Experimental Study on Discharge and Energy Dissipation of Baffle-Drop Shaft in Deep Tunnel Drainage System

-

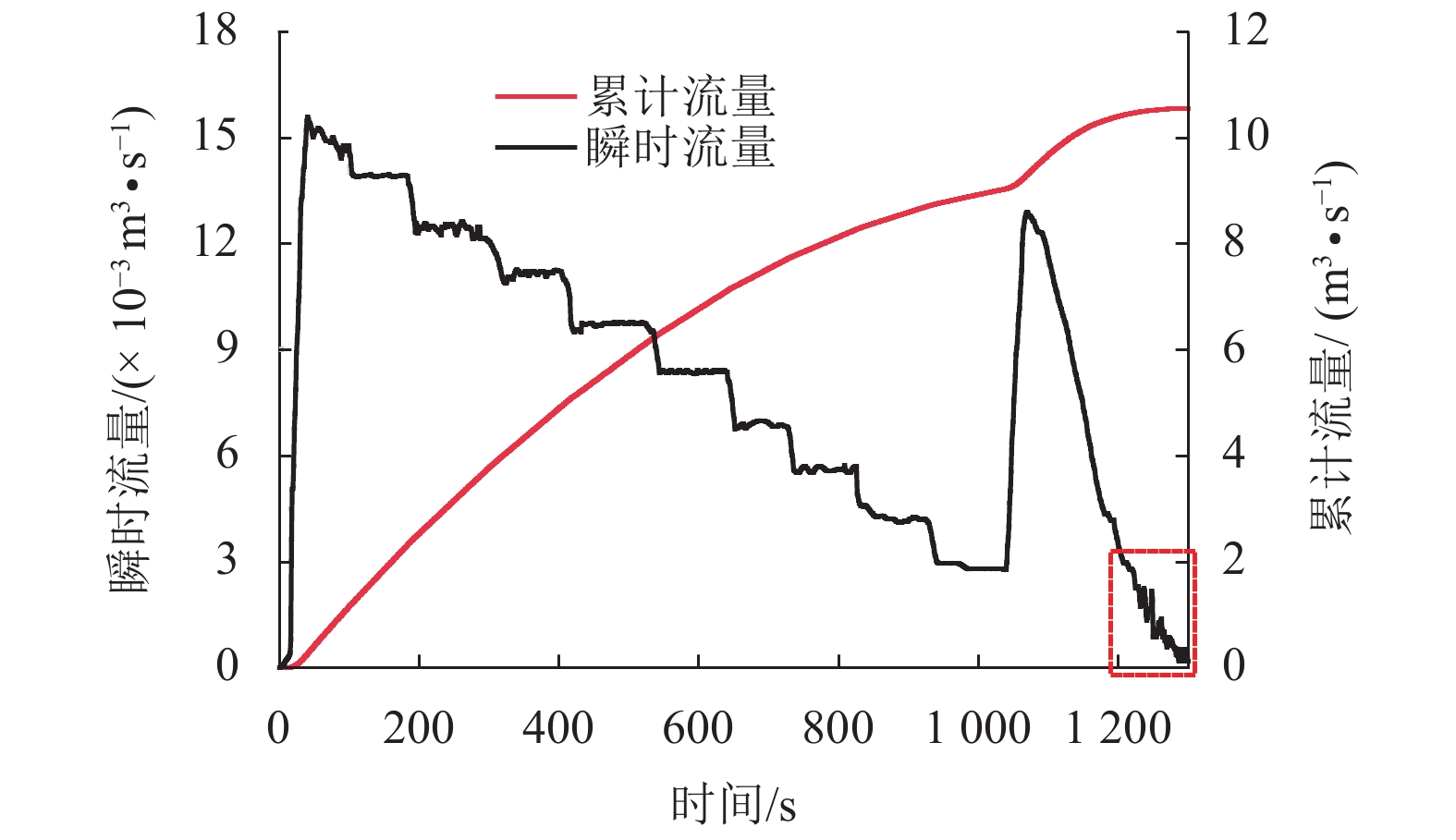

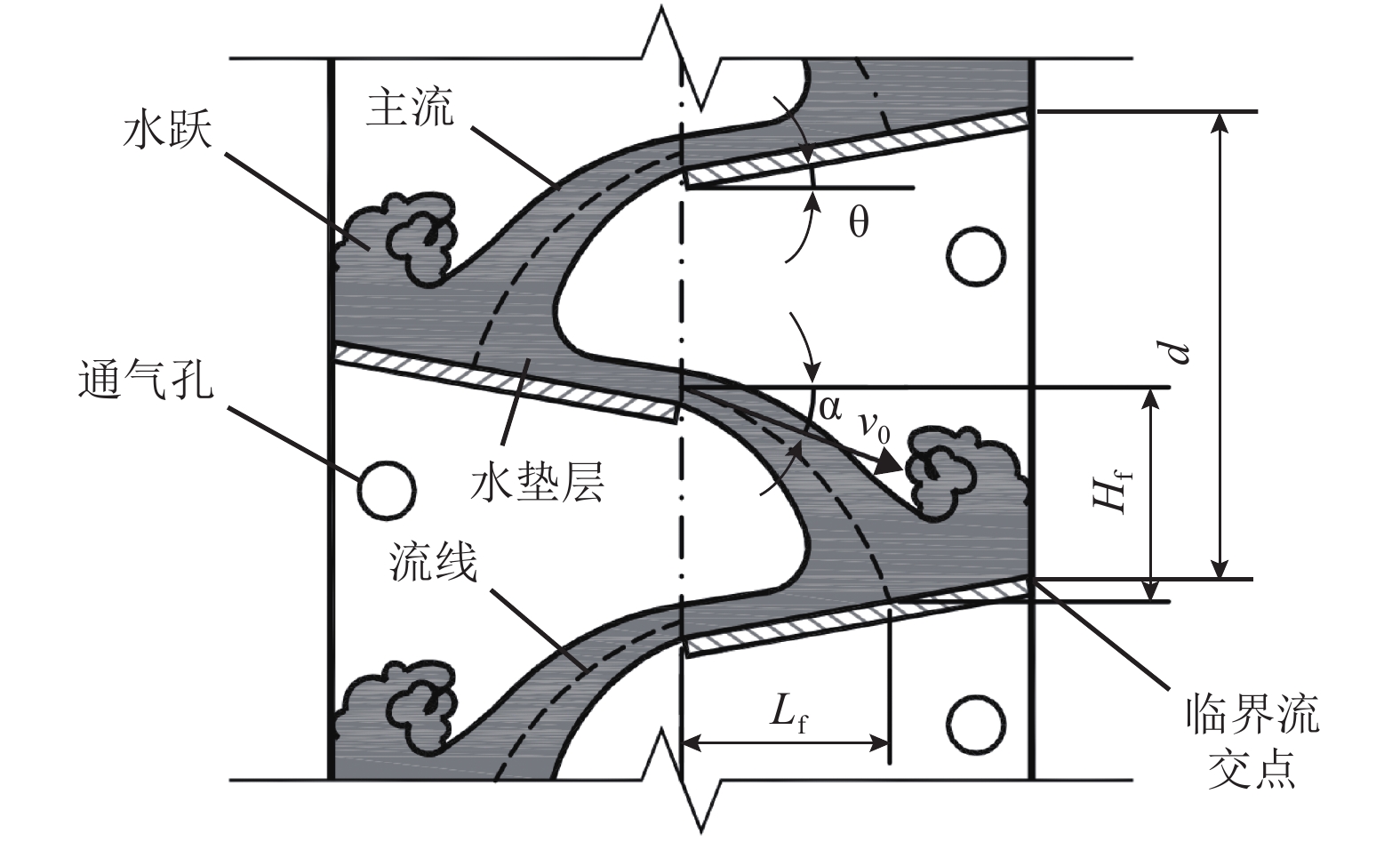

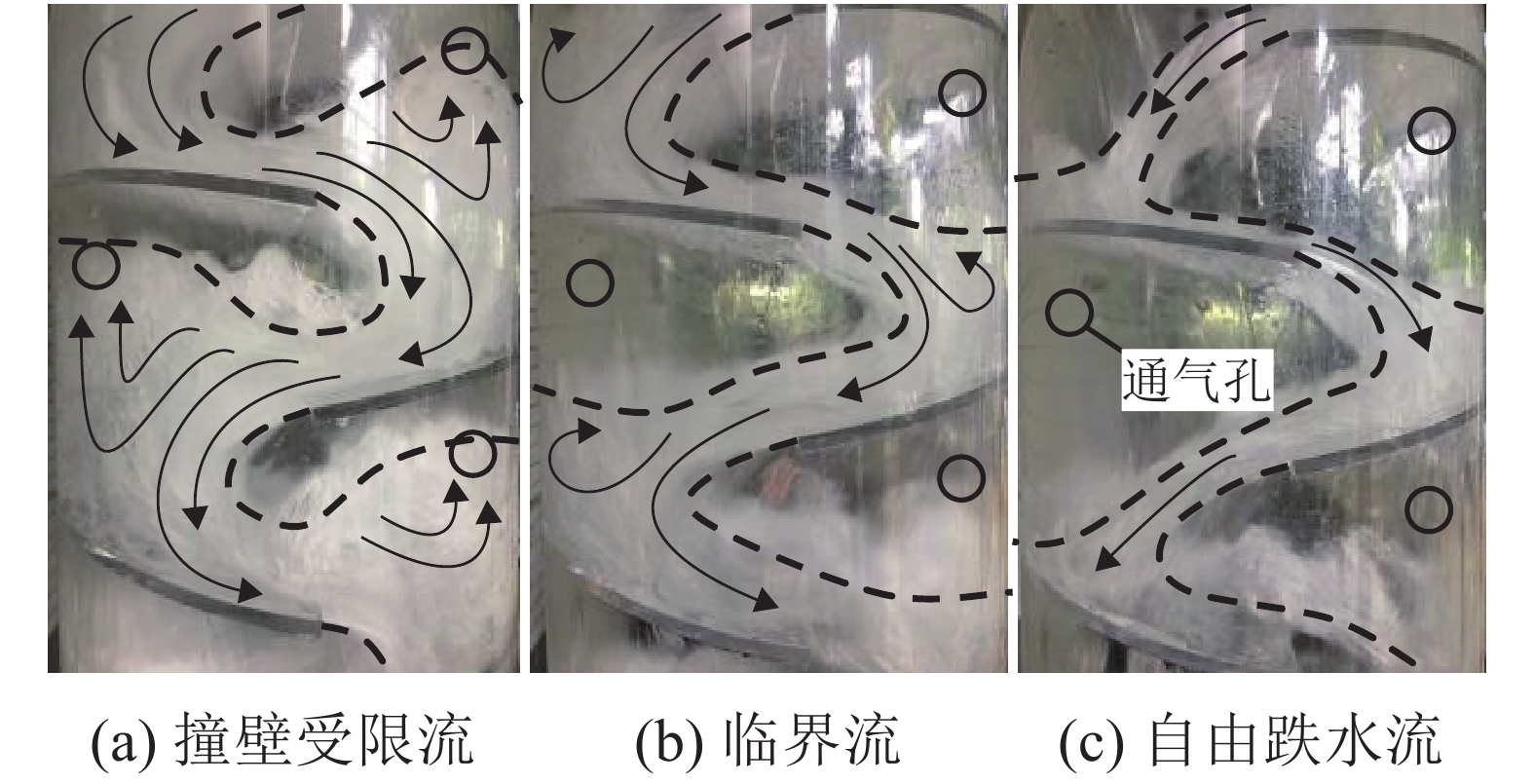

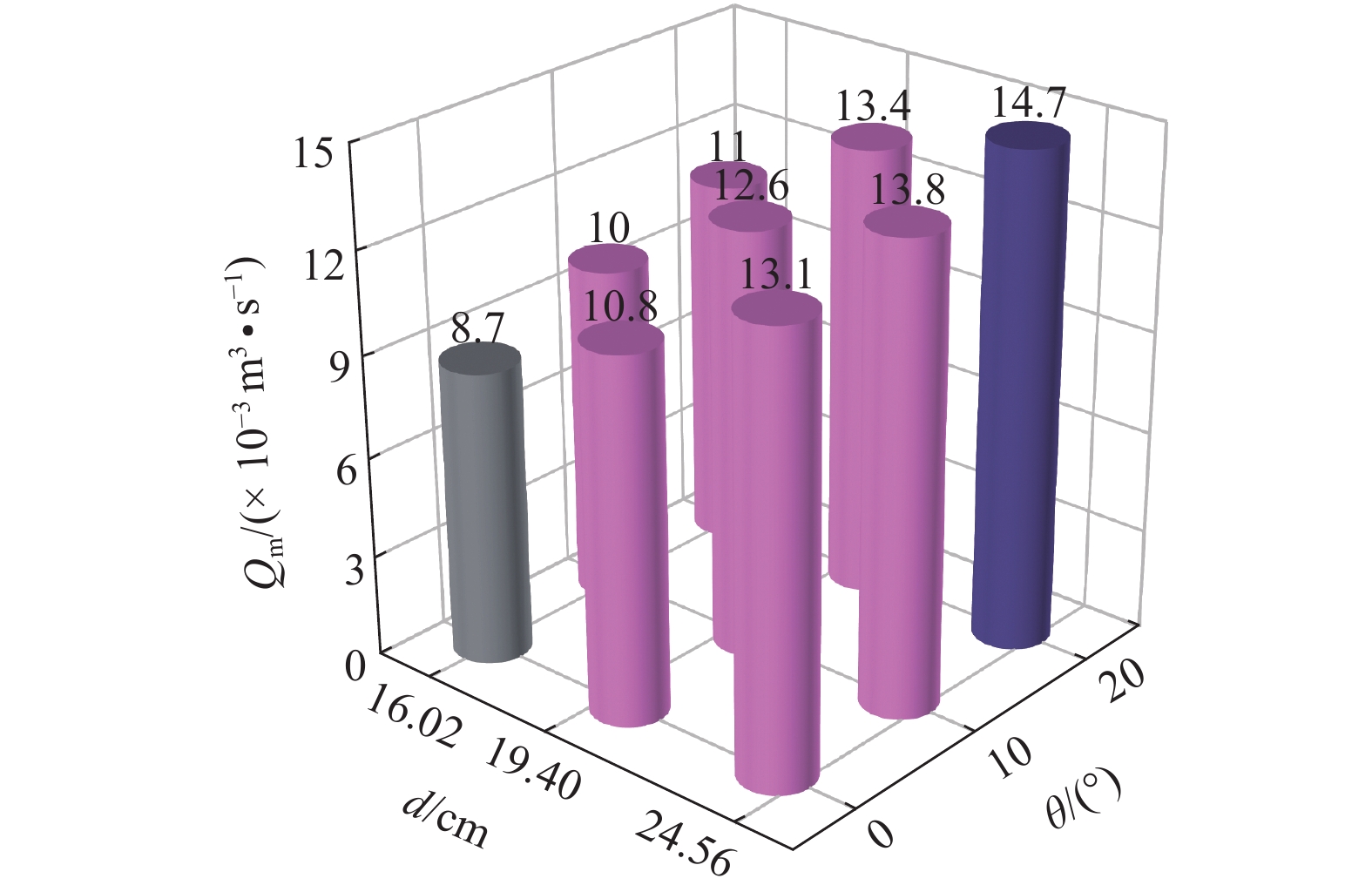

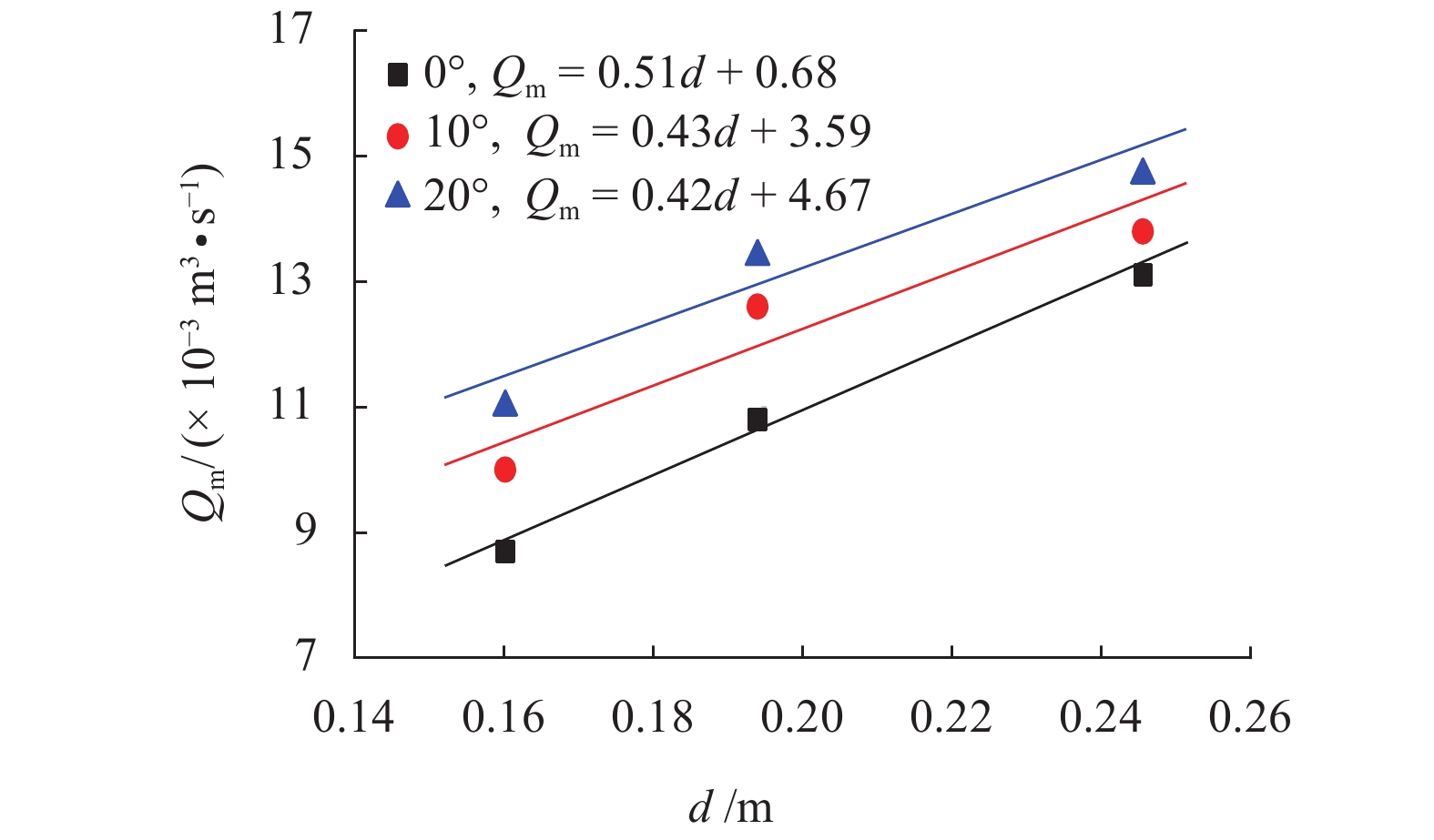

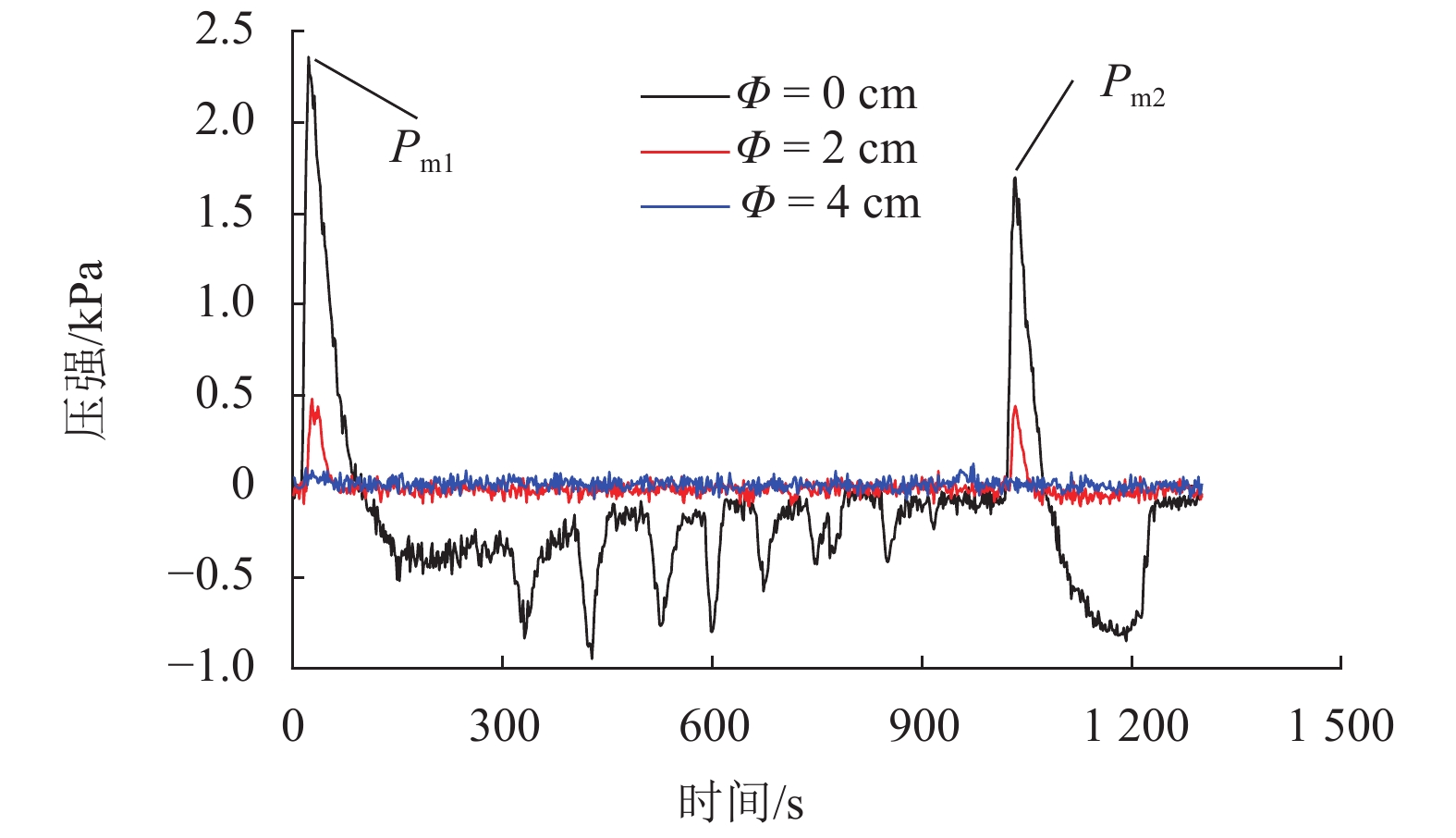

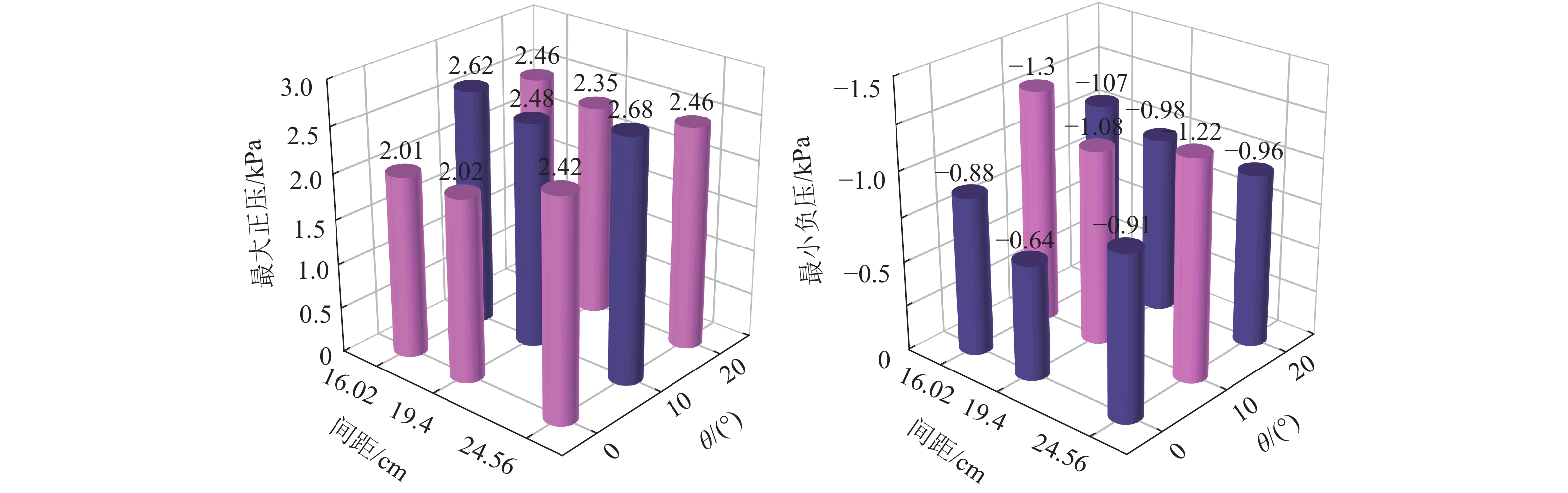

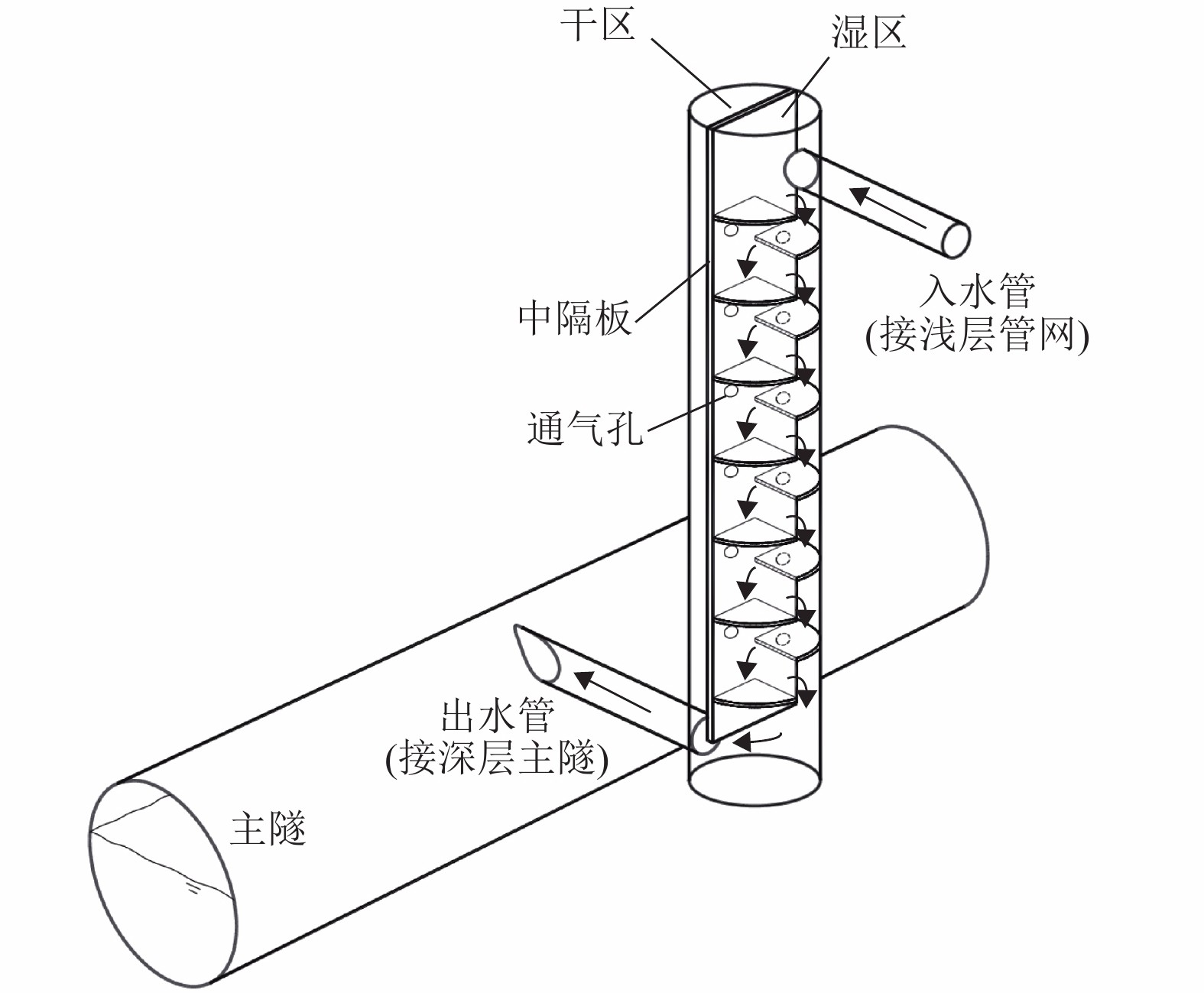

摘要: 针对深隧排水系统竖井泄流过程中高速气-水两相流动特性进行了水力模型试验研究,观测竖井内水流下泄过程中的型态,分析最大泄流量与折板间距的关系,计算不同工况下的竖井消能率,并揭示折板型竖井在泄流过程中的消能机理. 试验结果表明:竖井在泄流过程中存在3种水流型态:撞壁受限流、临界流和自由跌水流;泄流过程中水跃是水流在折板上消能的主要原因,水流流至井底与反向流体互相撞击破碎使竖井达到最终消能的目的;当竖井直径D = 0.4 m、折板间距d介于16.02~24.56 cm时,竖井最大泄流量介于(8.7~14.7) × 10−3 m3/s,且d与最大泄流量Qm存在线性关系;根据能量守恒定律推导出消能率公式,得到d = 19.4 cm、倾角θ = 10° 时的竖井消能率为最优;竖井盖板开孔直径 Ф 对竖井顶部压强的影响较大,当 Ф ≥ 4 cm时,竖井顶部相对压强基本为0,并且具有一定倾角的折板有利于加速竖井的泄流过程;上、中、下折板冲击力(Fu、Fm、Fd)呈现Fu > Fm > Fd 的分布规律,上、中、下折板最大面荷载分别为42.8、30.7、22.8 kN/m2. 深隧排水折板型竖井最佳泄流量和最优消能率的试验研究成果对深隧竖井工程的设计与运行提供了一定参考价值.Abstract: In order to study the transition characteristics with the high-speed air-water flow in the drop shaft of a deep tunnel drainage system, a hydraulic model test was conducted to observe the flow patterns in the process of drop shaft discharge, analyze the relationship between the maximum discharge and the baffle spacing, and calculate the energy dissipation rates of the drop shaft under different conditions. On this basis, the energy dissipation mechanism in the process of drop shaft discharge was revealed. Results show that there are three kinds of flow regimes in the discharge process of drop shaft, i.e., wall-impact confined flow, critical flow, and Free-drop flow. Hydraulic jump is the primary cause of energy dissipation of water on the baffle, and the collision of the water flow with the bottom-drop shaft fluid in the reverse direction and the resulted breakage achieve the ultimate purpose of energy dissipation. The maximum discharge of drop shaft is between 8.7 × 10−3 and 14.7 × 10−3 m3/s when the shaft diameter D = 0.4 m and the baffle spacing d ranges from 16.02 to 24.56 cm, and there is a linear relationship between the baffle spacing and the maximum discharge (Qm). The formula of energy dissipation rate is deduced according to the law of conservation of energy, from which the optimal energy dissipation rate of drop shaft is achieved at d = 19.4 cm and inclination angle θ = 10°. The aperture diameter (Ф) of the cover-plate has a great influence on the internal pressure of the drop shaft. When Ф ≥ 4 cm, the internal pressure is nearly 0; the baffle with a certain inclination angle is conducive to accelerating the discharge process of the drop shaft. The impact forces on the upper, middle and lower baffles (denoted by Fu, Fm and Fd, respectively) present a relation of Fu > Fm > Fd; the maximum surface loads of the upper, middle and lower baffles are 42.8, 30.7 and 22.8 kN/m2, respectively. The experimental results about the maximum discharge and optimal energy dissipation rate of baffle-drop shaft could provide a reference for the design and operation of the baffle-drop shaft of deep tunnel drainage systems.

-

表 1 试验采用的相似比尺

Table 1. Scale relations and ratios of model system

名称 比尺关系 相似常数 长度 λl 25.00 时间 λt = λl0.5 5.00 流速 λv = λl0.5 5.00 流量 λQ = λl2.5 3 125.00 力 λF = λρλl3 15 625.00 压强 λP = λρλl 25.00 糙率 λn = λl1/6 1.71 表 2 试验因素水平表

Table 2. Factors of the orthogonal test

折板间距 d/cm 折板倾角 θ/(°) Ф/cm 16.02 0 0 2 19.40 10 4 6 24.56 20 8 10 -

黄明利, 张志恩, 谭忠盛. 我国城市防洪排涝深层隧道建设模式[J]. 土木工程学报, 2017(增刊1): 76-81.HUANG Mingli, ZHANG Zhien, TAN Zhongsheng. Construction model of deep tunnel for urban flood control and drainage in China[J]. China Civil Engineering Journal, 2017(S1): 76-81. 王广华,李文涛,陈贻龙,等. 广州市东濠涌深层排水隧道工程前期研究[J]. 中国给水排水,2016,32(22): 7-13.WANG Guanghua, LI Wentao, CHEN Yilong, et al. Preliminary study on deep tunnel drainage engineering at Donghao Creek in Guangzhou[J]. China Water & Wastewater, 2016, 32(22): 7-13. ODGAARD A J, LYONS T C, CRAIG A J. Baffle drop structure design relationships[J]. Journal of Hydraulic Engineering, 2013, 139(9): 995-1002. doi: 10.1061/(ASCE)HY.1943-7900.0000761 王志刚,张东,张宏伟,等. 折板消能竖井中的折板功能分析[J]. 中国水利水电科学研究院学报,2015,13(4): 270-276.WANG Zhigang, ZHANG Dong, ZHANG Hongwei, et al. Functions of baffles in baffle-drop shaft[J]. Journal of China Institute of Water Resources and Hydropower Research, 2015, 13(4): 270-276. 王志刚,张东,张宏伟. 折板消能竖井水力转捩特征研究[J]. 水利水电技术,2015,46(12): 44-47.WANG Zhigang, ZHANG Dong, ZHANG Hongwei. Study on hydraulic transition characteristics of baffle-drop shaft[J]. Water Resources and Hydropower Engineering, 2015, 46(12): 44-47. 王斌, 邓家泉, 何贞俊, 等. 折板跌落式竖井设计约束条件研究[J]. 中国水利水电科学研究院学报, 2015, 13(5): 363-367.WANG Bin, DENG Jiaquan, HE Zhenjun, et al. A study on design constraints for baffle-drop shaft structure[J]. Journal of China Institute of Water Resources and Hydropower Research, 2015, 13(5): 363-367. 王斌, 邓家泉, 何贞俊, 等. 折板竖井结构优化试验研究[C]//第二十七届全国水动力学研讨会. 北京: 海洋出版社, 2015: 455-461. MARGEVICIUS A, SCHREIBER A, SWITALSKI R, et al. A baffling solution to a complex problem involving sewage drop structures[J]. Proceedings of the Water Environment Federation, 2010, 2010(6): 1-9. doi: 10.2175/193864710798216279 何贞俊,王斌,杨聿,等. 市政排水系统中竖井研究及应用进展[J]. 中国给水排水,2017(10): 49-53.HE Zhenjun, WANG Bin, YANG Yu, et al. Review on vertical shaft in urban wastewater drainage system[J]. China Water & Wastewater, 2017(10): 49-53. 刘家宏, 夏霖, 王浩, 等. 城市深隧排水系统典型案例分析[J]. 科学通报, 2017, 62(27): 3269-3276.LIU Jiahong, XIA Lin, WANG Hao, et al. Typical case analysis of deep tunnel drainage system in urban area[J]. Chinese Science Bulletin, 2017, 62(27): 3269-3276. 禹华谦, 陈春光, 麦继婷. 工程流体力学[M]. 成都: 西南交通大学出版社, 2013: 265. 中华人民共和国行业标准. 锅炉人孔和手孔装置: NB/T 47040—2013[S]. 北京: 新华出版社, 2013. 中华人民共和国船舶行业标准. 船用人孔盖: CB/T 4392—2014[S]. 北京: 中国船舶工业综合技术经济研究院, 2014. 中华人民共和国通信行业标准. 通信管道人孔和手孔图集: YD 5178—2009[S]. 北京: 北京邮电大学出版社, 2009. -

下载:

下载: