment and control of similar projects.

-

Key words:

- open caisson /

- risk identification /

- risk assessment /

- expert investigation /

- breakdown structure

-

表 1 风险概率等级区间划分标准

Table 1. Interval division standard of risk probability grades

等级 概率值区间 区间描述 1 P < 0.0003 几乎不可能发生 2 0.0003 ≤ P < 0.0030 很少发生 3 0.0030 ≤ P < 0.0300 偶尔发生 4 0.0300 ≤ P < 0.3000 可能发生 5 P ≥ 0.3000 频繁发生 表 2 风险等级划分标准

Table 2. Risk classification criteria

轻度Ⅰ 中度Ⅱ 高度Ⅲ 重大Ⅳ < 17/k [17/k~22.5/k) [22.5/k~23.75/k] > 23.75/k 表 3 沉井工程风险分解

Table 3. Risk decomposition table for caisson engineering

顶层指示 二级指标 三级指标 沉井施

工阶段

风险 R建设条件风险 R1 地质风险 R1-1 水文风险 R1-2 气象风险 R1-3 周边施工条件风险 R1-4 结构设计风险 R2 整体设计风险 R2-1 局部构造设计风险 R2-2 节段构造设计风险 R2-3 施工工艺风险 R3 结构或设备性能风险 R3-1 施工方法/工艺风险 R3-2 智能施工及技术风险 R3-3 几何姿态偏斜风险 R3-4 组织管理/监控

风险 R4施工防护风险 R4-1 监控与管理风险 R4-2 桥梁结构影响

风险 R5结构变位风险 R5-1 表 4 沉井施工风险调查表(部分)

Table 4. Questionnaire on the open caisson construction risks (part)

指标层元素 风险事件 当前状态 假定采取的缓解风险措施 风险发生概率级别 风险损失级别 评定理由 人员伤亡 经济损失 环境影响 W3-2 井底翻砂 水位监控 加强监测局部土层探查 4 1 4 1 常发事故 经过局部软弱土层 严格验算,规范施工 工艺详细要求 3 1 3 1 常发事故 沉井倾斜 可控不均匀下沉 加强监测,多手段纠斜 4 1 4 1 常发事故 沉井侧移 可控不均匀下沉 调直后下沉 4 1 4 1 常发事故 沉井扭转 可控不均匀下沉 可控偏斜施工 4 1 4 1 常发事故 井外塌陷 防护警示,陷坑填筑 正常施工 4 2 4 2 常发事故 沉井突沉 短期下沉困难 空气幕法助沉 4 2 4 1 发生风险小 表 5 二级指标元素判断矩阵

Table 5. Element judgment matrix of secondary indicators

R R1 R2 R3 R4 R5 权重 ωi R1 1 1/4 1/6 1/4 3 0.068 5 R2 4 1 1/2 4 7 0.306 6 R3 6 2 1 4 8 0.450 6 R4 4 1/4 1/4 1 4 0.137 1 R5 1/3 1/7 1/8 1/4 1 0.037 3 表 6 施工技术风险判断矩阵

Table 6. Risk judgment matrix of construction technology

R3 R3-1 R3-2 R3-3 R3-4 R3-1 1 1/3 1/6 1/5 R3-2 3 1 1/3 1/3 R3-3 6 3 1 2 R3-4 5 3 1/2 1 表 7 重大风险源加权风险值表

Table 7. Weighted risk values of major risk sources

序号 风险事件 WBS RBS 权重 加权风险值 1 沉井突沉 W3-3 R3-3 0.213 2.553 2 滞沉 W3-3 R3-3 0.213 2.099 3 井底翻砂 W3-3 R3-4 0.144 2.027 4 姿态偏斜 W3-3 R3-4 0.144 1.894 5 沉井扭转 W3-3 R3-4 0.144 1.950 6 井周塌陷 W3-3 R3-4 0.144 2.007 7 井底涌水 W3-3 R3-4 0.144 1.999 8 井壁/隔墙变形

过大或开裂W3-4 R3-3 0.213 1.863 9 刃脚及隔墙破损 W3-4 R2-2 0.079 1.877 10 纠偏纠斜失效 W3-5 R3-3 0.213 1.801 11 大堤变形超限 W3-4 R4-2 0.098 1.620 12 基础下土体扰动 W5-1 R3-3 0.213 1.833 13 电塔倾斜 W3-4 R4-2 0.098 1.808 14 不良性质地层 W3-2 R3-2 0.067 1.712 15 锚碇偏心力 W5-2 R2-1 0.195 1.685 16 井上墩柱偏心 W5-2 R2-1 0.195 1.697 表 8 风险类型比较(RBS)

Table 8. Comparison of risk types (RBS)

项目 R1 R2 R3 R4 R5-1 R1-1 R1-2 R1-3 R1-4 R2-1 R2-2 R2-3 R3-1 R3-2 R3-3 R3-4 R4-1 R4-2 权重 0.041 0.007 0.003 0.017 0.195 0.079 0.032 0.028 0.066 0.213 0.144 0.039 0.098 0.037 累计加权风险值 3.913 0.235 0.090 1.285 9.375 5.781 0.514 1.128 6.795 40.206 20.261 1.097 4.994 1.790 排序 7 13 14 9 3 5 12 10 4 1 2 11 6 8 表 9 工作风险比较(WBS)

Table 9. Comparison of construction works (WBS)

项目 W1 W2 W3 W4 W5 W6 W1-1 W1-2 W2-1 W2-2 W3-1 W3-2 W3-3 W3-4 W3-5 W4-1 W4-2 W4-3 W4-4 W5-1 W5-2 W6-1 W6-2 累计风险值 1.037 2.251 7.196 1.515 5.019 10.157 29.535 8.186 4.989 2.147 0.271 4.818 0.857 5.076 8.222 3.635 2.555 排序 15 12 5 14 7 2 1 4 8 13 17 9 16 6 3 10 11 -

[1] 褚晶磊,马建林,蒋炳楠,等. 水中沉井下沉期侧壁摩阻力分布试验研究[J]. 岩土工程学报,2019,41(4): 707-716.CHU Jinglei, MA Jianlin, JIANG Bingnan, et al. Experimental study on the distribution of side wall friction during the sinking period of submerged caisson[J]. Journal of Geotechnical Engineering, 2019, 41(4): 707-716. [2] 穆保岗,朱建民,龚维明,等. 悬索桥大型沉井排水下沉控制的关键问题分析[J]. 中国公路学报,2013,26(6): 118-127. doi: 10.3969/j.issn.1001-7372.2013.06.017MU Baogang, ZHU Jianmin, GONG Weiming, et al. Key issues of drainage subsidence control for large caisson of suspension bridge[J]. Journal of China Highway, 2013, 26(6): 118-127. doi: 10.3969/j.issn.1001-7372.2013.06.017 [3] 郑大超,朱斌. 武汉杨泗港长江大桥2号墩钢沉井施工关键技术[J]. 桥梁建设,2017,47(6): 106-110. doi: 10.3969/j.issn.1003-4722.2017.06.019ZHENG Dachao, ZHU Bin. Key technologies of steel caisson construction for pier 2 of yangsigang yangtze river bridge in Wuhan[J]. Bridge Construction, 2017, 47(6): 106-110. doi: 10.3969/j.issn.1003-4722.2017.06.019 [4] 余本俊. 大型钢沉井整节段制造、运输与现场接高施工技术[J]. 桥梁建设,2013,43(2): 110-115.YU Benjun. Construction technology of whole section manufacture,transportation and site connection of large steel caisson[J]. Bridge Construction, 2013, 43(2): 110-115. [5] HILLSON D. Using a risk breakdown structure in project management[J]. Journal of Facilities Management, 2003, 2(1): 85-97. doi: 10.1108/14725960410808131 [6] SIAMI-IRDEMOOSA E, DINDARLOO S R, SHARIF-ZADEH M. Work breakdown structure (WBS) develop-ment for underground construction[J]. Automation in Construction, 2015, 58: 85-94. doi: 10.1016/j.autcon.2015.07.016 [7] HILLSON D, GRIMALDI S, RAFELE C. Managing project risks using a cross risk breakdown matrix[J]. Risk Management, 2006, 8(1): 61-76. doi: 10.1057/palgrave.rm.8250004 [8] 陈国华,吴武生,徐三元,等. 基于WBS-RBS与AHP的跨海桥梁工程施工HSE风险评价[J]. 中国安全科学学报,2013,23(9): 51-57. doi: 10.3969/j.issn.1003-3033.2013.09.009CHEN Guohua, WU Wusheng, XU Sanyuan, et al. HSE risk assessment of cross-sea bridge construction based on WBS-RBS and AHP[J]. Chinese Journal of Safety Sciences, 2013, 23(9): 51-57. doi: 10.3969/j.issn.1003-3033.2013.09.009 [9] SAATY T L. Highlights and critical points in the theory and application of the analytic hierarchy process[J]. European Journal of Operational Research, 2007, 74(3): 426-447. [10] 丁闪闪,刘小勇,王遥,等. 基于蒙特卡罗法的桥梁施工阶段风险估计[J]. 安全与环境工程,2013,20(6): 121-125. doi: 10.3969/j.issn.1671-1556.2013.06.024DING Shanshan, LIU Xiaoyong, WANG Yao, et al. Risk estimation in bridge construction stage based on Monte Carlo method[J]. Safety and Environmental Engineering, 2013, 20(6): 121-125. doi: 10.3969/j.issn.1671-1556.2013.06.024 [11] 苏洁,张顶立,周正宇,等. 地铁隧道穿越既有桥梁安全风险评估及控制[J]. 岩石力学与工程学报,2015,34(增刊1): 3188-3195.SU Jie, ZHANG Dingli, ZHOU Zhengyu, et al. Safety risk assessment and control of subway tunnel crossing existing bridges[J]. Journal of Rock Mechanics and Engineering, 2015, 34(S1): 3188-3195. [12] 许振浩,李术才,李利平,等. 基于层次分析法的岩溶隧道突水突泥风险评估[J]. 岩土力学,2011,32(6): 1757-1766. doi: 10.3969/j.issn.1000-7598.2011.06.027XU Zhenhao, LI Shucai, LI Liping, et al. Risk assessment of water inrush and mud inrush in karst tunnel based on analytic hierarchy process[J]. Geomechanics, 2011, 32(6): 1757-1766. doi: 10.3969/j.issn.1000-7598.2011.06.027 [13] 程远,刘志彬,刘松玉,等. 基于层次分析法的大跨浅埋公路隧道施工风险识别[J]. 岩土工程学报,2011,33(增刊1): 198-202.CHENG Yuan, LIU Zhibin, LIU Songyu, et al. Risk identification of large-span shallow-buried highway tunnel construction based on AHP[J]. Journal of Geotechnical Engineering, 2011, 33(S1): 198-202. [14] 边亦海,黄宏伟,李剑. 可信性方法在深基坑施工期风险分析中的应用[J]. 地下空间与工程学报,2006,2(1): 70-73.BIAN Yihai, HUANG Hongwei, LI Jian. Application of credibility method in risk analysis of deep foundation pit construction period[J]. Journal of Underground Space and Engineering, 2006, 2(1): 70-73. [15] 陈洁金,周峰,阳军生,等. 山岭隧道塌方风险模糊层次分析[J]. 岩土力学,2009,30(8): 2365-2370. doi: 10.3969/j.issn.1000-7598.2009.08.030CHEN Jiejin, ZHOU Feng, YANG Junsheng, et al. Fuzzy analytic hierarchy process of landslide tunnel collapse risk[J]. Geotechnical Mechanics, 2009, 30(8): 2365-2370. doi: 10.3969/j.issn.1000-7598.2009.08.030 [16] 邓雪,李家铭,曾浩健,等. 层次分析法权重计算方法分析及其应用研究[J]. 数学的实践与认识,2012,42(7): 93-10. doi: 10.3969/j.issn.1000-0984.2012.07.012DENG Xue, LI Jiaming, ZENG Haojian, et al. Analytic hierarchy process weight calculation method analysis and application research[J]. Mathematics Practice and Understanding, 2012, 42(7): 93-10. doi: 10.3969/j.issn.1000-0984.2012.07.012 [17] 张杰. 大跨度桥梁施工期风险分析方法研究[D]. 上海: 同济大学, 2007. [18] 周健,王红卫,吴邵海. 盾构法施工风险的多态贝叶斯网络模型分析[J]. 同济大学学报(自然科学版),2013,41(2): 186-190,202.ZHOU Jian, WANG Hongwei, WU Shaohai. Polymor-phic bayesian network model analysis of shield construction risk[J]. Journal of Tongji University (Natural Science Edition), 2013, 41(2): 186-190,202. -

下载:

下载: