Generation Mechanism of Railway Disc Brake Squeal and Its Suppression Method

-

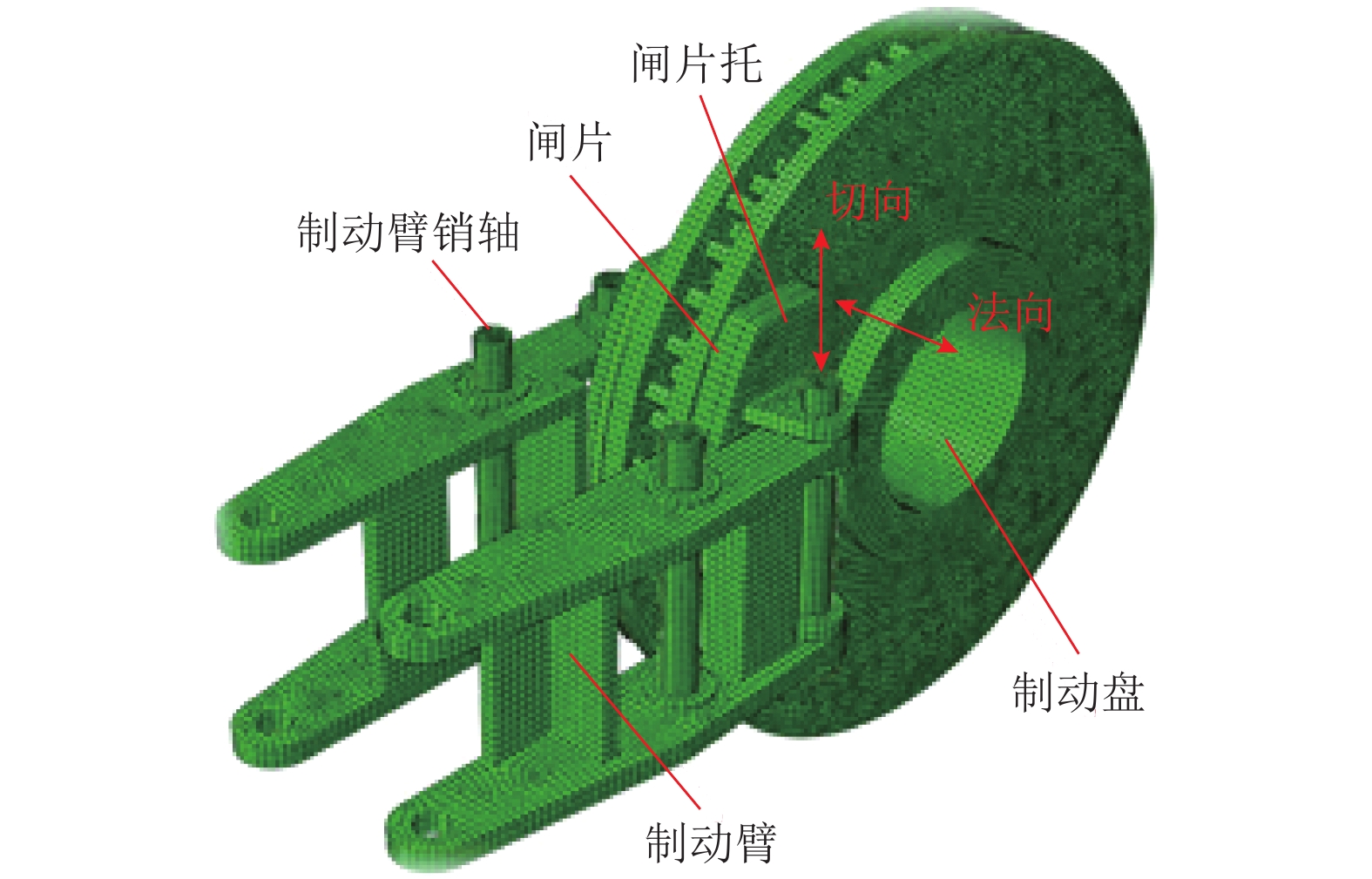

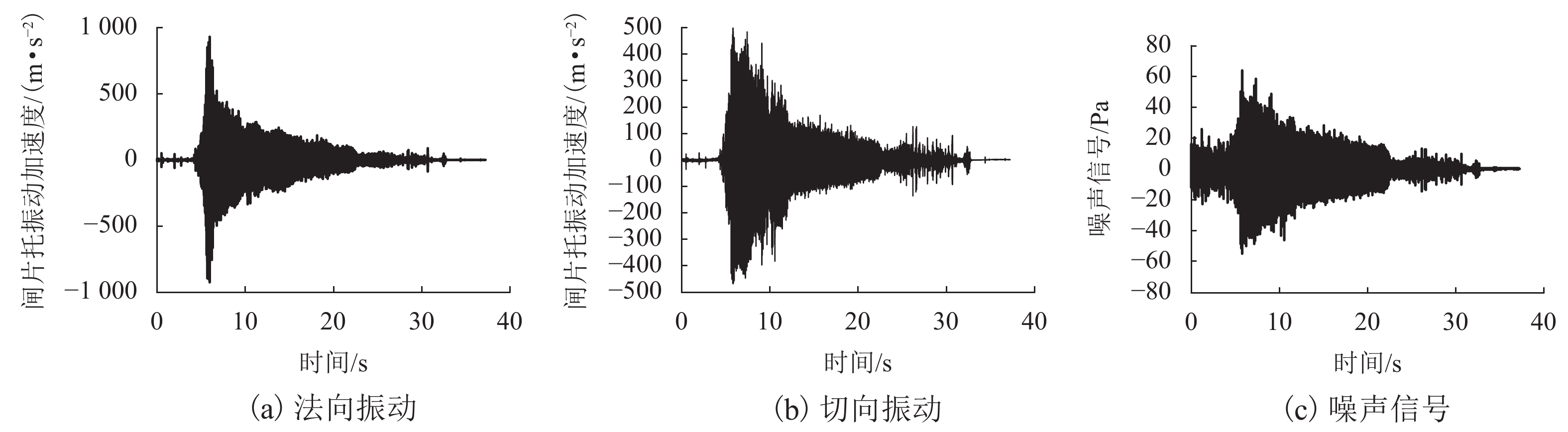

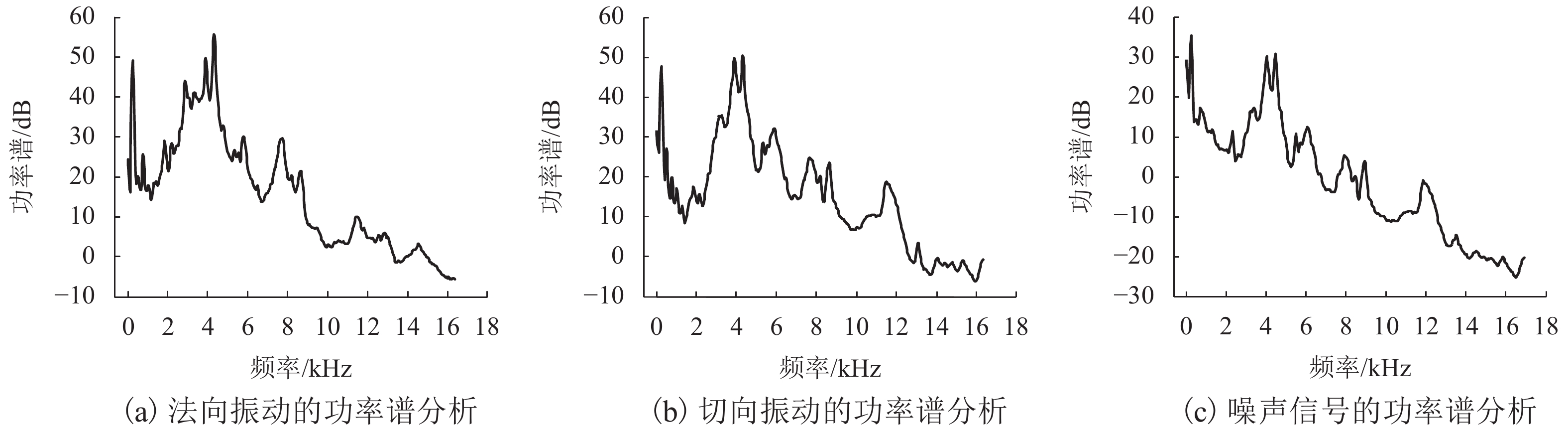

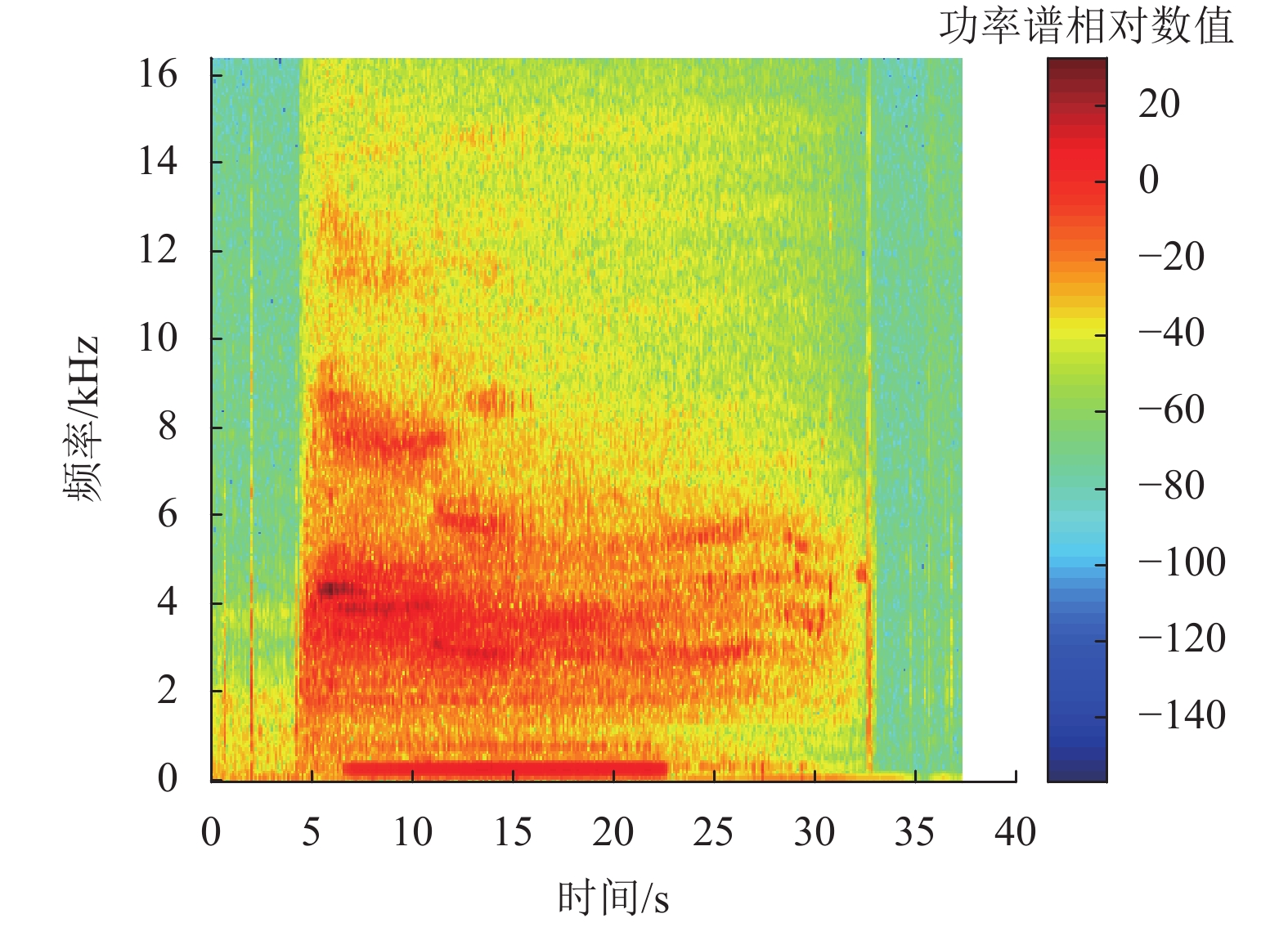

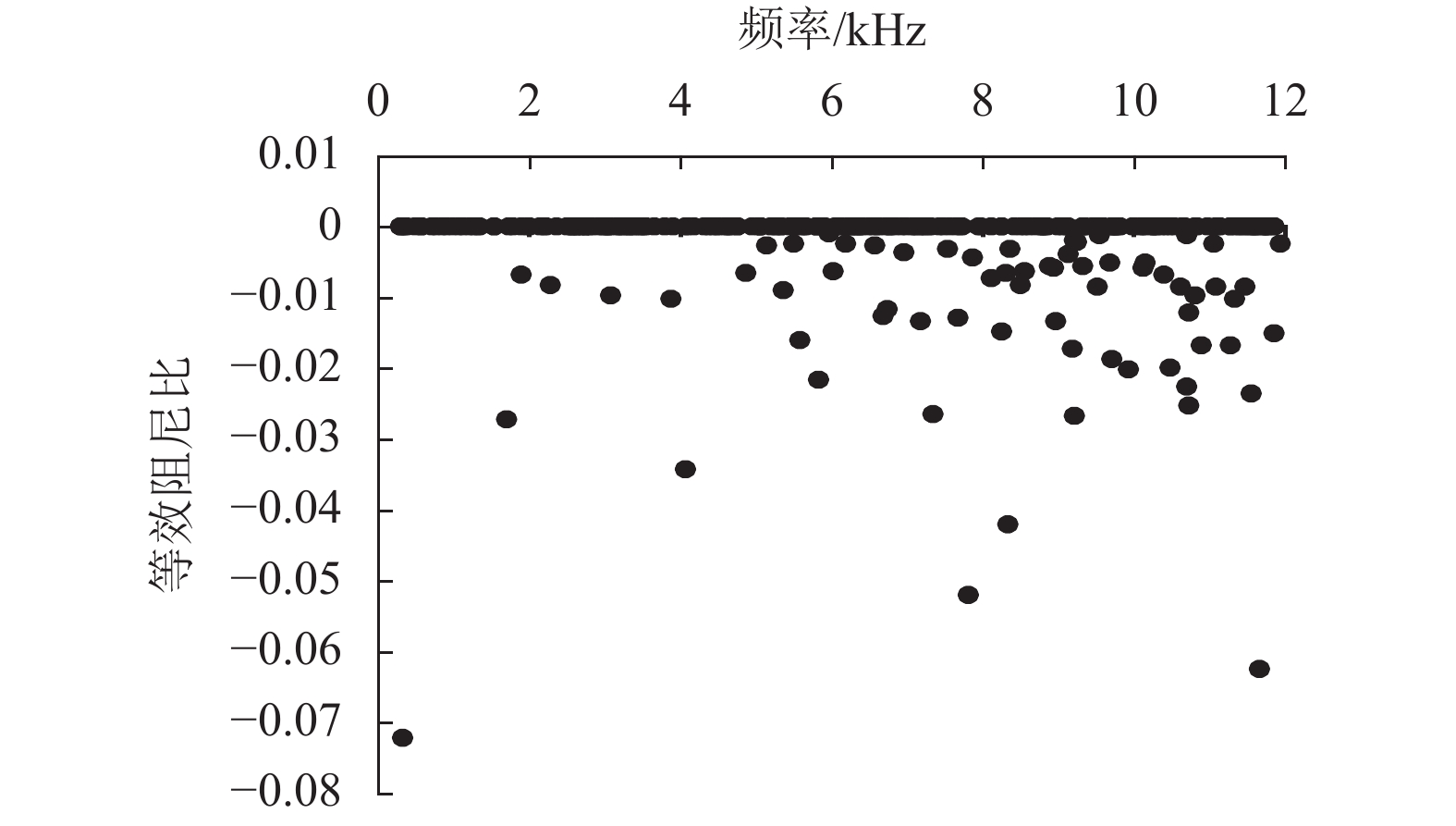

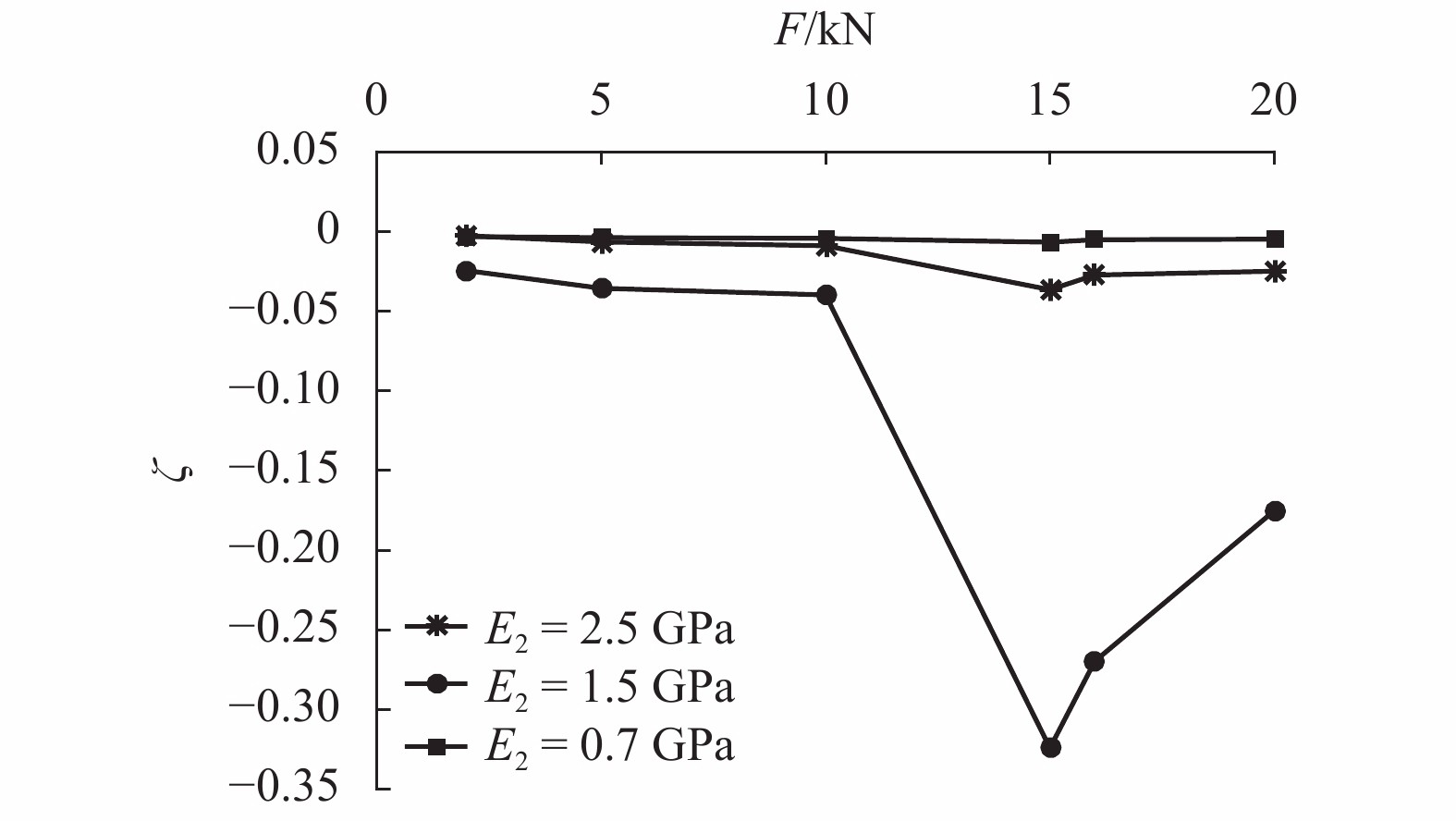

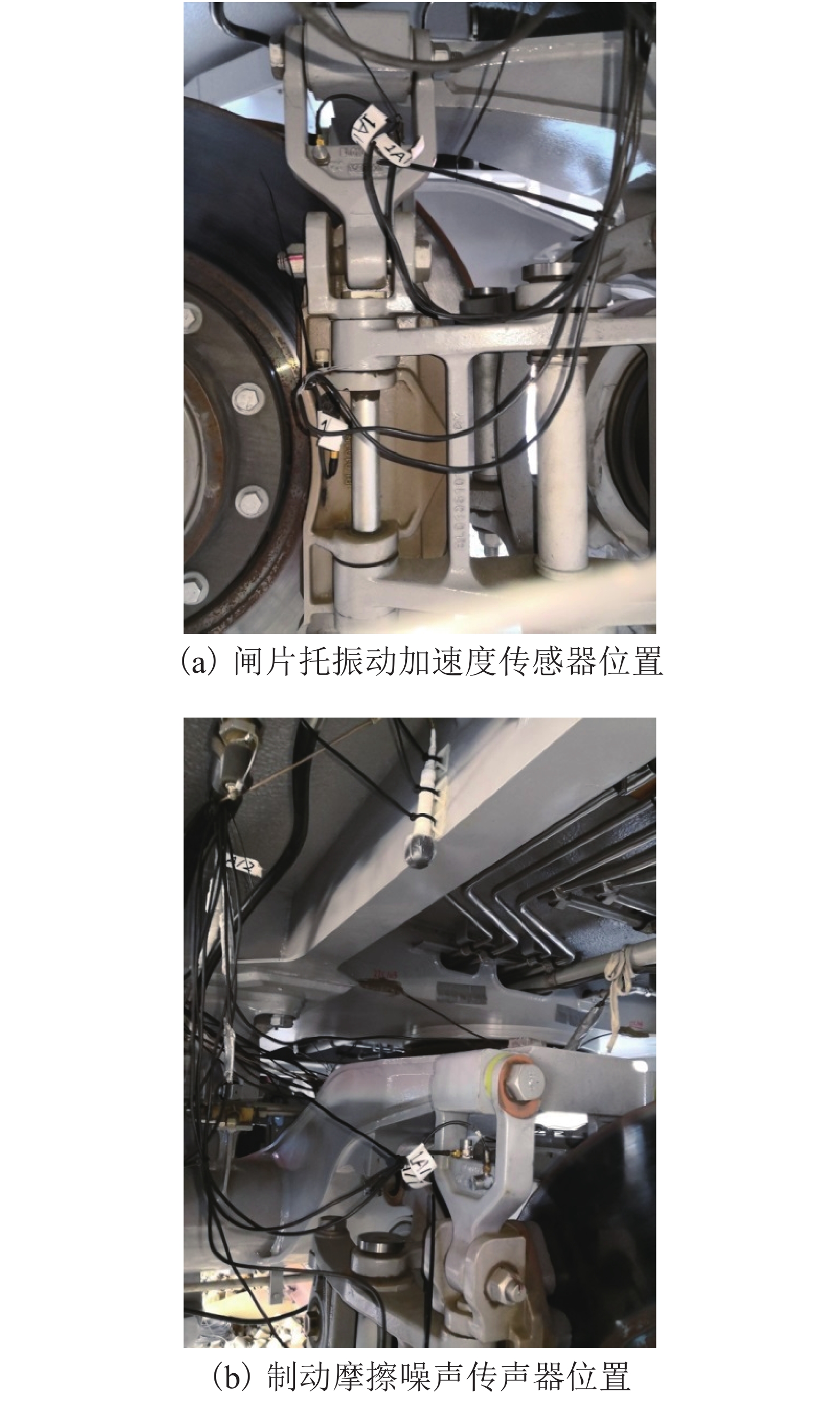

摘要: 为了研究铁路盘型制动噪声的发生规律及其影响因素,测量了列车运行过程中各种制动工况条件下盘型制动器的摩擦噪声,获得了列车盘形制动摩擦噪声的发生规律;基于模态耦合引起制动摩擦噪声的机理,使用试验测得的闸片和制动盘之间的摩擦系数,建立了由制动盘、闸片、闸片托、制动杠杆和销等组成的全尺寸盘型制动系统摩擦噪声有限元预测模型,研究了铁路盘型制动噪声的影响因素. 试验结果表明:盘型制动摩擦噪声的特征频率为256.78、3904.07 Hz和4320.38 Hz;在特定摩擦副的摩擦性能下,当制动缸推力为10.1 kN和12.3 kN时,盘型制动器最容易产生摩擦噪声,模型预测结果与实测摩擦噪声比较一致;制动闸片的弹性模量对盘型制动噪声有重要的影响,合理的闸片弹性模量有助于抑制制动摩擦噪声.Abstract: In order to study the generation mechanism of railway disc brake squeal and its influencing factors, the disc brake squeal of a railway brake unit for several different brake conditions in a field test was measured, and the generation mechanism of railway disc brake squeal was obtained. Based on the mechanism of brake friction squeal caused by modal coupling, a full-size prediction model of brake squeal was established, which included a disc, two brake pads, two pad holders, two levers, and several pins. The friction coefficients between the pads and disc from a laboratory test were used in the prediction of brake squeal. The factors affecting brake squeal were studied in the model. The test results show that the characteristic frequencies of disc brake friction squeal are 256.78, 3904.07 Hz and 4320.38 Hz, respectively. When the thrust force is equal to 10.1 kN and 12.3 kN, disc brakes are most likely to produce friction squeal in brake applications, the predicted results of the model are in agreement with the measured frictional squeal. The elastic modulus of the brake pad has an important influence on disc brake squeal, the reasonable elastic modulus of brake pad is helpful to suppress the brake friction squeal.

-

Key words:

- railway disc brake /

- brake squeal /

- friction-induced noise /

- mode coupling /

- brake pressure

-

表 1 摩擦噪声发生的记录

Table 1. Records of brake squeal occurrence

试验工况 140 km/h 120 km/h 100 km/h 80 km/h 60 km/h 50 km/h 30 km/h 紧急制动 无 无 无 无 无 无 无 最大常用复合制动 无 有 有 有 有 有 有 最大常用纯空气制动 无 无 无 无 无 无 无 快速复合制动 无 有 有 无 有 无 无 快速纯空气制动 无 无 无 无 无 无 无 -

LORANG X, FOY-MARGIOCCHI F, NGUYEN Q S, et al. TGV disc brake squeal[J]. Journal of Sound and Vibration, 2006, 293: 735-746. SINOU J J, LOYER A, CHIELLO O, et al. A global based on experiments and simulations for squeal prediction on industrial railway brakes[J]. Journal of Sound and Vibration, 2013, 332: 5068-5085. KINKAID N M, O’ REILLY O M, PAPADOPOULOS P. Automotive disc brake squeal[J]. Journal of Sound and Vibration, 2003, 267: 105-166. IBRAHIM R A. Friction-induced vibration,chatter,squeal,and chaos. part 2. dynamics and modeling[J]. Apply Mechanics Review, 1994, 47(7): 227-253. CROLLA D A, LANG A M. Brakes noise and vibrations-the state of the art[C]//Proceedings of the Leeds-Lyon Symposium on Tribology. Leeds: Elsevier, 1990, 165-174. SPURR R T. A theory of brake squeal[J]. Proceedings of the Automobile Division,Institution of Mechanical Engineers, 1961, 1: 33-52. NORTH M R. Disc brake squeal — a theoretical model[R]. Technical Report 1972/5. Warwickshire: Motor Industry Research Association, 1972. RHEE S K, TSANG P H S, WANG Y S. Friction-induced noise and vibration of disc brakes[J]. Wear, 1989, 133: 39-45. MOTTERSHEAD J E, CHAN S N. Brake squeal-an analysis of symmetry and flutter instability[C]//Proceedings of Friction-Induced Vibration, Chatter, Squeal, and Chaos. New York: American Society of Mechanical Engineers, 1992: 87-97. CHEN G X, ZHOU Z R. A self-excited vibration model based on special elastic vibration modes of friction systems and time delays between the normal and friction forces:a new mechanism for squealing noise[J]. Wear, 2007, 262: 1123-1139. 陈光雄,周仲荣. 摩擦噪声有限元预测[J]. 机械工程学报,2007,46(3): 164-168.CHEN Guangxiong, ZHOU Zhongrong. Finite element prediction of frictional squeal[J]. Journal of Mechanical Engineering, 2007, 46(3): 164-168. LIU P, ZHENG H, CAI C, et al. Analysis of disc brake squeal using the complex eigenvalue method[J]. Applied Acoustics, 2007, 68: 603-615. OUYANG H, NACK W, YUAN Y, et al. Numerical analysis of automotive disc brake squeal:a review[J]. International Journal of Vehicle Noise and Vibration, 2005, 1(3/4): 207-231. WANG D W, MO J L, LIU M Q, et al. Improving tribological behaviours and noise performance of railway disc brake by grooved surface texturing[J]. Wear, 2017, 376/377: 1586-1600. 李清,管迪华,杜永昌,等. 盘式制动器摩擦片形状设计对高频尖叫的影响[J]. 汽车安全与节能学报,2014,5(4): 360-366. doi: 10.3969/j.issn.1674-8484.2014.04.008LI Qing, GUAN Dihua, DU Yongchang, et al. Effect of pad shapes on disc brake squeal at high frequency[J]. Journal of Automotive Safety and Energy, 2014, 5(4): 360-366. doi: 10.3969/j.issn.1674-8484.2014.04.008 张立军,刁坤,孟德建,等. 盘-销系统摩擦尖叫的时变性:发生机理与关键影响因素[J]. 机械工程学报,2013,49(14): 99-105.ZHANG Lijun, DIAO Kun, MENG Dejian, et al. Time-varying characteristics of frictional squeal in pin-on-disc system:generation mechanism and key impact factors[J]. Journal of Mechanical Engineering, 2013, 49(14): 99-105. -

下载:

下载: