Meso-mechanical Effect of Track Slab Rebar Corrosion

-

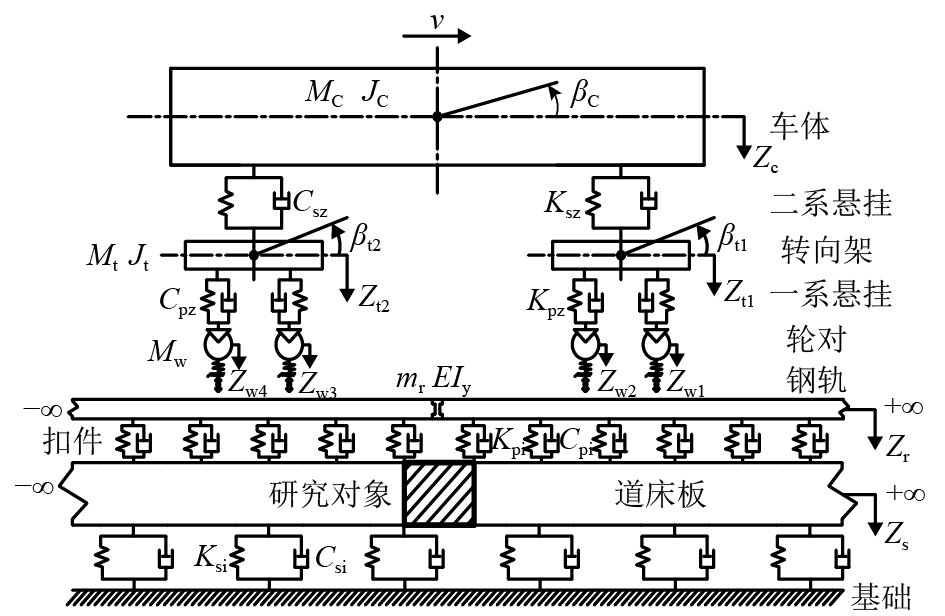

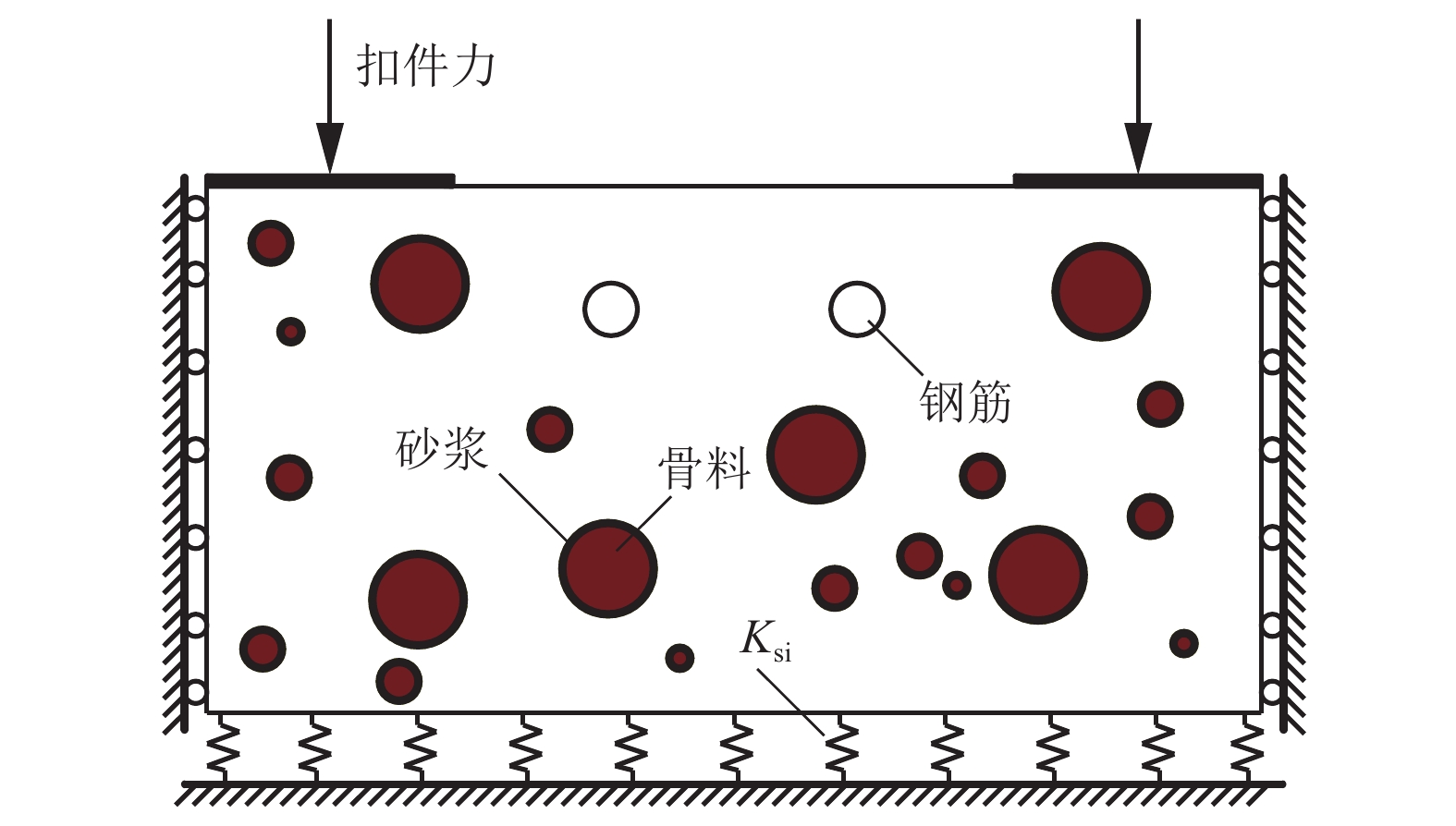

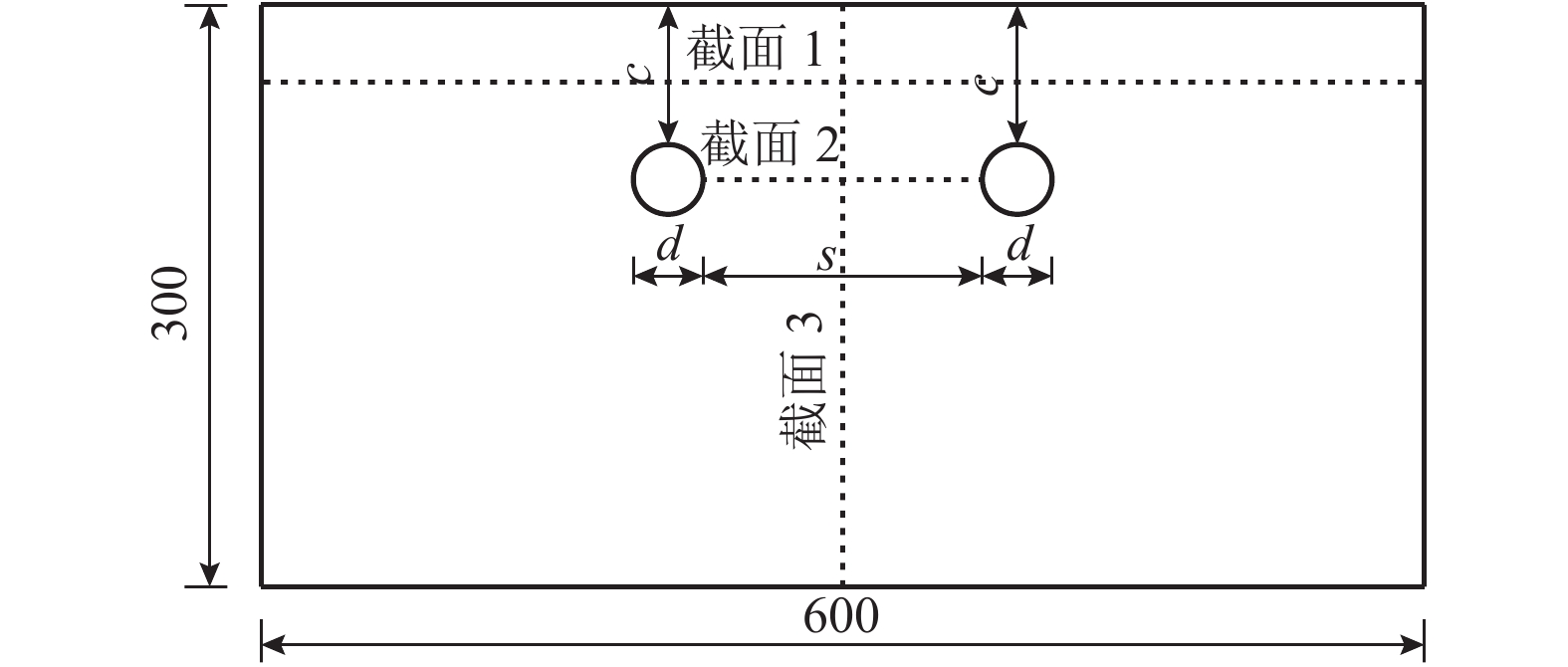

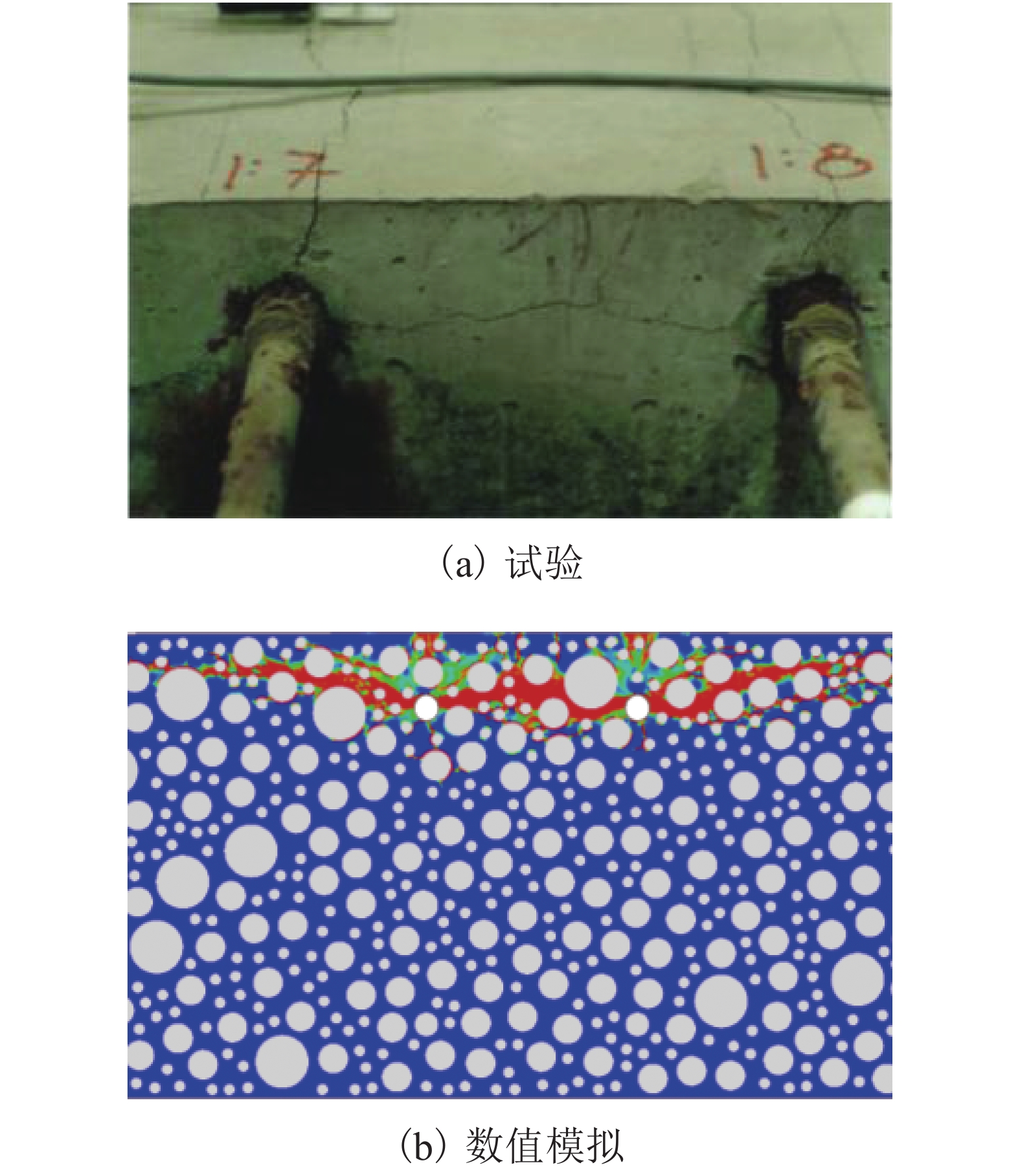

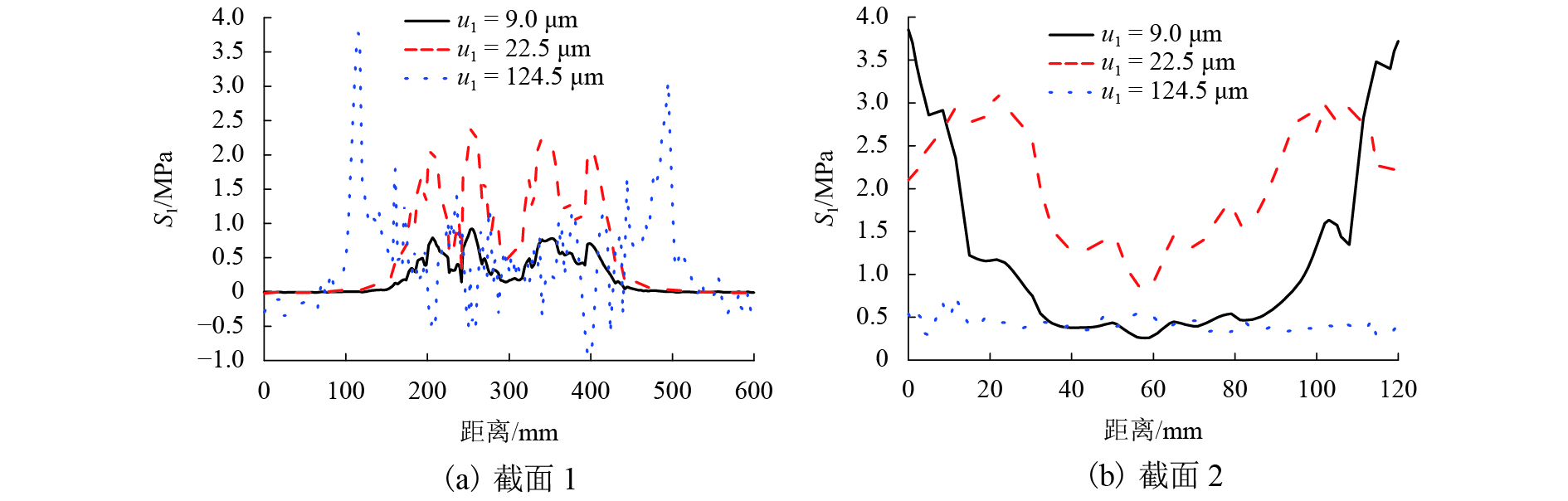

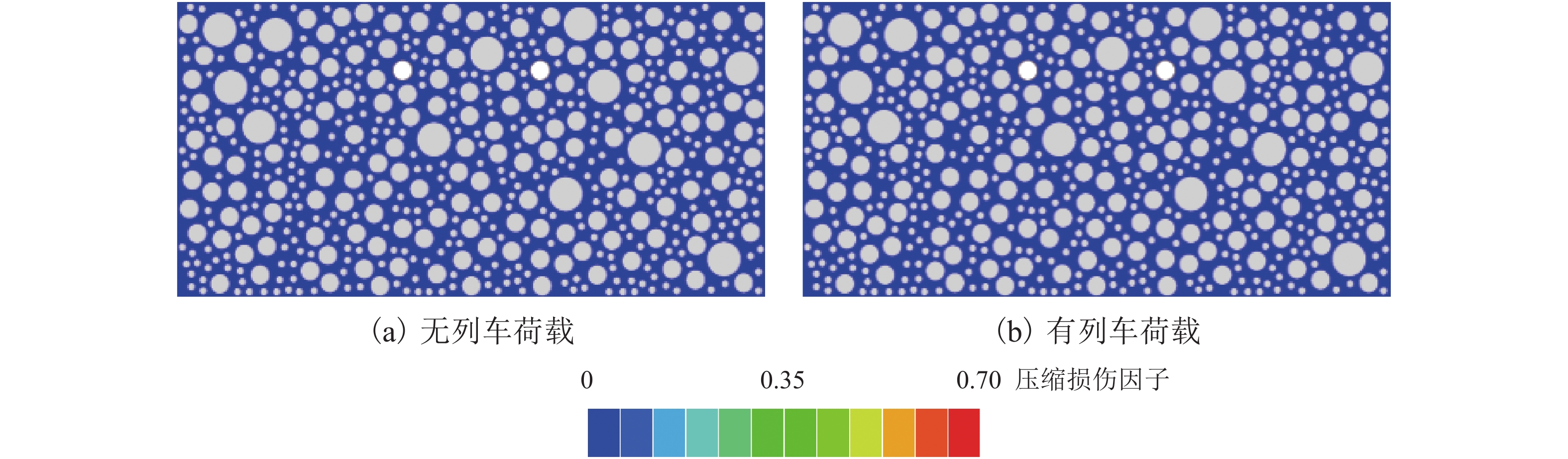

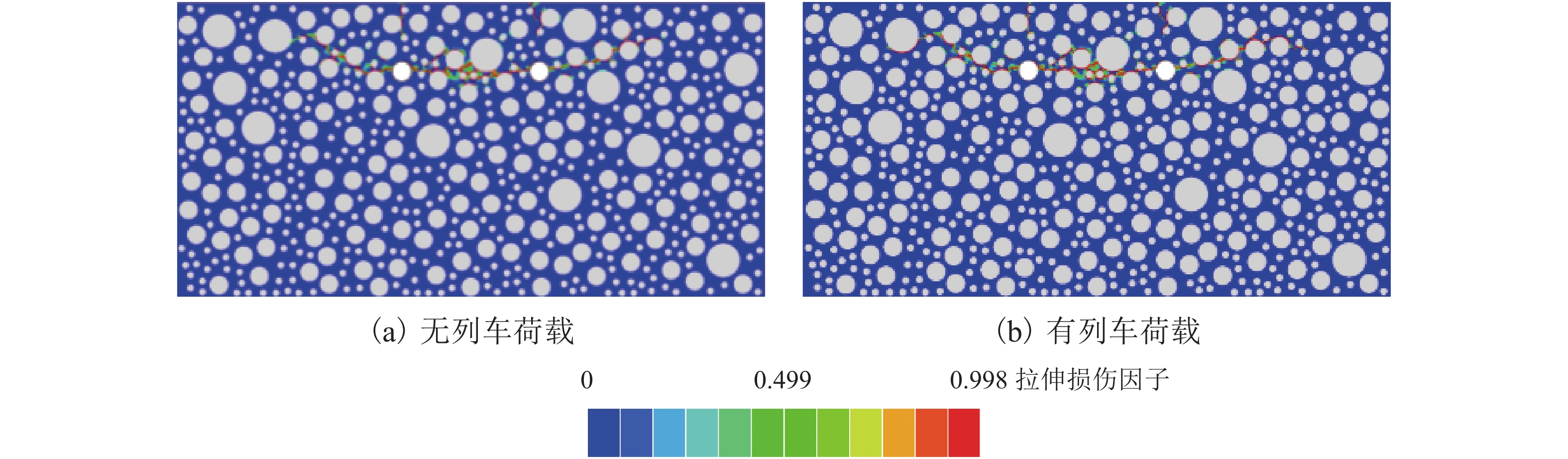

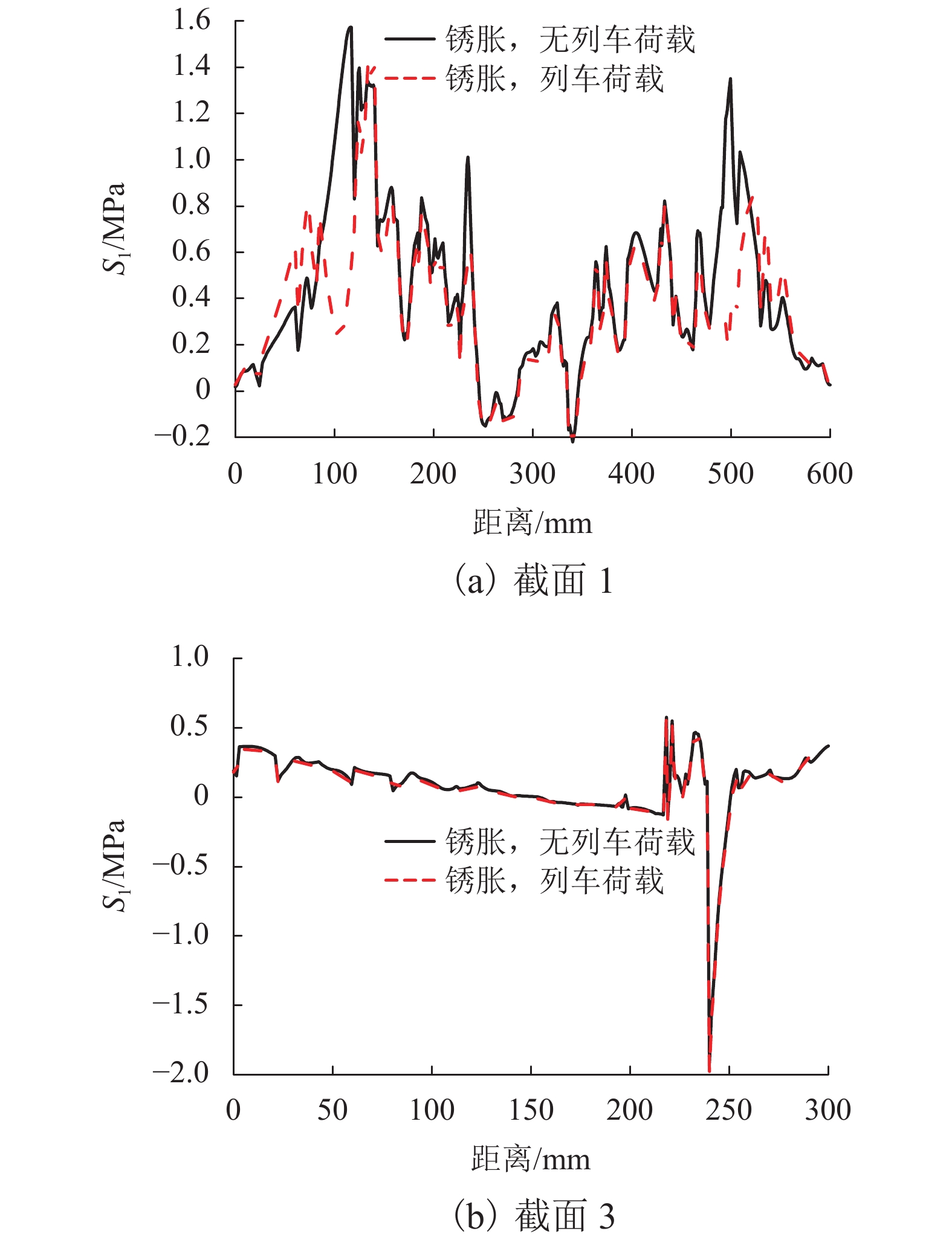

摘要: 为探究钢筋锈蚀对双块式无砟轨道道床板混凝土的影响,建立了道床板混凝土细观尺度力学模型,研究了钢筋锈蚀时不同钢筋直径、间距、保护层厚度的道床板受力性能及损伤破坏模式,分析了列车荷载和温度荷载对锈胀钢筋混凝土道床板力学性能的影响. 研究结果表明:钢筋锈蚀引起的道床板开裂模式主要与钢筋保护层厚度有关,与钢筋直径和间距关系小;道床板内部裂缝贯通时的锈胀位移随着钢筋间距的增大而增大,当保护层厚度为60 mm,钢筋间距为120 mm时,61.2 μm的钢筋锈胀位移就会引起道床板内部裂缝贯通;列车荷载对锈蚀后的道床板损伤影响小,且会使道床板受力趋于均匀;整体降温30 ℃和负温度梯度荷载均会使锈胀道床板拉伸损伤进一步明显增大,在道床板水平及垂向产生贯通裂缝;整体升温30 ℃和正温度梯度荷载作用对锈胀道床板损伤影响小.Abstract: To explore the effect of rebar corrosion on double-block ballastless track slab concretes, a meso-scale mechanical model of track slab concretes was built to study the mechanical properties and damage modes of the slabs with different rebar diameters, spacing and cover thicknesses, the effect of train and temperature loads on the mechanical property of reinforced concrete track slabs with corrosion was analyzed. The results show that the cracking mode of track slabs induced by rebar corrosion mainly depends on the thickness of rebar cover but rarely relies on the diameter or spacing of rebar. In the event the internal cracks of the slabs connect together, the expansion displacement of rebar increases with the increase of the rebar spacing. When the cover thickness is 60 mm and the rebar spacing is 120 mm, the rebar corrosion displacement of 61.2 μm would result in the internal coalescence cracks. The train load has little effect on the slabs with corrosion crack, and may make the stress on the slabs tend to be uniform. The temperature cooling of 30 °C and the negative temperature gradient may cause the further significant increase of the tension damages of slabs with corrosion, at the same time it may cause the coalescence cracks through along the horizontal and vertical directions of slabs. The temperature rise of 30 °C and the positive temperature gradient barely have effect on the damages of the track slabs with corrosion.

-

Key words:

- ballastless track /

- rebar corrosion /

- meso-mechanics /

- train load /

- temperature load /

- damage mode

-

表 1 力学参数

Table 1. Mechanical Parameters

材料 弹性模量/GPa 泊松比 抗拉强度/MPa 骨料 70.0 0.16 − 砂浆 25.8 0.20 1.86 界面 23.4 0.22 1.53 表 2 工况表

Table 2. Operating Conditions

工况 d/mm c/mm s/mm s/c (1) 14 40 80 2 (2) 16 40 120 3 (3) 20 40 160 4 (4) 20 60 120 2 (5) 14 60 180 3 (6) 16 60 240 4 (7) 16 80 160 2 (8) 20 80 240 3 (9) 14 80 320 4 表 3 混凝土裂缝贯通时的锈胀位移

Table 3. Corrosion displacement when concrete cracks connect together

μm 工况 锈胀位移u1 内部裂缝贯通 外部裂缝贯通 (1) 65.5 74.4 (2) 75.7 64.5 (3) 135.7 222.1 (4) 61.2 — (5) 102.7 — (6) 157.2 — (7) 82.0 — (8) 121.3 — (9) 226.4 — -

何华武. 无碴轨道技术[M]. 北京: 中国铁道出版社, 2005: 11-26. 赵国堂. 高速铁路无碴轨道结构[M]. 北京: 中国铁道出版社, 2006: 23-34. ANDRADE C, ALONSO C, MOLINA F J. Cover cracking as a function of bar corrosion:part 1—experimental test[J]. Materials and Structures, 1993, 26(8): 453-464. doi: 10.1007/BF02472805 OH B H, KIM K H, JANG B S. Critical corrosion amount to cause cracking of reinforced concrete structures[J]. ACI Materials Journal, 2009, 106(4): 333-339. ZHANG R, CASTEL A, FRANCOIS R. Concrete cover cracking with reinforcement corrosion of RC beam during chloride-induced corrosion process[J]. Cement and Concrete Research, 2010, 40(3): 415-425. doi: 10.1016/j.cemconres.2009.09.026 LIU Y P, WEYERS R E. Modeling the time-to-corrosion cracking in chloride contaminated reinforced concrete structure[J]. ACI Material Journal, 1998, 95(6): 675-681. 郑建军,周欣竹. 钢筋混凝土结构锈蚀损伤的解析解[J]. 水利学报,2004,35(12): 62-68. doi: 10.3321/j.issn:0559-9350.2004.12.011ZHENG Jianjun, ZHOU Xinzhu. The analytical solution of the corrosion damage of reinforced concrete structures[J]. Journal of Hydraulic Engineering, 2004, 35(12): 62-68. doi: 10.3321/j.issn:0559-9350.2004.12.011 ZHAO Y X, IN W L. Modeling the amount of steel corrosion at the cracking of concrete cover[J]. Advances in Structural Engineering, 2006, 9(5): 687-696. doi: 10.1260/136943306778827556 VAL D V, CHERNIN L, STEWART M G. Experimental and numerical investigation of corrosion-induced cover cracking in reinforced concrete structures[J]. Journal of Structural Engineering,ASCE, 2009, 135(4): 376-385. doi: 10.1061/(ASCE)0733-9445(2009)135:4(376) SHAIKH F, UDDIN A, MOHAMED M, et al. Cover cracking of reinforced concrete beams due to corrosion of steel[J]. ACI Materials Journal, 2007, 104(2): 153-161. JANG B S, OH B H. Effects of non-uniform corrosion on the cracking and service life of reinforced concrete structures[J]. Cement and Concrete Research, 2010, 40(9): 1441-1450. doi: 10.1016/j.cemconres.2010.03.018 赵羽习. 钢筋锈蚀引起混凝土结构锈裂综述[J]. 东南大学学报(自然科学版),2013,43(5): 1122-1134.ZHAO Yuxi. State-of-art of corrosion-induced cracking of reinforced concrete structures[J]. Journal of Southeast University (Natural Science Edition), 2013, 43(5): 1122-1134. 郭建光,元强,曾志平. 桥上CRTS Ⅱ型板式轨道裂缝及钢筋锈蚀时变规律[J]. 铁道科学与工程学报,2014,13(8): 1466-1473.GUO Jianguang, YUAN Qiang, ZENG Zhiping. Monitoring of the evolution of crack and steel bar corrosion of CRTS Ⅱ slab trackon bridge[J]. Journal of Railway Science and Engineering, 2014, 13(8): 1466-1473. 王青,卫军,董荣珍. CRTSⅡ 型板式无砟轨道板局部锈胀裂耐久性寿命预测[J]. 混凝土,2014,(12): 134-138. doi: 10.3969/j.issn.1002-3550.2014.12.036WANG Qing, WEI Jun, DONG Rongzhen. Durability life predict ion of CRTSⅡ ballast less track slab for the local corrosion-induced cracking[J]. Concrete, 2014,(12): 134-138. doi: 10.3969/j.issn.1002-3550.2014.12.036 WANG Q, WEI J, LIU X, et al. A new two-staged model to predict corrosion degree of steel bars in cracked concrete area[J]. Journal of Wuhan University of Technology-Mater, 2014, 29(5): 960-965. doi: 10.1007/s11595-014-1028-y 中华人民共和国铁道部. 铁路混凝土结构耐久性设计规范: TB 10005—2010[S]. 北京: 中国铁道出版社, 2011. YUAN Y, JI Y. Modeling corroded section configuration of steel bar in concrete structure[J]. Construction and Building Materials, 2009, 23(6): 2461-2466. doi: 10.1016/j.conbuildmat.2008.09.026 张仁波,杜修力,金浏. 相邻钢筋非均匀锈蚀引发混凝土保护层开裂的细观数值模拟[J]. 建筑科学与工程学报,2014,31(3): 98-104. doi: 10.3969/j.issn.1673-2049.2014.03.019ZHANG Renbo, DU Xiuli, JIN Liu. Meso-scale numerical simulation on crack process of concrte cover induced by adjacent rebar non-uniform corrosion[J]. Journal of Architecture and Civil Engineering, 2014, 31(3): 98-104. doi: 10.3969/j.issn.1673-2049.2014.03.019 段玉振. 双 块式轨道轨枕松动影响及维修方法研究[D]. 成都: 西南交通大学, 2013: 15-17. 翟婉明. 车辆-轨道耦合动力学[M]. 4版. 北京: 科学出版社, 2015: 11-150. 刘学毅, 赵坪锐. 客运专线无砟轨道设计理论与方法[M]. 成都: 西南交通大学出版社, 2010: 106-115. SAVIJA B, LUKOVIC M, PACHECO J, et al. Cracking of the concrete cover due to reinforcement corrosion:a two-dimensional lattice model study[J]. Construction and Building Materials, 2013, 44: 626-638. doi: 10.1016/j.conbuildmat.2013.03.063 DU X L, JIN L. Meso-scale numerical investigation on cracking of cover concrete induced by corrosion of reinforcing steel[J]. Engineering Failure Analysis, 2014, 39: 21-33. doi: 10.1016/j.engfailanal.2014.01.011 LEE J, FENVES G L. Plastic-damage model for cyclic loading of concrete structure[J]. Journal of Engineering Mechanics, 1988, 124(8): 892-900. LEON C, DIMITRI V. Prediction of corrosion-induced cover cracking in reinforced concrete structures[J]. Construction and Building Materials, 2011, 25(4): 1854-1869. doi: 10.1016/j.conbuildmat.2010.11.074 -

下载:

下载: