Effect of Key Block Position on Straight Assembling Segmental Lining Structure under High Water Pressure

-

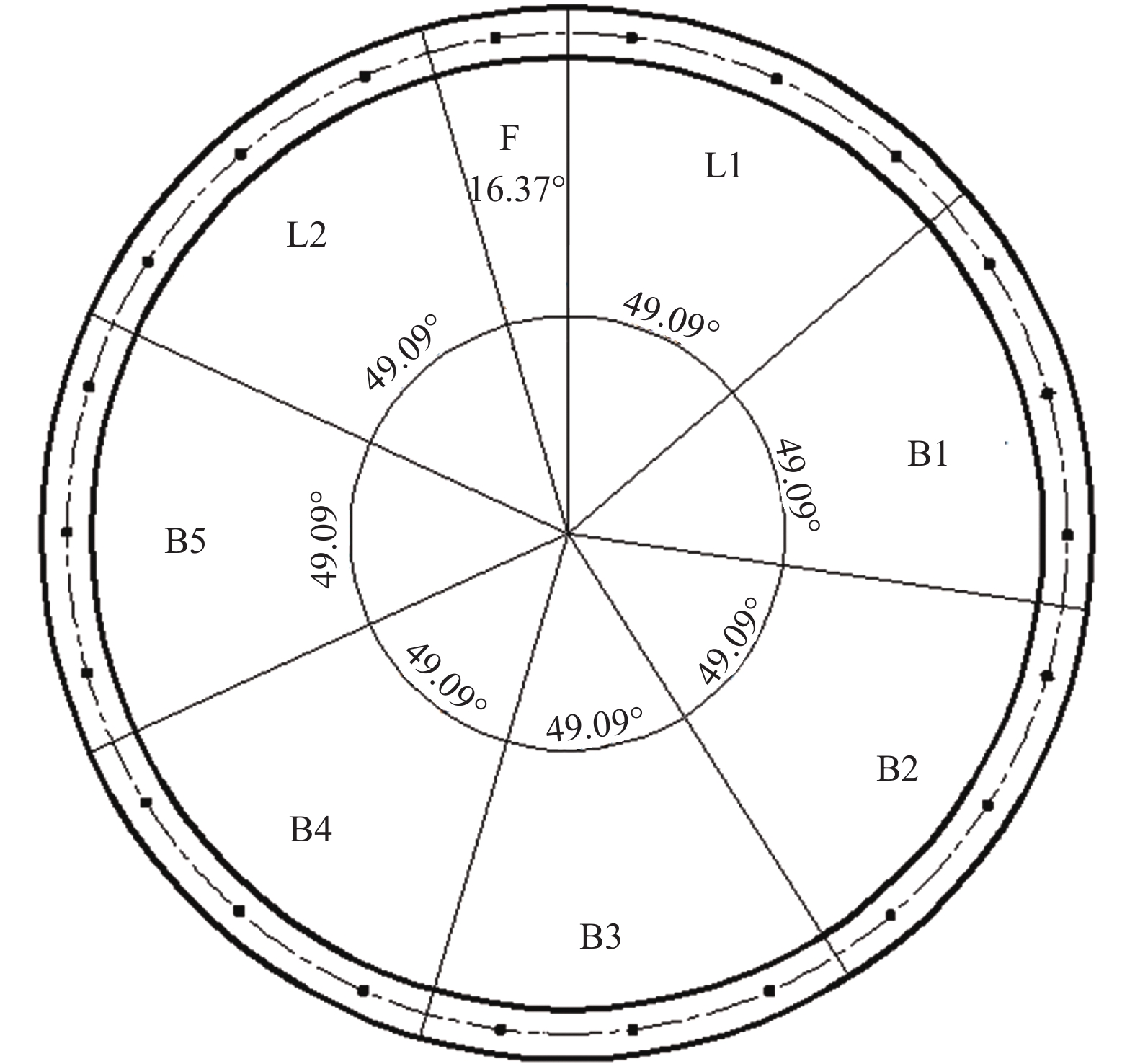

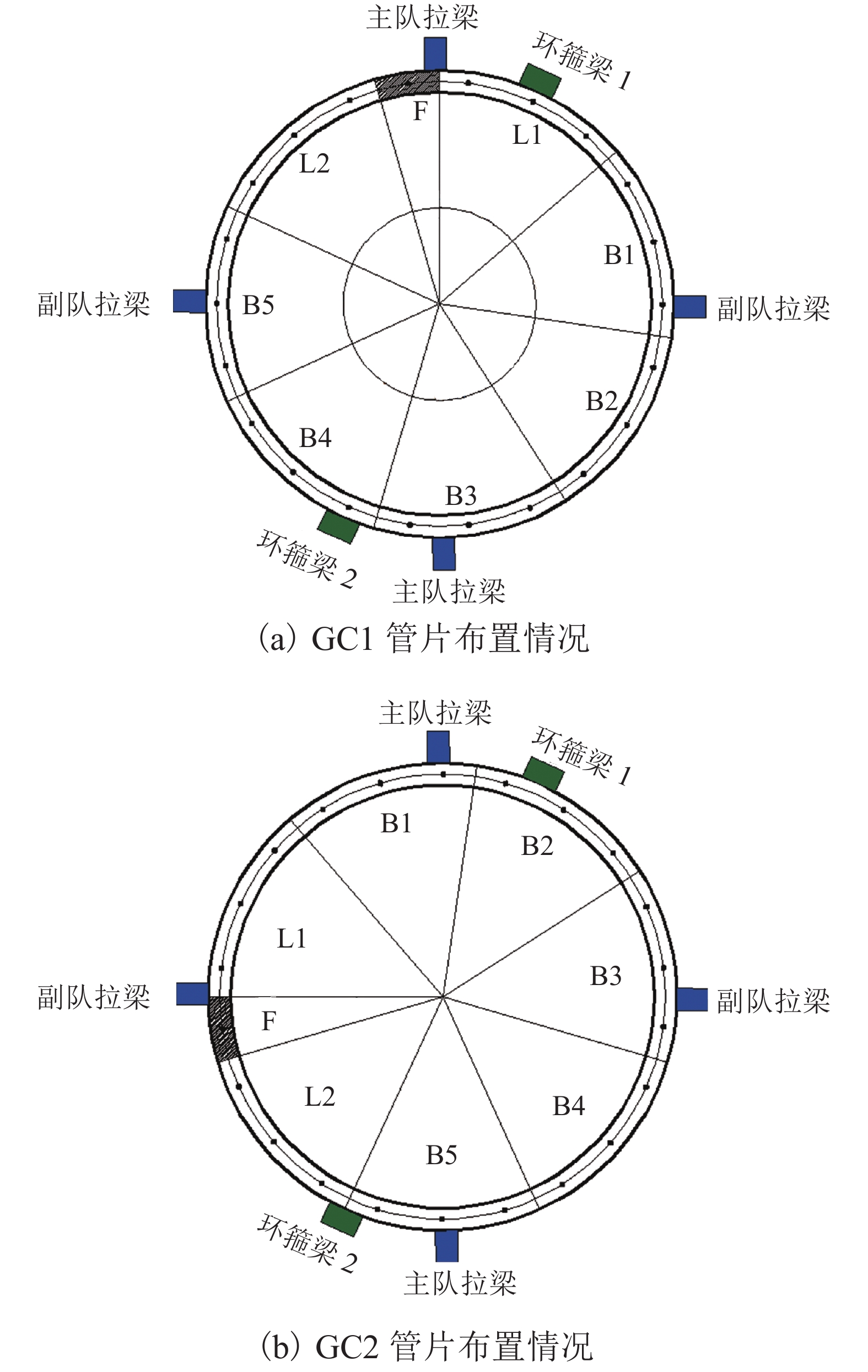

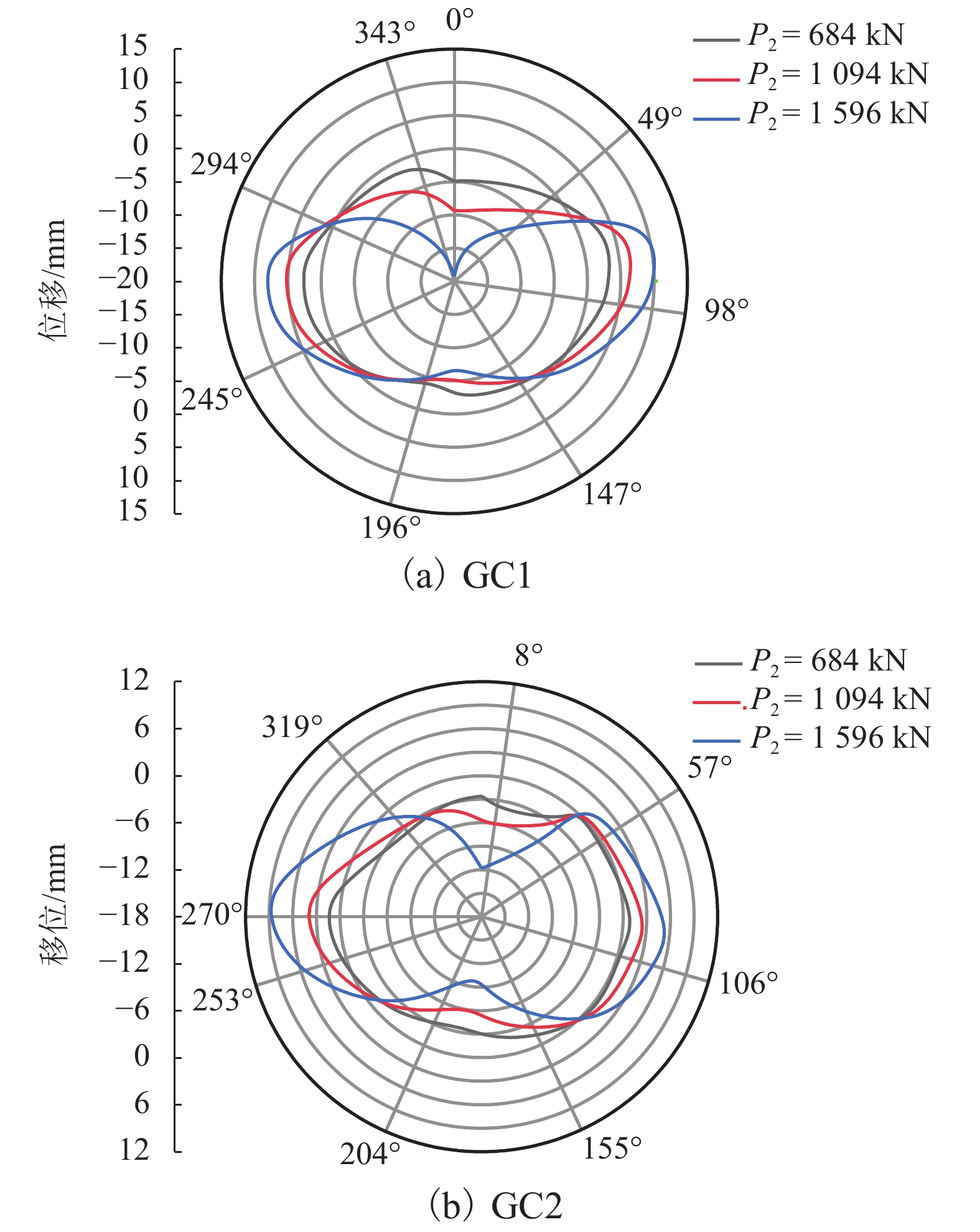

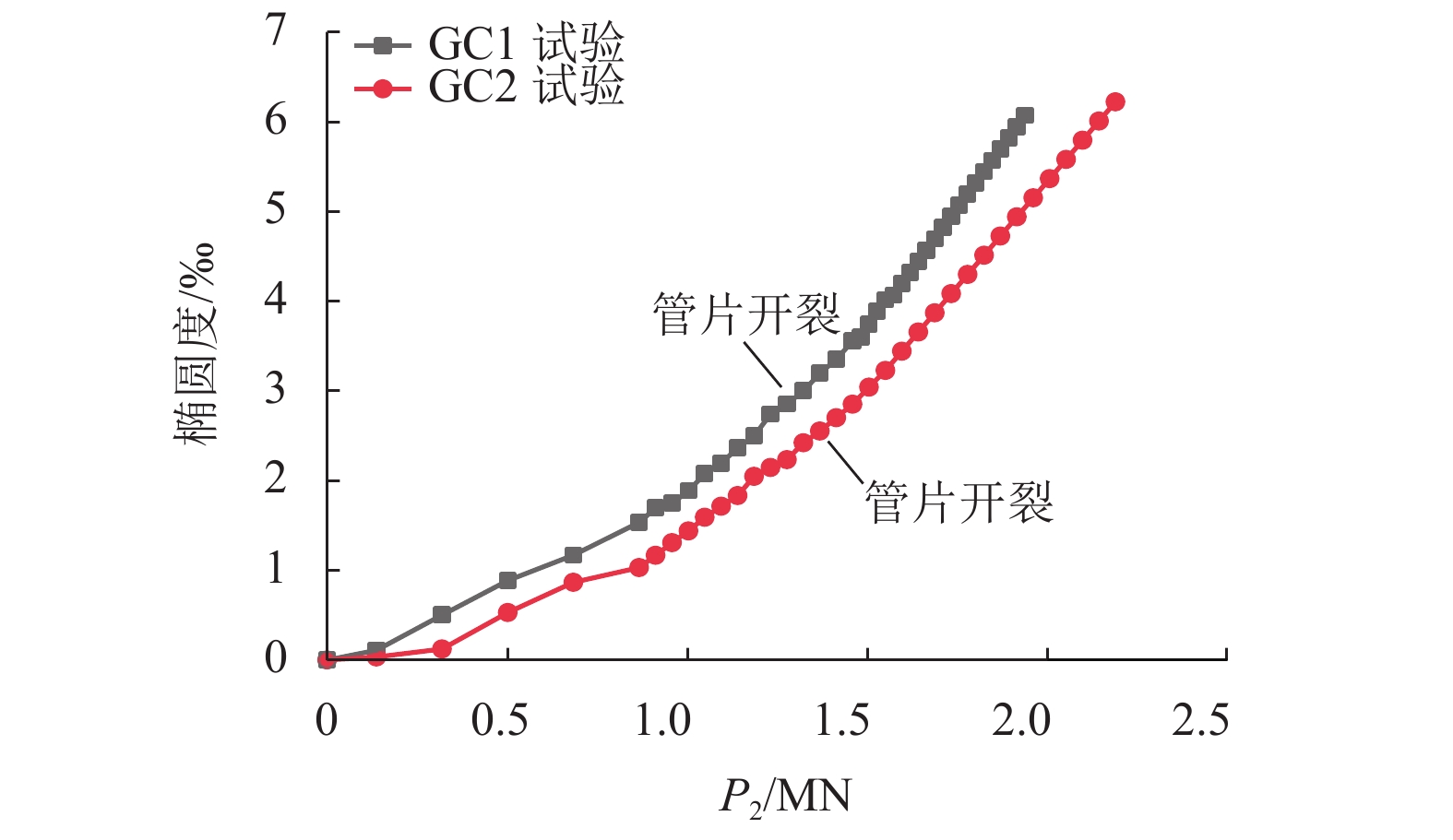

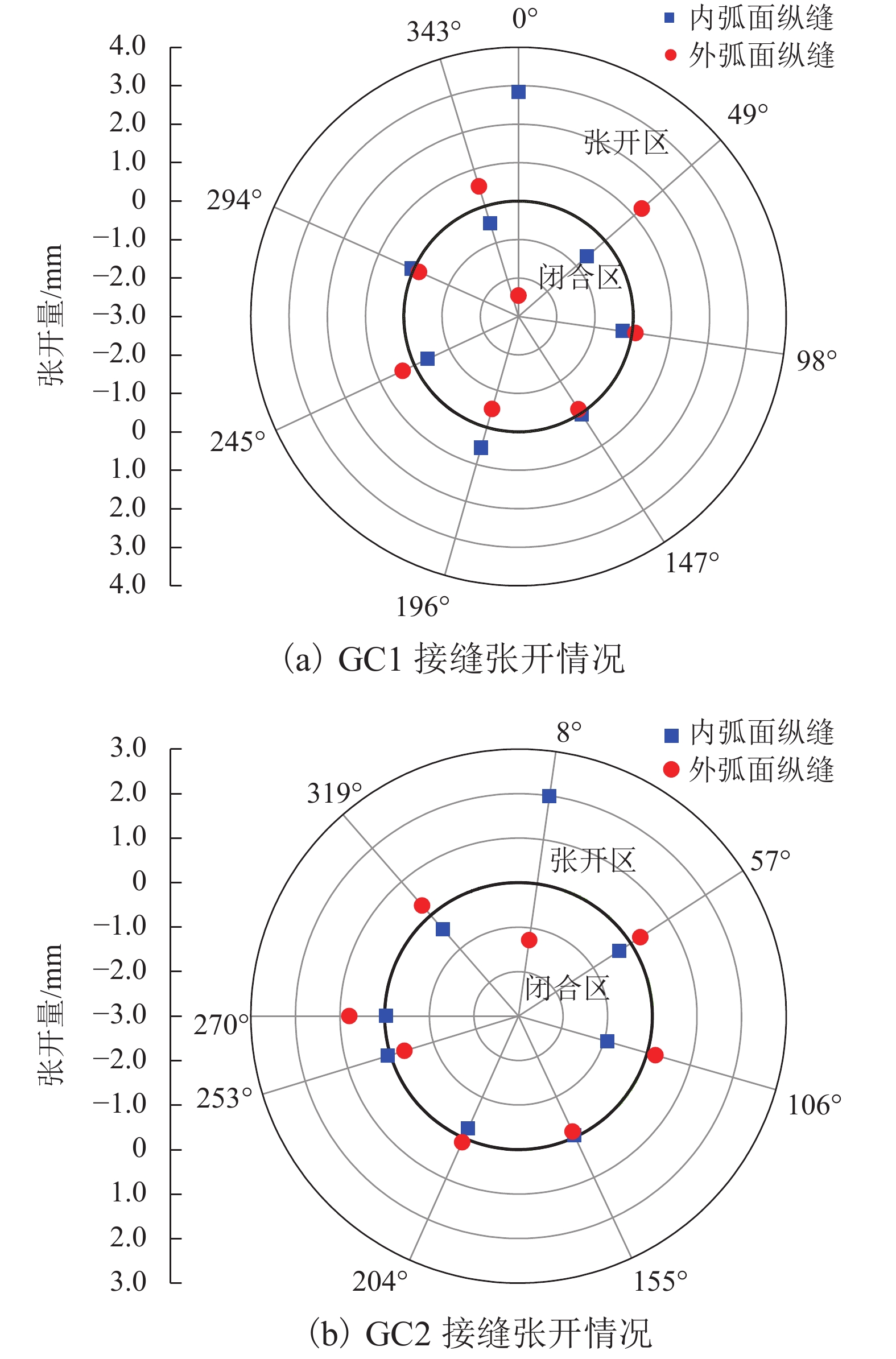

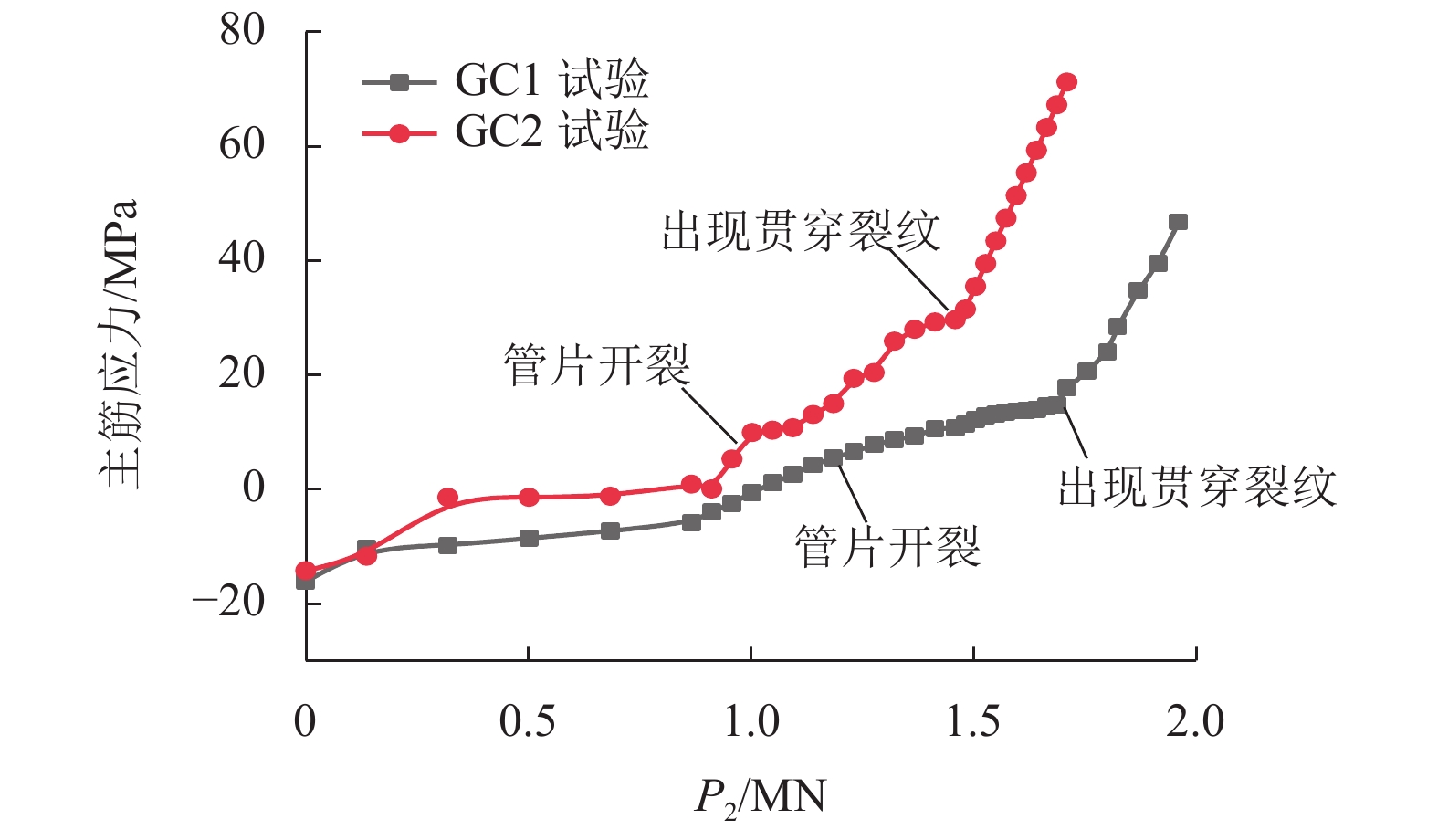

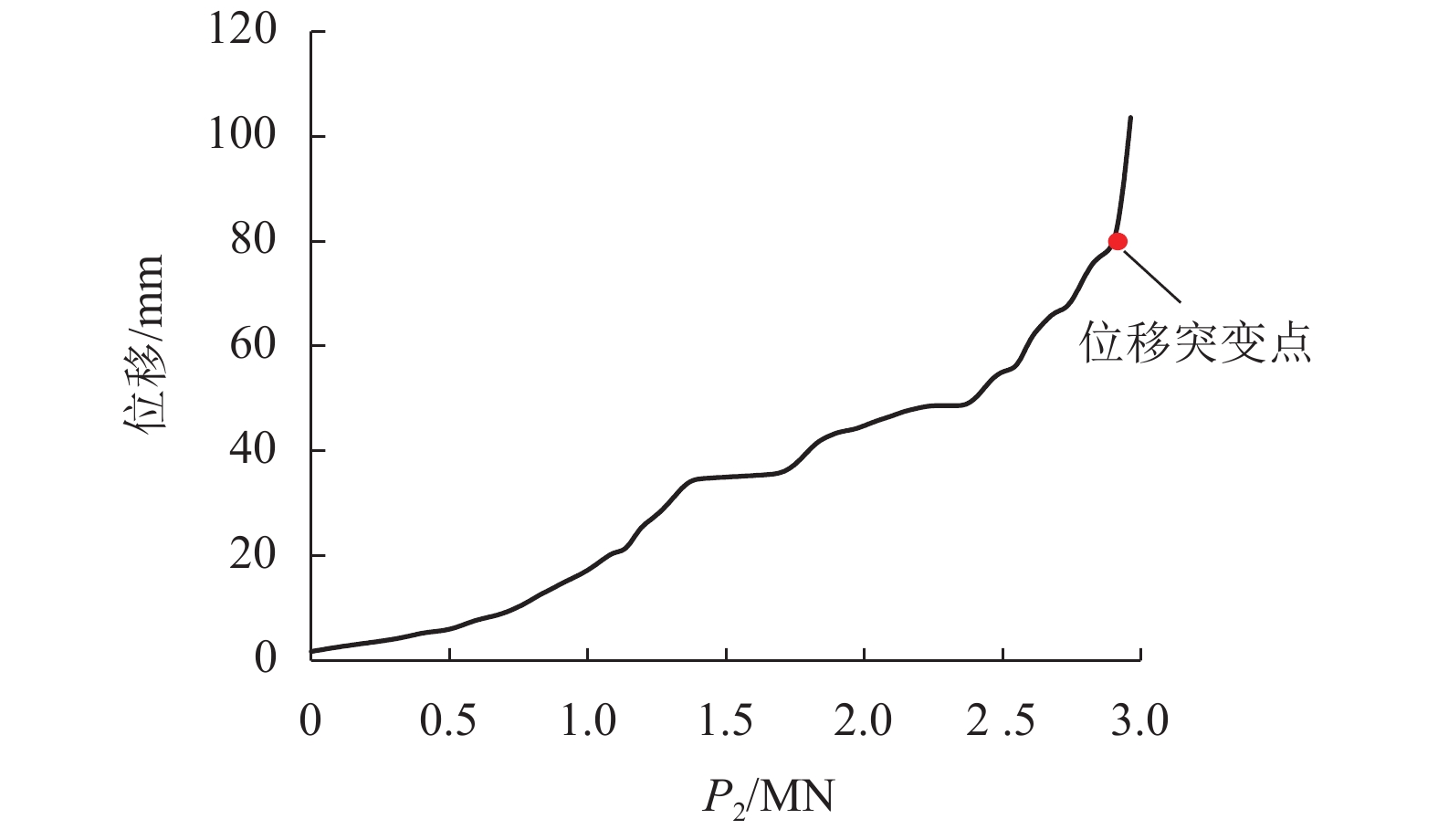

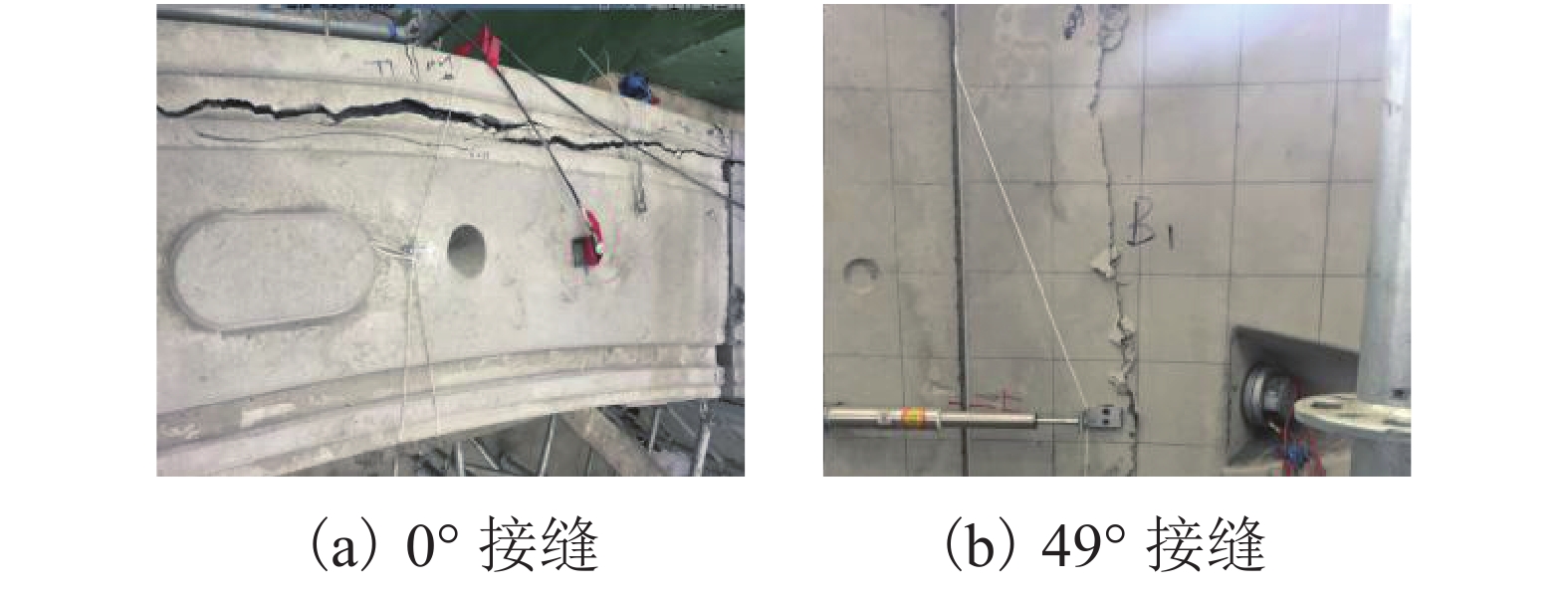

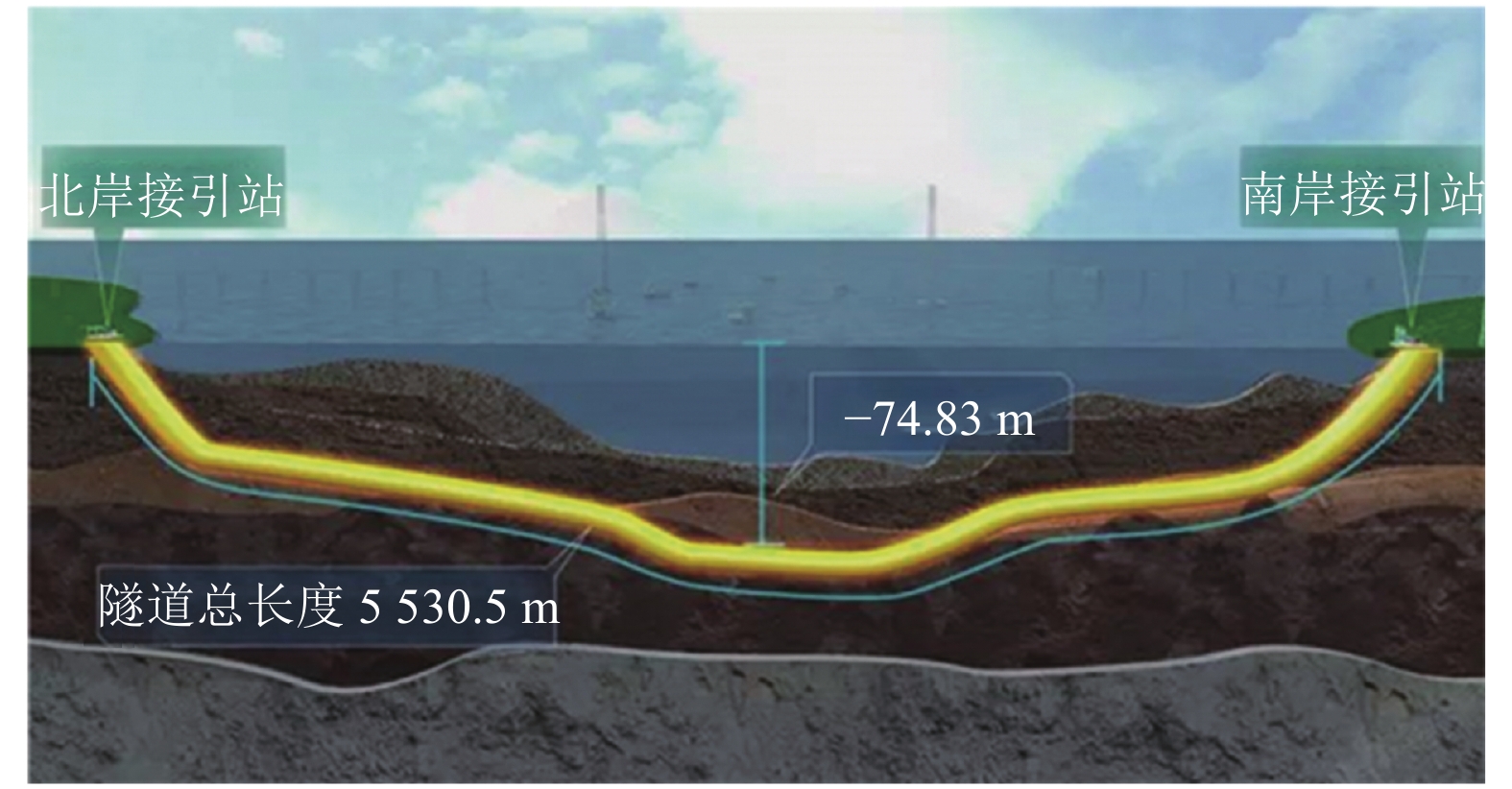

摘要: 为了探明封顶块位置对盾构隧道管片结构力学行为的影响,基于苏通GIL (gas-insulated transmission)综合管廊隧道工程,选取封顶块在拱顶和拱腰两种代表性工况,开展了高水压条件下的通缝拼装管片结构原型试验,从管片结构的变形、受力、裂纹开展情况和最终破坏状态等方面对两种工况的试验结果进行分析. 研究结果表明:不同封顶块位置对管片结构的影响总体表现为对结构整体刚度的削弱不同,其形成的刚度削弱区域抵抗指向洞外变形的能力要强于指向洞内变形的能力;封顶块位于拱腰时结构整体刚度更大,管片结构椭圆度和单点最大位移均分别减小了39.8%和38.2%;封顶块位于拱顶时结构抗弯刚度削弱明显,易出现较大的纵缝张开,而封顶块位于拱腰时管片最大纵缝张开量明显减小,仅为前者的53.3%,且连接螺栓受力减小了54.4%;封顶块位于拱腰时,管片环拱底内弧面更容易产生裂纹、开裂荷载相对更小,管片内部主筋更早进入受拉状态;封顶块位于拱顶时管片结构由于纵缝张开量较大,在较高水压的情况下破坏始于纵缝处混凝土的压剪破坏进而导致的结构失稳.Abstract: In order to find out the influence of the key block position on the mechanical behavior of the segmental structure of a shield tunnel, based on the Sutong GIL (gas-insulated transmission) integrated pipe gallery tunnel project, two typical working conditions, i.e., the key block being located at the vault and the waist, are selected to carry out the prototype test of the straight assembling segmental lining structure under high water pressure, and the test results in the two conditions are analyzed from the deformation, stress, crack development and final failure state of the segmental structure. The results show that the influence of different position of key blocks on the segmental structure is generally manifested in the different weakening of the overall stiffness of the structure, and the stiffness-weakening area formed has a stronger ability to resist the deformation outside the tunnel than that inside the tunnel. Compared with the key block at the vault, when the key block is located at the arch waist, the overall rigidity of the structure is greater, the ellipticity of the segmental structure and the maximum single-point displacement are reduced by 39.8% and 38.2%, respectively. When the key block is located at the vault, the bending stiffness of the structure is weakened obviously, and the large longitudinal joint is easy to open; while when the top block is located at the arch waist, the maximum longitudinal joint opening of segment is reduced obviously, which is only 53.3% of the former, and the force of the connecting bolt is reduced by 54.4%. In addition, when the key block is located at the arch waist, the arc surface in the bottom of the segmental structure is more prone to cracks, the cracking load is relatively smaller, and the main reinforcement inside the structure enters the tension state earlier; when the key block is located at the vault, the longitudinal joint opening of the segmental structure is large, and the structural instability is caused by the compressive shear failure of the concrete, which starts from the longitudinal joint in the case of high tensile force.

-

Key words:

- shield tunnel /

- assembling lining /

- high water pressure /

- key block position /

- mechanical behavior /

- failure mode

-

表 1 试验分组

Table 1. Test grouping

试验编号 拼装方式 封顶块位置 GC1 通缝拼装 拱顶 GC2 通缝拼装 左拱腰 -

何川,封坤. 大型水下盾构隧道结构研究现状与展望[J]. 西南交通大学学报,2011,46(1): 1-11. doi: 10.3969/j.issn.0258-2724.2011.01.001HE Chuan, FENG Kun. Current status and prospects of large underwater shield tunnel structure research[J]. Journal of Southwest Jiaotong University, 2011, 46(1): 1-11. doi: 10.3969/j.issn.0258-2724.2011.01.001 ITA-Working Group Research. Processed recommendation for design of lining of shield tunnel[R]. Lausanne: Tunneling Association, 1997. 张少辉. 不同拼装方式下管片结构的力学行为研究[D]. 成都: 西南交通大学, 2004. 曾东洋,何川. 拼装方式对盾构隧道衬砌结构变形和内力的影响分析[J]. 现代隧道技术,2005(2): 1-6. doi: 10.3969/j.issn.1009-6582.2005.02.001ZENG Dongyang, HE Chuan. Analysis of the influence of assembling method on deformation and internal force of shield tunnel lining structure[J]. Modern Tunnel Technology, 2005(2): 1-6. doi: 10.3969/j.issn.1009-6582.2005.02.001 叶宇航,柳献,刘震,等. 类矩形盾构隧道衬砌结构设计模型研究[J]. 西南交通大学学报,2019,54(6): 1187-1195. doi: CNKI:SUN:XNJT.0.2019-06-009YE Yuhang, LIU Xian, LIU Zhen, et al. Study on design model of quasi-rectangular shield tunnel linings[J]. Journal of Southwest Jiaotong University, 2019, 54(6): 1187-1195. doi: CNKI:SUN:XNJT.0.2019-06-009 邱月,何川,封坤,等. 盾构隧道管片衬砌拼装效应局部原型结构加载试验[J]. 中国公路学报,2017,30(8): 156-163,215. doi: 10.3969/j.issn.1001-7372.2017.08.018QIU Yue, HE Chuan, FENG Kun, et al. The loading test of partial prototype structure of shield tunnel segment lining assembly[J]. China Journal of Highway and Transport, 2017, 30(8): 156-163,215. doi: 10.3969/j.issn.1001-7372.2017.08.018 王士民,申兴柱,何祥凡,等. 不同拼装方式下盾构隧道管片衬砌受力与破坏模式模型试验研究[J]. 土木工程学报,2017,50(6): 114-124.WANG Shimin, SHEN Xingzhu, HE Xiangfan, et al. Model test study on stress and failure modes of shield tunnel lining under different assembly methods[J]. China Civil Engineering Journal, 2017, 50(6): 114-124. 封坤, 何川, 邹育麟. 大断面越江盾构隧道管片拼装方式对结构内力的影响效应研究[J]. 工程力学, 2012, 29(6): 114-124.FENG Kun, HE Chuan, ZOU Yulin. Study on the effect of the assembly method of the large-section cross-river shield tunnel on the internal force of the structure[J]. Engineering Mechanics, 2012, 29(6): 114-124. 李围,何川. 超大断面越江盾构隧道结构设计与力学分析[J]. 中国公路学报,2007(3): 76-80. doi: 10.3321/j.issn:1001-7372.2007.03.014LI Wei, HE Chuan. Structural design and mechanical analysis of super large cross-section cross-river shield tunnel[J]. China Journal of Highway and Transport, 2007(3): 76-80. doi: 10.3321/j.issn:1001-7372.2007.03.014 宋成辉. 软土地层地铁盾构通用环管片结构设计研究[J]. 地下空间与工程学报,2011,7(4): 733-740.SONG Chenghui. Research on the structure design of general ring segments of metro shields in soft soil layers[J]. Chinese Journal of Underground Space and Engineering, 2011, 7(4): 733-740. 于娇. 水下大直径盾构隧道管片衬砌力学特性及接缝防水研究[D]. 北京: 北京交通大学, 2010. 高波,吴挺,彭红霞,等. 盾构隧道管片拼装纵缝变形规律研究[J]. 现代隧道技术,2014,51(5): 145-149.GAO Bo, WU Ting, PENG Hongxia, et al. Study on the deformation law of longitudinal joints of shield tunnel segmental sturcutre[J]. Modern Tunnel Technology, 2014, 51(5): 145-149. 王士民,于清洋,彭博,等. 封顶块位置对盾构隧道管片结构力学特征与破坏形态的影响分析[J]. 土木工程学报,2016,49(6): 123-132.WANG Shimin, YU Qingyang, PENG Bo, et al. Analysis of the influence of the position of the capping block on the mechanical characteristics and failure modes of the shield tunnel segment[J]. China Civil Engineering Journal, 2016, 49(6): 123-132. 封坤,何川,苏宗贤. 南京长江隧道原型管片结构破坏试验研究[J]. 西南交通大学学报,2011,46(4): 564-571. doi: 10.3969/j.issn.0258-2724.2011.04.007FENG Kun, HE Chuan, SU Zongxian. Experimental study on destruction of prototype segments of Nanjing yangtze river tunnel[J]. Journal of Southwest Jiaotong University, 2011, 46(4): 564-571. doi: 10.3969/j.issn.0258-2724.2011.04.007 何川,封坤,晏启祥. 高速铁路水下盾构隧道管片内力分布规律研究[J]. 铁道学报,2012,34(4): 101-109. doi: 10.3969/j.issn.1001-8360.2012.04.017HE Chuan, FENG Kun, YAN Qixiang. Study on the internal force distribution law of the underwater shield tunnel of high speed railway[J]. Journal of the China Railway Society, 2012, 34(4): 101-109. doi: 10.3969/j.issn.1001-8360.2012.04.017 毕湘利,柳献,王志秀,等. 通缝拼装盾构隧道结构极限承载力的足尺试验研究[J]. 土木工程学报,2014,47(10): 117-127.BI Xiangli, LIU Xian, WANG Zhixiu, et al. Full-scale experimental study on ultimate bearing capacity of shielded tunnel structure with joint seams[J]. China Civil Engineering Journal, 2014, 47(10): 117-127. LIU Xian, DONG Zibo, BAI Yun, et al. Investigation of the structural effect induced by stagger joints in segmental tunnel linings:First results from full-scale ring tests[J]. Tunnelling and Underground Space Technology, 217, 66: 1-18. 何川,封坤,苏宗贤. 大断面水下盾构隧道原型结构加载试验系统的研发与应用[J]. 岩石力学与工程学报,2011,30(2): 254-266.HE Chuan, FENG Kun, SU Zongxian. Development and application of prototype test loading system for large-section underwater shield tunnel[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2): 254-266. 中华人民共和国住房与城乡建设部. 盾构法隧道施工与验收规范: GB 50466—2017[S]. 北京: 北京中国建筑工业出版社, 2017. 邓朝辉. 盾构隧道管片接缝防水设计[J]. 铁道建筑技术, 2008(增刊1): 157-159, 163.DENG Zhaohui. Waterproof design of joints of shield tunnel segments[J]. Railway Construction Technology, 2008(S1): 157-159, 163. -

下载:

下载: