Stress Relaxation Behavior and Mechanism of Rock Joint Planes with Different Roughness

-

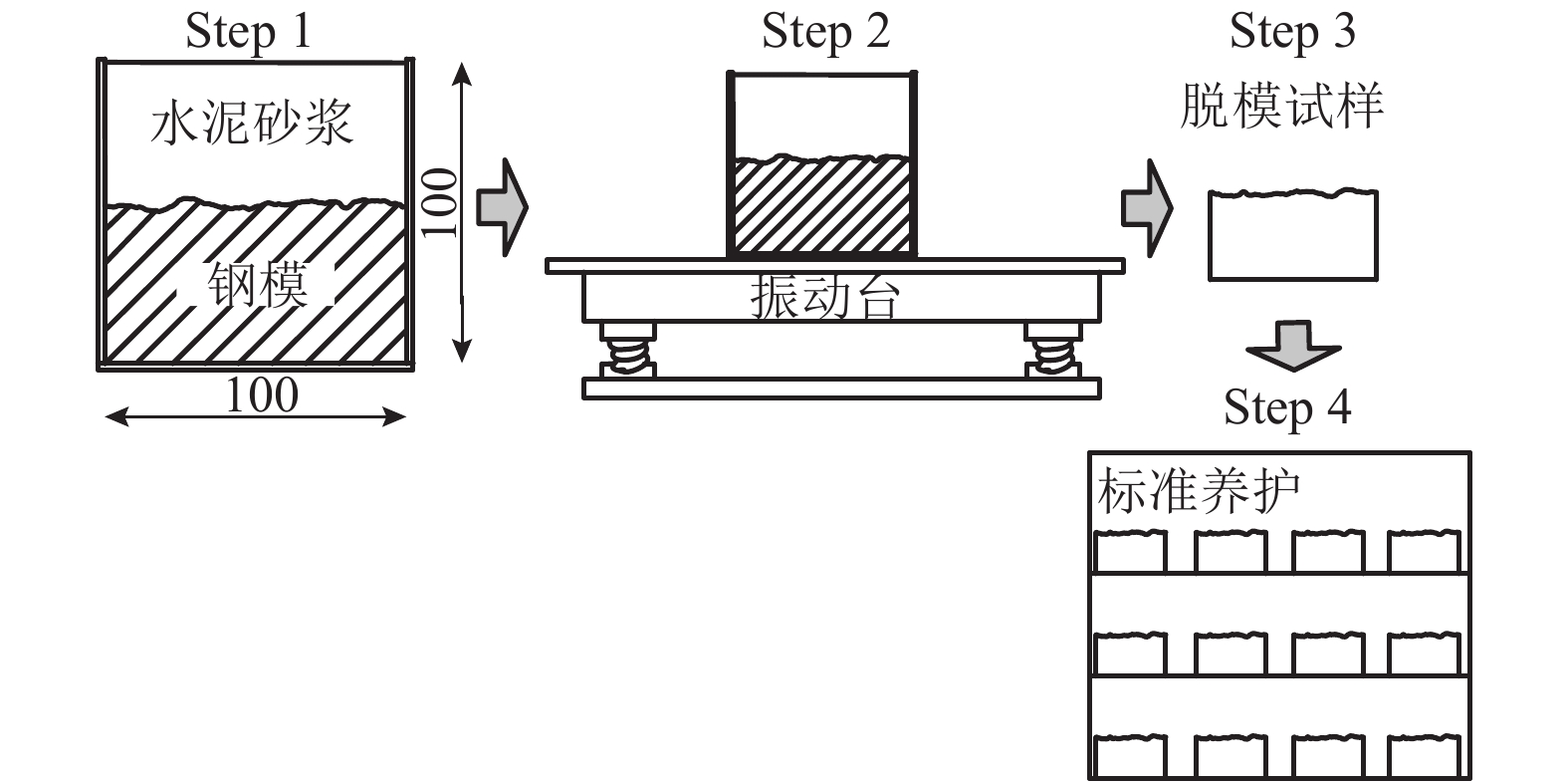

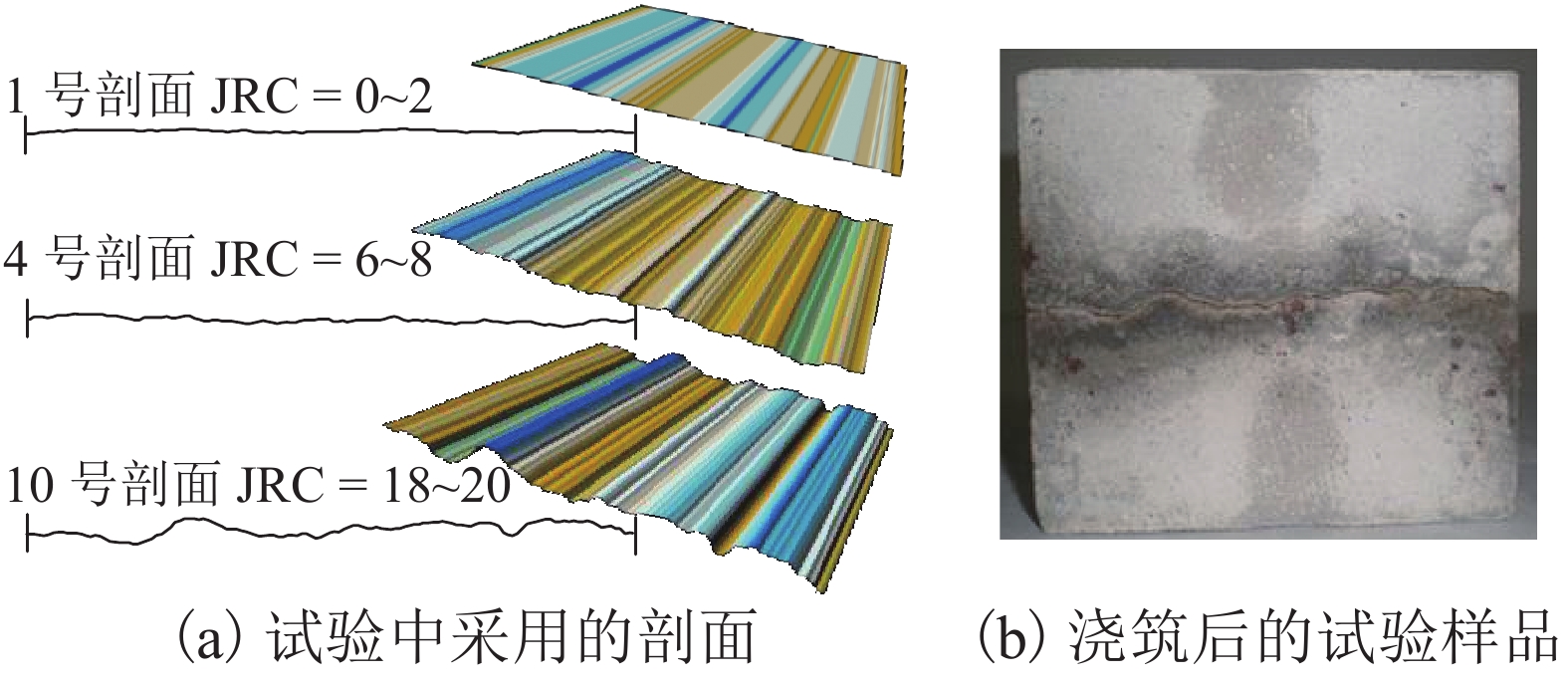

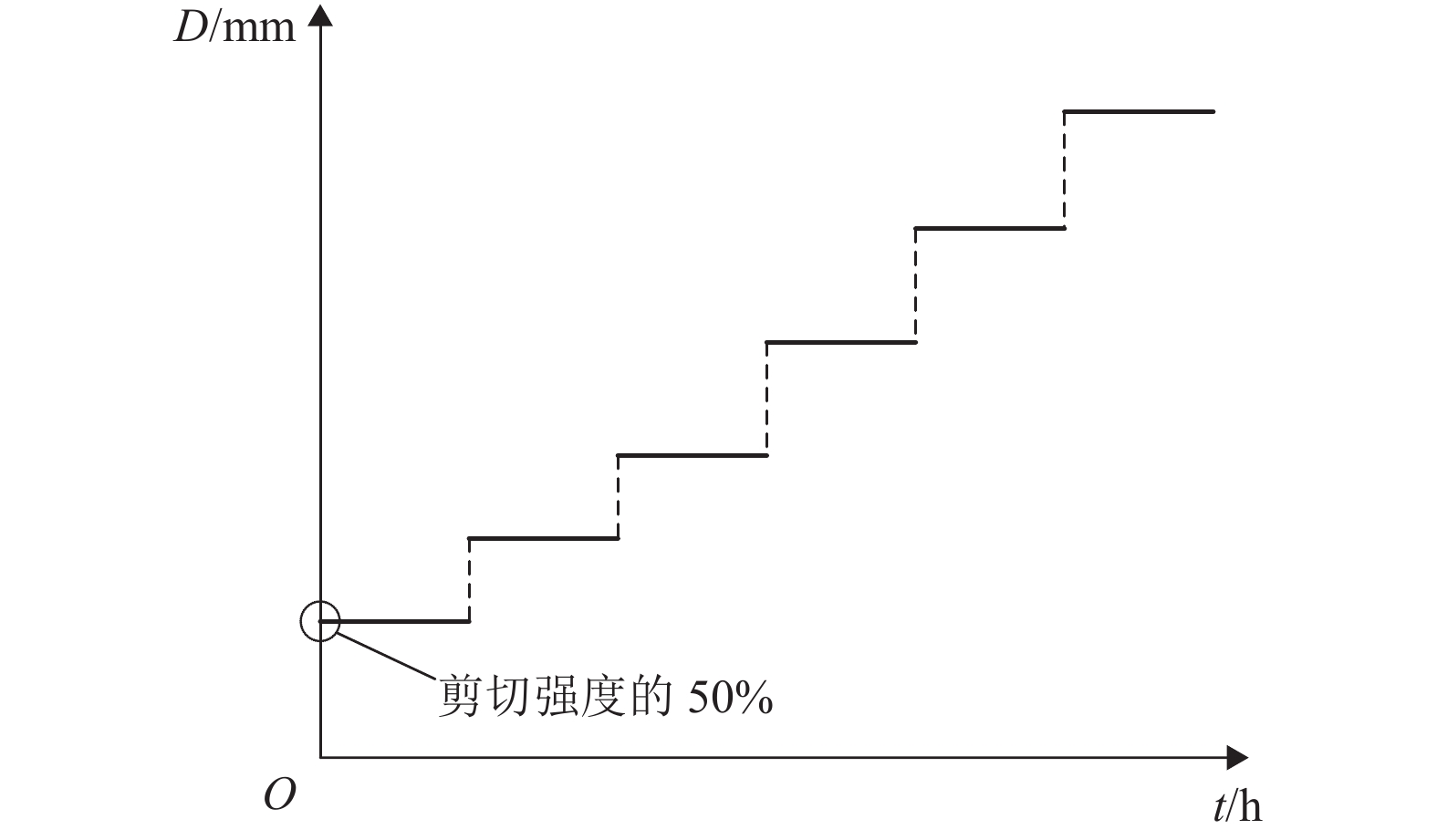

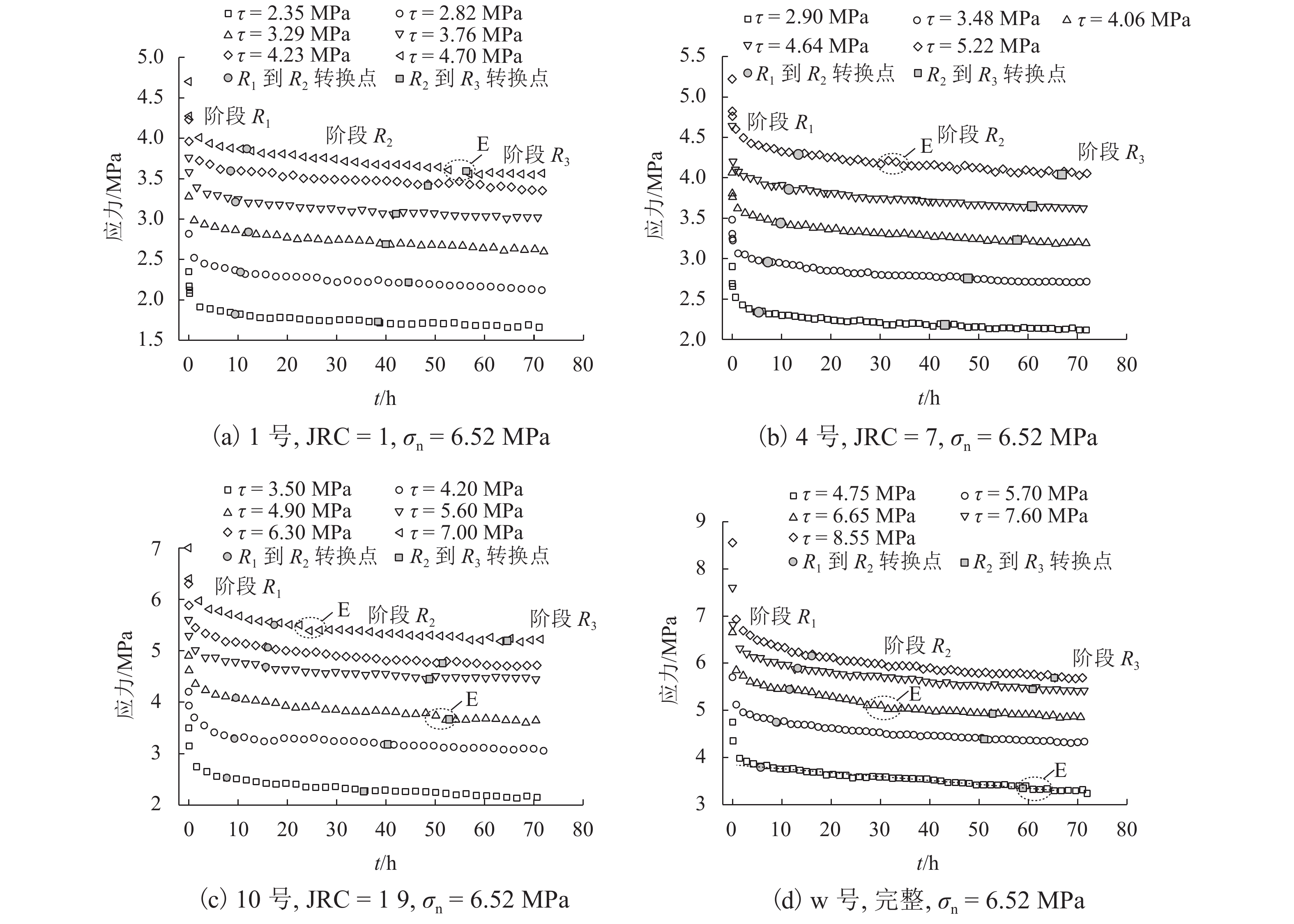

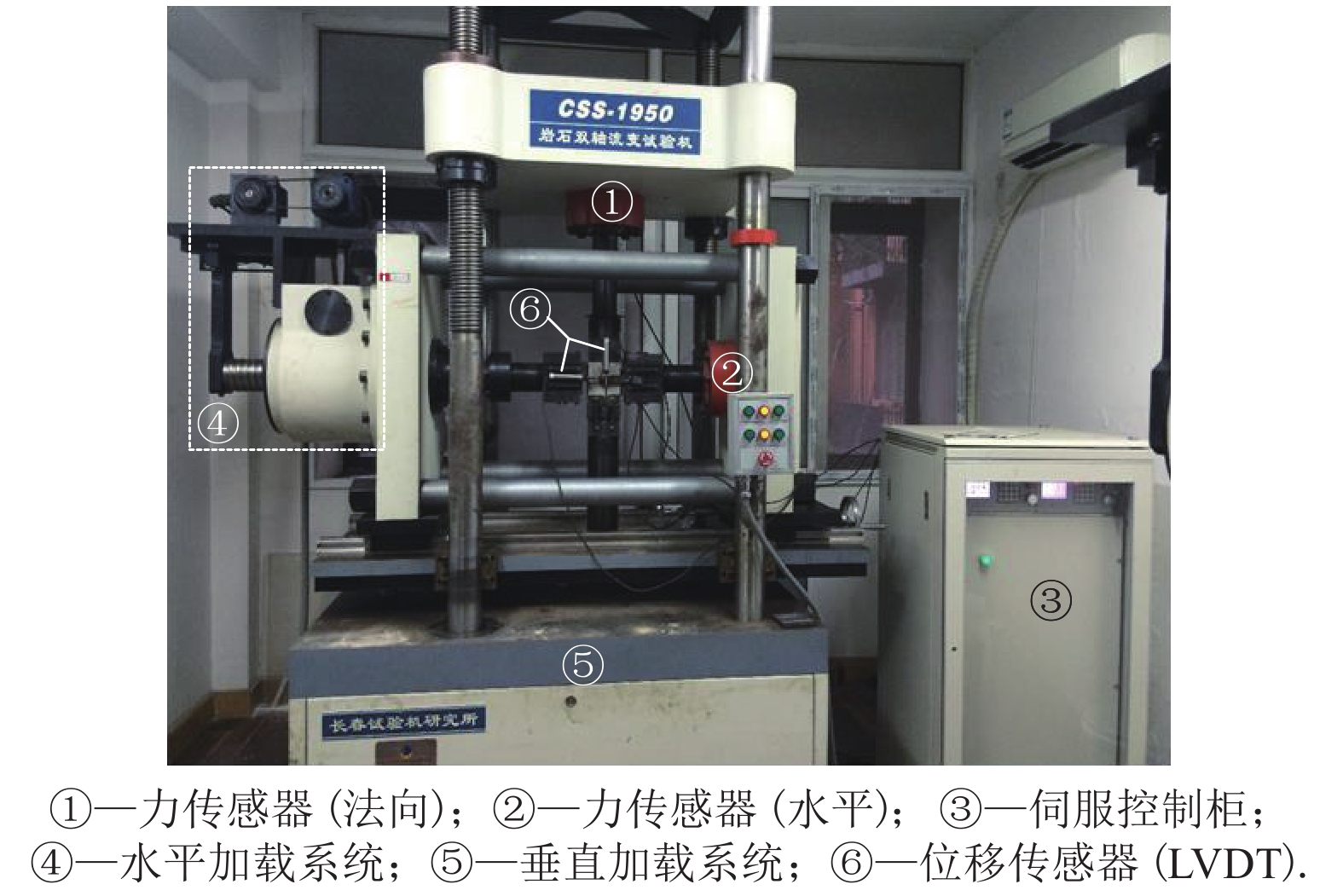

摘要: 应力松弛是岩体节理面时效特性的重要组成部分,也是影响岩体工程长期稳定性的重要因素. 为研究不同粗糙度岩体节理面的应力松弛特性,并进一步探索节理面的应力松弛机理,选取Barton标准剖面为人工模拟节理面的表面形态,并用水泥砂浆浇筑成型;然后,对其进行了分级加载剪切应力松弛试验,研究了不同粗糙度节理面在不同初始应力水平下的应力松弛曲线及应力松弛速率曲线特征,给出了松弛应力与初始应力之间的关系,并结合试验现象分析了应力松弛的发生机理. 研究成果表明:随着初始松弛应力的升高,松弛应力先减小后增大,即岩体节理面应力松弛能力先减弱后增大,该现象与剪切过程中节理面的变形和裂隙发展有关,应力松弛是试验机为保持变形不变而不断调整,同时内部裂隙发育导致其内部抗力减小,进而引起应力下降的过程,并且粗糙度(JRC)越大,应力松弛能力越强.Abstract: Stress relaxation is an important part of time-dependent behavior of rock joints, and also an important factor affecting the long-term stability of engineering rock masses. To study the stress relaxation characteristics of rock joints with different roughness and further explore the stress relaxation mechanism of rock joint planes, samples with artificial joint surfaces based on Barton’s standard profile lines were prepared by pouring cement mortar into shape. Then, shear stress relaxation tests with a multi-stage loading process were conducted to investigate characteristics of stress relaxation curves and stress relaxation rate curves for joint surfaces with different joint roughness coefficient (JRC) under different initial stress levels, the relationships between initial stress and relaxation stress were obtained, and the mechanism of stress relaxation was analyzed from the test phenomena. The results show that with the increase of the initial stress, the relaxation stress decreases first and then increases; that is, the stress relaxation ability of the rock joint planes decreases first and then increases. This phenomenon is related to the deformation and crack development of joint planes during the shear tests. The stress relaxation is a process in which the test machine constantly adjusts to keep the deformation unchanged and the development of internal cracks leads to the reduction of internal resistance, further resulting in the decrease of shear stress; moreover, the stress relaxation ability of the rock joint planes increases with the increasing of JRC.

-

表 1 不同粗糙度节理面的剪切强度

Table 1. Shear strength of joints with different JRCs

JRC 剪切强度/MPa 1 4.90 7 5.77 19 7.20 完整 8.55 表 2 分级加载剪切应力松弛试验应力表

Table 2. Shear stresses of multi-stage relaxation tests

JRC 试验

编号初始应力 τi /MPa 破坏应

力/MPa松弛时

间/h1 1 2.35、2.82、3.29、

3.76、4.23、4.704.90 432 7 4 2.90、3.48、4.06、

4.64、5.225.77 360 19 10 3.50、4.20、4.90、

5.60、6.30、7.007.20 432 完整 w 4.75、5.70、6.65、

7.60、8.558.90 360 -

许文松,赵光明,孟祥瑞,等. 大理岩真三轴单面卸荷条件下加卸载试验研究[J]. 西南交通大学学报,2019,54(3): 526-534.XU Wensong, ZHAO Guangming, Meng Xiangrui, et al. Test study on true-tiaxial loading and unloading for marble with unloaded single face[J]. Journal of Southwest Jiaotong University, 2019, 54(3): 526-534. HUDSON J A, HARRISON J P. Engineering rock mechanics: an introduction to the principles[M]. Oxford: Pergamon Press, 1997: 359-360. FAHIMIFAR A, SOROUSH H. Effect of time on the stress–strain behaviour of a single rock joint[J]. Bulletin of Engineering Geology and the Environment, 2005, 64(4): 383-396. doi: 10.1007/s10064-005-0003-4 刘昂,沈明荣,蒋景彩,等. 基于应力松弛试验的结构面长期强度确定方法[J]. 岩石力学与工程学报,2014,33(9): 1916-1924.LIU Ang, SHEN Mingrong, JIANG Jingcai, et al. Determining long-term strength of rock with discontinuity using shear stress relaxation test[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(9): 1916-1924. 田光辉,沈明荣,周文锋,等. 分级加载条件下的锯齿状结构面剪切松弛特性[J]. 哈尔滨工业大学学报,2016,48(12): 108-113. doi: 10.11918/j.issn.0367-6234.2016.12.015TIAN Guanghui, SHEN Mingrong, ZHOU Wenfeng, et al. Shear relaxation characteristic of serrate structure surface under stepwise loading[J]. Journal of Harbin Institute of Technology, 2016, 48(12): 108-113. doi: 10.11918/j.issn.0367-6234.2016.12.015 PENG S S. Time-dependent aspects of rock behavior as measured by a servo-controlled hydraulic testing machine[J] International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1973, 10(3): 235-246. 陈宗基,石泽全,于智海,等. 用 8000 KN多功能三轴仪测量脆性岩石的扩容、蠕变及松弛[J]. 岩石力学与工程学报,1989,8(2): 97-118.CHEN Zongji, SHI Zequan, YU Zhihai, et al. Dilatancy creep and relaxation of brittle rocks measured with 8000 kN multipurpose triaxial apparatus[J]. Chinese Journal of Rock Mechanics and Engineering, 1989, 8(2): 97-118. 唐礼忠,潘长良. 岩石在峰值荷载变形条件下的松弛试验研究[J]. 岩土力学,2003,24(6): 940-942. doi: 10.3969/j.issn.1000-7598.2003.06.014TANG Lizhong, PAN Changliang. Experiment study on properties of stress relaxation of rock under deformation at peak load[J]. Rock and Soil Mechanics, 2003, 24(6): 940-942. doi: 10.3969/j.issn.1000-7598.2003.06.014 于怀昌,李亚丽,刘汉东. 粉砂质泥岩常规力学、蠕变以及应力松弛特性的对比研究[J]. 岩石力学与工程学报,2012,31(1): 60-70. doi: 10.3969/j.issn.1000-6915.2012.01.008YU Huaichang, LI Yali, LIU Handong. Comparative study of conventional mechanical,creep and stress relaxation properties of silty mudstone under triaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(1): 60-70. doi: 10.3969/j.issn.1000-6915.2012.01.008 田洪铭,陈卫忠,肖正龙,等. 泥质粉砂岩高围压三轴压缩松弛试验研究[J]. 岩土工程学报,2015,37(8): 1433-1439. doi: 10.11779/CJGE201508011TIAN Hongming, CHEN Weizhong, XIAO Zhenglong, et al. Triaxial stress relaxation properties of argillaceous siltstone under high confining pressure[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(8): 1433-1439. doi: 10.11779/CJGE201508011 PARASKEVOPOULOU C, PERRAS M, DIEDERICHS M, et al. The three stages of stress relaxation-Observations for the time-dependent behavior of brittle rocks based on laboratory testing[J]. Engineering Geology, 2017, 216: 56-75. doi: 10.1016/j.enggeo.2016.11.010 WANG Zhen, SHEN Mingrong, DING Wenqi, et al. Time-dependent behavior of rough discontinuities under shearing conditions[J]. Journal of Geophysics and Engineering, 2017, 15(1): 51-61. WANG Zhen, GU Linlin, SHEN Mingrong, et al. Influence of shear rate on the shear strength of discontinuities with different joint roughness coefficients[J]. Geotechnical Testing Journal, 2020, 43(3): 683-700. 李正旺, 汤山茂德, 吉冈上也, 等. 岩石隧洞掘进过程中松弛区域的声发射评价[J]. 岩石力学与工程学报, 2001, 20(增刊1): 1177–1181.LI Zhengwang, SHIGENORI Y, KOJI H, et al. Study of estimation of loosened region around rock cavern by acoustic emission technique[J]. Chinese Journal of Rock Mechanics and Engineering, 2001, 20(S1): 1177-1181. -

下载:

下载: