Axial Bearing Capacity of Angle Parallel Reinforcement for High Voltage Transmission Towers

-

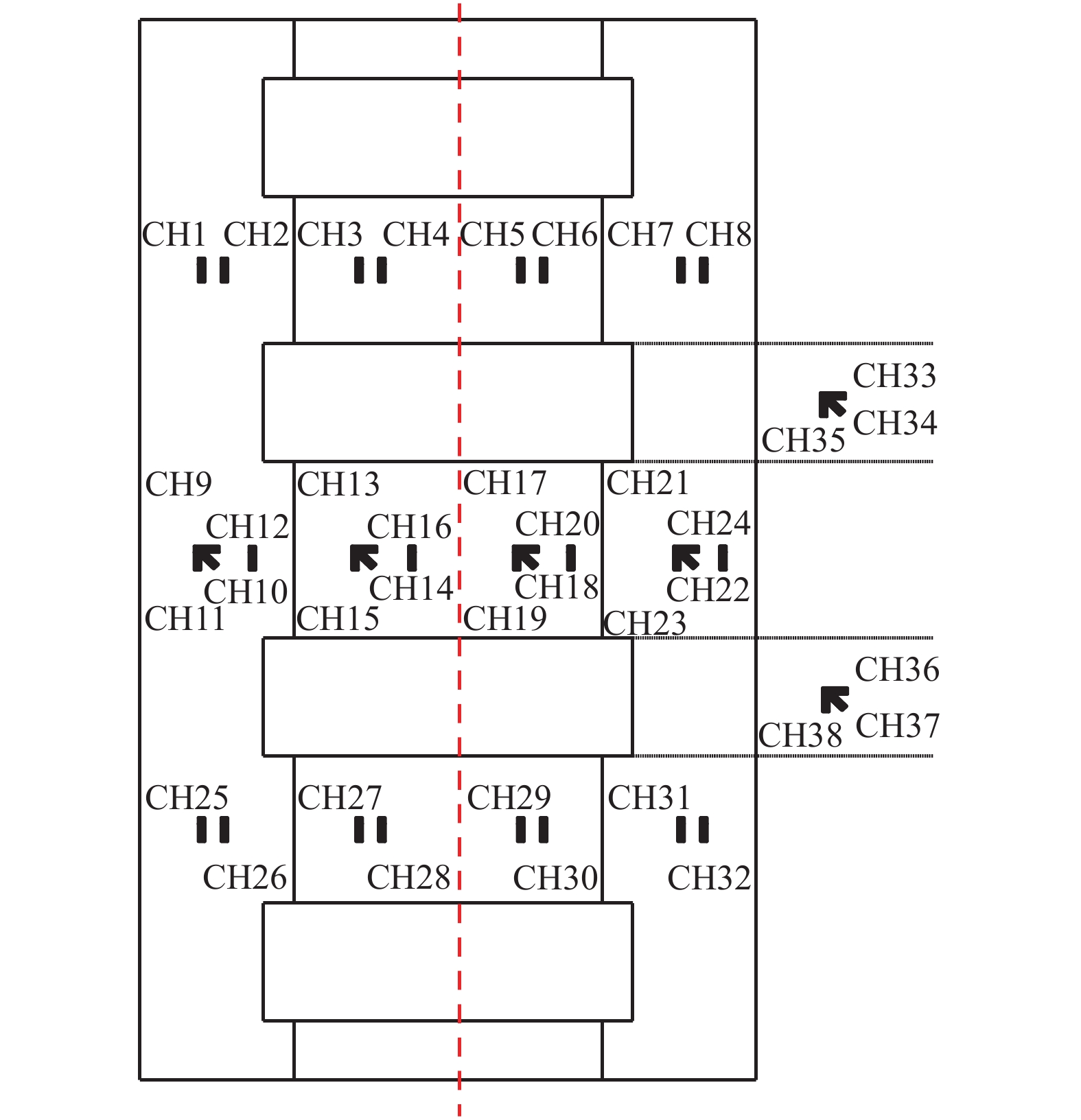

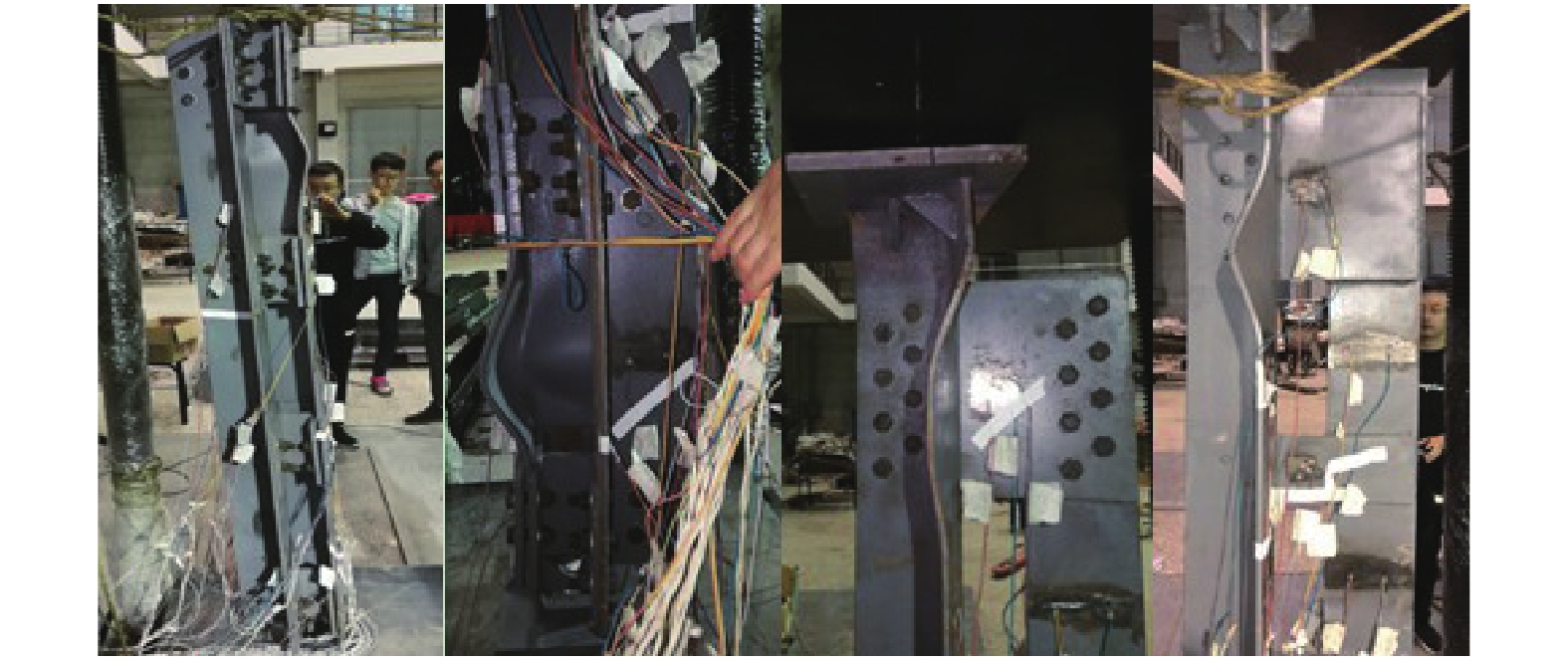

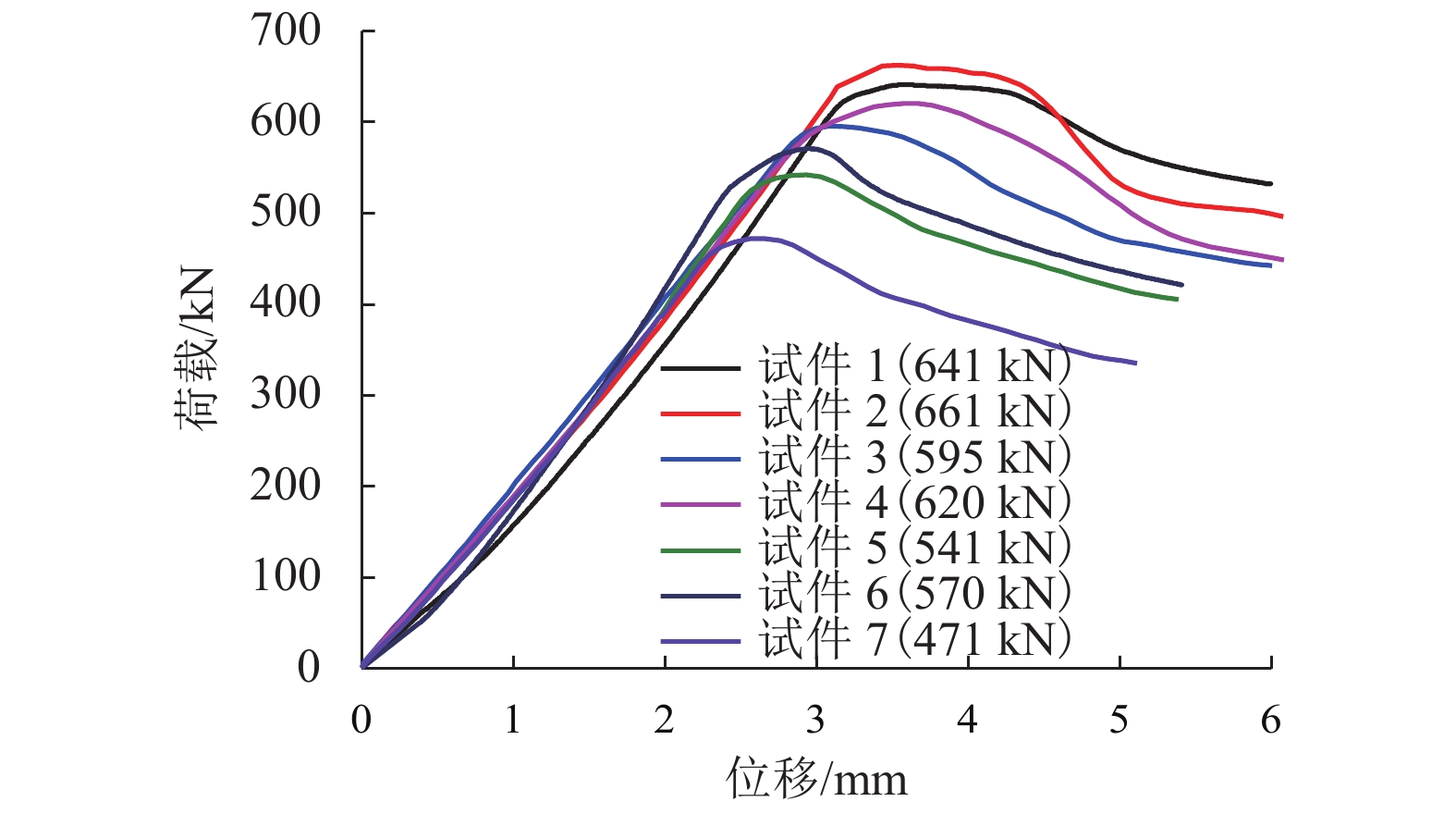

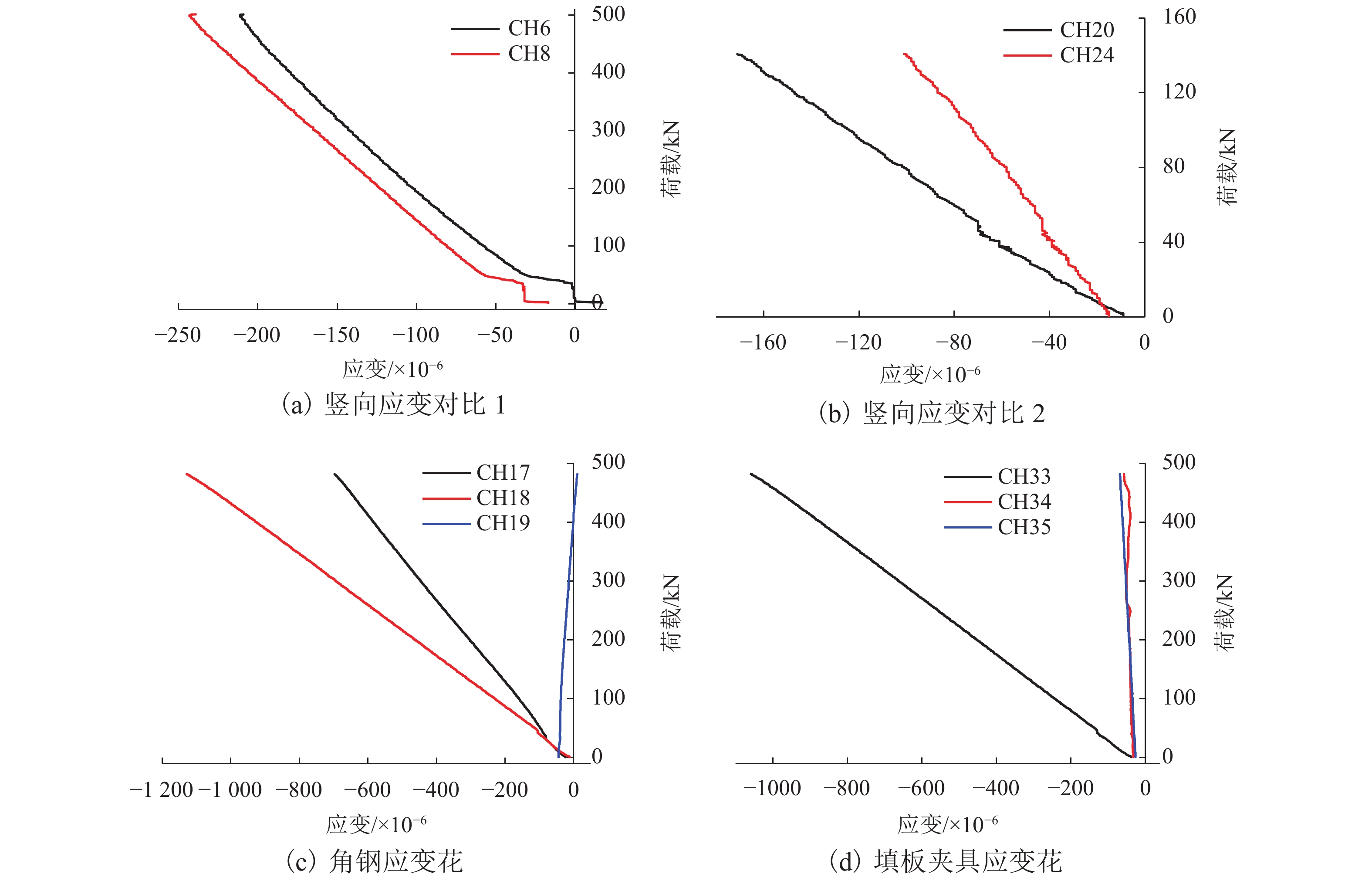

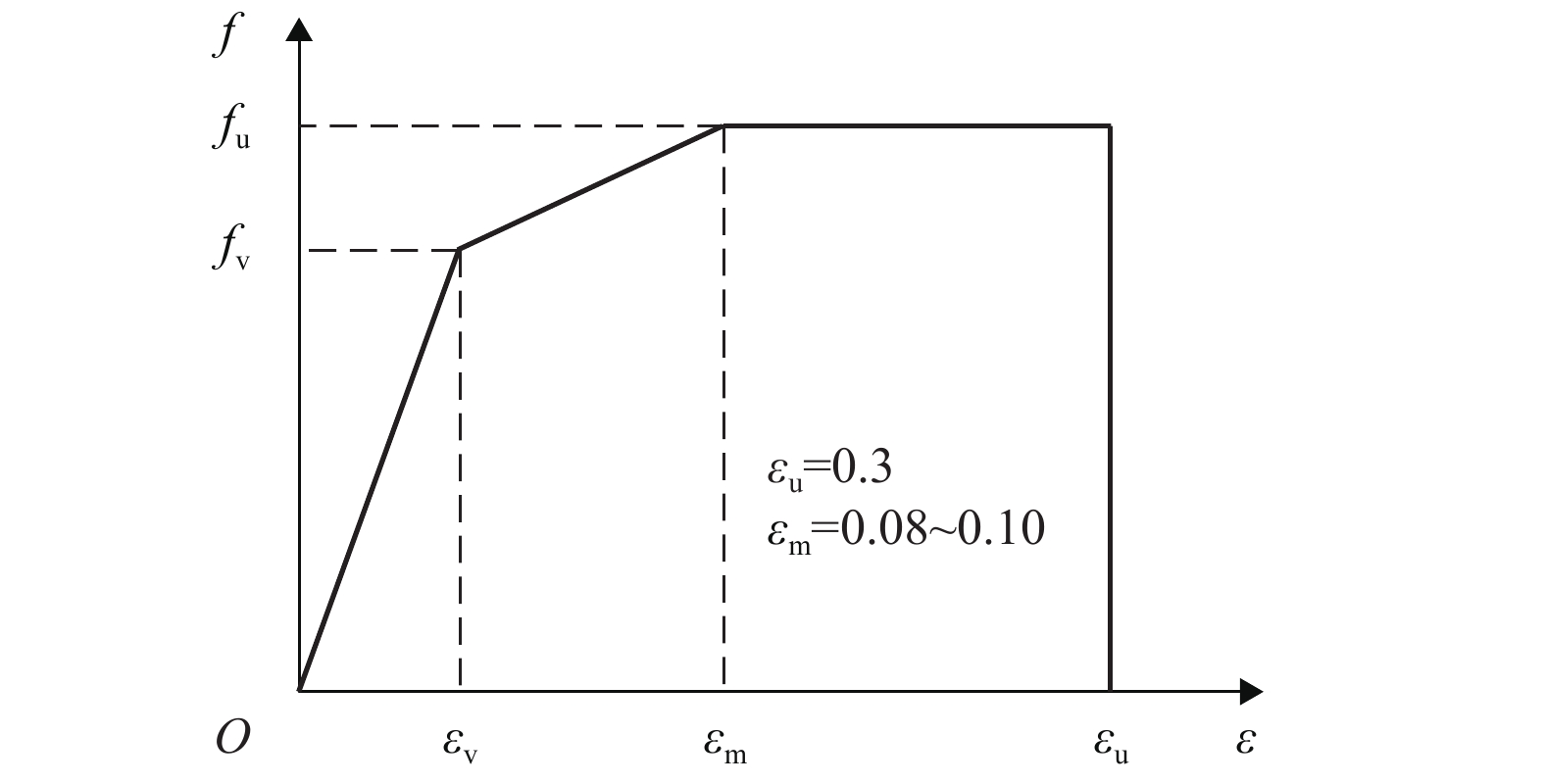

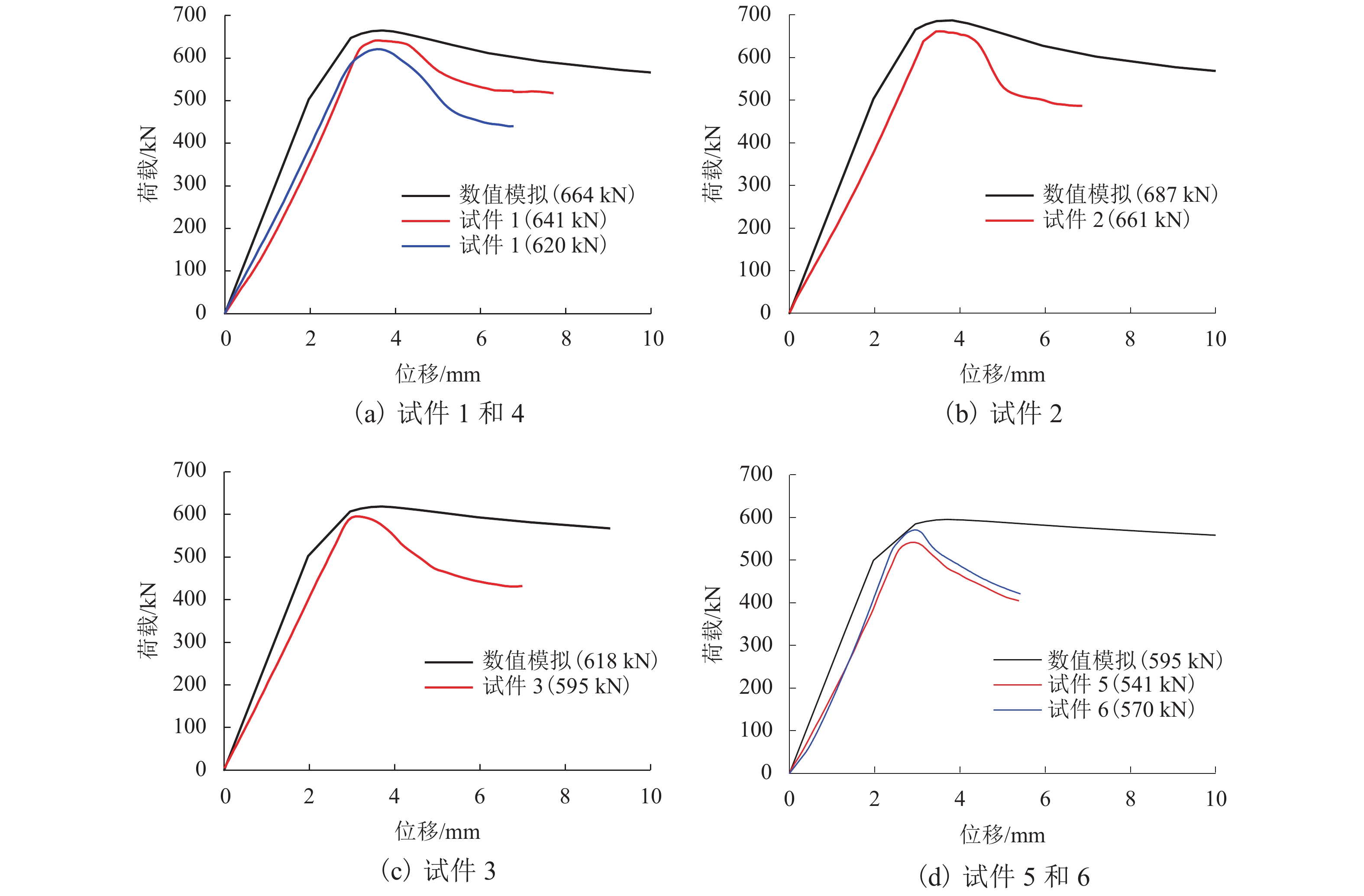

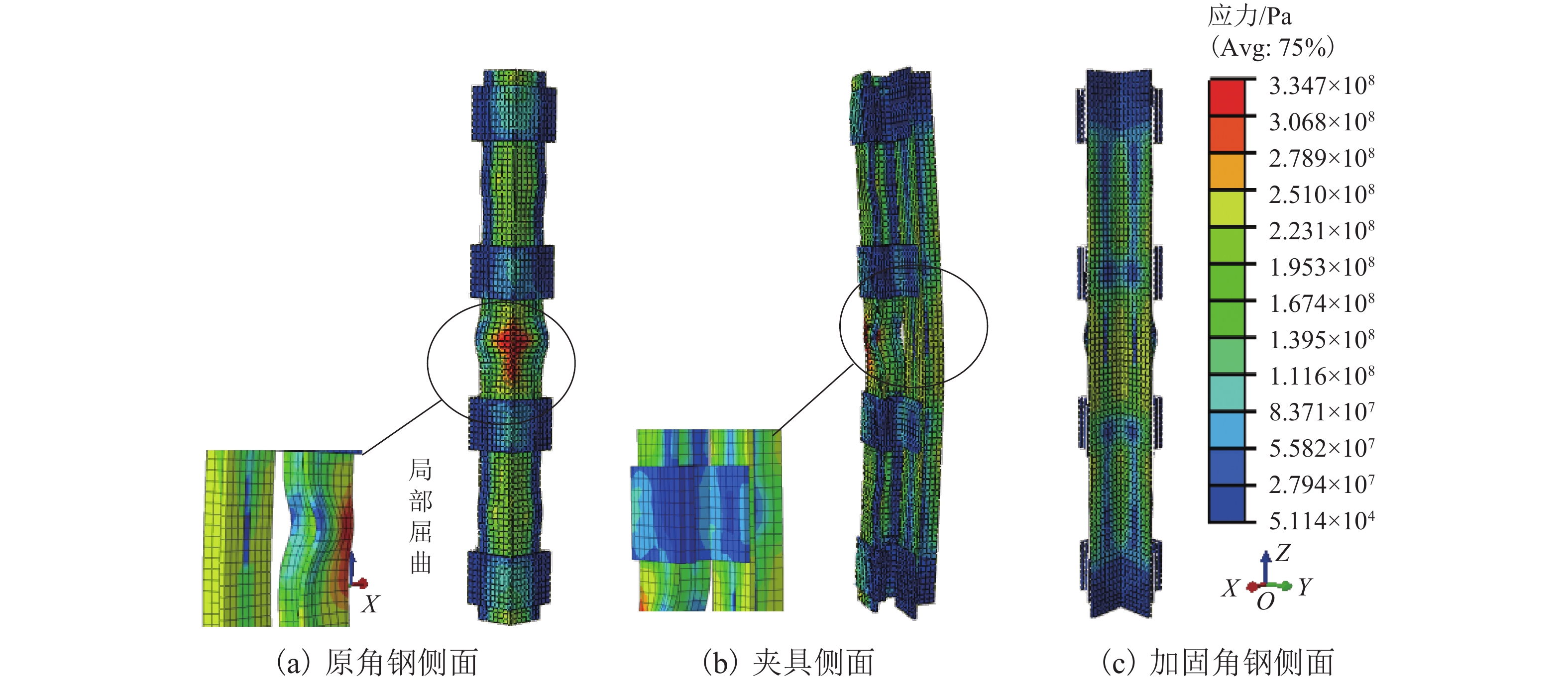

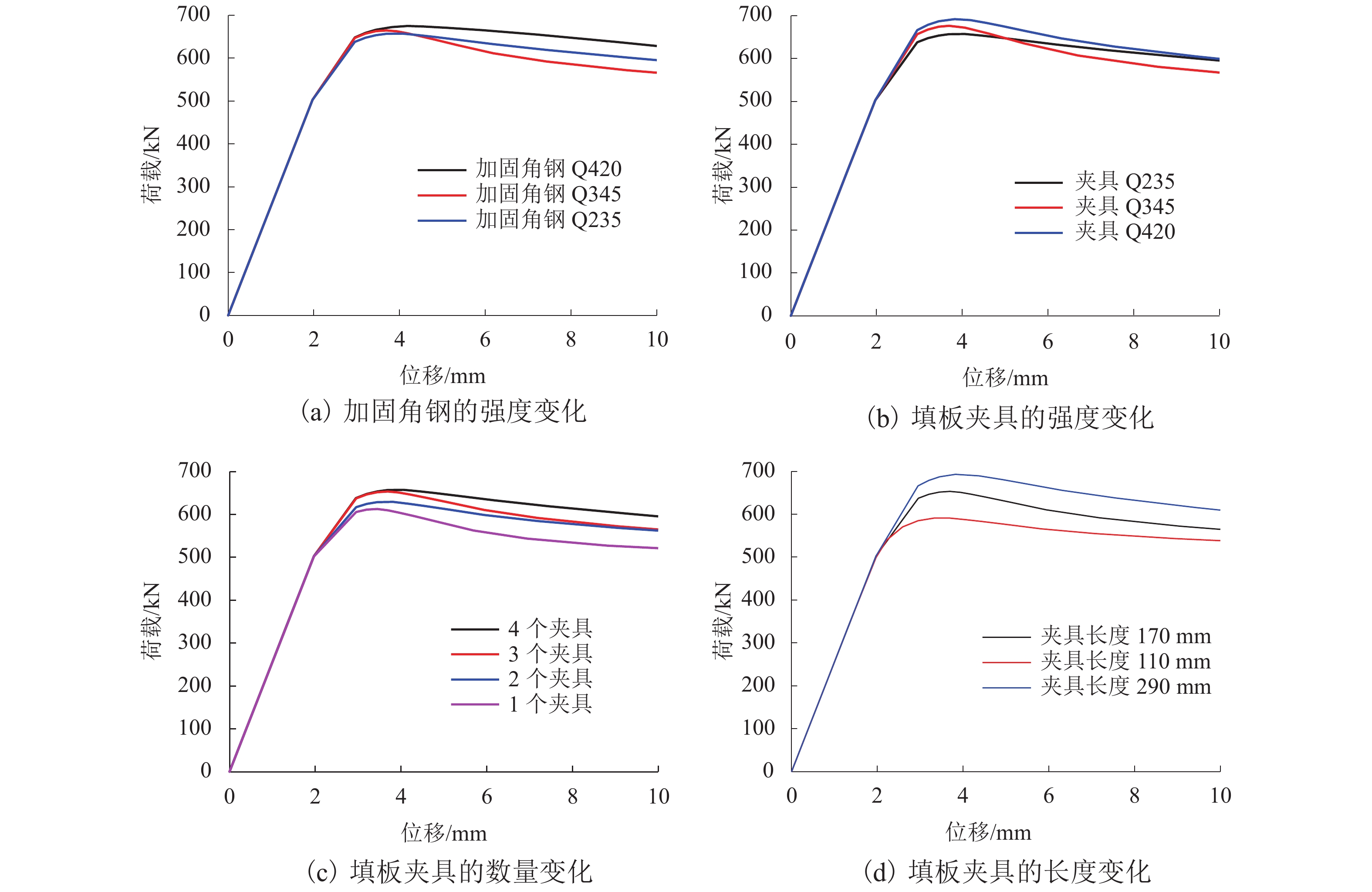

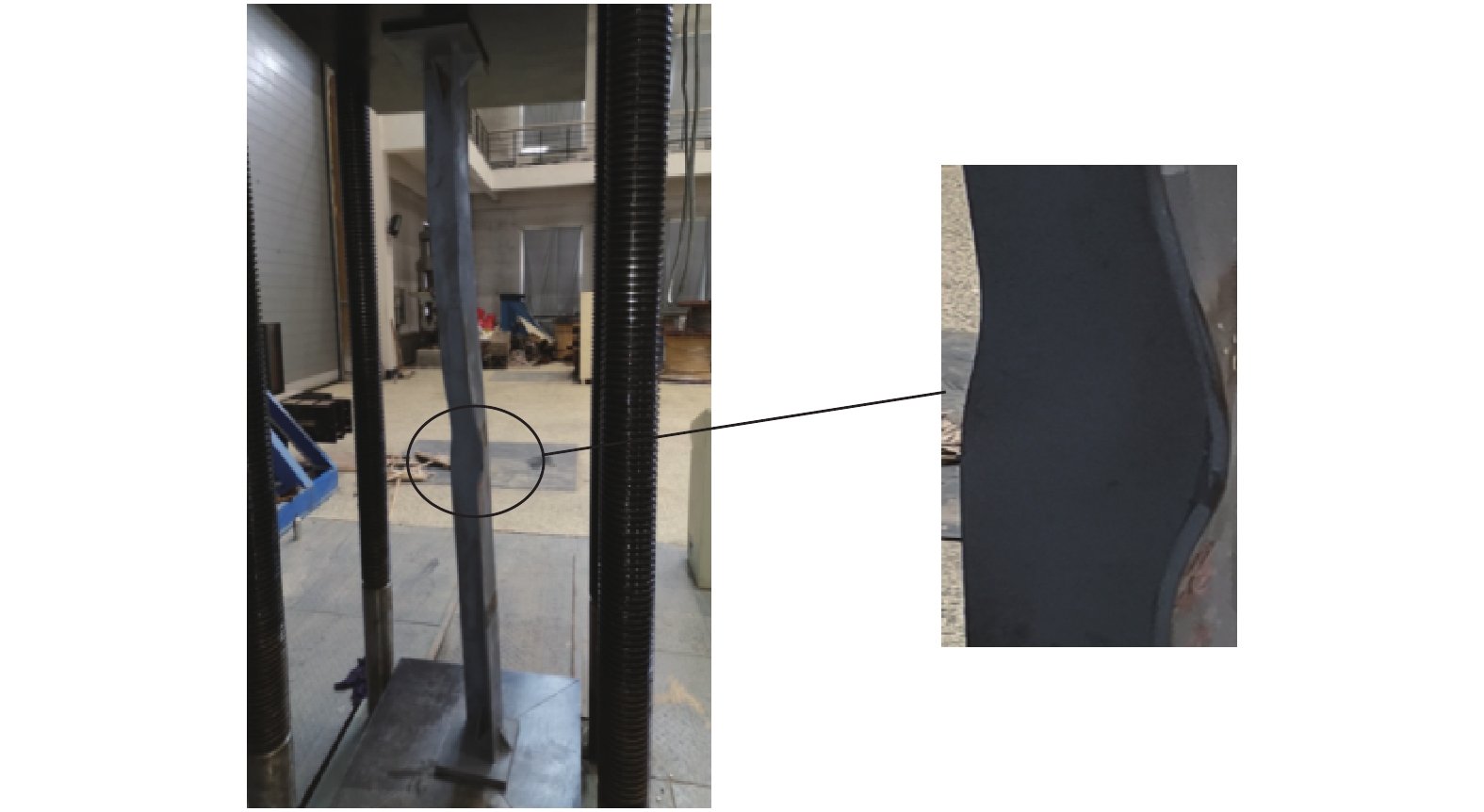

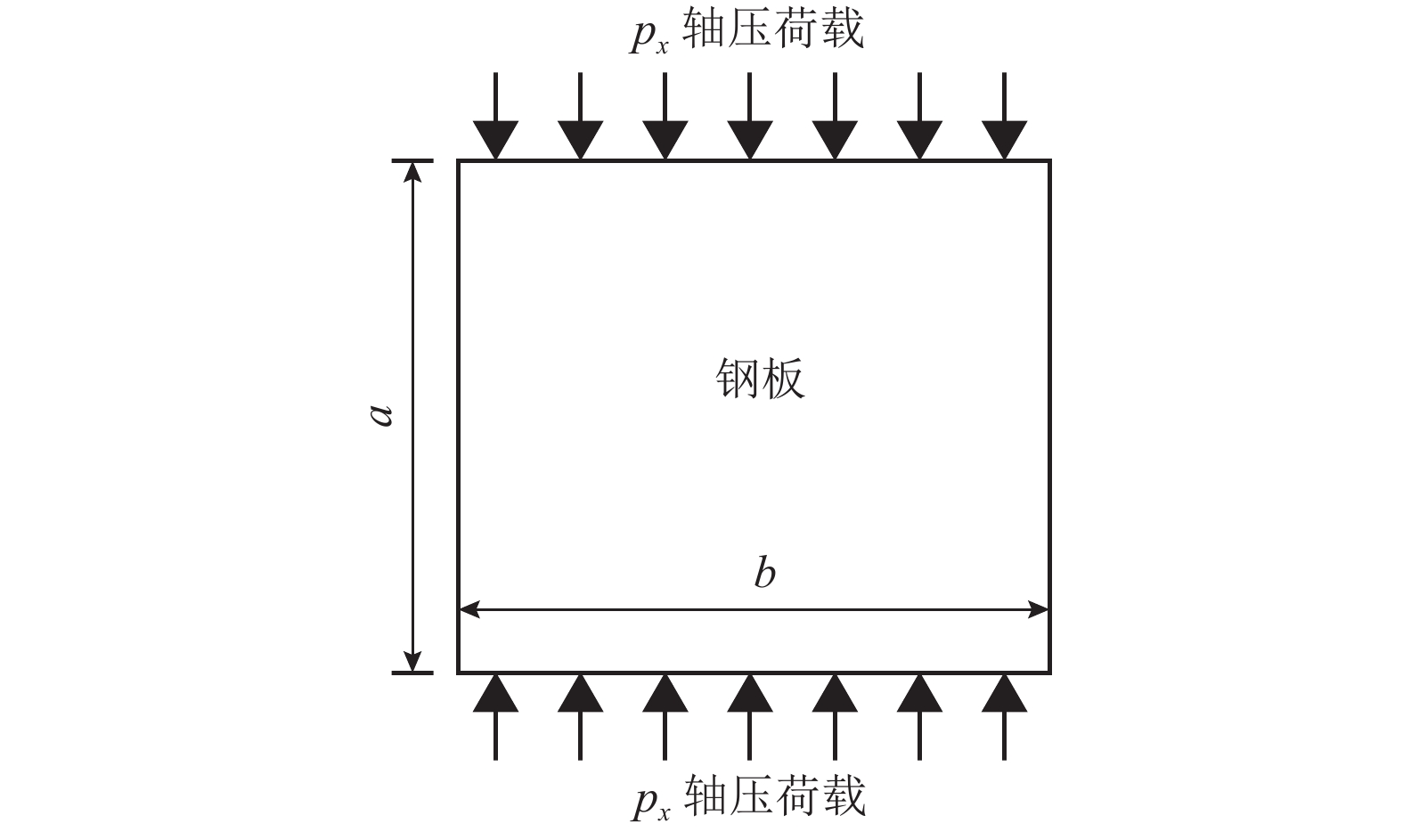

摘要: 提高输电杆塔主材局部稳定性的承载力,可有效地避免输电塔倒塌事故的发生. 为此,通过6个轴心受压角钢并联加固试验、1个单角钢轴心受压试验和分析13个有限元模型,得到了试件的荷载-位移曲线和荷载-应变曲线以及构件的Mises应力云图,确定了试件的受力规律和应变规律以及设计参数对构件承载力的影响规律. 分析表明:试件原角钢的局部屈曲失稳为试件主要破坏形式;加固角钢的单元最大强度达到223.1 MPa;填板夹具的单元最大强度达到83.7 MPa;试件整体应变以竖向应变为主,填板夹具以剪切应变为主;均匀受压板理论的屈曲公式可以较好地计算出该加固试件的极限承载力;角钢并联加固法可以提高单角钢40%承载能力.Abstract: The risk of transmission tower collapse can be effectively controlled by improving the bearing capacity of its local stability. Through the test of six-angle parallel reinforcement under axial compression, a single-angle axial compression test and the analysis of 13 finite element models, the load-displacement curves of the specimens, the load-strain curves and Mises stress nephogram are obtained. Further the laws of stress and strain of the specimens and how design parameters affect the component bearing capacity are explored. The results show that the local buckling instability is the main failure mode of the specimens. The maximum strength of the reinforced angle unit reaches 223.1 MPa, and the maximum strength of the board clamp element reaches 83.7 MPa. The overall strain of the specimen is mainly vertical strain, and that of the board clamp is mainly shear strain. The buckling formula of uniform plate theory can calculate the ultimate bearing capacity of the reinforced specimen. The parallel reinforcement can improve the bearing capacity of single angle by 40%.

-

Key words:

- transmission tower /

- angle /

- reinforcement /

- axial compression test /

- numerical simulation /

- bearing capacity analysis

-

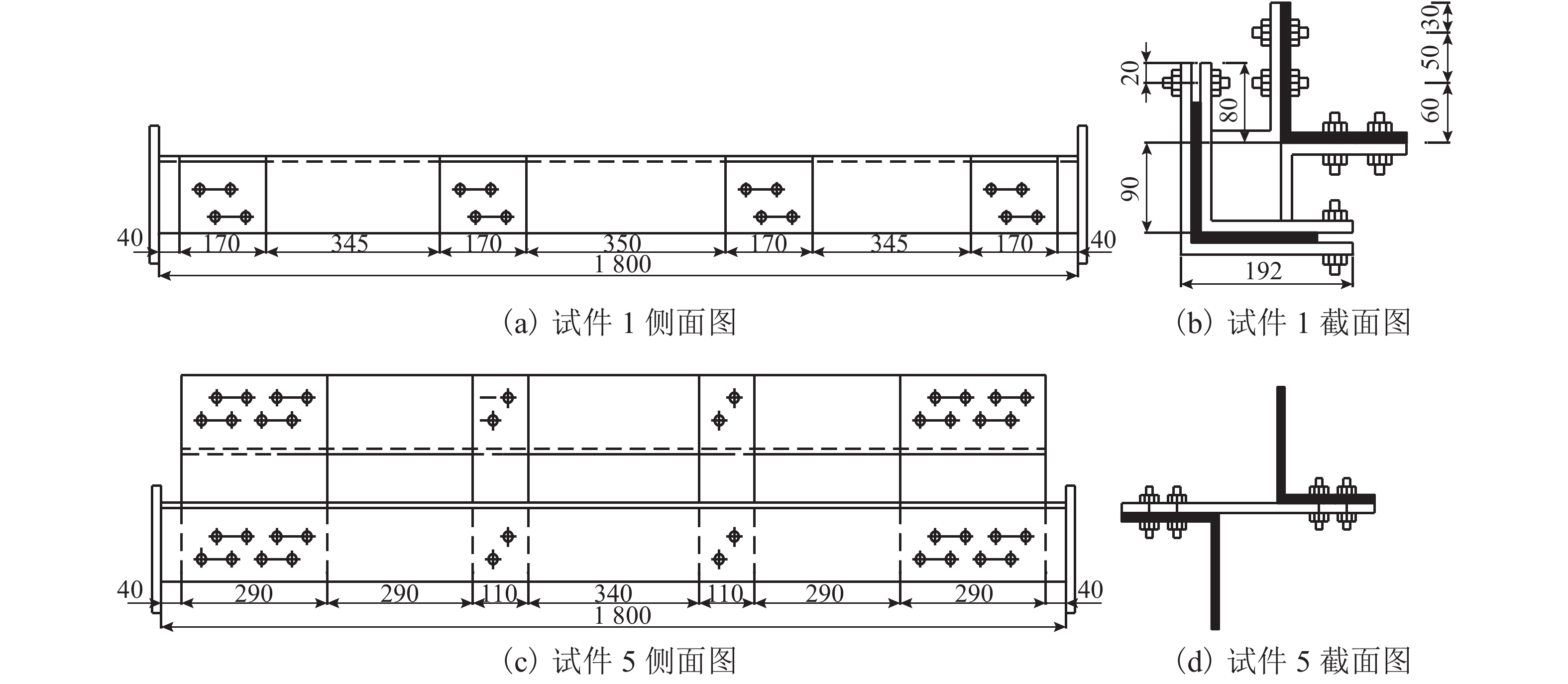

表 1 试件的几何尺寸和材料参数

Table 1. Geometric dimensions and material parameters of specimens

试件 输电塔圆角钢长度/mm 加固角钢长度/mm 连接方式 连接件位置及数量/个 连接件长度/mm 1 1 800 1 700 填板夹具 端部:2 170 中部:2 170 2 1 800 1 700 填板夹具 端部:2 290 中部∶2 110 3 1 800 1 700 填板夹具 端部∶2 290 中部∶1 110 4 1 800 1 700 填板夹具+螺栓打孔 端部∶2 170 中部∶2 170 5 1 800 1 700 填板夹具 端部∶2 290 中部∶2 110 6 1 800 1 700 填板焊接 端部∶2 290 中部∶2 110 7 1 800 — — — — 注:原角钢和加固角钢均为Q235-∟140 × 10等边角钢. 表 2 有限元值对比

Table 2. Comparison of finite element results

试件名称 数值模

拟值/kN试件 1/其他

模拟值试件 1 641 1.000 试件 1-加固角钢 Q345 664 0.965 试件 1-加固角钢 Q420 674 0.951 试件 1-夹具 Q345 679 0.944 试件 1-夹具 Q420 691 0.928 试件 1-3 个夹具 636 1.008 试件 1-2 个夹具 620 1.034 试件 1-1 个夹具 608 1.054 试件 1-夹具长度 110 mm 583 1.099 试件 1-夹具长度 290 mm 695 0.922 表 3 试验数据与公式和数值模拟数据对比

Table 3. Comparison between experimental data and numerical simulation data

试件 试验值/kN 试验值/式(2)值 试验值/数值模拟值 式(2)值/数值模拟值 1 641 1.017 0.967 0.950 2 661 1.049 0.962 0.917 3 595 0.944 0.963 1.019 4 620 0.984 0.935 0.950 5 541 0.859 0.909 1.059 6 570 0.905 0.958 1.059 -

张文亮,于永清,宿志以,等. 湖南电网2008年冰雪灾害调研分析[J]. 电网技术,2008,32(8): 1-5.ZHANG Wenliang, YU Yongqing, SU Zhiyi, et al. Investigation and analysis of icing and snowing disaster happened in Hunan power grid in 2008[J]. Power System Technology, 2008, 32(8): 1-5. 李成榕,吕玉珍,崔翔,等. 冰雪灾害条件下我国电网安全运行面临的问题[J]. 电网技术,2008,32(4): 14-22.LI Chengrong, LU Yuzhen, CUI Xiang, et al. Research issues for safe operation of power grid in China under ice-snow disasters[J]. Power System Technology, 2008, 32(4): 14-22. 刘学武,夏开全,高燕,等. 构件并联法加固输电塔的试验研究及设计建议[J]. 西安建筑科技大学学报(自然科学版),2011,43(6): 838-844. doi: 10.3969/j.issn.1006-7930.2011.06.012LIU Xuewu, XIA Kaiquan, GAO Yan, et al. Study on strengthening the structure and its design for the transmission tower[J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 2011, 43(6): 838-844. doi: 10.3969/j.issn.1006-7930.2011.06.012 刘海锋,朱彬荣,孙珍茂,等. 大宽厚比对称填板双角钢十形组合构件轴压试验与设计方法对比[J]. 建筑结构学报,2018,39(7): 123-130.LIU Haifeng, ZHU Binrong, SUN Zhenmao, et al. Experimental study on axial compressive strength and evaluation of design criteria for closely star-battened angle column with symmetrical battens of large width-to-thickness ratio[J]. Journal of Building Structures, 2018, 39(7): 123-130. 刘红军,李正良. 双角钢十字组合截面偏心压杆承载力研究[J]. 四川大学学报(工程科学版),2012,44(1): 63-68.LIU Hongjun, LI Zhengliang. Study on ultimate strength of eccentric compression members with combined angle iron cross-section[J]. Journal of Sichuan University (Engineering Science Edition), 2012, 44(1): 63-68. 李正良,黄海斌,赵楠,等. 高强度双角钢十字组合截面双节间压杆受力性能研究[J]. 四川大学学报(工程科学版),2015,47(2): 64-74.LI Zhengliang, HUANG Haibin, ZHAO Nan, et al. Study on mechanical performance of double internodes compression member of high-strength dual-angle cross combined section[J]. Journal of Sichuan University (Engineering Science Edition), 2015, 47(2): 64-74. 杨隆宇,李正良. 双角钢十字组合截面构件铰支轴心受压承载力研究[J]. 西南交通大学学报,2011,46(5): 752-757. doi: 10.3969/j.issn.0258-2724.2011.05.007YANG Lougyu, LI Zheugliang. Bearing capacity of pinned-end built-up cruciform section members formed by two equal-leg angles under compression load[J]. Journal of Southwest Jiaotong University, 2011, 46(5): 752-757. doi: 10.3969/j.issn.0258-2724.2011.05.007 郭彦林,王小安,朱博莉,等. 四角钢组合约束型防屈曲支撑的轴压试验研究[J]. 土木工程学报,2017,50(4): 1-12,115.GUO Yanlin, WANG Xiaoan, ZHU Boli, et al. Experimental study on a four-angle assembled buckling-restrained brace subjected to axial compressive load[J]. China Civil Engineering Journal, 2017, 50(4): 1-12,115. KOMATSU H, ISIHII K, FUKUSHIMA A. Experimental study on buckling strength of angle steel compression members with built-up bracing[J]. Japanese Society of Steel Construction, 2009, 16: 27-34. 中华人民共和国住房和城乡建设部. 钢结构加固技术规范: CECS77—96[S]. 北京: 中国计划出版社, 1996. 中华人民共和国住房和城乡建设部. 钢结构设计规范标准: GB 50017—2017[S]. 北京: 中国建筑工业出版社, 2017. 陈骥. 钢结构稳定理论与设计[M]. 北京: 科学出版社, 2003. 张有佳,李小军. 基于钢板弹性屈曲理论的组合墙轴压试验研究[J]. 应用基础与工程科学学报,2015,23(6): 1198-1209.ZHANG Youjia, LI Xiaojun. Axial compression experimental study of composite walls based on steel plate elastic bucking theory[J]. Journal of Basic Science and Engineering, 2015, 23(6): 1198-1209. -

下载:

下载: