Investigation on Thermo-Mechanical Coupling Characteristics of Disc Brake System of High-Speed Train

-

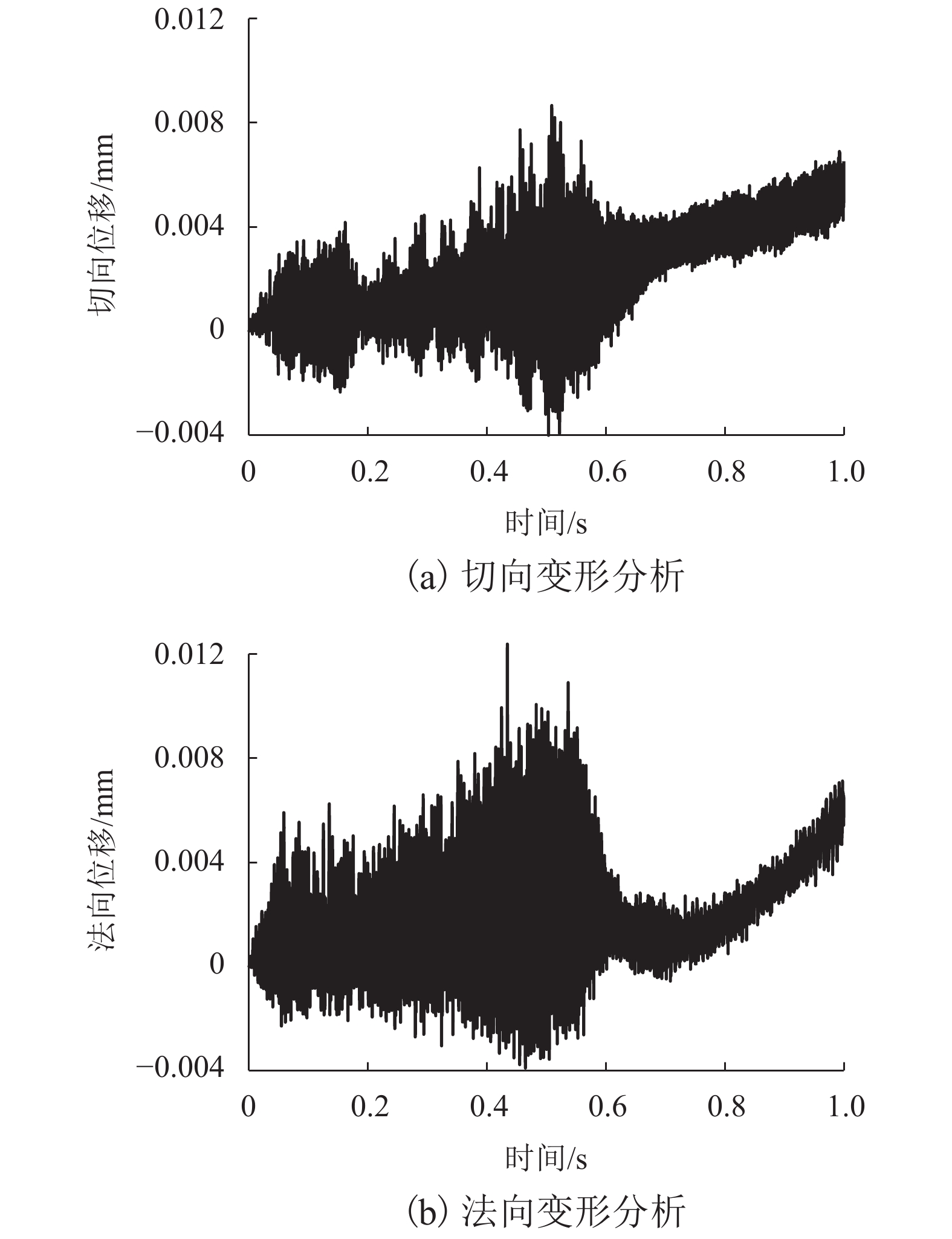

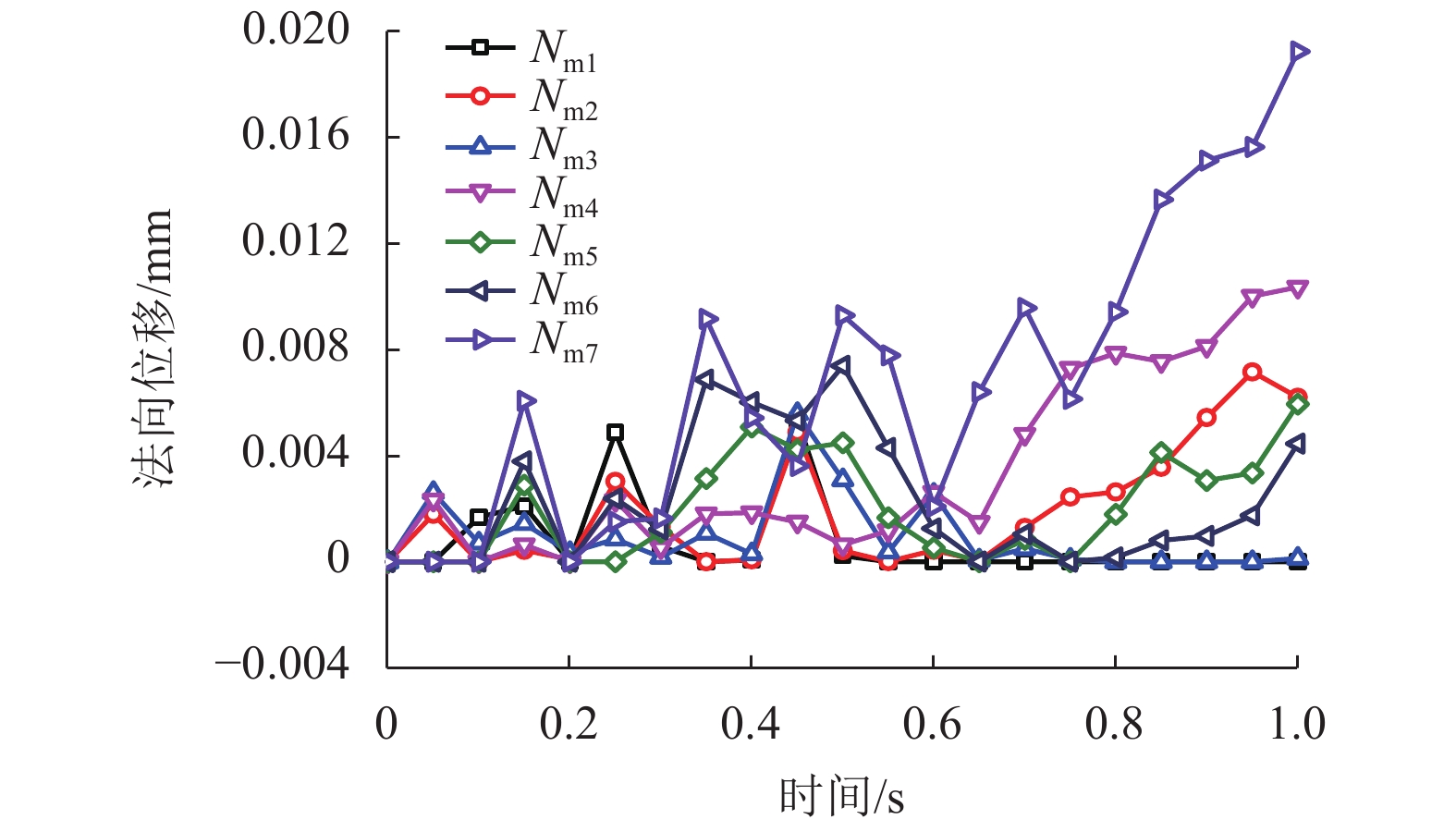

摘要: 为了研究热机耦合对高速列车制动系统动力学行为的影响,建立了高速列车制动系统三维瞬态热机耦合有限元模型,进行拖曳制动状态下热机耦合特性的计算与分析;采用ABAQUS/Explicit热-位移瞬态分析法,探讨列车制动过程中的温度分布特性和振动行为,并与忽略热机耦合状态的系统动力学行为进行对比分析. 研究结果表明:制动过程中闸片温度动态变化,且会形成局部高温区导致热斑形成;由于制动盘和闸片发生一定程度弹性翘曲变形,导致闸片温度周向分布和径向分布出现复杂的温度分布特性,在闸片的内外径处和进/出摩擦区域的温度分布差异显著;制动过程中闸片在法向和切向上的振荡程度逐渐减弱,但是总体变形量逐渐增大,位移形变量达到6 μm;热变形主要发生在闸片两侧,闸片在进摩擦区的变形量(35 μm)明显大于出摩擦区处(25 μm),而闸片的中部出现明显的"凹陷",即随着制动进行,闸片中部区域没有出现明显的热变形;在热机耦合状态下,制动系统振动先增大后降低,整体振动强度比忽略热机耦合时强;界面接触力的波动程度先增大后降低,总体呈上升趋势.Abstract: To study the effect of thermo-mechanical coupling on the dynamic behavior of high-speed train disc braking system, a three dimensional transient thermo-mechanical coupling finite element model of high-speed train braking system was established, and thermo-mechanical coupling characteristics were calculated and analyzed. The ABAQUS/Explicit heat-displacement transient analysis method was used to discuss the temperature distribution characteristics and vibration behavior during brake process. Additionally, the system dynamic behavior was compared with the situation when ignores the thermo-mechanical coupling state. The results show that the temperature distribution of brake pad is in the process of dynamic change, and local high temperature zone will be formed on the pad surface and accordingly lead to hot spots. Due to the elastic heat deformation of disc and pad in a certain extent, the temperature distribution characteristics of brake pad in circular and radial directions are complicated. In the process of braking, the oscillations of brake pad in both the normal and tangential directions gradually become weaken, but the overall deformation tends to increase gradually, and the deformed displacement can reach 6 μm. Thermal deformation mainly occurs on two sides of the pad, the amount of deformation in the entering friction area (35 μm) is visibly larger than that in the out friction area (25 μm), and the center of the pad presents an obvious “sunken” phenomenon, which indicates that there is no significant thermal deformation generated in the center of the pad. The vibration of the braking system increases firstly and then decreases and the vibration level is stronger than that in the case of ignoring the thermomechanical coupling of brake system. The fluctuation level of interface contact force firstly increases and then decreases, but it possesses a visible increase trend.

-

表 1 有限元模型网格特征

Table 1. Mesh characteristics of the finite element model

部件 单元类型 单元数/个 节点数/个 制动盘 C3D8RT 21144 32812 闸片 C3D8RT 10477 13668 闸片托 C3D8RT 16348 21401 制动夹钳 C3D8T 15658 4507 盘毂 C3D8T 8581 6149 -

钱坤才,吴射章,乔青锋,等. 高寒雨雪气候下高速动车组盘片摩擦副摩擦性能[J]. 西南交通大学学报,2017,52(6): 1188-1192. doi: 10.3969/j.issn.0258-2724.2017.06.020QIAN Kuncai, WU Shezhang, QIAO Qingfeng, et al. Friction performance of brake disks and blocks for high-speed EMU trains in cold,rainy and snowy weather[J]. Journal of Southwest Jiaotong University, 2017, 52(6): 1188-1192. doi: 10.3969/j.issn.0258-2724.2017.06.020 杨国伟,魏宇杰,赵桂林,等. 高速列车的关键力学问题[J]. 力学进展,2015,45(1): 217-460.YANG Guowei, WEI Yujie, ZHAO Guilin, et al. Current research progress in the mechanics of high speed rails[J]. Advances in Mechanics, 2015, 45(1): 217-460. 莫继良,王东伟,李建熹,等. 摩擦热对界面磨损及制动系统稳定性的影响[J]. 上海交通大学学报,2018,52(5): 217-460.MO Jiliang, WANG Dongwei, LI Jianxi, et al. Effect of friction heat on interfacial wear and brake system stability[J]. Journal of Shanghai Jiaotong University, 2018, 52(5): 217-460. 刘静娟,刘莹,康光林,等. 高速列车通风式制动盘的散热特性分析[J]. 机械科学与技术,2018,37(6): 937-940.LIU Jingjuan, LIU Ying, KANG Guanglin, et al. Analysis of heat dissipation performance for ventilated brake disc in high speed train[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(6): 937-940. 石晓玲,李强,宋占勋,等. 高速列车锻钢制动盘热疲劳裂纹耦合扩展特性研究[J]. 机械工程学报,2016,52(10): 126-132. doi: 10.3901/JME.2016.10.126SHI Xiaoling, LI Qiang, SONG Zhanxun, et al. Research on coupled extension characteristic of thermal fatigue cracks at forged brake disc for high speed train[J]. Journal of Mechanical Engineering, 2016, 52(10): 126-132. doi: 10.3901/JME.2016.10.126 杨智勇,韩建民,李卫京. 制动盘制动过程的热机耦合仿真[J]. 机械工程学报,2010,46(2): 88-92. doi: 10.3901/JME.2010.02.088YANG Zhiyong, HAN Jianmin, LI Weijing. Thermo-mechanical coupling simulation of braking process of brake disc[J]. Journal of Mechanical Engineering, 2010, 46(2): 88-92. doi: 10.3901/JME.2010.02.088 周素霞, 杨月, 谢基龙. 高速列车制动盘瞬态温度和热应力分布仿真分析[J]. 机械工程学报, 2011, 47(22): 126-131.ZHOU Suxia, YANG Yue, XIE Jilong. Analysis of transient temperature and thermal stress distribution on the high speed strain brake disk by simulation[J]. Journal of Mechanical Engineering, 2011, 47(22): 126-131 张琪, 王玉光, 周小江, 等. 不同地铁车轮结构几何参数下踏面制动热负荷分析[J]. 计算机辅助工程, 2016, 25(2): 19-24.ZHANG Qi, WANG Yuguang, ZHOU Xiaojiang, et al. Analysis on tread braking thermal load under different geometric parameters of subway train wheel structure[J]. Computer Aided Engineering, 2016, 25(2): 19-24. LORANG X, FOY-MARGIOCCHIS F, NGUYEN Q S, et al. TGV disc brake squeal[J]. Journal of Sound and Vibration, 2006, 293: 735-746. doi: 10.1016/j.jsv.2005.12.006 孟繁辉,刘艳,吴影,等. 高速列车制动盘制动过程的有限元模拟及表面划伤对应力场的影响研究[J]. 机械工程学报,2018,54(12): 42-48. doi: 10.3901/JME.2018.12.042MENG Fanhui, LIU Yan, WU Ying, et al. Research on finite element simulation of braking process of high speed train brake disc and influence of surface scratch on stress field[J]. Journal of Mechanical Engineering, 2018, 54(12): 42-48. doi: 10.3901/JME.2018.12.042 刘莹,宋涛. 风电主轴盘形制动器温度场的数值模拟[J]. 机械设计,2015,32(4): 105-109.LIU Ying, SONG Tao. Simulation of friction temperature field for disc brake of mineral car[J]. Journal of Mechanical Design, 2015, 32(4): 105-109. 张立军,陈远,刁坤,等. 盘式制动器接触压力与热机耦合特性仿真分析[J]. 同济大学学报(自然科学版),2013,41(10): 1554-1562.ZHANG Lijun, CHEN Yuan, DIAO Kun, et al. Computational investigation into disc-pad pressure distribution and thermomechanical coupling characteristics of brake pads in disc brake[J]. Journal of Tongji University (Natural Science), 2013, 41(10): 1554-1562. OUYANG H, ABUBAKAR A R, LI L J. A combined analysis of heat conduction,contact pressure and transient vibration of a disk brake[J]. International journal of Vehicle Design, 2009, 51(1/2): 190-206. doi: 10.1504/IJVD.2009.027121 ABUBAKAR A R, ABDUL HAMID M K, MOHAMAD M, et al. Numerical analysis of disc brake squeal considering temperature dependent friction coefficient[J]. Journal Mekanikal, 2006, 22: 26-38. THURESSON D. Influence of material properties on sliding contact braking applications[J]. Wear, 2004, 257: 451-460. doi: 10.1016/j.wear.2004.01.009 -

下载:

下载: