Supercapacitor Thermal Behavior of Trams with Different Spatial Structures

-

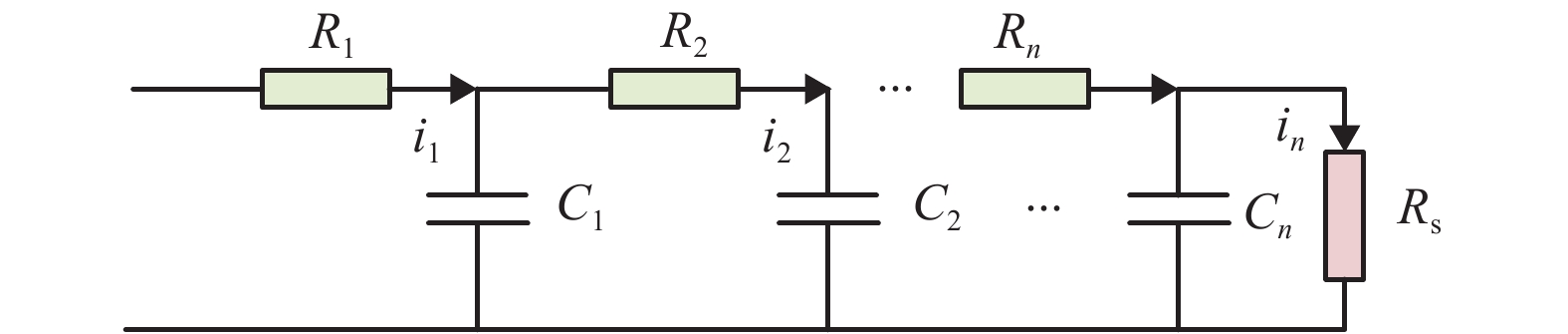

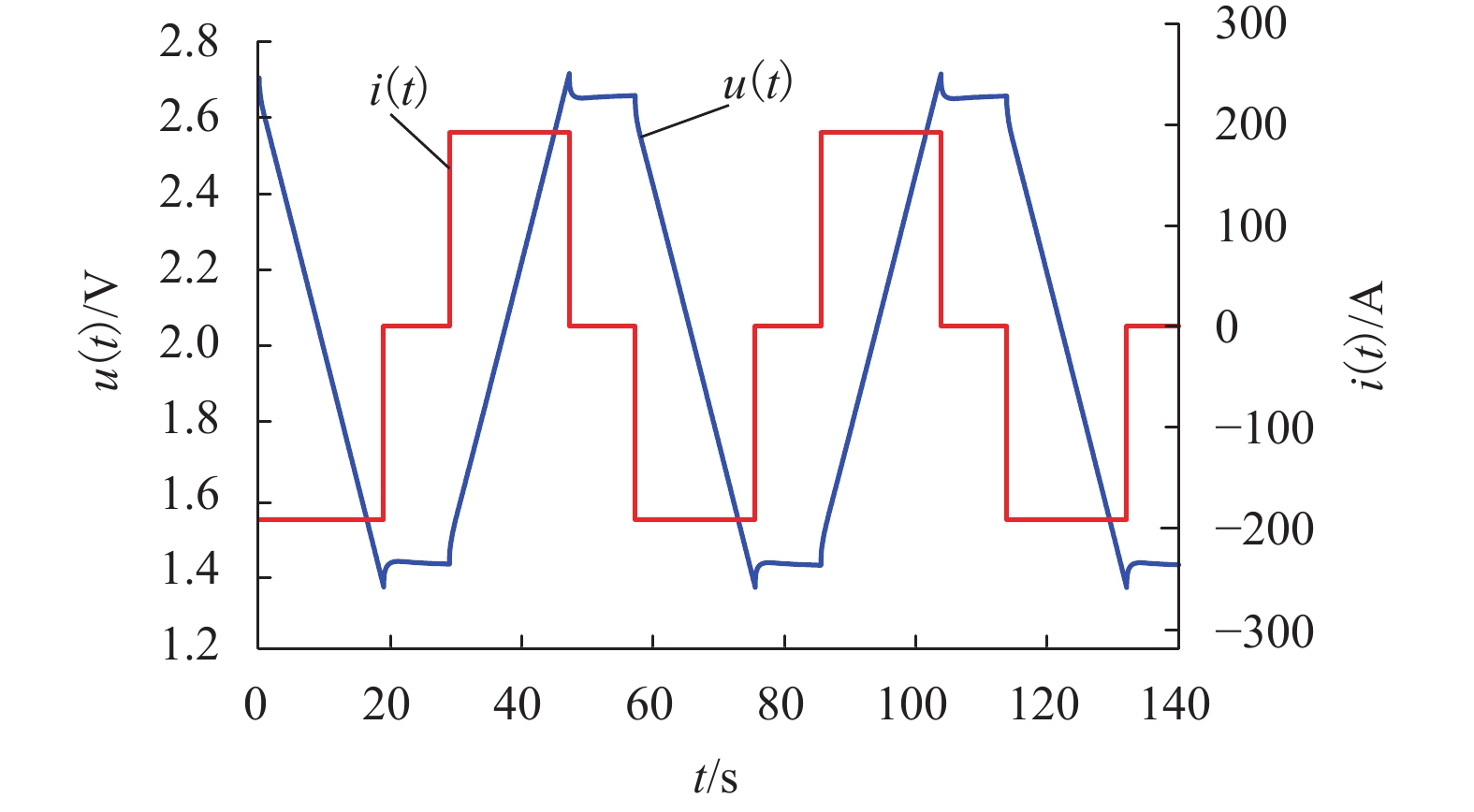

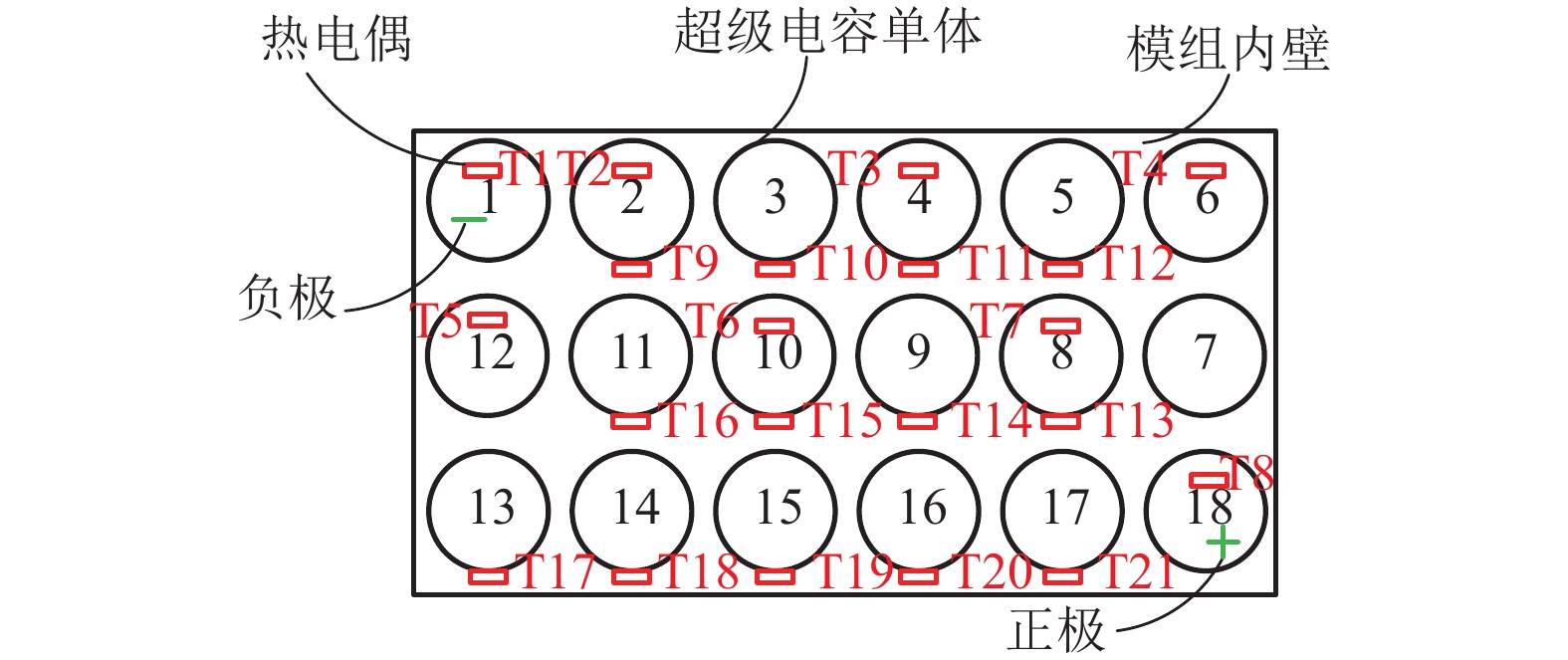

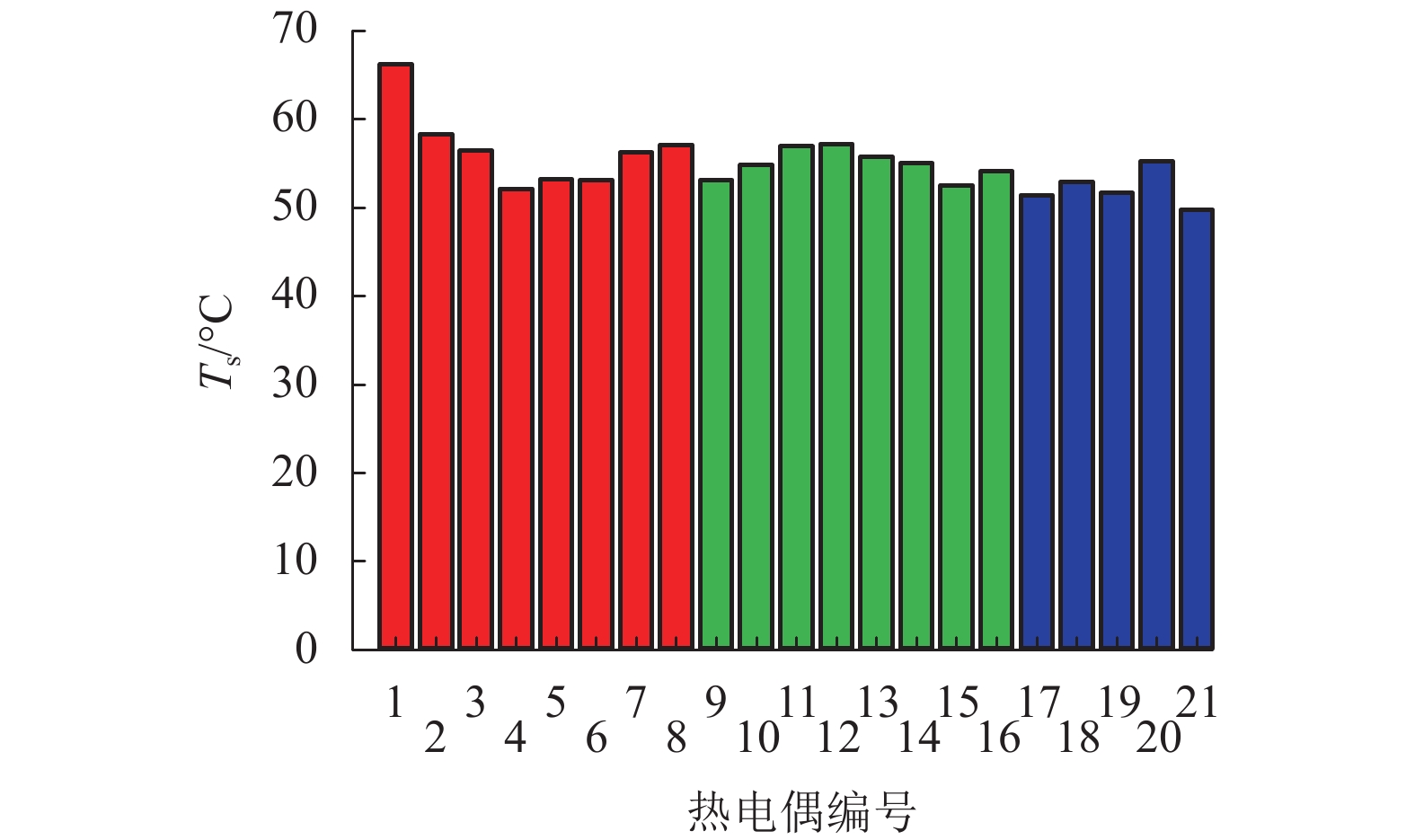

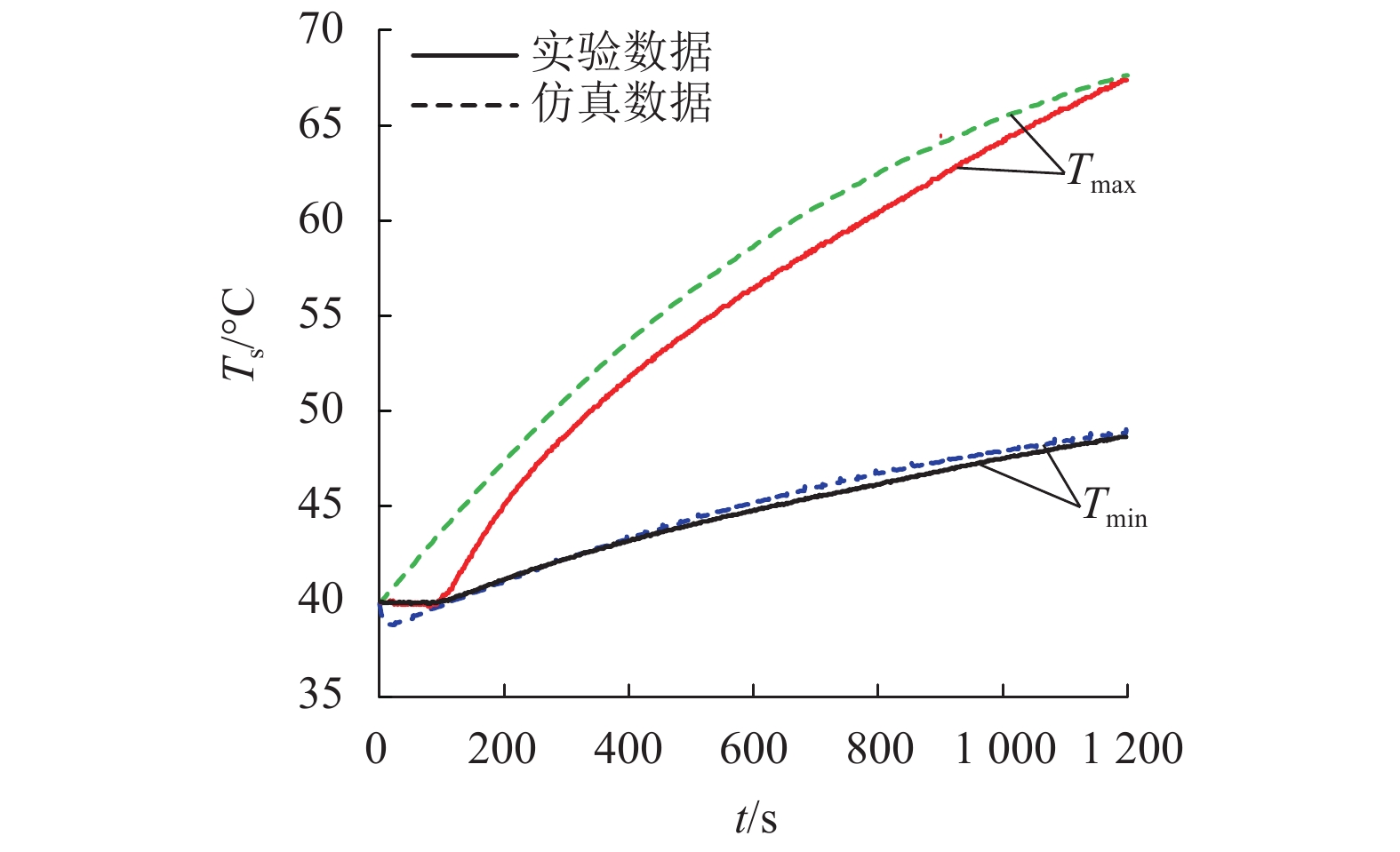

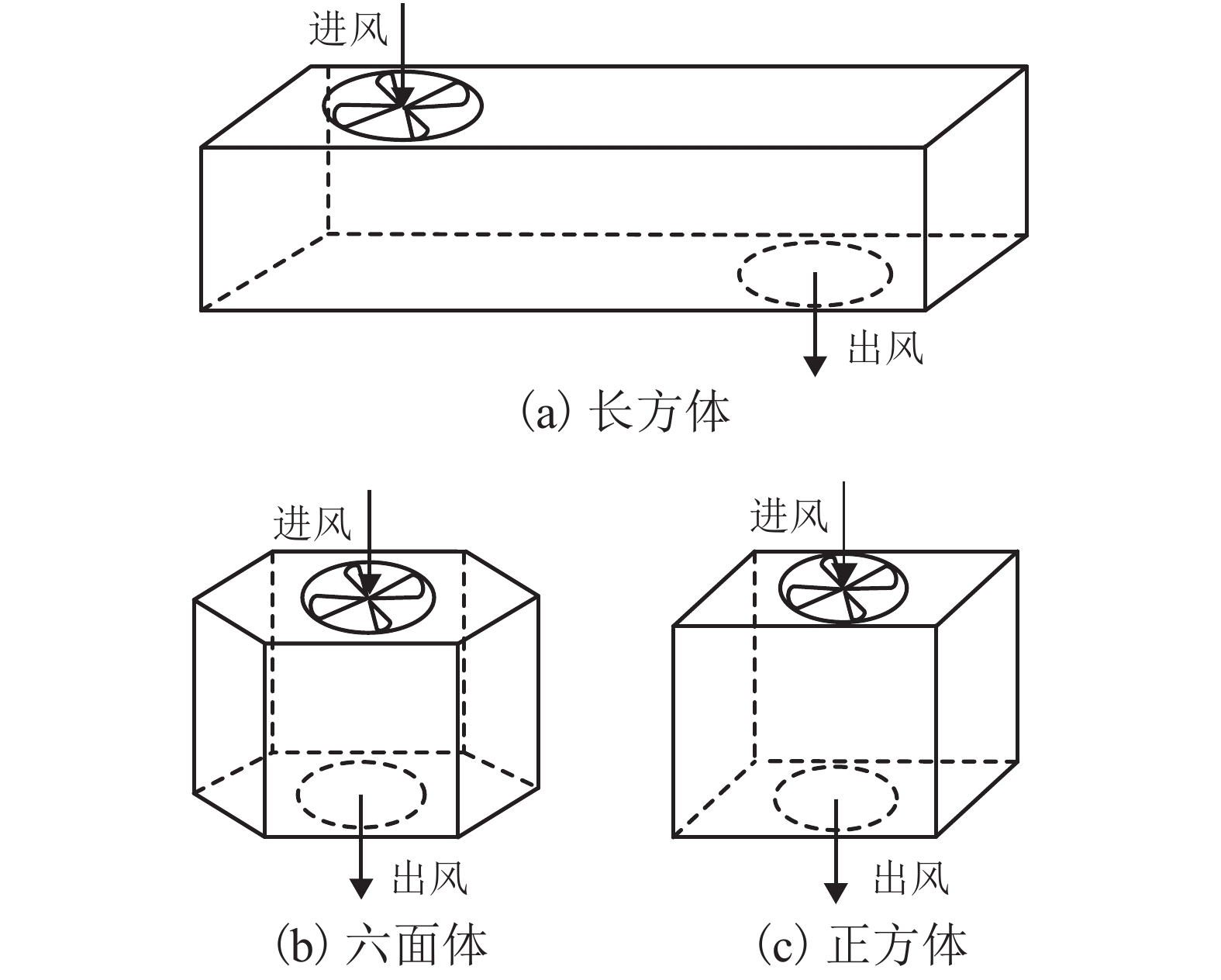

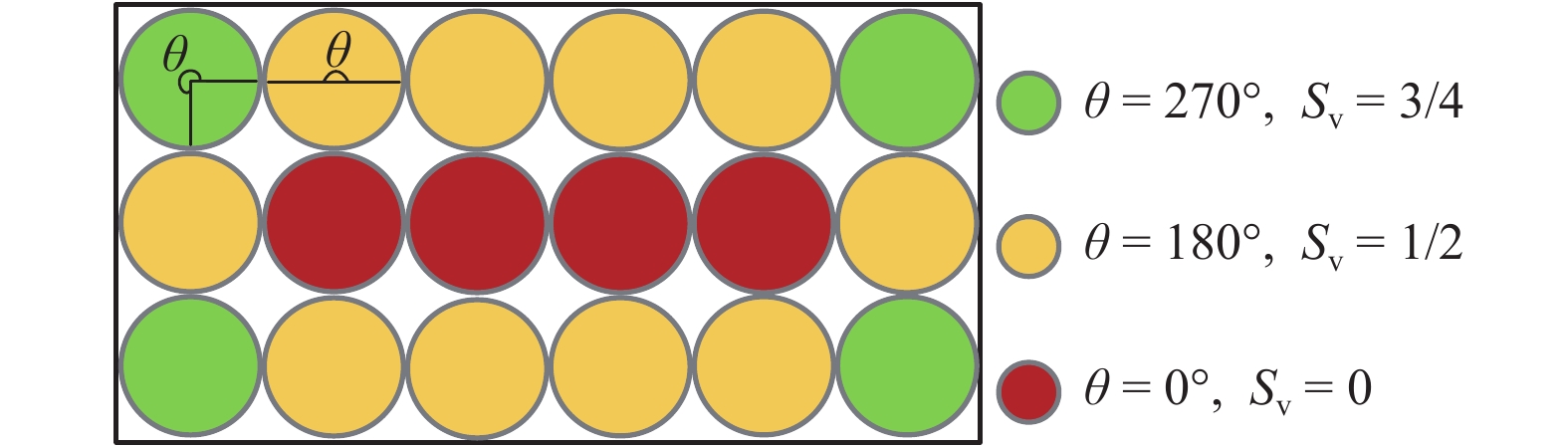

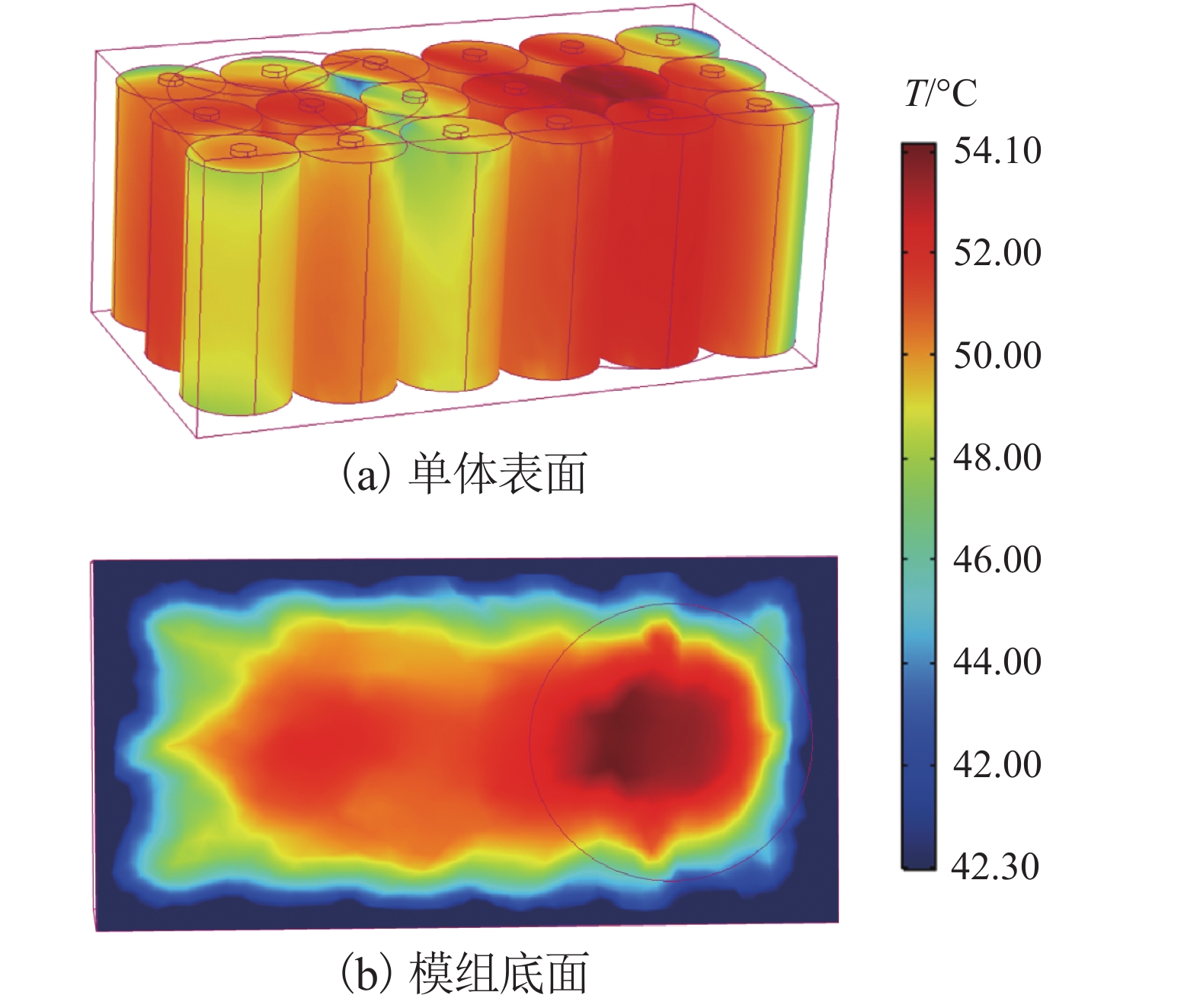

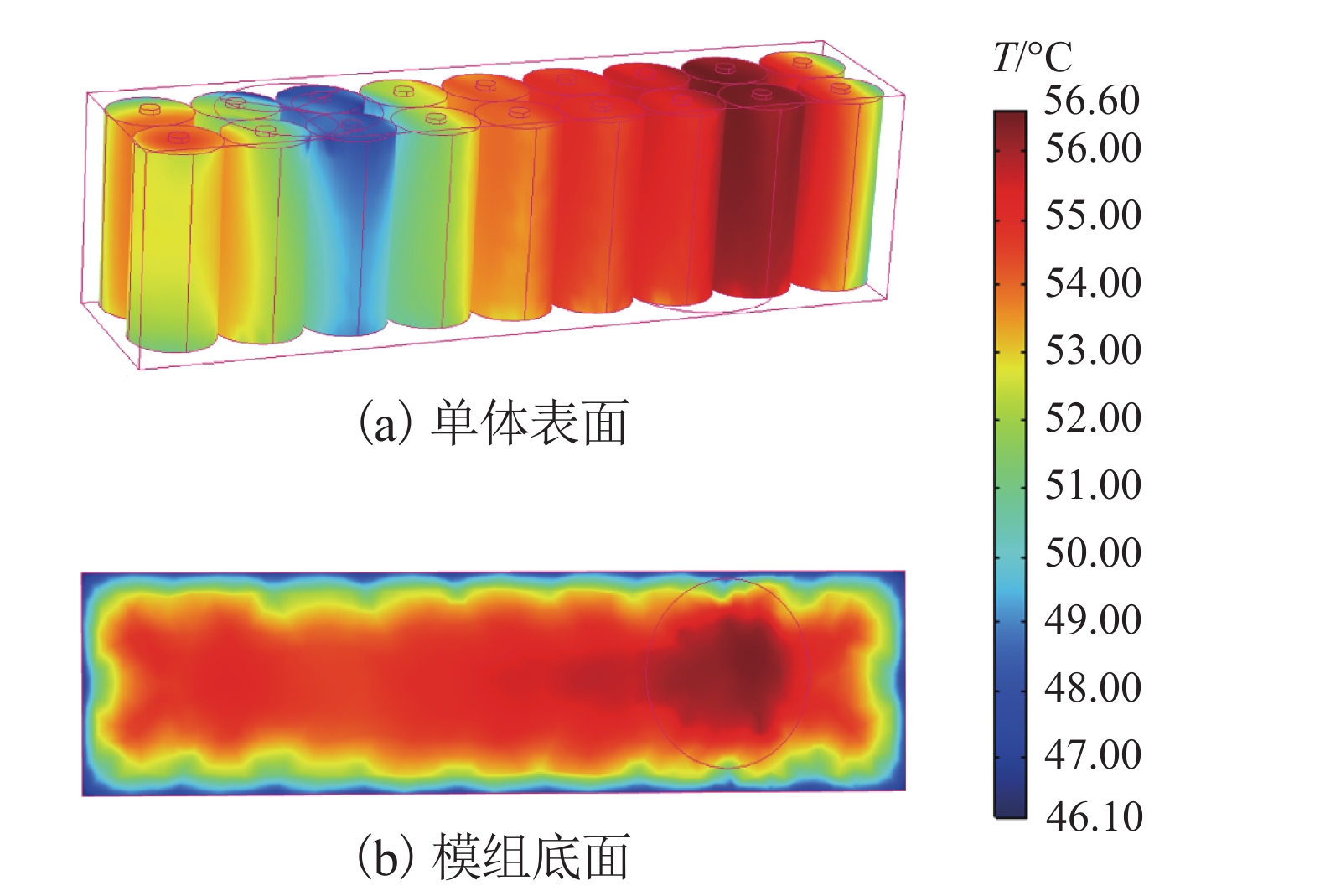

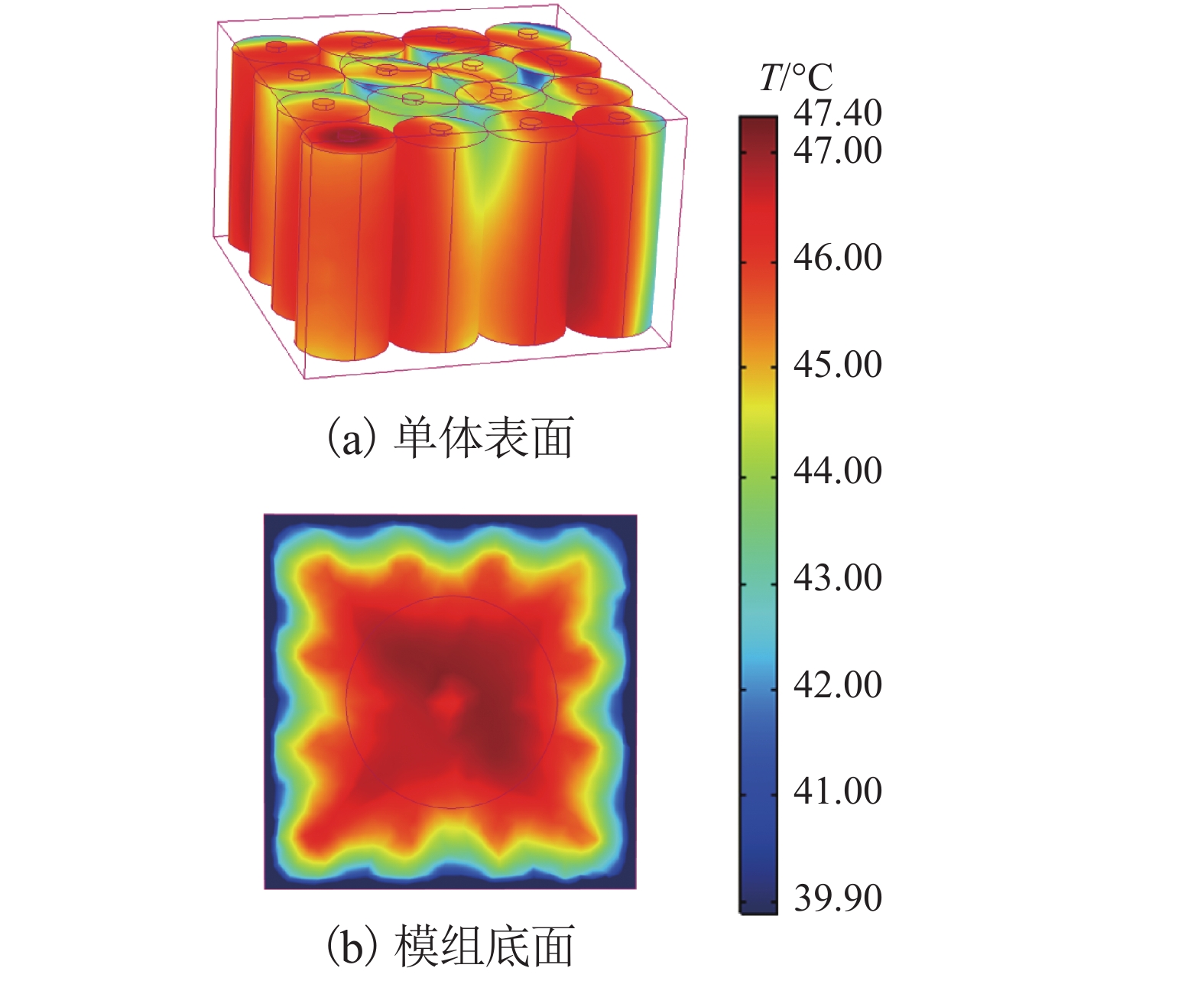

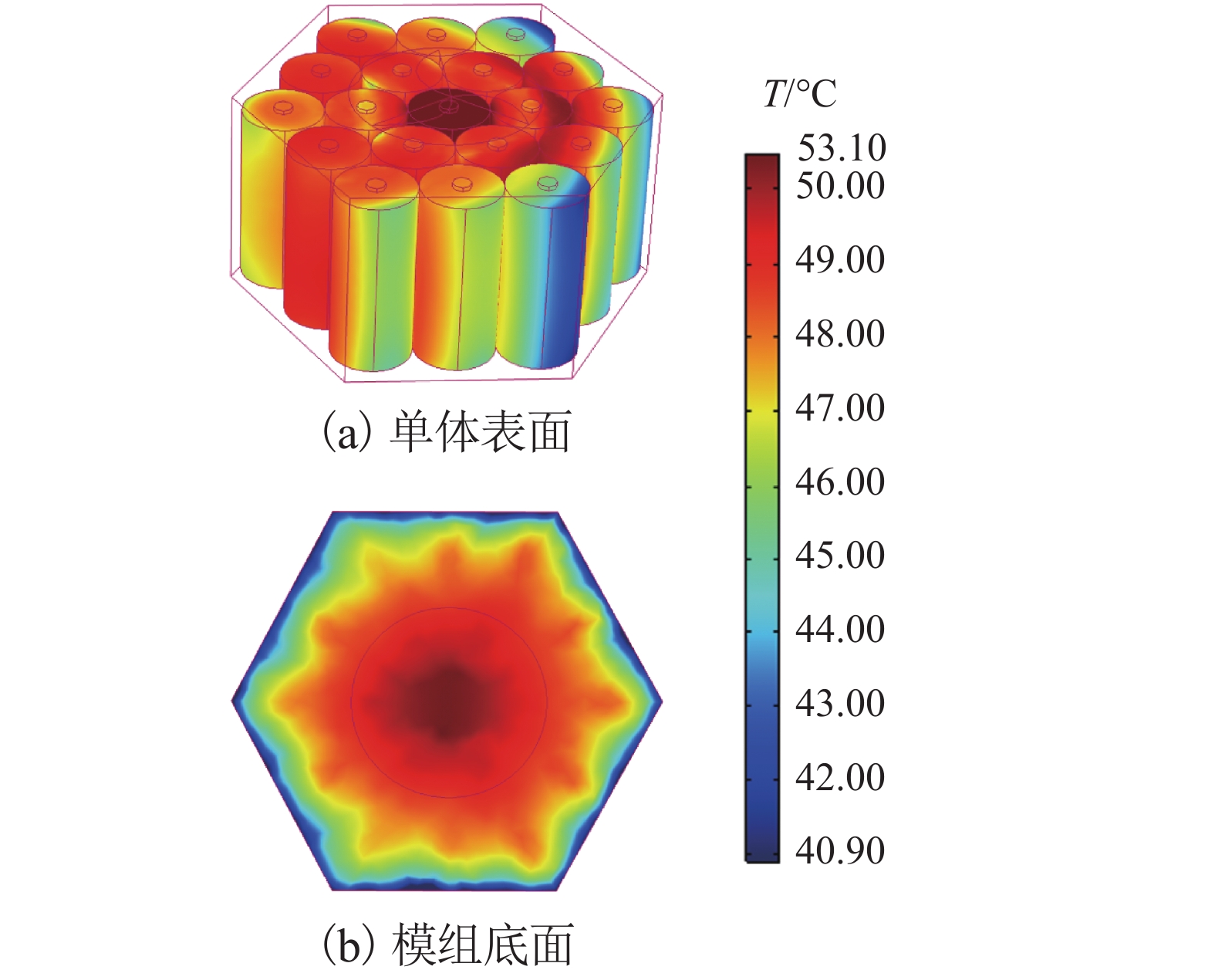

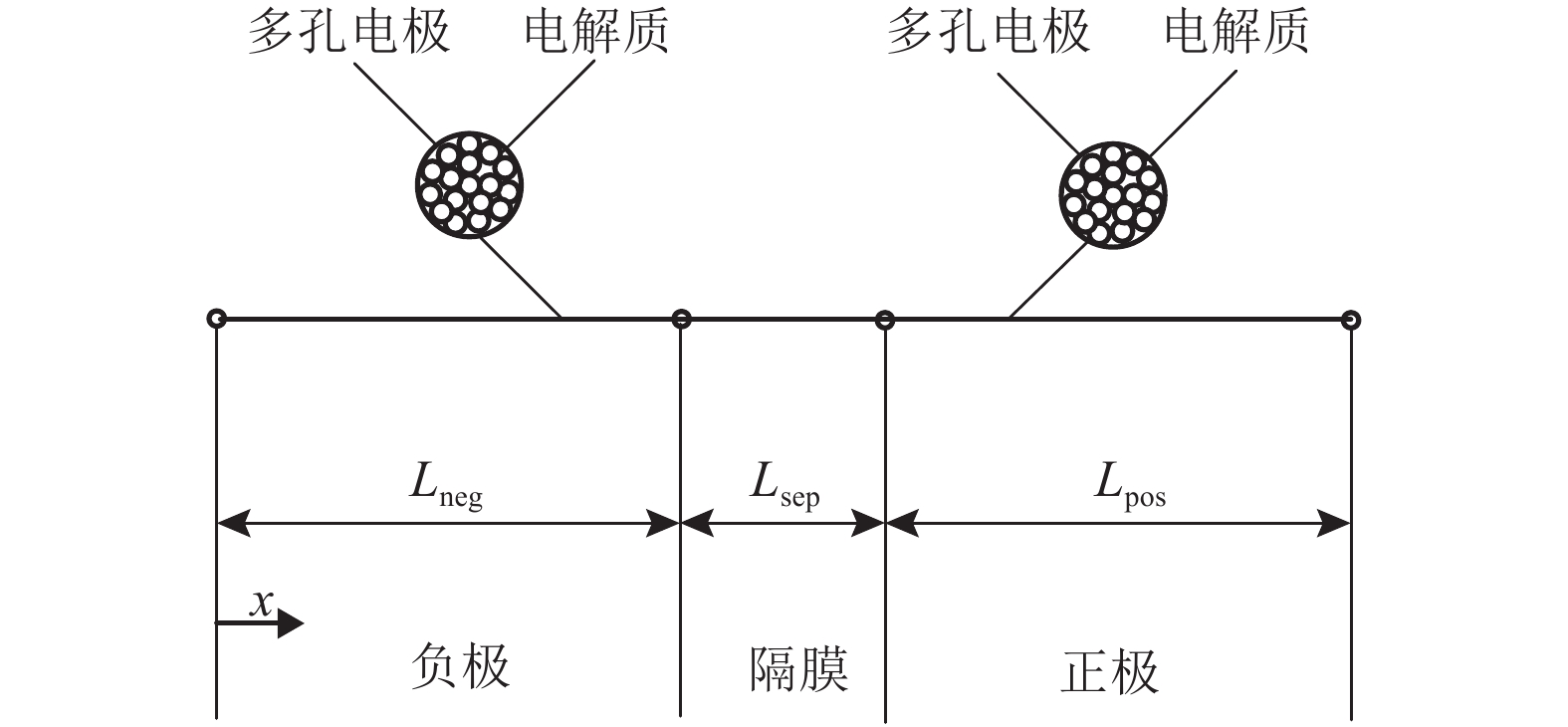

摘要: 为了减轻有轨电车超级电容模组因温度引起的性能衰减,基于超级电容器的单体结构,研究单体不同空间结构对超级电容模组热行为的影响. 首先,建立超级电容电化学-热耦合模型,并搭建实验平台验证模型的有效性;其次,定义“自然对流换热比表面积”,通过最高温度、最大温差、单体温度波动率和空间利用率4个指标对截面为3 × 6、2 × 9的长方体结构、截面为4 × 4的正方体结构和六面体结构的超级电容模组的温度特性和体积特征进行评估. 研究表明:气流路径的长度、对流换热比表面积以及强制对流换热的单体数量会影响散热的效果,具有短而宽流动路径的空间结构冷却效果更好;正方体结构是冷却效果和均温方面的最优选择;对于空间利用率和冷却效率而言,六面体结构是最佳选择.Abstract: In order to relieve supercapacitor module degradation in trams due to temperatures, the influence of spatial structures on the thermal behavior of the supercapacitor module was studied on the basis of the single unit structure of the supercapacitor. Firstly, the supercapacitor electrochemical-thermal coupling model was established, and the experimental platform was built to validate the model. Secondly, the surface area of natural convection heat transfer was defined. The temperature and volumetric characteristics of supercapacitor modules in the forms of 3 × 6 rectangle, 2 × 9 rectangle, 4 × 4 cube and hexagon, were evaluated by four indexes including the maximum temperature, maximum temperature difference, single temperature fluctuation and space utilization. This work shows that the length of the airflow path, surface area of natural convection heat transfer, and the number of the units with forced convection heat transfer will affect heat dissipation effect. The space structure with short and wide flow path has better cooling effect; the cubic structure is the best choice in terms of cooling effect and temperature uniformity; and the hexagonal structure is the best choice as regard to space utilization and cooling efficiency.

-

Key words:

- tram /

- supercapacitor /

- spatial structure /

- temperature characteristics /

- volumetric characteristics

-

表 1 超级电容仿真参数

Table 1. Supercapacitor simulation parameters

名称 恒压热容/

(J•(kg•℃)−1)密度/

(kg•m−3)导热系数/

(W•(m•K)−1)铝壳 2 700 900 238 空气区 1.23 1 006.43 0.03 正负极柱 2 700 900 238 隔膜 930 1 900 0.38 电解液 2 141 1 205 0.16 多孔电极 700 700 5 表 2 仿真与实验结果对比

Table 2. Comparison of simulation and experimental results

验证方式 Tmax/℃ ΔTmax/℃ 实验 66.20 16.50 仿真 67.12 16.65 相对误差/% 1.38 0.90 表 3 不同结构的温度特性与体积特征

Table 3. Temperature and volumetric characteristics of different structures

排列结构 Tmax/℃ ΔTmax/℃ δ/% Ct/% 2 × 9 56.64 7.32 65.57 0.11 3 × 6 54.10 6.60 65.54 0.14 4 × 4 47.38 3.00 64.83 0.07 六面体 53.10 7.75 74.52 0.09 -

薛美根,杨立峰,程杰. 现代有轨电车主要特征与国内外发展研究[J]. 城市交通,2008,6(6): 88-91. doi: 10.3969/j.issn.1672-5328.2008.06.016XUE Meigen, YANG Lifeng CHENG Jie. Modern trams:characteristics & development both at home and abroad[J]. Urban Transport of China, 2008, 6(6): 88-91. doi: 10.3969/j.issn.1672-5328.2008.06.016 臧宇,许广鹏,关和宁,等. 国内现代有轨电车车辆发展状况综述[J]. 现代城市轨道交通,2016(2): 1-6. doi: 10.3969/j.issn.1672-7533.2016.02.001ZANG Yu, XU Guangpeng, GUAN Hening. Overview of development of domestic modern tramcar vehicles[J]. Modern Urban Transit, 2016(2): 1-6. doi: 10.3969/j.issn.1672-7533.2016.02.001 王梅. 我国现代有轨电车发展的现状、趋势与思考[J]. 交通与港航, 2017, 4(1): 14-14.WANG Mei. The status quo, trends and reflections on the development of modern tramways in China public utilities[J]. Communication & Shipping, 2017, 4(1): 14-14. 柴适. 有轨电车供电新技术[J]. 交通与港航,2011,25(4): 53-54. doi: 10.3969/j.issn.1001-599X.2011.04.017CHAI Shi. New technology for tramcar power supply[J]. Communication & Shipping, 2011, 25(4): 53-54. doi: 10.3969/j.issn.1001-599X.2011.04.017 陈志雄. 现代有轨电车无接触网技术应用分析[J]. 城市轨道交通研究,2014,17(4): 117-121.CHEN Zhixiong. Analysis of catenary-free technology applied in modern trams[J]. Urban Mass Transit, 2014, 17(4): 117-121. 陈宽,阮殿波,傅冠生. 轨道交通用超级电容器研发概述[J]. 电池,2014,4(5): 296-298. doi: 10.3969/j.issn.1001-1579.2014.05.015CHEN Kuan, RUAN Dianbo, FU Guansheng. Research and development summary of supercapacitor used in rail transit[J]. Battery Bimonthly, 2014, 4(5): 296-298. doi: 10.3969/j.issn.1001-1579.2014.05.015 马丽洁,廖文江,高宗余. 城轨列车车载超级电容储能控制策略研究[J]. 电工技术学报,2015(增刊1): 63-68.MA Lijie, LIAO Wenjiang, GAO Zongyu. Research on AC side series supercapacitor regenerative braking[J]. Transactions of China Electrotechnical Society, 2015(S1): 63-68. 赵军,范晓云. 超级电容有轨电车供电系统研究[J]. 电力电子技术,2017(6): 86-88.ZHAO Jun, FAN Xiaoyun. Research on the power supply system for the supercapacitor tramcar[J]. Power Electronics, 2017(6): 86-88. 张婷婷,张伟先,胡润文. 基于超级电容的有轨电车储能电源系统介绍[J]. 技术与市场,2016,23(5): 98-99. doi: 10.3969/j.issn.1006-8554.2016.05.044ZHANG Tingting, ZHANG Xianwei, HU Runwen. Introduction of rail electric energy storage power system based on supercapacitor[J]. Technology & Market, 2016, 23(5): 98-99. doi: 10.3969/j.issn.1006-8554.2016.05.044 顾帅,韦莉,张逸成,等. 超级电容器不一致性研究现状及展望[J]. 中国电机工程学报,2015,35(11): 2862-2869.GU Shuai, WEI Li, ZHANG Yicheng, et al. Review of nonuniformity research and analysis on supercapacitor[J]. Proceedings of the CSEE, 2015, 35(11): 2862-2869. GUALOUS H, BOUQUAIN D, BERTHON A, et al. Experimental study of supercapacitor serial resistance and capacitance variations with temperature[J]. Journal of Power Sources, 2003, 123(1): 86-93. doi: 10.1016/S0378-7753(03)00527-5 顾帅, 韦莉, 张逸成, 等. 超级电容器老化特征与寿命测试研究展望[J]. 中国电机工程学报, 2013, 33(21): 145-153.GU Shuai, WEI Li, ZHANG Yicheng, et al. Prospects of ageing characteristic and life test research on supercapacitors[J]. Proceedings of the CSEE, 2013, 33(21): 145-153. 李岩松,郑美娜,石云飞,等. 卷绕式超级电容器封装单元结构对其热行为影响的研究[J]. 中国电机工程学报,2016,36(17): 4762-4770.LI Yansong, ZHENG Meina, SHI Yunfei, et al. Study on thermal behavior influences of spiral wound supercapacitors with package units structure[J]. Proceedings of the CSEE, 2016, 36(17): 4762-4770. 张莉,宋金岩,邹积岩. 混合型超级电容器的封装结构及其温度场研究[J]. 电子元件与材料,2005,24(11): 30-32. doi: 10.3969/j.issn.1001-2028.2005.11.011ZHANG Li, SONG Jinyan, ZOU Jiyan. Investigations on packaging structure and temperature field of hybrid supercapacitors[J]. Electronic Components & Materials, 2005, 24(11): 30-32. doi: 10.3969/j.issn.1001-2028.2005.11.011 VOICU I, LOUAHLIA H, GUALOUS H, et al. Thermal management and forced air-cooling of supercapacitors stack[J]. Applied Thermal Engineering, 2015, 85: 89-99. doi: 10.1016/j.applthermaleng.2015.04.003 NEWMAN J, TIEDEMANN W. Porous-electrode theory with battery applications[J]. AIChE Journal, 1975, 21(1): 25-41. doi: 10.1002/aic.690210103 张兴磊,王文,华黎,等. 恒流充放电过程中双电层电容器温度特性[J]. 化工学报,2016,67(4): 1207-1214.ZHANG Xinglei , WANG Wen , HUA Li, et al. Temperature characteristic of electric double layer capacitor under galvanostatic cycling[J]. CIESC Journal, 2016, 67(4): 1207-1214. SCHIFFER J, LINZEN D, SAUER D U. Heat generation in double layer capacitors[J]. Journal of Power Sources, 2006, 160(1): 765-772. doi: 10.1016/j.jpowsour.2005.12.070 郑美娜. 超级电容器的多物理场动力学行为研究[D]. 北京: 华北电力大学(北京), 2016. YVES B. 储能技术[M]. 唐西胜, 译. 北京: 机械工业出版社, 2013: 177-178. 张莹,刘开宇,张伟,等. 二氧化锰超级电容器的电极电化学性质[J]. 化学学报,2008,66(8): 909-913. doi: 10.3321/j.issn:0567-7351.2008.08.013ZHANG Ying, LIU Kaiyu, ZHANG Wei, et al. Electrochemical performance of electrodes in MnO2 supercapacitor[J]. Acta Chimica Sinica, 2008, 66(8): 909-913. doi: 10.3321/j.issn:0567-7351.2008.08.013 WANG T, TSENG K J, ZHAO J, et al. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies[J]. Applied Energy, 2014, 134: 229-238. -

下载:

下载: