|

黄发荣, 焦杨声. 酚醛树脂及其应用[M]. 北京: 化学工业出版社, 2003: 1-27.

|

|

伊廷会. 高性能酚醛树脂改性研究进展[J]. 化工进展,2001,20(9): 13-16.YI Tinghui. Advance in the modifying research of high performance phenolic resin[J]. Chemical Industry and Engineering Progress, 2001, 20(9): 13-16.

|

|

侯海周,胡毅亭,彭金华. 酚醛层压材料的冲击力学行为及本构模型[J]. 爆炸与冲击,2015,35(6): 858-863.HOU Haizhou, HU Yiting, PENG Jinhua. Dynamic behavior and constitutive model of phenolic cotton fabric material under impact loading[J]. Explosion and Shock Waves, 2015, 35(6): 858-863.

|

|

BERTRAND P A. Oil absorption into cotton-phenolic material[J]. Journal of Materials Research, 1993, 8(7): 1749-1757. doi: 10.1557/JMR.1993.1749

|

|

孙小波,王枫,葛世军,等. 航天长寿命轴承润滑技术[J]. 轴承,2012,3: 24-29.SUN Xiaobo, WANG Feng, GE Shijun, et al. Long life lubricating technology for bearing used in aerospace[J]. Bearing, 2012, 3: 24-29.

|

|

张迪,王超,卿涛,等. 空间用多孔聚合物轴承保持架材料研究进展[J]. 机械工程学报,2018,54(9): 17-26.ZHANG Di, WANG Chao, QING Tao, et al. Research progress of porous polymide bearing retainer materials used in aerospace[J]. Journal of Mechanical Engineering, 2018, 54(9): 17-26.

|

|

TRICK K A, SALIBA T E. Mechanisms of the pyrolysis of phenolic Resin in a carbon/phenolic composite[J]. Carbon, 1995, 33(11): 1509-1511. doi: 10.1016/0008-6223(95)00092-R

|

|

KIM Y A, KAMIO S, TAJIRI T, et al. Enhanced thermal conductivity of carbon fiber/phenolic resin composites by the introduction of carbon nanotubes[J]. Applied Physics Letters, 2007, 90(9): 27-67. doi: 10.1063/1.2710778

|

|

黄俊钦,林有希. 耐高温改性酚醛树脂基复合摩擦材料研究进展[J]. 工程塑料应用,2014,42(1): 116-120.HUANG Junqin, LIN Youxi. Research progress on high temperature resistant modified phenolic resin matrix composite friction materials[J]. Engineering Plastics Application, 2014, 42(1): 116-120.

|

|

王超,陈帅,张玉玲,等. 酚醛层压布管保持架高精密加工工艺改进[J]. 轴承,2017,12: 12-13.WANG Chao, CHEN Shuai, ZHANG Yuling, et al. Improvement on high precision progressing technology for cages made of phenolic cloth laminated tube[J]. Bearing, 2017, 12: 12-13.

|

|

HEIMBS S, SCHMEER S, MIDDENDORF P. Strain rate effects in phenolic composites and phenolic-impregnated honeycomb structures[J]. Composites Science and Technology, 2007, 67(13): 2827-2837. doi: 10.1016/j.compscitech.2007.01.027

|

|

LI D S, LU Z X, JIANG N, et al. High strain rate behavior and failure mechanism of three-dimensional five-directional carbon/phenolic braided composites under transverse compression[J]. Composites Part B Engineering, 2011, 42(2): 309-317. doi: 10.1016/j.compositesb.2010.11.011

|

|

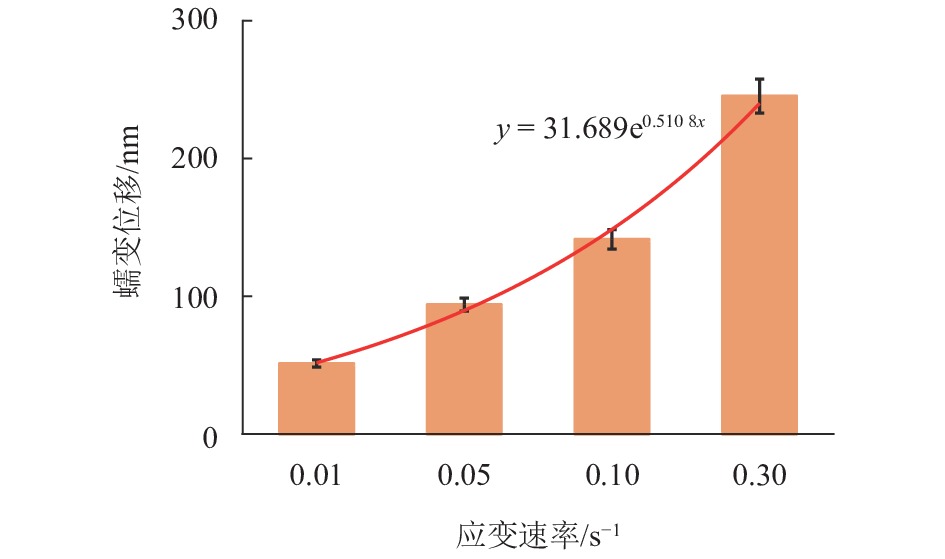

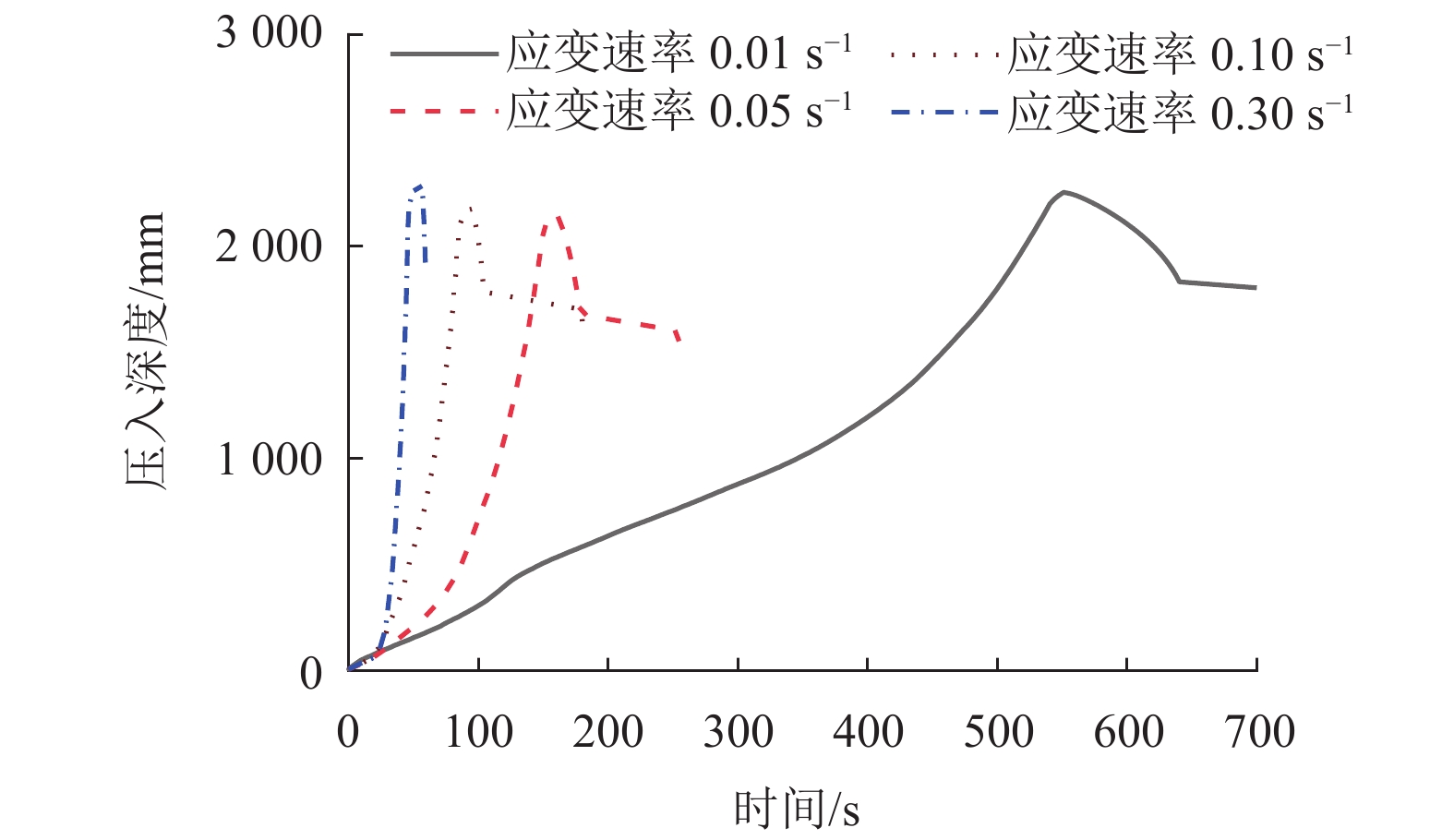

张国尚,荆洪阳,徐连勇,等. 纳米压痕法研究80 Au/20 Sn焊料蠕变应力指数[J]. 焊接学报,2009,30(8): 73-76.ZHANG Guoshang, JING Hongyang, XU Lianyong, et al. Study of on the creep stress exponent of 80 Au/20 Sn solder by nanoindentation[J]. Transactions of the China Welding Institution, 2009, 30(8): 73-76.

|

|

贾春楠,肖革胜,袁国政,等. 纳米压入法研究无铅焊料应变率敏感性[J]. 功能材料,2015,46(1): 1046-1050.JIA Chunnan, XIAO Gesheng, YUAN Guozheng, et al. Nanoindentation characterization of strain rate sensitivity of lead-free solders[J]. Journal of Functional Materials, 2015, 46(1): 1046-1050.

|

|

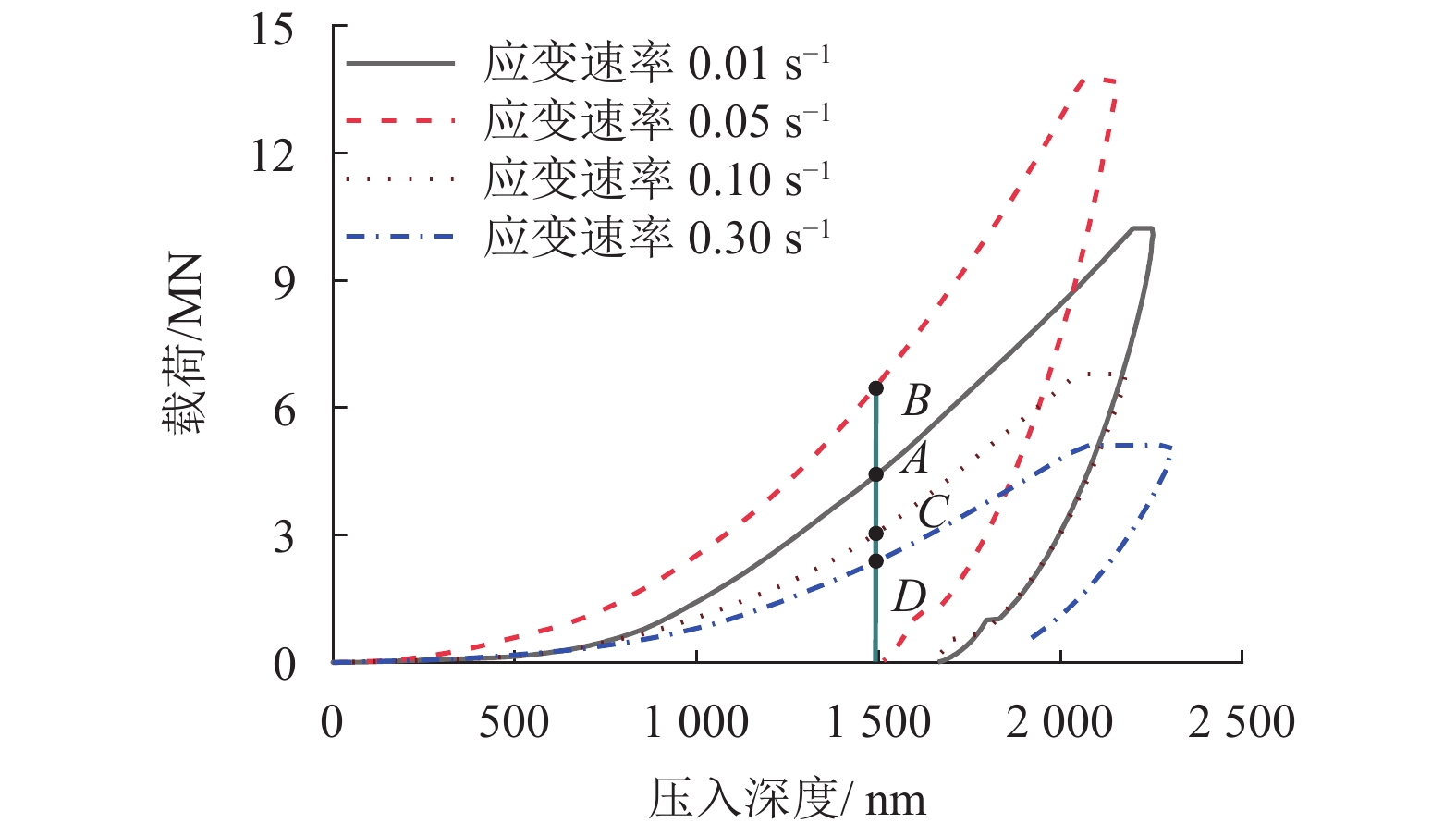

OLIVER W C, PHARR G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments[J]. Journal of Materials Research, 1992, 7(6): 1564-1583. doi: 10.1557/JMR.1992.1564

|

|

NIX W D, GAO H. Indentation size effects in crystalline materials:a law for strain gradient plasticity[J]. Journal of the Mechanics and Physics of Solids, 1998, 46(3): 411-425.

|

|

周亮,姚英学. 微纳米尺度压痕硬度尺寸效应的研究进展[J]. 哈尔滨工业大学学报,2008,40(4): 597-602.ZHOU Liang, YAO Yingxue. Research development of hardness indentation size effect at micro/nano scale[J]. Journal of Harbin Institute of Technology, 2008, 40(4): 597-602.

|

|

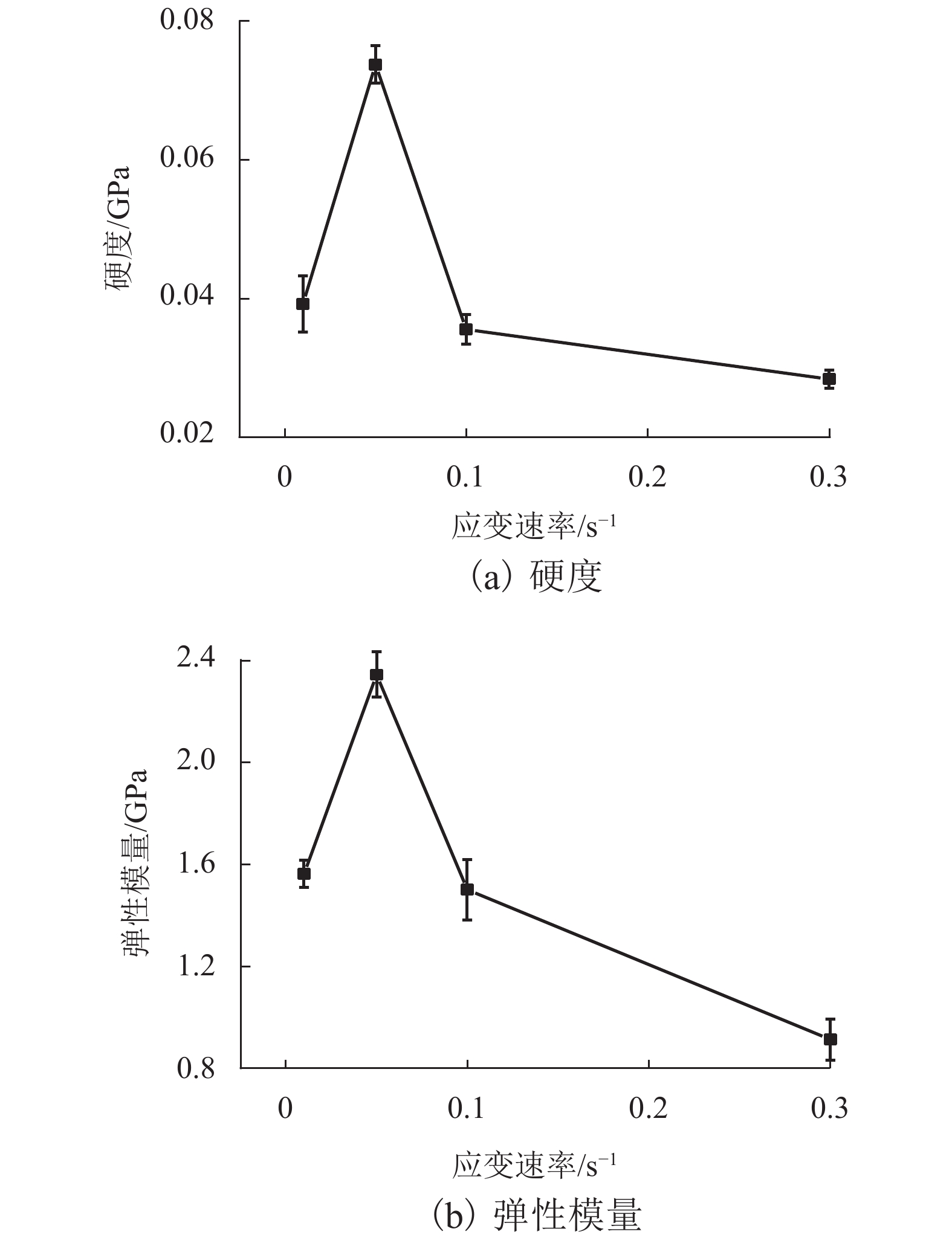

ALMASRI A H, VOYIADJIS G Z. Effect of strain rate on the dynamic hardness in metals[J]. Journal of Engineering Materials and Technology, 2007, 129(4): 505-512. doi: 10.1115/1.2744430

|

|

王尧,朱晓莹,刘贵民. Cu/Ni和Cu/Nb纳米多层膜的应变率敏感性[J]. 金属学报,2017,53(2): 57-65.WANG Yao, ZHU Xiaoying, LIU Guimin. Strain rate sensitivity of Cu/Ni and Cu/Nb nanoscale multilayers[J]. Acta Metallurgica Sinica, 2017,53(2): 57-65.

|

|

ZHANG Y F, ZHENG J, YU J X et al. Impact of strain rate on the hardness and elastic modulus of human tooth enamel[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 78: 491-495.

|

|

张伍连,丁辛,杨旭东. 机织建筑膜材料的广义Kelvin-Voigt蠕变模型[J]. 天津工业大学学报,2011,30(4): 19-22.ZHANG Wulian, DINTG Xin, YANG Xudong. General kelvin-voigt creep model of fabric architectural membrane[J]. Journal of TianJin Polytechnic University, 2011, 30(4): 19-22.

|

|

SUN Y, SHI L P, ZHOU C L, et al. Preparation and properties of phenolic resin impregnated quartz fiber tile ablative composite[J]. Key Engineering Materials, 2016, 697(4): 28-32.

|

|

张泰华. 微/纳米力学测试技术[M]. 北京: 科学出版社, 2013: 29-38.

|

|

陈绪煌. 聚丙烯/茂金属催化乙烯-丙烯共聚物相结构的演变与性能[D]. 天津: 天津大学, 2007.

|

|

魏无际. 高分子化学与物理基础[M]. 2版. 北京: 化学工业出版社, 2018: 218-242.

|

下载:

下载: