Simulation of Ⅰ - Ⅱ Mixed Mode Cracking Behavior of Ultra-Dense Asphalt Concrete

-

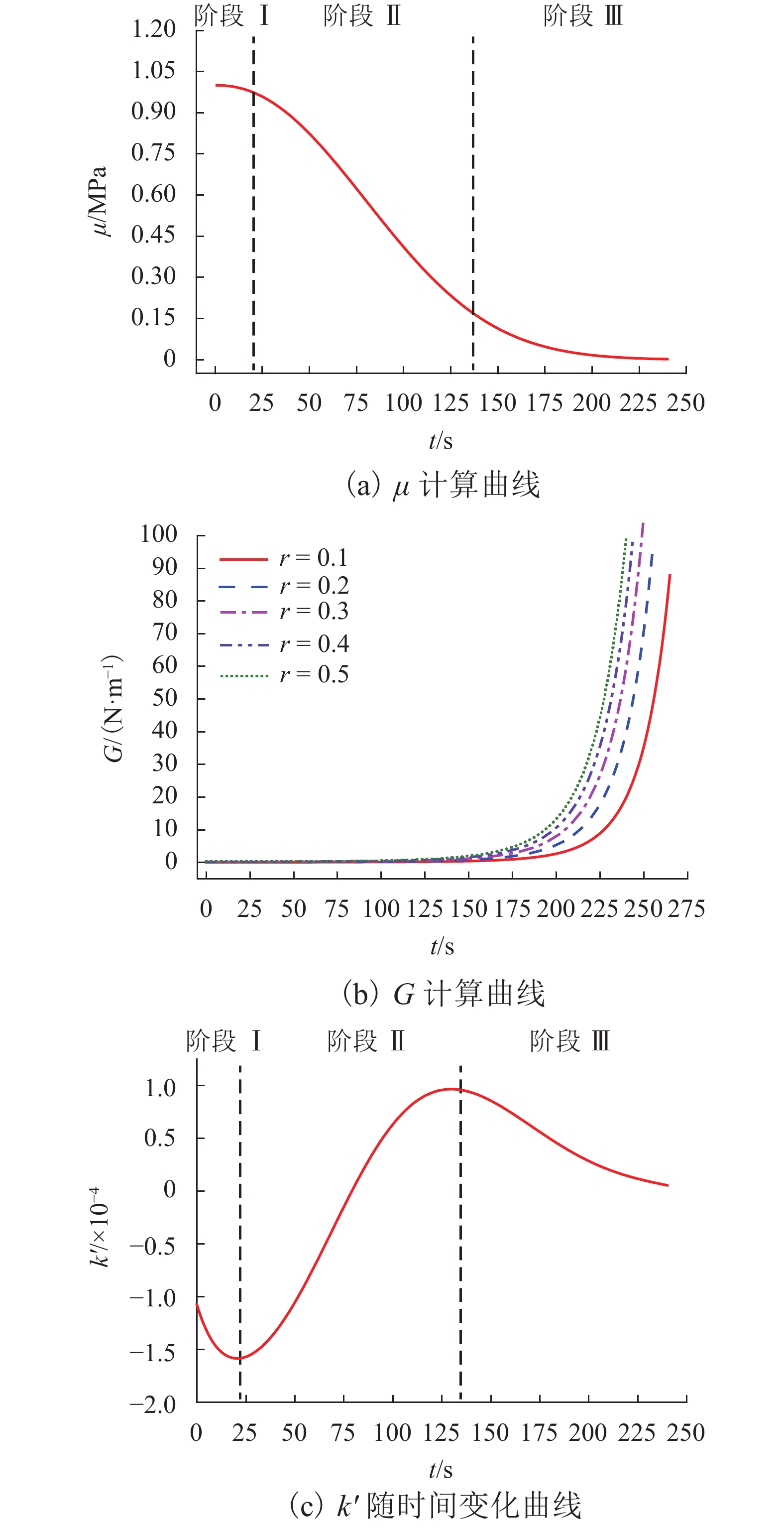

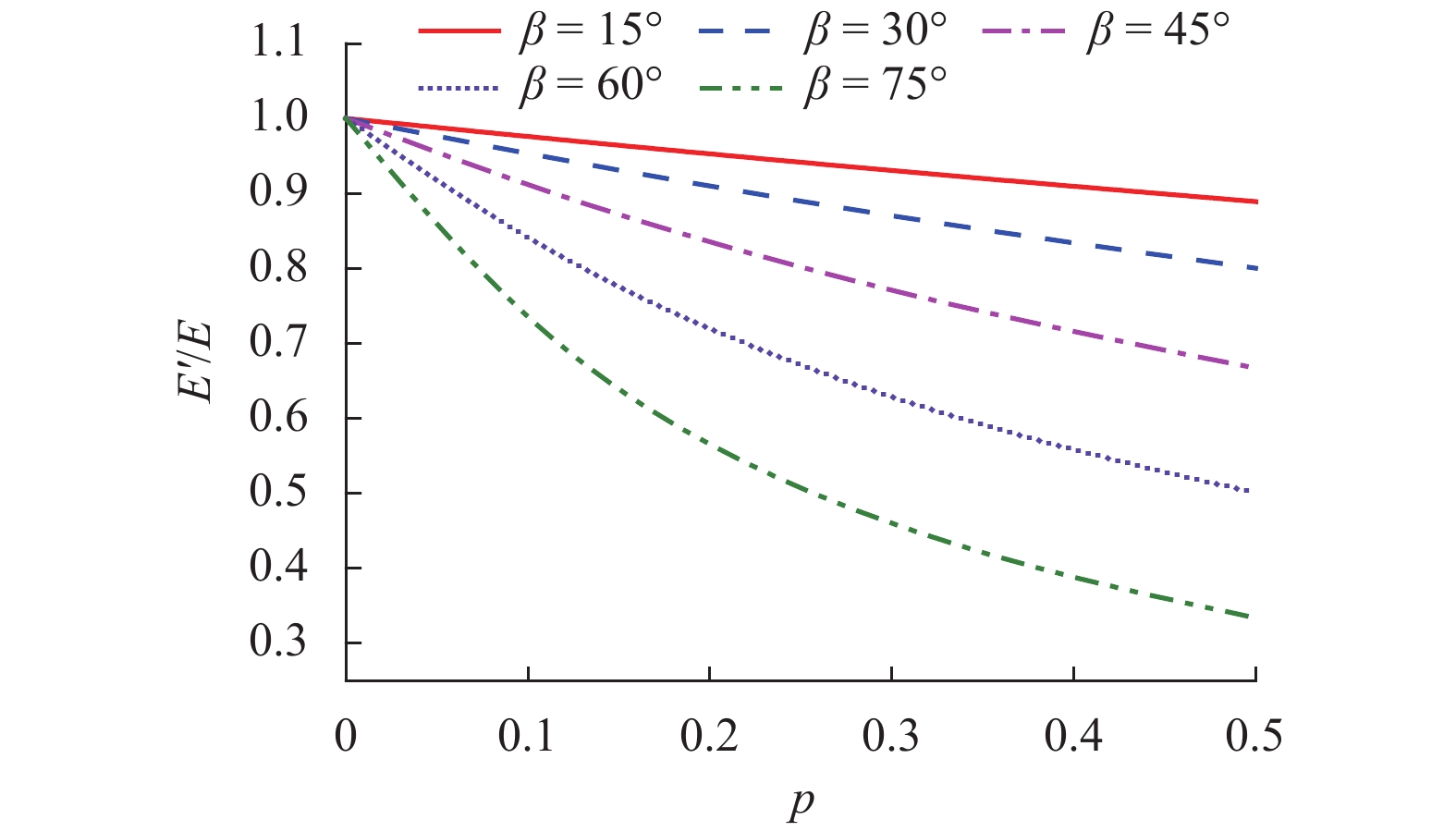

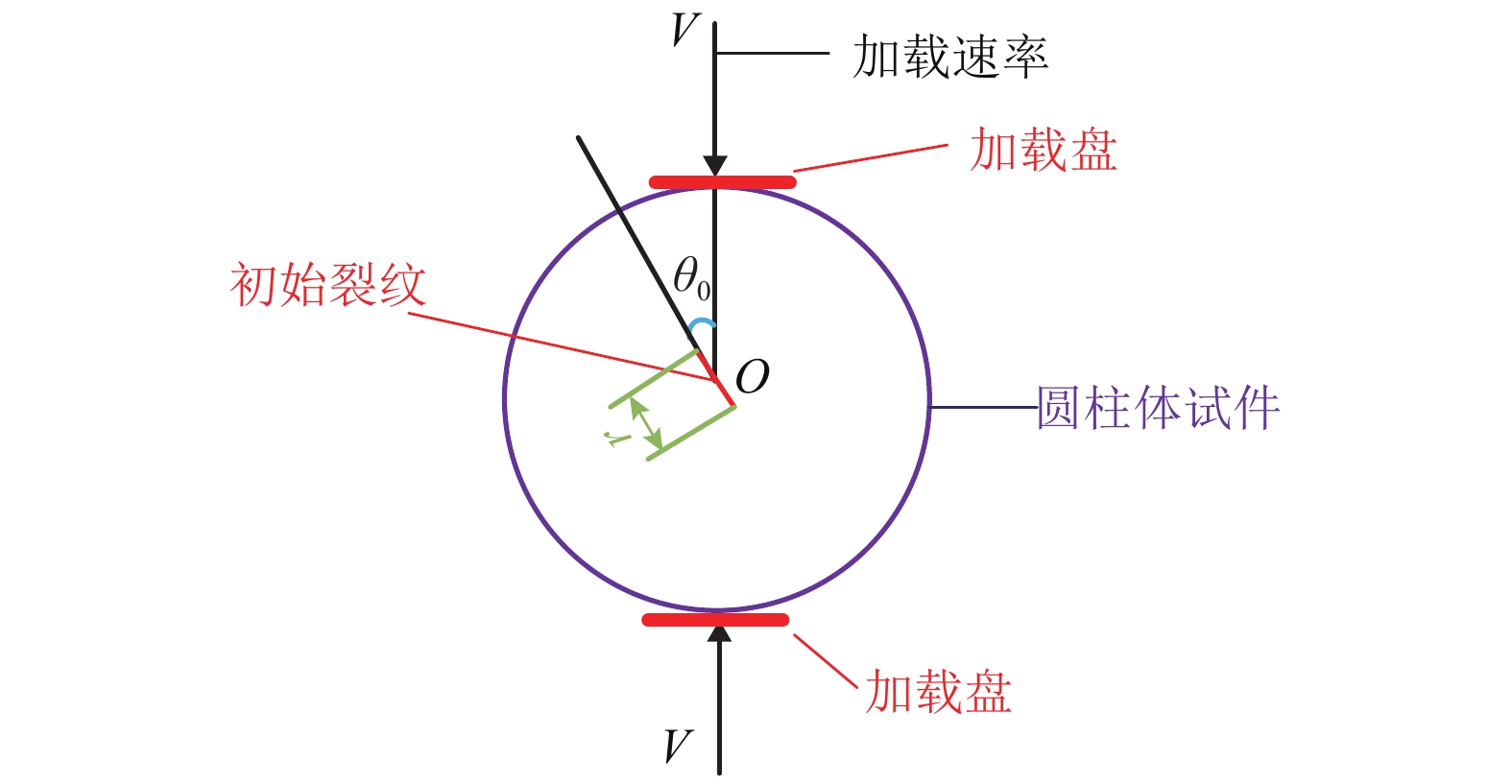

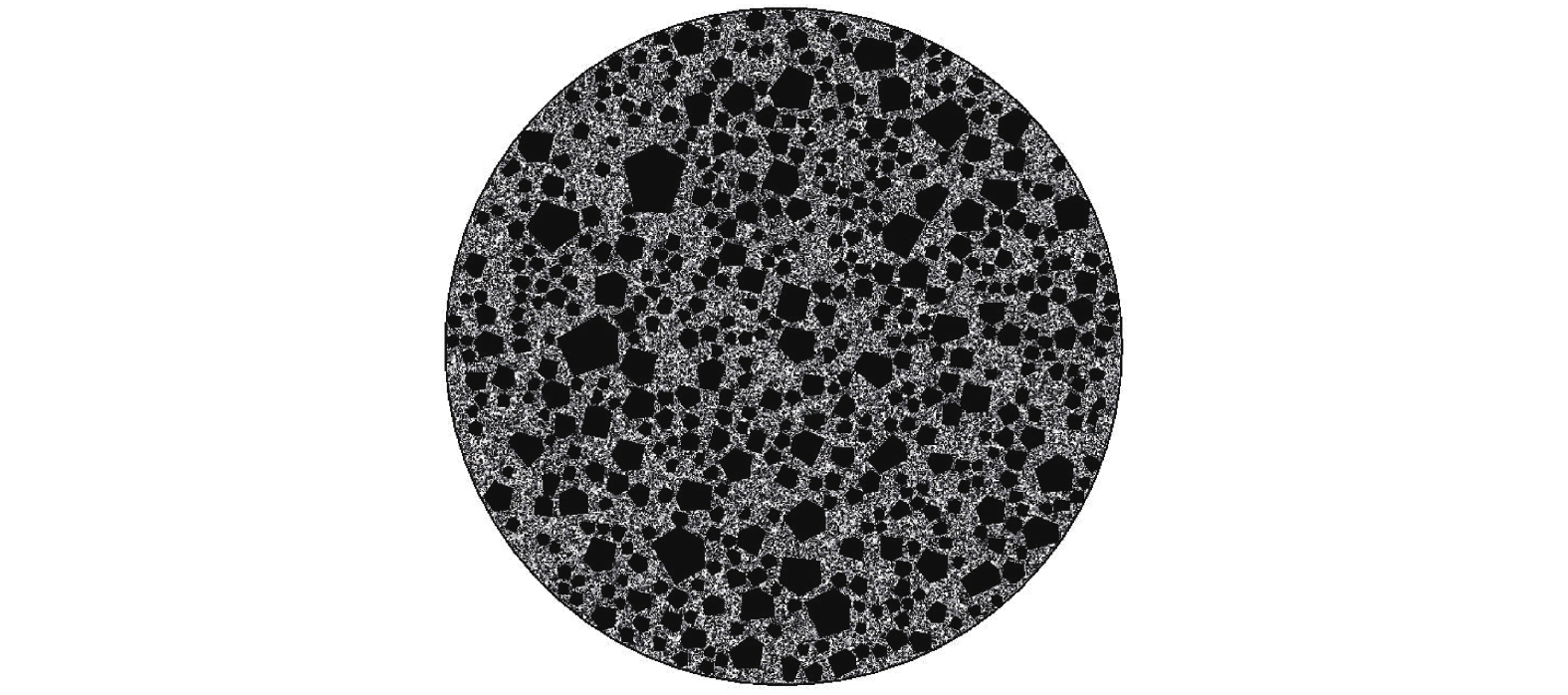

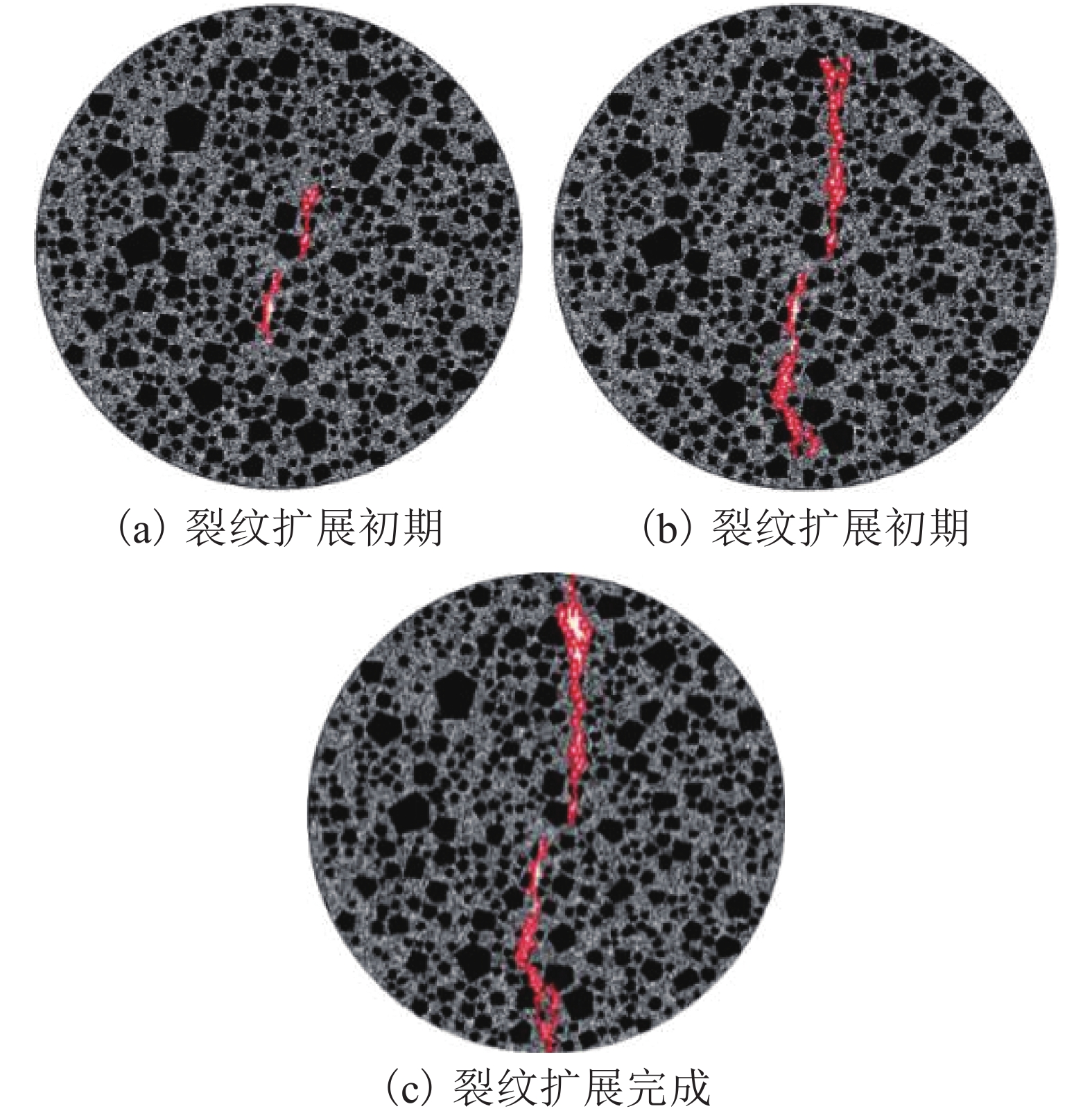

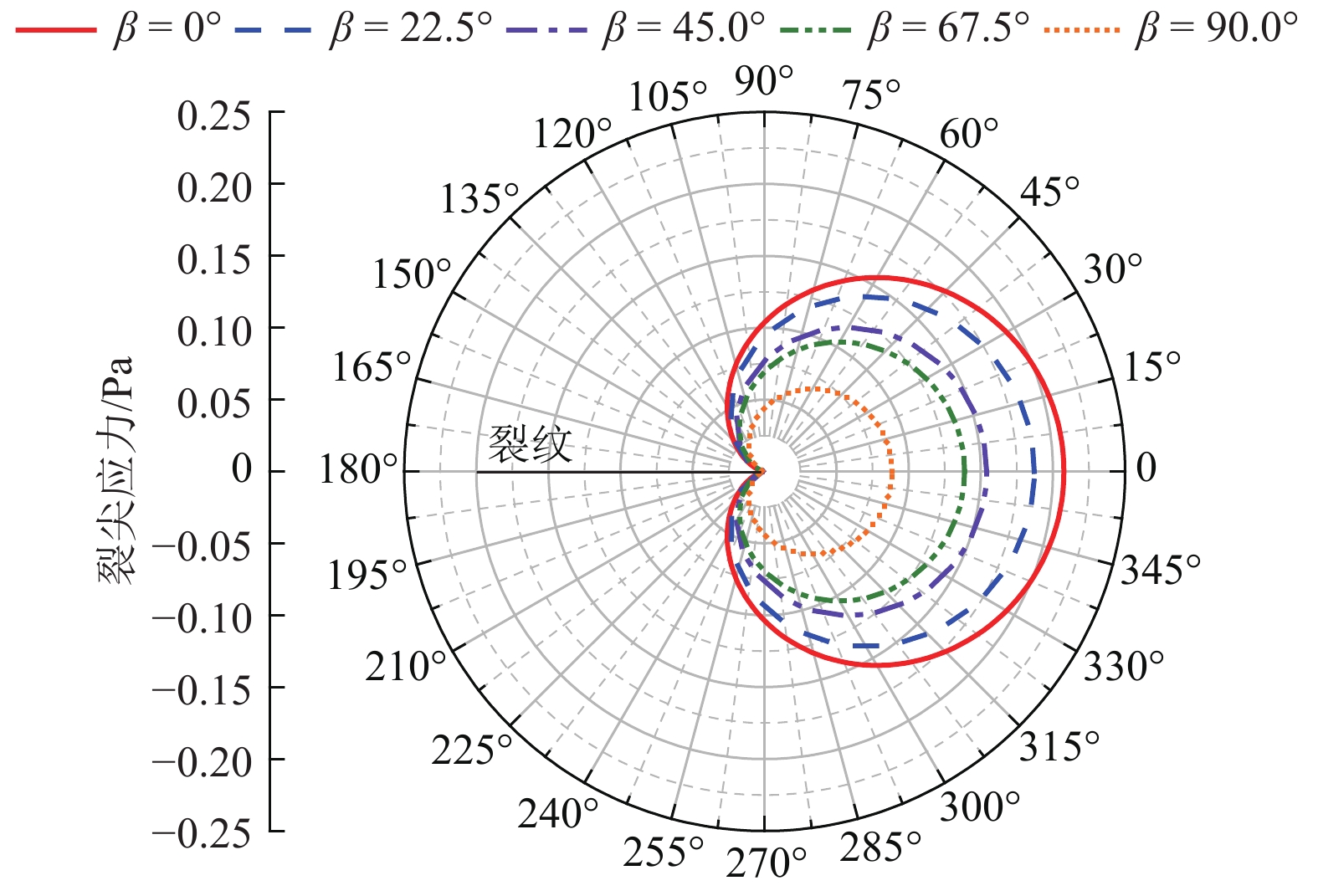

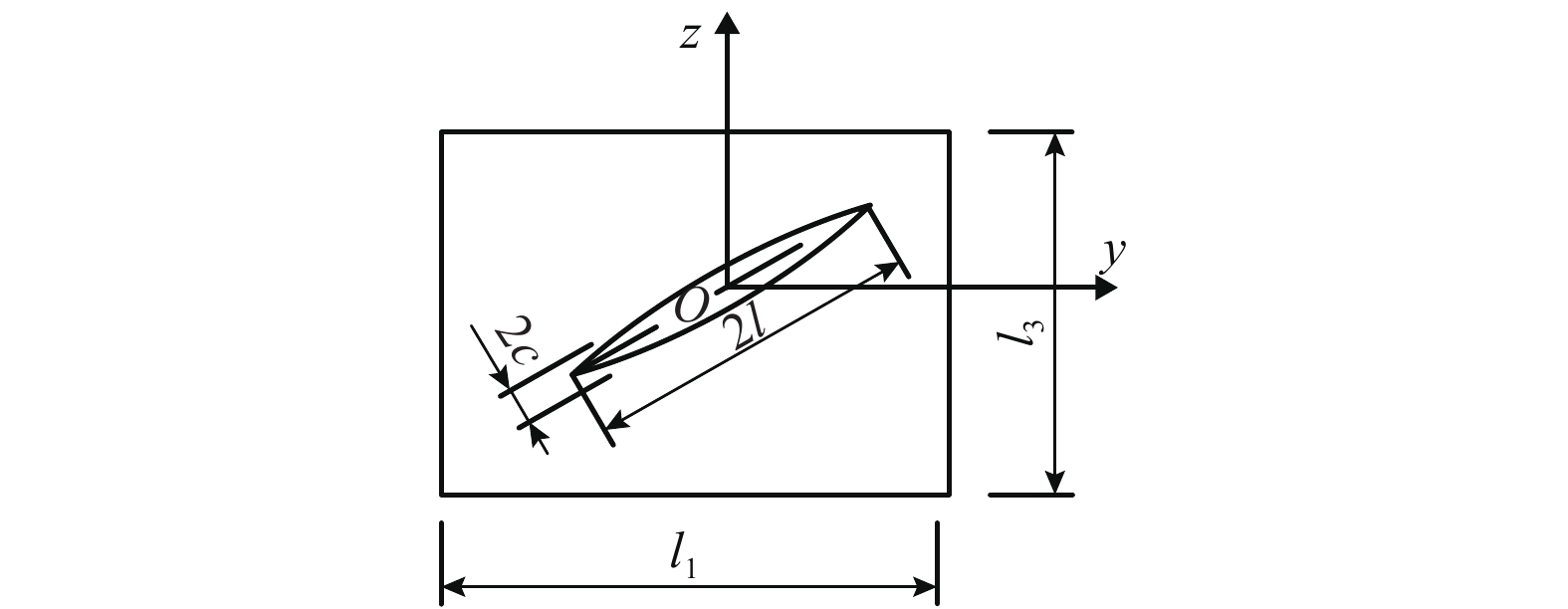

摘要: 为了研究低温地区超密实型沥青混凝土内部Ⅰ - Ⅱ复合型微裂纹扩展规律,基于Eshelby等效夹杂理论和最大周向应力断裂准则,建立了当复合型裂纹发生失稳型扩展时其内部微裂纹偏转角β与应力场之间的关系,并确定了扩展方向;建立沥青混凝土细观离散元模型,考虑沥青混凝土的黏弹性,分析了内部微裂纹β对复合裂纹扩展的影响规律. 研究结果表明:对二维平面问题,β的变化主要引起裂纹在沥青混凝土中分布状态的变化,在极大程度上造成了沥青混凝土的宏观有效弹性模量和剪切模量在时域内的减小;在常荷载作用下,β的增大造成了宏观裂纹孕育和扩展历程的缩短,还致使复合型裂纹由Ⅰ型裂纹逐渐转变为Ⅱ型裂纹;β的增大不仅使裂尖域内应力场发生一定偏转,而且导致裂尖域内应力场和衰坏区的减小.

-

关键词:

- 道路工程 /

- 超密实型沥青混凝土 /

- Ⅰ - Ⅱ复合型裂纹 /

- Eshelby等效夹杂 /

- 离散元模型

Abstract: This work aims to study the propagation behavior of Ⅰ - Ⅱ mixed mode micro-cracks in the ultra-dense asphalt concrete in cold regions. Based on the Eshelby equivalent inclusion theory and the maximum circumferential stress fracture criterion, the relationship between the declination angle β and the stress field is established for the composite cracks propagating in unstable mode, and whereby the crack propagation direction is determined. Then, a two-dimensional mesoscopic discrete element model of asphalt concrete is built; taking the viscoelasticity of asphalt concrete into consideration, the model is used to simulate the mixed mode micromechanical fracture behavior of the ultra-dense asphalt concrete. The influence of declination angle β on the unstable crack growth is analyzed. Results are obtained as follows: For the two-dimensional plane problems, the change of declination angle β mainly causes the change of crack distribution in asphalt concrete, greatly reducing the effective modulus and shear modulus of asphalt concrete in the time domain. Under the action of constant load, the increase of declination angle β shortens the process of crack initiation and propagation in the ultra-dense asphalt concrete, causing the fracture mode gradually transformed from type Ⅰ cracking into type Ⅱ cracking. Meanwhile, the increase of declination angle β not only causes a certain deflection of the stress field near the crack tip, but also leads to a decrease of the stress field and failure zone in the crack tip region. -

表 1 超密实型沥青混凝土级配

Table 1. Gradation of Ultra-dense asphalt concrete

筛孔尺寸/mm 16.0 13.2 9.5 4.75 2.36 1.18 0.60 0.30 0.15 0.075 通过率/% 100.0 97.5 84.0 62.5 42.5 32.0 24.0 15.5 11.0 6.0 表 2 Burgers模型宏观参数

Table 2. Macroscopic parameters of Burgers model

参数 E1/MPa E2/MPa η1/(MPa•s) η2/(MPa•s) 取值 0.586 0.368 108.112 28.135 表 3 Burgers模型微观参数

Table 3. Microscopic parameters of Burgers model

参数 Kkn/(× 103 Pa•m) Ckn/(× 105 Pa•m•s) Kmn/(× 103 Pa•m) Cmn/(× 105 Pa•m•s) 取值 1.47 1.13 2.34 4.32 参数 Kks/(× 105 Pa•m) Cks/(× 104 Pa•m•s) Kms/(× 103 Pa•m) Cms/(× 105 Pa•m•s) 取值 5.89 4.50 1.56 1.73 表 4 裂纹扩展过程中的相关参数

Table 4. Parameters related to crack propagation

β/(°) 阶段Ⅰ 阶段Ⅱ 阶段Ⅲ θ0/(°) 应力强度因子/(MPa•mm1/2) 裂纹数量/条 ΔλⅠ 裂纹数量/条 ΔλⅡ 裂纹数量/条 KⅠ KⅡ 0 1 4.389 87 16 0.264 13 593 0 2210.86 0.120 22.5 1 4.360 40 31 0.253 60 462 25.9 2129.32 415.130 45.0 1 4.358 98 37 0.250 02 446 44.2 1836.62 853.565 67.5 1 4.354 11 52 0.188 89 388 63.2 1454.09 1171.250 90.0 1 4.349 15 66 0.173 85 355 90.0 0.11 1928.300 注:ΔλⅠ为裂纹孕育阶段经历时间对数,即第一条微裂纹出现时间;ΔλⅡ为裂纹快速扩展阶段经历时间对数,即初始裂纹出现到裂纹发生快速增长经历的时间;KⅠ、KⅡ分别为Ⅰ、Ⅱ型裂纹的应力强度因子. -

JACOBS M M J, HOPMAN P C, MOLENAAR A A A. Application of fracture mechanics principles to analyze cracking in asphalt concrete (with discussion)[J]. Journal of the Association of Asphalt Paving Technologists, 1996, 65: 1-39. 罗睿,黄晓明,陆原,等. 基层对层间连续路面应力强度因子影响的研究[J]. 东南大学学报(自然科学版),2001,31(3): 61-64.LUO Rui, HUANG Xiaoming, LU Yuan, et al. Influence of base layer on the stress intensity factor of pavement with continual layers[J]. Journal of Southeast University (Natural Science Edition), 2001, 31(3): 61-64. 曾梦澜,马正军,易昕. 广义 Paris 公式预测沥青路面的疲劳寿命[J]. 湖南大学学报(自然科学版),2005,32(6): 20-23.ZENG Menglan, MA Zhengjun, YI Xin. Prediction of fatigue life of asphalt pavements using generaliazed Paris law[J]. Journal of Hunan University (Natural Sciences), 2005, 32(6): 20-23. 郑健龙,张起森. 半刚性基层沥青路面表面裂缝的热效应分析[J]. 长沙交通学院学报,1992,8(2): 1-12.ZHENG Jianlong, ZHANG Qisen. Thermal effect analysis of surface cracks in semi-rigid base asphalt pavement[J]. Journal of Changsha Communications Institute, 1992, 8(2): 1-12. 周志刚,张起森. 结构层组合对路面裂缝扩展的影响[J]. 中国公路学报,1997,10(2): 5-10.ZHOU Zhigang, ZHANG Qisen. Influence of layer-combination on pavement cracking[J]. China Journal of Highway and Transport, 1997, 10(2): 5-10. LI X J, MARASTEANU M O, KVASNAK A, et al. Factors study in low-temperature fracture resistance of asphalt concrete[J]. Journal of Materials in Civil Engineering, 2010, 22(2): 145-152. doi: 10.1061/(ASCE)0899-1561(2010)22:2(145) 高磊. 乳化沥青冷再生混合料的裂纹发展行为及抗裂机理研究[D]. 南京: 东南大学, 2016. AMERI M, MANSOURIAN A, PIRMHOHAMMAD S, et al. Mixed mode fracture resistance of asphalt concrete mixtures[J]. Engineering Fracture Mechanics, 2012, 93: 153-167. doi: 10.1016/j.engfracmech.2012.06.015 周志刚,袁秀湘,谭华. 沥青混合料预缺口试件直接拉伸疲劳损伤分析[J]. 中国公路学报,2013,26(1): 30-37. doi: 10.3969/j.issn.1001-7372.2013.01.005ZHOU Zhigang, YUAN Xiuxiang, TAN Hua. Fatigue damage analysis of asphalt mixture specimen with pre-made gaps in direct tension test[J]. China Journal of Highway and Transport, 2013, 26(1): 30-37. doi: 10.3969/j.issn.1001-7372.2013.01.005 李萍,马科,念腾飞,等. 基于权函数法的沥青混合料预切口小梁的断裂理论与裂纹扩展试验的研究[J]. 公路交通科技,2016,33(5): 21-27. doi: 10.3969/j.issn.1002-0268.2016.05.004LI Ping, MA Ke, NIAN Tengfei, et al. Study on fracture theory and crack propagation test of aspahlt mixture pre-made beam based on weight function method[J]. Jounal of Highway and Transportation Research and Development, 2016, 33(5): 21-27. doi: 10.3969/j.issn.1002-0268.2016.05.004 翟鹏程,陆阳. 粗集料磨耗的虚拟试验分析[J]. 公路交通科技,2014,31(4): 45-51. doi: 10.3969/j.issn.1002-0268.2014.04.008ZHAI Pengcheng, LU Yang. Virtual test analysis of coarse aggregate abrasion[J]. Journal of Highway and Transportation Research and Development, 2014, 31(4): 45-51. doi: 10.3969/j.issn.1002-0268.2014.04.008 YOU Z P, LIU Y, DAI Q L. Three-dimensional microstructural-based discrete element viscoelastic modeling of creep compliance tests for asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2010, 23(1): 79-87. KIM H W, WAGONER M P, BUTTLAR W G. Micromechanical fracture modeling of asphalt concrete using a single-edge notched beam test[J]. Materials and Structures, 2009, 42(5): 677-689. doi: 10.1617/s11527-008-9412-8 陈俊,黄晓明. 基于离散元法的沥青混合料虚拟疲劳试验方法[J]. 吉林大学学报(工学版),2010,40(2): 435-440.CHEN Jun, HUANG Xiaoming. Virtual fatigue tests of aspahlt mixture based on discrete element method[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(2): 435-440. 任大龙,万水,李文虎. 含界面裂纹的GFRP沥青混合料巴西盘断裂力学分析[J]. 哈尔滨工业大学学报,2016,48(3): 95-100. doi: 10.11918/j.issn.0367-6234.2016.03.016REN Dalong, WAN Shui, LI Wenhu. Fracture mechanics analysis of GFRP asphalt mixtures brazilian disk with interface crack[J]. Journal of Harbin Institute of Technology, 2016, 48(3): 95-100. doi: 10.11918/j.issn.0367-6234.2016.03.016 王自强, 段祝平. 塑性细观力学[M]. 北京: 科学出版社, 1995: 1667. GU L H, CHEN L C, ZHANG W G, et al. Mesostructural modeling of dynamic modulus and phase angle master curves of rubber modified asphalt mixture[J]. Materials, 2019, 12: 1667. doi: 10.3390/ma12101667 帅词俊,段吉安,王炯. 关于黏弹性材料的广义Maxwell模型[J]. 力学学报,2006,38(4): 565-569. doi: 10.3321/j.issn:0459-1879.2006.04.018SHUAI Cijun, DUAN Ji’an, WANG Jiong. A method of establishing generalized Maxwell model for viscoelastic materia[J]. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(4): 565-569. doi: 10.3321/j.issn:0459-1879.2006.04.018 曾杰. 季冻区沥青混凝土强化基床表层轨下基础结构计算方法与耐久性研究[D]. 成都: 西南交通大学, 2018. 冷严. 季冻区高速铁路沥青混凝土强化基床表层材料制备技术与综合性能试验研究[D]. 成都: 西南交通大学, 2018. 张淳源. 双轴载荷作用下理想线粘弹体的裂纹尖端应力、位移场[J]. 湘潭大学自然科学学报,1982(2): 93-99. LIU Y, DAI Q L, YOU Z P. Viscoelastic model for discrete element simulation of asphalt mixtures[J]. Journal of Engineering Mechanics, 2009, 135(4): 324-333. doi: 10.1061/(ASCE)0733-9399(2009)135:4(324) -

下载:

下载: