Experimental Study on Deformation Behavior of Polypropylene Fiber Reinforced Concrete Beams

-

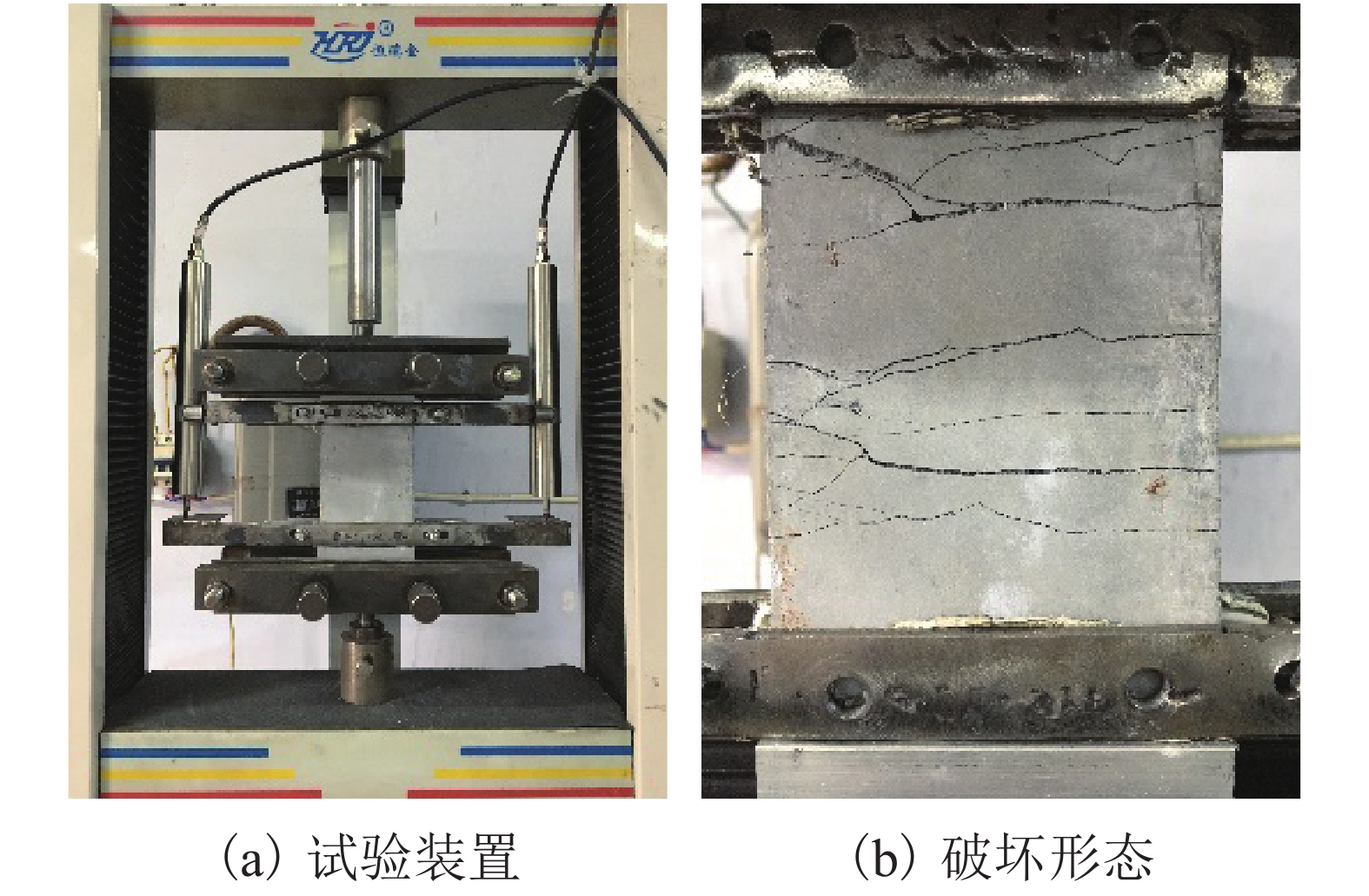

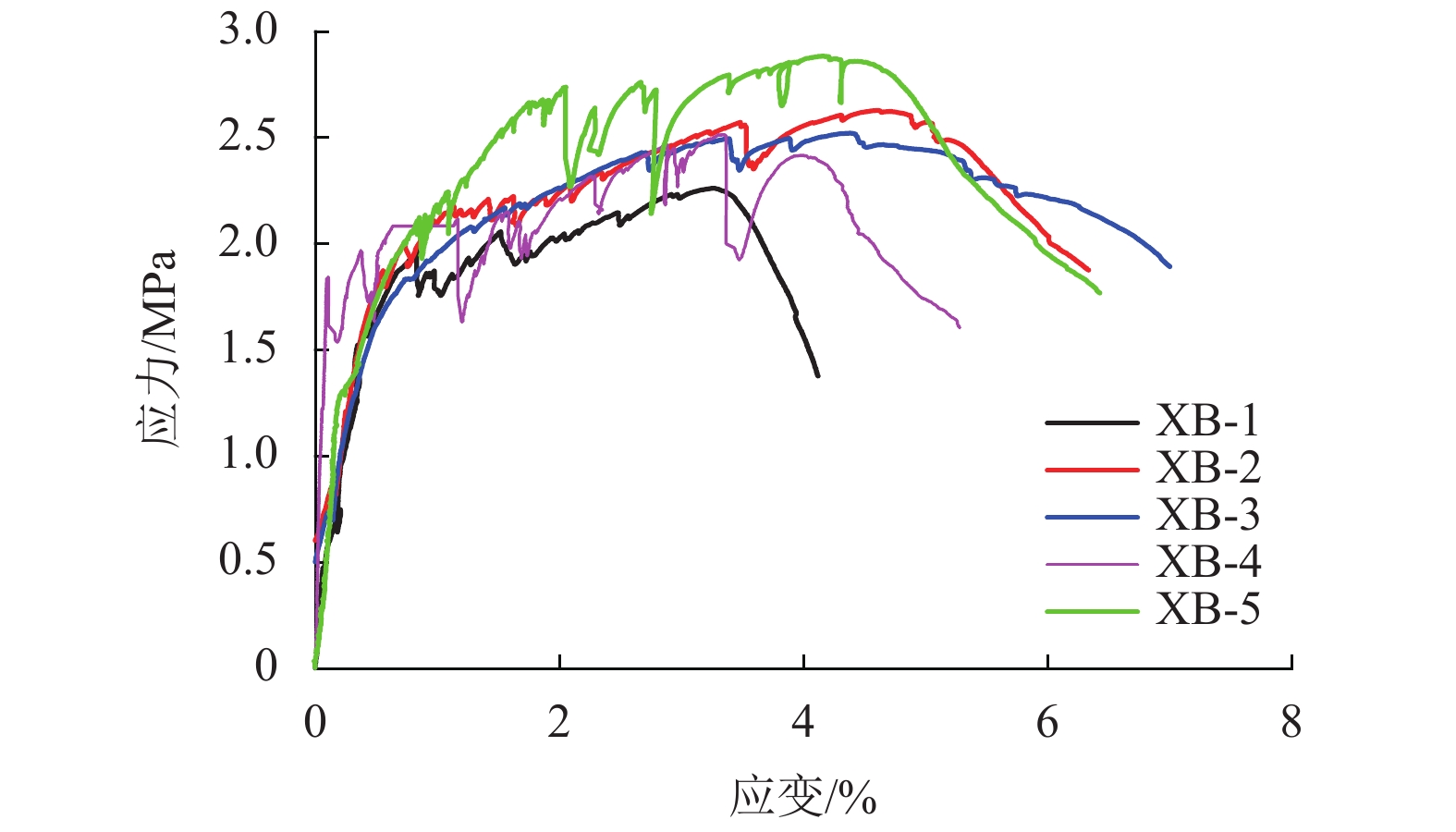

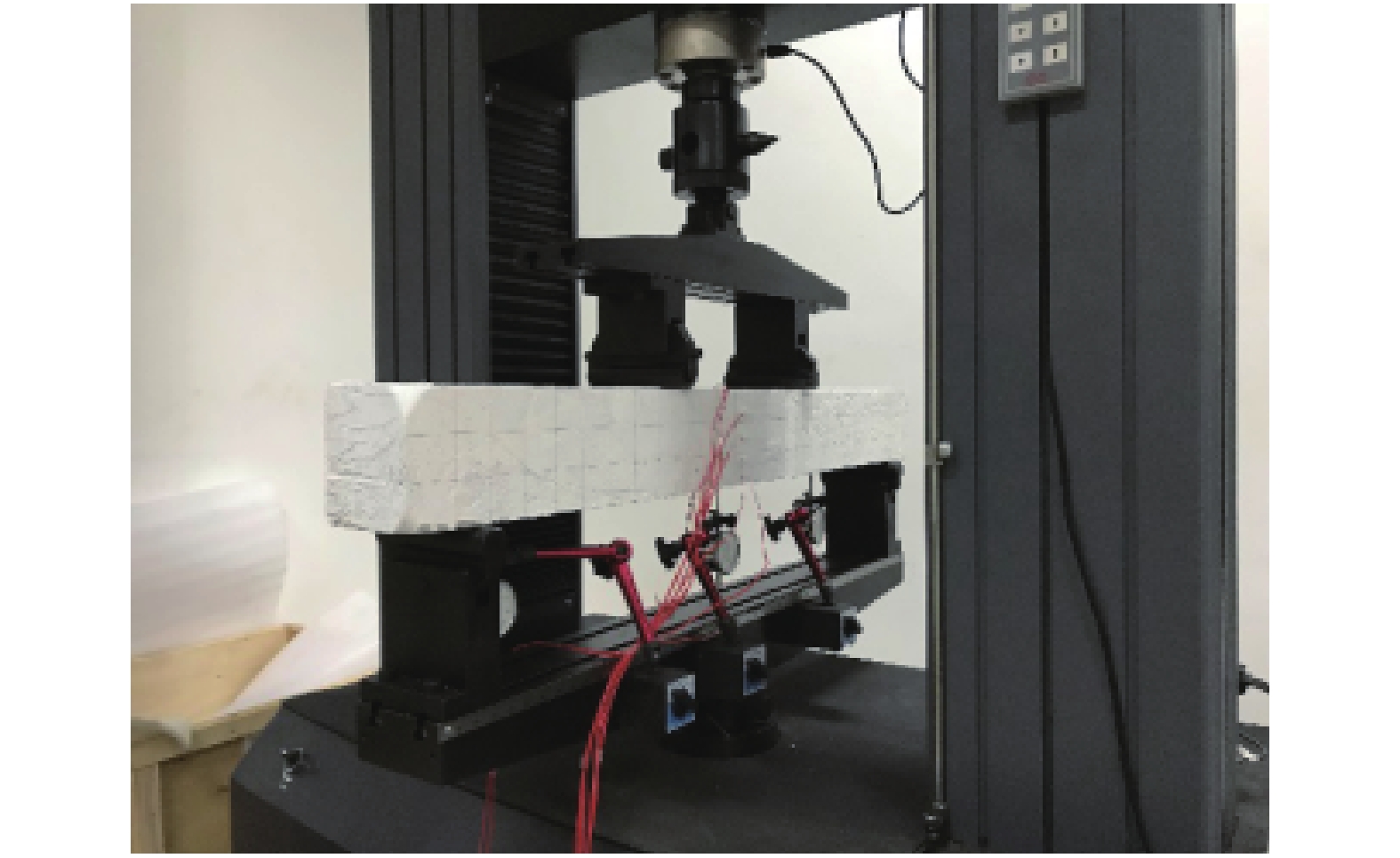

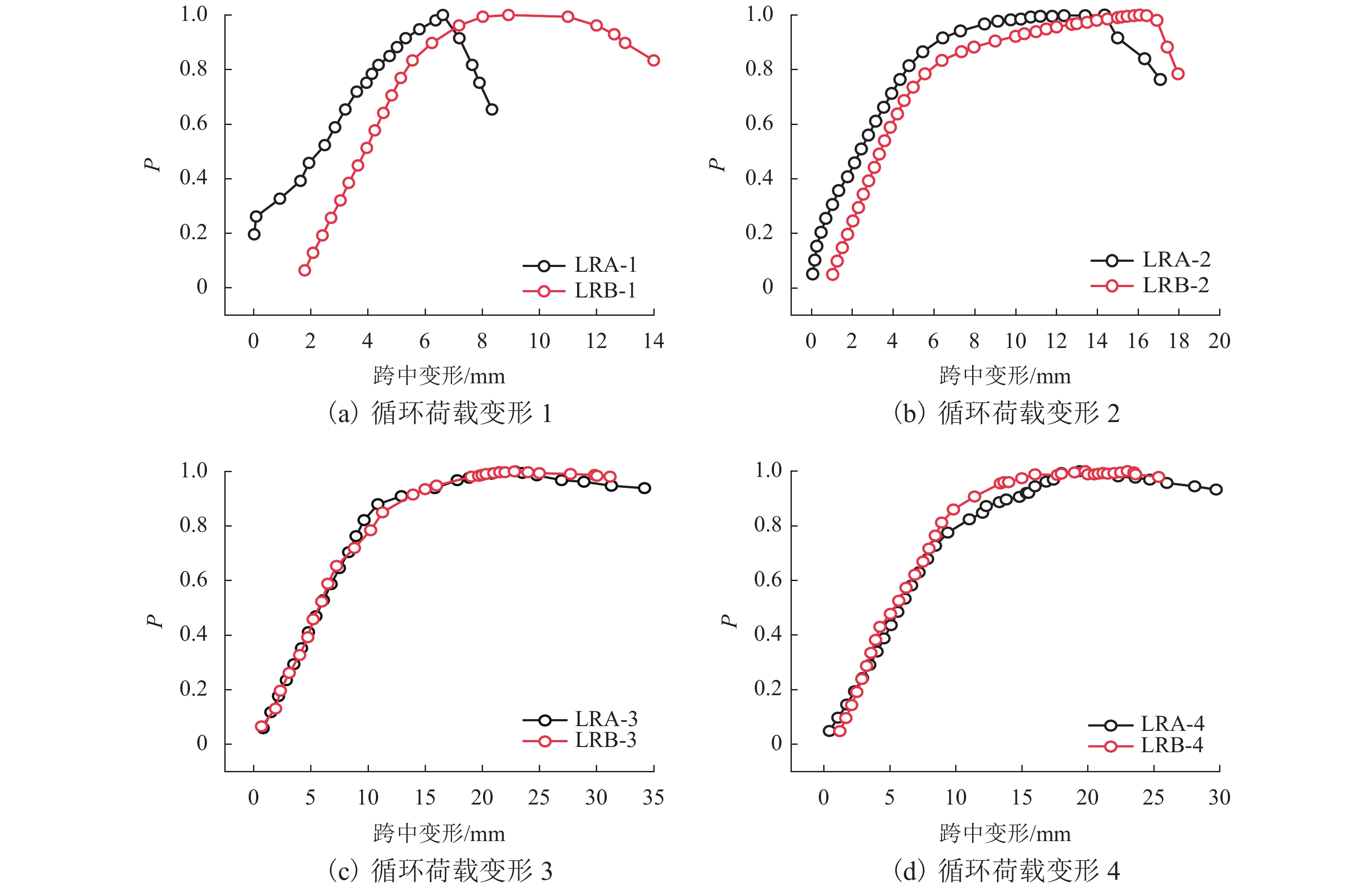

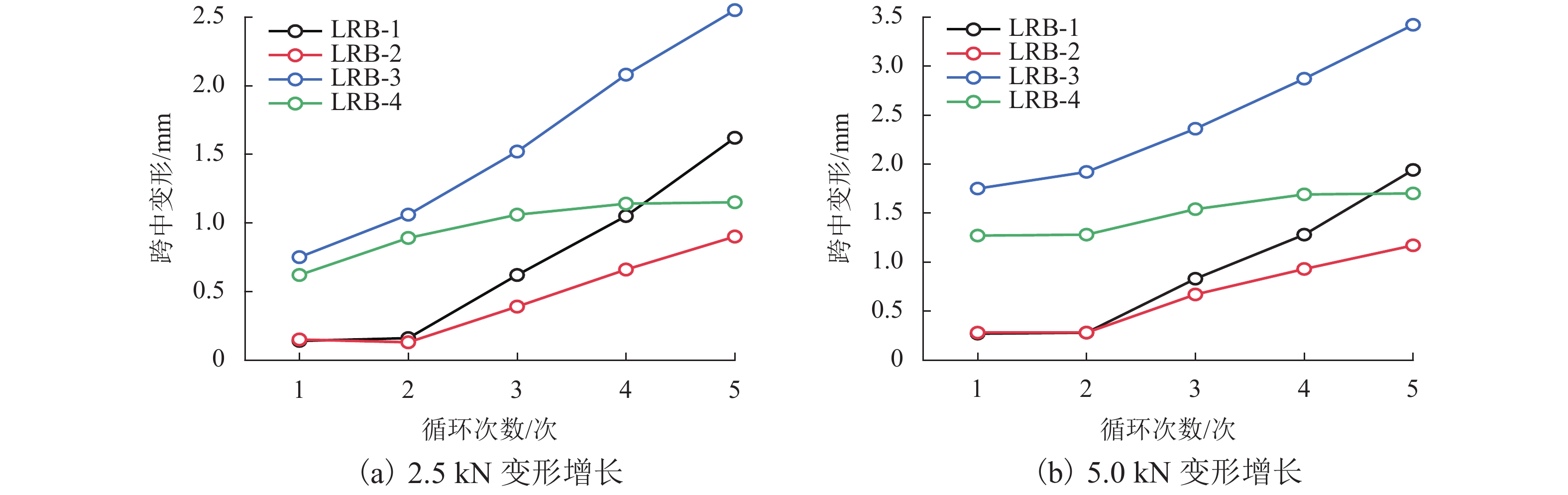

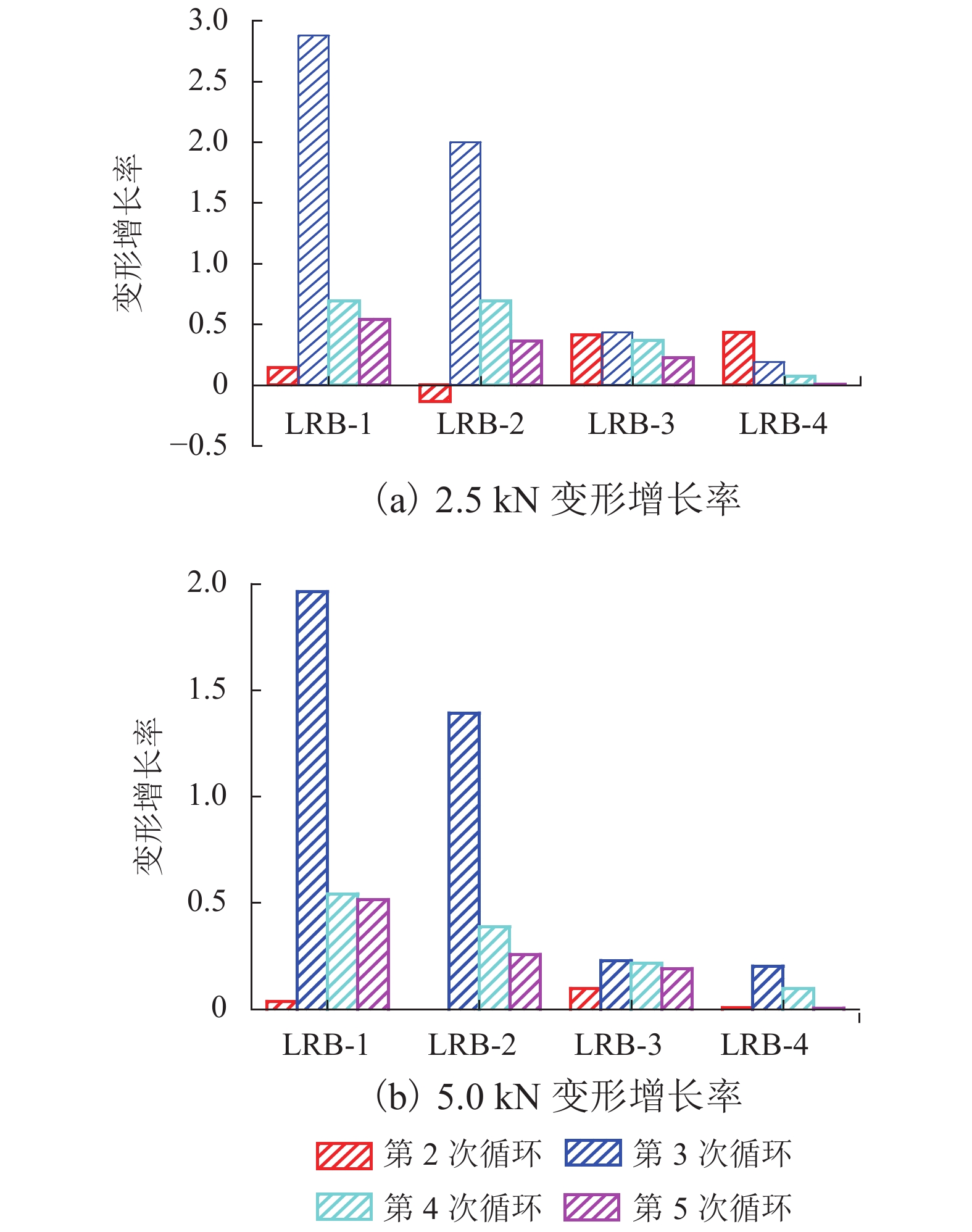

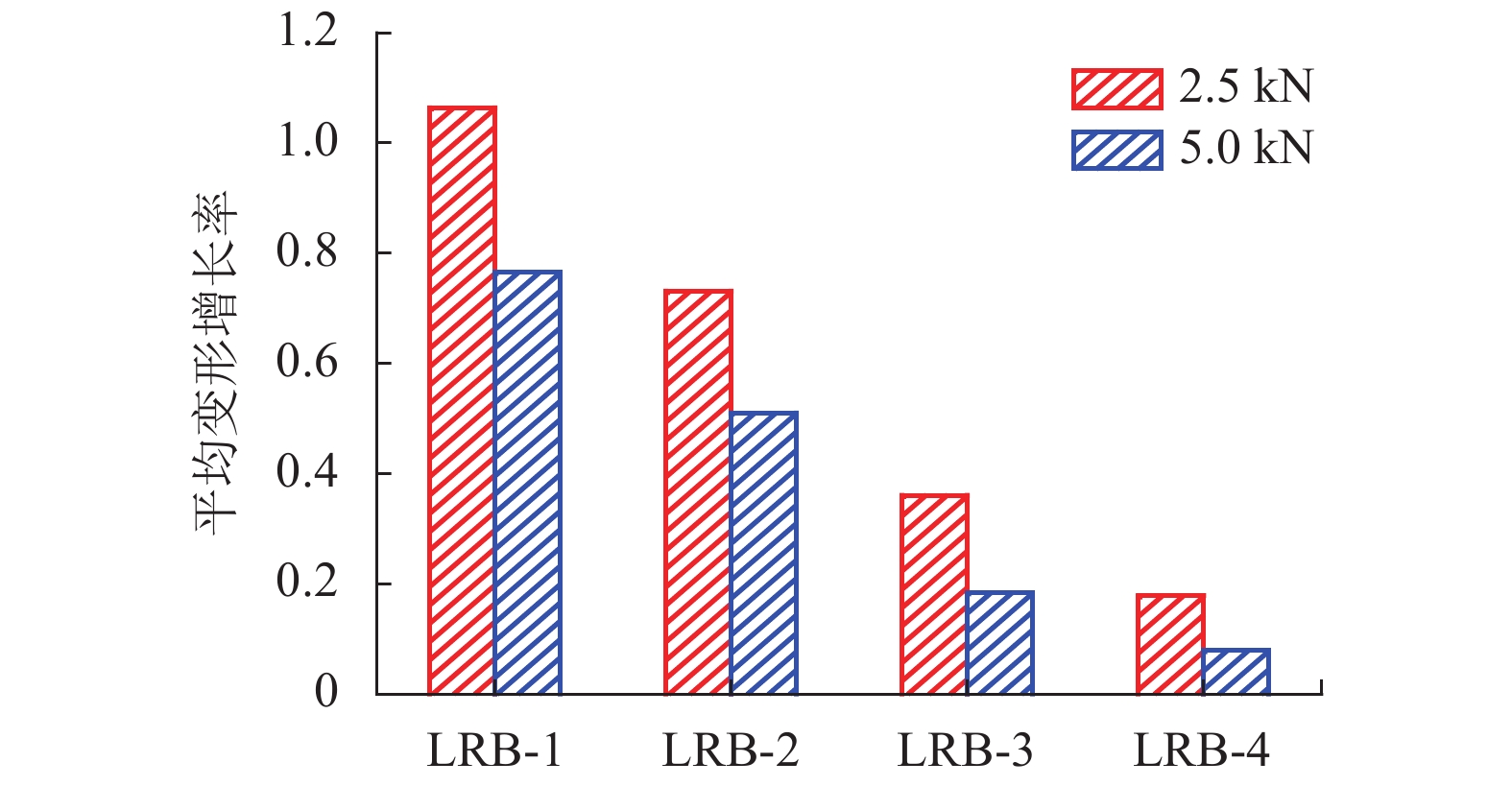

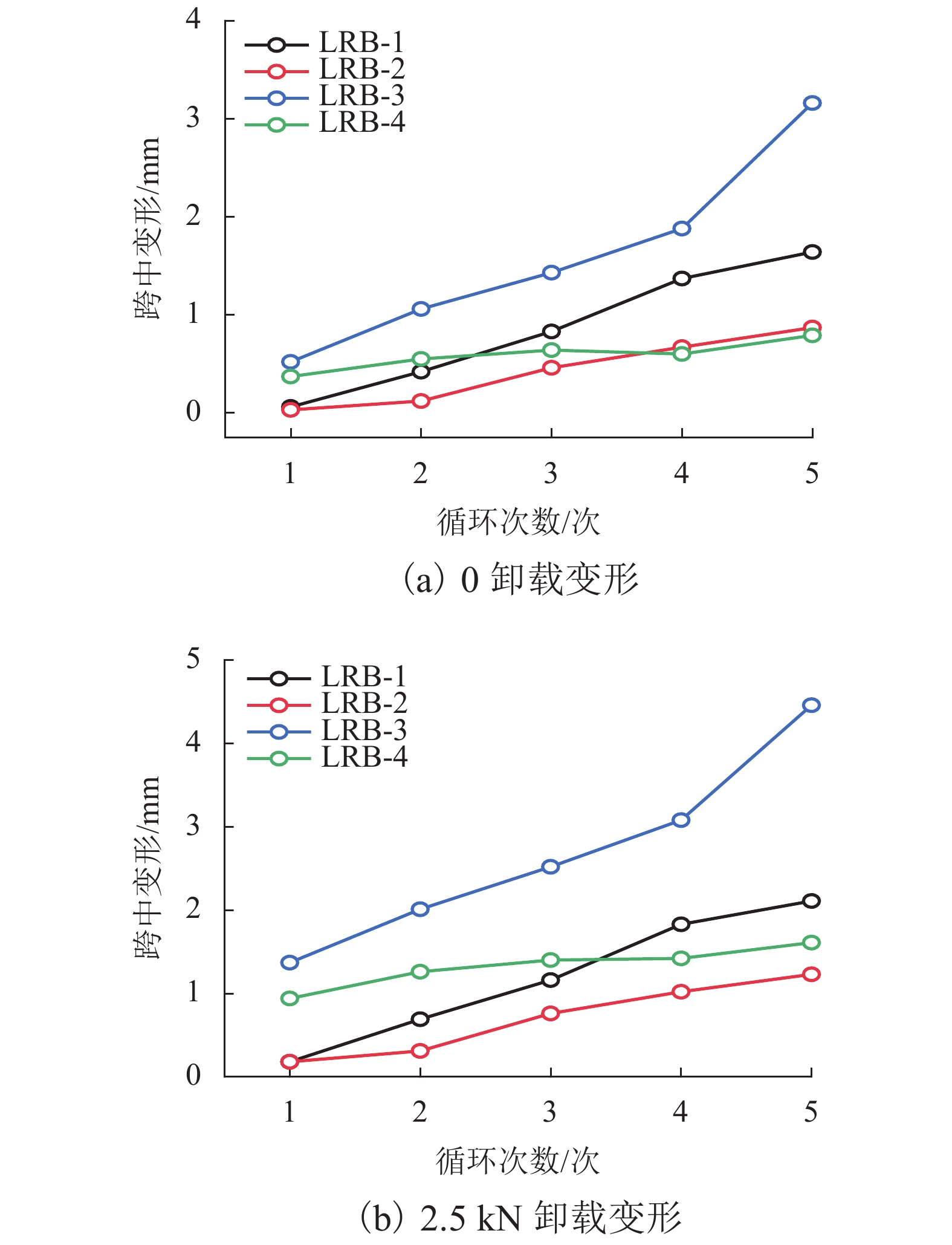

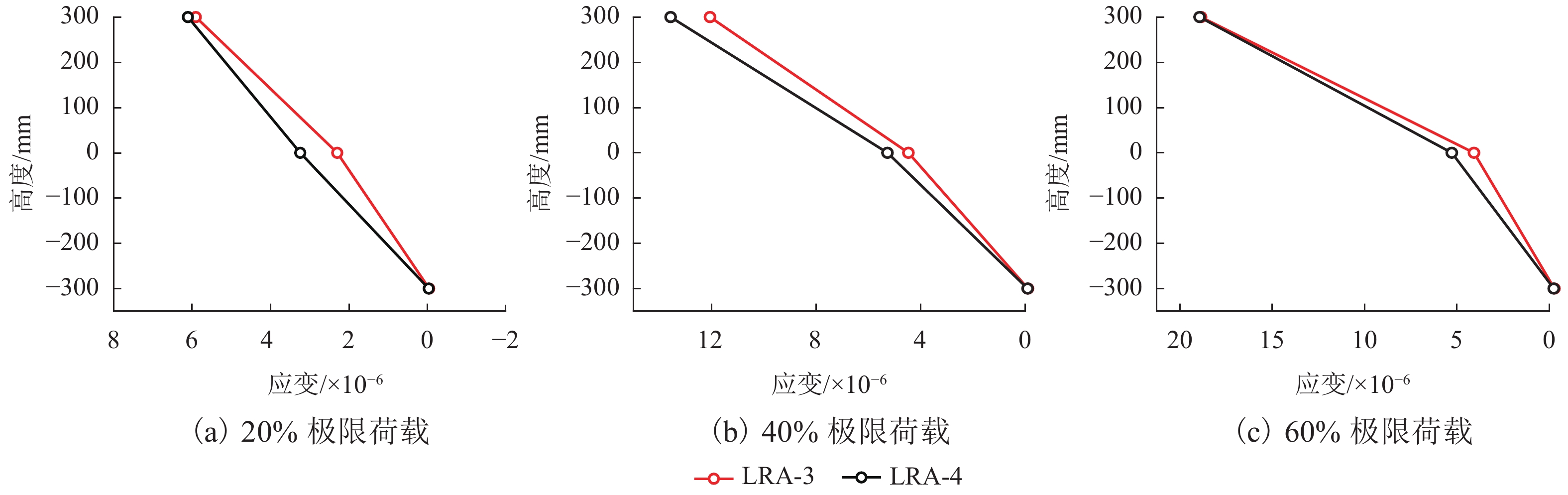

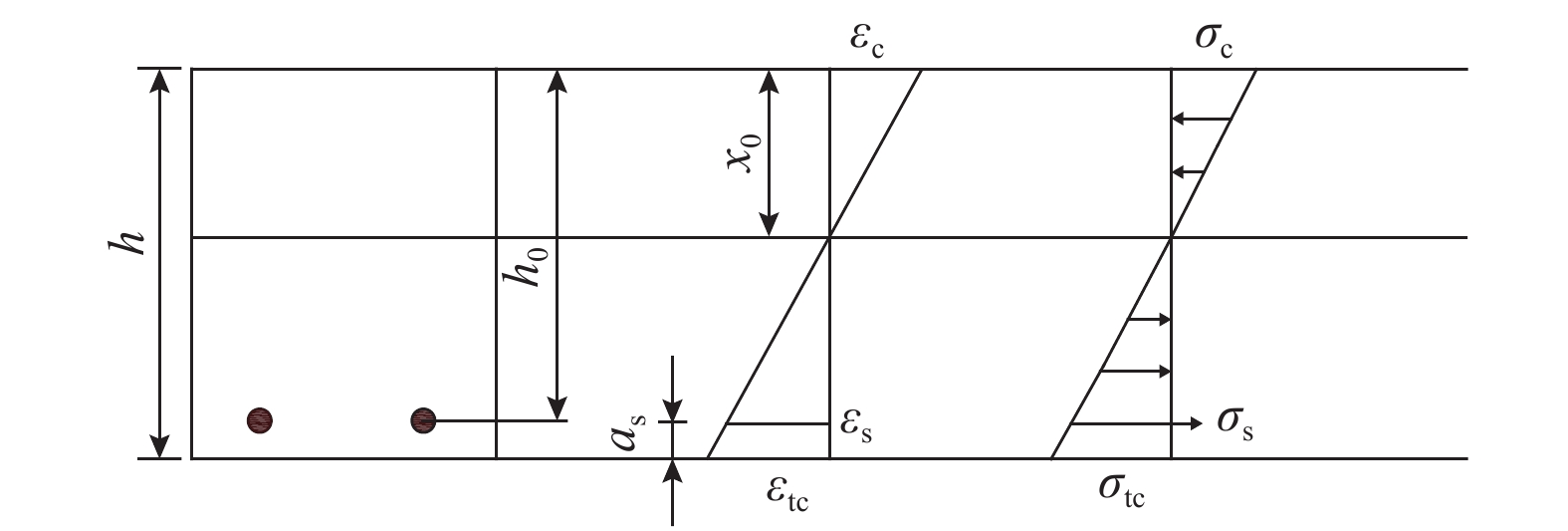

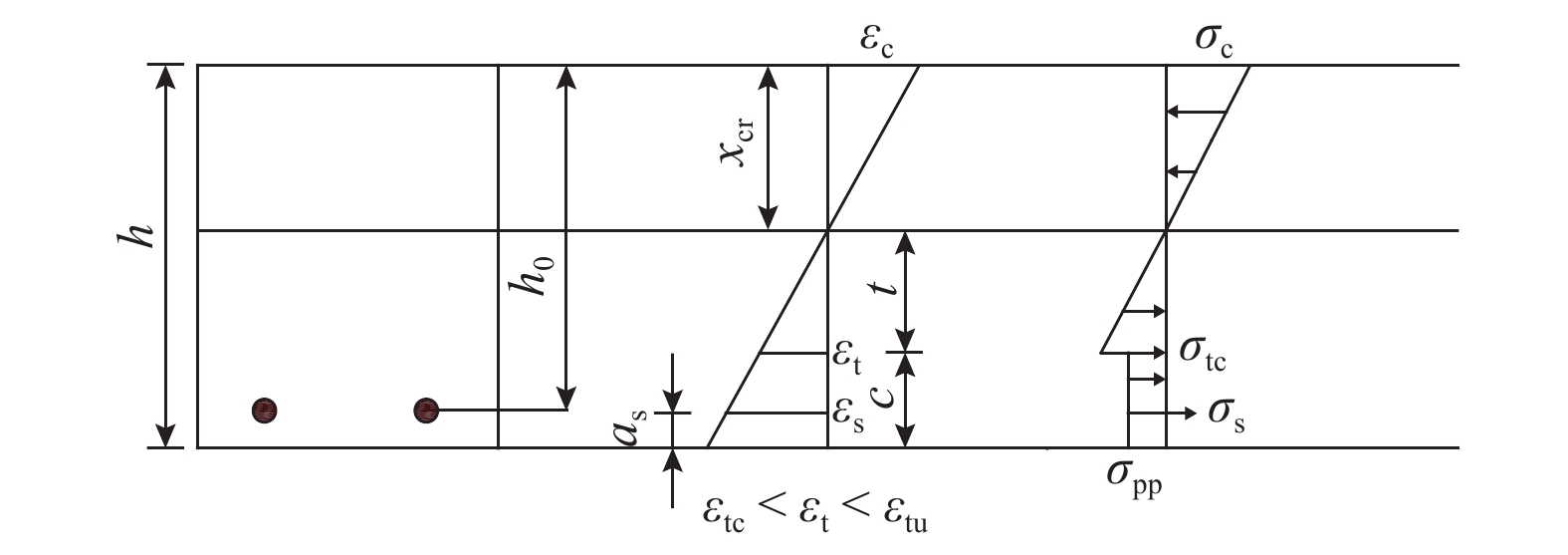

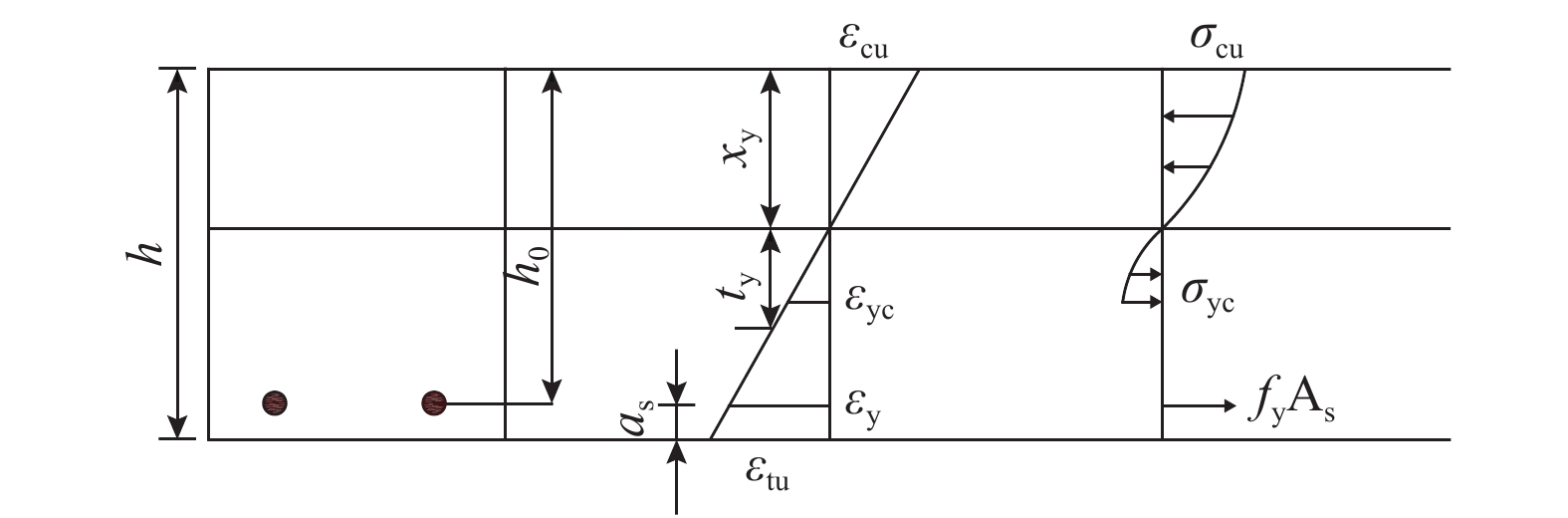

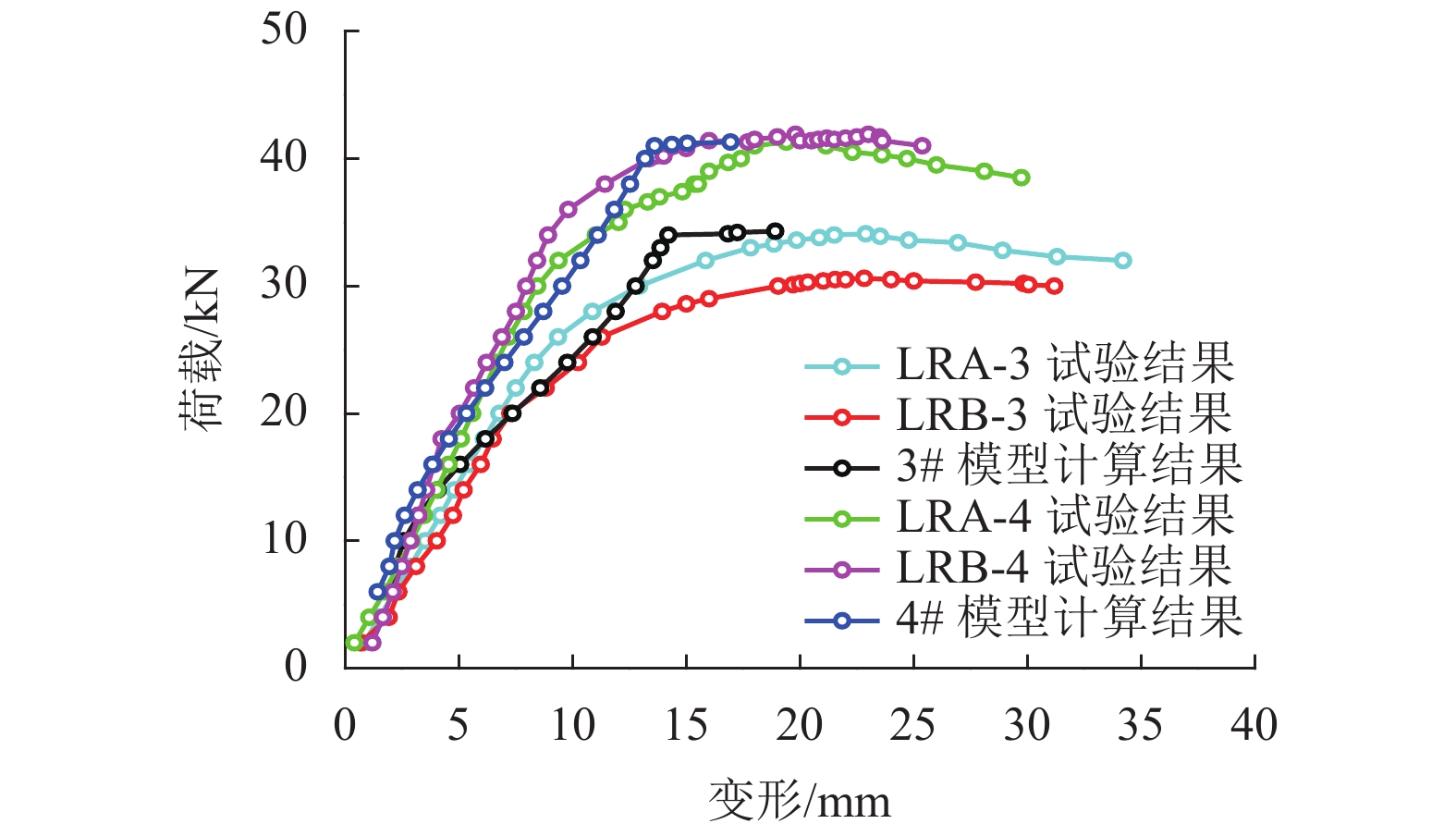

摘要: 为探究PP-ECC梁与RC梁变形发展规律的区别,通过逐级加载和循环加载两种加载制度对4根PP-ECC梁和4根RC梁进行抗弯试验;同时,基于有效惯性矩法推导出适用于短期荷载作用下PP-ECC梁的最大变形计算公式. 研究结果表明:逐级加载下,PP-ECC梁呈现出更为明显的塑性变形阶段,与RC梁相比,PP-ECC梁经过5次循环加载后的循环荷载变形曲线与原曲线拟合度较好;循环加载过程中,PP-ECC梁在基准荷载下的加载变形增长率和卸载变形增长率均小于相同配筋率的RC梁,呈现出更好的抗损伤变形能力和变形恢复能力;基于有效惯性矩法推导出的变形修正模型计算结果与试验结果拟合度较好,可应用于实际工程对PP-ECC梁在短期荷载作用下最大变形的计算.Abstract: In order to explore the difference in deformation behaviors of polypropylene engineered cementitious composite (PP-ECC) beam and reinforced concrete (RC) beam, bending resistance tests were performed on four PP-ECC beams and four RC beams using two loading systems, i.e., step loading and cyclic loading. Meanwhile, based on the effective moment of inertia method, the maximum deformation calculation formula applicable to the PP-ECC beams under short-term loads was derived. The results show that the PP-ECC beam undergoes a more obvious plastic deformation stage under successive loading. Compared with the RC beam, the deformation curve of the PP-ECC beam after 5 cycles of cyclic loading fits better with the original curve. During cyclic loading, the growth rates of the loading and unloading deformation of PP-ECC beams under the reference load are both lower than those of RC beams with the same reinforcement ratio, showing better damage resistance and deformation recovery ability. In general, the calculated results of deformation correction model based on the effective moment of inertia method fit well with the test results, and the proposed method can be applied to the calculation of maximum deformation of PP-ECC beams under short-term load in practical engineering.

-

表 1 试件参数

Table 1. Sample parameters

编号 加载

方式材料 纵筋直

径/mm纵筋

型号箍筋直

径/mm箍筋

型号LRA-1 LRA C30 8 HRB400 6 Q235 LRA-2 C30 10 HRB400 6 Q235 LRA-3 PP-ECC 8 HRB400 6 Q235 LRA-4 PP-ECC 10 HRB400 6 Q235 LRB-1 LRB C30 8 HRB400 6 Q235 LRB-2 C30 10 HRB400 6 Q235 LRB-3 PP-ECC 8 HRB400 6 Q235 LRB-4 PP-ECC 10 HRB400 6 Q235 表 2 PP纤维性能指标

Table 2. PP fiber performance indexes

参数 长度/

mm密度/

(kg•m−3)直径/

μm抗拉强

度/MPa弹性模

量/GPa伸长

率/%取值 12 0.91 × 103 20 480 5.00 15 表 3 PP-ECC性能指标

Table 3. PP-ECC performance indexes

参数 开裂抗拉强度/

MPa开裂抗拉应变/

%极限抗拉强度/

MPa极限抗拉应变/

%极限抗压强度/

MPa极限抗压应变/

%弹性

模量E/GPa取值 0.84 0.09 2.32 3.8 32.09 0.41 13.35 表 4 C30混凝土性能指标

Table 4. C30 concrete performance indexes

参数 抗压强度/MPa 抗压应变/% 弹性模量/GPa 取值 33.47 0.09 24.80 表 5 HRB400钢筋性能指标

Table 5. HRB400 steel performance indexes

参数 直径/

mm截面面

积/mm2屈服强

度/MPa极限强

度/MPa弹性模

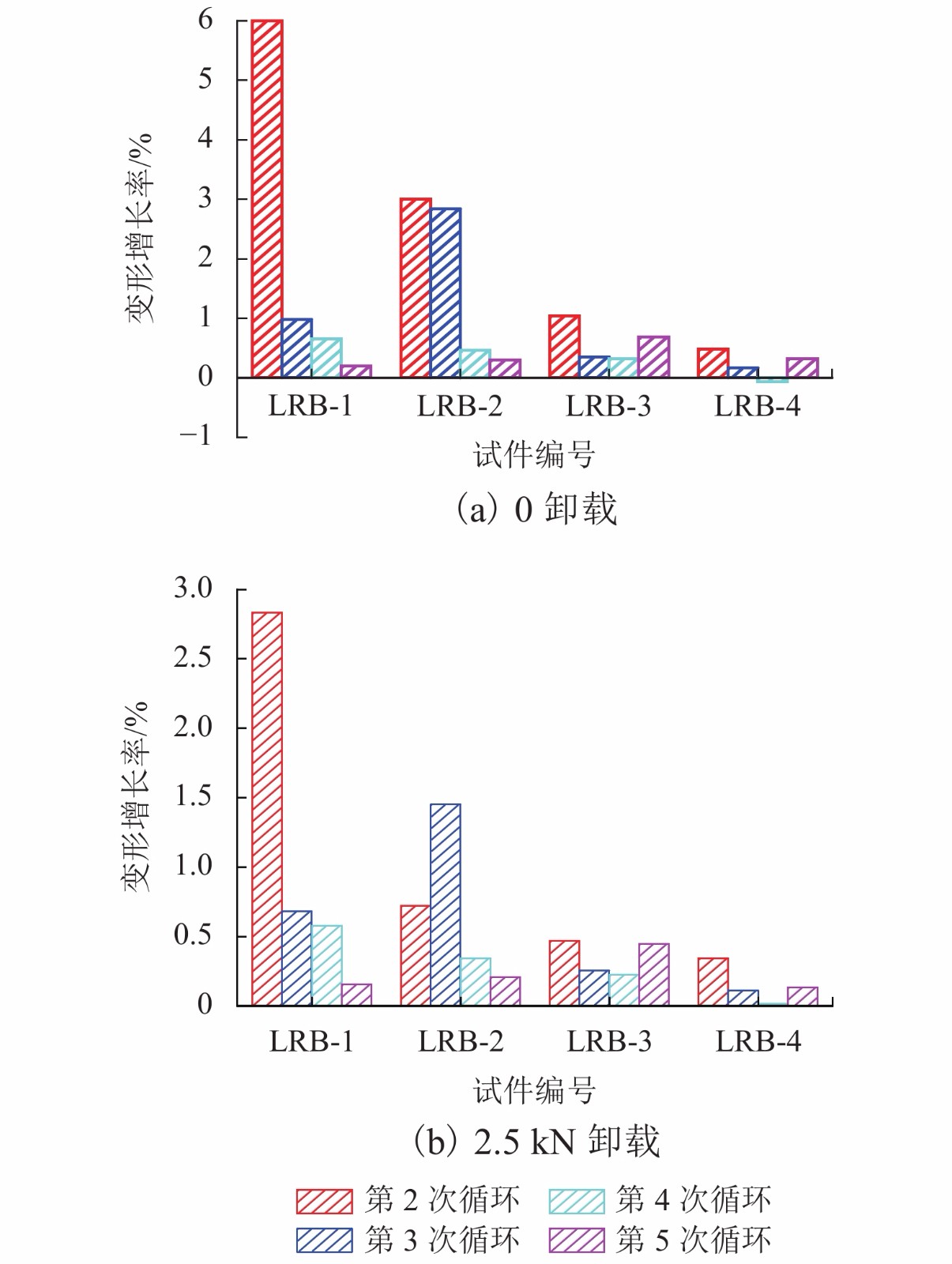

量/GPa取值 8 50.24 406 576 197.00 10 78.50 411 535 203.00 表 6 卸载变形增长

Table 6. Unloading deformation growth

编号 平均卸载变形增长率/% 卸载变形增长方差/mm 0 2.5 kN 0 2.5 kN LRB-1 195.59 106.13 5.530 1.090 LRB-2 164.71 68.05 1.620 0.230 LRB-3 59.58 34.78 0.086 0.012 LRB-4 22.61 14.99 0.041 0.014 -

俞家欢. 超强韧性纤维混凝土的性能及应用[M]. 北京: 中国建筑工业出版社, 2012: 183-184. KANDA T, LI V C. New micro-mechanics design theory for pseudo strain hardening cementitious composite[J]. ASCE Journal of Engineering Mechanics, 1999, 125(4): 373-381. doi: 10.1061/(ASCE)0733-9399(1999)125:4(373) YAO Ding, YU Kequan, YU Jianggao, et al. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study[J]. Construction and Building Materials, 2018, 177: 102-115. doi: 10.1016/j.conbuildmat.2018.05.122 王玉清,刘潇,刘曙光,等. PVA-ECC徐变性能试验研究[J]. 建筑材料学报,2019,23(4): 823-830,845.WANG Yuqing, LIU Xiao, LIU Shuguang, et al. Experimental study on creep behaviors of PVA-ECC[J]. Journal of Building Materials, 2019, 23(4): 823-830,845. MENG D, LEE C K. Flexural and shear behaviours of plain and reinforced polyvinyl alcohol-engineered cementitious composite beams[J]. Engineering Structures, 2017, 151: 261-272. doi: 10.1016/j.engstruct.2017.08.036 HOSSAIN K M A, ALAM S, ANWAR M S, et al. High performance composite slabs with profiled steel deck and engineered cementitious composites-strength and shear bond characteristics[J]. Construction and Building Materials, 2016, 125: 227-240. doi: 10.1016/j.conbuildmat.2016.08.021 CAI Jingming, PAN Jinlong, ZHOU Xiangming, et al. Flexural behavior of basalt FRP reinforced ECC and concrete beams[J]. Construction and Building Materials, 2017, 142: 423-430. doi: 10.1016/j.conbuildmat.2017.03.087 CHEN Y, YU J, LEUNG C K Y. Use of high strength strain-hardening cementitious composites for flexural repair of concrete structures with significant steel corrosion[J]. Construction and Building Materials, 2018, 167: 325-337. doi: 10.1016/j.conbuildmat.2018.02.009 MOHAMMAD M R, LEE C K, SAFAT A, et al. Flexural behaviour of steel composite beams encased by engineered cementitious composites[J]. Journal of Constructional Steel Research, 2018, 143: 279-290. doi: 10.1016/j.jcsr.2018.01.004 IEVA P, GREGOR F. Phenomenological interpretation of the shear behavior of reinforced engineered cementitious composite beams[J]. Cement and Concrete Composites, 2016, 73: 213-225. doi: 10.1016/j.cemconcomp.2016.07.018 俞家欢,邹静辉. FRP筋增强PP-ECC梁滞回性能试验研究[J]. 土木工程学报,2012,45(增刊2): 84-88.YU Jiahuan, ZOU Jinghui. Experimental study on FRP reinforced PPECC beams under reverse cyclic loading[J]. China Civil Engineering Journal, 2012, 45(S2): 84-88. 袁方,陈梦成,王文波. 往复荷载下钢筋增强ECC梁的抗剪性能研究[J]. 铁道学报,2018,40(8): 146-153. doi: 10.3969/j.issn.1001-8360.2018.08.019YUAN Fang, CHEN Mengcheng, WANG Wenbo. Study on shear behavior of steel reinforced ECC beams under reversed cyclic loading[J]. Journal of the China Railway Society, 2018, 40(8): 146-153. doi: 10.3969/j.issn.1001-8360.2018.08.019 樊健生,施正捷. 钢-ECC组合梁负弯矩受弯性能试验研究[J]. 土木工程学报,2017,50(4): 64-72.FAN Jiansheng, SHI Zhengjie. Experimental research on negative bending behavior of steel-ECC composite beams[J]. China Civil Engineering Journal, 2017, 50(4): 64-72. WEN J G, ASHRAF F A, YU J M, et al. Flexural behaviors of ECC-concrete composite reinforced with steel bars[J]. Construction and Building Materials, 2018, 159: 175-188. doi: 10.1016/j.conbuildmat.2017.10.101 QUDAH S, MAALEJ M. Application of engineered cementitious composites (ECC) in interior beam-column connections for enhanced seismic resistance[J]. Engineering Structure, 2014, 69: 235-245. doi: 10.1016/j.engstruct.2014.03.026 ELGAWADY M A, DAWOOD H M. Analysis of segmental piers consisted of concrete filled FRP tubes[J]. Engineering Structure, 2012, 38: 142-152. doi: 10.1016/j.engstruct.2012.01.001 李福海,胡丁涵,余泳江,等. PP-ECC梁抗弯性能试验研究[J]. 西南交通大学学报,2019,54(2): 272-281.LI Fuhai, HU Dinghan, YU Yongjiang, et al. Experimental study on flexural capacity of PP-ECC beam[J]. Journal of Southwest Jiaotong University, 2019, 54(2): 272-281. 贾毅,赵人达,占玉林,等. PP-ECC用于墩底塑性铰区域的抗震性能试验[J]. 中国公路学报,2019,32(7): 100-110.JIA Yi, ZHAO Renda, ZHAN Yulin, et al. Experimental investigation on seismic behavior of bridge piers with polypropylene-engineered cementitious composite in plastic hinge regions[J]. China Journal of Highway and Transport, 2019, 32(7): 100-110. 周双. 纤维增强水泥基复合材料试验研究及其桥梁无缝化改造中的应用[D]. 成都: 西南交通大学, 2017. 李碧雄,廖桥,章一萍,等. 超高强钢筋工程用水泥基复合材料[J]. 吉林大学学报(工学版),2019,49(4): 1153-1161.LI Bixiong, LIAO Qiao, Zhang Yiping, et al. Theoretical on flexural behavior of ultra high strength rebar reinforced engineered cementitious composites beam[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1153-1161. 陈绪军. FRP片材加固钢筋混凝土梁挠度计算方法研究[J]. 铁道学报,2017,39(11): 103-107. doi: 10.3969/j.issn.1001-8360.2017.11.016CHEN Xujun. Study on deflection calculation method for reinforced concrete beams strengthened with FRP sheets[J]. Journal of the China Railway Society, 2017, 39(11): 103-107. doi: 10.3969/j.issn.1001-8360.2017.11.016 周建民,陈硕,王晓锋,等. 高强钢筋混凝土梁短期变形计算方法研究[J]. 同济大学学报(自然科学版),2013,41(4): 503-509.ZHOU Jianmin, CHEN Shuo, WANG Xiaofeng, et al. Calculation method of short-term deformation of concrete beams with high strength steel bars[J]. Journal of Tongji University (Natural Science), 2013, 41(4): 503-509. American Concrete Institute. Building code requirements for structural concrete and commentary: ACI 318-11[S]. Detroit: ACI Committee 318, 2011. 宁喜亮. 钢筋纤维自密实混凝土梁受弯承载力与裂缝研究[D]. 大连: 大连理工大学, 2015. -

下载:

下载: