|

XIE J, WANG J, ZHANG B, et al. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete[J]. Construction and Building Materials, 2019, 204: 384-398. doi: 10.1016/j.conbuildmat.2019.01.191

|

|

CRETESCU I, HARJA M, TEODOSIU C, et al. Synthesis and characterisation of a binder cement replacement based on alkali activation of fly ash waste[J]. Process Safety and Environmental Protection, 2018, 119: 23-35. doi: 10.1016/j.psep.2018.07.011

|

|

WIANGLOR K, SINTHUPINYO S, PIYAWORAPAIBOON M, et al. Effect of alkali-activated metakaolin cement on compressive strength of mortars[J]. Applied Clay Science, 2017, 141: 272-279. doi: 10.1016/j.clay.2017.01.025

|

|

PART W K, RAMLI M, CHEAH C B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products[J]. Construction and Building Materials, 2015, 77: 370-395. doi: 10.1016/j.conbuildmat.2014.12.065

|

|

BAKHAREV T. Geopolymeric materials prepared using class F fly ash and elevated temperature curing[J]. Cement and Concrete Research, 2005, 35(6): 1224-1232. doi: 10.1016/j.cemconres.2004.06.031

|

|

RATTANASAK U, CHINDAPRASIRT P. Influence of NaOH solution on the synthesis of fly ash geopolymer[J]. Minerals Engineering, 2009, 22(12): 1073-1078. doi: 10.1016/j.mineng.2009.03.022

|

|

PANIAS D, GIANNOPOULOU I P, PERRAKI T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2007, 301(1): 246-254.

|

|

龙涛, 石宵爽, 王清远, 等. 粉煤灰基地聚物再生混凝土的力学性能和微观结构[J]. 四川大学学报(工程科学版), 2013, 45(增刊1): 43-47.LONG Tao, SHI Xiaoshuang, WANG Qingyuan, et al. Mechanical properties and microstructure of fly ash based geopolymeric polymer recycled concrete[J]. Journal of Sichuan University (Engineering Science Edition), 2013, 45(S1): 43-47.

|

|

PAN Z, TAO Z, CAO Y F, et al. Compressive strength and microstructure of alkali-activated fly ash/slag binders at high temperature[J]. Cement and Concrete Composites, 2018, 86: 9-18. doi: 10.1016/j.cemconcomp.2017.09.011

|

|

HAMIDI R M, MAN Z, AZIZLI K A. Concentration of NaOH and the Effect on the properties of fly ash based Geopolymer[J]. Procedia Engineering, 2016, 148: 189-193. doi: 10.1016/j.proeng.2016.06.568

|

|

ATIŞ C D, GÖRÜR E B, Karahan O, et al. Very high strength (120 MPa)class F fly ash geopolymer mortar activated at different NaOH amount,heat curing temperature and heat curing duration[J]. Construction and Building Materials, 2015, 96: 673-678. doi: 10.1016/j.conbuildmat.2015.08.089

|

|

SOMNA K, JATURAPITAKKUL C, KAJITVICHYANUKUL P, et al. NaOH-activated ground fly ash geopolymer cured at ambient temperature[J]. Fuel, 2011, 90(6): 2118-2124. doi: 10.1016/j.fuel.2011.01.018

|

|

李星烨. 碱激发粉煤灰砂浆性能研究[D]. 成都: 西南交通大学, 2018

|

|

CHINDAPRASIRT P, JATURAPITAKKUL C, CHALEE W, et al. Comparative study on the characteristics of fly ash and bottom ash geopolymers[J]. Waste Management, 2009, 29(2): 539-543. doi: 10.1016/j.wasman.2008.06.023

|

|

LEE W K W, DEVENTER J S. The effects of inorganic salt contamination on the strength and durability of geopolymers[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2002, 211(2): 115-126.

|

|

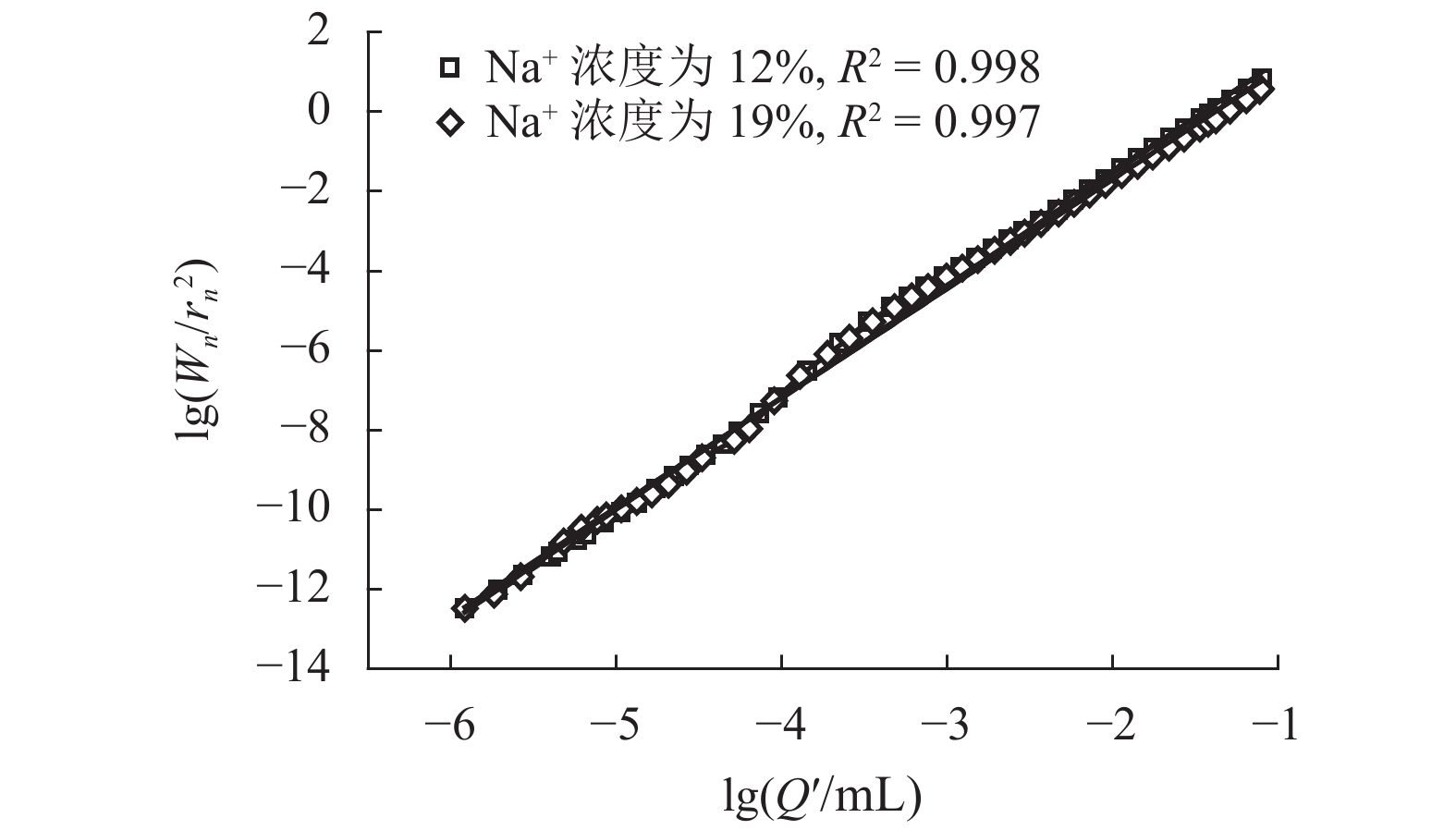

YANG W C, GE Y, YUAN J, et al. Pore fractal characteristic of cement pastes with inorganic salts[C]//International Conference of Concrete Pavement. Haikou: [s.n.], 2009: 101-115.

|

|

JI X, CHAN S Y, FENG N. Fractal model for simulating the space-filling process of cement hydrates and fractal dimensions of pore structure of cement-based materials[J]. Cement and Concrete Research, 1997, 27(11): 1691-1699. doi: 10.1016/S0008-8846(97)00157-9

|

|

金珊珊,张金喜,李爽. 混凝土孔结构分形特征的研究现状与进展[J]. 混凝土,2009(10): 34-37,42.JIN Shanshan, ZHANG Jinxi, LI Shuang. Current situation and development of fractal characteristic of pore structure of concrete[J]. Concrete, 2009(10): 34-37,42.

|

|

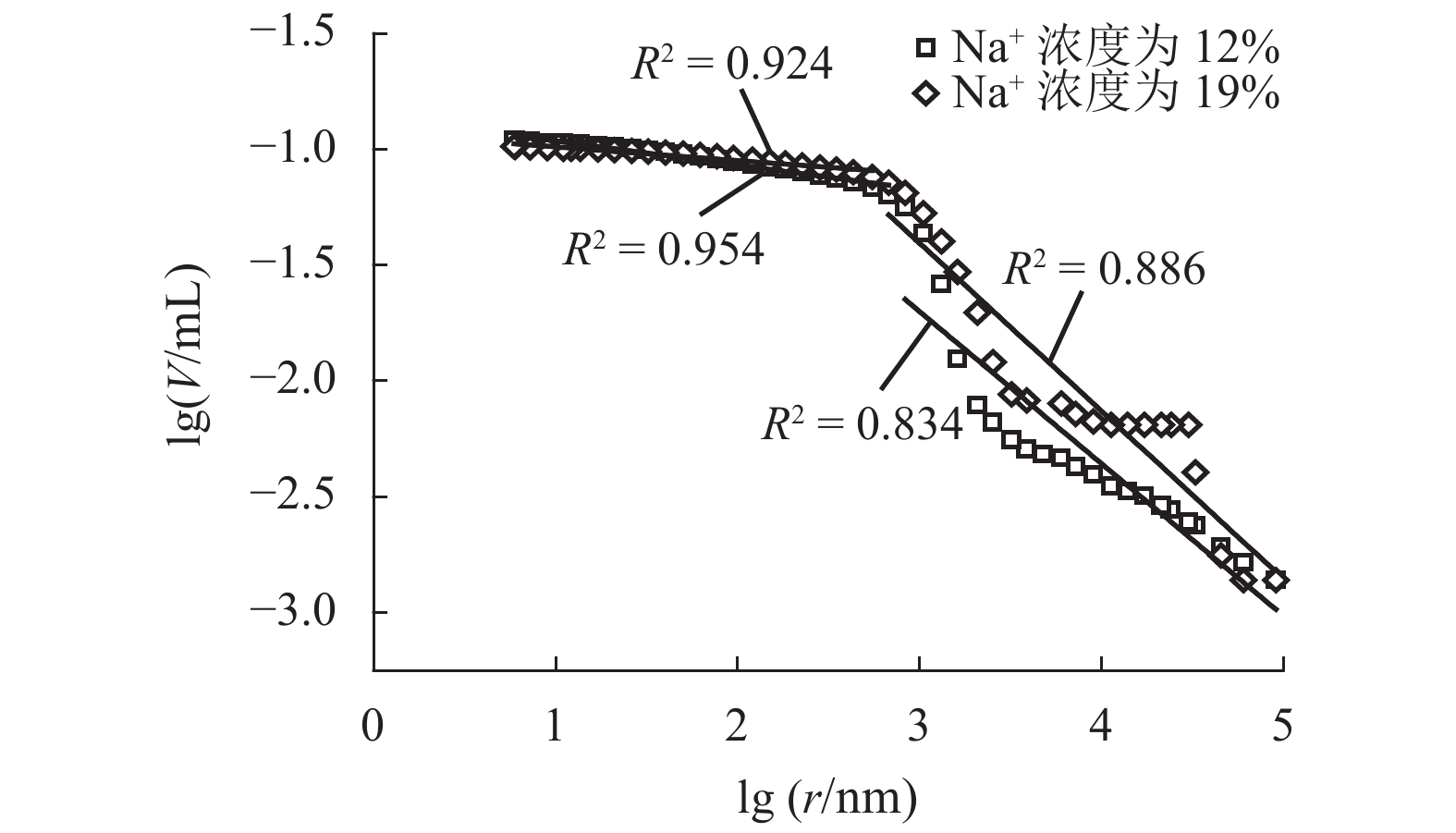

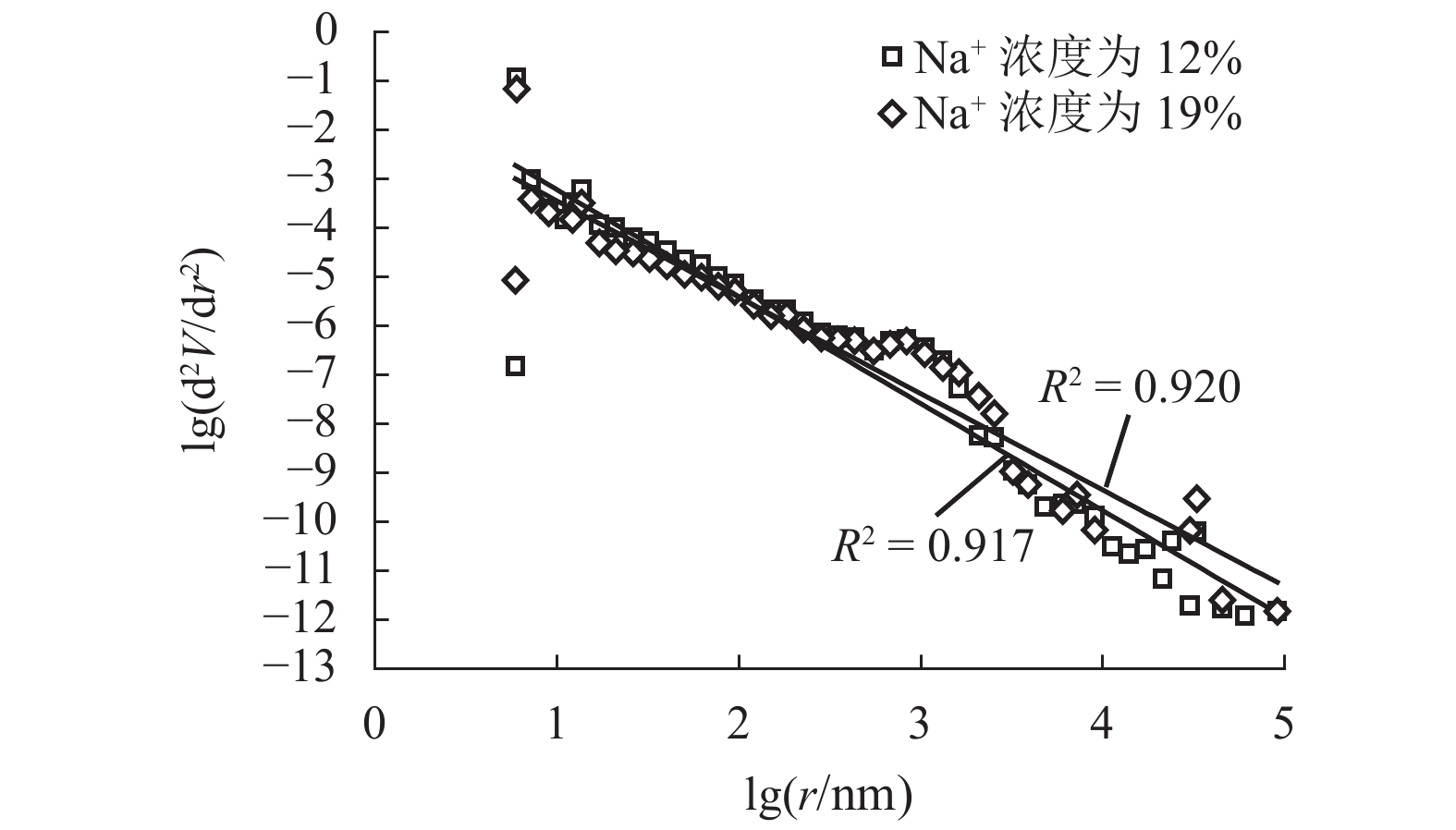

ZHANG B, LIU W, LIU X. Scale-dependent nature of the surface fractal dimension for bi-and multi-disperse porous solids by mercury porosimetry[J]. Applied Surface Science, 2006, 253(3): 1349-1355. doi: 10.1016/j.apsusc.2006.02.009

|

下载:

下载: