Impact Wear Properties of Hypereutectic Rail Joints Welded by Two Welding Processes

-

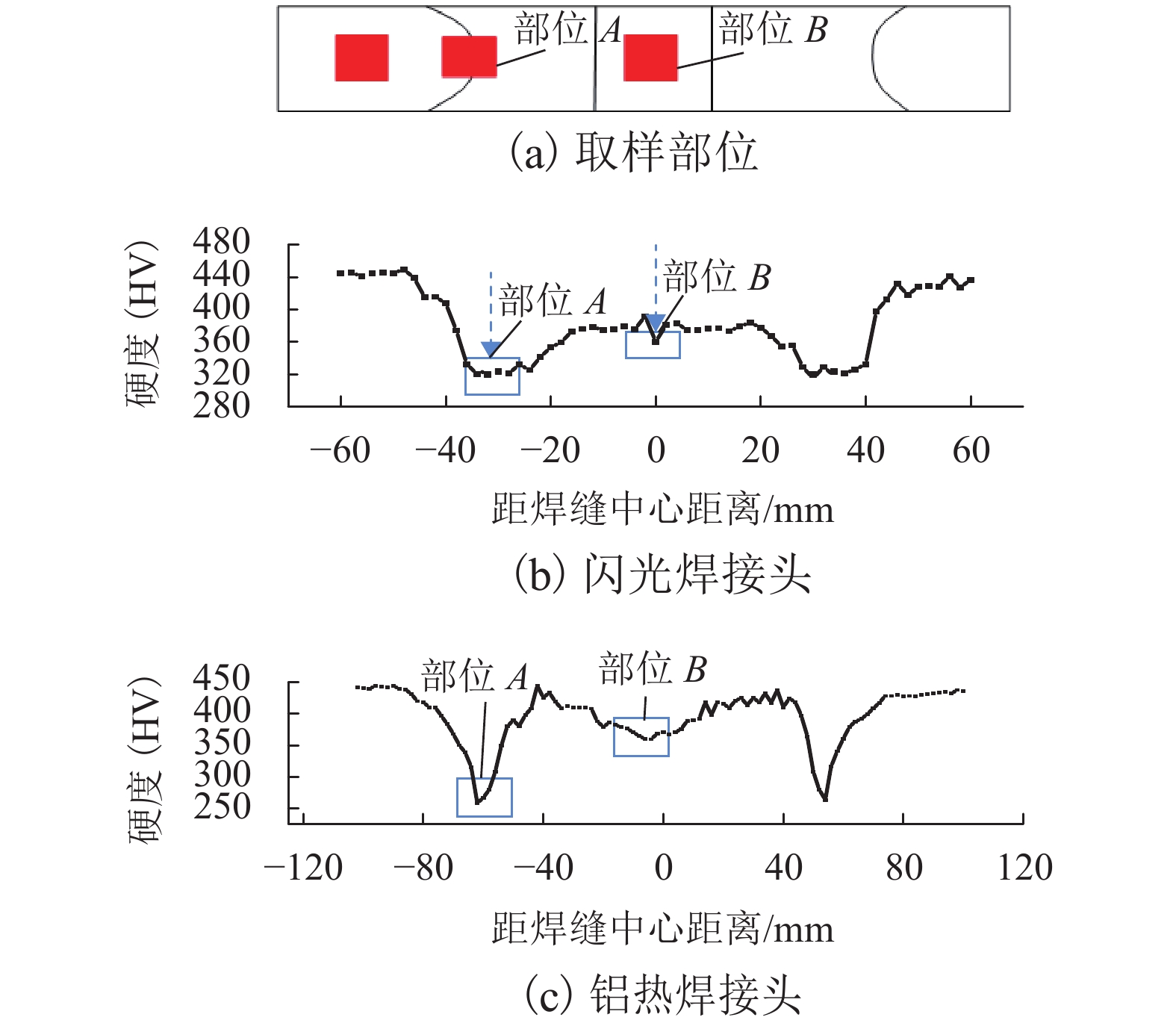

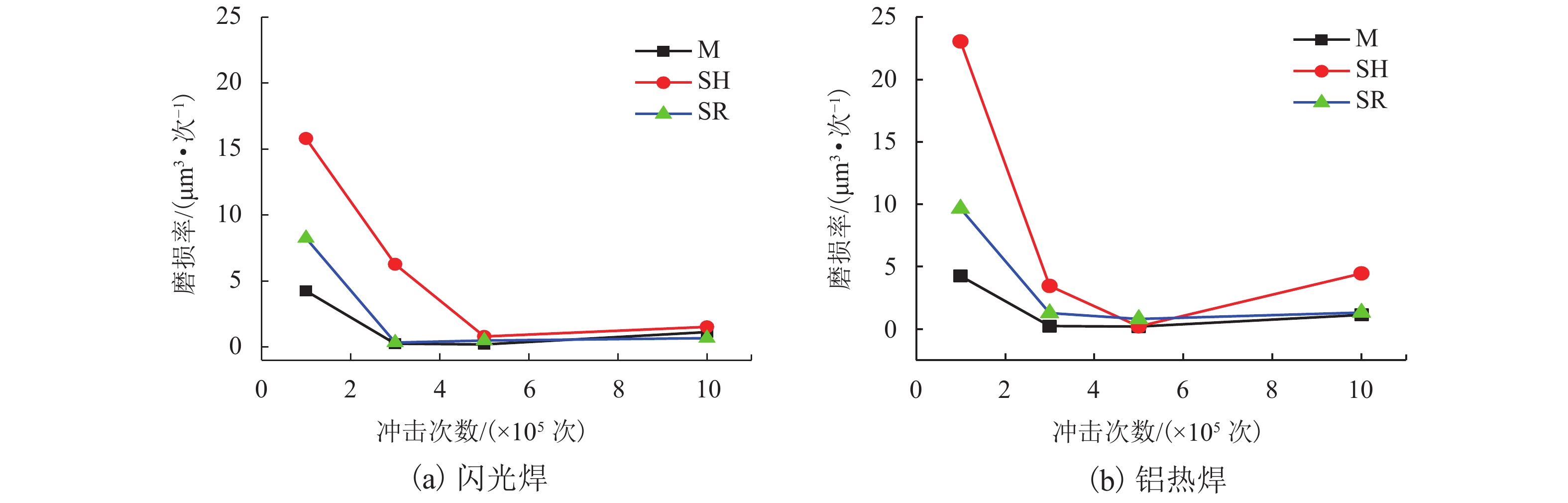

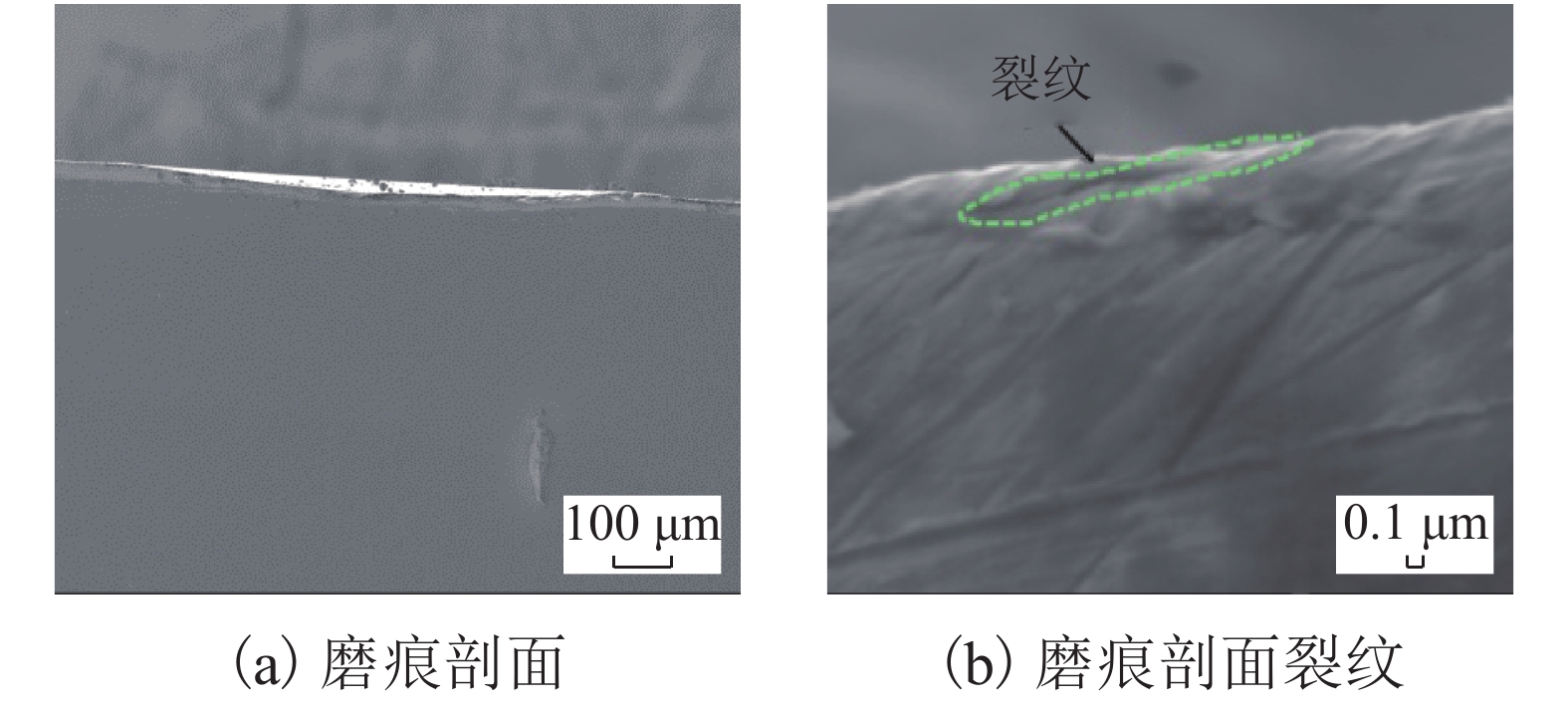

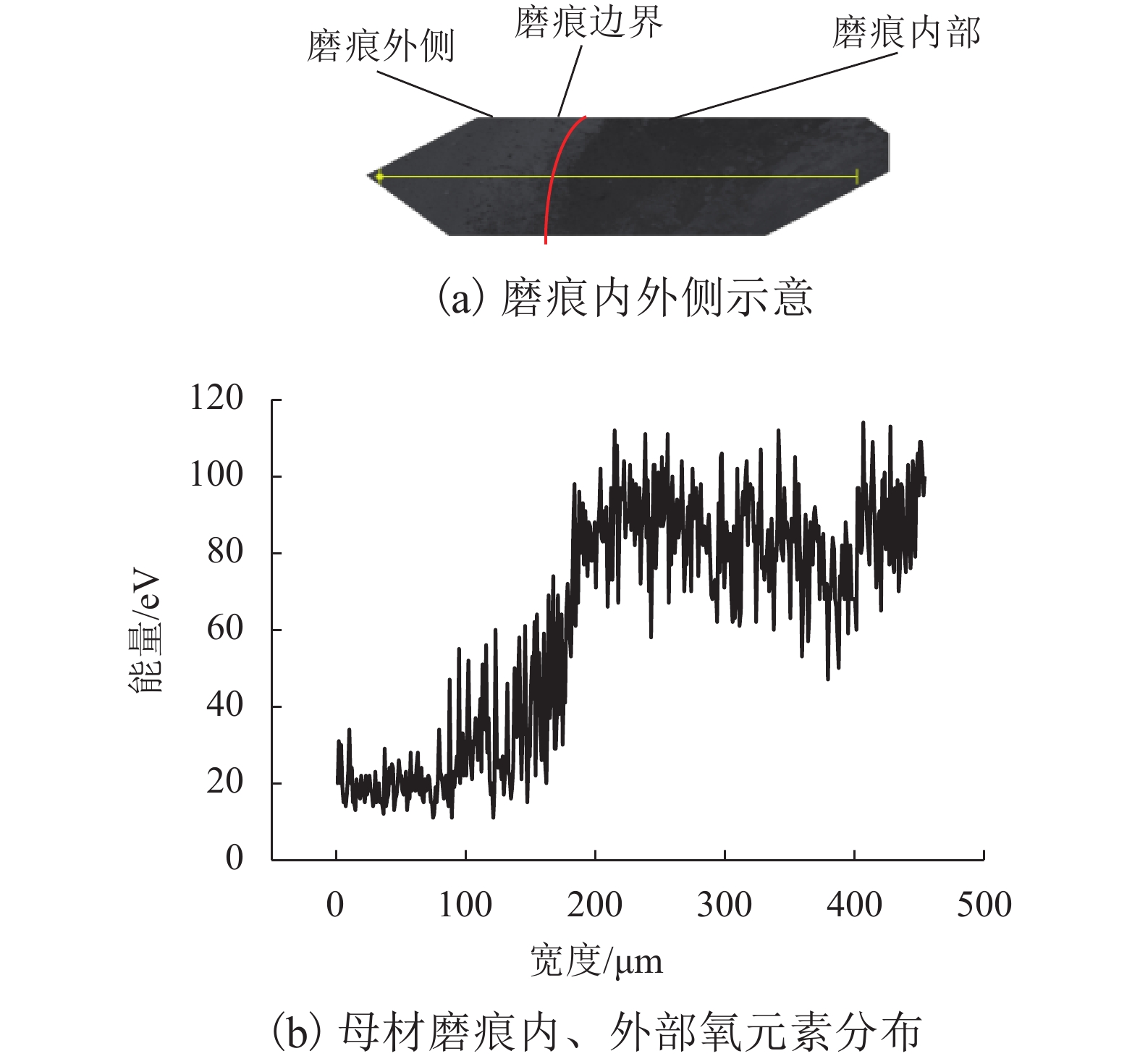

摘要: 为研究闪光焊、铝热焊两种焊接工艺下过共析钢轨焊接接头的冲击损伤演变行为以及性能差异,在自制的冲击磨损试验机上对过共析钢轨焊缝、热影响区软化部位及母材进行了不同冲击次数下的模拟实验. 研究结果表明:随着冲击次数的增加,钢轨焊接接头的冲击磨损均经历着塑性变形、点蚀破坏和疲劳剥落的过程,冲击损伤是疲劳磨损和氧化磨损共同作用的结果;由于焊接工艺导致的接头组织结构和力学性能的差异,热影响区软化部位冲击时塑性变形最严重,磨损体积和磨损率最大,抗冲击性能最差;由于对闪光焊焊接接头进行了焊后正火热处理,其组织结构及抗冲击性能明显优于铝热焊;硬度对焊接接头的抗冲击性能有显著影响,硬度越高,抗冲击性能越好,疲劳剥落出现的时间越晚.Abstract: In order to study the impact damage evolution behavior and the impact performance difference of the hypereutectic rail welding joints welded by flash welding and aluminothermic welding, the impact simulation experiments of the hypereutectoid rail welding seam, the softening part of heat-affected zone and the base metal under different impact cycles were carried out by using a self-made impact wear tester. The results show that the impact wear of the rail welded joints underwent the processes of plastic deformation, pitting failure and fatigue spalling with the increasing impact cycles, and the impact damage is the result of combined action of fatigue wear and oxidation wear. Due to the differences in joint microstructure and mechanical properties caused by different welding processes, the softening part of the heat-affected zone exhibited the most severe plastic deformation, the largest wear volume and wear rate, and the worst impact resistance. The microstructure and impact resistance of the flash welding joint are better than those of the aluminothermic welding joint because of the normal heat treatment after welding. Hardness has a significant effect on the impact resistance of welded joints. The higher the hardness, the better the impact resistance and the later the fatigue spalling.

-

Key words:

- hypereutectoid rail /

- flash welding /

- aluminothermic welding /

- impact wear /

- spalling fatigue

-

表 1 钢轨材料化学成分质量分数

Table 1. Chemical composition of rail materials (mass fraction )

% C Si Mn P Cr V 0.850~

1.0000.100~

0.8000.400~

1.300≤ 0.025 ≤ 0.700 ≤ 0.120 表 2 不同冲击次数下的磨损结果

Table 2. Wear results under different impact times

次数/

( × 105 次)磨损结果 M SR SH LR LH 1 磨损深度/μm 4.4 10 7.4 11.2 7.0 3 4.8 13.1 7.5 13.2 8.0 5 4.8 13.2 8.2 14.3 9.8 10 9.1 18.7 9.2 21.0 10.7 1 磨损体积/cm3 0.42 1.57 0.82 2.30 0.96 3 0.47 2.83 0.89 2.99 1.22 5 0.51 2.98 0.99 3.03 1.38 10 1.07 3.75 1.32 5.25 2.04 1 磨损率/(μm3•次−1) 4.24 15.79 8.23 23.04 9.65 3 0.24 6.25 0.33 3.44 1.27 5 0.19 0.78 0.49 0.20 0.80 10 1.12 1.52 0.66 4.45 1.31 -

LI Z, ZHAO X, ESVELD C, et al. An investigation into the causes of squats—correlation analysis and numerical modeling[J]. Wear, 2008, 265(9): 1349-1355. ABE N, FUKUI Y, NAGAFUJI T, et al. Maintenance of rail welded part by grinding its irregularities for elongation of rail service life[R]. [S.l.]: Railway Technical Research Institute, 1994. DUKKIPATI R V, DONG R. The dynamic effects of conventional freight car running over a dipped-joint[J]. Vehicle System Dynamics, 1999, 31(2): 95-111. doi: 10.1076/vesd.31.2.95.2095 FRY G T, LAWRENCE F V, ROBINSON A R. A model for fatigue defect nucleation in thermite rail welds[J]. Fatigue & Fracture of Engineering Materials & Structures, 1996, 19(6): 655-668. CHEN Y C, KUANG J H. Contact stress variations near the insulated rail joints[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2002, 216(4): 265-273. doi: 10.1243/095440902321029217 SEO J W, JUN H K, KWON S J, et al. Rolling contact fatigue and wear of two different rail steels under rolling–sliding contact[J]. International Journal of Fatigue, 2016, 83(2): 184-194. SKYTTEBOL A, JOSEFSON B L, RINGSBERG J W. Fatigue crack growth in a welded rail under the influence of residual stresses[J]. Engineering Fracture Mechanics, 2005, 72(2): 271-285. doi: 10.1016/j.engfracmech.2004.04.009 ZHAI W M, WANG Q C, LU Z W, et al. Dynamic effects of vehicles on tracks in the case of raising train speeds[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2001, 215(2): 125-135. doi: 10.1243/0954409011531459 WANG W J, LIU C, HE C G, et al. Investigation on impact wear and damage mechanism of railway rail weld joint and rail materials[J]. Wear, 2017, 376(4): 1938-1946. 王艳. Ti6A14V合金及其改性层的冲击磨损行为研究[D]. 成都: 西南交通大学, 2011. 李学敏. 冲击载荷下热喷涂涂层的塑性变形行为分析[J]. 甘肃工业大学学报,1997,23(2): 26-31.LI Xuemin. Behavior analysis of abrasion and plastic deformation of Cr 3C 2-25% NiCr hot-sprayed coatings under repeated impact[J]. Journal of Gansu University of Technology, 1997, 23(2): 26-31. 蔡振兵,王璋,朱旻昊. 硬质涂层冲击、冲蚀性能的研究进展[J]. 机械工程学报,2018,53(24): 12-24.CAI Zhenbing, WANG Zhang, ZHU Minhao. Review on impact and erosion wear research of hard coatings[J]. Journal of Mechanical Engineering, 2018, 53(24): 12-24. 王璋,蔡振兵,孙阳,等. 纯铁在球/面接触下的冲击微动磨损行为研究[J]. 摩擦学学报,2017,37(2): 225-232.WANG Zhang, CAI Zhenbing, SUN Yang, et al. Impact fretting wear behavior of pure iron under ball-to-flat contact[J]. Tribology, 2017, 37(2): 225-232. 傅戈雁,石世宏,欧阳八生,等. 覆层零件多冲碰撞试验与失效特征[J]. 材料科学与工程学报,2004,22(2): 216-219. doi: 10.3969/j.issn.1673-2812.2004.02.016FU Geyan, SHI Shihong, OUYANG Basheng, et al. Repeated impact test and failure characteristic of mechanical components with cladding layer[J]. Journal of Materials Science & Engineering, 2004, 22(2): 216-219. doi: 10.3969/j.issn.1673-2812.2004.02.016 SUH N P. An overview of the delamination theory of wear[J]. Wear, 1977, 44(1): 1-16. doi: 10.1016/0043-1648(77)90081-3 LISKIEWICZ T, FOUVRY S, WENDLER B. Impact of variable loading conditions on fretting wear[J]. Surface and Coatings Technology, 2003, 163(5): 465-471. 杨业元. 新型Mn-B系贝氏体钢磨球磨损及破碎机理研究[D]. 北京: 清华大学, 1995. 杨业元,方鸿生,郑燕康,等. 碳钢的高应力冲击磨损行为研究[J]. 摩擦学学报,1996,16(2): 120-124. doi: 10.3321/j.issn:1004-0595.1996.02.004YANG Yeyuan, FANG Hongsheng, ZHENG Yankang, et al. High-stress impact wear behaviours of carbon steels[J]. Tribology, 1996, 16(2): 120-124. doi: 10.3321/j.issn:1004-0595.1996.02.004 -

下载:

下载: